Patents

Literature

48results about How to "Braking force is strong" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

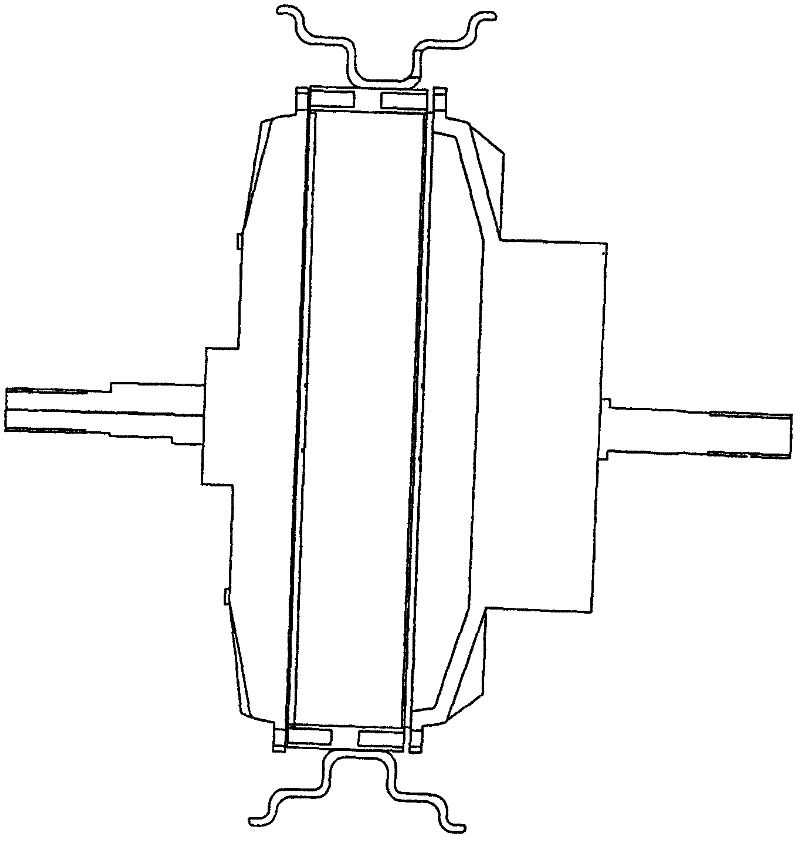

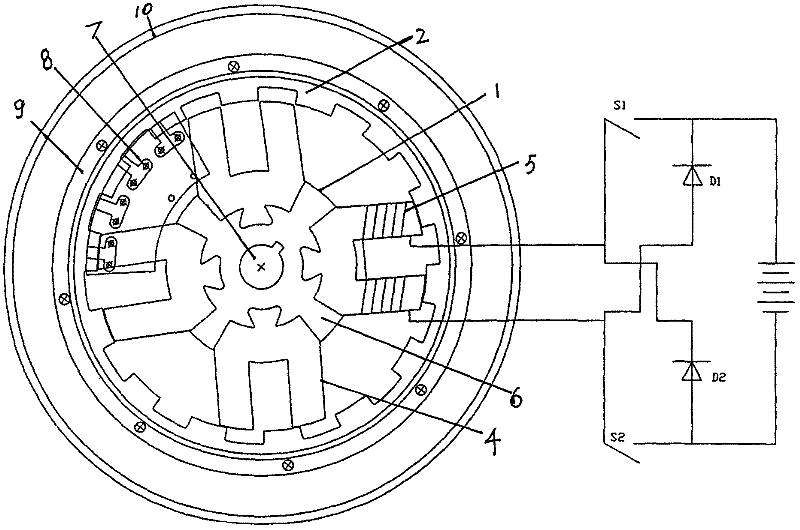

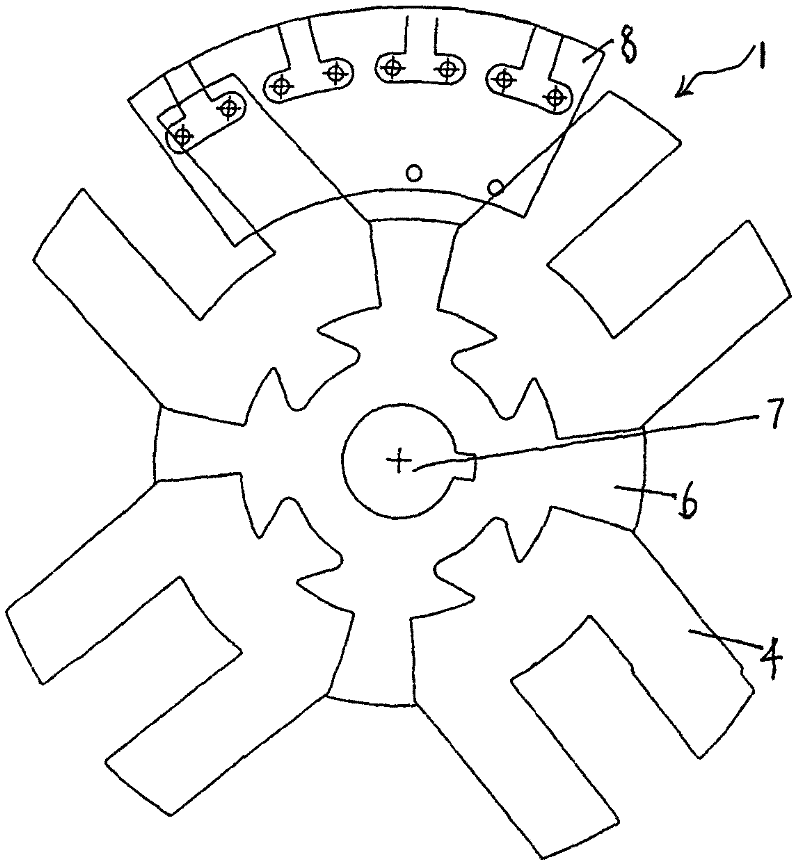

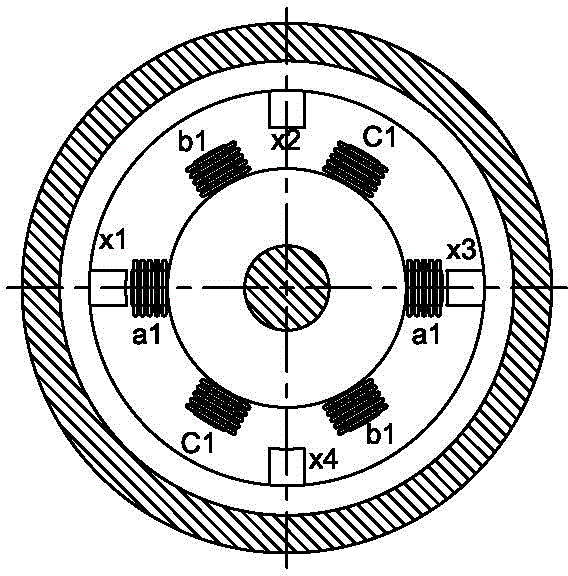

U-shaped switched reluctance motor

InactiveCN102364845AReduce volumeReduce weightMagnetic circuit rotating partsMagnetic circuit stationary partsReluctance motorConductor Coil

The invention discloses a U-shaped switched reluctance motor which comprises a stator, a rotor and a side cover, wherein windings are respectively arranged on opposite salient poles in the stator; the windings in radial opposite poles are connected in series to form a group; the two windings are respectively connected with a switch and a diode which are respectively connected with an anode and a cathode of a power supply; the stator comprises a shield magnet, a central shaft, position plates and U-shaped salient poles; the central shaft is embedded in the center of the shield magnet; the position plates are arranged on the shield magnet; four groups of U-shaped salient poles are uniformly embedded into the shield magnet; and the U-shaped salient poles are provided with opposite salient poles. The U-shaped switched reluctance motor has low start current, large torque and long endurance and is applied to an electric bicycle and an electric motorcycle.

