Patents

Literature

45 results about "Circumferential Profile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

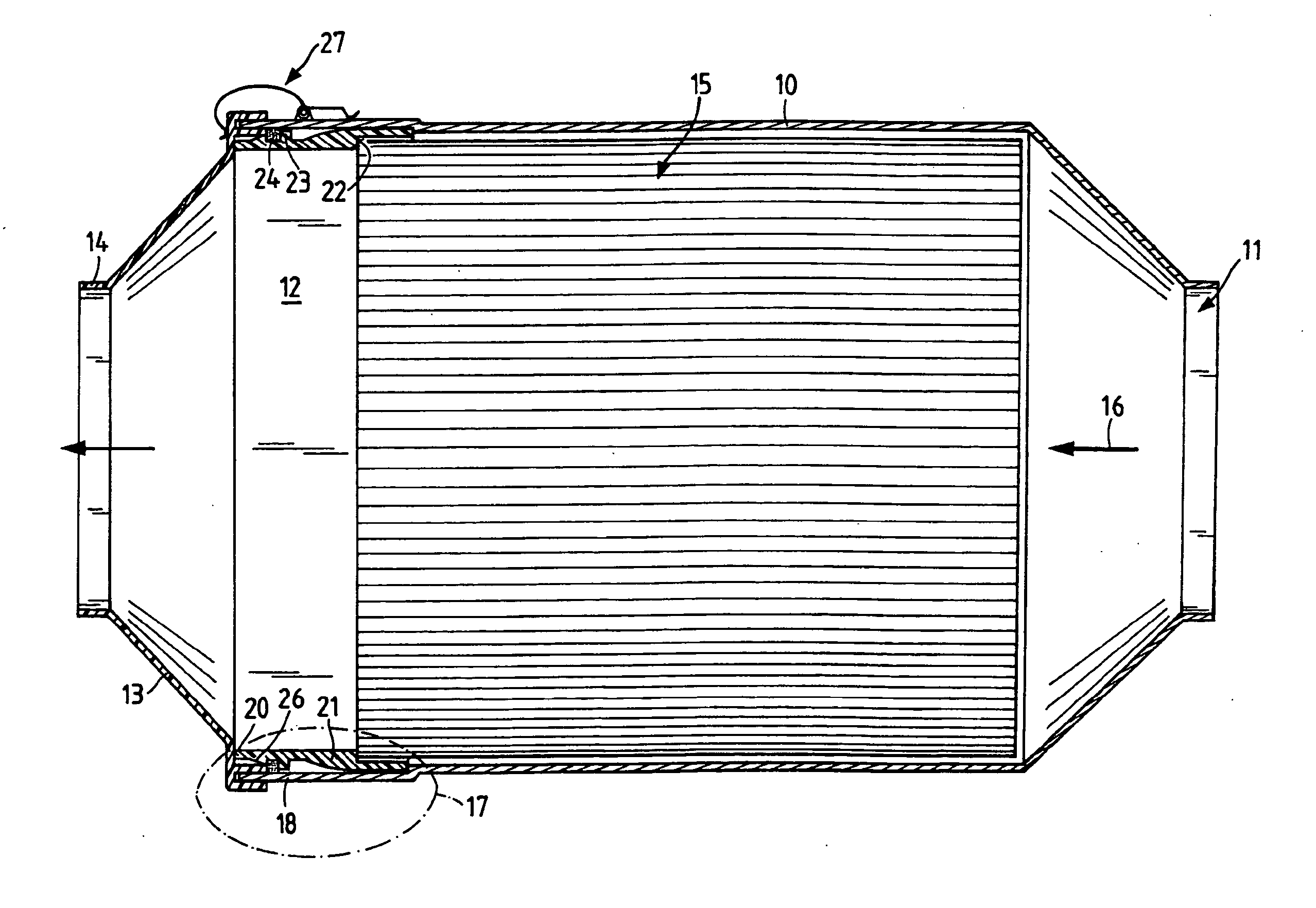

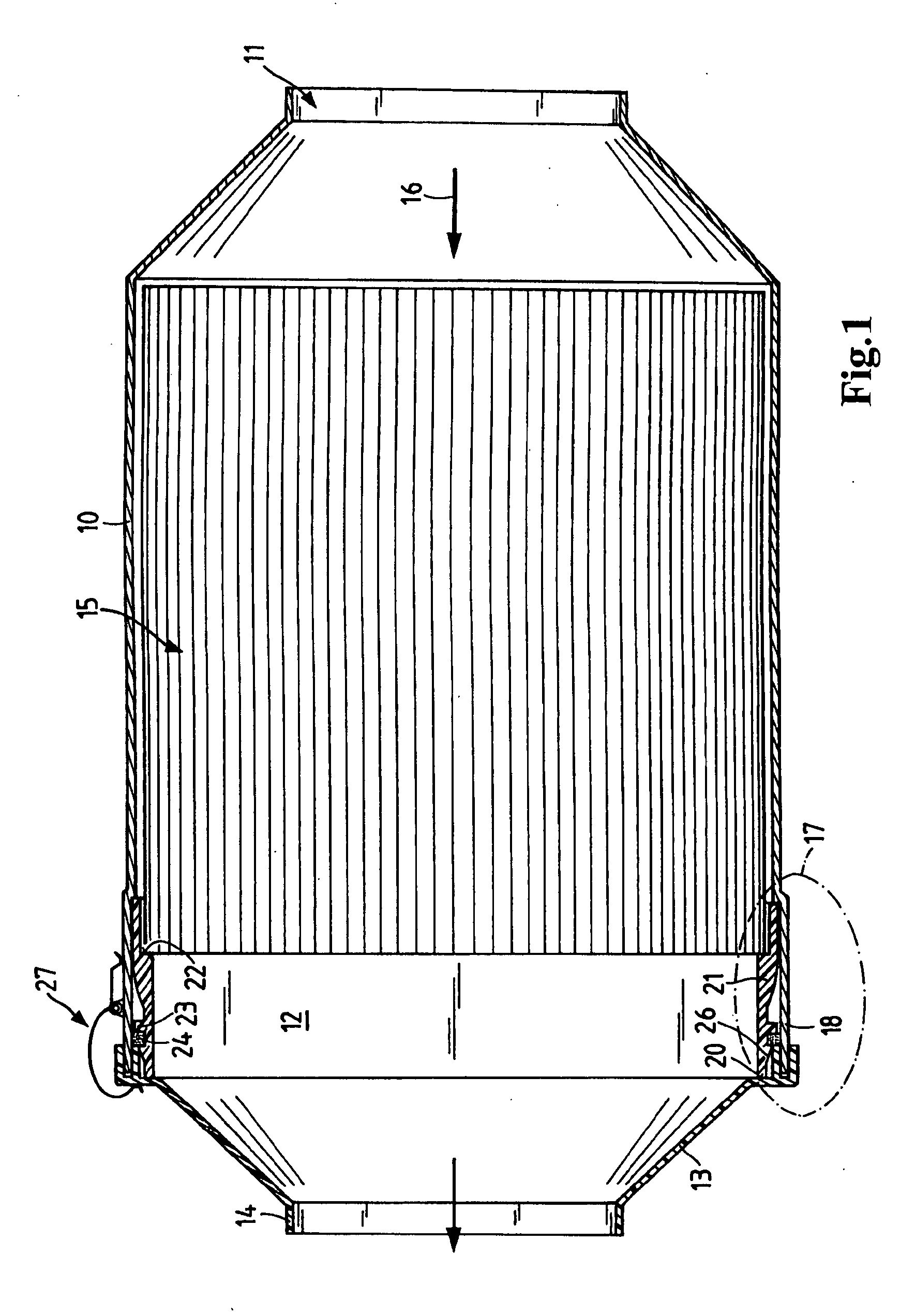

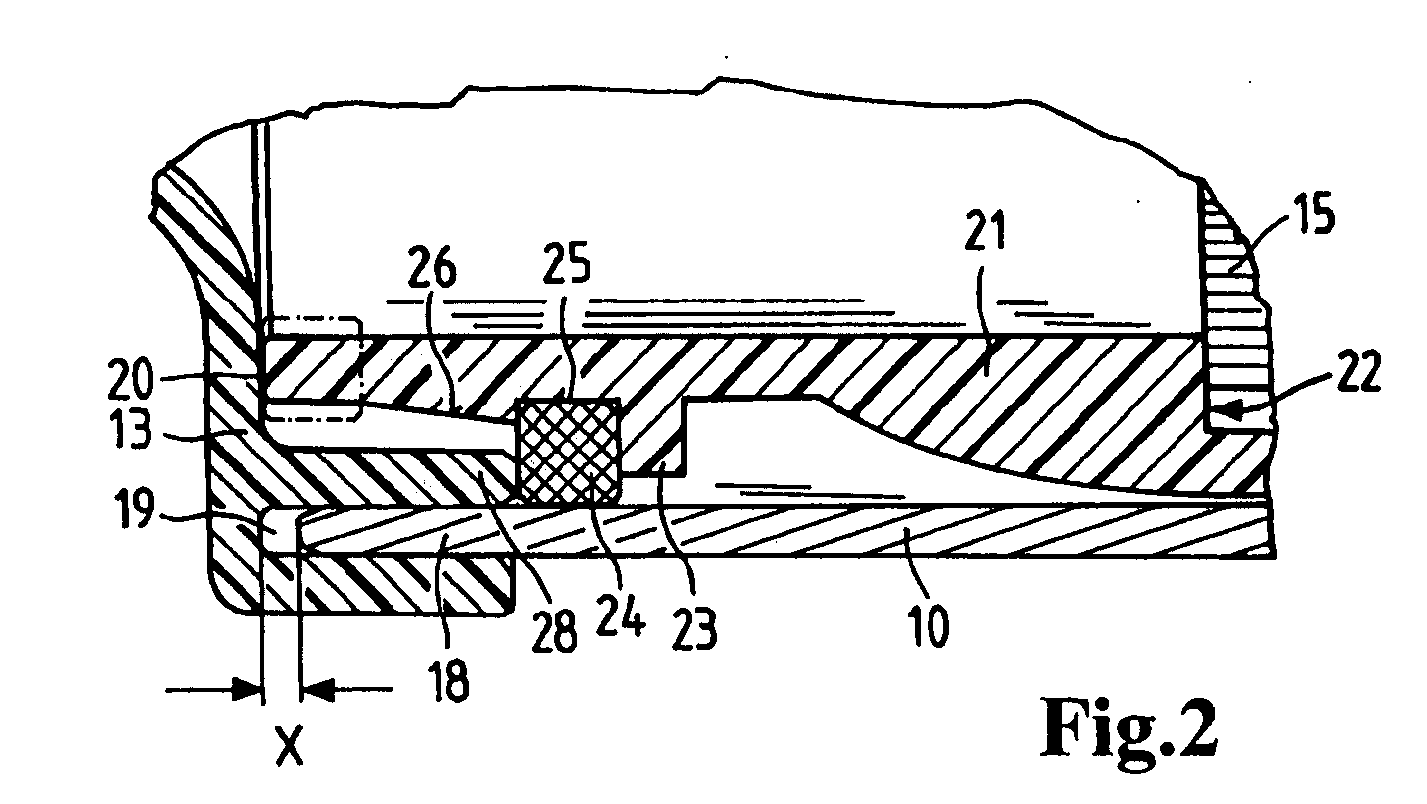

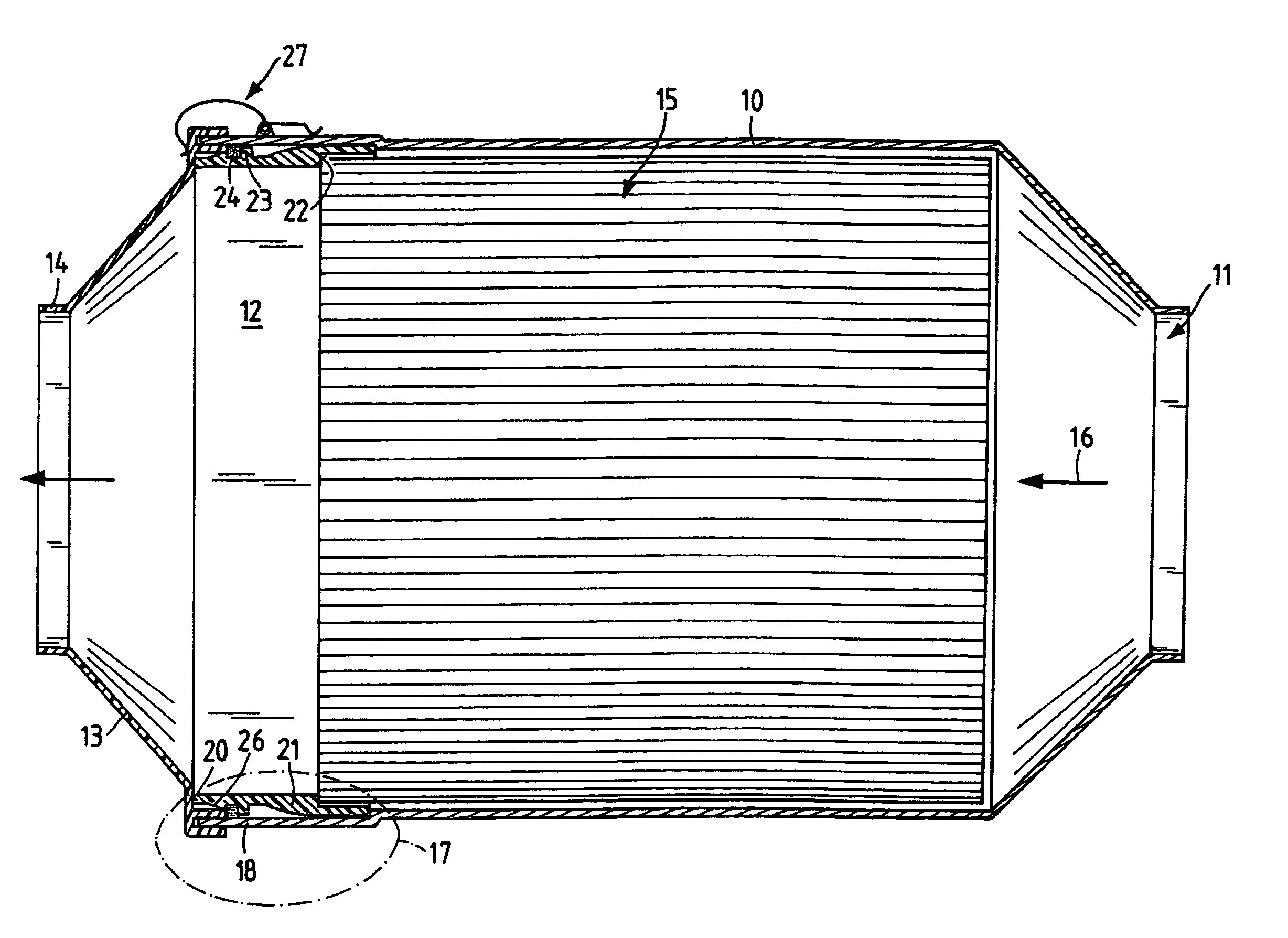

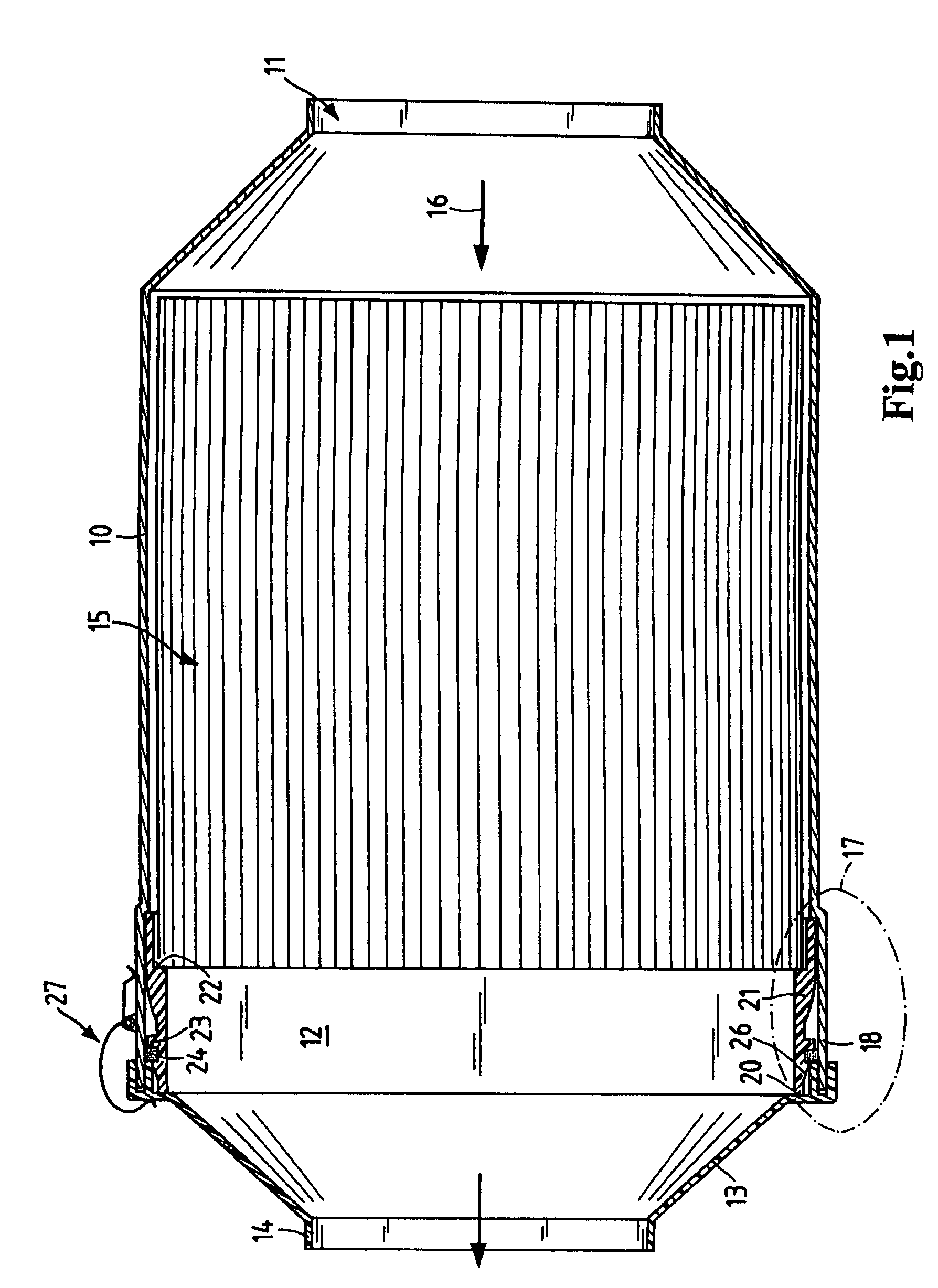

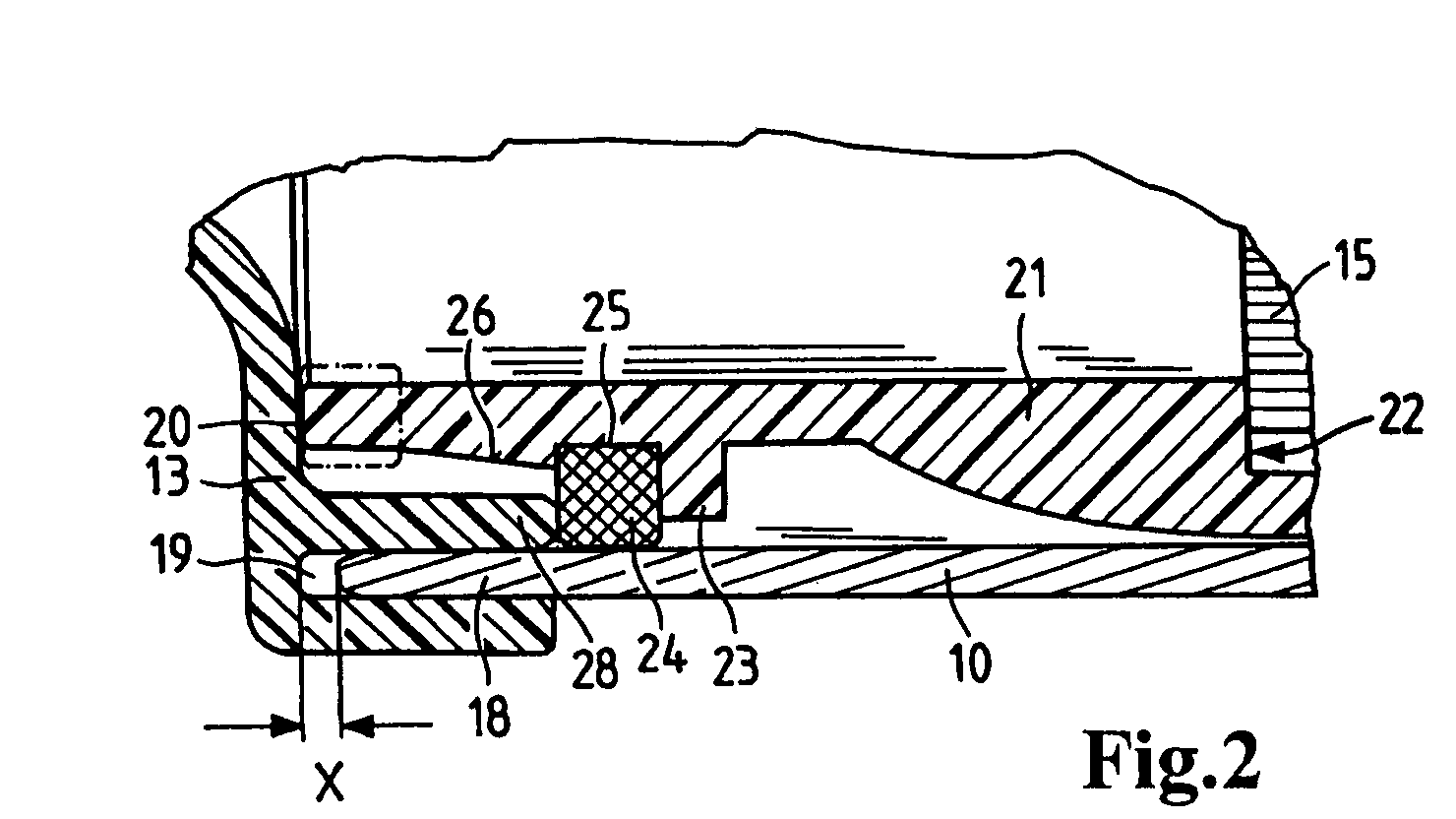

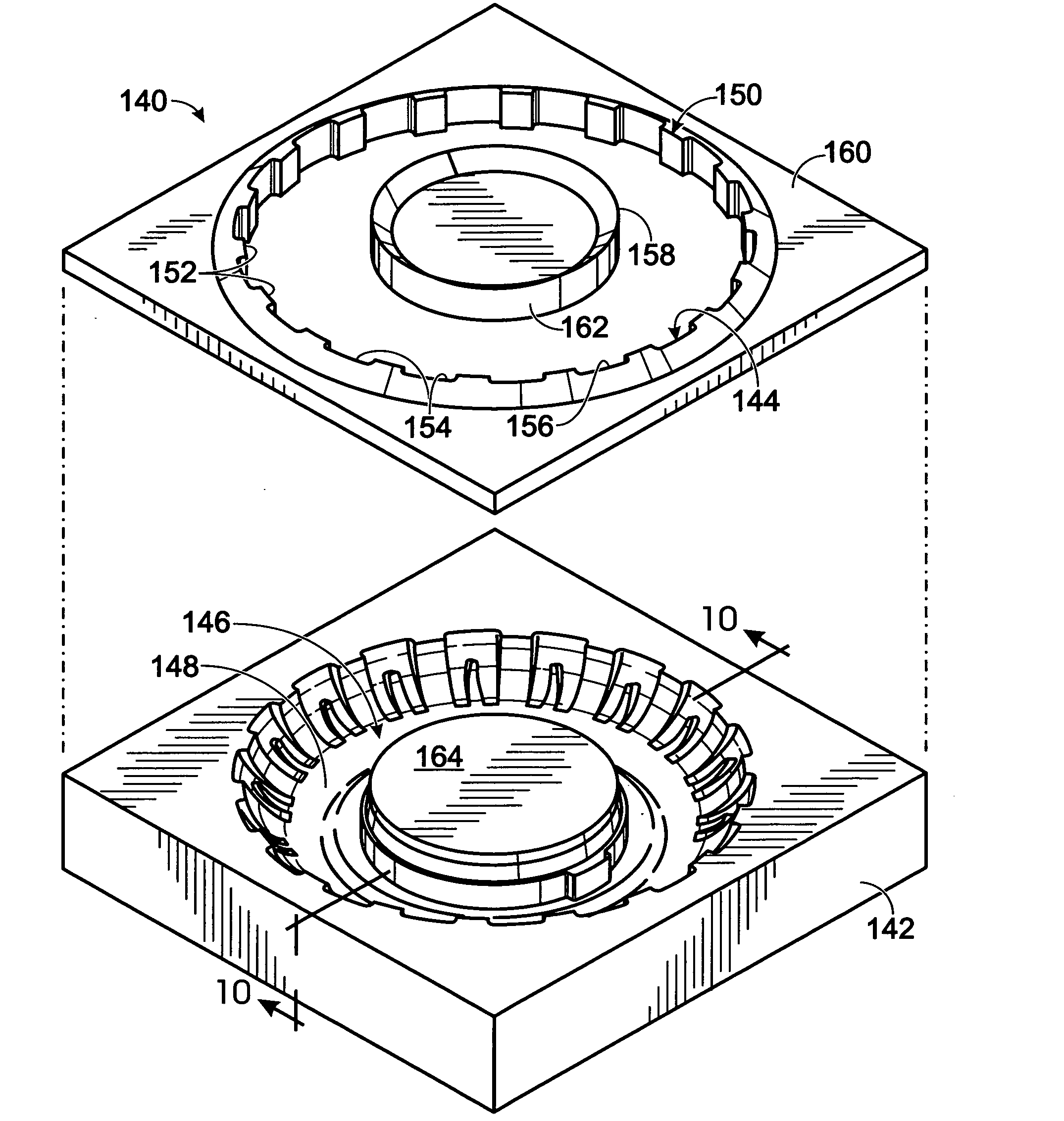

Compact filter comprising a square seal

ActiveUS20070261662A1Improve space utilizationSimple designCombination devicesGas treatmentCircumferential ProfileBiomedical engineering

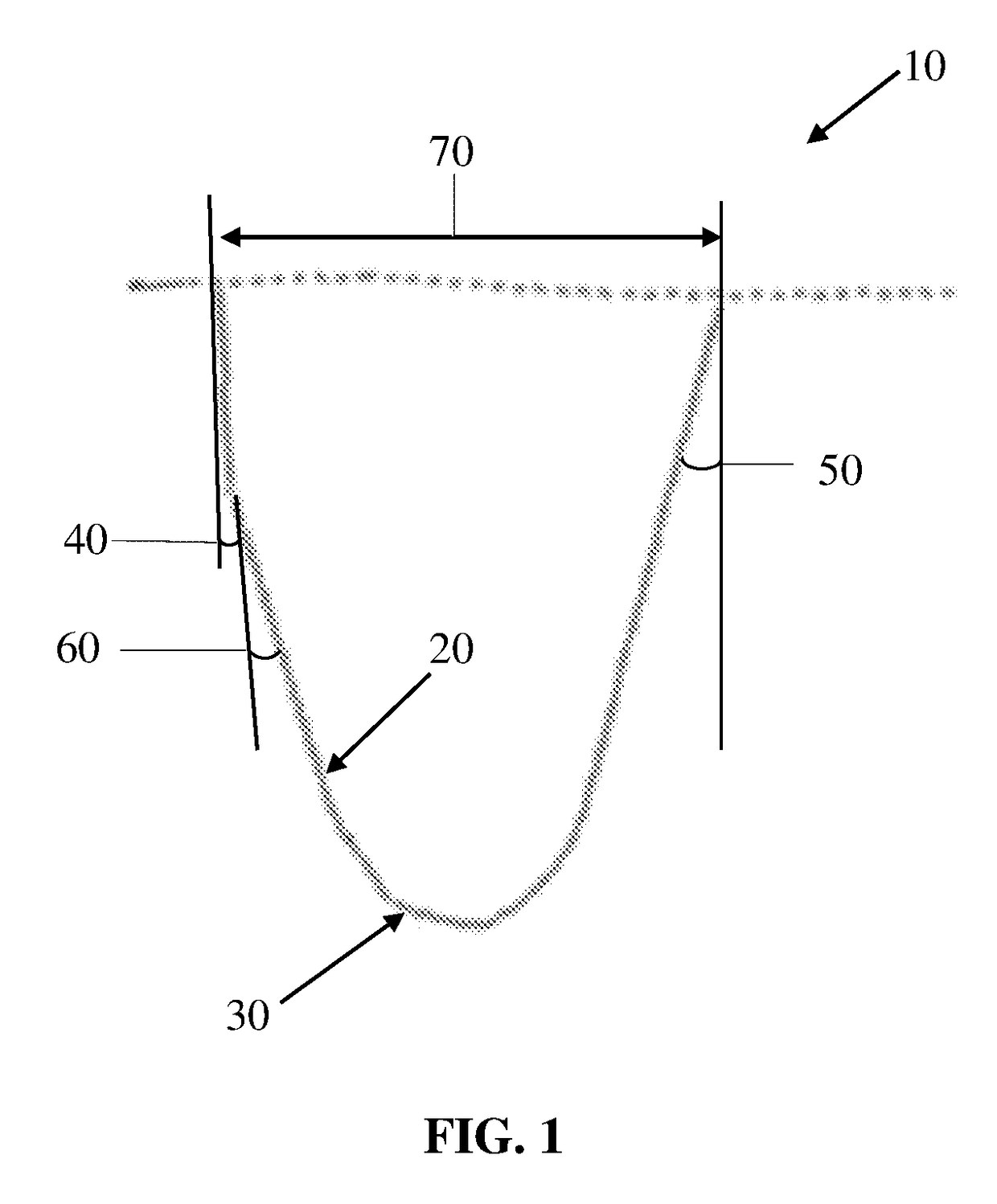

A filter element comprising a spirally wound filter through which a fluid to be filtered flows axially and which is provided with a mounting ring on the circumference of the wound filter secured to the wound filter by a welded, adhesive, extruded or fused joint. The mounting ring is provided with a circumferential profiled seal which engages a housing in which the filter element is installed to provide a seal between an unfiltered fluid side of the filter element and a filtered fluid side of the filter element.

Owner:MANN HUMMEL GMBH

Compact filter comprising a square seal

ActiveUS7396377B2Improve space utilizationSimple designCombination devicesGas treatmentCircumferential ProfileBiomedical engineering

A filter element comprising a spirally wound filter through which a fluid to be filtered flows axially and which is provided with a mounting ring on the circumference of the wound filter secured to the wound filter by a welded, adhesive, extruded or fused joint. The mounting ring is provided with a circumferential profiled seal which engages a housing in which the filter element is installed to provide a seal between an unfiltered fluid side of the filter element and a filtered fluid side of the filter element.

