Centrifugal ventilator

A centrifugal fan and eccentric technology, applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problem that the centrifugal fan cannot meet the requirements of large flow coefficient and large pressure coefficient at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The centrifugal fan of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

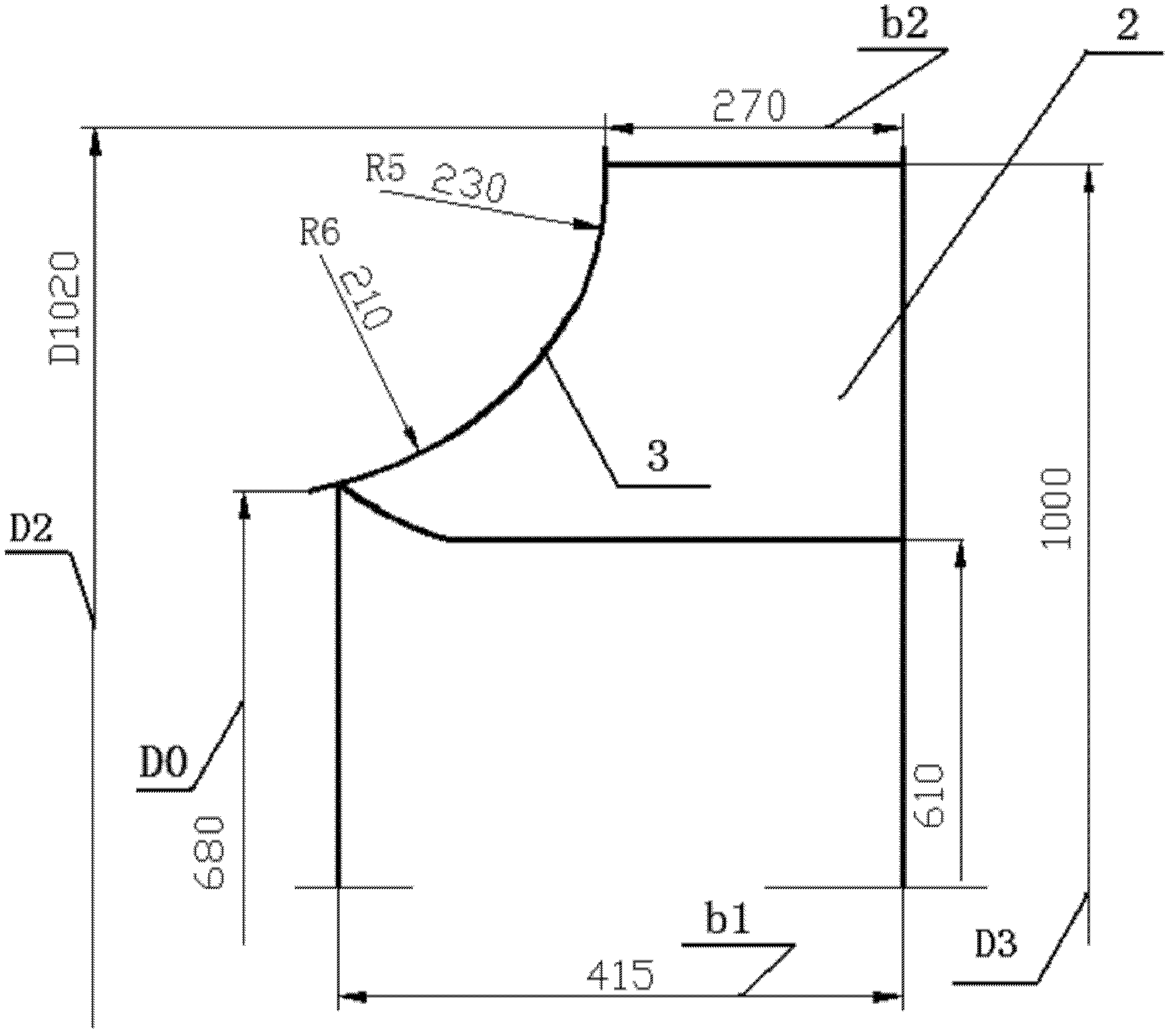

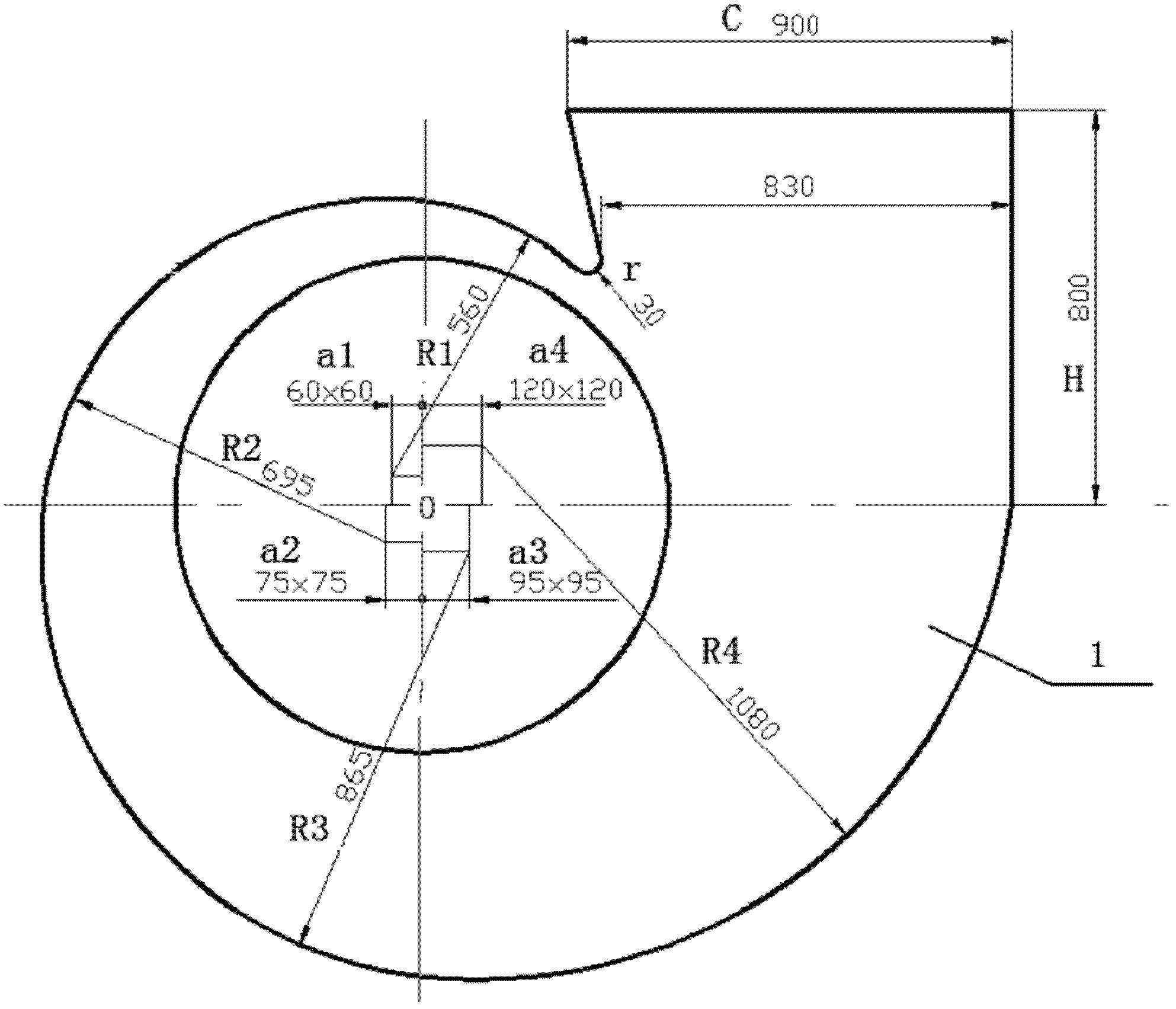

[0031] As shown in the figure, the centrifugal fan of the present invention includes a volute 1 of the centrifugal fan and an impeller 4 formed of a plurality of blades 2 in the volute 1 of the centrifugal fan, and the profile of the blade 2 is Two-dimensional double-arc structure, the two arcs have opposite bending directions, and are smoothly connected at a radius Rc of 730-750mm (optimally 740mm). The radii of R6 are 230mm and 210mm respectively; the profile line of the volute 1 in the circumferential direction is smoothly connected by segmented eccentric arcs.