Owner:ZHEJIANG YIEN ELECTROMECHANICAL TECH

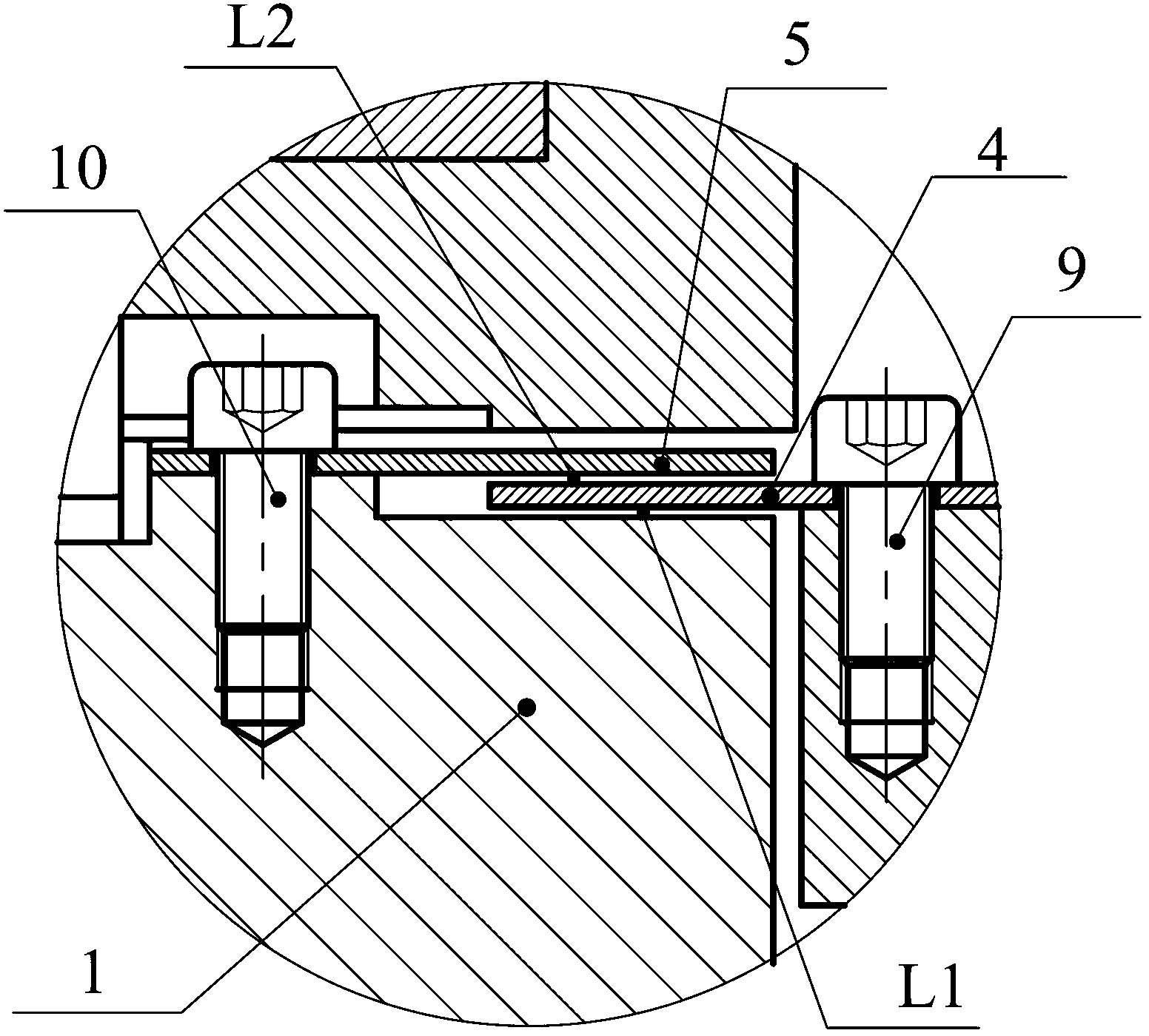

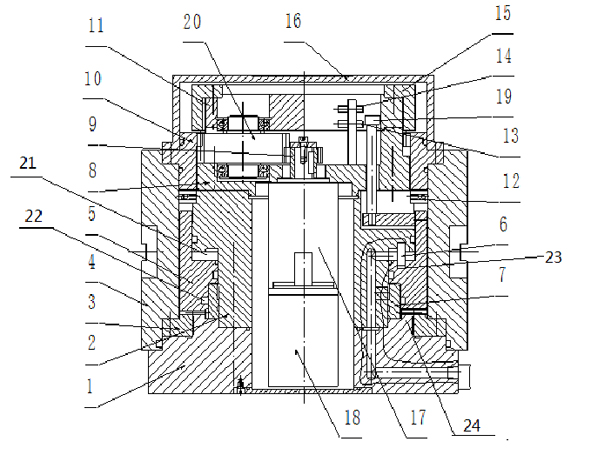

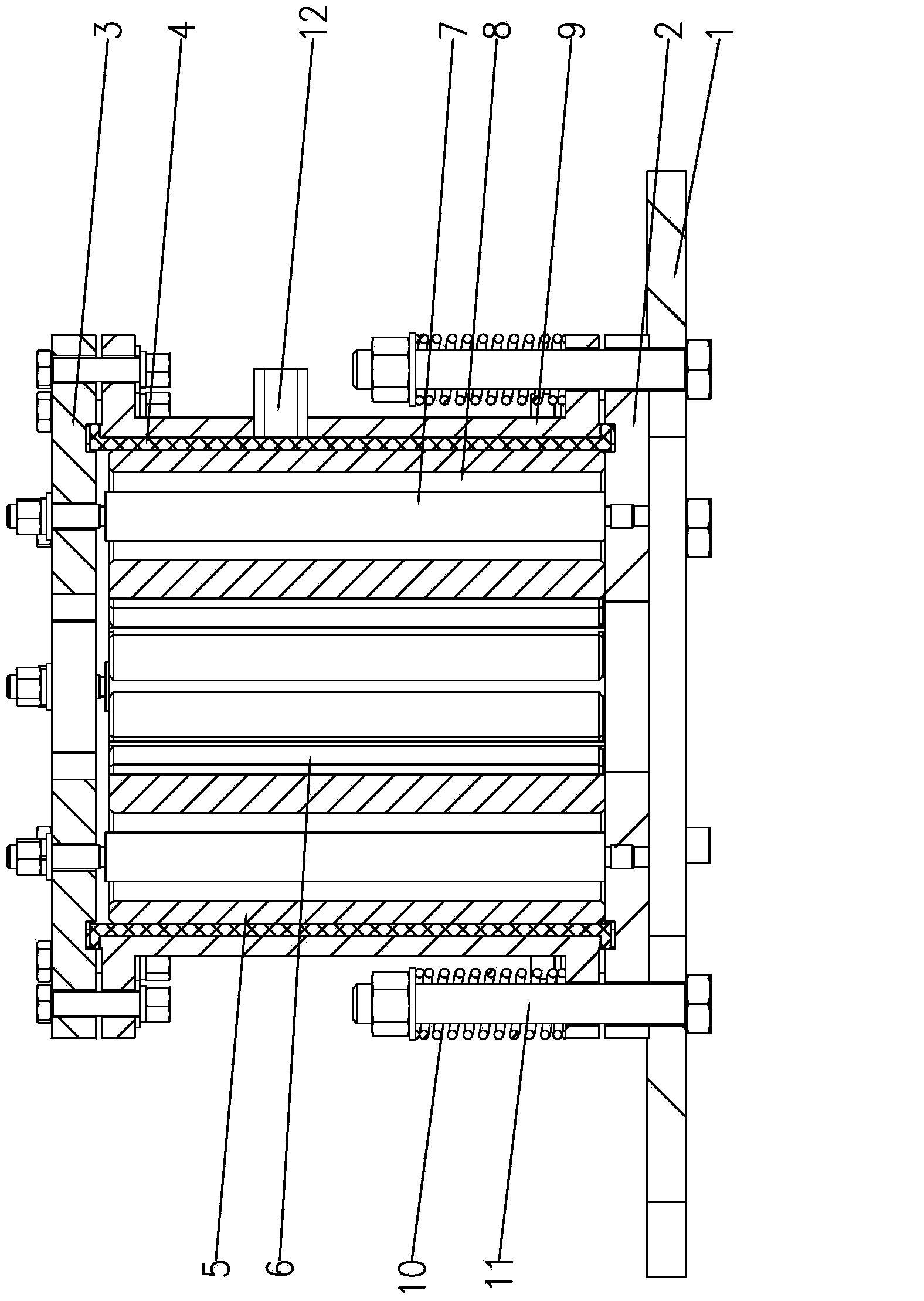

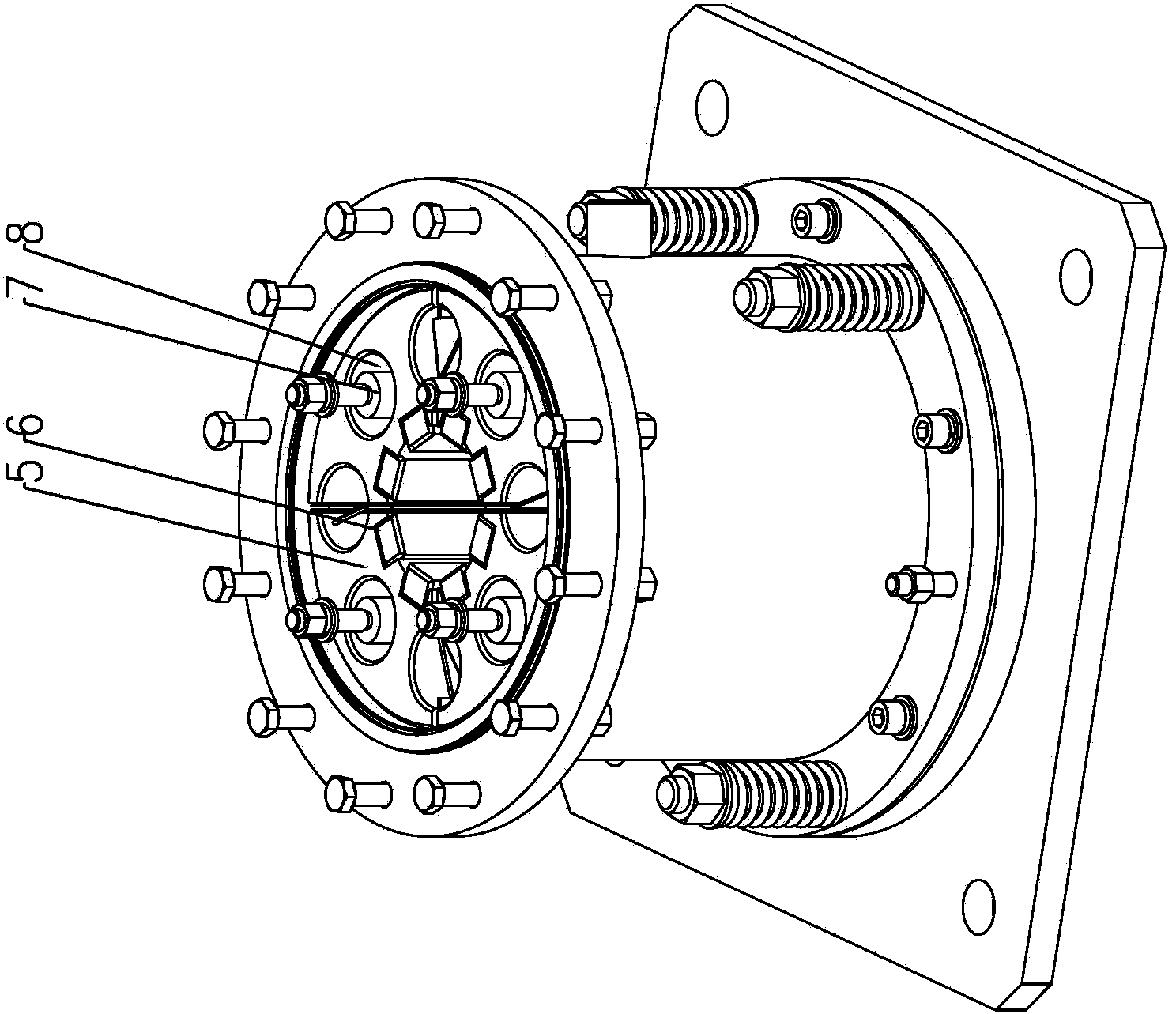

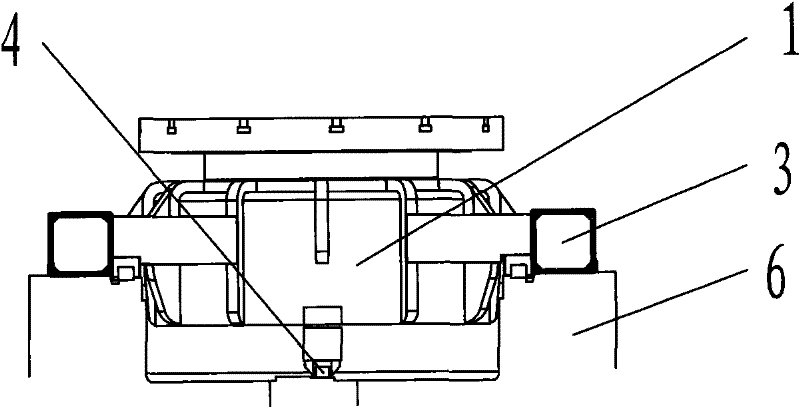

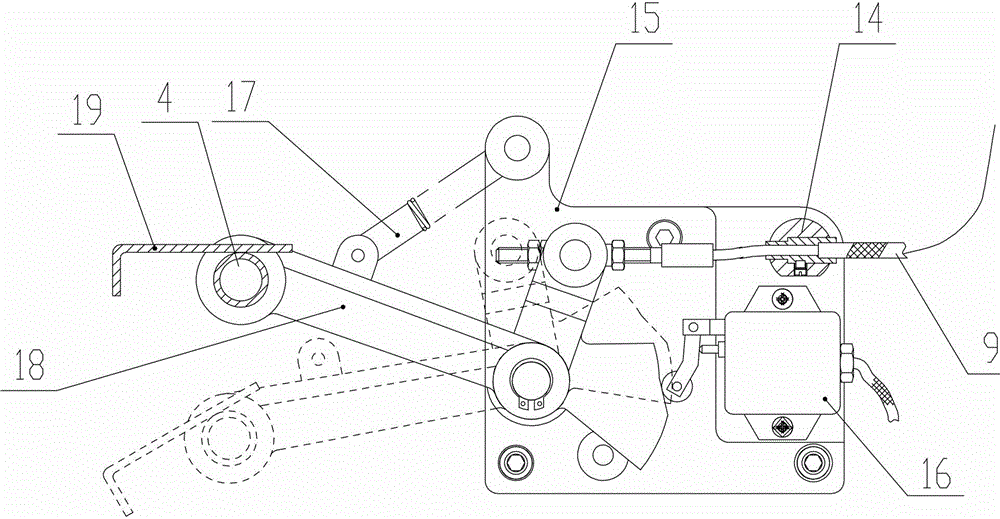

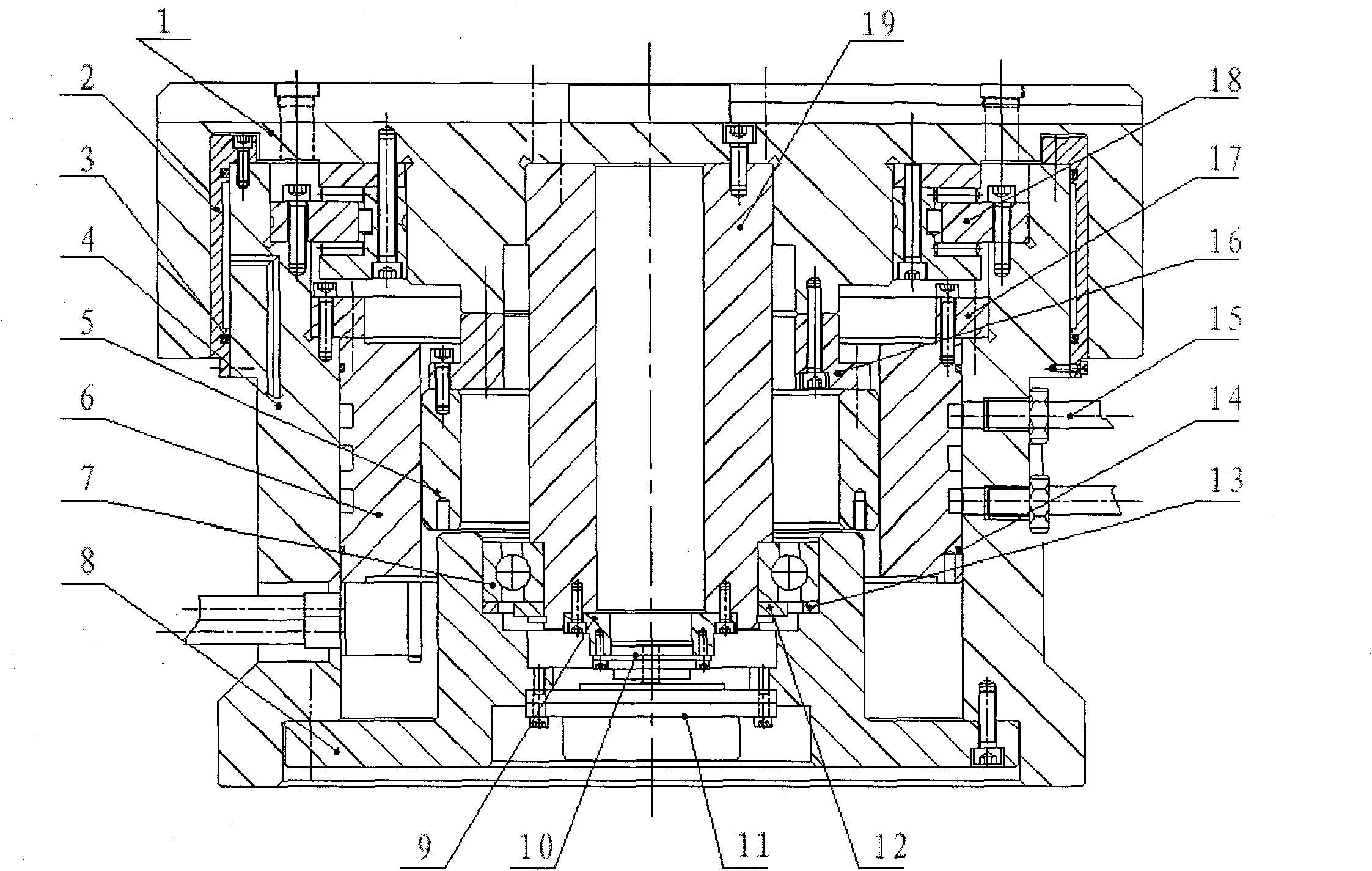

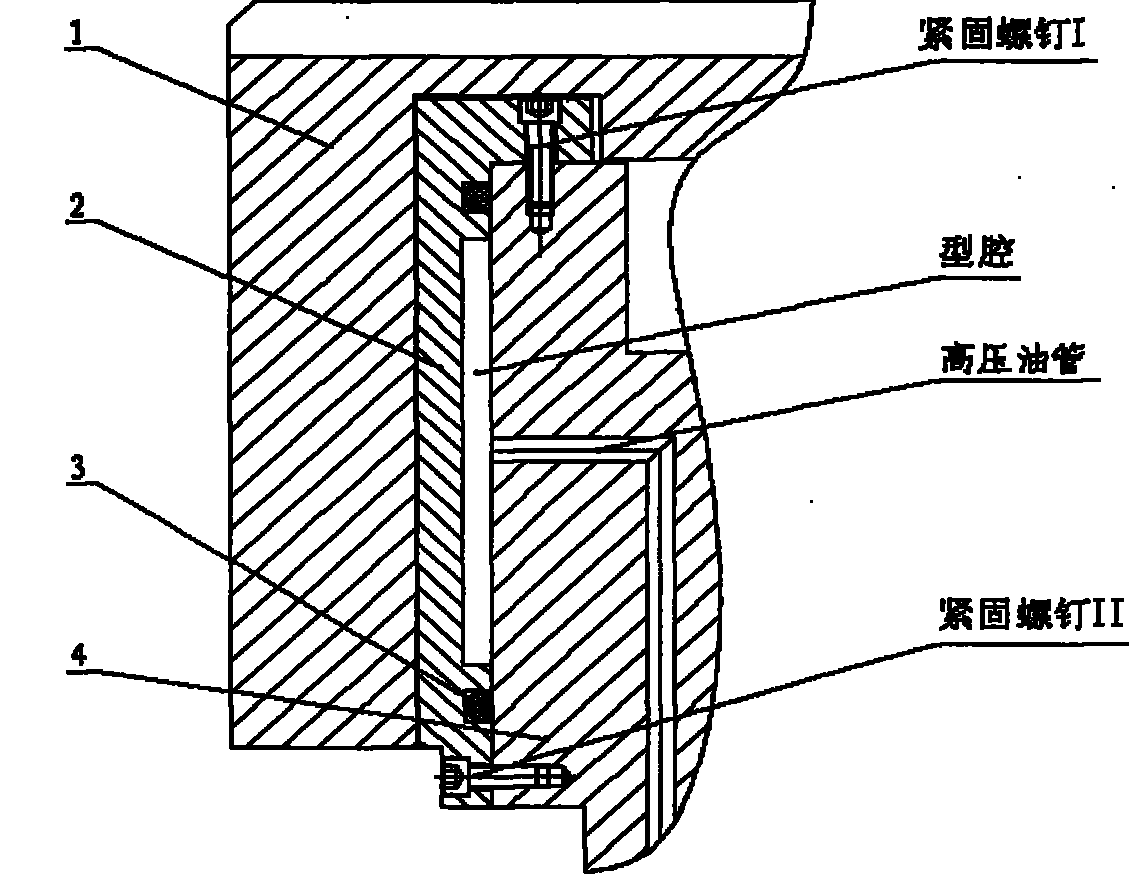

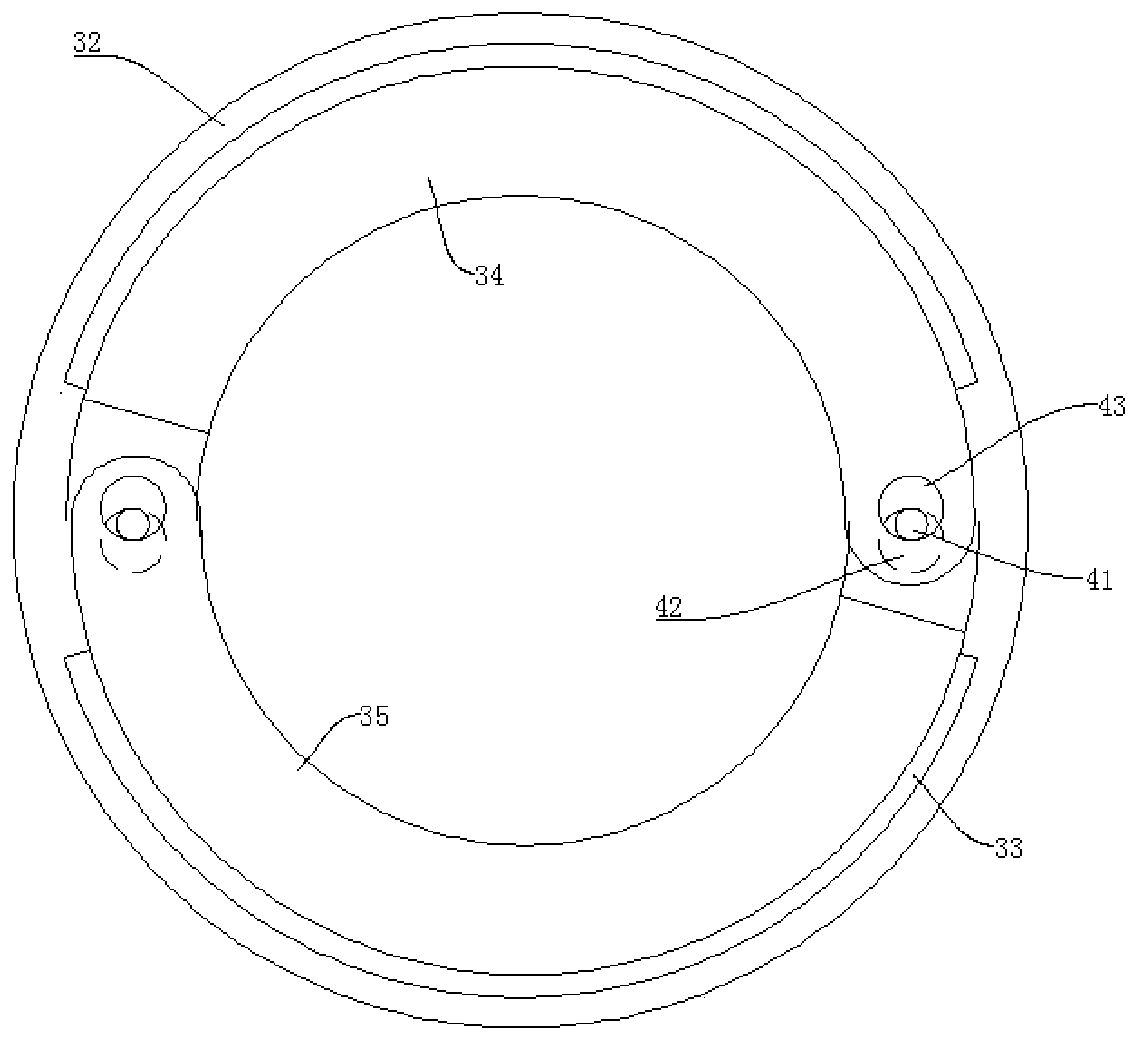