Owner:MANN HUMMEL GMBH

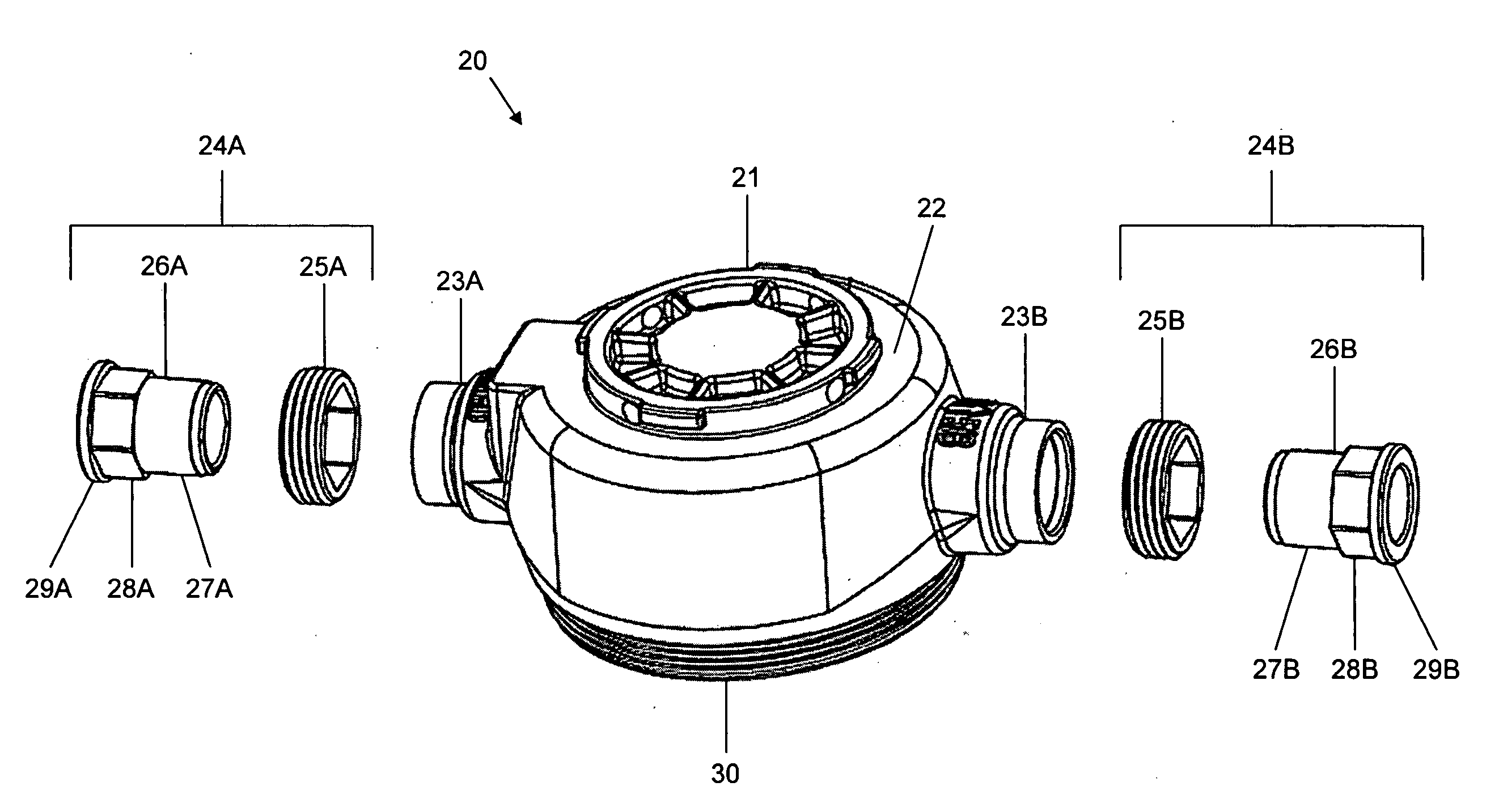

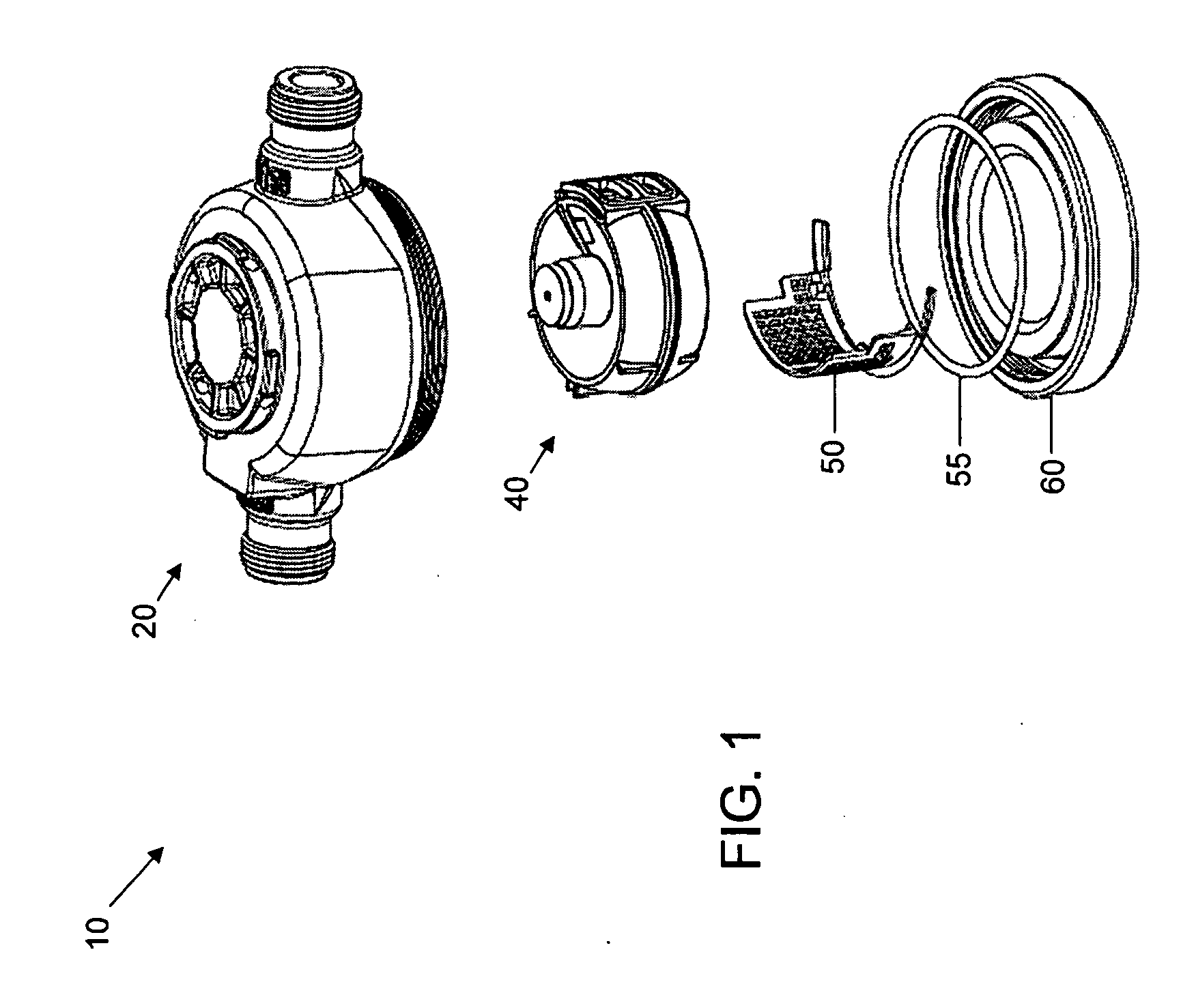

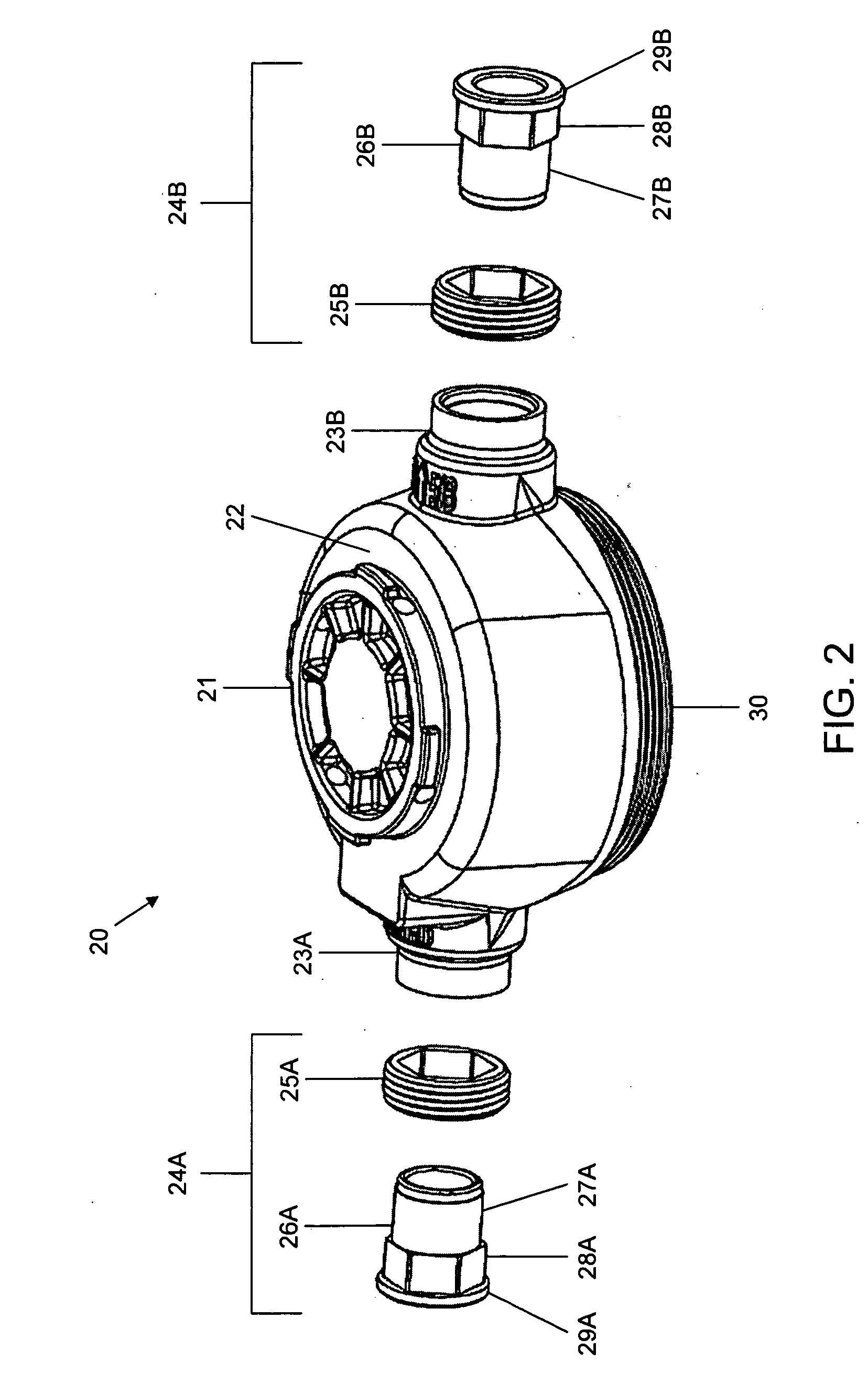

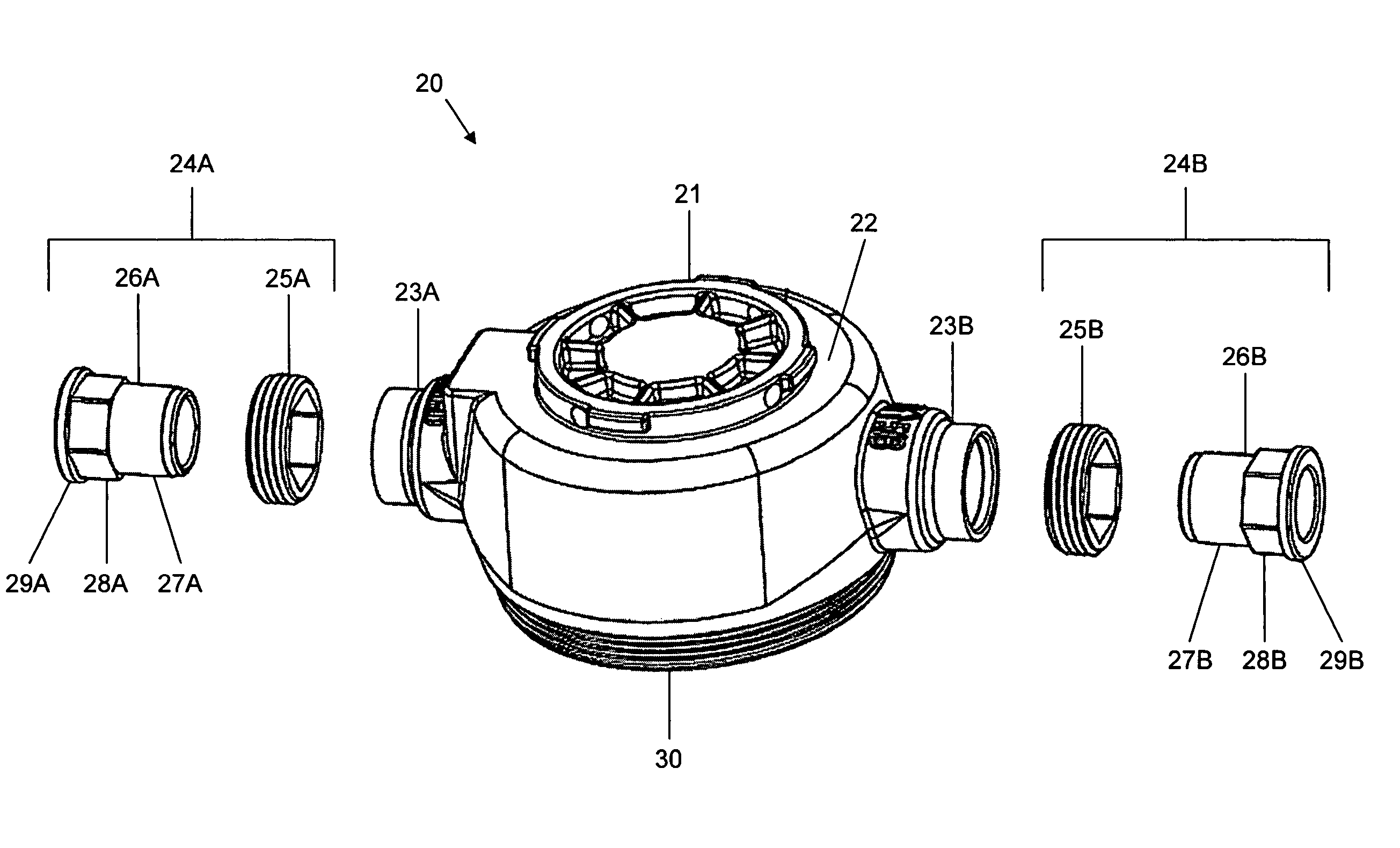

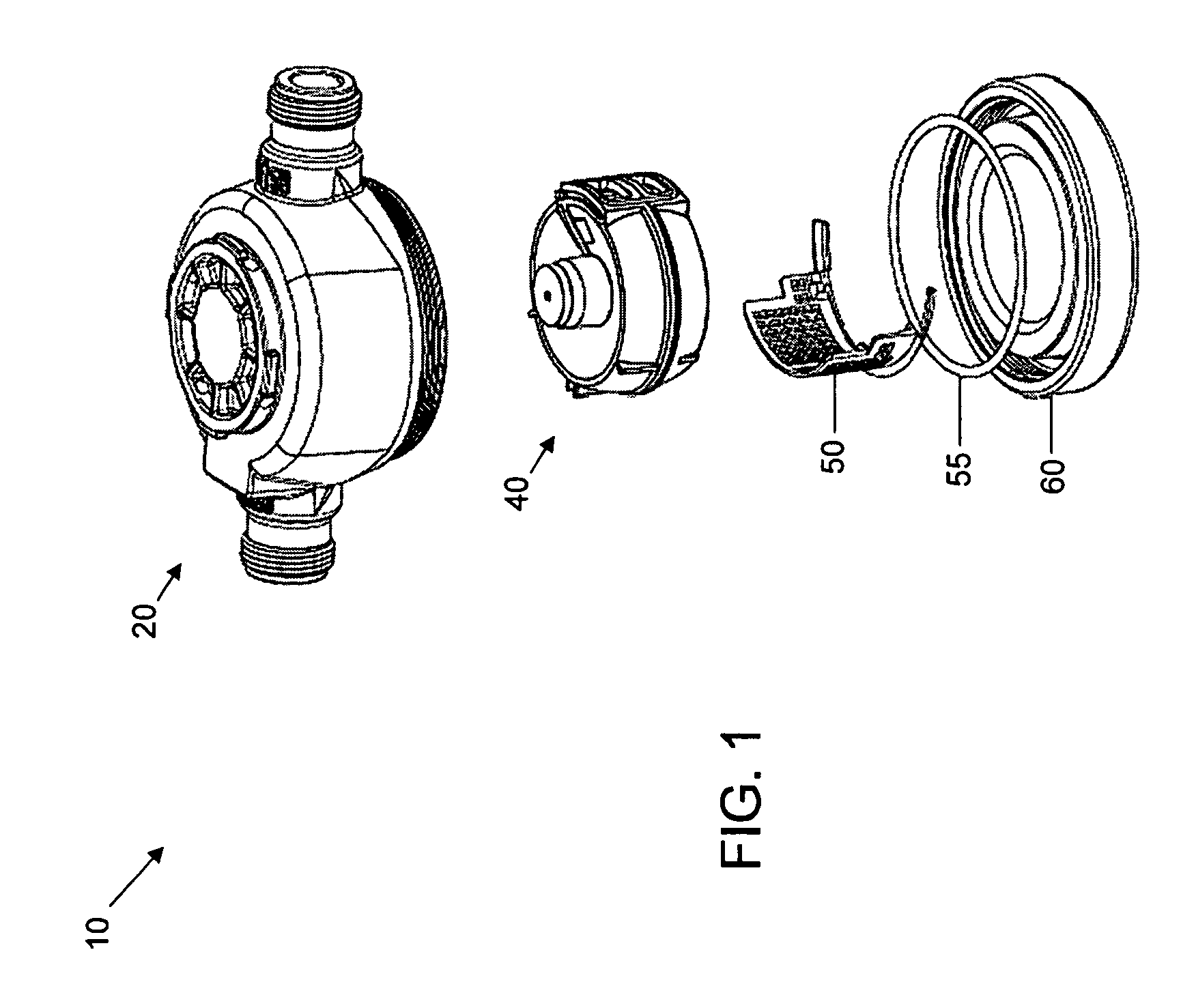

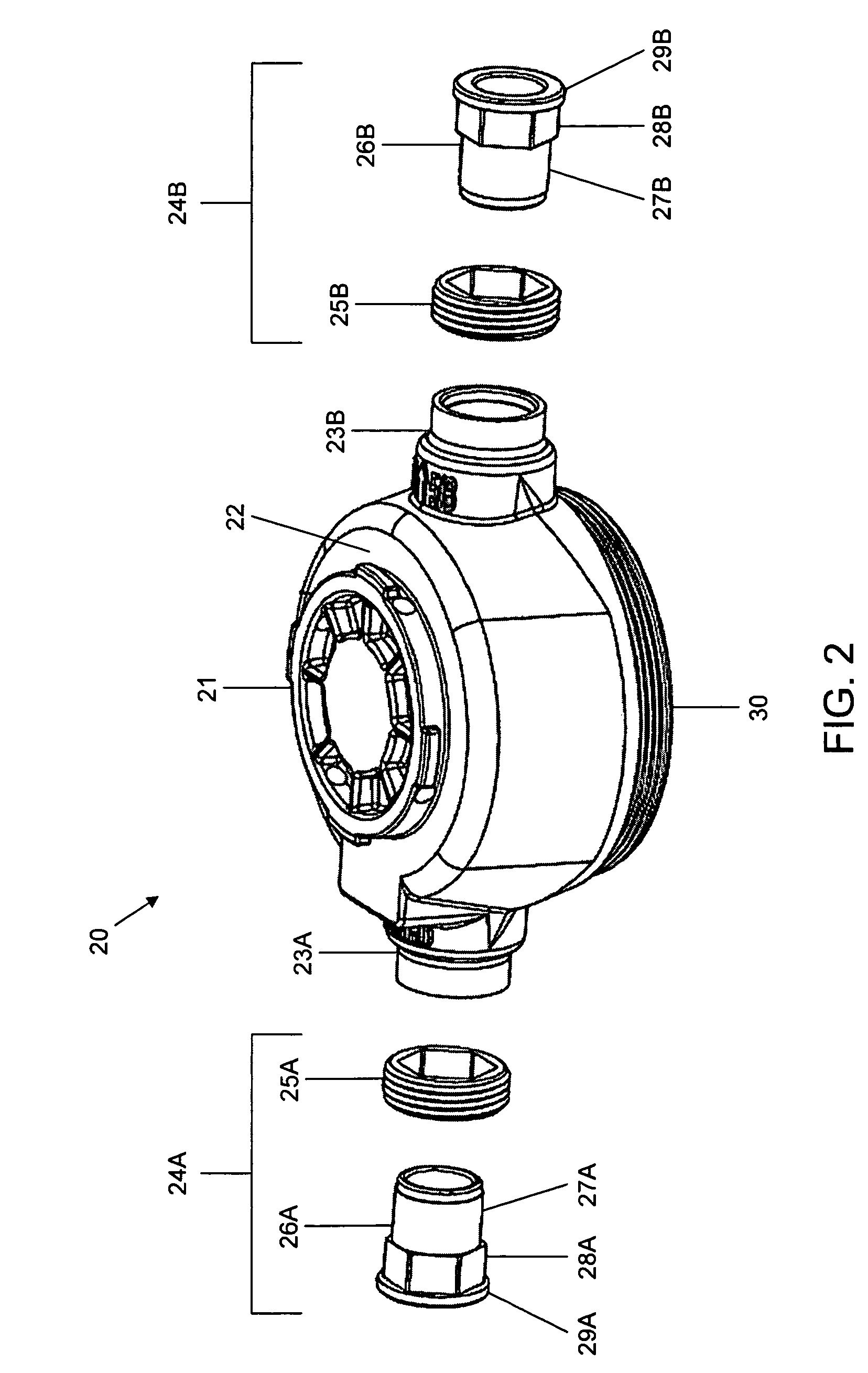

Plastic water meter with metal threads

Embodiments of the present invention generally relate to flow meters and more particularly to improved plastic water flow meters for commercial or residential use. In various embodiments, a plastic water meter is provided that may include metal threads for connecting the water meter to a water system. In particular, the plastic water meter may include at least one spud that is shaped to receive and engage a plastic spud insert, in which the plastic spud insert may include a metal ring with a threaded outer surface. The plastic spud insert may include an annular lip portion extending outwardly to discourage removal of the metal ring when the spud insert is engaged with the water meter. Furthermore, the plastic spud insert and the inner surface of the metal ring may have complementary circumferential profiles to discourage relative rotation between the metal ring and the spud insert.

Owner:MUELLER INT LLC

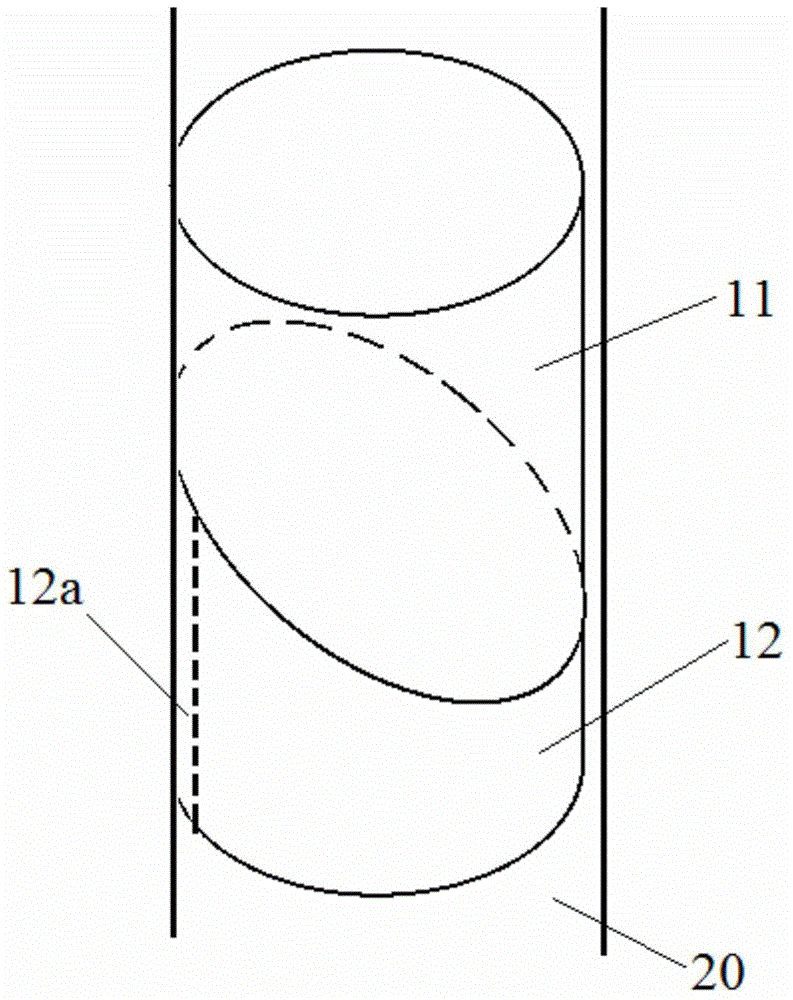

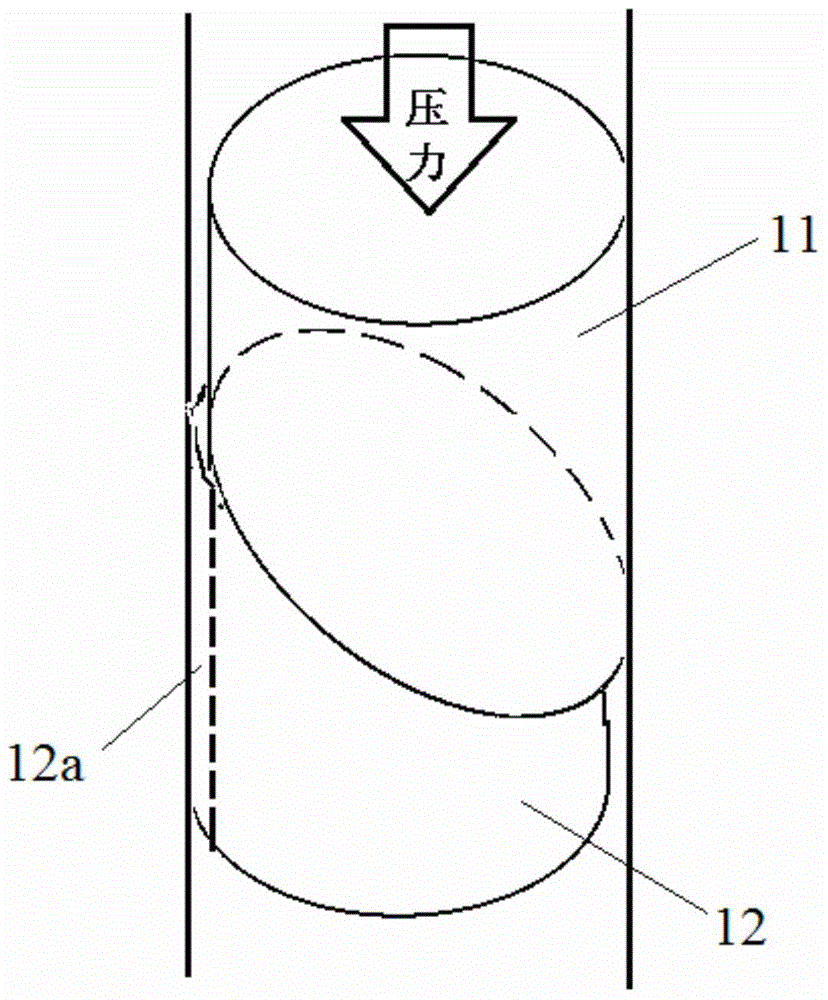

Thin film medical device and delivery system

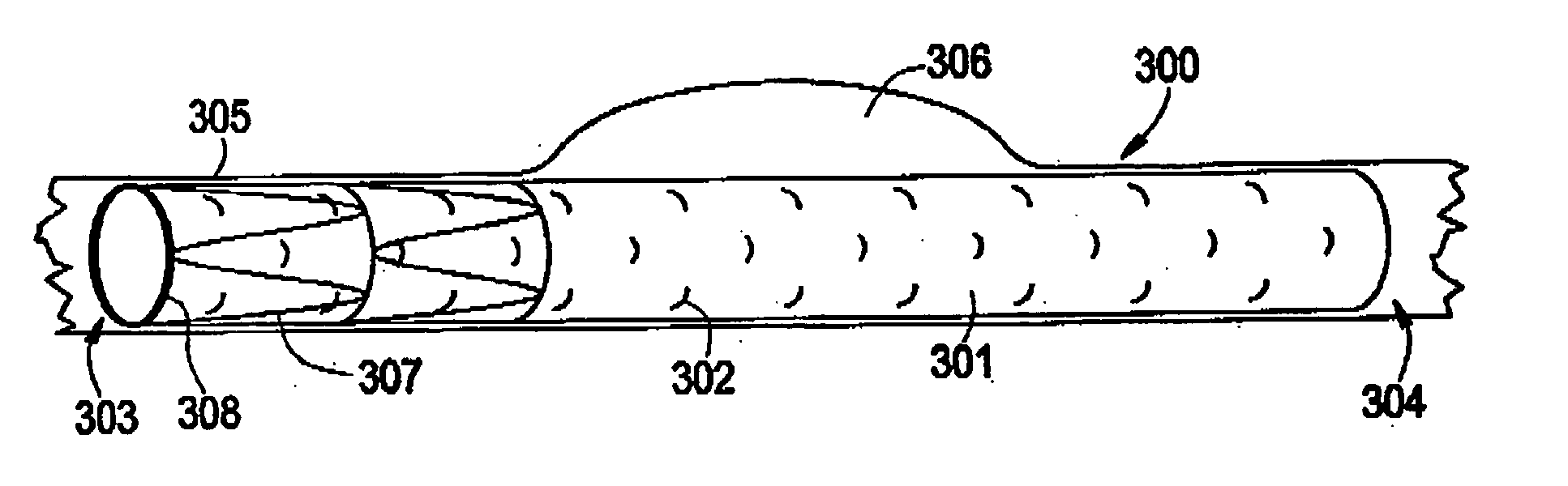

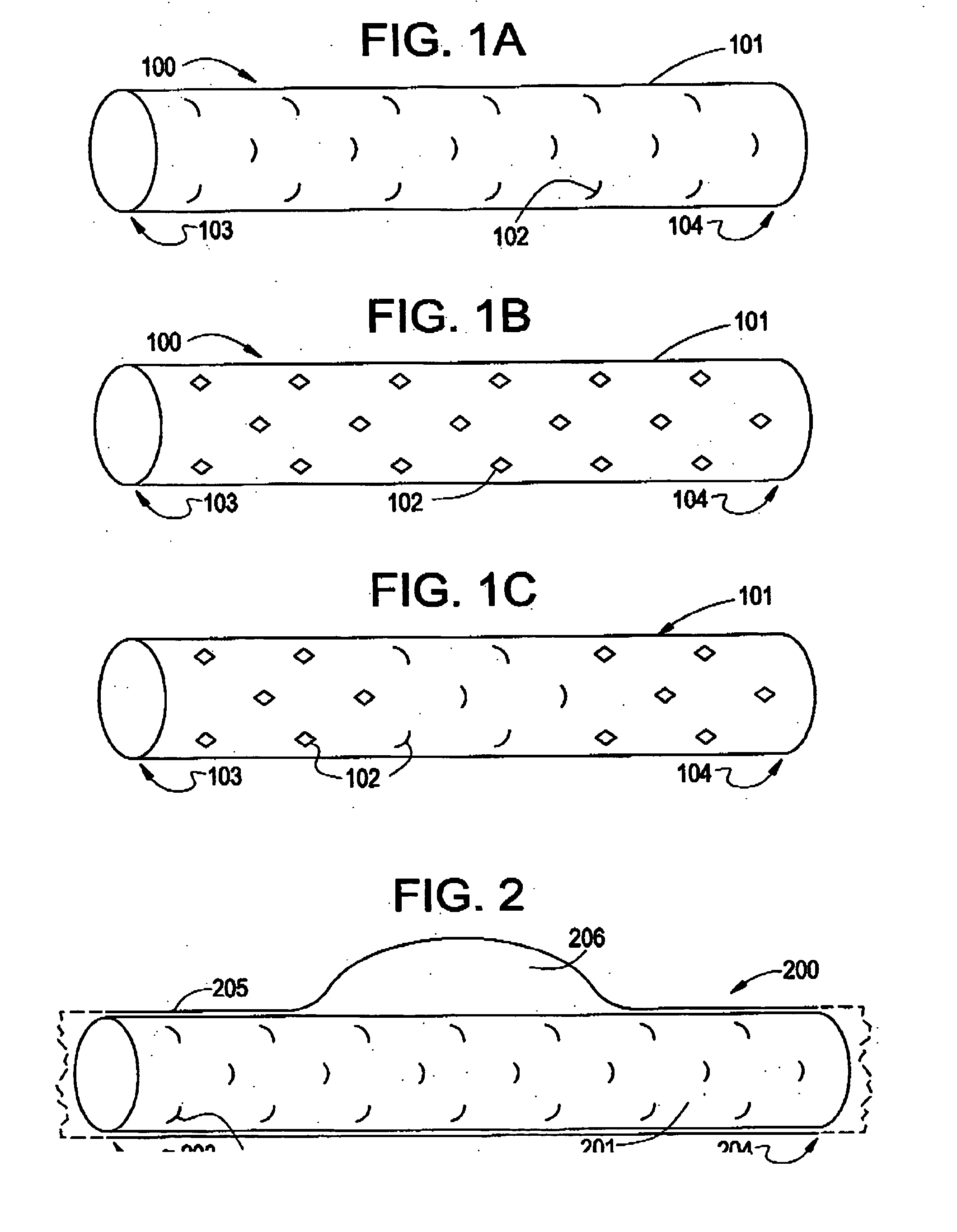

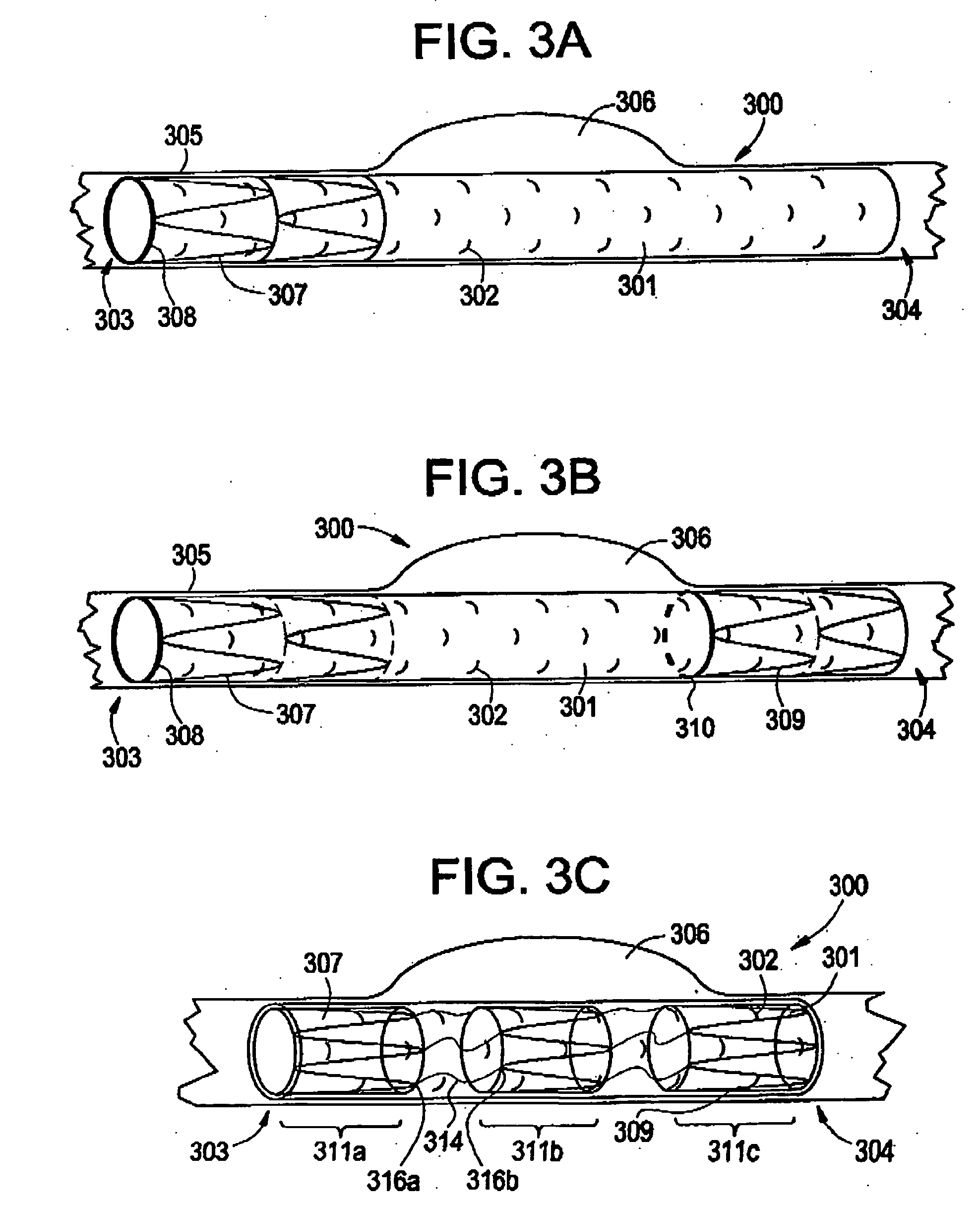

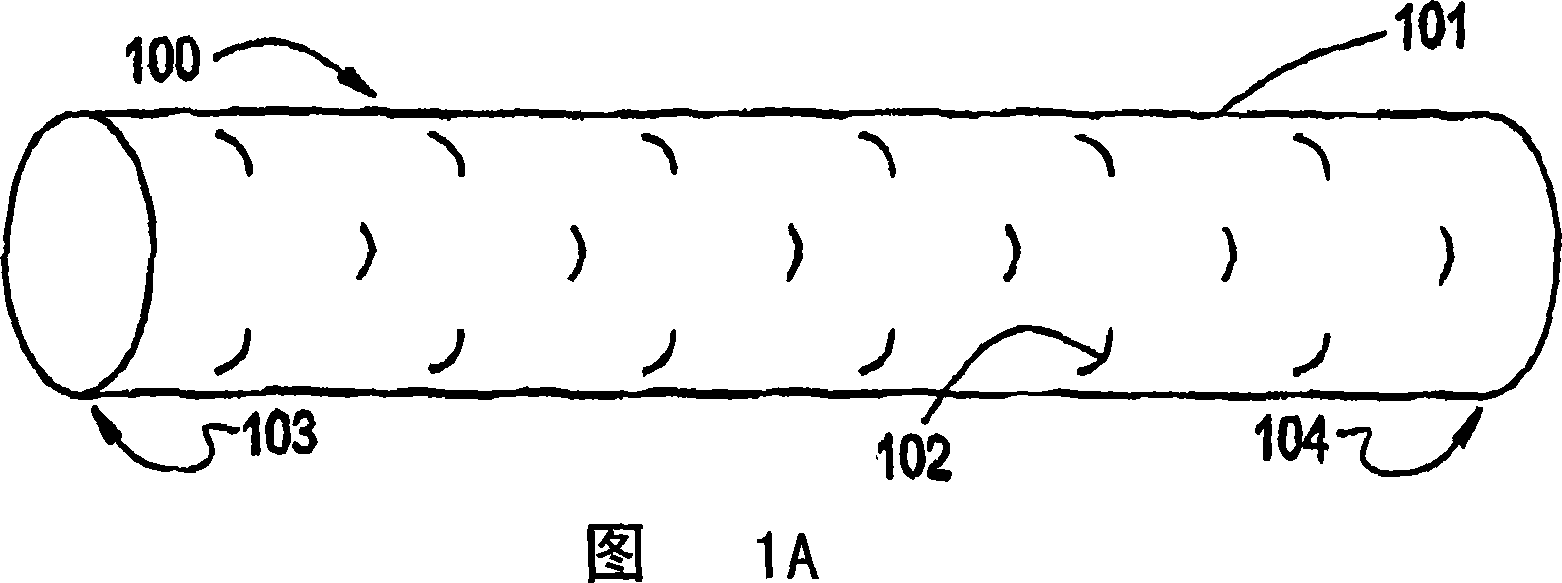

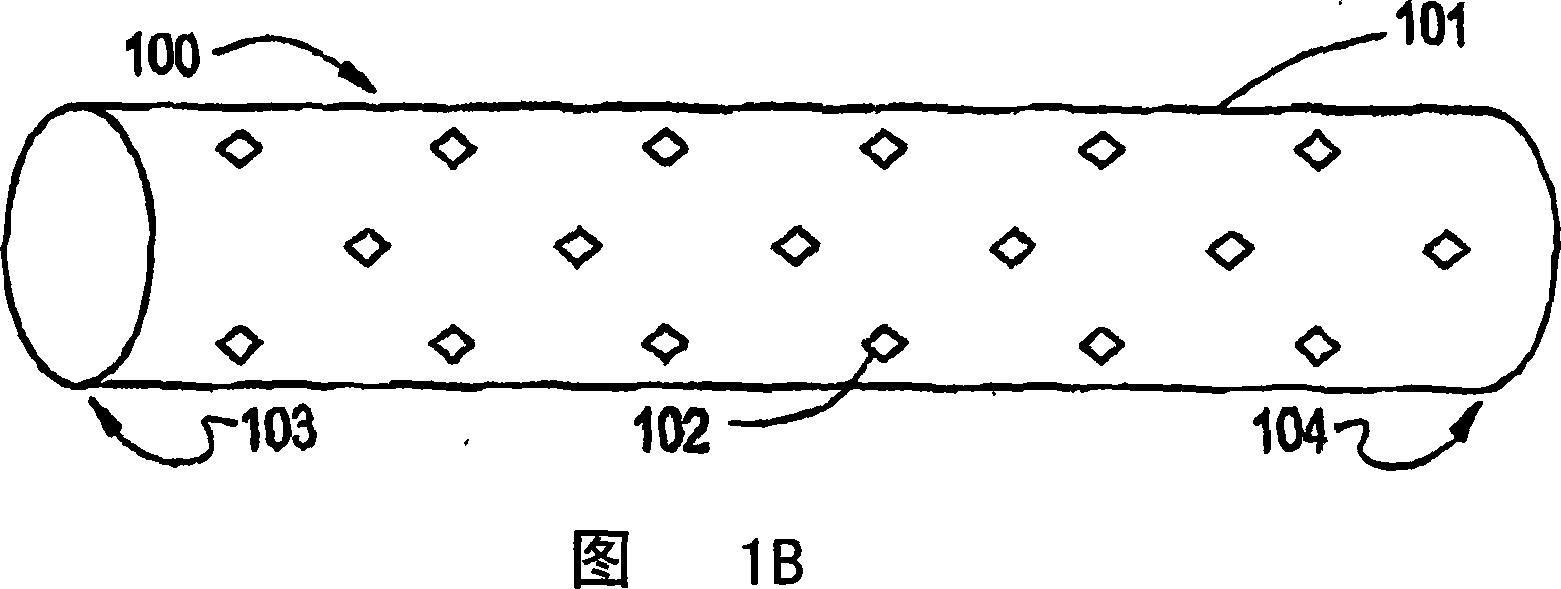

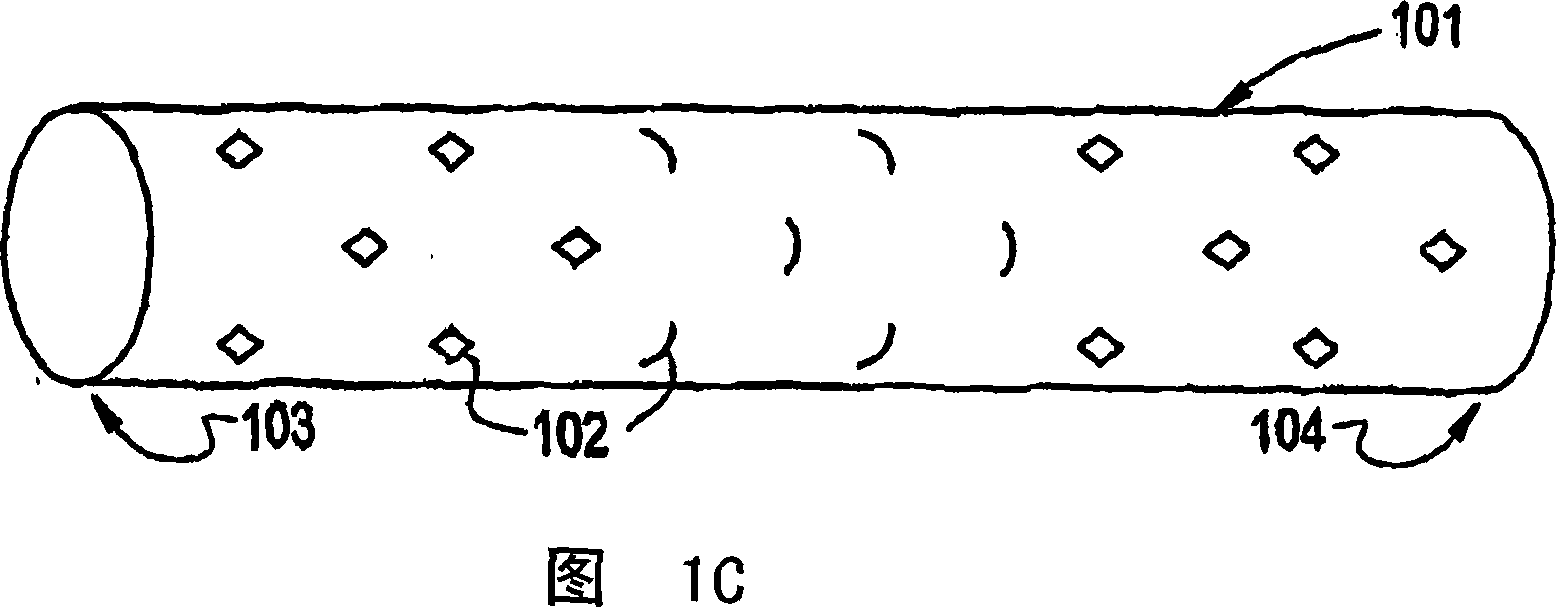

The present invention relates to an intraluminal thin film medical device particularly well suited for occlusion of an aneurysm, vessel side branch or dissection of a body lumen or duct, such as an artery or vein. The medical device has a thin film tube capable of being longitudinally stretched by the application of mechanical energy to achieve a smaller circumferential profile, and self-expand to the pre-stretched length and diameter upon release of the mechanical energy. To assist the thin film during expansion a plurality of slots are incised in the tube wall. The slots open and assist the thin film tube to longitudinally stretch, and substantially close when the thin film tube self-expands to the pre-stretched length and diameter.

Owner:FELLER FREDERICK III

Plastic water meter with metal threads

Embodiments of the present invention generally relate to flow meters and more particularly to improved plastic water flow meters for commercial or residential use. In various embodiments, a plastic water meter is provided that may include metal threads for connecting the water meter to a water system. In particular, the plastic water meter may include at least one spud that is shaped to receive and engage a plastic spud insert, in which the plastic spud insert may include a metal ring with a threaded outer surface. The plastic spud insert may include an annular lip portion extending outwardly to discourage removal of the metal ring when the spud insert is engaged with the water meter. Furthermore, the plastic spud insert and the inner surface of the metal ring may have complementary circumferential profiles to discourage relative rotation between the metal ring and the spud insert.

