A method for calibrating multi-camera visual inspection equipment

A technology of multi-camera vision and detection equipment, applied in image analysis, instrumentation, computing, etc., can solve problems such as complex operation and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

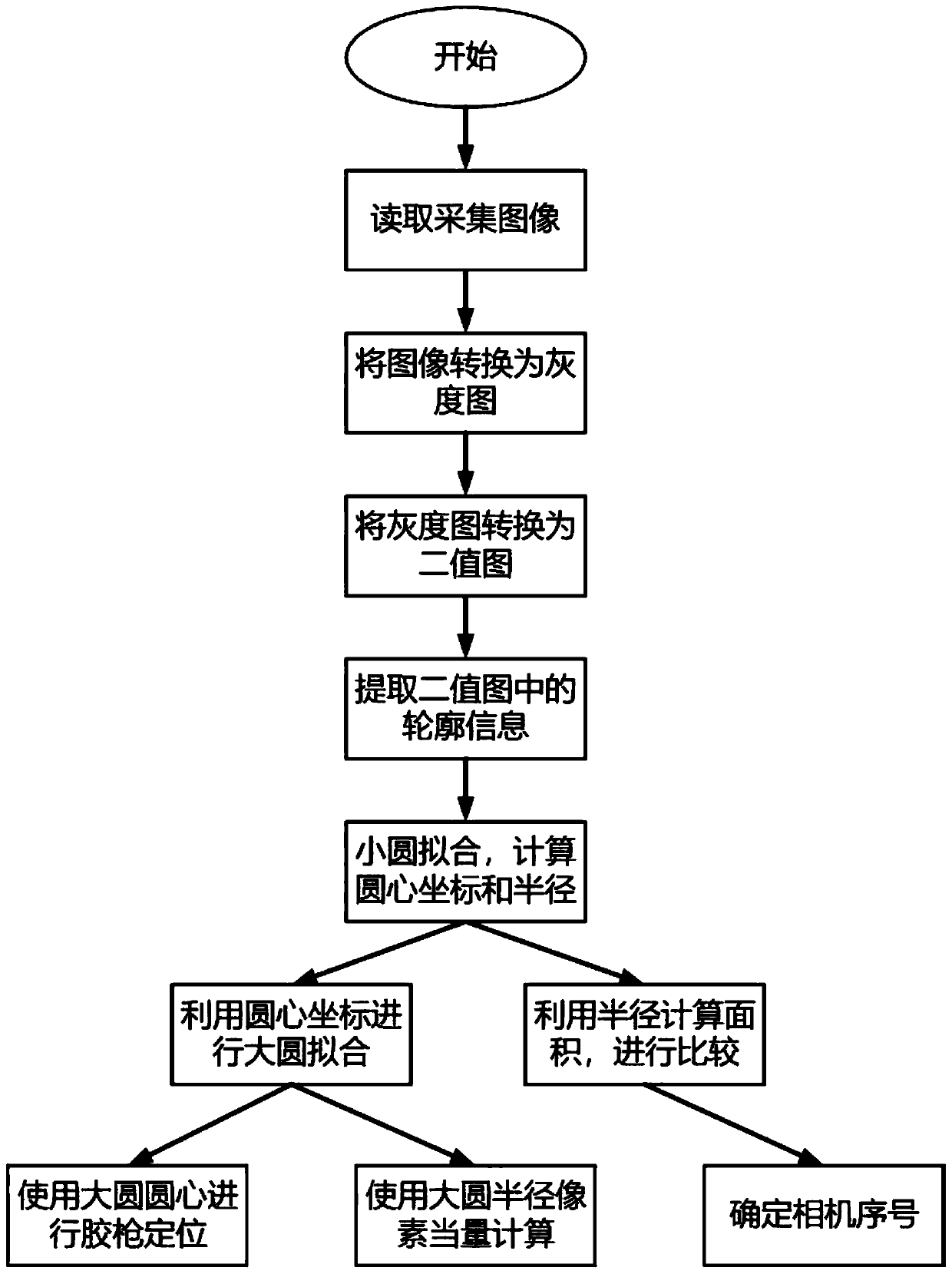

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, the case where the number of cameras is 3 is listed, a method for calibrating multi-camera visual inspection equipment, the multi-camera visual inspection equipment is set in industrial equipment (specifically, this industrial equipment can be a glue gun, or can be It is other similar equipment), and 3 cameras are evenly distributed on the circumference with the center of the detection equipment as the center, and the angle between two adjacent cameras is 120°, including the following steps:

[0048] Step 1. Place the calibration plate under the detection equipment. The calibration plate includes 3 characteristic mark circles with unequal diameters; the centers of the 3 feature mark circles are located on the same circumference of the calibration plate; The angle is also 120°, corresponding to the camera position one by one;

[0049]Adjust the position of the multi-camera visual inspection equipment so that the field of view of a single camera contai...