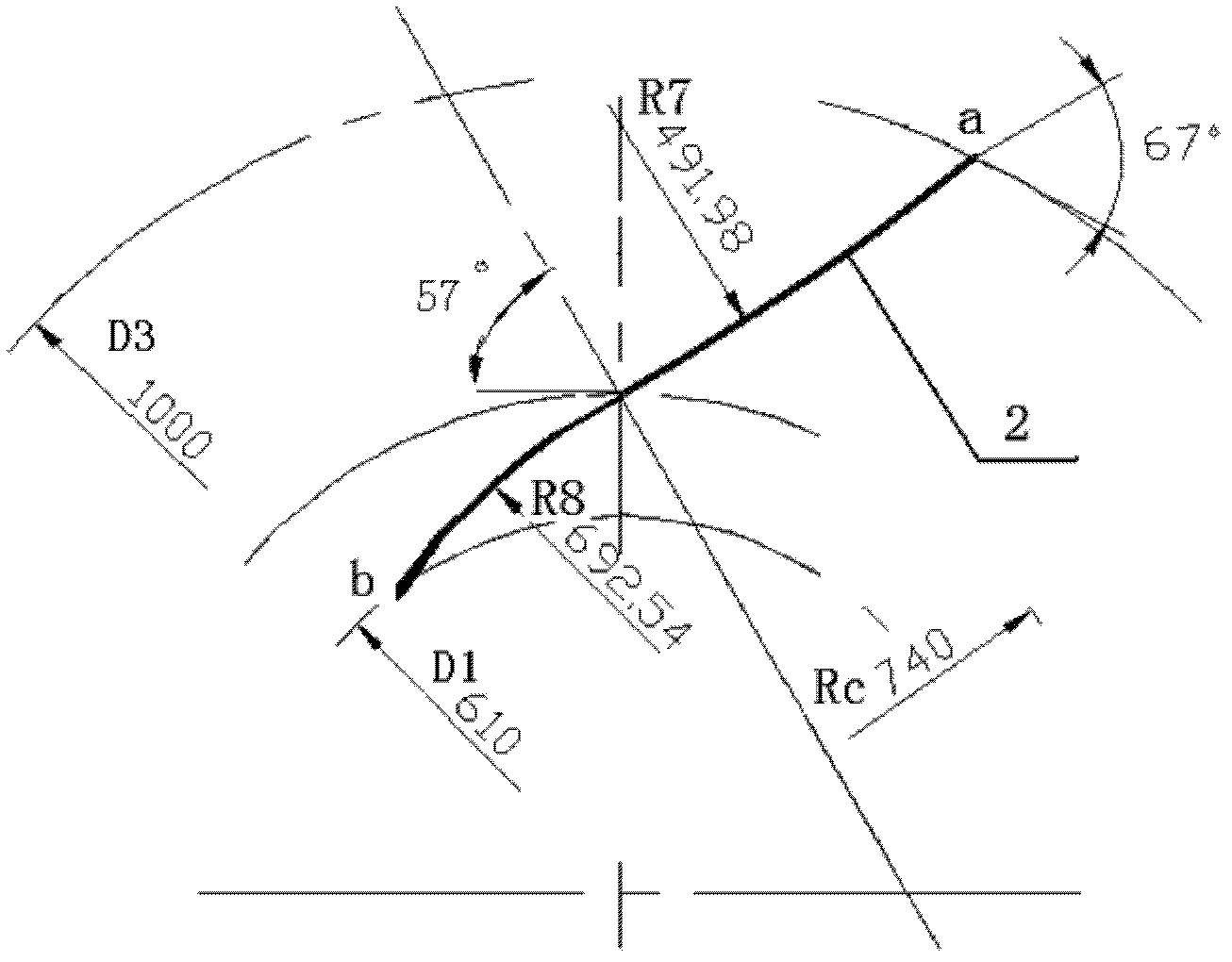

[0032] Such as figure 2 As shown, the starting point and the end point of the 2-shaped line of the blade are to make an oblique straight line at the connection point with a tangent angle of 57° to the circle Rc, and to make a radius R7 of 417 to 417° on the oblique...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com