Owner:MUELLER INT LLC

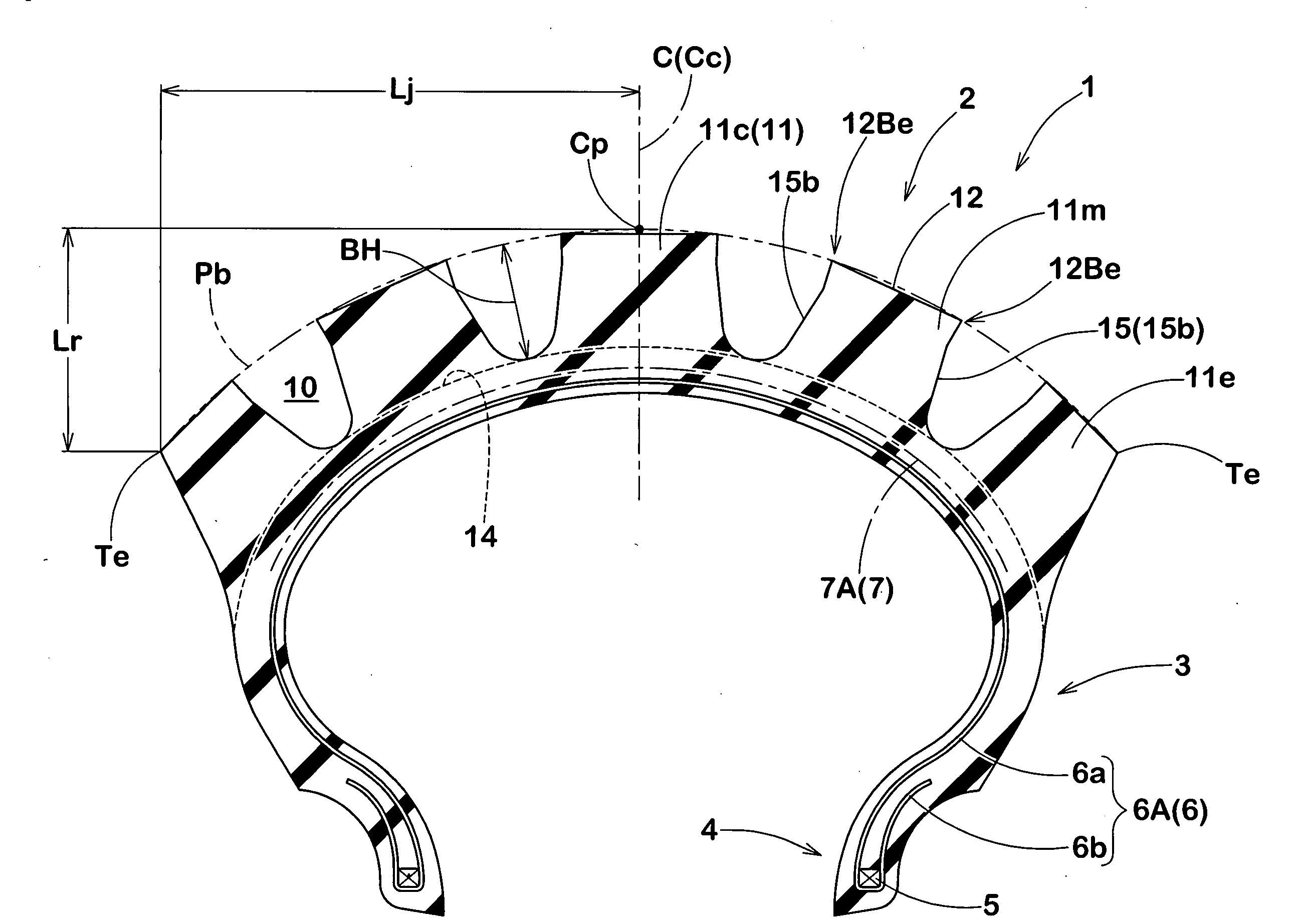

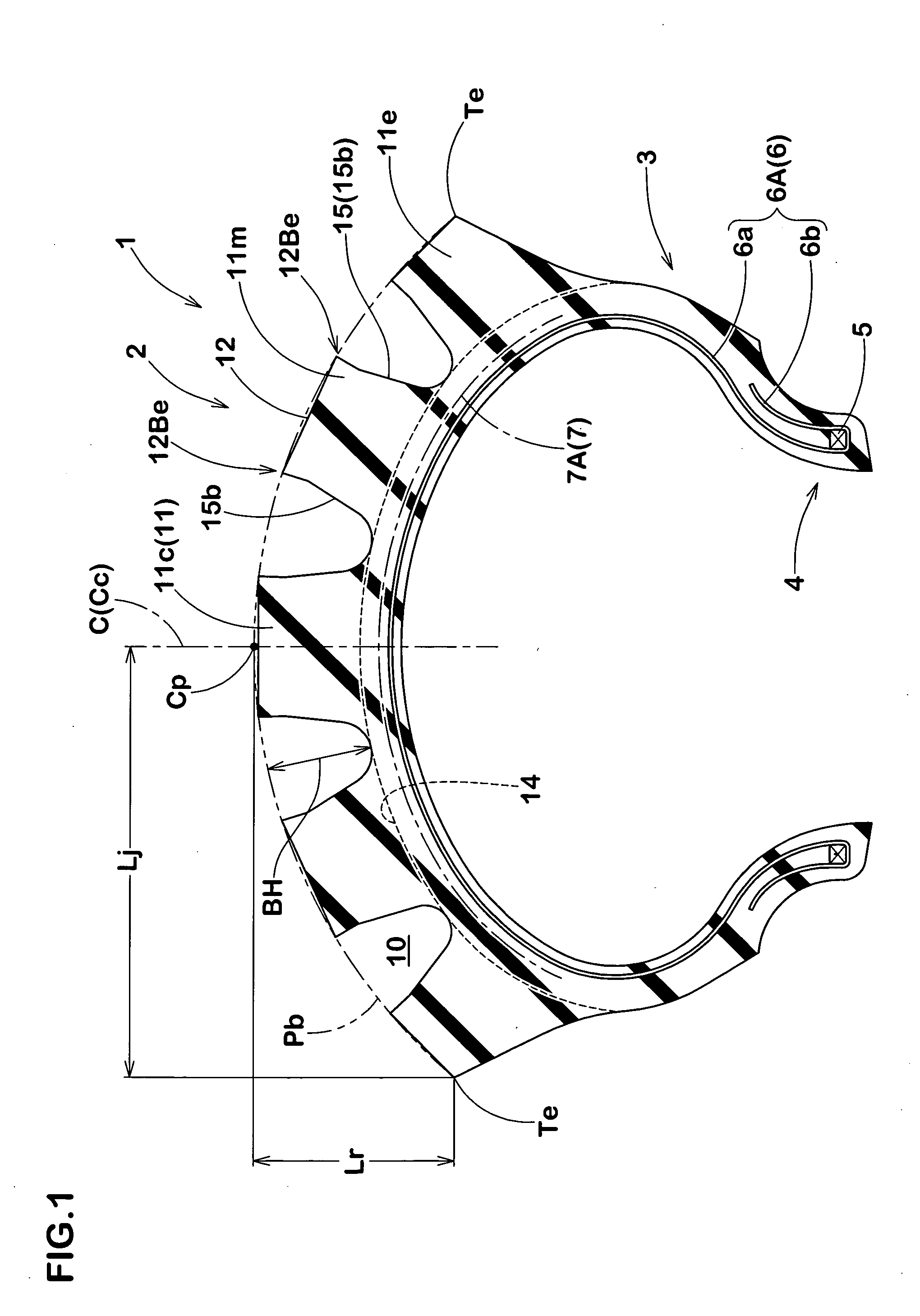

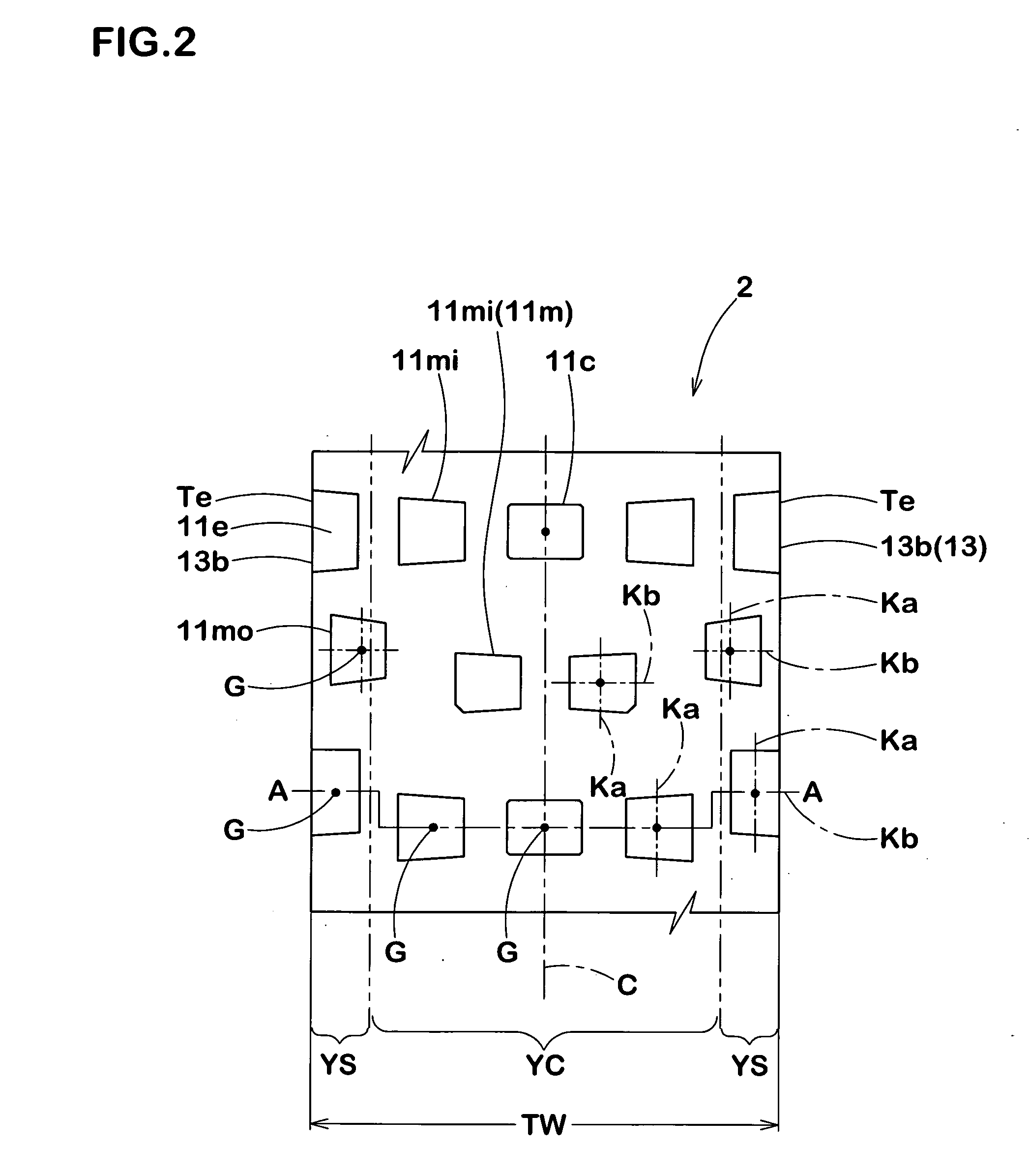

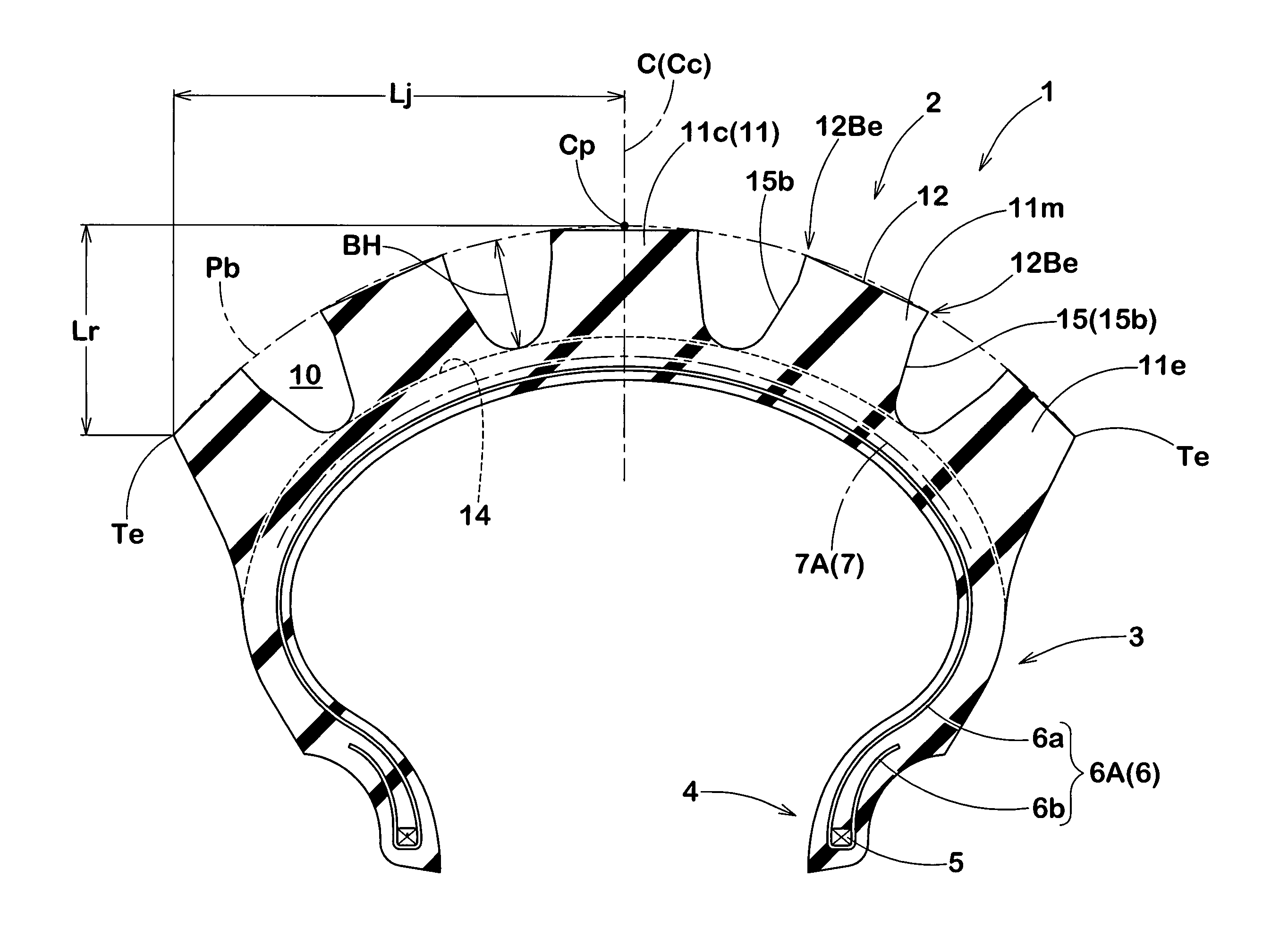

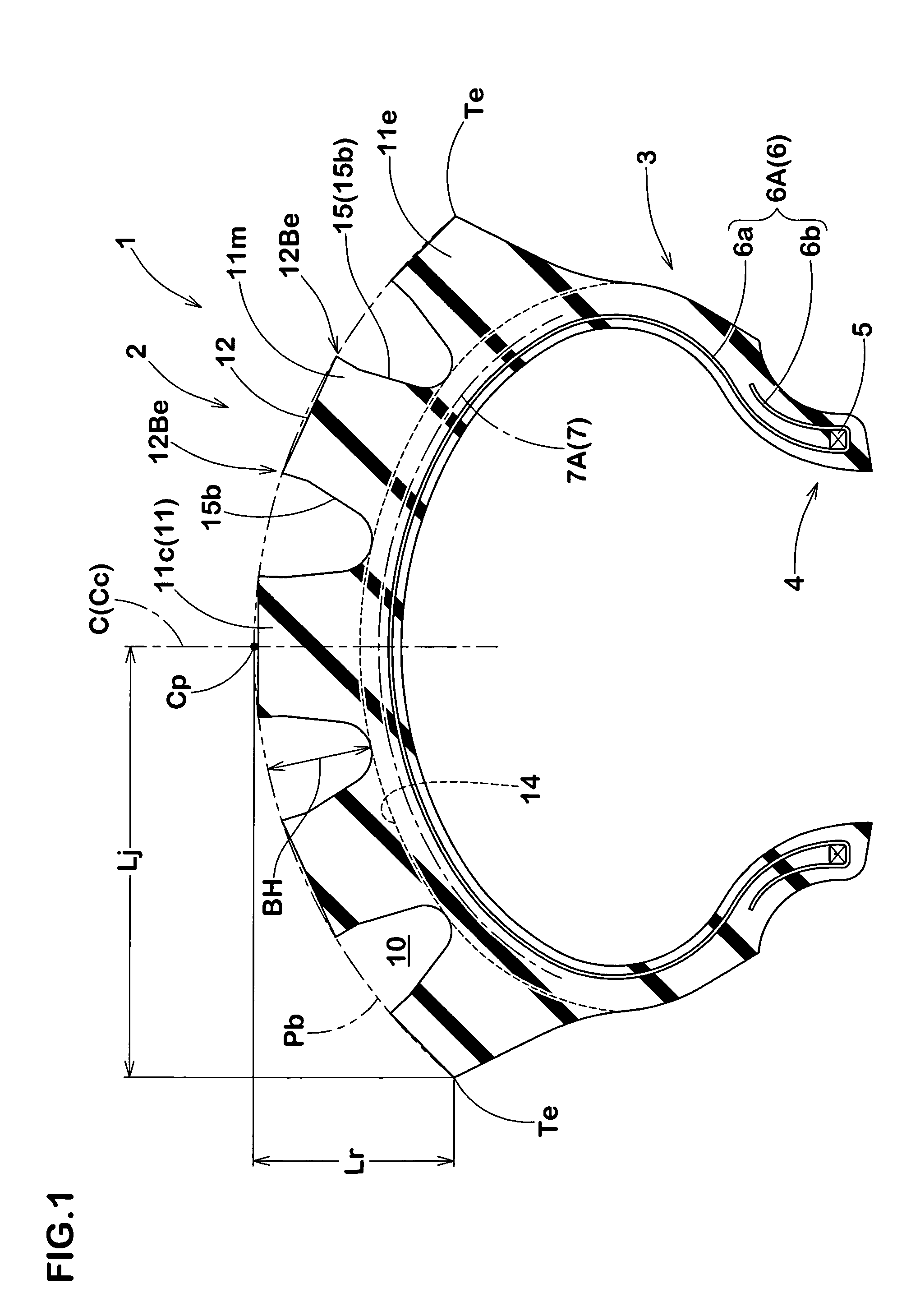

Motorcycle tire for off-road traveling

InactiveUS20080283167A1Enhance the edge effectImprove traction performanceOff-road vehicle tyresMotorcycle tyresCircumferential ProfileGround contact

An off-road motorcycle tire having a block pattern comprising a plurality of blocks 11 defined by tread grooves 10, each block 11 having a circumferential profile 16 of top surface 12 in the form of a straight line or a circular arc having a radius Ra of curvature of at least 500 mm, in which the circumferential profile denotes a profile in the circumferential section which passes through the centroid G of the top surface 12 and is parallel to the tire equatorial plane Cc. According to the invention, the ground contact pressure at the periphery of the top surface of blocks 11 is prevented from lowering to enhance the edge effect.

Owner:SUMITOMO RUBBER IND LTD

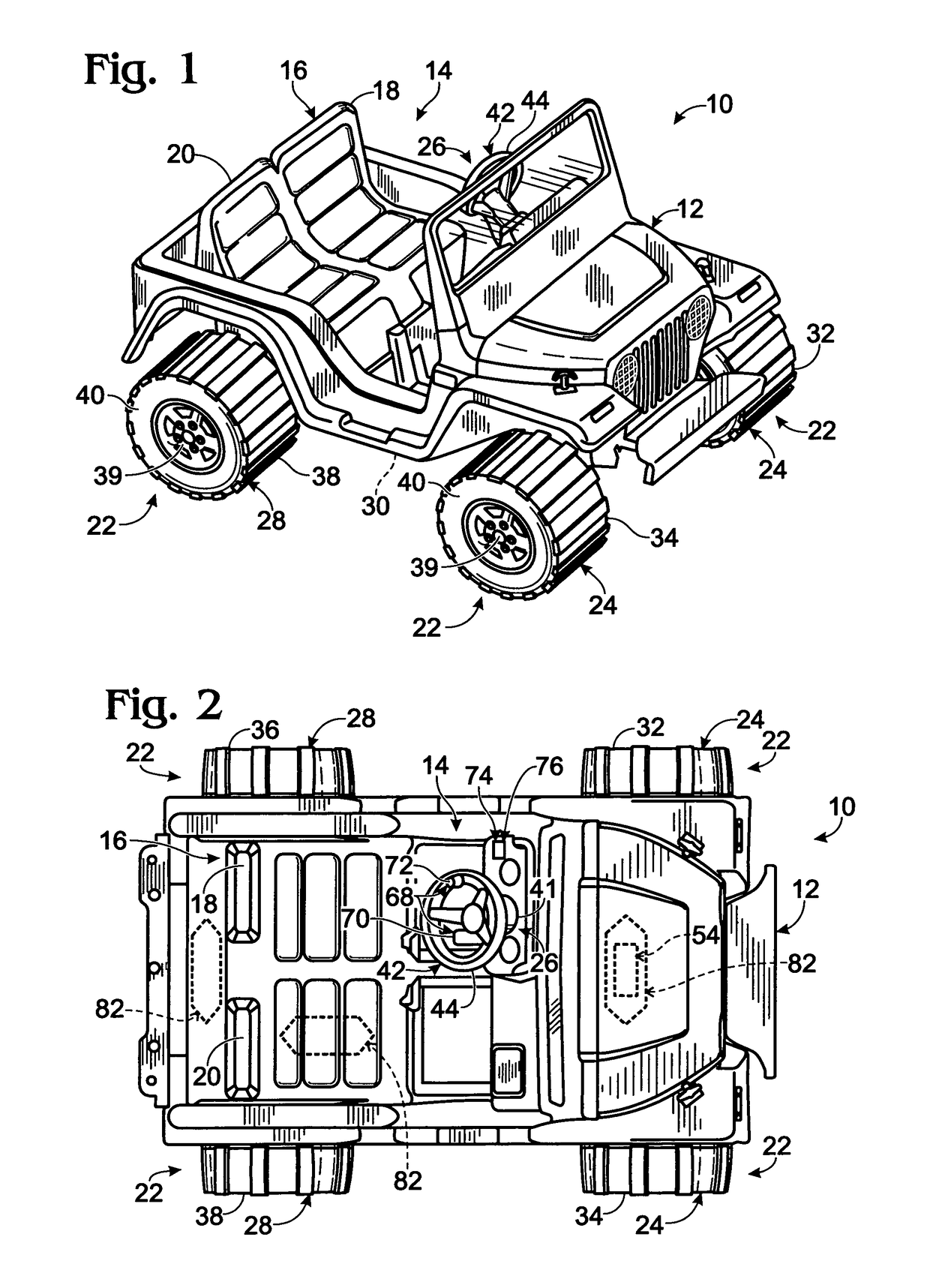

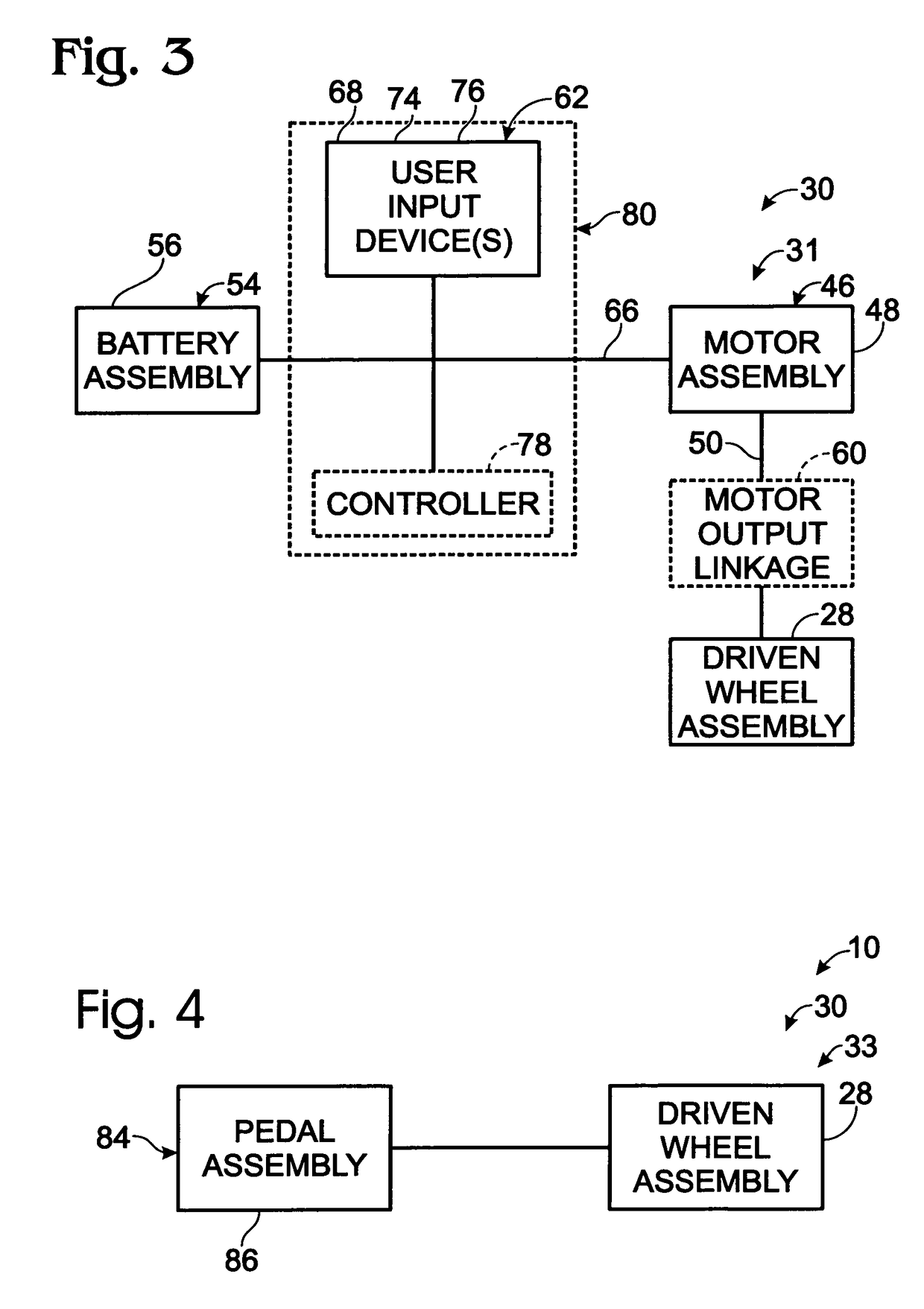

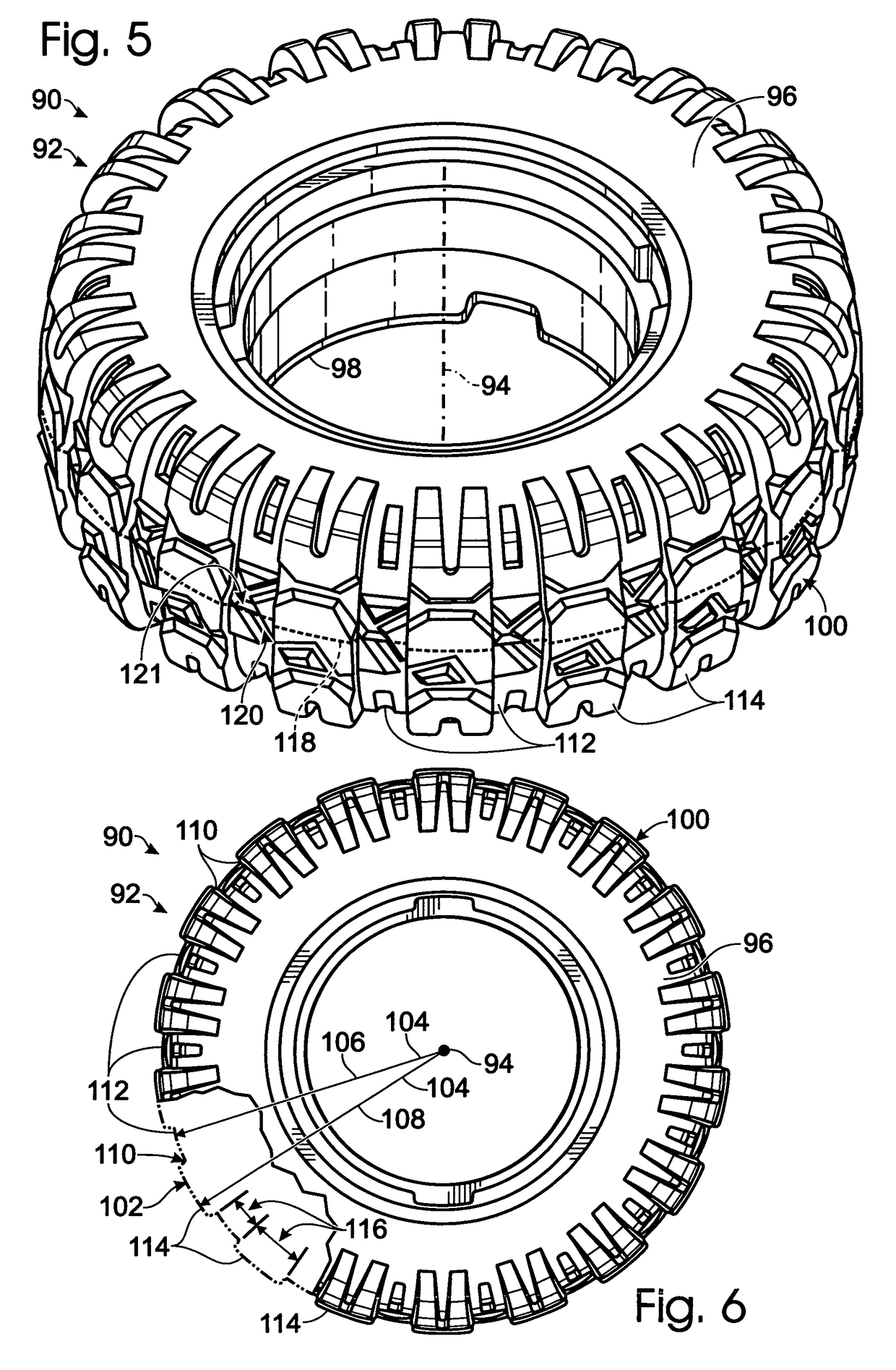

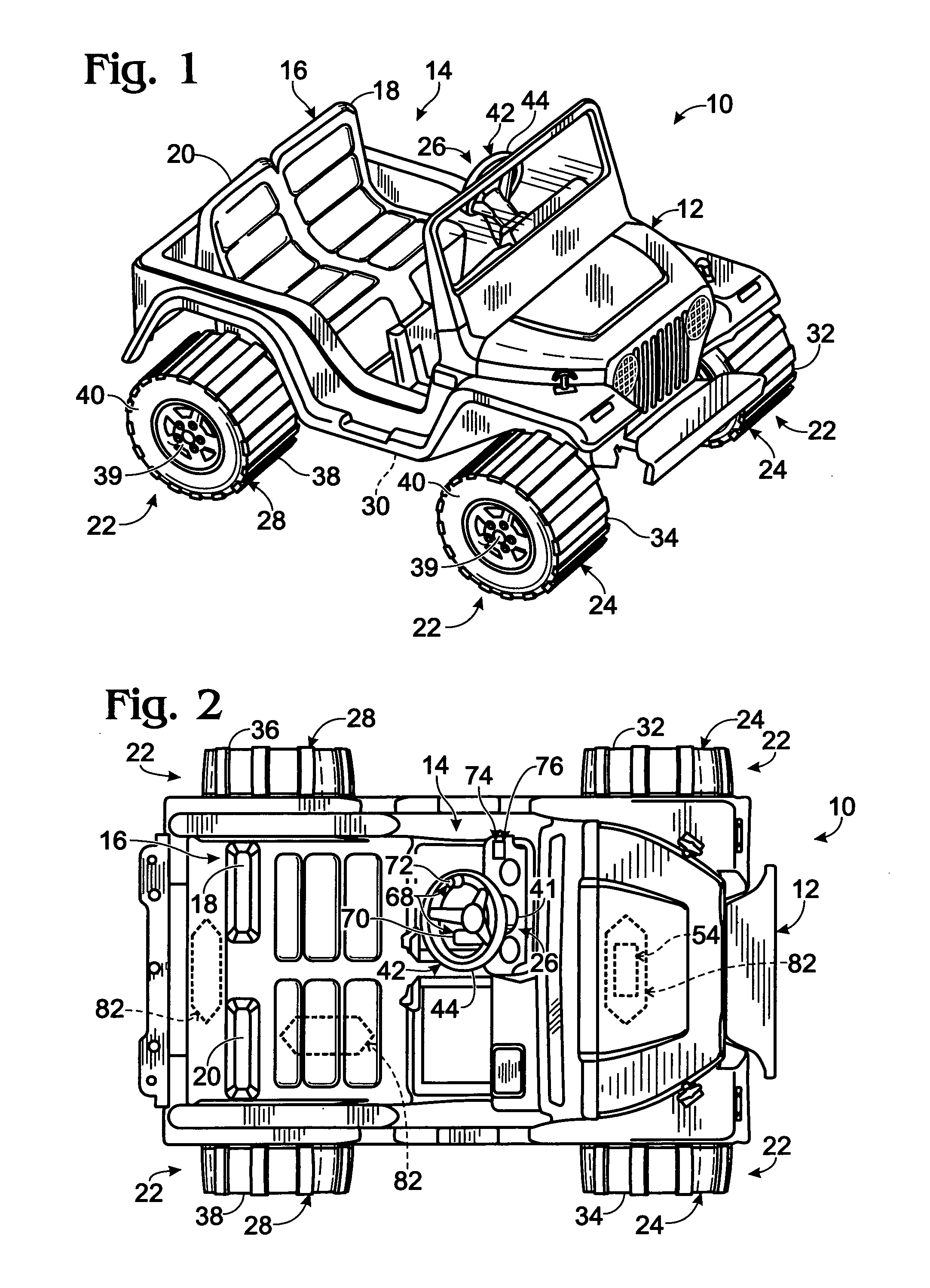

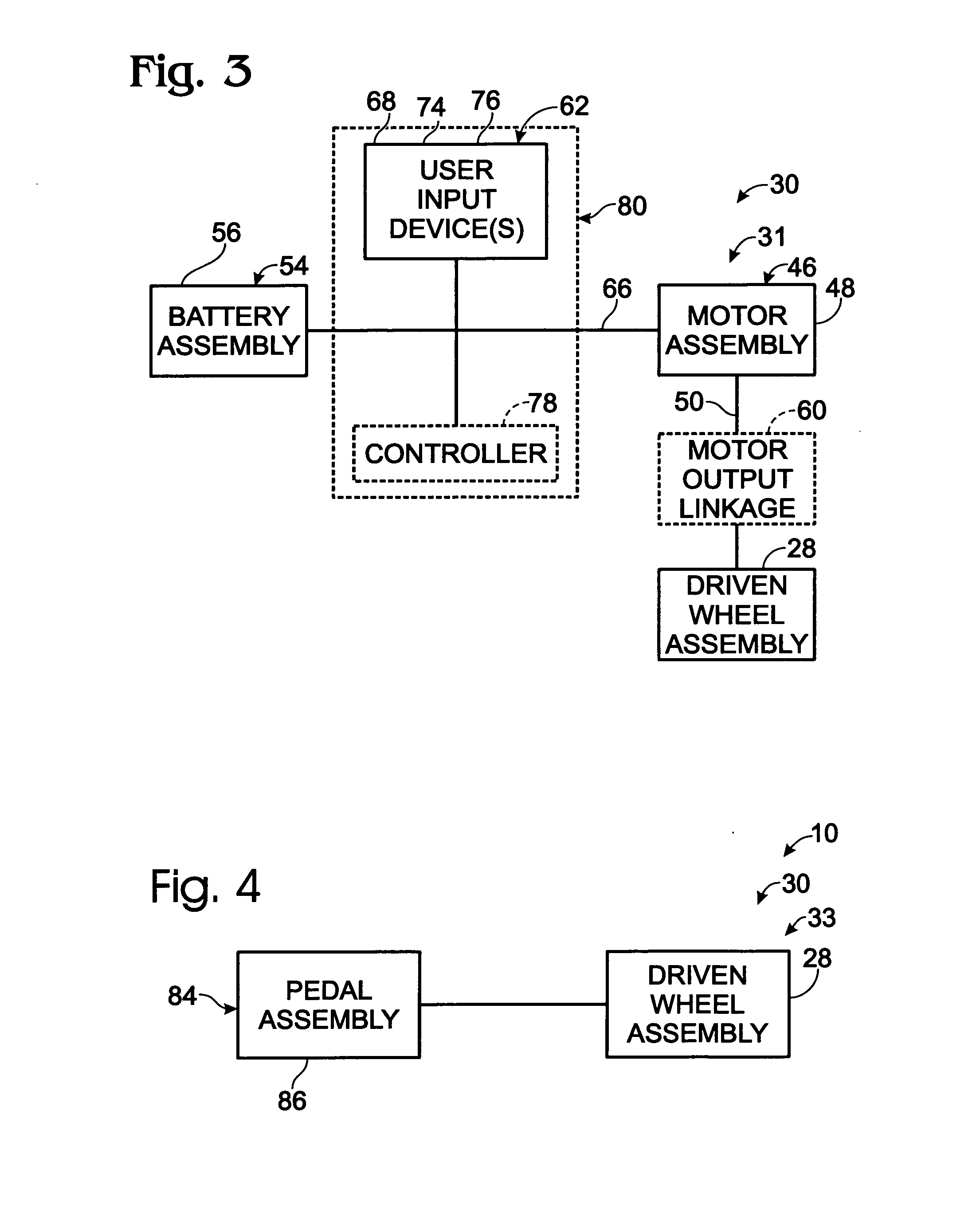

Blow-molded wheels having undulating treads, methods for producing the same, and children's ride-on vehicles including the same

Improved blow-molded wheels, methods for producing the same, and children's ride-on vehicles including the same are disclosed. The blow-molded wheels may include a blow-molded wheel body that is configured to rotate about an axis and has a tread surface that extends circumferentially around the wheel body and may have a circumferential profile that is defined as the locus of points at which the radial distance from the axis to the tread surface is greatest at each position around the circumference of the tread surface. The radial distance from the axis to the circumferential profile may change from a first radius to a second radius that is larger than the first radius at a plurality of spaced-apart positions along the circumferential profile. The method for producing the blow-molded wheels may include providing a mold with pinch-off rings that have an opening configured to form the circumferential profile.

Owner:MATTEL INC

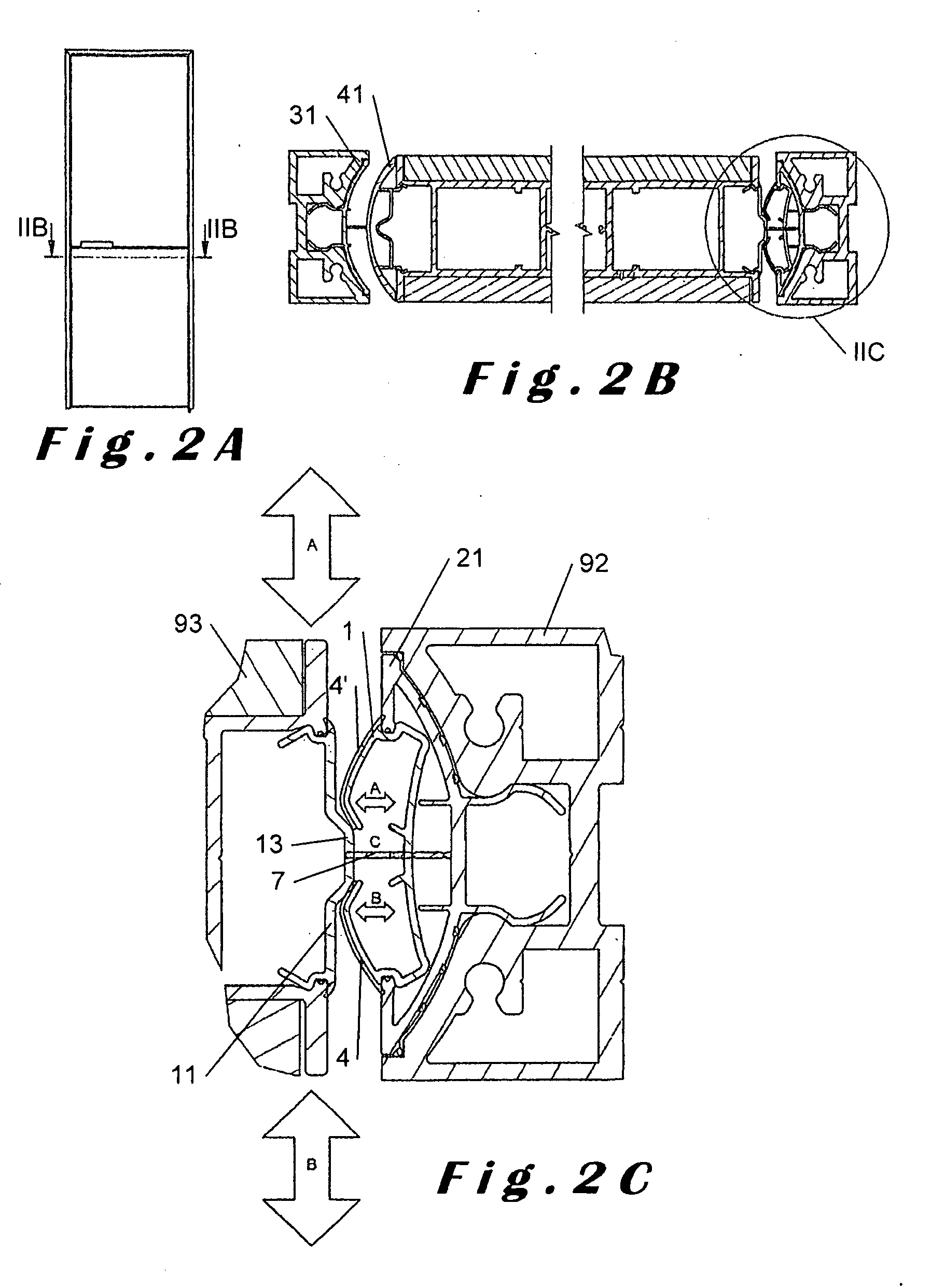

Door with closing profile and integrated ventilation

InactiveUS20090211161A1Reduce pressureReduce gapRevolving doorsVentilation arrangementEngineeringCircumferential Profile

A closing profile for mounting on one of two opposite members of a door assembly, at least one of the opposite members being a rotatable door, the closing profile including a mounting member by means of which the closing profile is mounted to a reveal part of the one member of the door assembly and a flexible member connected to the mounting member, the flexible member being shaped for engaging a complementary edge part on the other member of the door assembly and for releasably maintaining the door in a closed position. The closing profile may have a hollow space between the flexible member and the mounting member to enable the flexible member to deform resiliently towards the mounting member upon opening the door, and the flexible member is preferably longitudinally divided into two wings, each being provided for engaging the complementary edge part and maintaining the closed position in one direction of opening the door, the wings being bendable independently from each other towards the mounting member. A door assembly includes a door and a door frame mountable in a wall opening and a number of circumferential profiles fixable to the door and / or the door frame for optically closing gaps between the door and the wall opening, the door optionally having an oblong grip profile which divides the door into separate door panel segments extending on opposite sides of the grip profile, wherein at least a first of the circumferential profiles and / or the oblong grip profile has an integrated ventilation system and is constructed such that the integrated ventilation system is hidden in the profile and penetration of light therethrough is avoided.