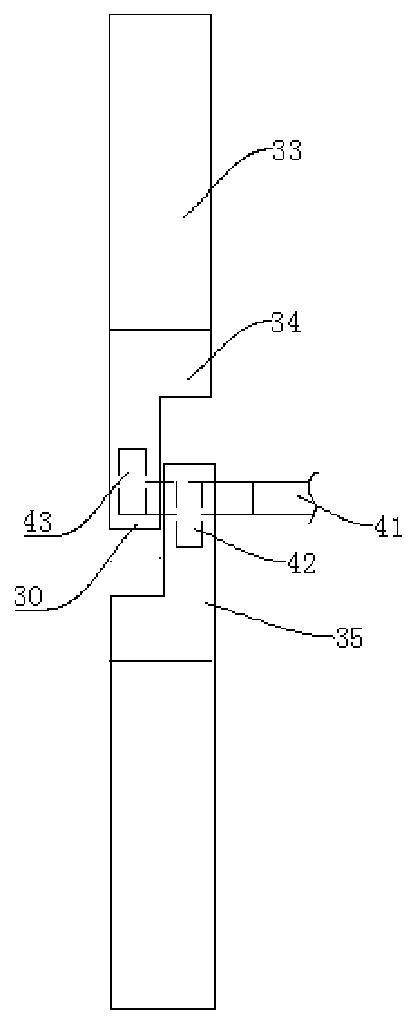

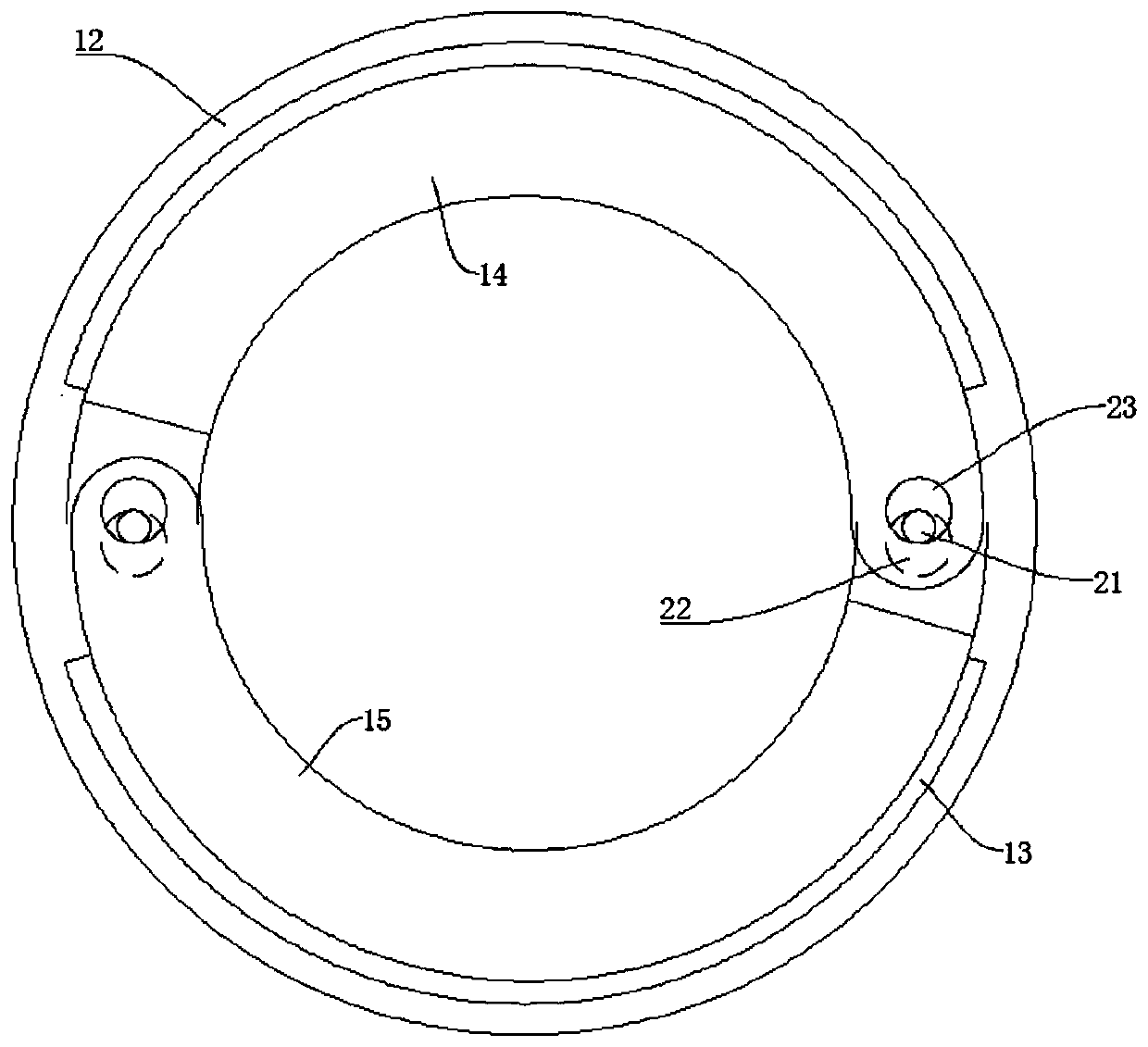

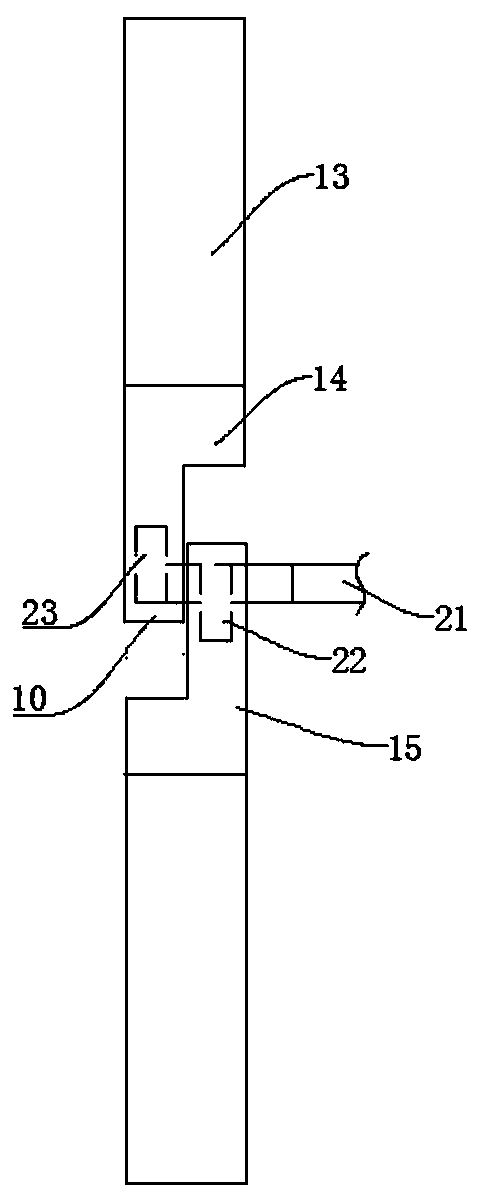

Tight braking device for numeric control rotary table

InactiveCN102837196AAchieve brake tightImprove rigidityLarge fixed membersNumerical controlEngineering

The invention discloses a tight braking device for a numeric control rotary table. The tight braking device comprises a base, an oil cylinder, an oil separator and a first annular friction plate, wherein the first annular friction plate is fixedly arranged on a rotary disk; a piston hole is formed in the base; a piston of the oil cylinder extends into the piston hole; the oil cylinder is connected with the oil separator; the first annular friction plate is positioned between the base and the oil cylinder; and a second annular friction plate is arranged between the first annular friction plate and the oil cylinder and is fixedly arranged on the base. The tight braking device has the advantages that the oil cylinder directly acts on the second annular friction plate; the second annular friction plate is fixed on the base; the base is immovable and constraints the circumferential direction of the second annular friction plate; during tight braking, the oil cylinder and the second annular friction plate are positioned in a communicated static state; and when the first annular friction plate which is fixed with the rotary disk together is simultaneously subjected to action forces of two friction surfaces, a braking force is greater and the tight braking reliability is high. Therefore, the rigidity of the numerical control rotary table is improved and the guarantee for machining workpieces with high precision by the machine tool is provided.

