Blast hole plugging device and method

A technology for plugging devices and blastholes, which is applied in blasting and other directions, and can solve problems such as poor blasting effect and short action time of blasting gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

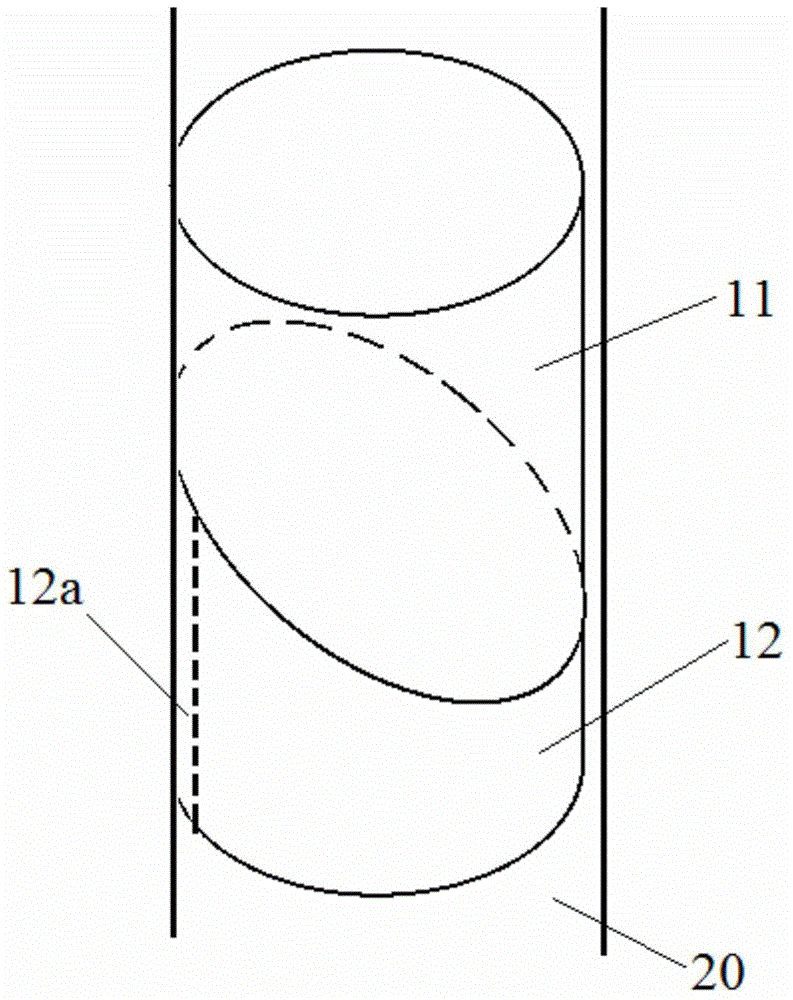

Embodiment 1

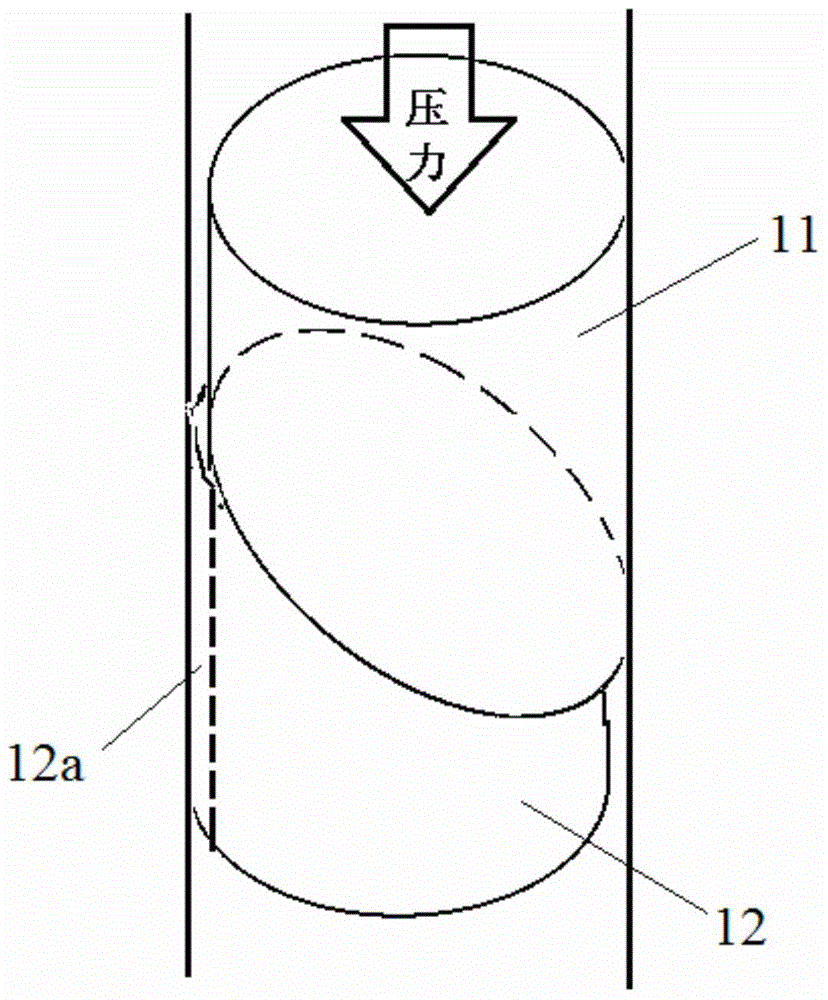

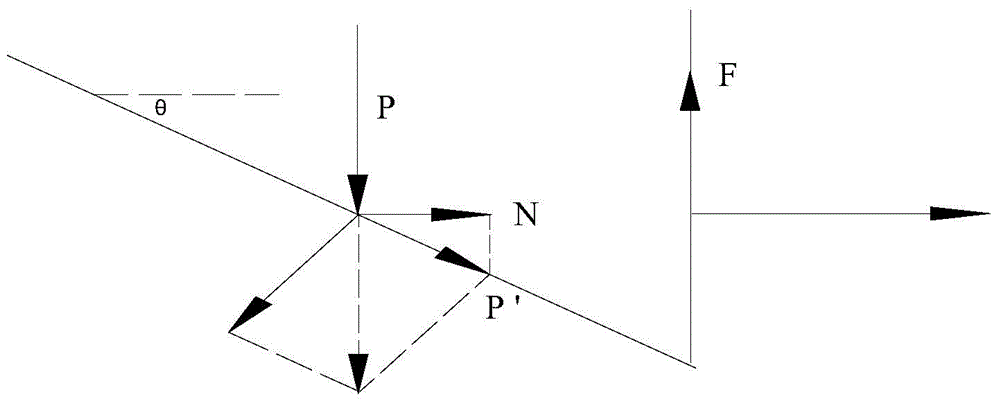

[0052] The blasthole 20 is a circular hole, and its diameter is 89mm. Correspondingly, the first plugging part 11 and the second plugging part 12 are cylindrical, and its diameter is 75-80mm. The height of the blasthole plugging device (here The "height of the blast hole plugging device" refers to the height of the first plugging part 11 and the second plugging part 12 when the first plugging part 11 and the second plugging part 12 form surface contact with each other through the first surface and the second surface The overall height of part 12) is 60mm, the included angle between the first surface and the axis of the blasthole 20 and the included angle between the second surface and the axis of the blasthole 20 are both 22°, the diameter of the through hole 13 is 10mm, when When the cross section of the first groove 12 a of the second blocking portion 12 is a semicircle, its diameter is 28 mm or the like.

[0053] When the blasthole 20 is inclined upwards ("upward" here refe...

Embodiment 2

[0055] The blasthole 20 is a circular hole, and its diameter is 89mm. Correspondingly, the first plugging part 11 and the second plugging part 12 are cylindrical, and its diameter is 75-80mm. The height of the blasthole plugging device (here The "height of the blast hole plugging device" refers to the height of the first plugging part 11 and the second plugging part 12 when the first plugging part 11 and the second plugging part 12 form surface contact with each other through the first surface and the second surface The overall height of part 12) is 60mm, the included angle between the first surface and the axis of the blasthole 20 and the included angle between the second surface and the axis of the blasthole 20 are 18°, the diameter of the through hole 13 is 10mm, when When the cross section of the first groove 12 a of the second blocking portion 12 is a semicircle, its diameter is 28 mm or the like.

[0056] When the blasthole 20 is inclined downwards ("downward" here refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com