Owner:INDOOR COLLECTION NV

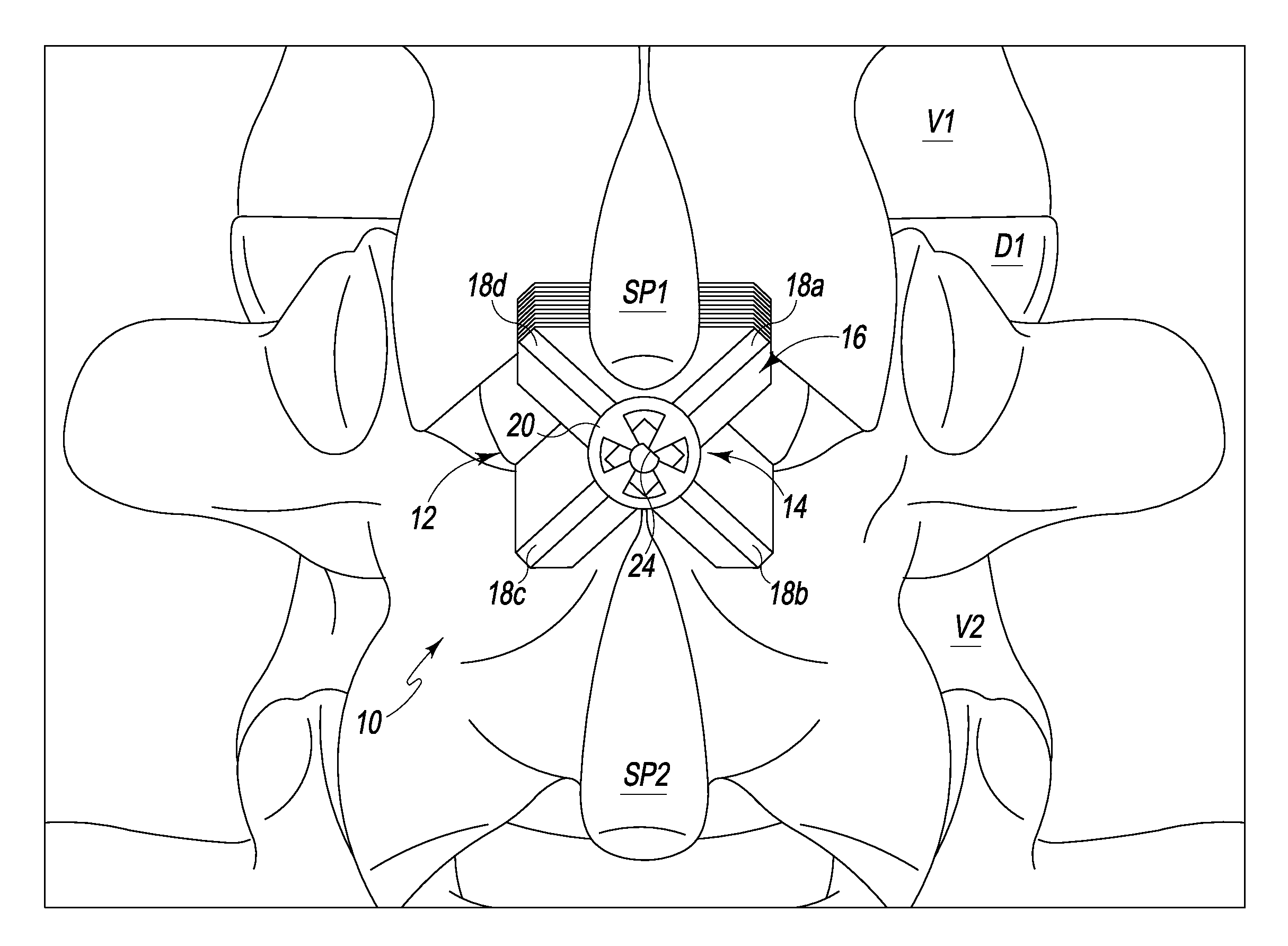

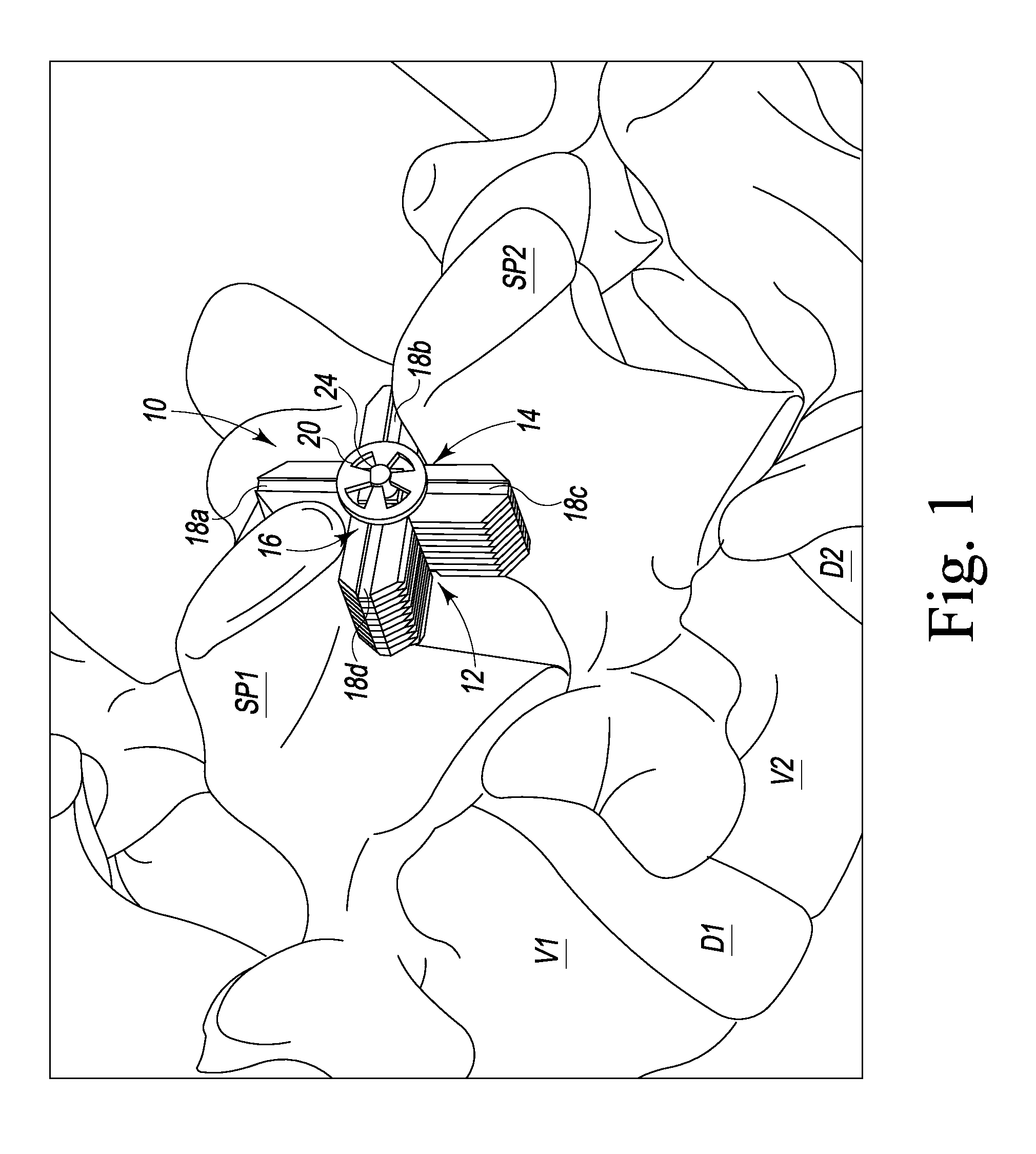

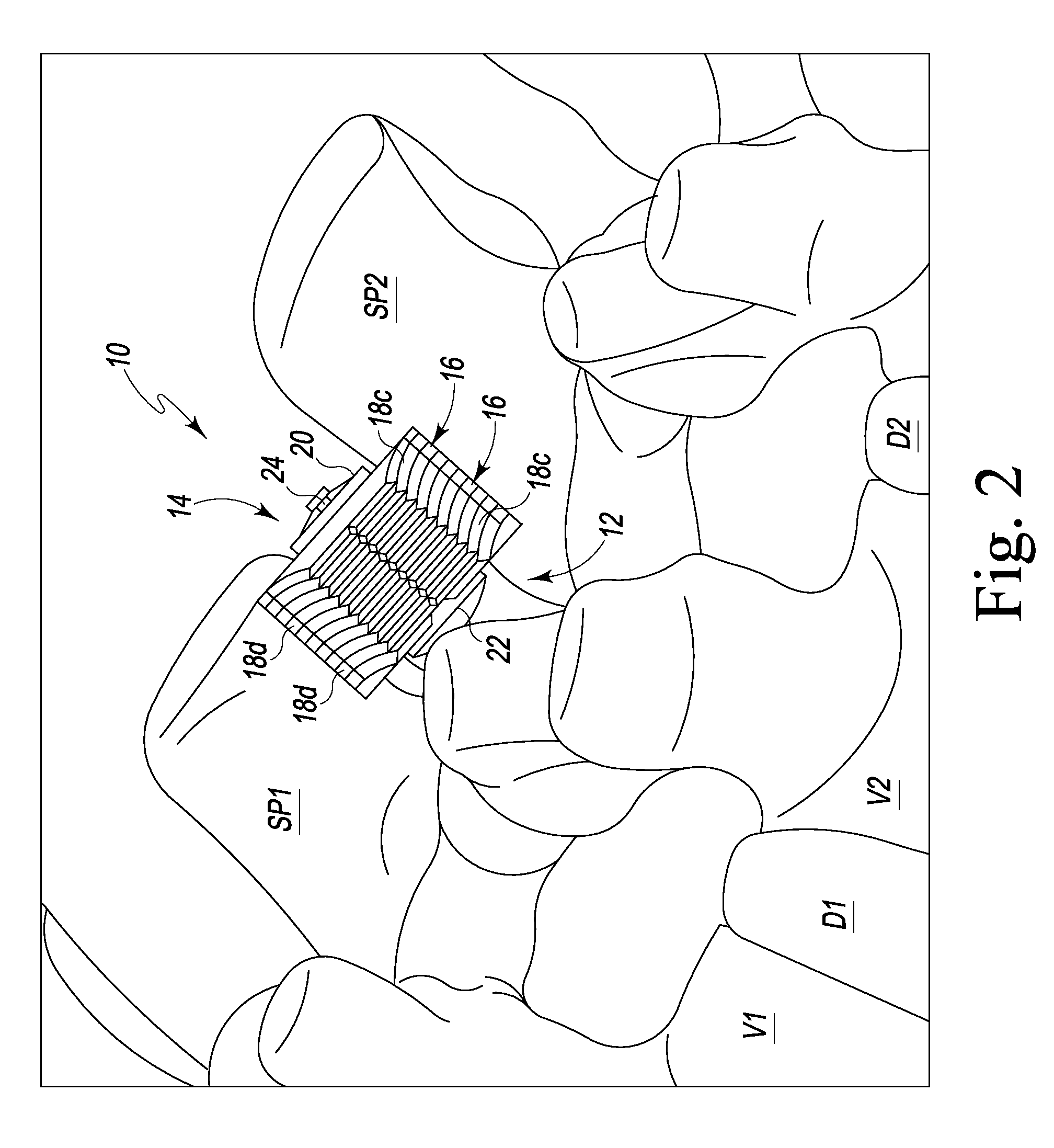

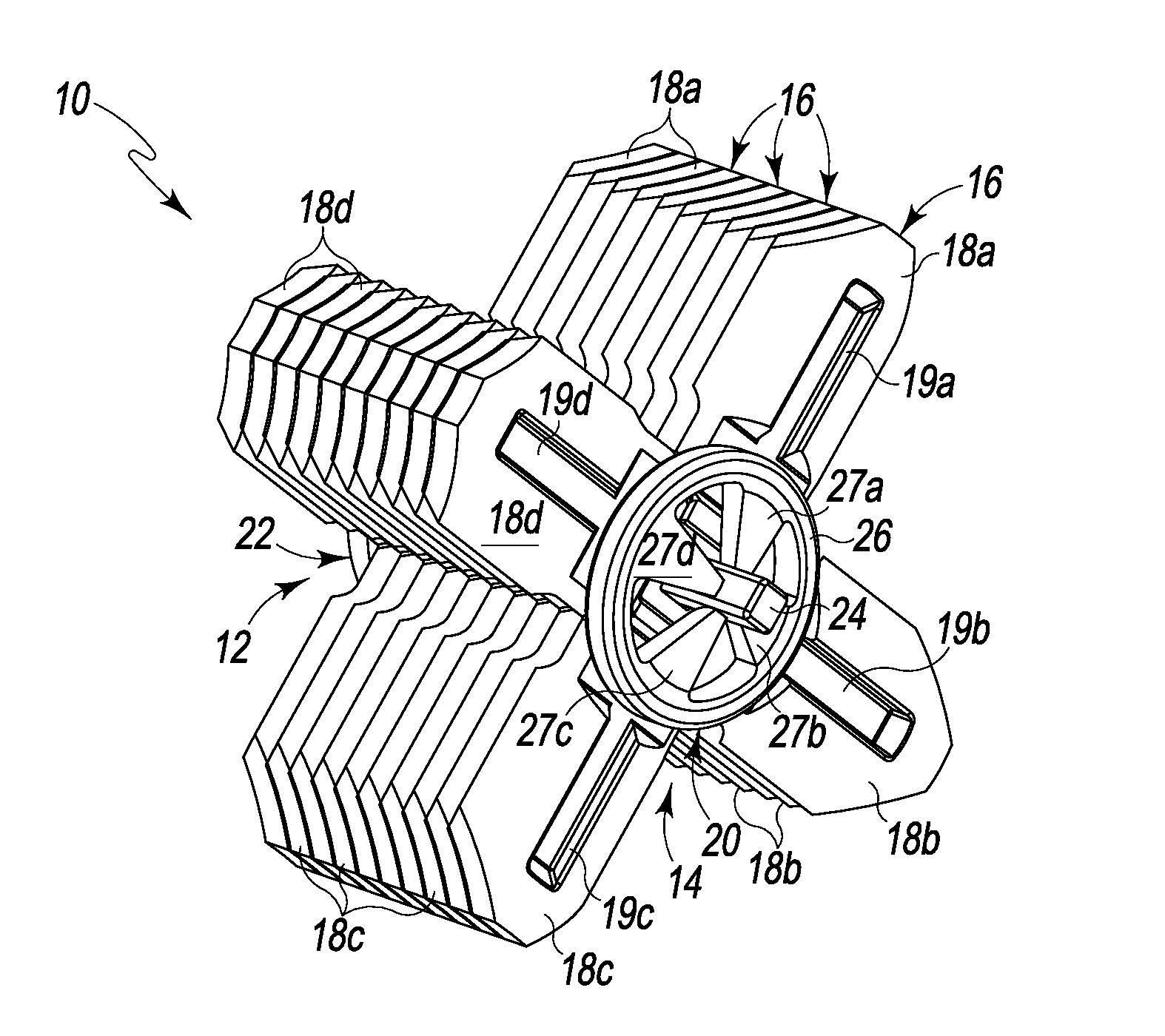

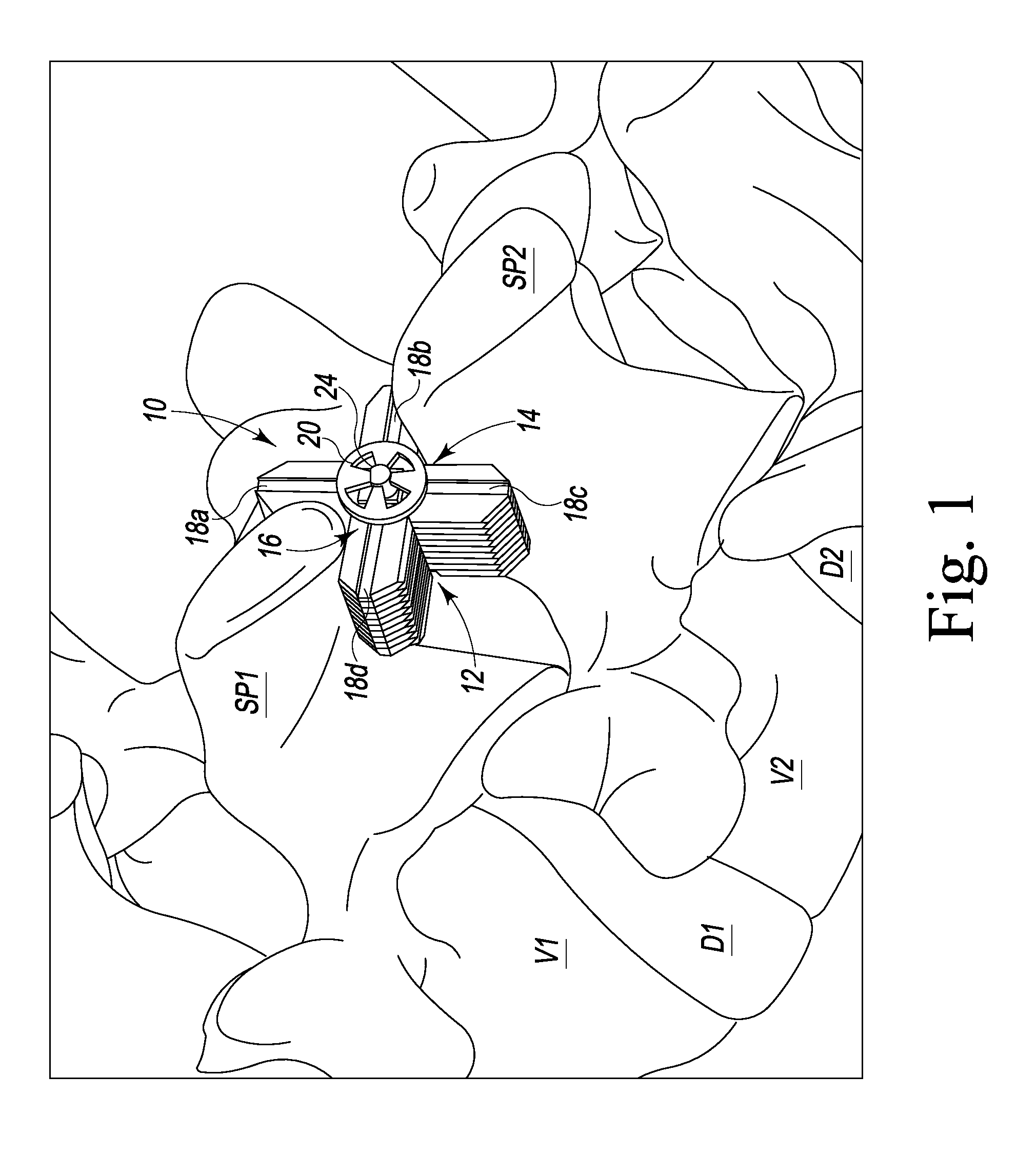

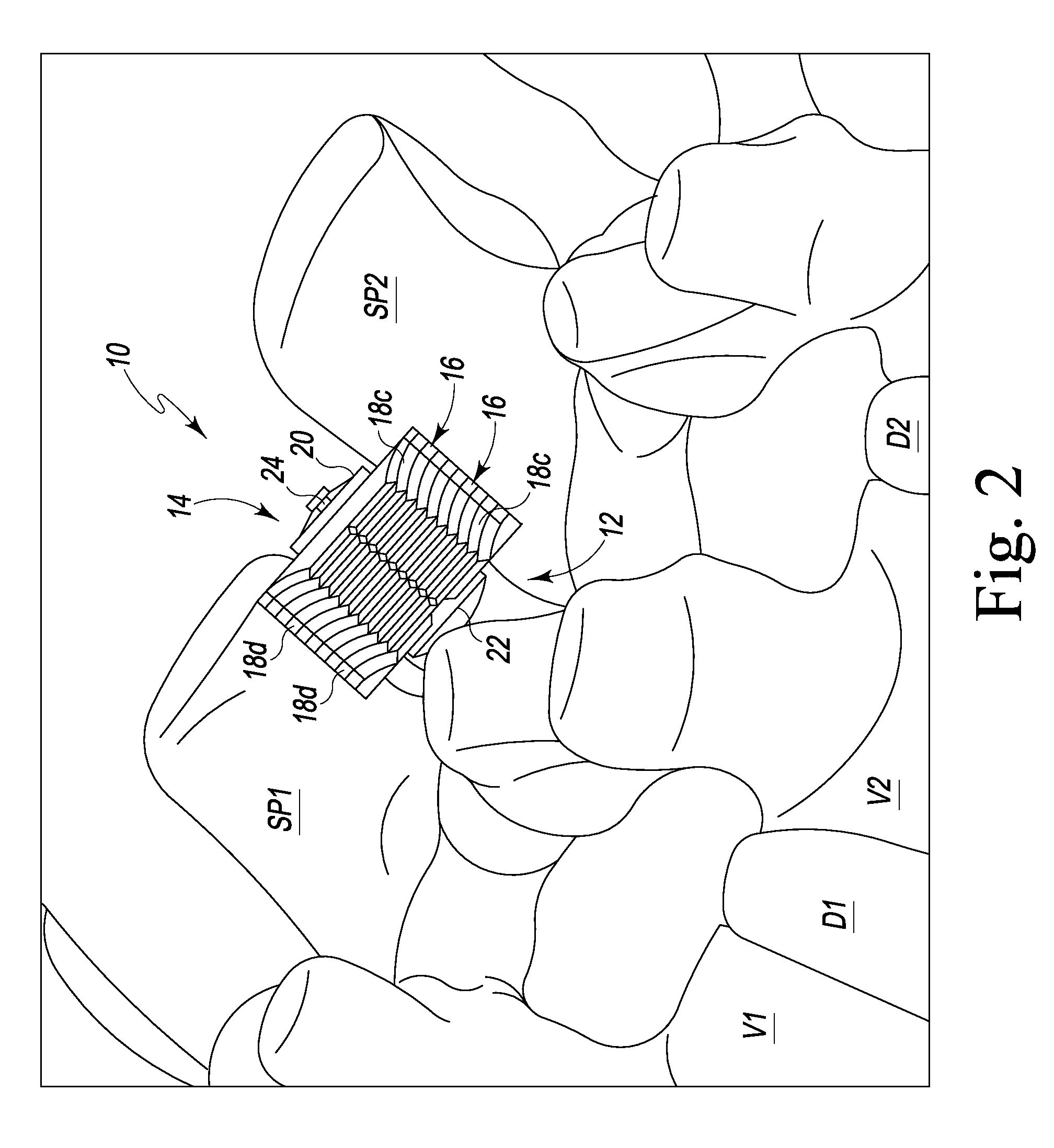

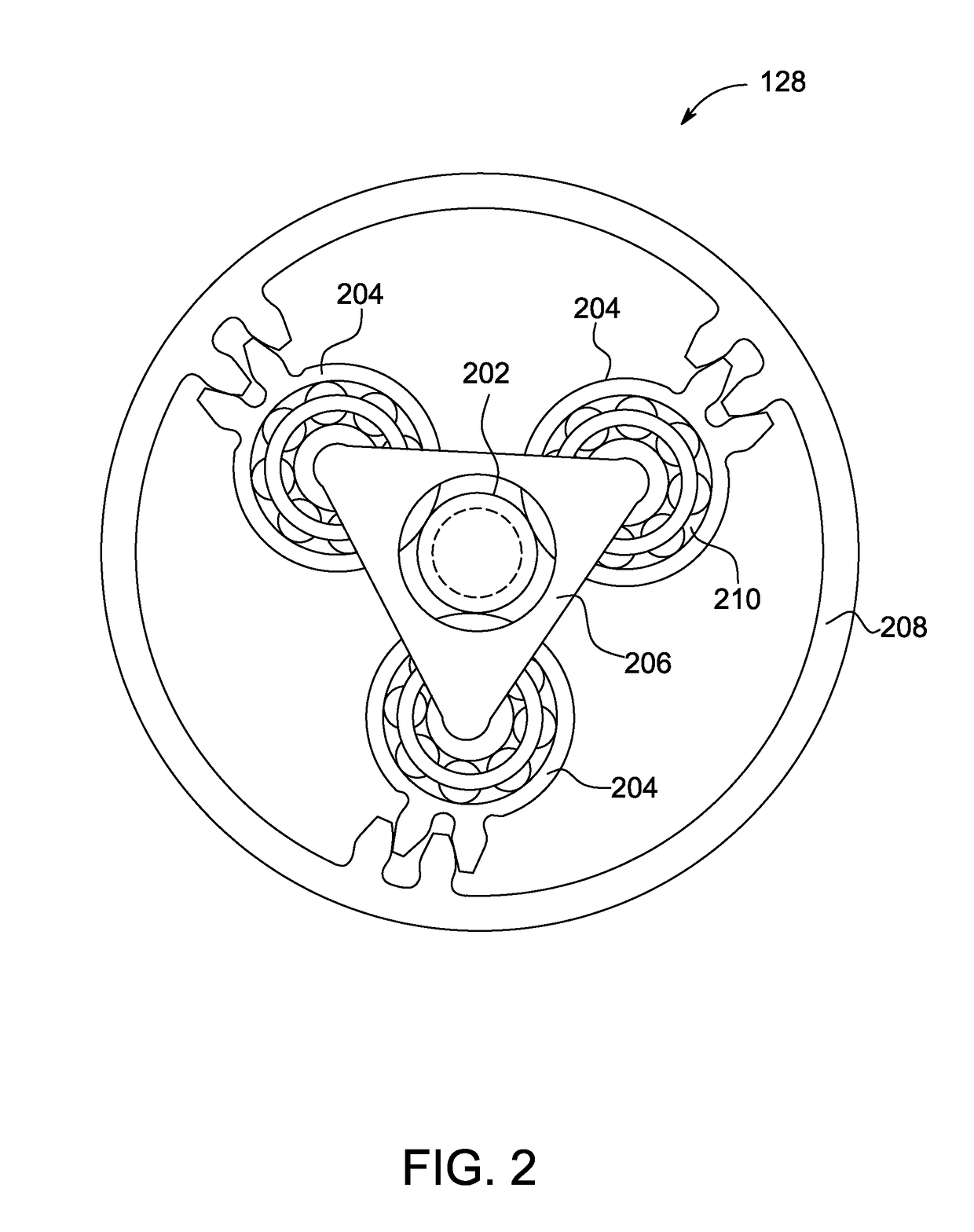

Spinous Process Spacer

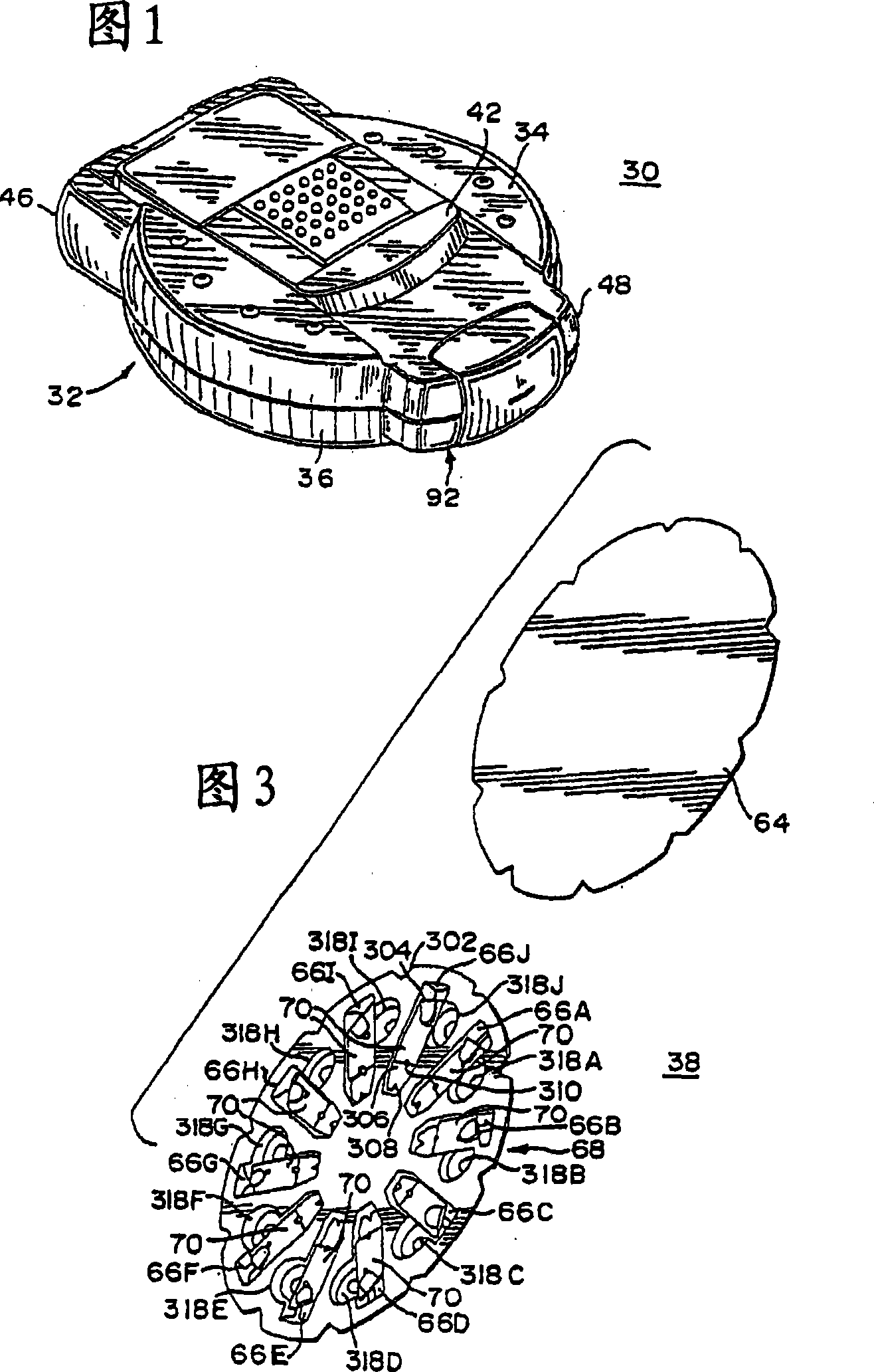

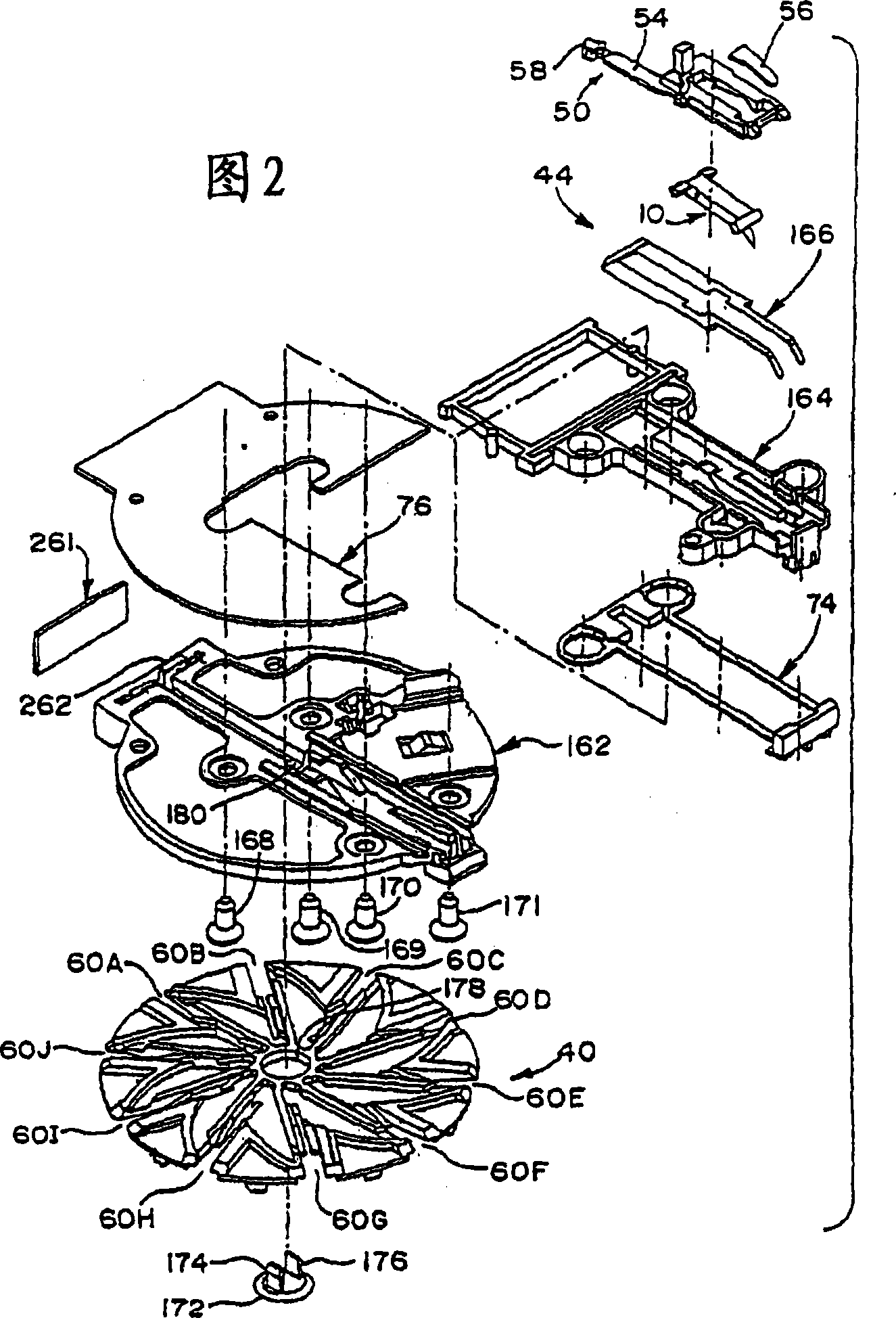

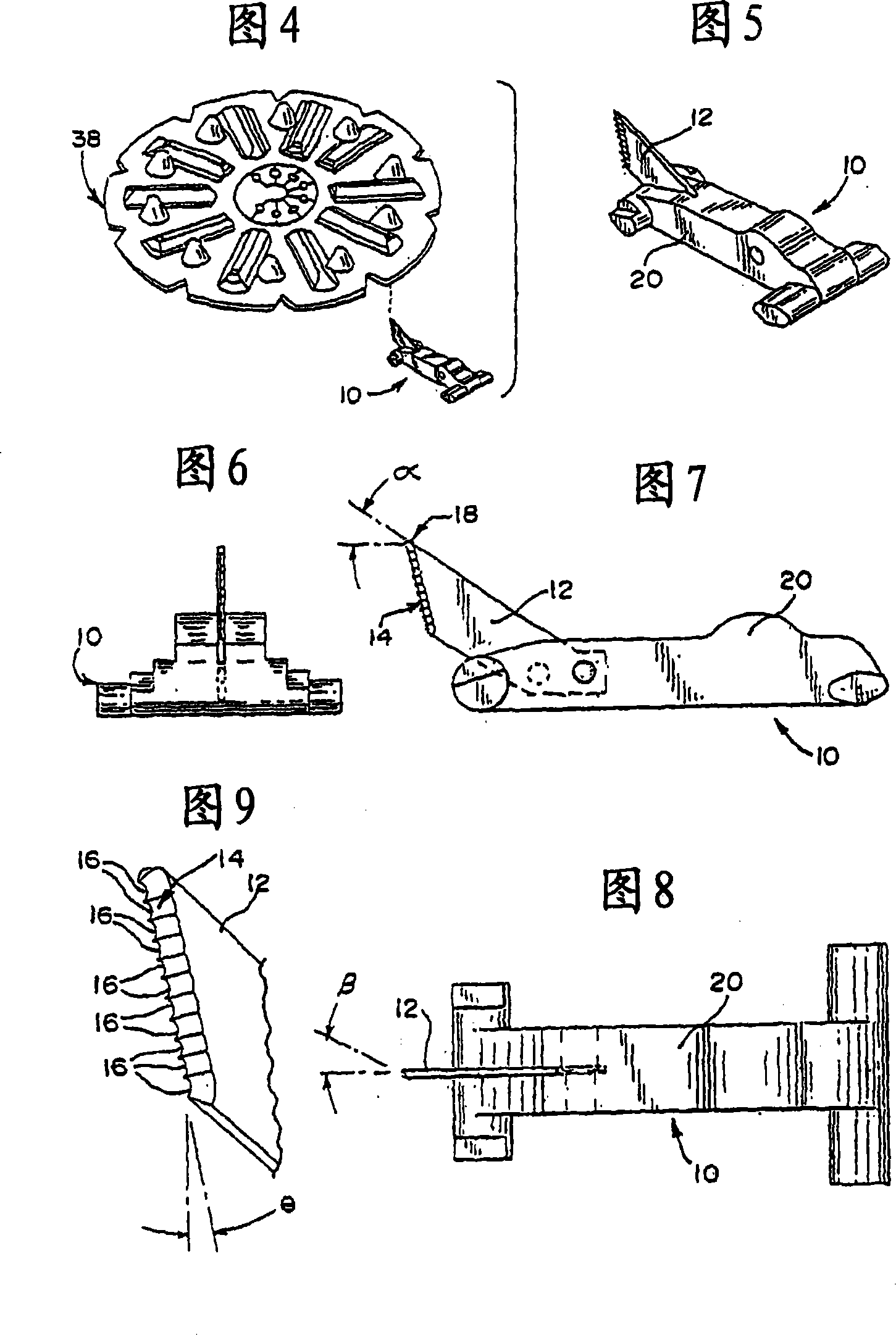

ActiveUS20110029021A1Risk minimizationInternal osteosythesisJoint implantsMedicineCircumferential Profile

A spinous process spacer that is designed to maintain a desired spatial relationship between adjacent vertebrae, is configured for introduction into a spinal implant site in a compressed state and then expands in situ. Once expanded, formations of the present spinal spacer form areas, pockets or spaces that receive at least one bony portion of each adjacent vertebra. The present spinous process spacer has a changeable circumferential profile wherein a first circumferential profile is smaller than a second circumferential profile in order to provide / achieve its compressed and expanded states. The first circumferential profile defines the collapsed position or state while the second circumferential profile defines the position or state. Upon implantation, the present spinous process spacer is not fixed to any bony structure of the vertebrae but provides support. In this regard, use of the spinous process spacer, by itself, will not result in vertebral fusion. However, fusion can result with the use of bone graft packed about the spinous processes (and the spinous process spacer) or in conjunction with the use of an intervertebral body spacer.

Owner:LIFE SPINE INC

Blow-molded wheels having undulating treads, methods for producing the same, and children's ride-on vehicles including the same

ActiveUS20080006456A1Children cyclesElectric propulsion mountingCircumferential ProfileMechanical engineering

Improved blow-molded wheels, methods for producing the same, and children's ride-on vehicles including the same are disclosed. The blow-molded wheels may include a blow-molded wheel body that is configured to rotate about an axis and has a tread surface that extends circumferentially around the wheel body and may have a circumferential profile that is defined as the locus of points at which the radial distance from the axis to the tread surface is greatest at each position around the circumference of the tread surface. The radial distance from the axis to the circumferential profile may change from a first radius to a second radius that is larger than the first radius at a plurality of spaced-apart positions along the circumferential profile. The method for producing the blow-molded wheels may include providing a mold with pinch-off rings that have an opening configured to form the circumferential profile.

