Screw pump reverse rotation preventing braking method

A screw pump, anti-reverse technology, applied in pump control, machine/engine, mechanical equipment, etc., can solve the problems of unreleased reverse energy, fast reverse speed, disintegration of pulleys, etc., to facilitate integrated installation, Increased braking force and reliable braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

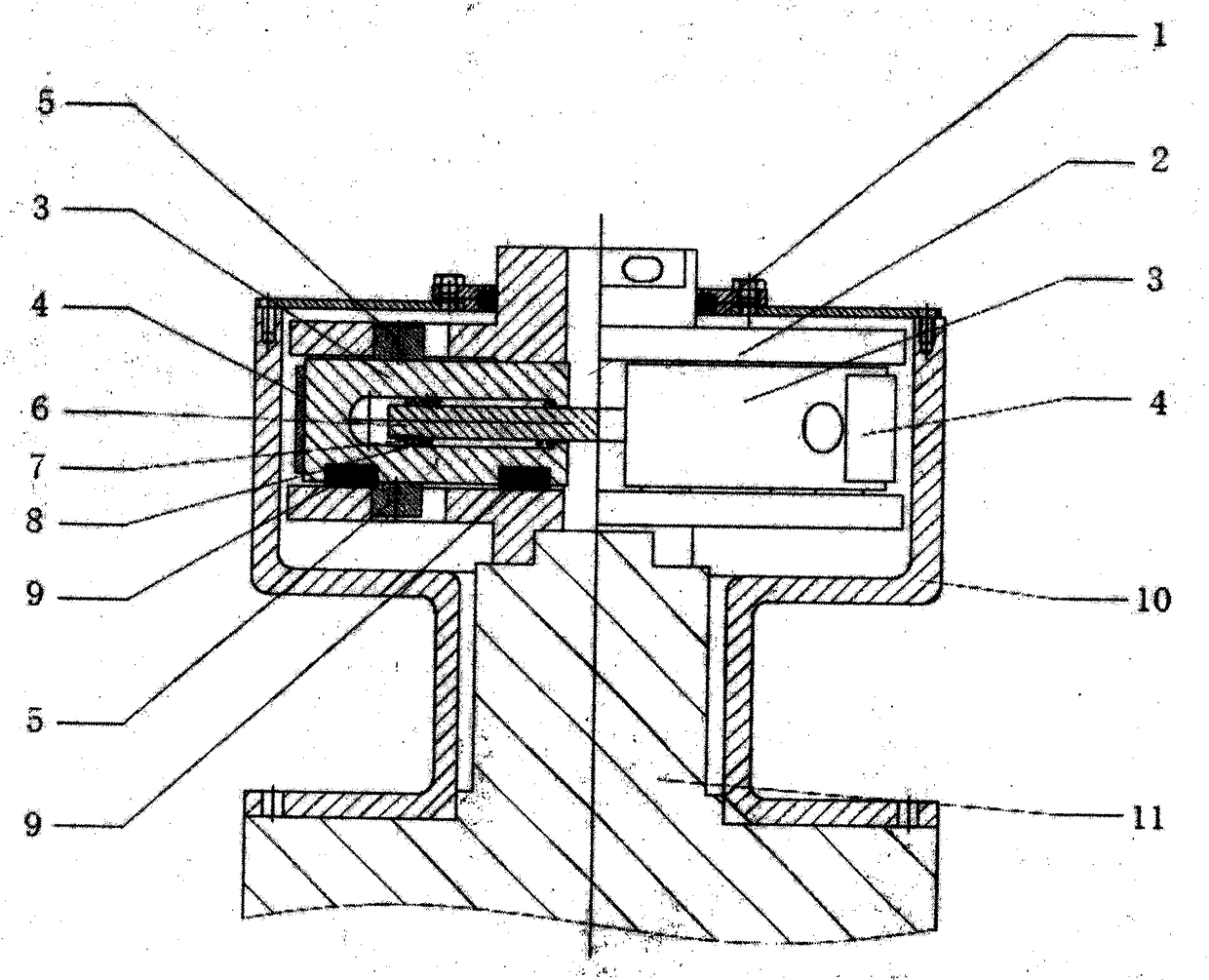

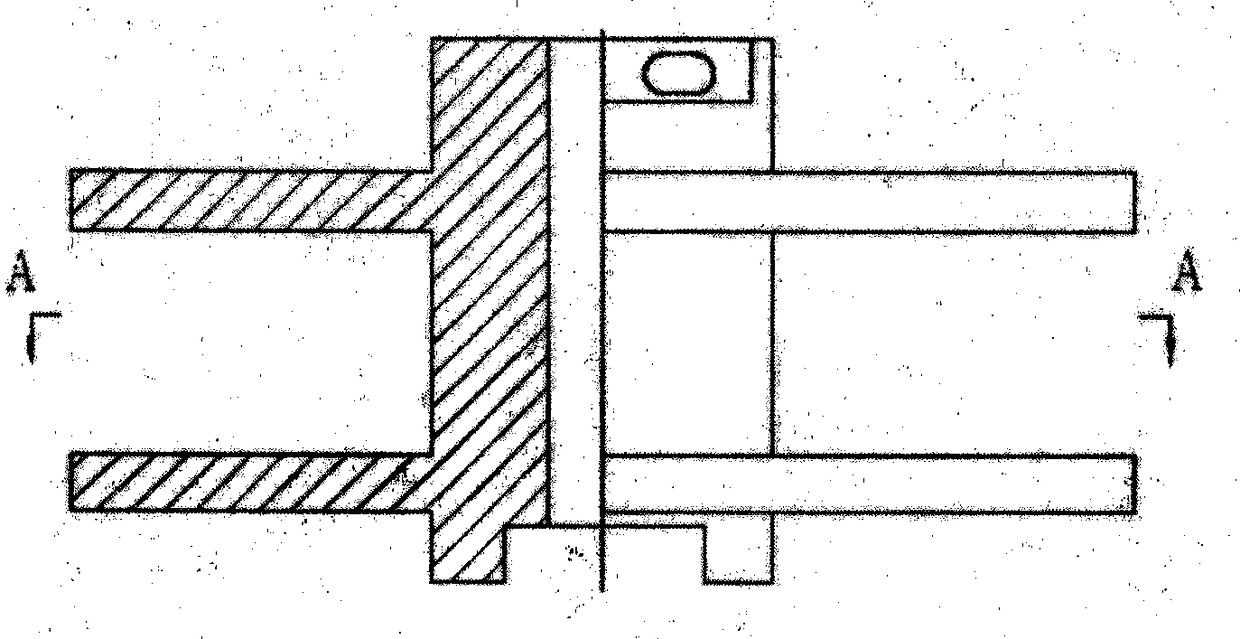

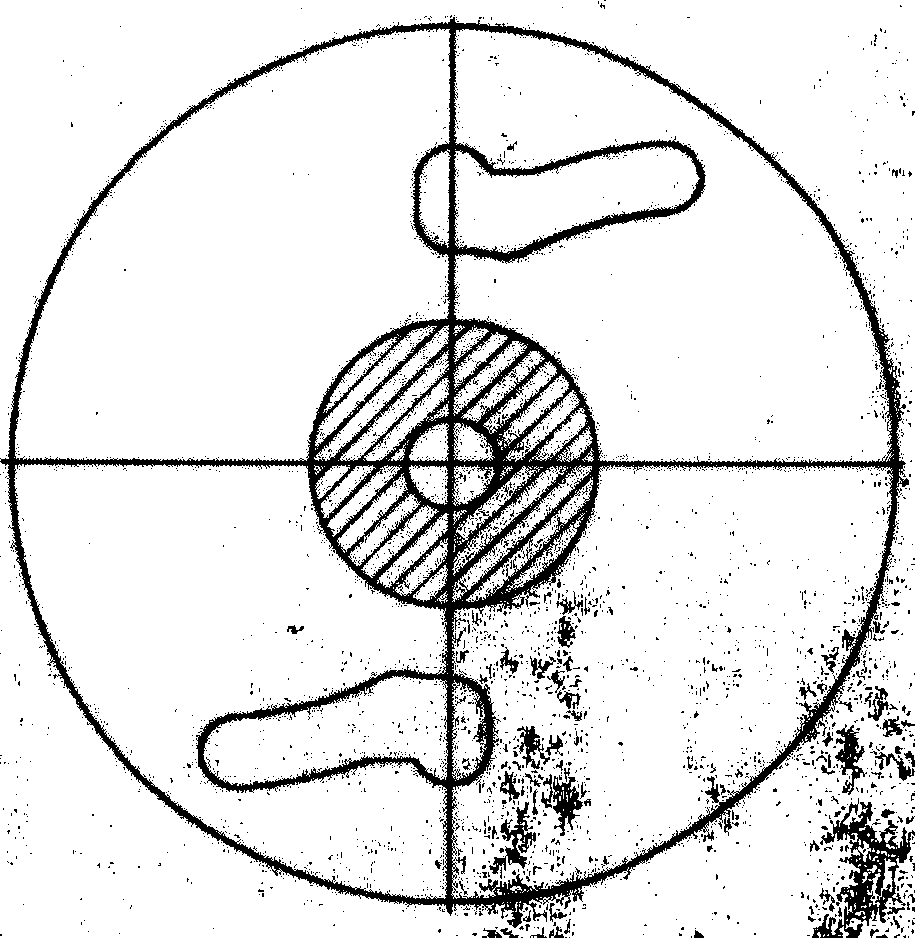

[0020] see figure 1 , this patent mainly consists of upper cover (1), centrifugal bracket (2), centrifugal block (3), brake pad (4), limit bolt (5), connecting bolt (6), round nut (7), spring ( 8), polytetrafluoro pad (9), outer casing (10) form.

[0021] Working process of the present invention is as follows:

[0022] When installing, respectively insert 2 brake pads (4) and 6 PTFE pads (9) into the corresponding positions of the two centrifugal blocks (3), then place the centrifugal support (2) horizontally, place the embedded brake The two centrifugal blocks (3) of the piece (4) and the polytetrafluoro pad (9) are placed between the upper and lower working surfaces of the centrifugal support (2), and then the four limit bolts (5) are respectively passed through the centrifugal support (2 ) are connected to the centrifugal block (3) to ensure that the centrifugal block (3) can only move along the track of the limit groove of the centrifugal support (2), and finally use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com