Owner:NINGBO HAITIAN PRECISION MASCH CO LTD

Screw pump reverse rotation preventing braking method

InactiveCN108331748AWork lessSynchronous operationMachines/enginesPump controlCentrifugal forceScrew pump

Owner:DAQING SENENPU MACHINERY MFG

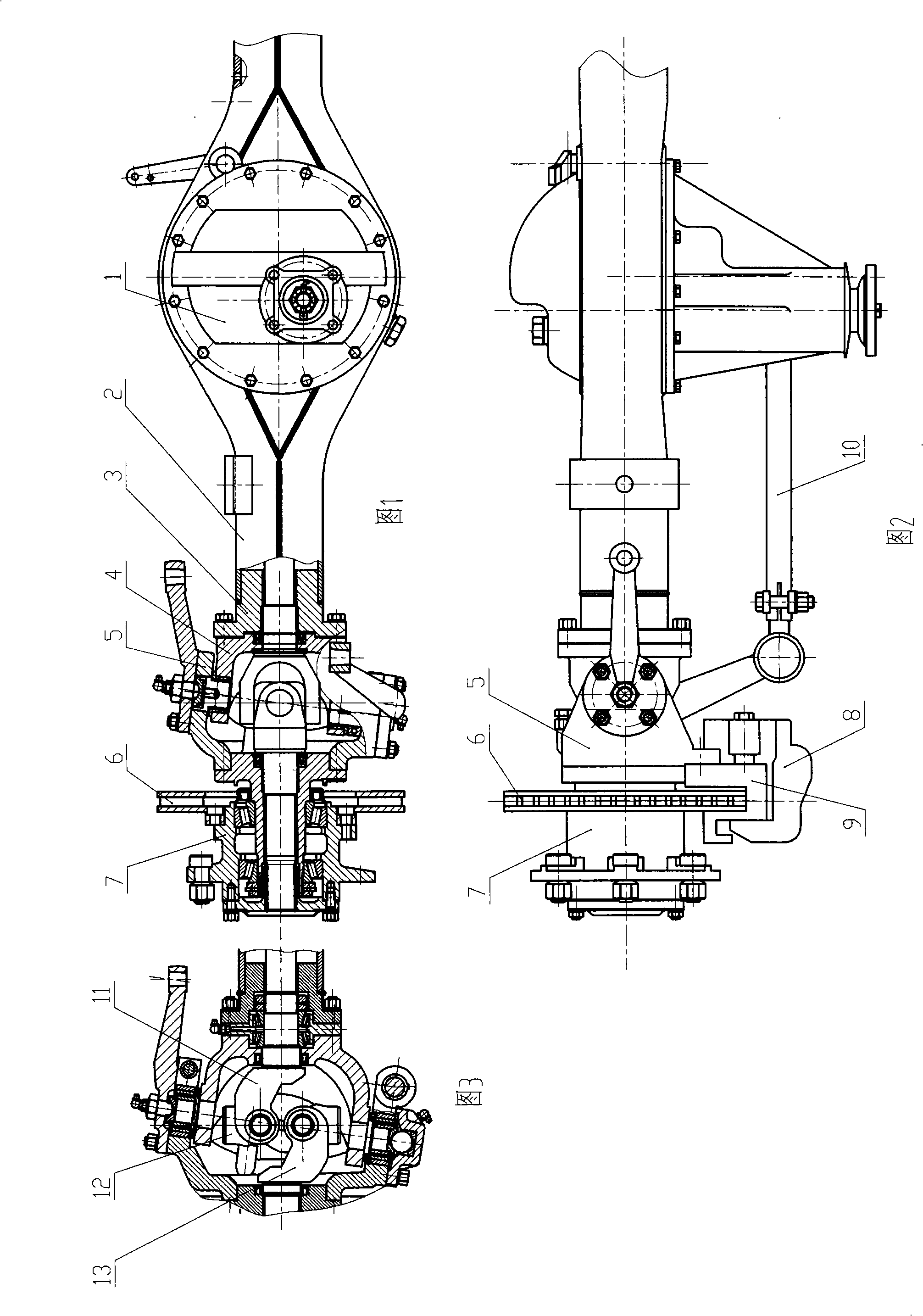

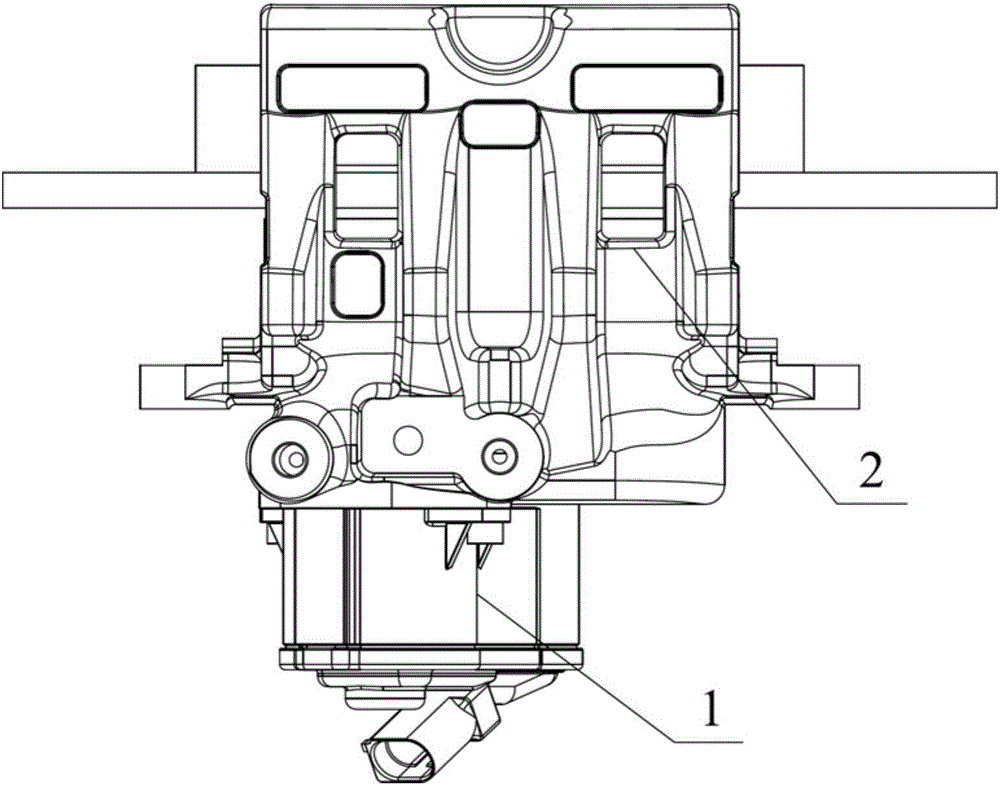

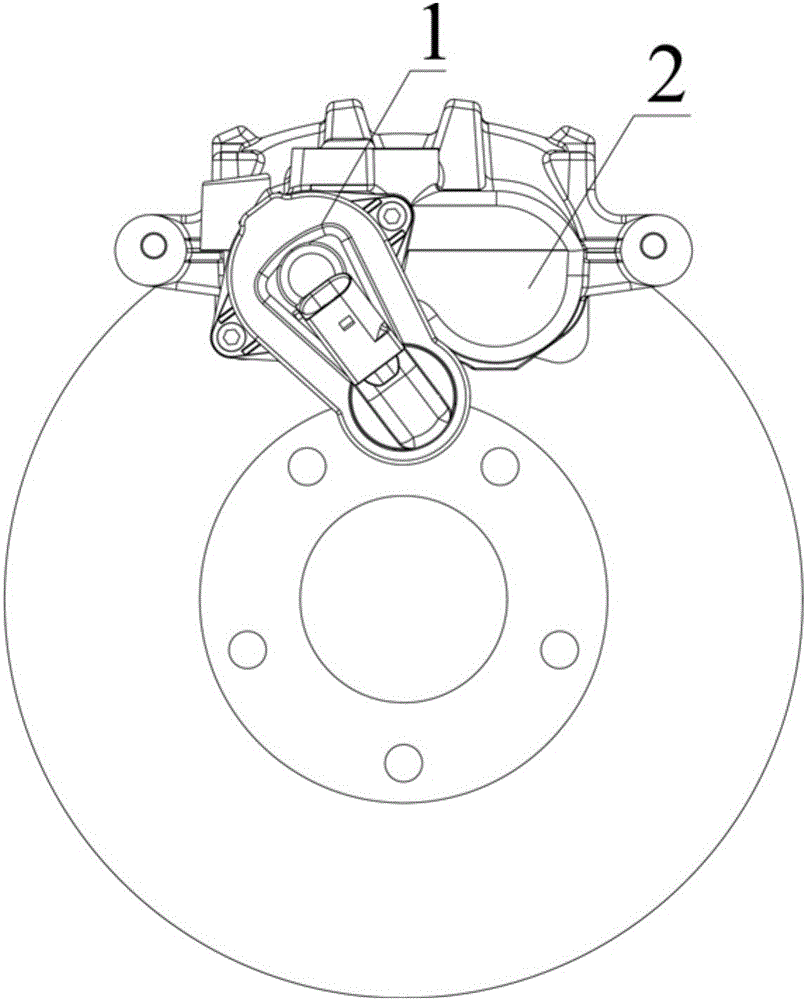

Roadlouse drive front axle

InactiveCN101301843AImprove performanceReduce volumeBraking element arrangementsSteering linkagesCircular discInterior space

A front drive bridge of a roadlouse relates to the front bridge structure of an automobile, which is characterized in that a steering knuckle is in U-shaped structure; two U-shaped openings of two U-shaped brackets are sheathed together by the dynamic matching of pin rolls; the bottom part of the internal U-shaped bracket is fixed on the flange of a bridge shell; the bottom part of the external U-shaped bracket is fixed on the shell of an external semi-shaft; a braking mechanism is a dish braking mechanism; the