Owner:MATTEL INC

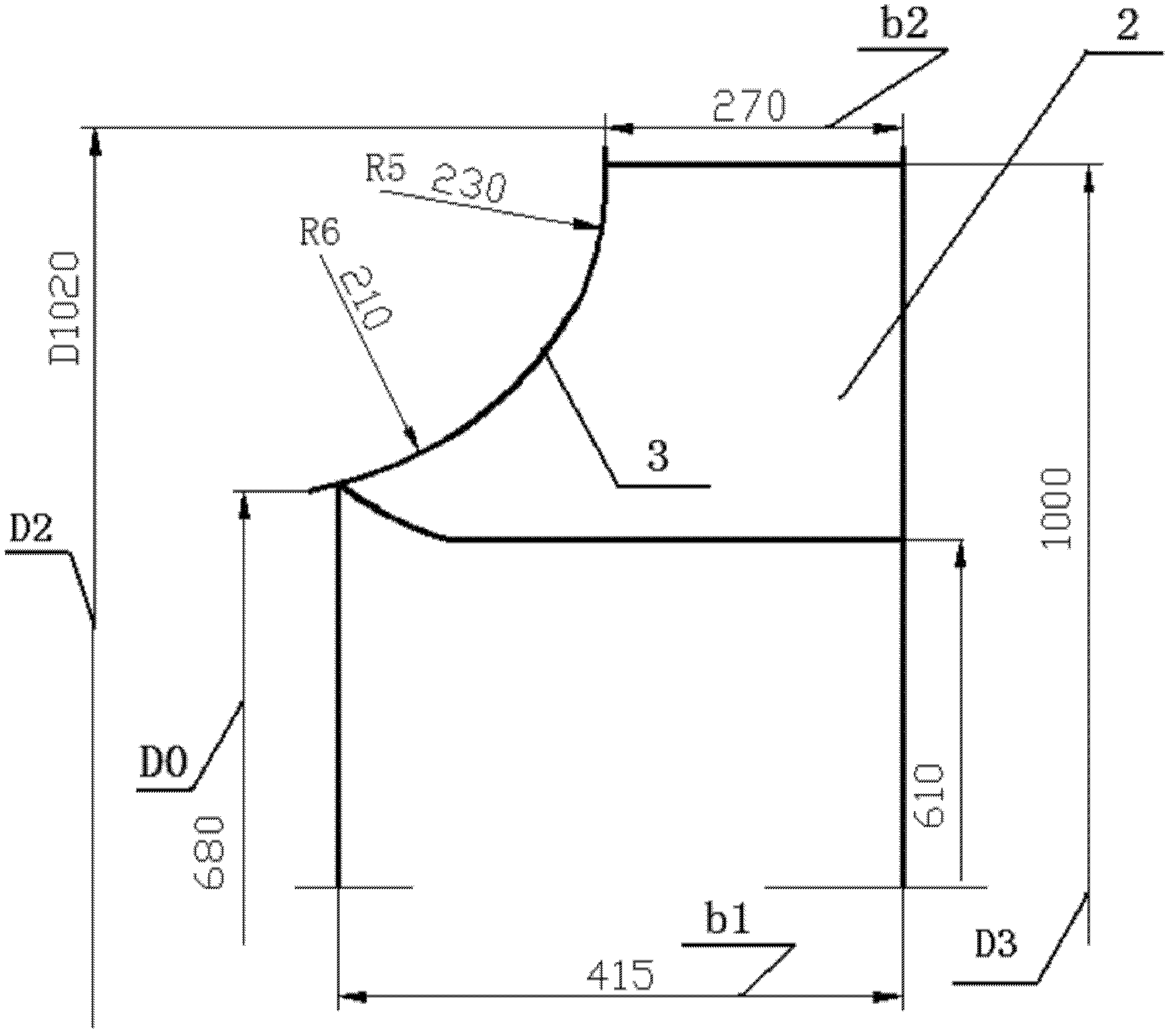

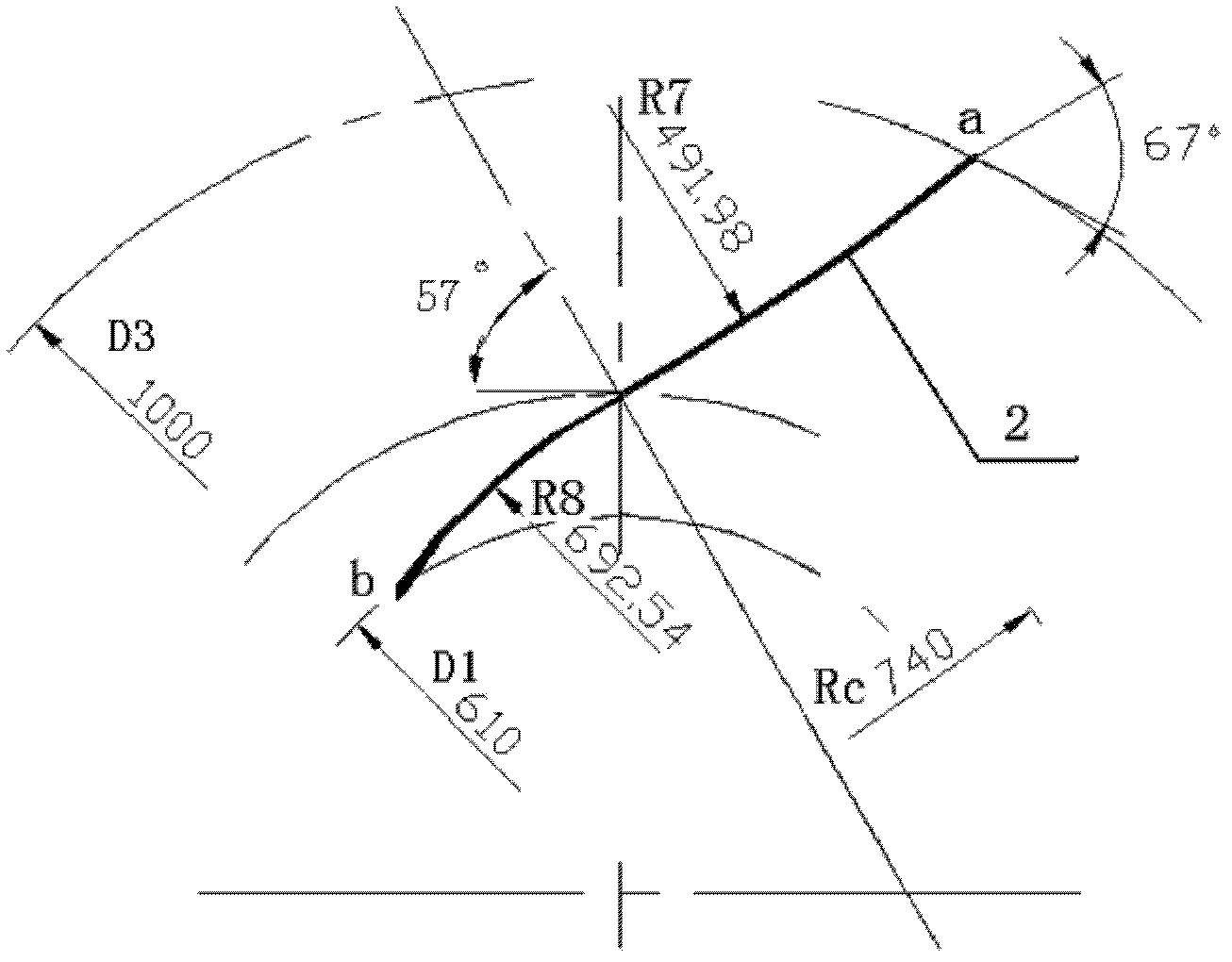

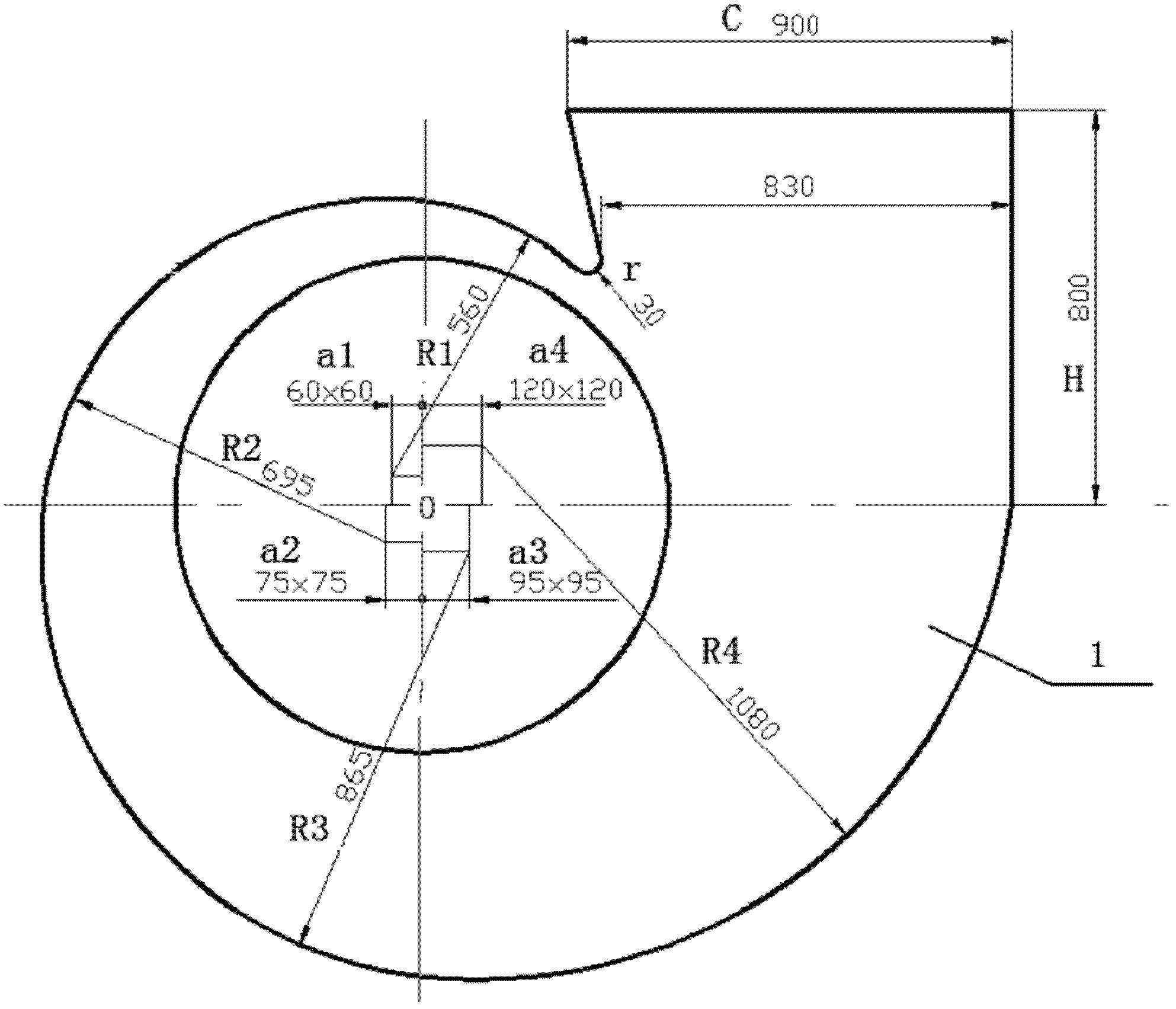

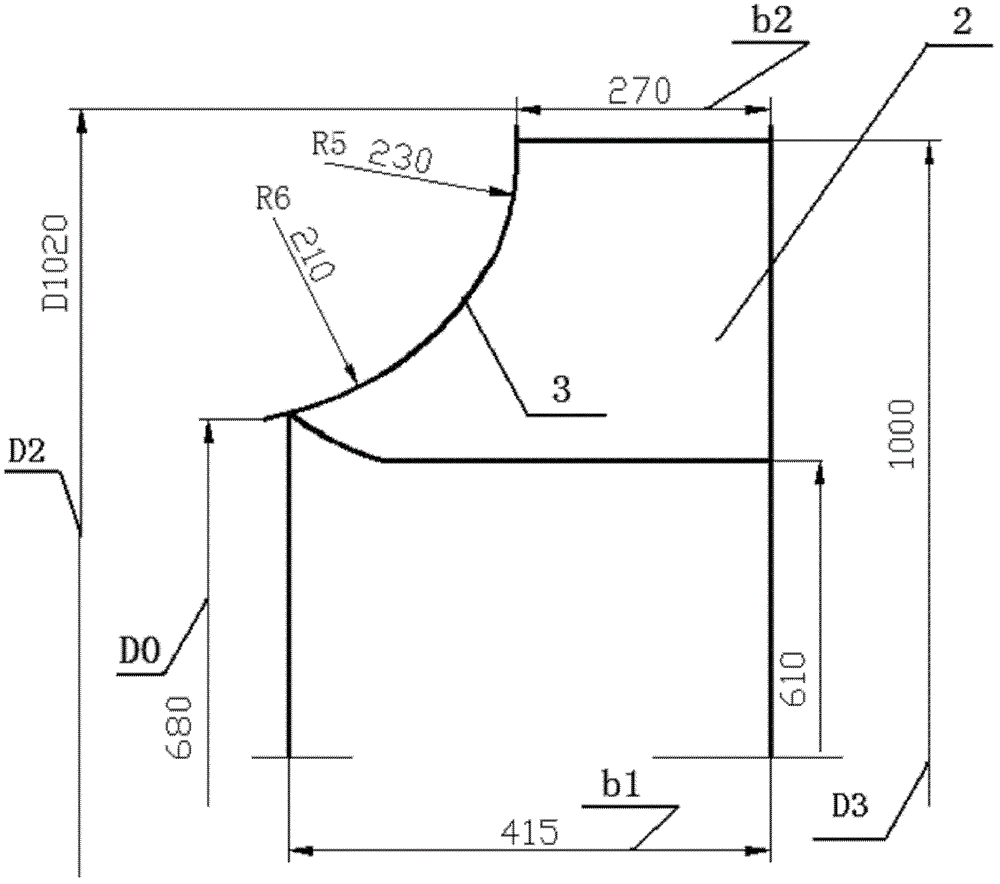

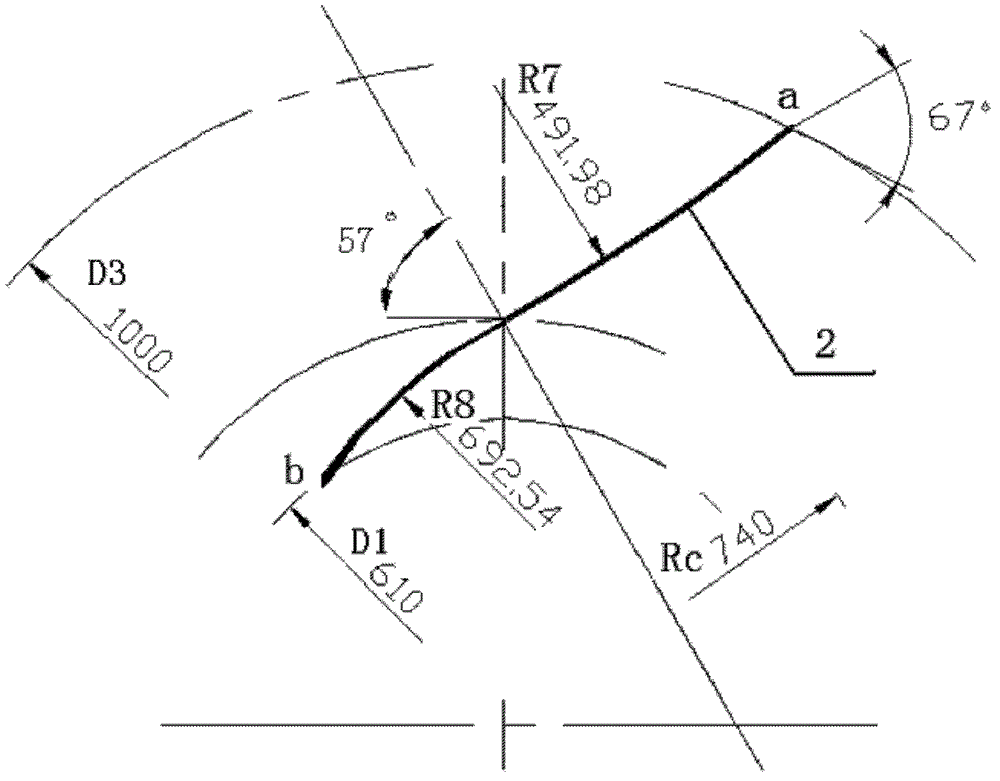

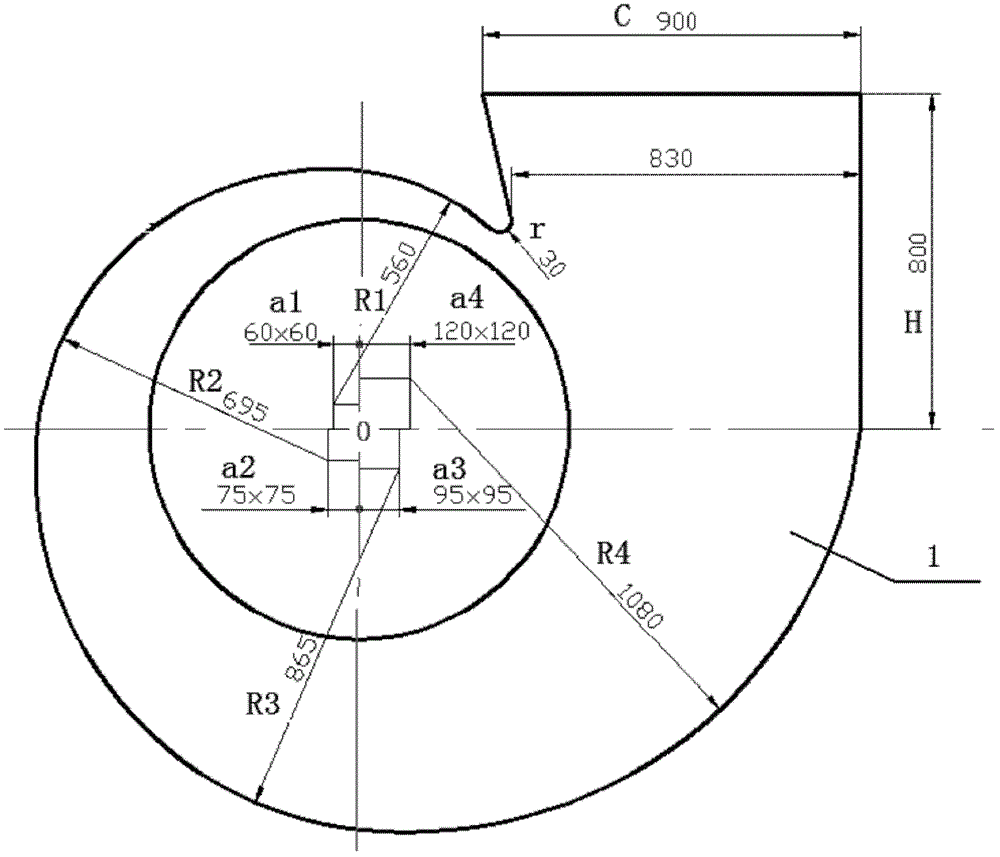

Centrifugal ventilator

ActiveCN102562660AHigh pressure coefficientImprove flow coefficientPump componentsPumpsImpellerEngineering

A centrifugal ventilator comprises a volute casing thereof and an impeller, wherein the impeller consists of a plurality of blades and is arranged in the volute casing of the centrifugal ventilator. The profile of each blade is in a two-dimensional double-arc structure, the two arcs bend to opposite directions and are connected smoothly at the position with the radius Rc ranging from 730mm to 750mm, the profile of a cap of the impeller is in double-arc transitional connection, the radiuses of the two arcs are respectively 230mm and 210mm, the outlet of the impeller has a rotary diffuser structure, and the circumferential profile of the volute casing is in smooth sectional eccentric arc connection. The flow coefficient of the centrifugal ventilator is 0.24, which is increased by 40% as compared with that of the L6-46 centrifugal ventilator and is increased by 90% as compared with that of Y5-58 centrifugal ventilator; the pressure coefficient is 1.234, which is increased by 40% as compared with that of a T4-79 centrifugal ventilator, and is increased by 11% as compared with that of the Y5-58 centrifugal ventilator; and the efficiency of the centrifugal ventilator is 86%, which is close to the highest efficiency point of a high-flow low-pressure high-efficiency ventilator, and is higher than the maximum efficiency value of a medium-flow high-pressure ventilator.

Owner:TIANJIN UNIV

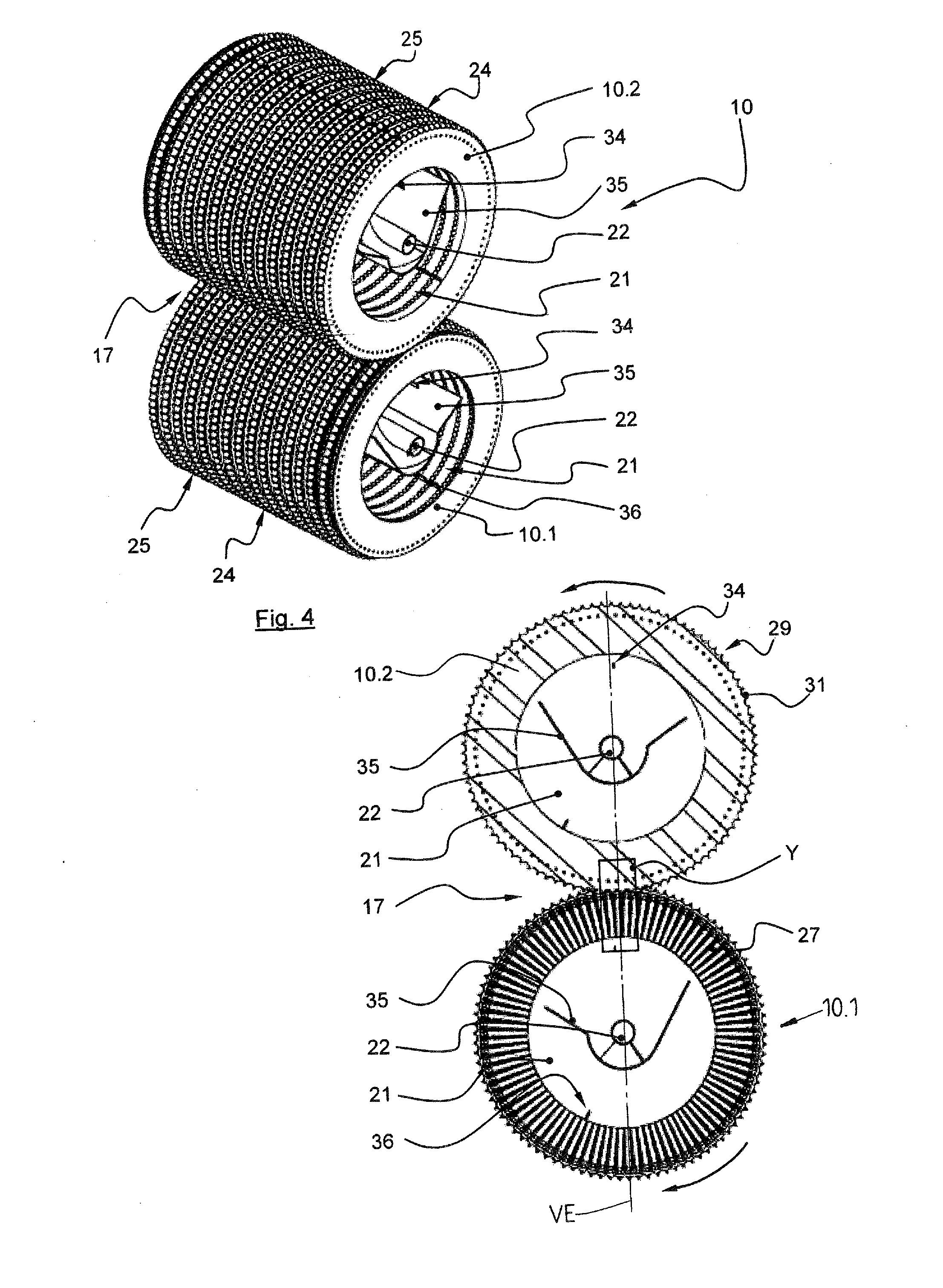

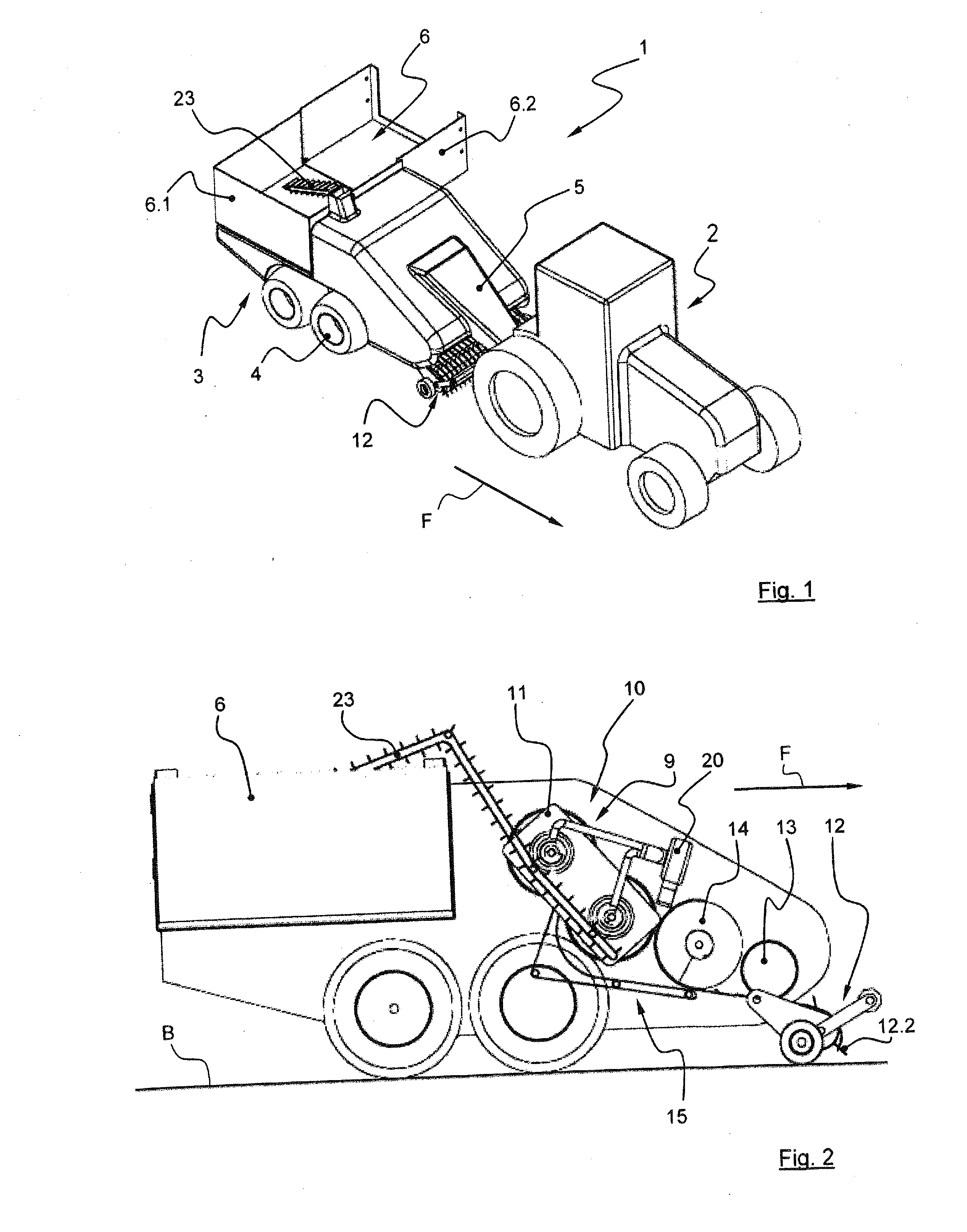

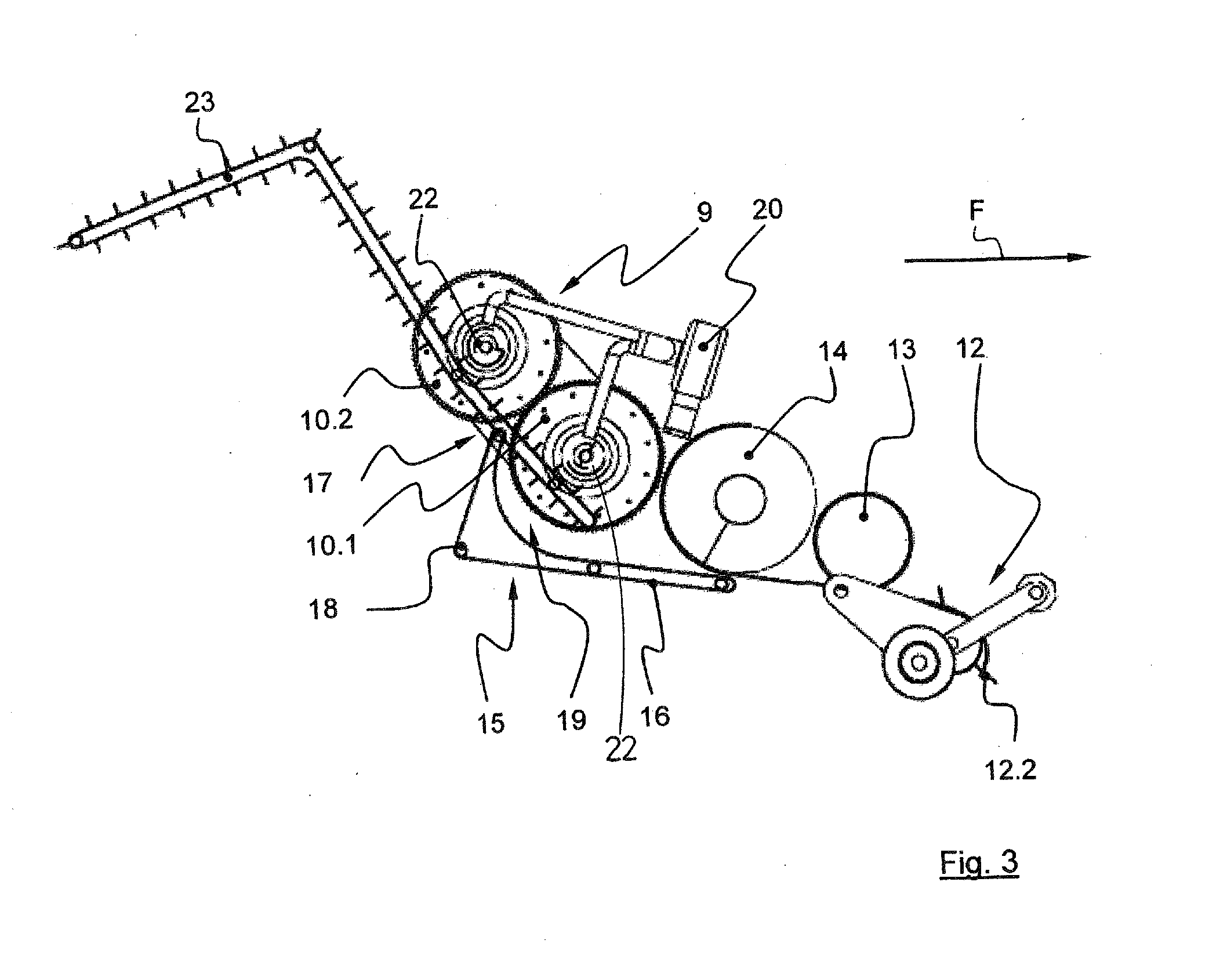

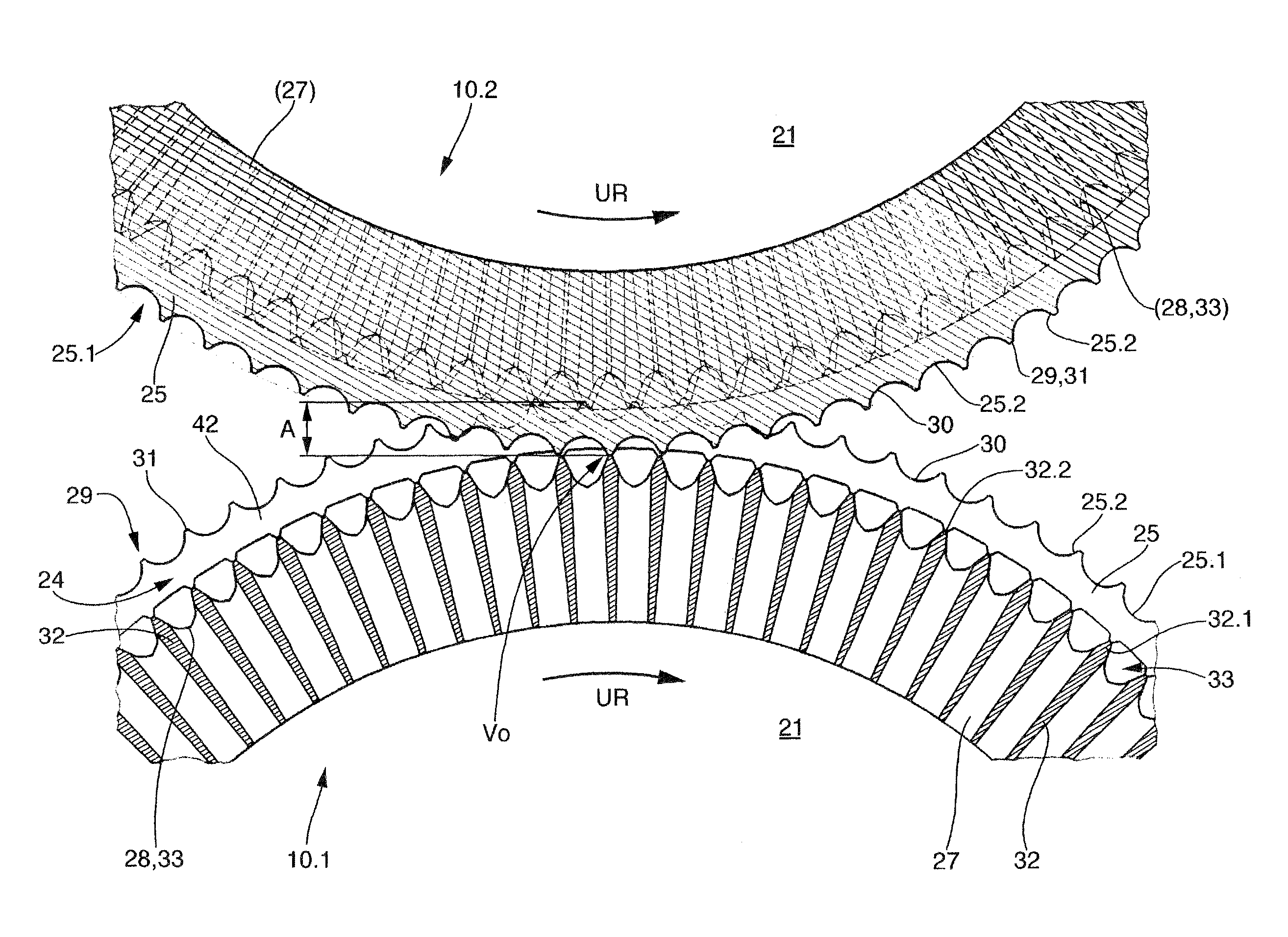

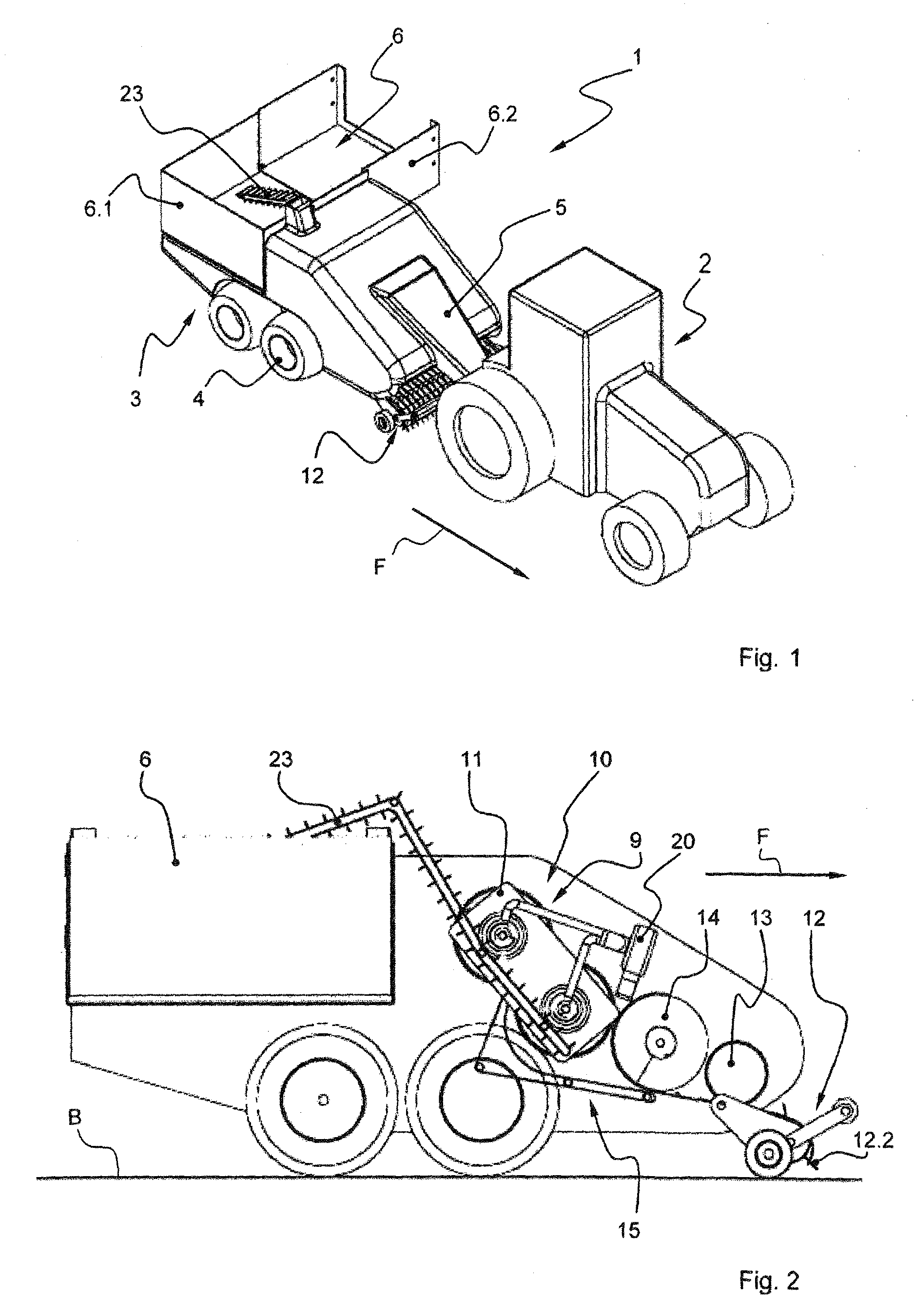

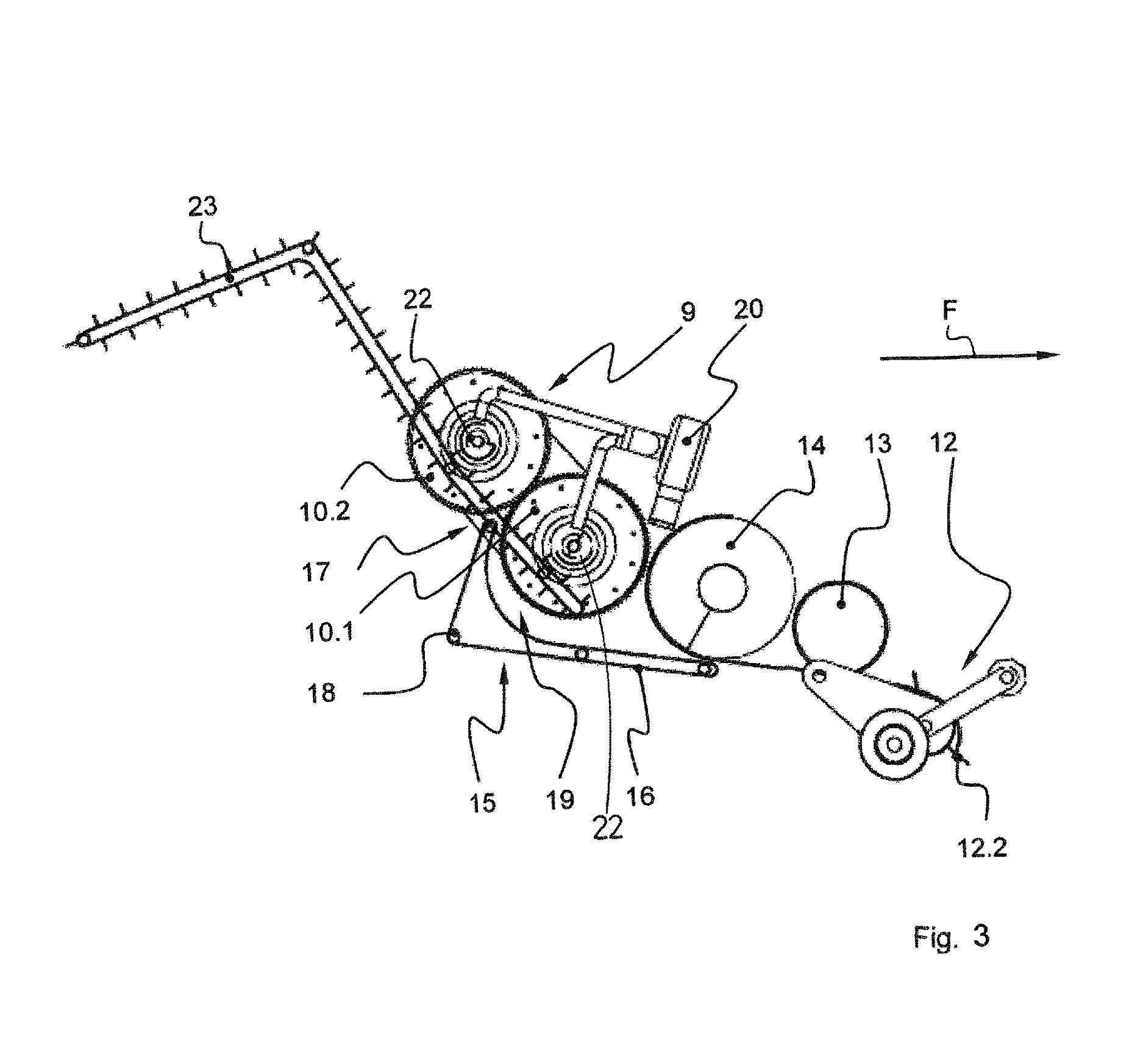

Apparatus for compacting fibrous plant material, especially for compacting stalk material

ActiveUS20150217527A1Reduced risk of cloggingDough-sheeters/rolling-machines/rolling-pinsConfectioneryFiberCircumferential Profile

An apparatus for compacting stalk material, having a feeding device for feeding material to be pressed, having at least one pair of press drums which can be driven in opposite directions and which each have circumferential receiving grooves and compression rings in an alternate manner alongside one another in the axial direction, wherein the compression rings of one press drum engage in the receiving grooves of the other press drum, wherein at least one press drum is provided with a cavity and wherein this at least one press drum has a multiplicity of radially extending press channels in a manner distributed over the circumference, said press channels in each case connecting the groove bottom of the receiving grooves to the cavity, provision is made for the compression rings to have a circumferential profile having protrusions formed for example by radially external teeth having tooth tips.