Embodiment 2

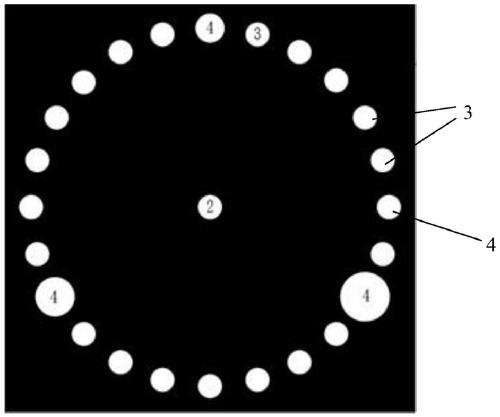

[0066] A method for calibrating multi-camera visual inspection equipment. The multi-camera visual inspection equipment is set on industrial equipment (specifically, the industrial equipment can be a glue gun or other similar equipment), and the inspection equipment center 3 cameras are evenly distributed on the circumference of the circle center, and the angle between two adjacent cameras is 120°, such as figure 2 shown, including the following steps:

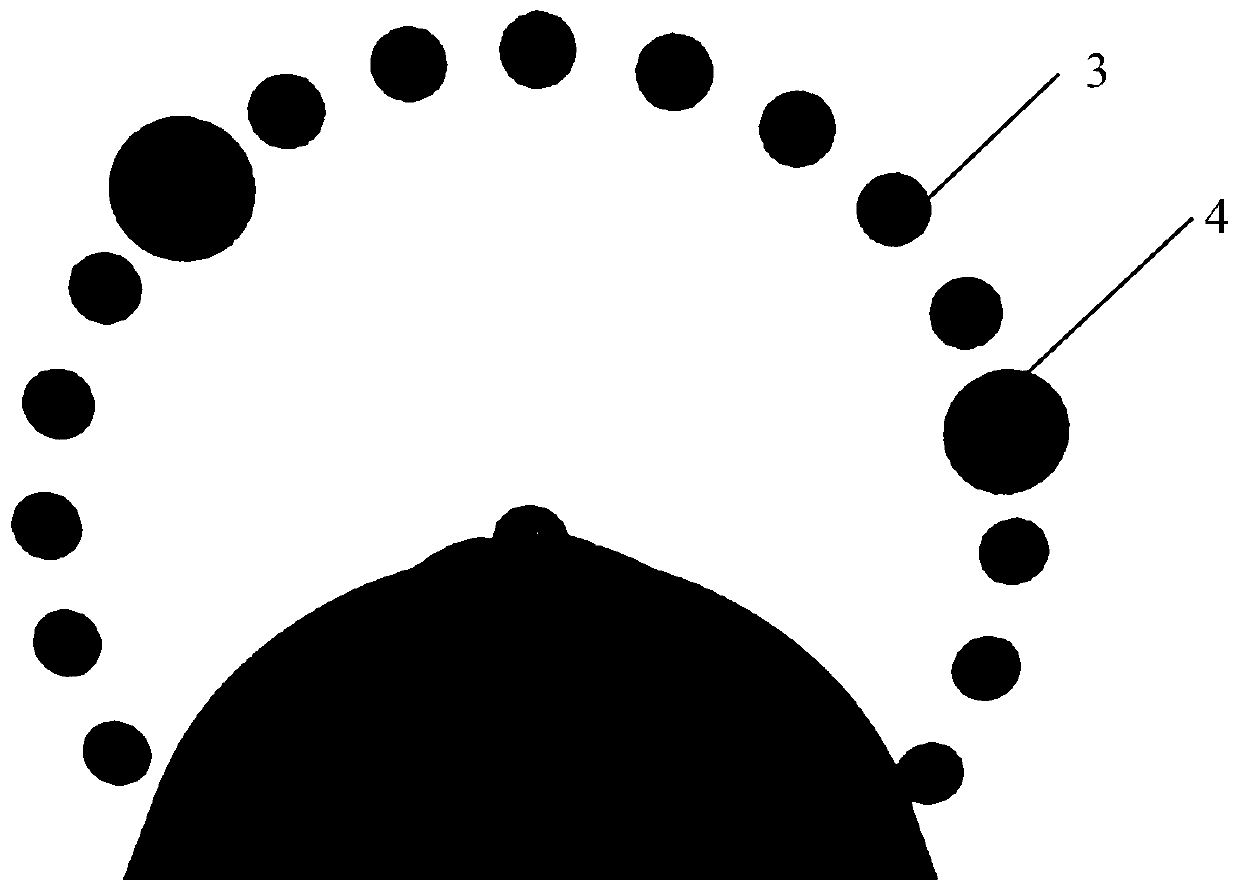

[0067] Step 1. Place the calibration plate under the testing equipment, such as image 3 As shown, the calibration plate includes a plurality of equal common sign circles 3 with equal diameters and three characteristic sign circles 4 with unequal diameters; the centers of the common sign circles 3 and the feature sign circles 4 are located on the same circumference, and the circle is denoted as circle I; The diameter of characteristic sign circle 4 is greater than the diameter of common sign circle 3; The center position of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com