Owner:KALVERKAMP KLEMENS DE +1

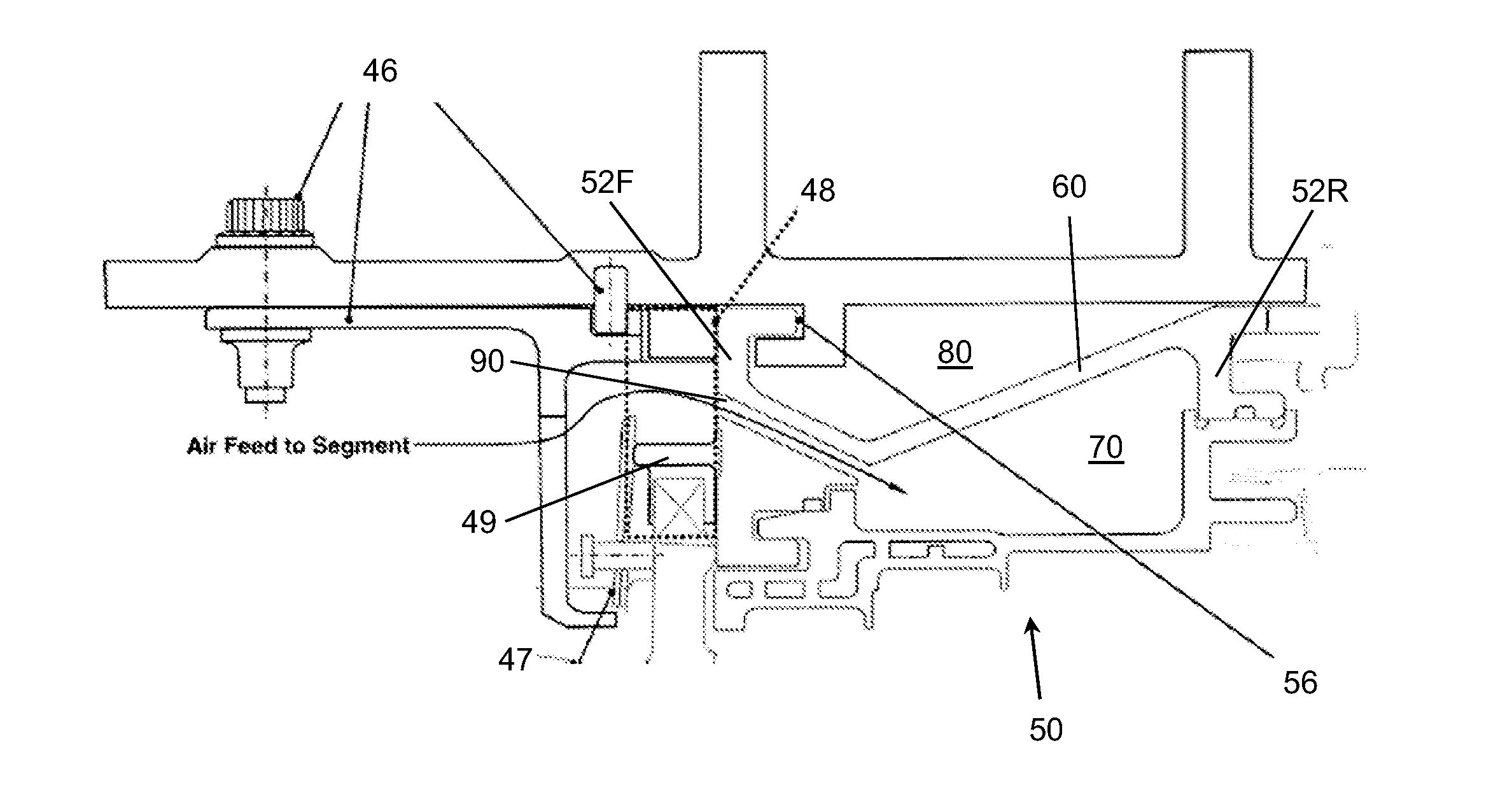

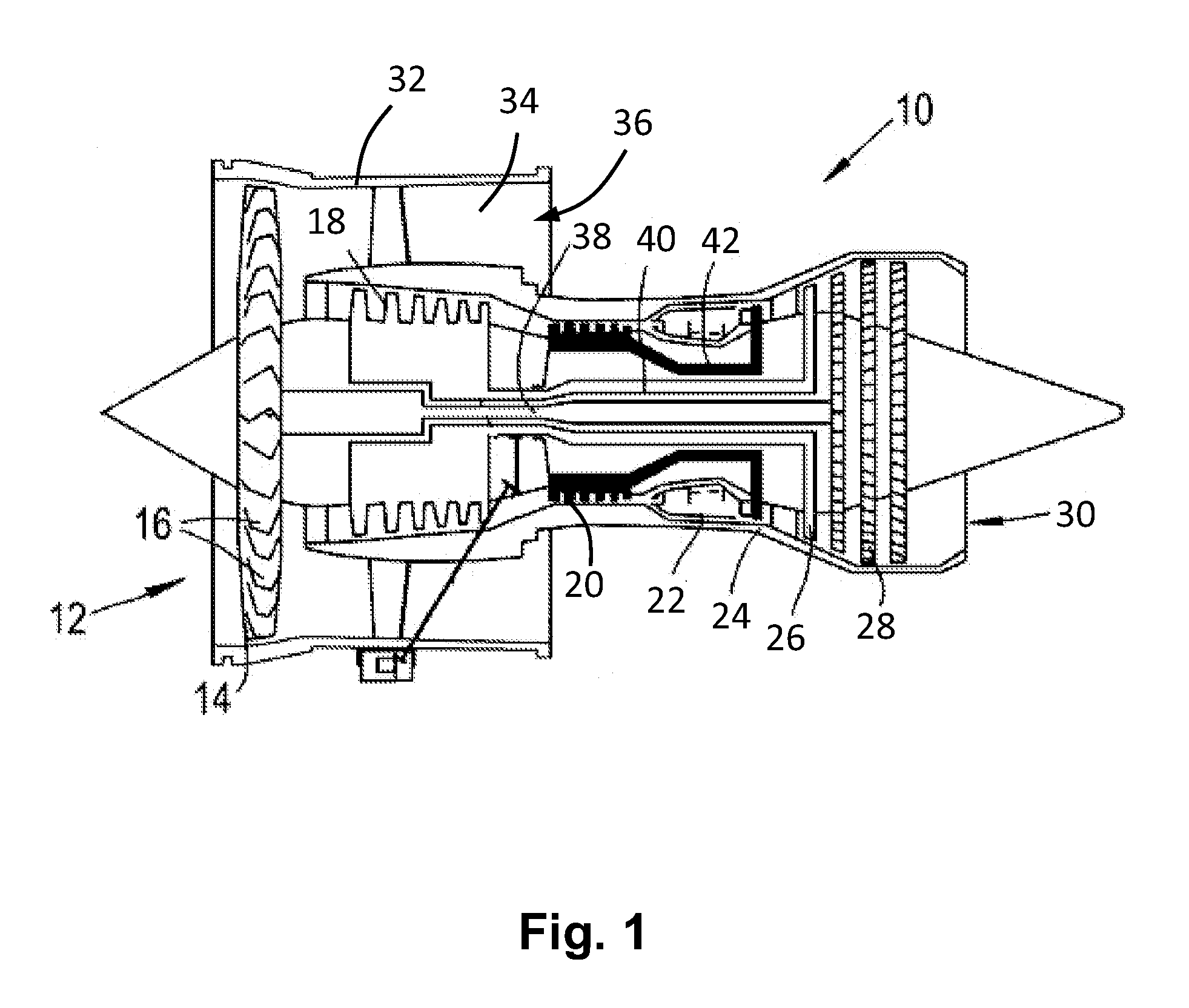

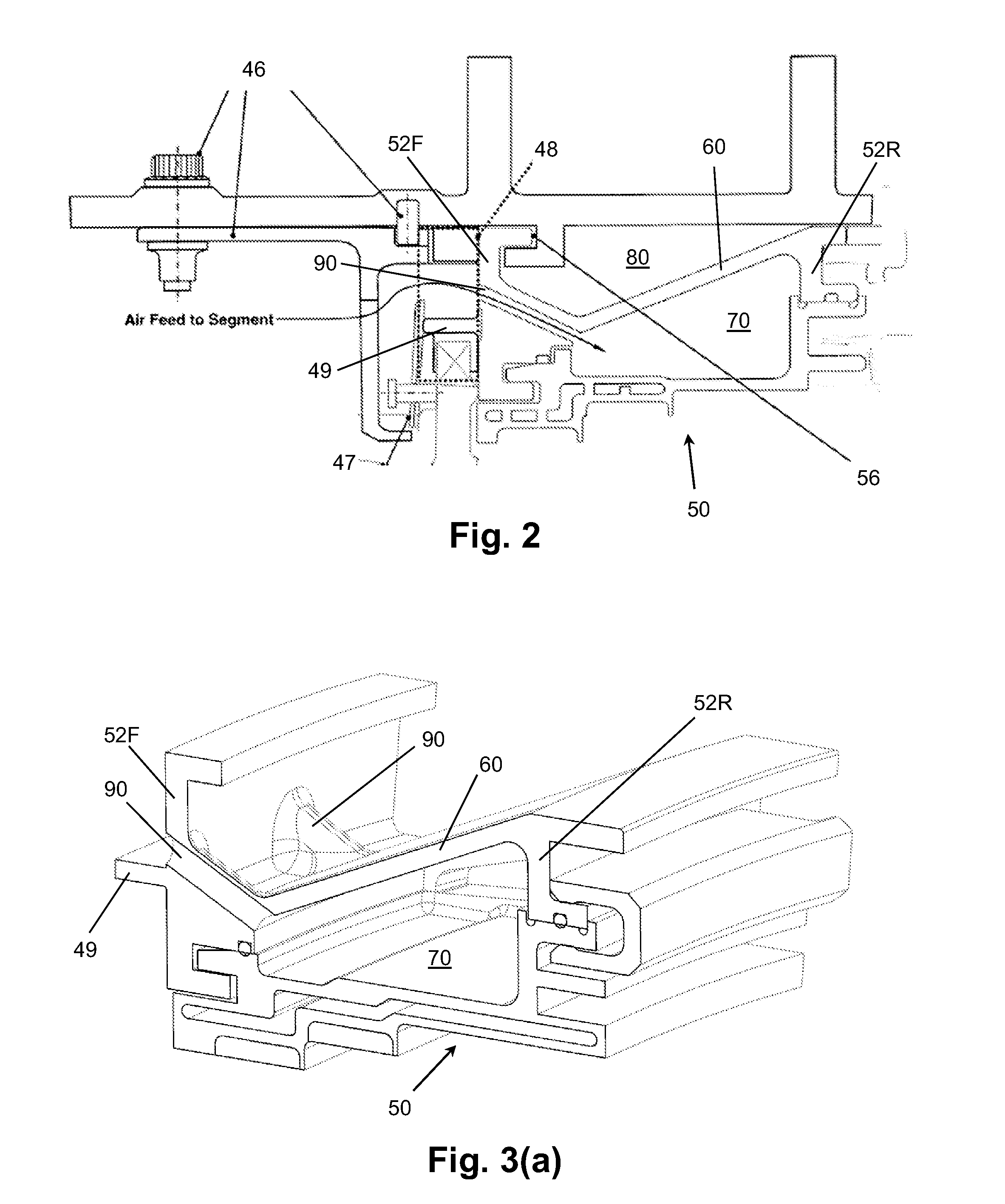

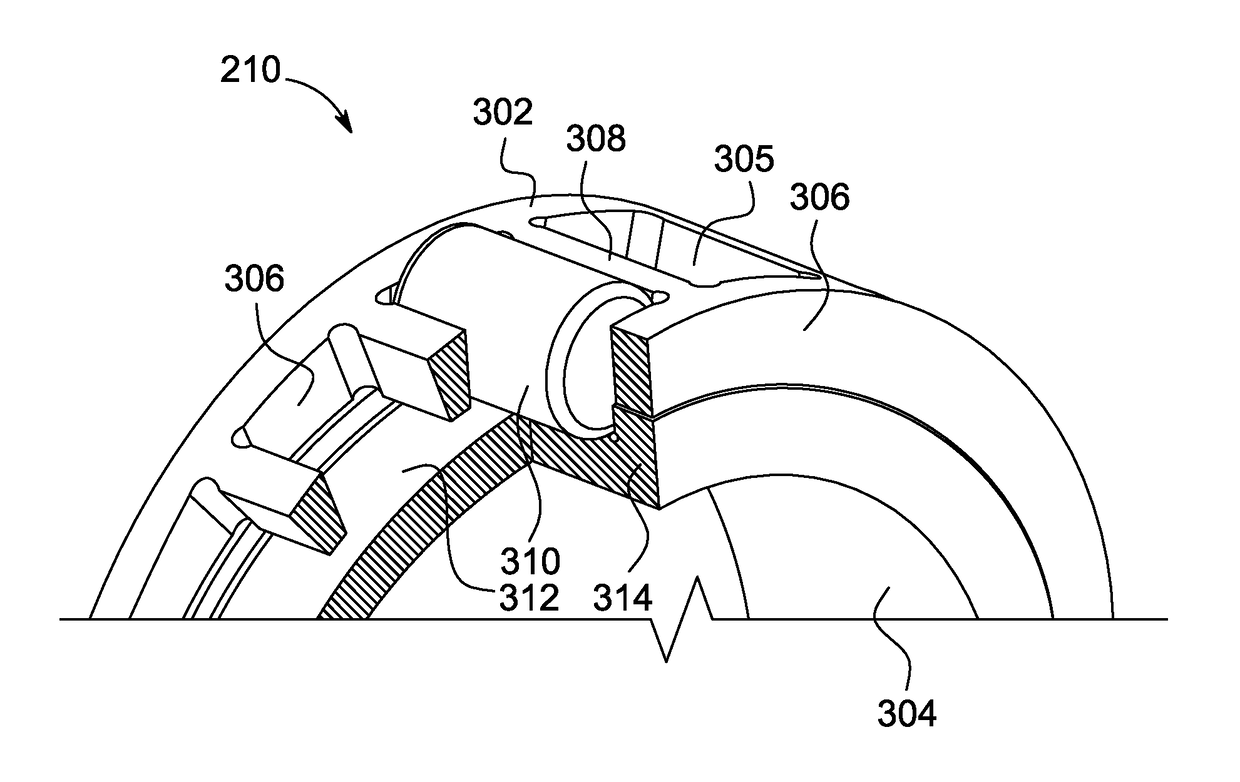

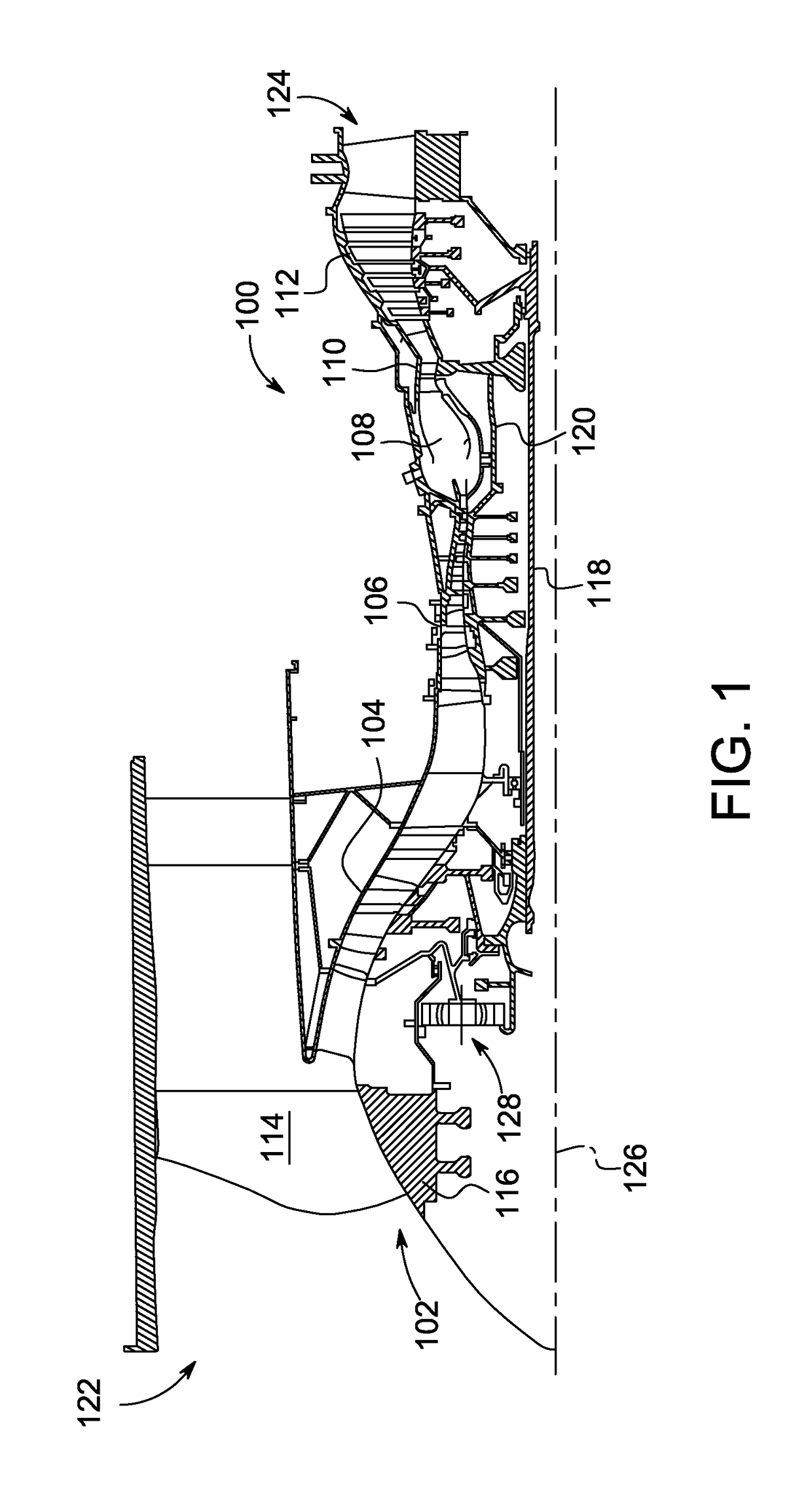

Carriers for turbine components

ActiveUS20160090840A1To offer comfortExpand accessEngine manufactureBlade accessoriesCircumferential ProfileTurbine

A carrier segment for forming a carrier section for one or more gas turbine engine components, the carrier segment including a carrier wall extending between front and rear carrier ends and having a circumferential profile, the carrier segment being configured for defining radially inwardly thereof a chamber for receiving cooling air from an outboard feed source via the front end, wherein the circumferential profile of the carrier wall is undulating, e.g. with a simple waveform configuration or a more complex arrangement of interleaved series of oppositely oriented part-conical surface formations.

Owner:ROLLS ROYCE PLC

Tire groove

A tire includes a tread portion having at least one circumferential main groove extending in a circumferential direction of the tire and spaced axially apart from an equator of the tire. The groove has a circumferential profile shape including an inner wall portion extending radially inward from an axially inner edge of the groove, an inner arc portion continuous with the inner wall portion and having a smaller radius of curvature than the inner wall portion, an outer wall portion extending radially inward from an axially outer edge of the groove and having a larger length than the inner wall portion, an outer arc portion continuous with the outer wall portion and having a smaller radius of curvature than the outer wall portion, and a groove bottom portion extending straight from the outer arc portion toward the inner arc portion while being inclined in a radially inward direction whereby the groove bottom portion has a constant radius of curvature.

Owner:THE GOODYEAR TIRE & RUBBER CO

Spinous process spacer

ActiveUS8998954B2Risk minimizationInternal osteosythesisJoint implantsMedicineCircumferential Profile

A spinous process spacer that is designed to maintain a desired spatial relationship between adjacent vertebrae, is configured for introduction into a spinal implant site in a compressed state and then expands in situ. Once expanded, formations of the present spinal spacer form areas, pockets or spaces that receive at least one bony portion of each adjacent vertebra. The present spinous process spacer has a changeable circumferential profile wherein a first circumferential profile is smaller than a second circumferential profile in order to provide / achieve its compressed and expanded states. The first circumferential profile defines the collapsed position or state while the second circumferential profile defines the position or state. Upon implantation, the present spinous process spacer is not fixed to any bony structure of the vertebrae but provides support. In this regard, use of the spinous process spacer, by itself, will not result in vertebral fusion. However, fusion can result with the use of bone graft packed about the spinous processes (and the spinous process spacer) or in conjunction with the use of an intervertebral body spacer.

Owner:LIFE SPINE INC

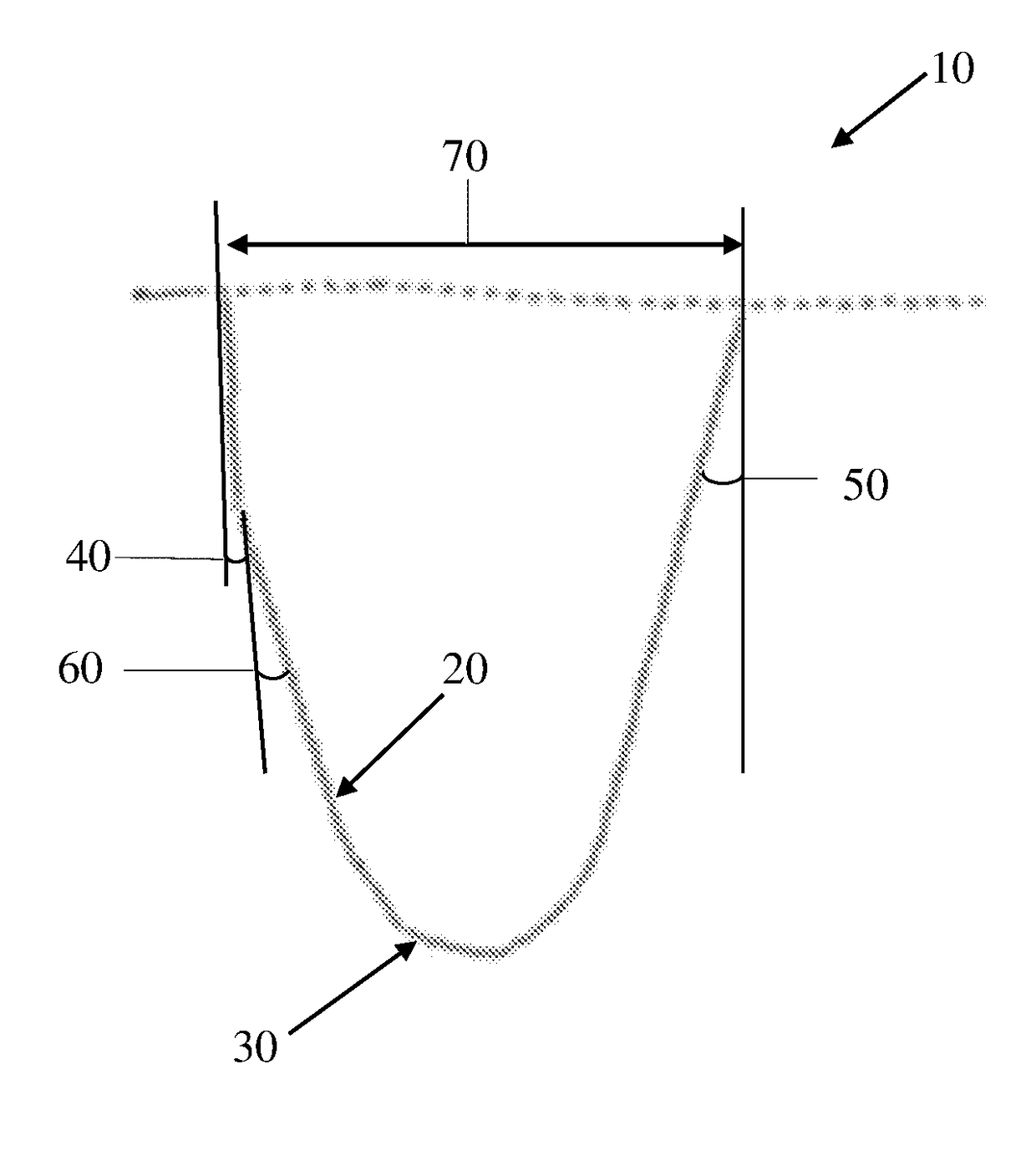

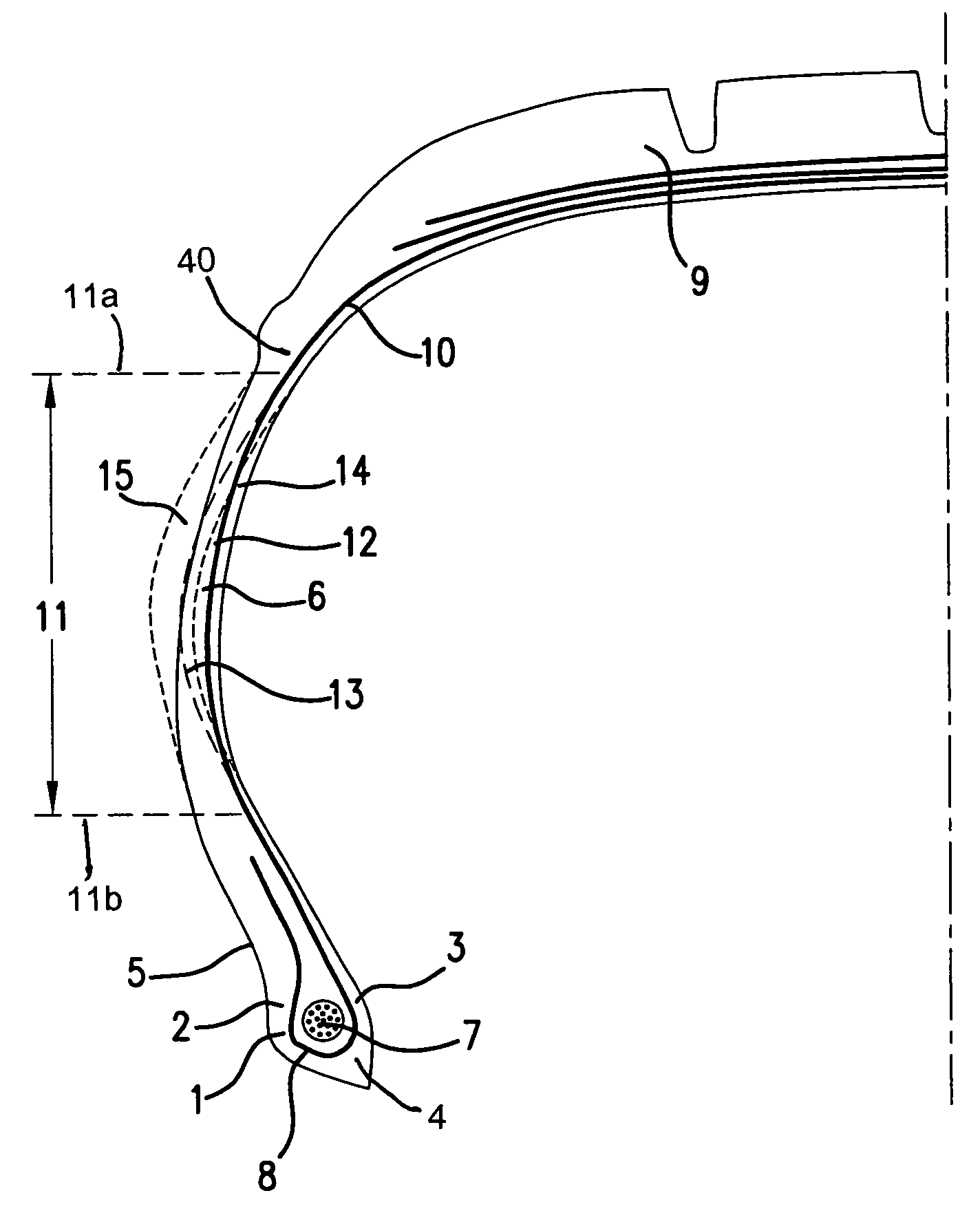

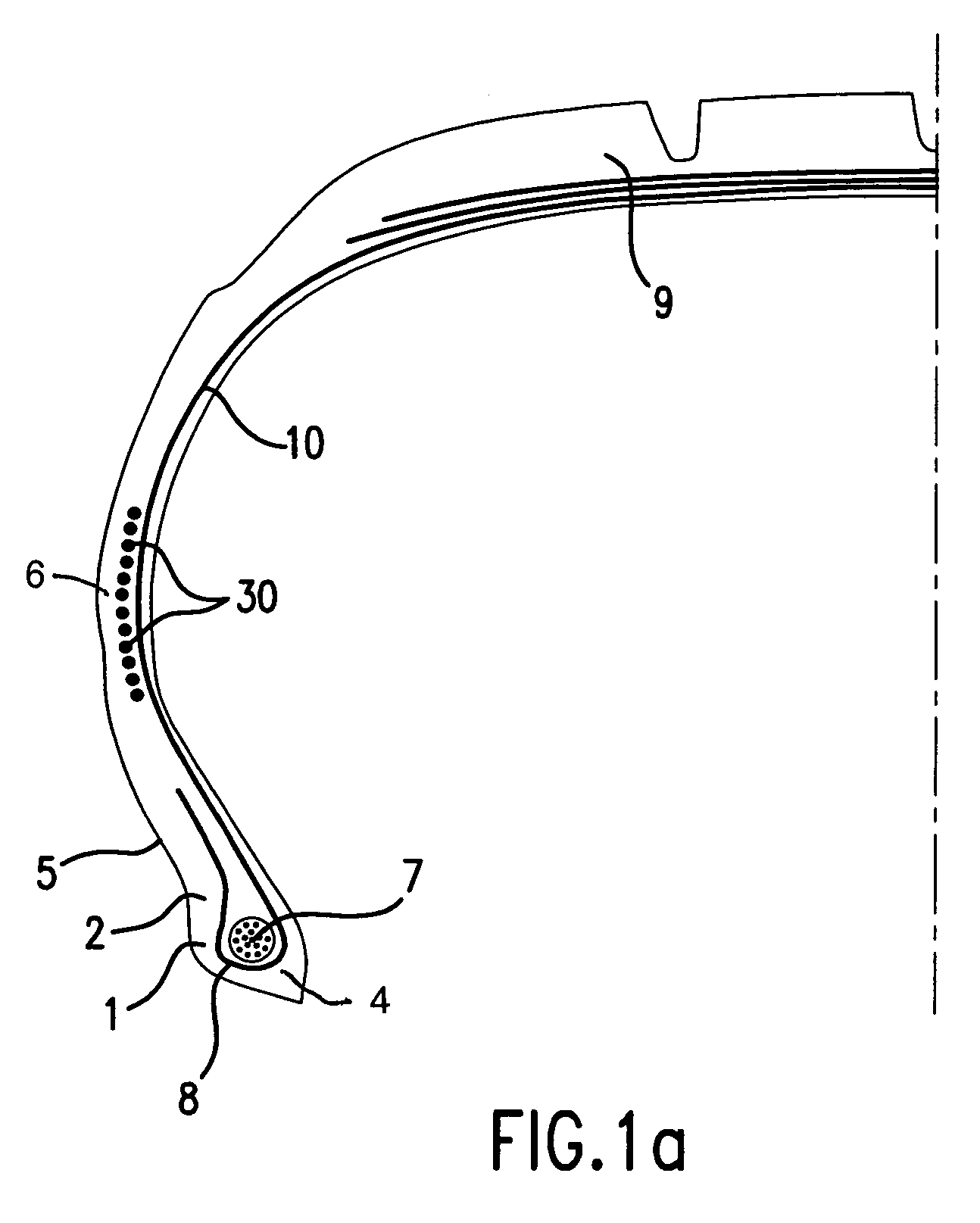

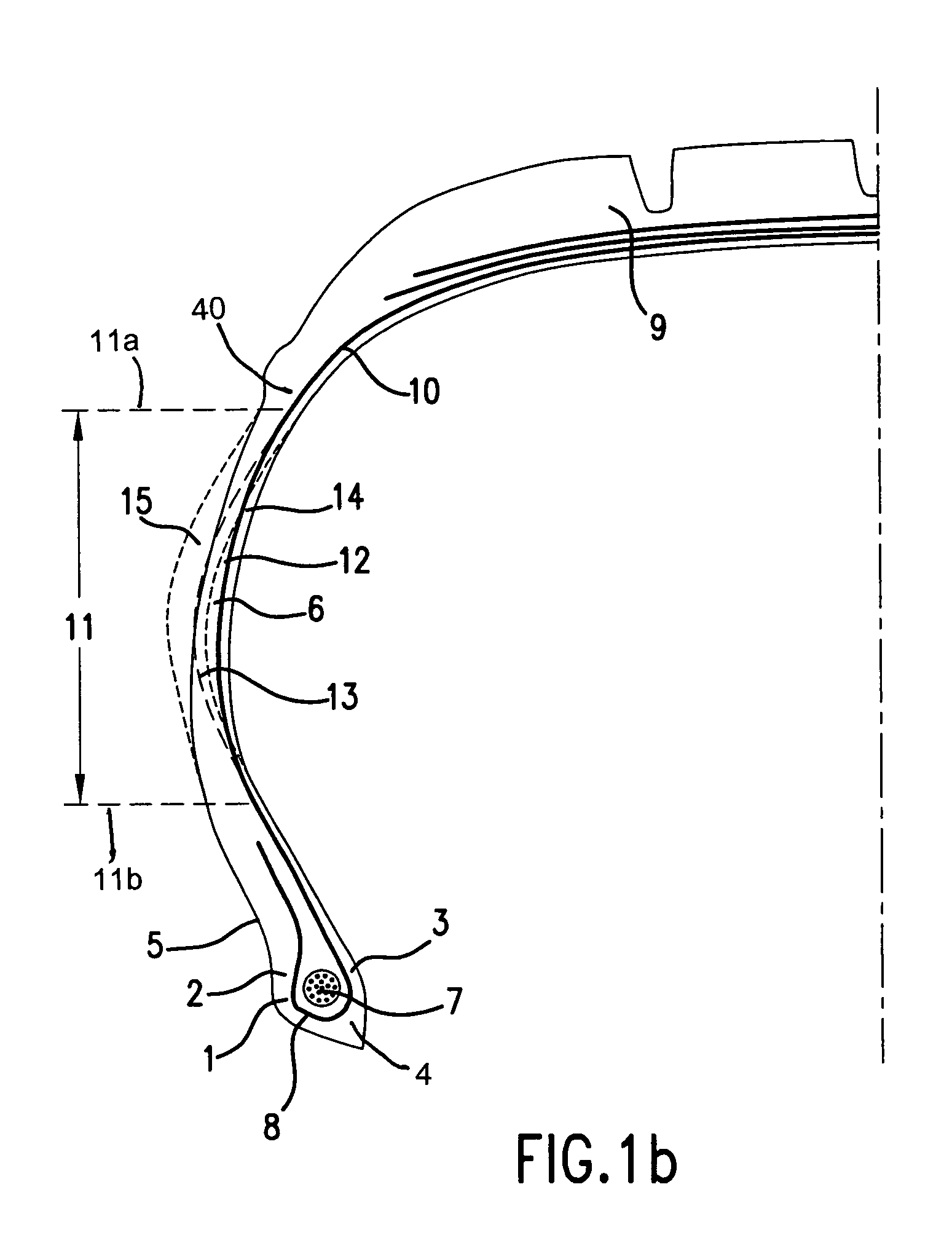

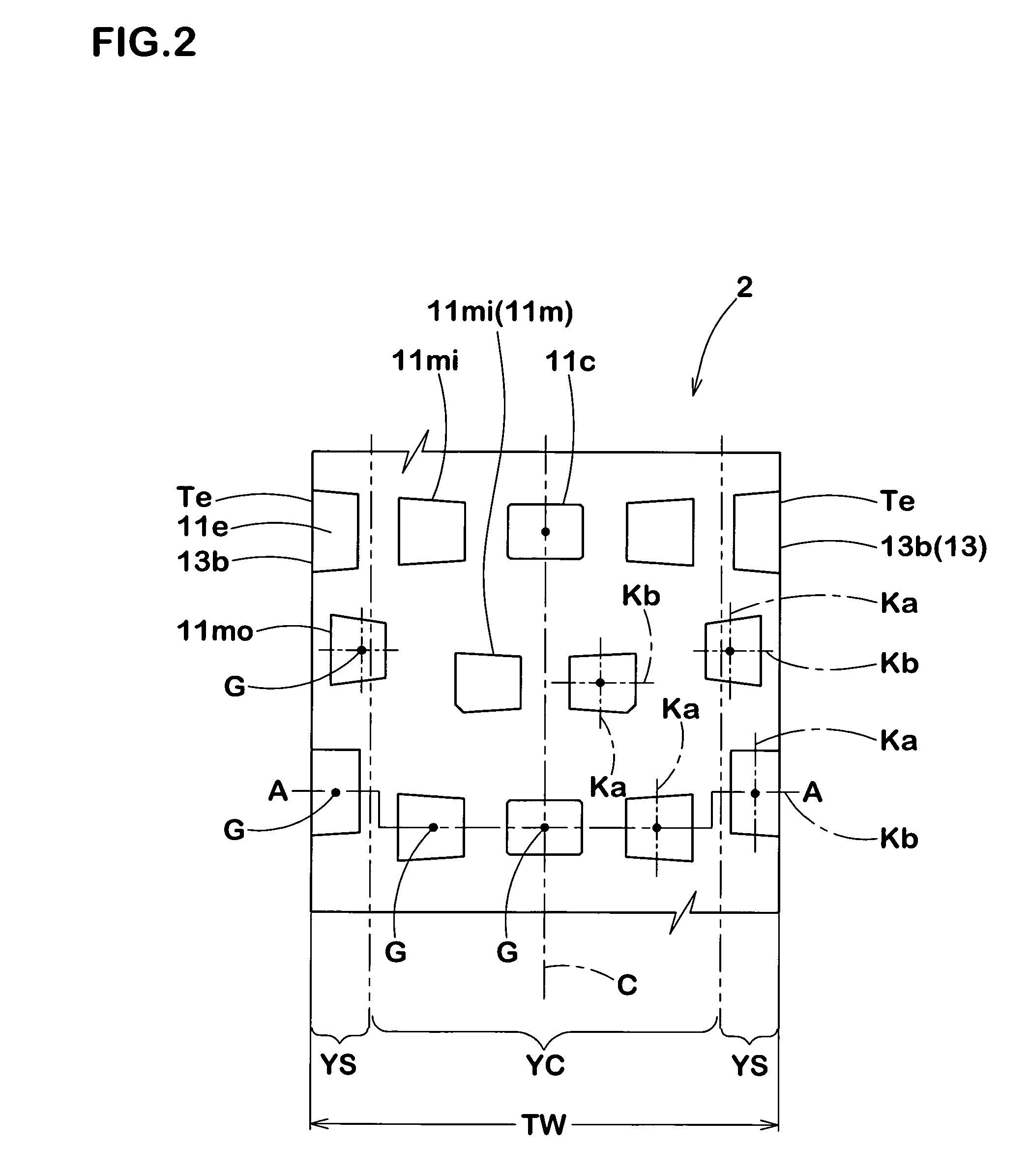

Extended mobility tire with undulating sidewalls

InactiveUS7281557B2Eliminate majorityImprove mobilitySpecial tyresPneumatic tyre reinforcementsTire beadCircumferential Profile

A tire includes at least one carcass-type reinforcement structure anchored on each side in a bead, each bead being extended radially towards the outside by a sidewall having at least one substantially resilient circumferential cord disposed in the substantially median portion of the sidewalls. The carcass-type reinforcement structure includes a ply of carcass cords extending from the bead to the crown within a sidewall. The carcass cords are arranged in such a way that, in a sidewall zone restricted to the median portion of the sidewall, the carcass cords exhibit different respective axial positions, so as to form around the circumference a succession of substantially regular undulations defining an undulating circumferential profile. Outside of the sidewall zone, the carcass cords of the ply do not form undulations. At reduced pressure the undulations tend to straighten out and rigidify the sidewall in such a way as to be able to bear the load.

Owner:MICHELIN RECH & TECH SA

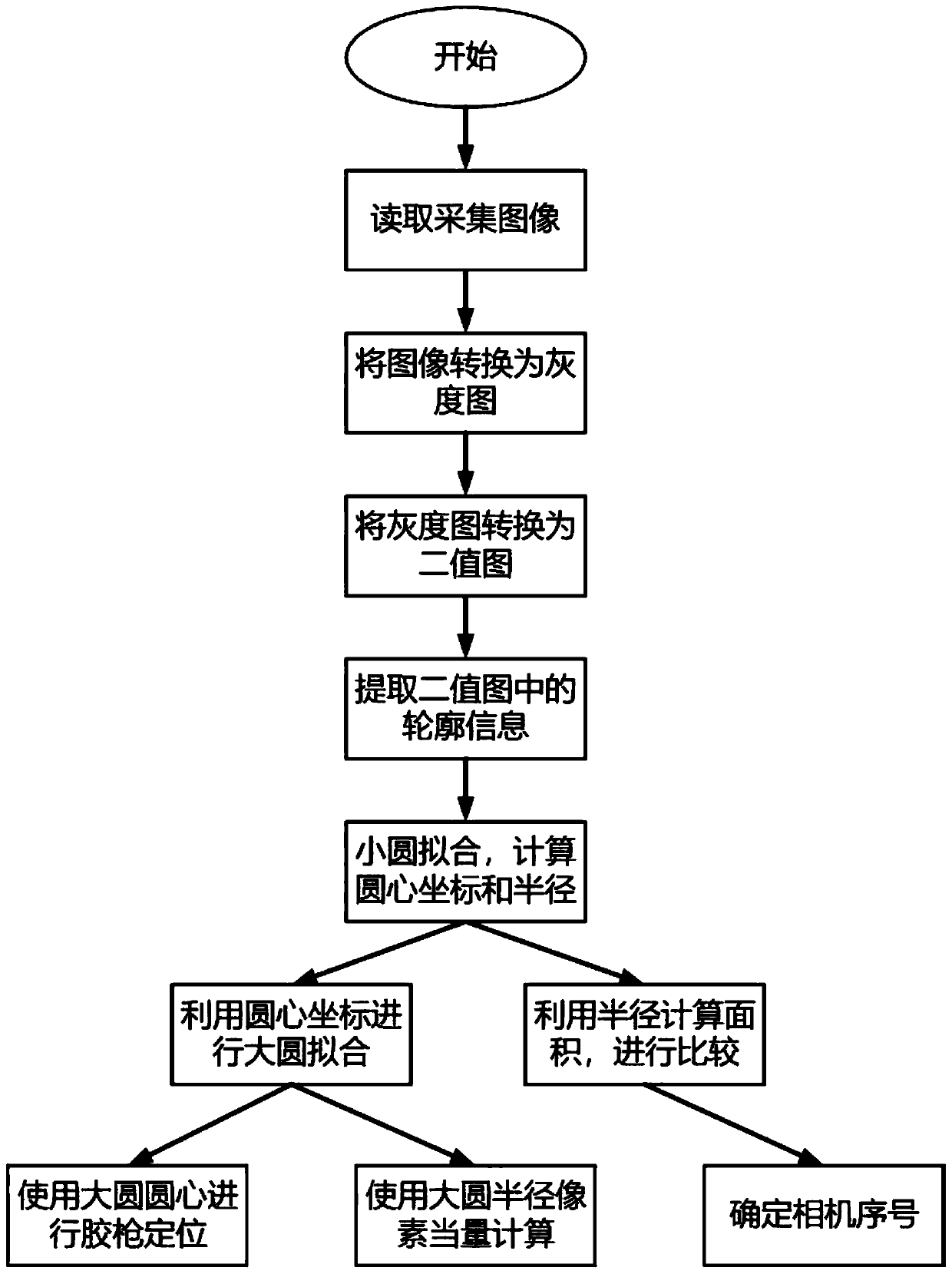

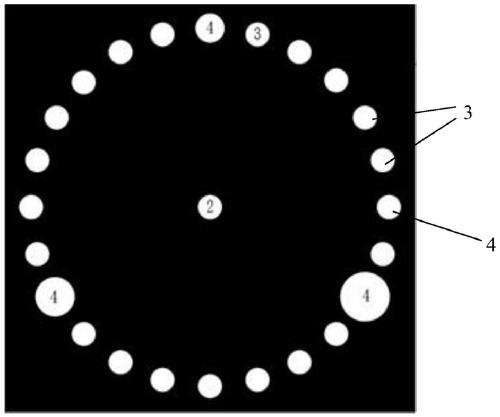

A method for calibrating multi-camera visual inspection equipment

ActiveCN109920010BEasy CalibrationEfficient calibrationImage analysisImaging processingVisual inspection

The invention discloses a method for calibrating multi-camera visual inspection equipment. The multi-camera visual inspection equipment is sleeved on industrial equipment, and N cameras are uniformlydistributed on the circumference taking the center of the detection equipment as the center of a circle, and the method comprises the following steps: 1, placing a calibration plate below the detection equipment with the calibration plate comprising a plurality of common mark circles with equal diameters and N characteristic mark circles with unequal diameters; locating The center of the common mark circle and the center of the characteristic mark circle on the same circumference. wherein the diameter of the characteristic mark circle is different from that of a common mark circle; Wherein theview field of each camera at least comprises one characteristic mark circle; enabling the N camera fields of view to cover the whole calibration plate after being spliced; utilizing an image processing method to fit circle centers and radiuses of the common mark circle and the characteristic mark circle, and determining a camera number according to the size of the characteristic mark circle; andfitting the circle center and the radius of the large circle by using the fitted circumferential contour line, and calibrating the coordinate position and the pixel equivalent of the center of the detection equipment.

Owner:易思维(杭州)科技股份有限公司

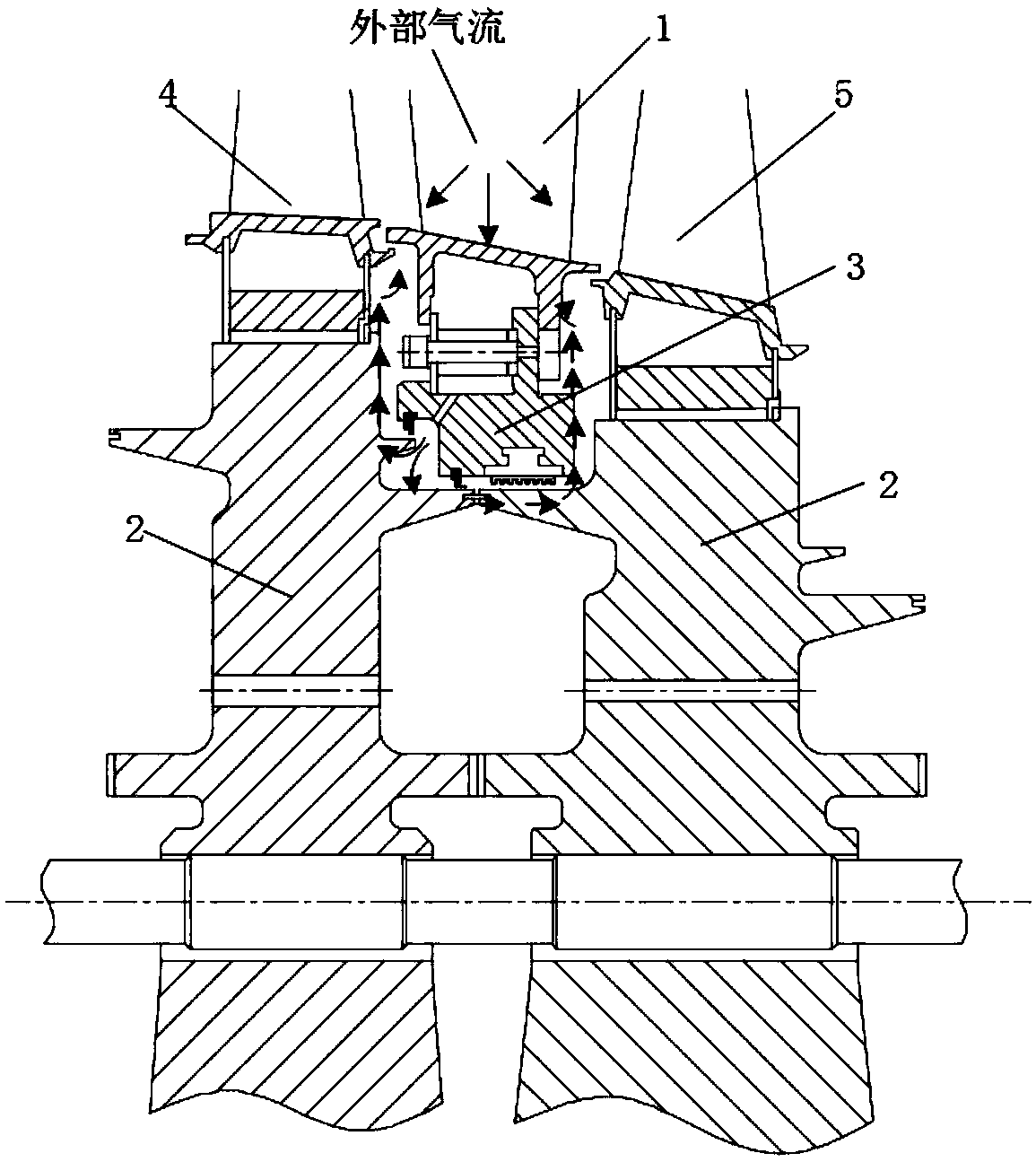

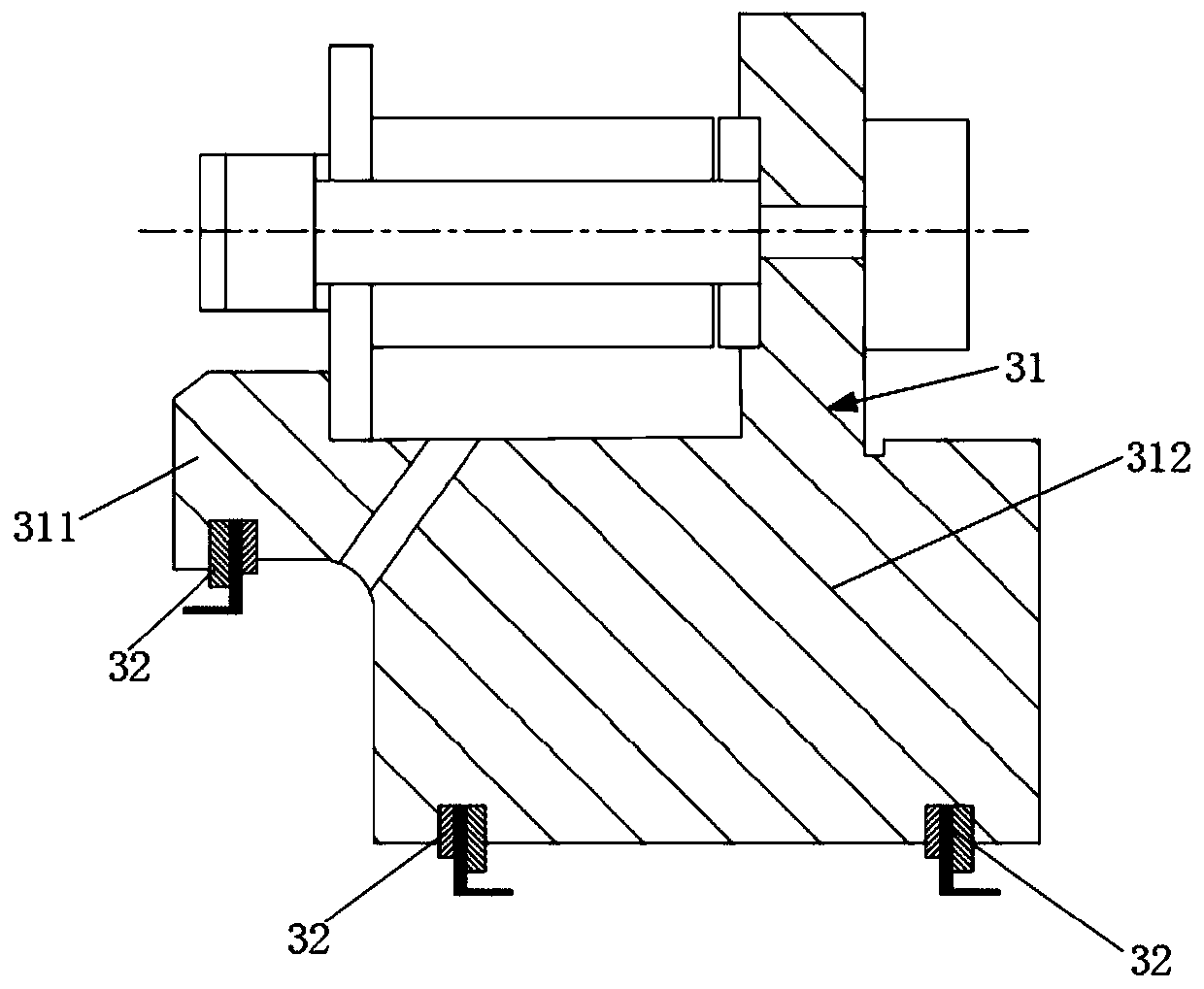

Sealing assembly for gas turbine and gas turbine

PendingCN111379628ANot easy to wearExtended service lifeGas turbine plantsLeakage preventionThermodynamicsEngineering

The invention discloses a sealing assembly for a gas turbine and the gas turbine. The sealing assembly comprises a sealing ring, the sealing ring comprises a first section and a second section which are sequentially connected along the axial direction of the sealing ring, the cross sectional area of the inner circumferential profile of the first section is larger than the cross sectional area of the inner circumferential profile of the second section, the length of the first section along the axial direction of the sealing ring is smaller than the length of the second section along the axial direction of the sealing ring, at least one of the inner peripheral surface of the first section and the inner peripheral surface of the second section is provided with a fingertip sealing component, and the fingertip sealing component and a rotating body are spaced along the radial direction of the sealing ring. The sealing assembly for the gas turbine is not likely to wear and long in service life, and the sealing effect is improved.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

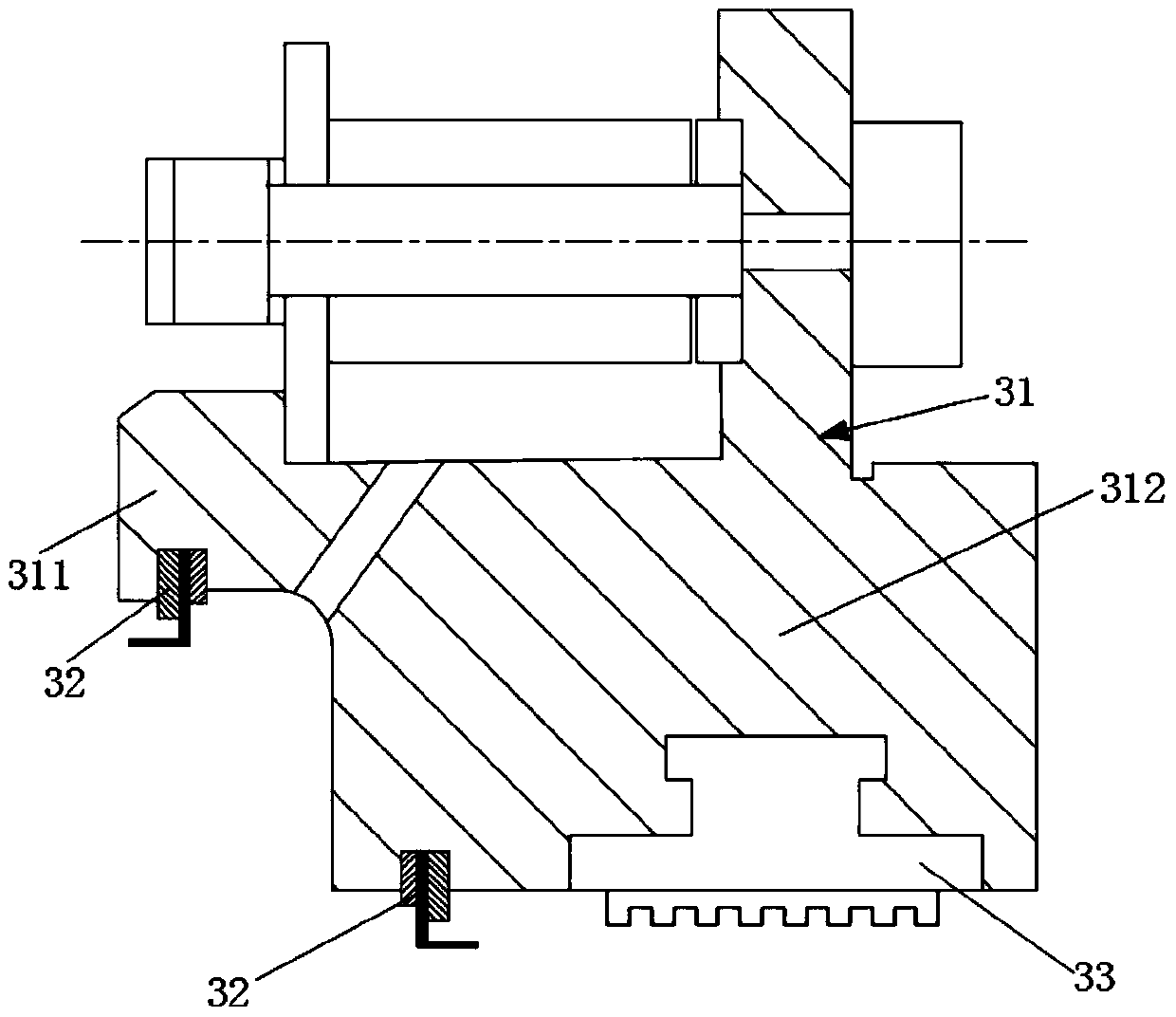

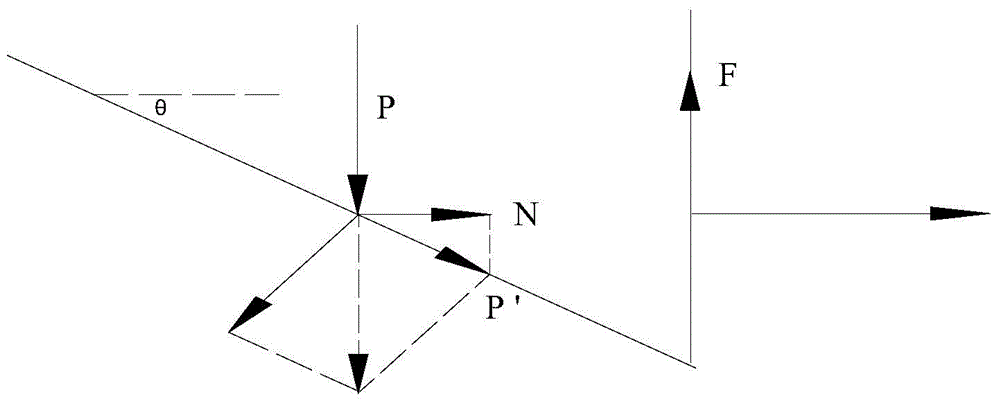

Blast hole plugging device and method

The invention discloses a blast hole plugging device and method. The blast hole plugging device comprises a first plugging part and a second plugging part, wherein the second plugging part is near a blast hole opening and is fixed with the inner wall of a blast hole, the circumferential profile of the first plugging part and the circumferential profile of the second plugging part are matched with the hole diameter of the blast hole, the first plugging part is provided with a first surface forming an angle with the axial line of the blast hole, the second plugging part is provided with a second surface forming an angle with the axial line of the blast hole, and the first plugging part and the second plugging part mutually form surface contact through the first surface and the second surface. In the blasting process, the first plugging part moves along the second surface due to the pressure of detonation gas in the blast hole, i.e., the first plugging part and the second plugging part generate relative malposition, the first plugging part exerts the positive pressure on the inner wall of the blast hole, and the pressure of the detonation gas is greater, so the generated friction is also greater, and the moving of the first plugging part and the second plugging part towards the outer part of the blast hole is retarded through the friction force, so that the acting time of the detonation gas is increased, and a good blasting effect is achieved.

Owner:北京安赢堡科技发展有限公司

Blood glucose sensor dispensing instrument having a serrated knife

InactiveCN101023351AReduce the likelihood of cloggingOvercome problemsStentsBlood vesselsGlucose sensorsMechanical energy

The present application relates to an intraluminal thin film medical device (100) particularly well suited for occlusion of an aneurysm, vessel side branch or dissection of a body lumen or duct, such as an artery or vein. The medical device has a thin film tube (101) capable of being longitudinally stretched by the application of mechanical energy to achieve a smaller circumferential profile, and self-expand to the pre-stretched length and diameter upon release of the mechanical energy. To assist the thin film during expansion a plurality of slots (102) are incised in the tube wall. The slots open and assist the thin film tube to longitudinally stretch, and substantially close when the thin film tube self-expands to the pre-stretched length and diameter.A sensor dispensing instrument comprises a housing, a sensor pack, a sensor, and a knife blade assembly. The sensor pack is disposed within the housing and has a sensor cavity and a protective covering. The sensor is disposed within the sensor cavity. The knife blade assembly is operably disposed within the housing and has a serrated edge for cutting the protective covering.

Owner:BAYER HEALTHCARE LLC

Thin film medical device and delivery system

The present invention relates to an intraluminal thin film medical device particularly well suited for occlusion of an aneurysm, vessel side branch or dissection of a body lumen or duct, such as an artery or vein. The medical device has a thin film tube capable of being longitudinally stretched by the application of mechanical energy to achieve a smaller circumferential profile, and self-expand to the pre-stretched length and diameter upon release of the mechanical energy. To assist the thin film during expansion a plurality of slots are incised in the tube wall. The slots open and assist the thin film tube to longitudinally stretch, and substantially close when the thin film tube self-expands to the pre-stretched length and diameter.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

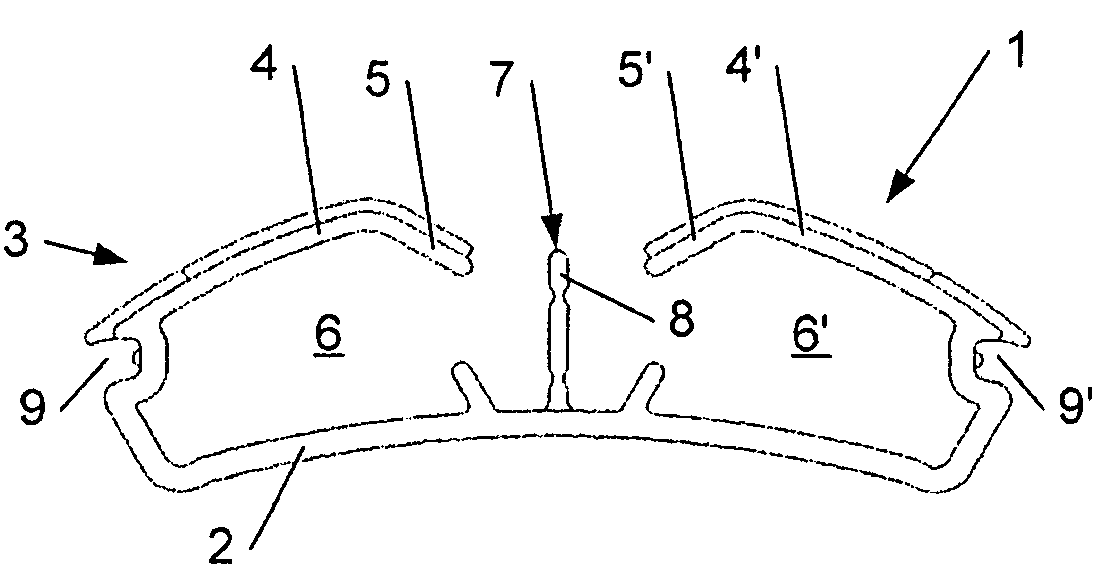

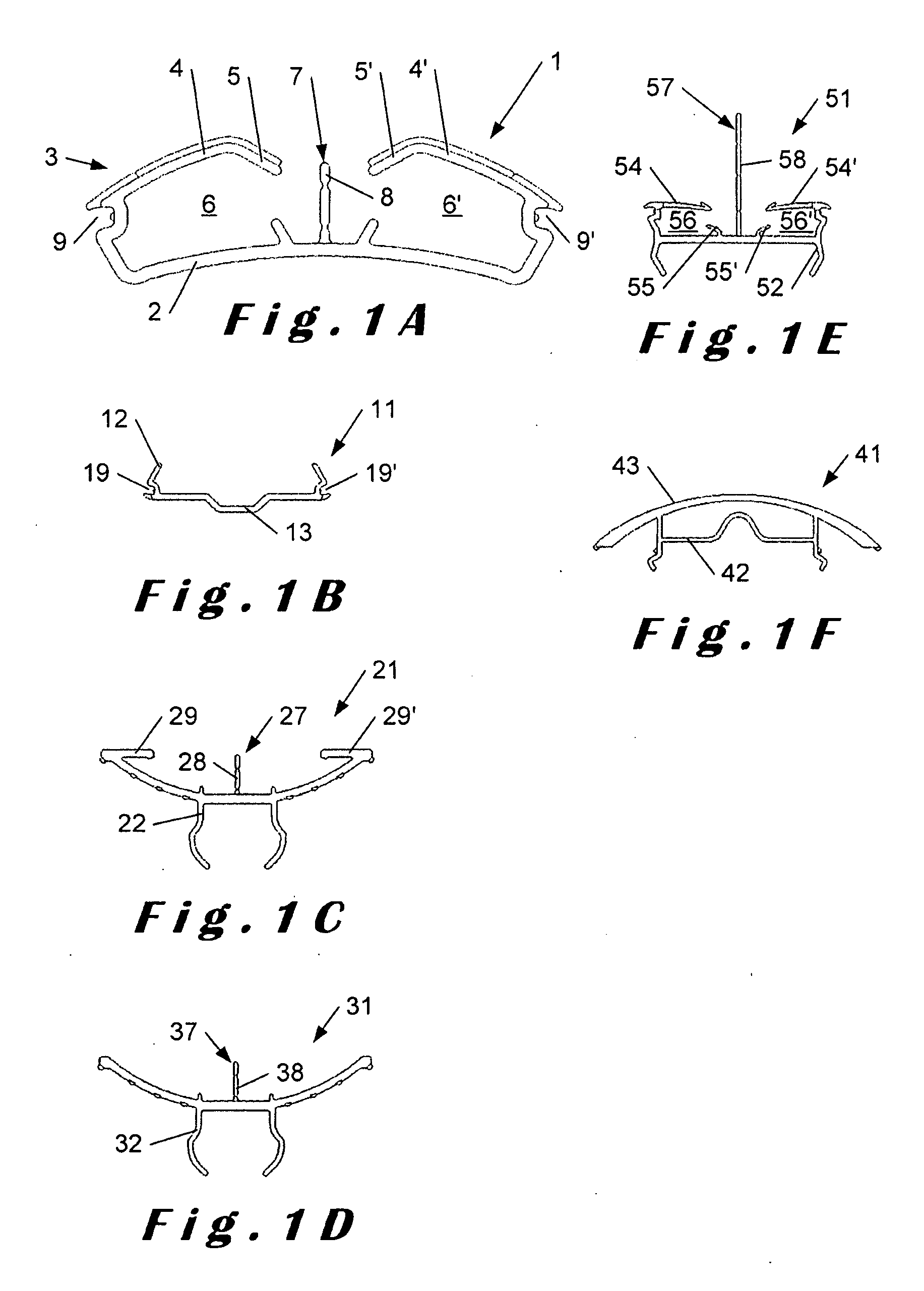

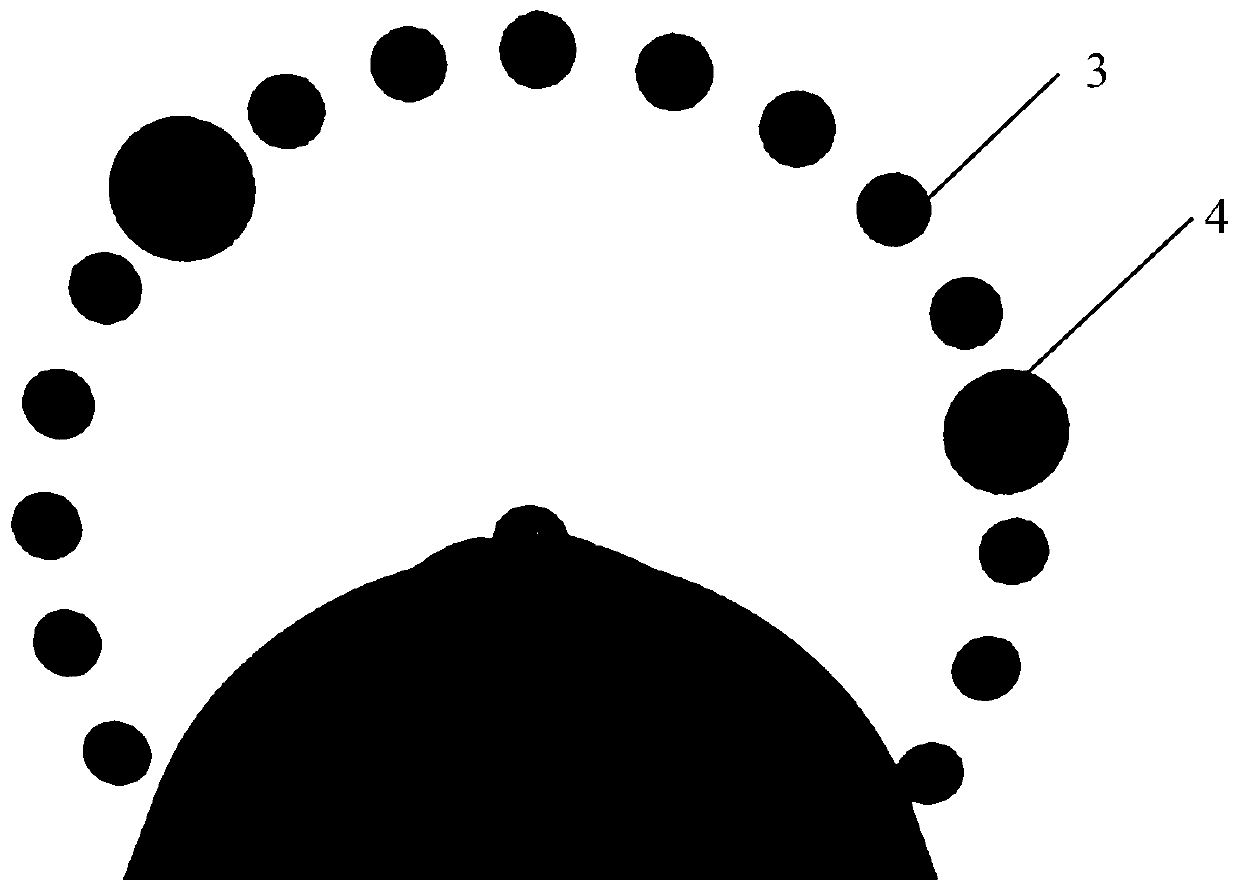

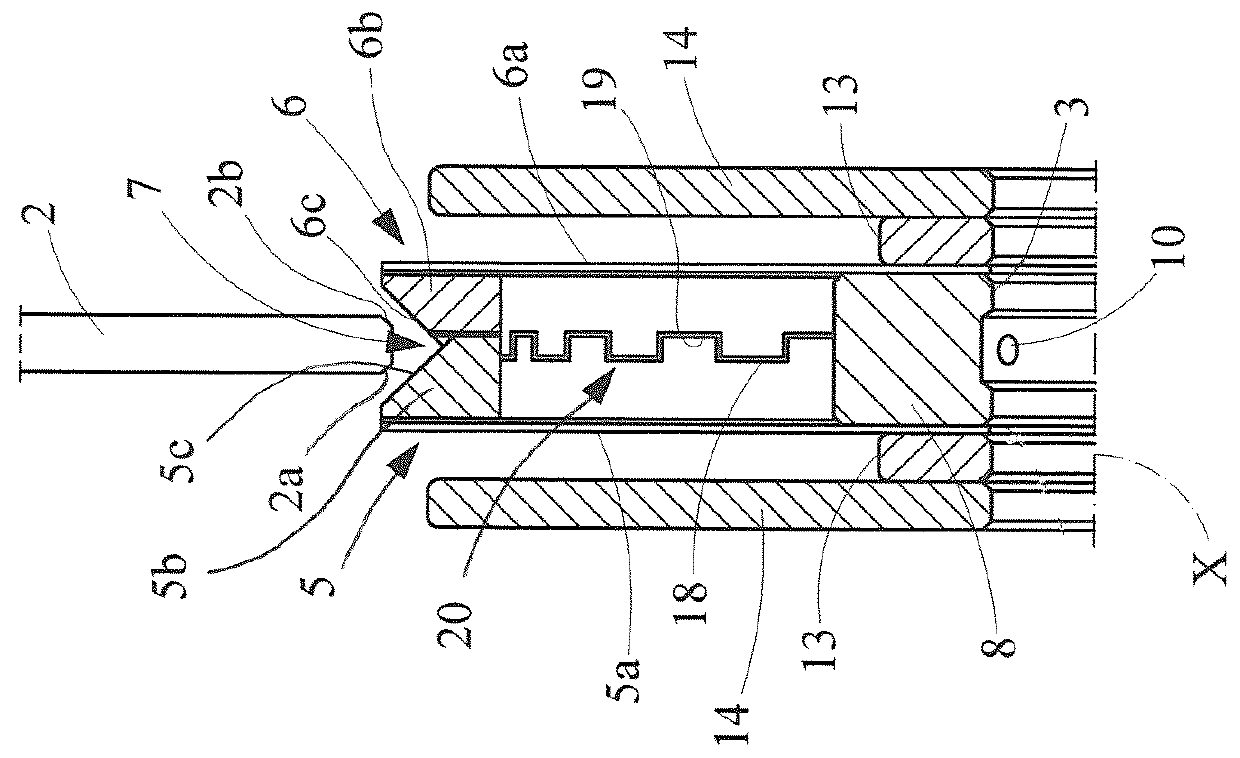

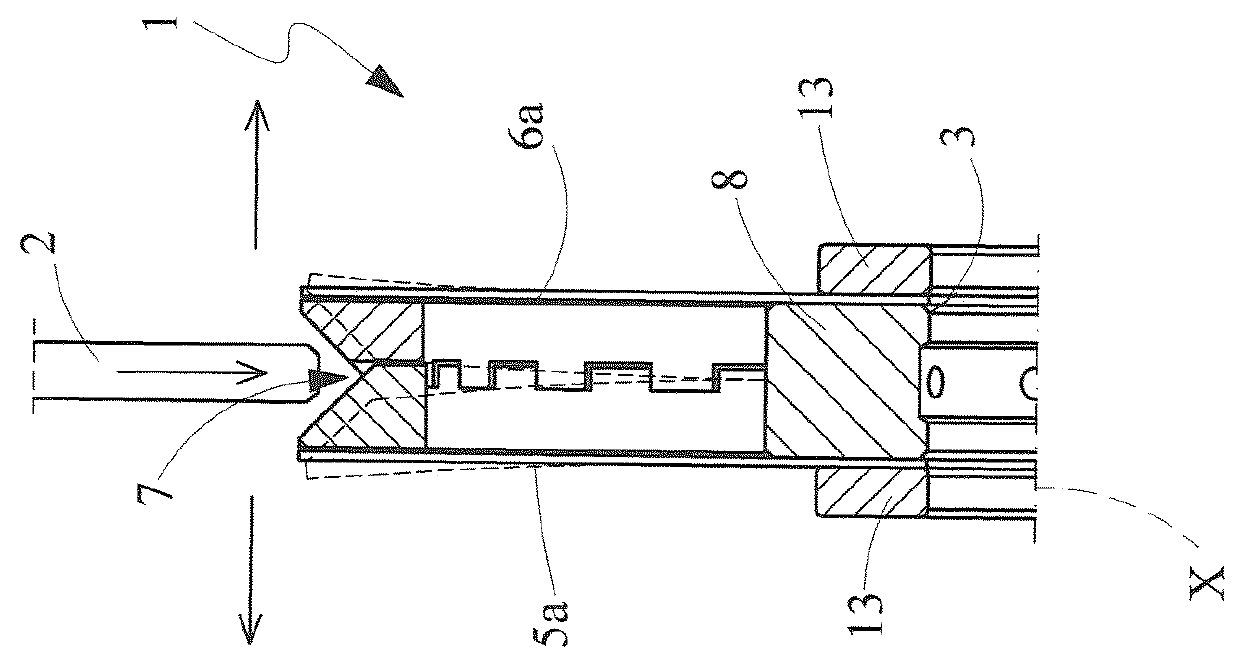

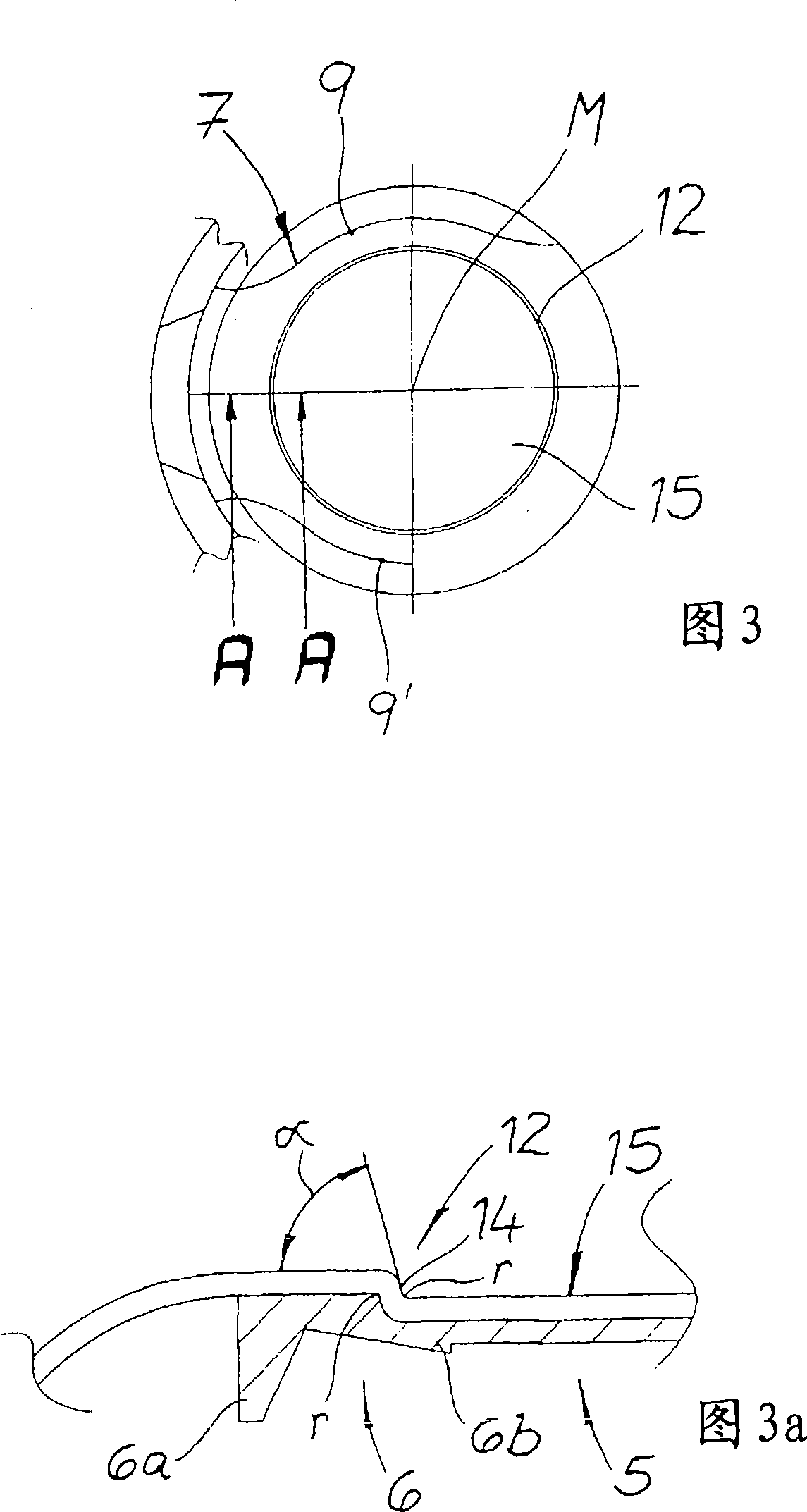

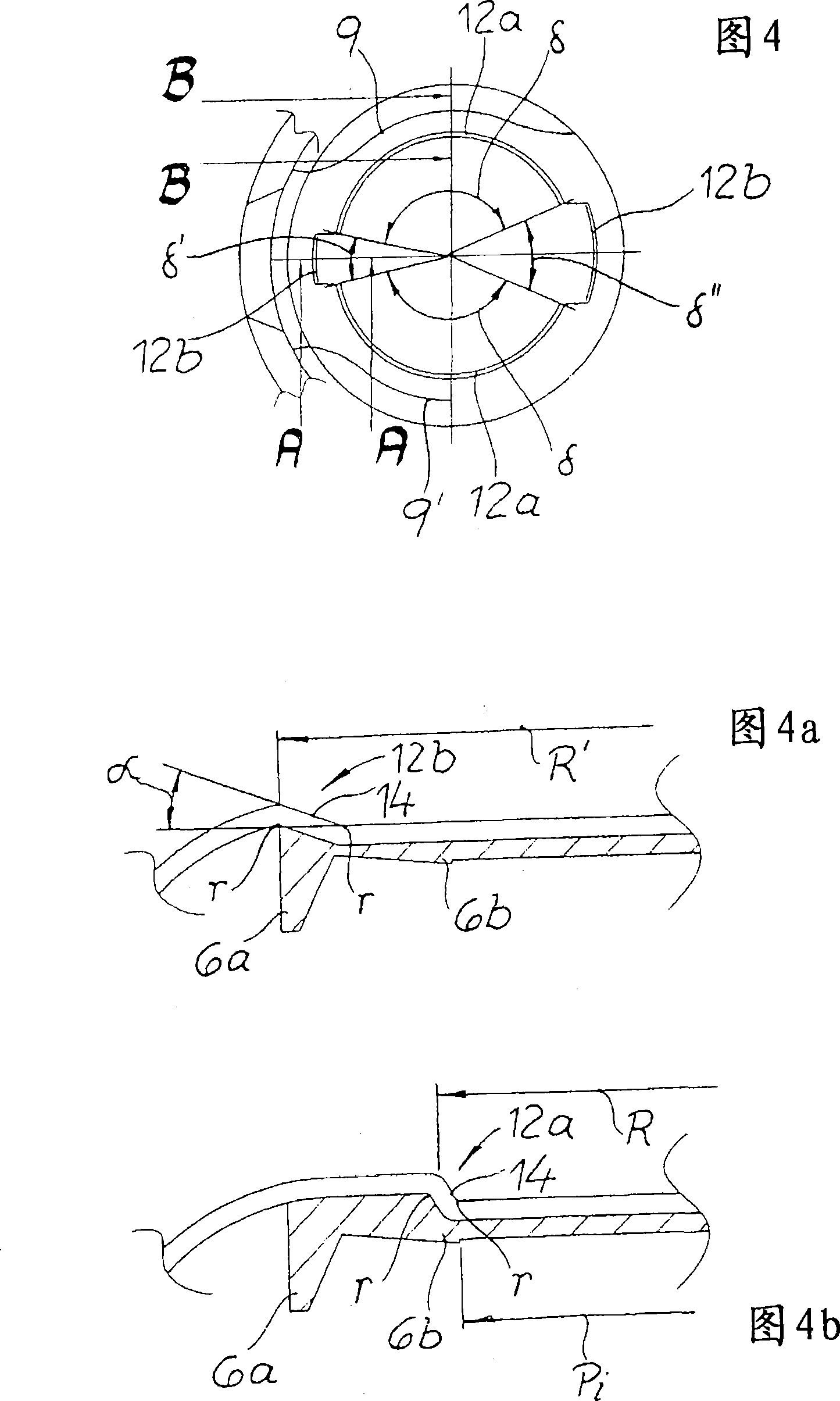

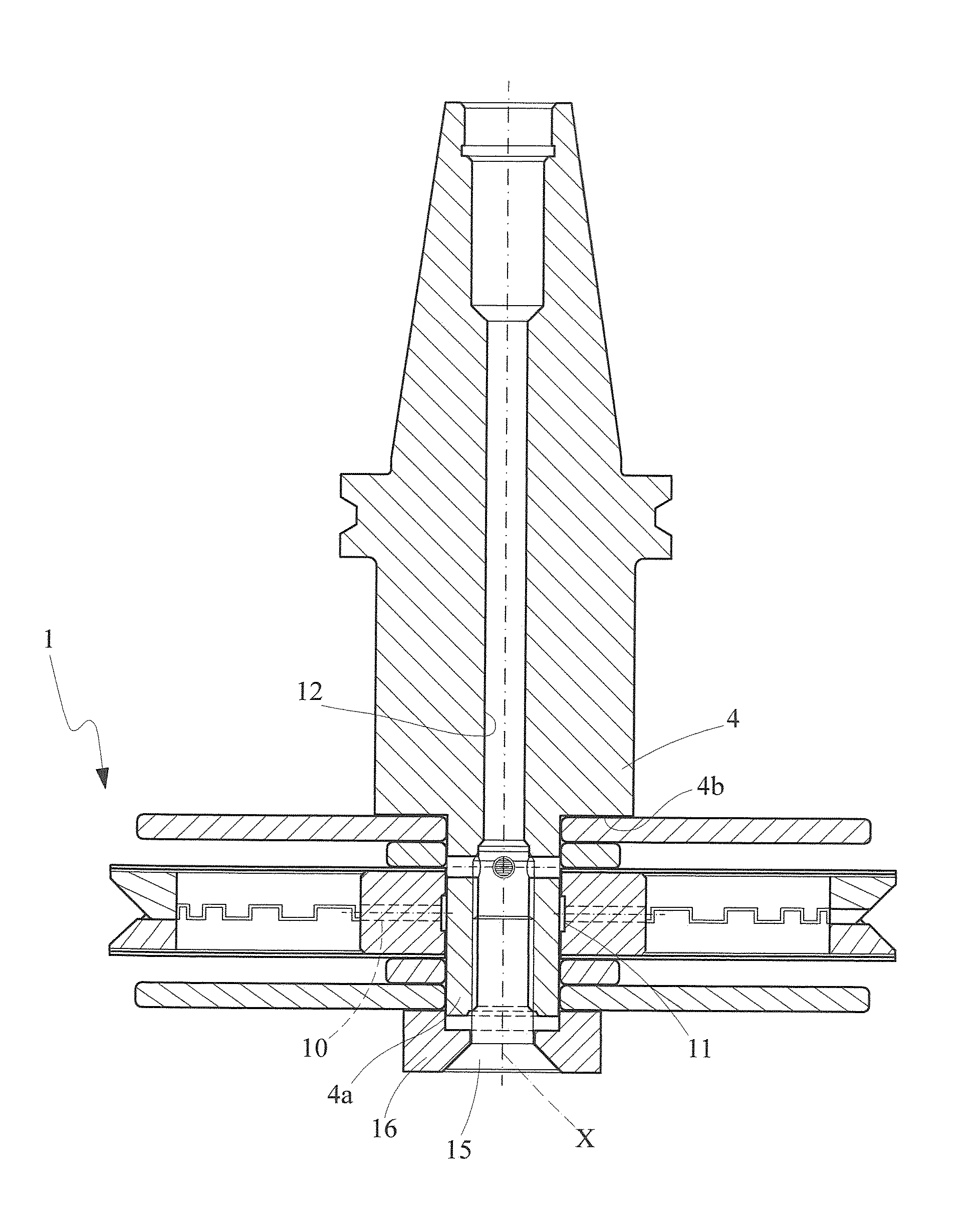

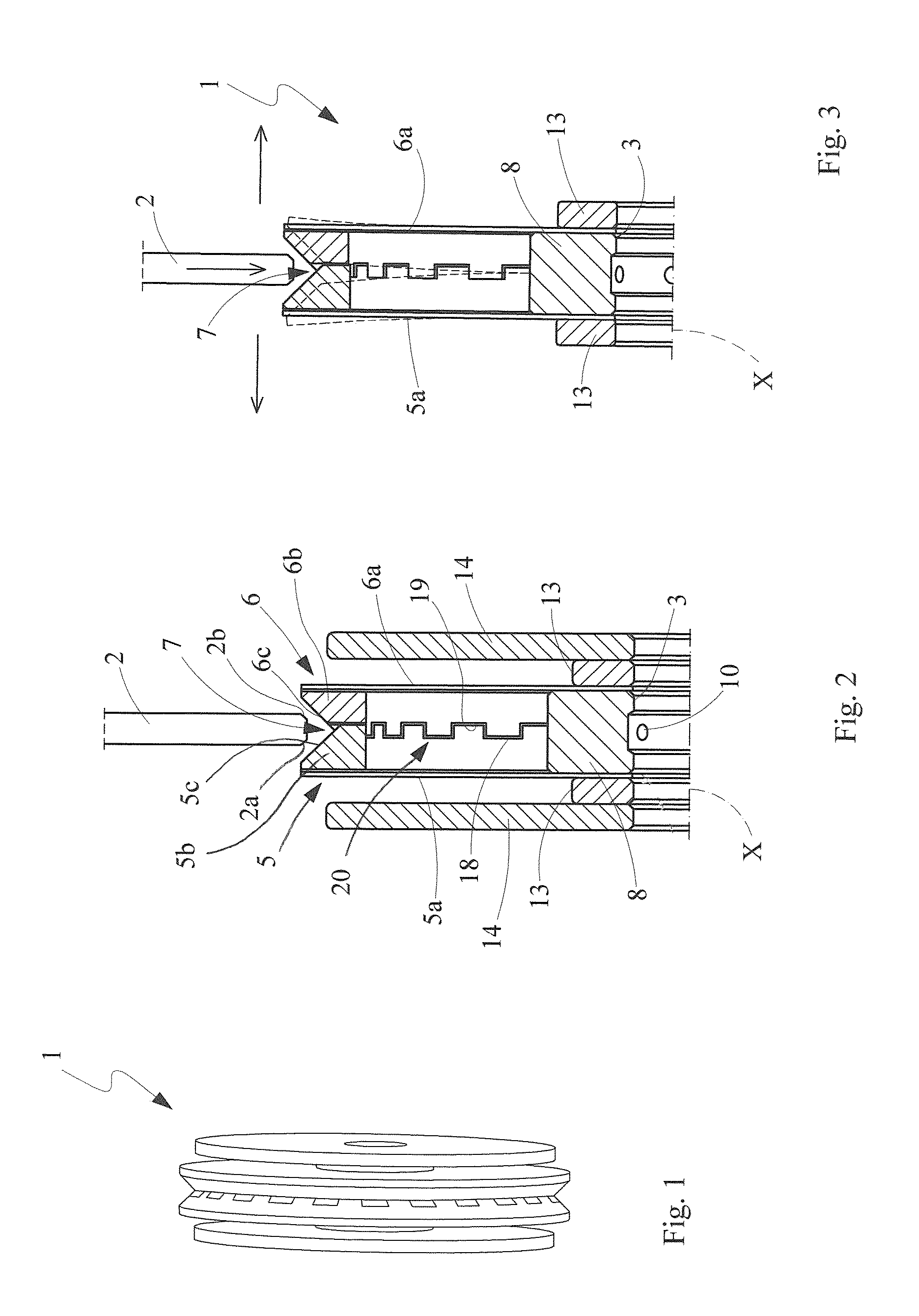

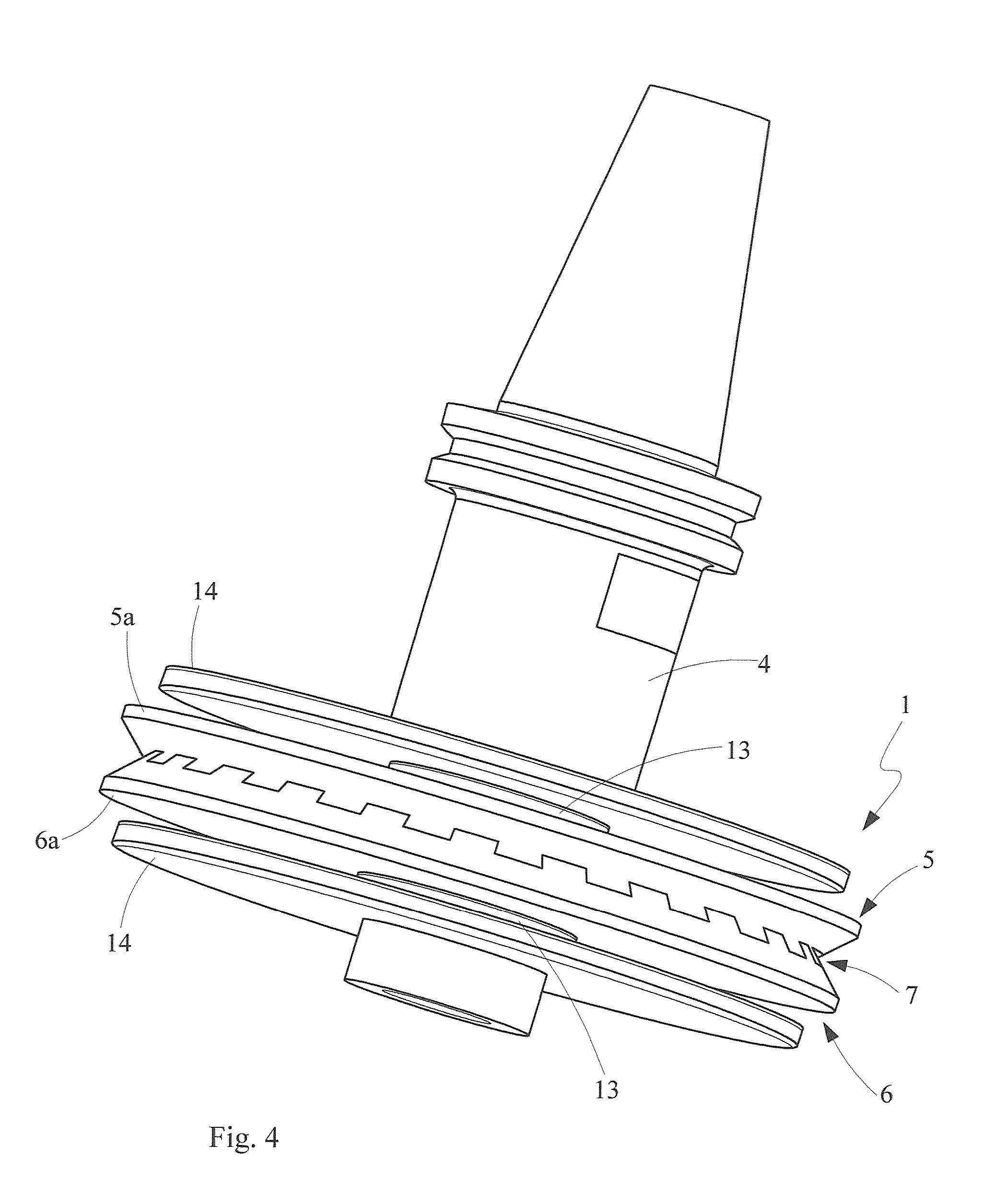

Grinding wheel, particularly for grinding processing operations carried out on sheets of glass, ceramic material or similar materials

There is described a grinding wheel (1), particularly for grinding operations carried out on sheets of glass (2), ceramic material or similar materials, comprising a disc-shaped support with abrasive material arranged on the circumferential profile of the support, and an opposing central hole (3) for attachment to a drive shaft (4) of the grinding wheel. The disc-shaped support comprises a pair of opposed disc-shaped grinding wheel bodies (5, 6) coupled in a facing position so as to define together the abrasive grinding surface (5c, 6c) along the circumferential profile, and each of the disc-shaped bodies (5, 6) has a predetermined resilience such that the disc-shaped bodies (5, 6) can be flexed away from each other in the zone of contact with the component being ground, for the purpose of consequently applying pressure to the component in the grinding operation.

Owner:ADI

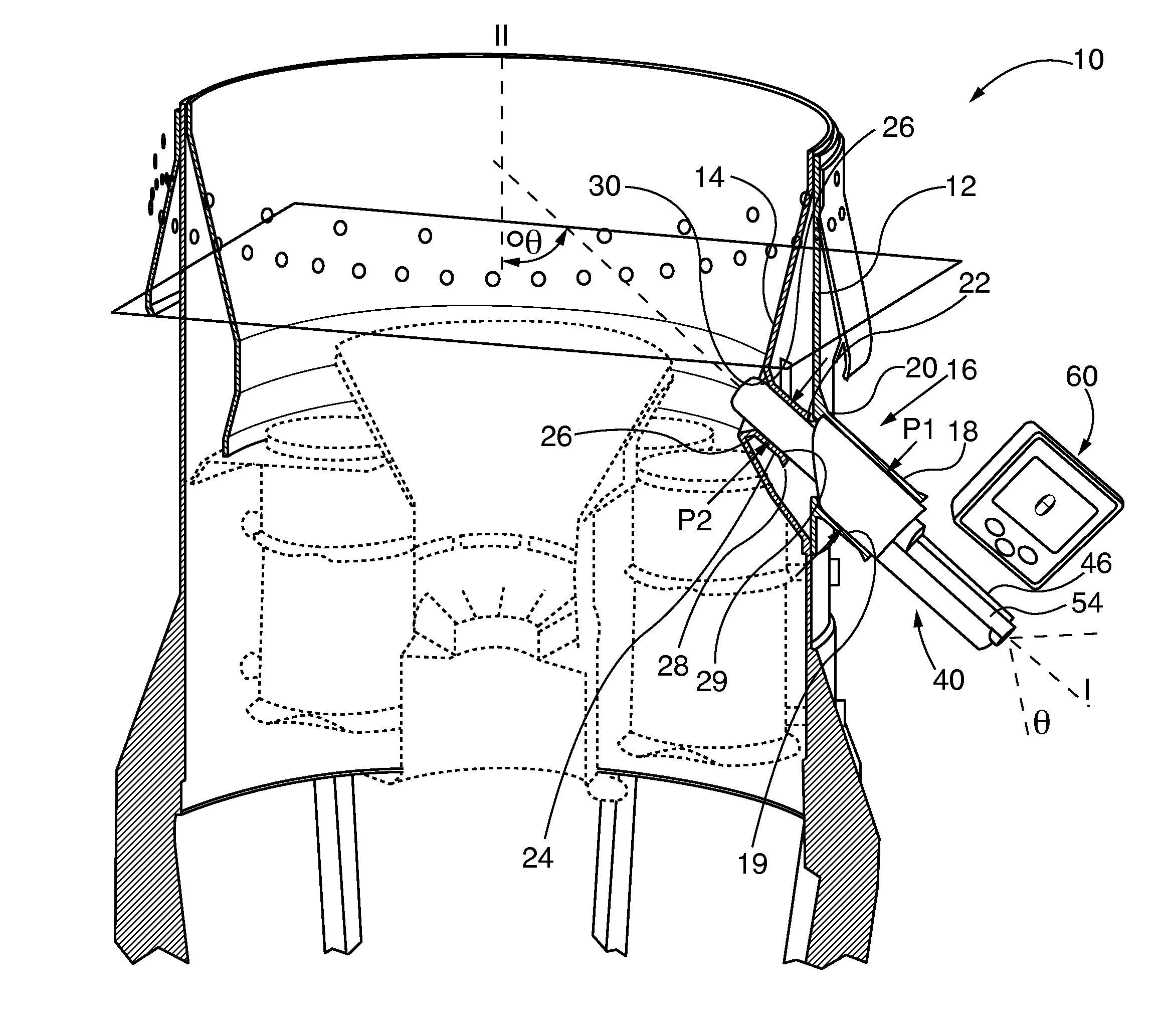

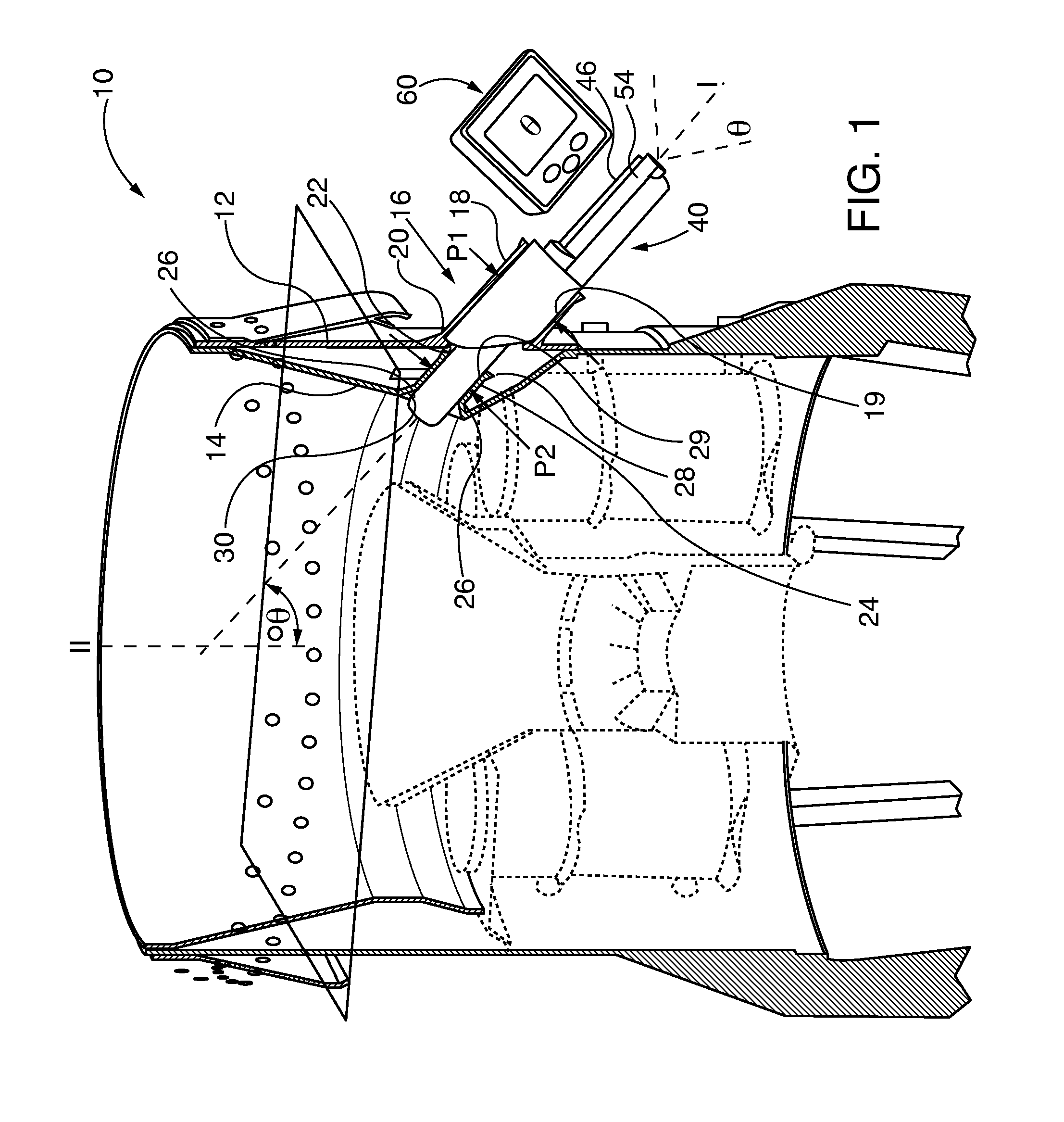

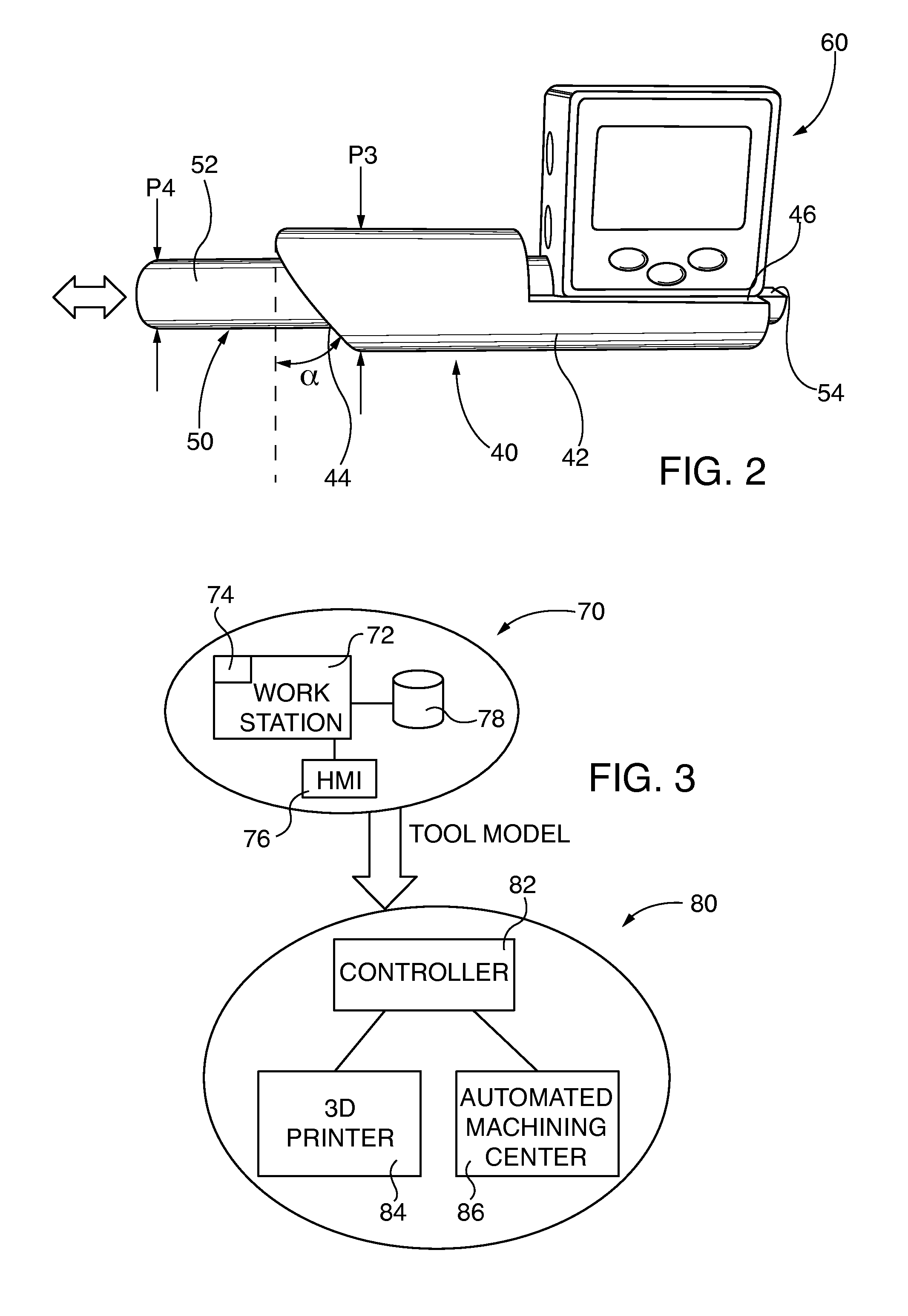

Combustion turbine engine combustor basket igniter port alignment verification tool and method for validating igniter alignment

ActiveUS20150377491A1Mitigate mechanical binding issueMitigate mechanical binding issuesAngles/taper measurementsAdditive manufacturing apparatusCombustorEngineering

A combustion turbine engine combustor igniter port alignment and dimensional verification tool is insertable in guide tube and igniter boss portions of the igniter port. The tool has concentrically nested outer and inner sleeves, having respective circumferential profiles that are separately slidably insertable within corresponding igniter port guide tube and igniter boss portions that have inner circumferential profiles in conformance with minimal dimension specifications. Concentric alignment of the guide tube and igniter boss is validated by inserting the nested outer and inner sleeves into the igniter port. The verification tool is capable of validating igniter port alignment and dimensions before the combustor is installed in a combustion turbine engine.

Owner:SIEMENS ENERGY INC

Motorcycle tire for off-road traveling

InactiveUS7874330B2Enhance the edge effectTraction performance can beOff-road vehicle tyresMotorcycle tyresGround contactEdge effects

An off-road motorcycle tire having a block pattern comprising a plurality of blocks 11 defined by tread grooves 10, each block 11 having a circumferential profile 16 of top surface 12 in the form of a straight line or a circular arc having a radius Ra of curvature of at least 500 mm, in which the circumferential profile denotes a profile in the circumferential section which passes through the centroid G of the top surface 12 and is parallel to the tire equatorial plane Cc. According to the invention, the ground contact pressure at the periphery of the top surface of blocks 11 is prevented from lowering to enhance the edge effect.

Owner:SUMITOMO RUBBER IND LTD

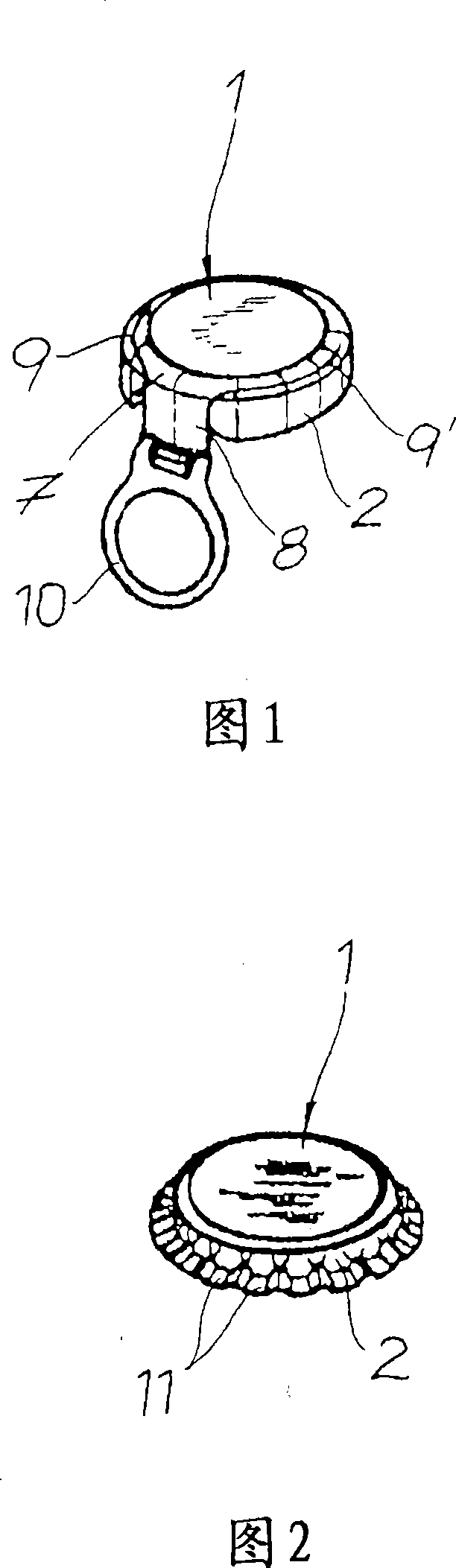

Closure for a container, especially a bottle

The invention relates to a closure for a container, especially a bottle, comprising an upper covering panel and a circumferential collar adjoining the panel on the outside, wherein a sealing insert is arranged on the underside of the covering panel which has a circumferential profile seal on the outside. The upper covering panel has at least one partly circumferential embossing which interacts with the profile seal forming a valve.

Owner:斯文阿克马格纳森

Roller element bearing with preloaded hydrodynamic cage guides

A bearing includes an inner ring having an outer surface and a cage having both an inner surface and an outer surface. The cage inner surface is positioned to be in opposition to the inner ring outer surface. The bearing further includes an outer ring having both an inner surface and an outer surface. The outer ring inner surface is positioned to be in opposition to the cage outer surface. One or more of the inner ring outer surface, the cage inner surface, the cage outer surface, and the outer ring inner surface defines a non-circular circumferential profile.

Owner:GENERAL ELECTRIC CO

Centrifugal ventilator

ActiveCN102562660BHigh pressure coefficientImprove flow coefficientPump componentsPumpsImpellerEngineering

A centrifugal ventilator comprises a volute casing thereof and an impeller, wherein the impeller consists of a plurality of blades and is arranged in the volute casing of the centrifugal ventilator. The profile of each blade is in a two-dimensional double-arc structure, the two arcs bend to opposite directions and are connected smoothly at the position with the radius Rc ranging from 730mm to 750mm, the profile of a cap of the impeller is in double-arc transitional connection, the radiuses of the two arcs are respectively 230mm and 210mm, the outlet of the impeller has a rotary diffuser structure, and the circumferential profile of the volute casing is in smooth sectional eccentric arc connection. The flow coefficient of the centrifugal ventilator is 0.24, which is increased by 40% as compared with that of the L6-46 centrifugal ventilator and is increased by 90% as compared with that of Y5-58 centrifugal ventilator; the pressure coefficient is 1.234, which is increased by 40% as compared with that of a T4-79 centrifugal ventilator, and is increased by 11% as compared with that of the Y5-58 centrifugal ventilator; and the efficiency of the centrifugal ventilator is 86%, which is close to the highest efficiency point of a high-flow low-pressure high-efficiency ventilator, and is higher than the maximum efficiency value of a medium-flow high-pressure ventilator.

Owner:TIANJIN UNIV

Grinding wheel, particularly for grinding processing operations carried out on sheets of glass, ceramic material or similar materials

There is described a grinding wheel (1), particularly for grinding operations carried out on sheets of glass (2), ceramic material or similar materials, comprising a disc-shaped support with abrasive material arranged on the circumferential profile of the support, and an opposing central hole (3) for attachment to a drive shaft (4) of the grinding wheel. The disc-shaped support comprises a pair of opposed disc-shaped grinding wheel bodies (5, 6) coupled in a facing position so as to define together the abrasive grinding surface (5c, 6c) along the circumferential profile, and each of the disc-shaped bodies (5, 6) has a predetermined resilience such that the disc-shaped bodies (5, 6) can be flexed away from each other in the zone of contact with the component being ground, for the purpose of consequently applying pressure to the component in the grinding operation.

Owner:ADI

Apparatus for compacting fibrous plant material, especially for compacting stalk material

An apparatus for compacting stalk material, having a feeding device for feeding material to be pressed, having at least one pair of press drums which can be driven in opposite directions and which each have circumferential receiving grooves and compression rings in an alternate manner alongside one another in the axial direction, wherein the compression rings of one press drum engage in the receiving grooves of the other press drum, wherein at least one press drum is provided with a cavity and wherein this at least one press drum has a multiplicity of radially extending press channels in a manner distributed over the circumference, said press channels in each case connecting the groove bottom of the receiving grooves to the cavity, provision is made for the compression rings to have a circumferential profile having protrusions formed for example by radially external teeth having tooth tips.

Owner:KALVERKAMP KLEMENS DE +1

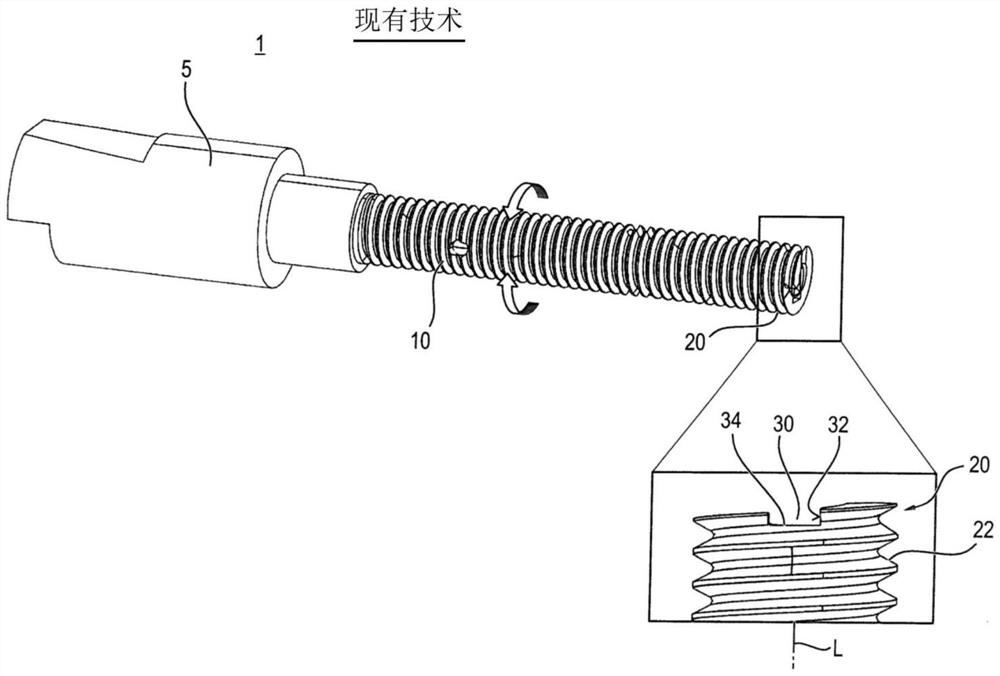

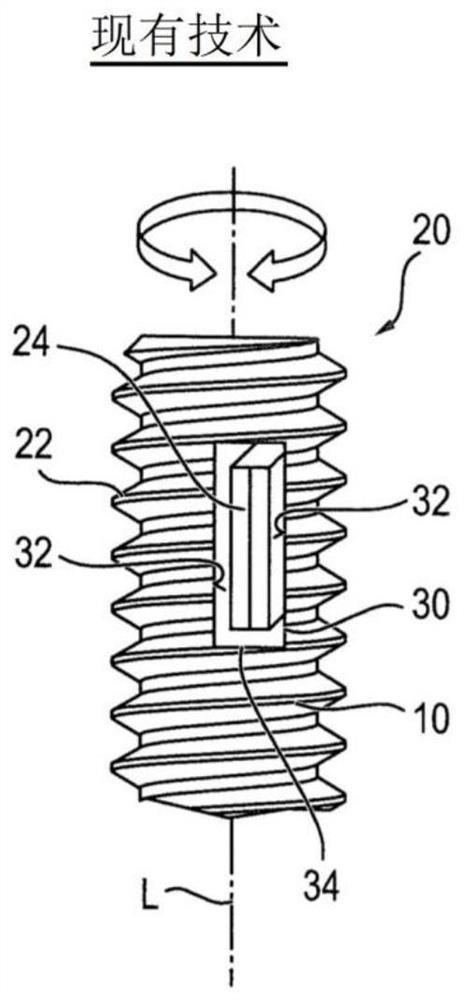

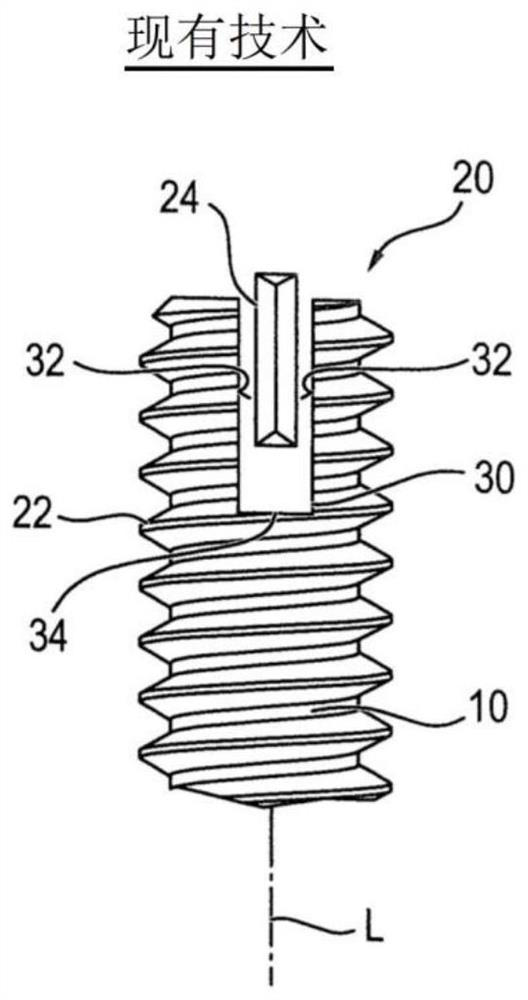

Tool for installing or removing wire thread inserts and method of manufacture

ActiveCN109641346BWill not cause failureEliminate Corner ProfilesSpannersWrenchesEngineeringCircumferential Profile

The invention relates to a tool (1) for installing or removing a wire thread insert and a method for its manufacture. The spindle body inserted in the tool (1) has a radial recess (30) through which the engagement end (24) of the mounting blade engages the wire thread insert. The radial recess (30) has a curved circumferential profile or at least one relief notch (40) for mechanical tension relief in the spindle body (10).

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com