U-shaped supporting seat of the dish braking mechanism is fixed on the shell of the external semi-shaft; the disk of the disk braking mechanism is fixed on the rotating hub seat of the external semi-shaft. The front drive bridge has the advantages that the U-shaped steering knuckle and the disk braking mechanism are simultaneously used in the front drive bridge of the roadlouse; when the two are matched to be used in the front bridge to steer, the braking speed is greatly quickened; braking force is also increased; the operation is flexible and the security is better. While the use of the U-shaped steering knuckle leads the mounting of a three-pin universal joint to be possible. The three-pin universal joint has the characteristics of small size, large transfer torque and constant speed drive. The front drive bridge has the advantages of flexible steering, fast braking speed, large braking force and large transfer moment to improve the comprehensive property of the roadlouse.

Owner:肖宗礼

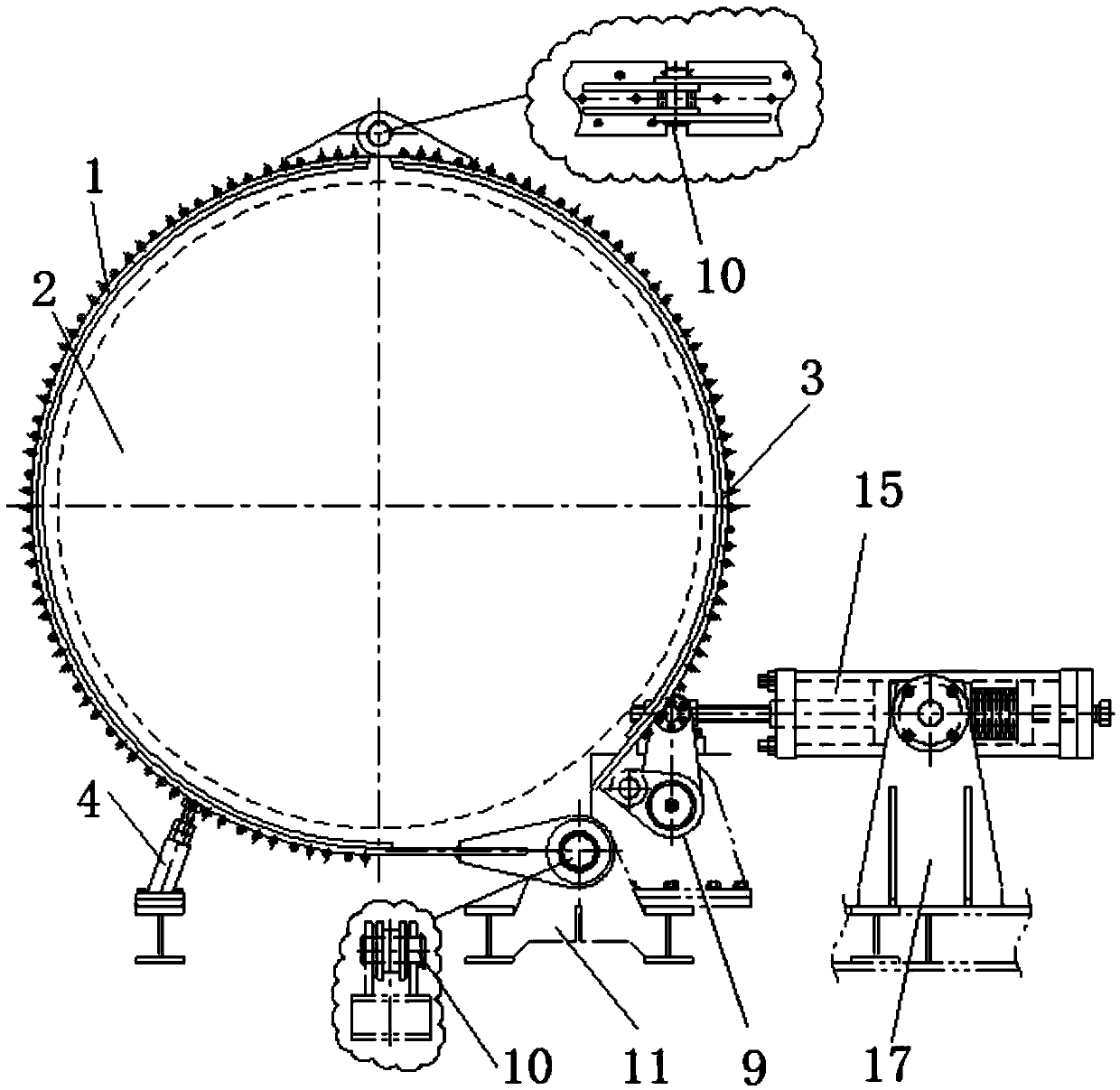

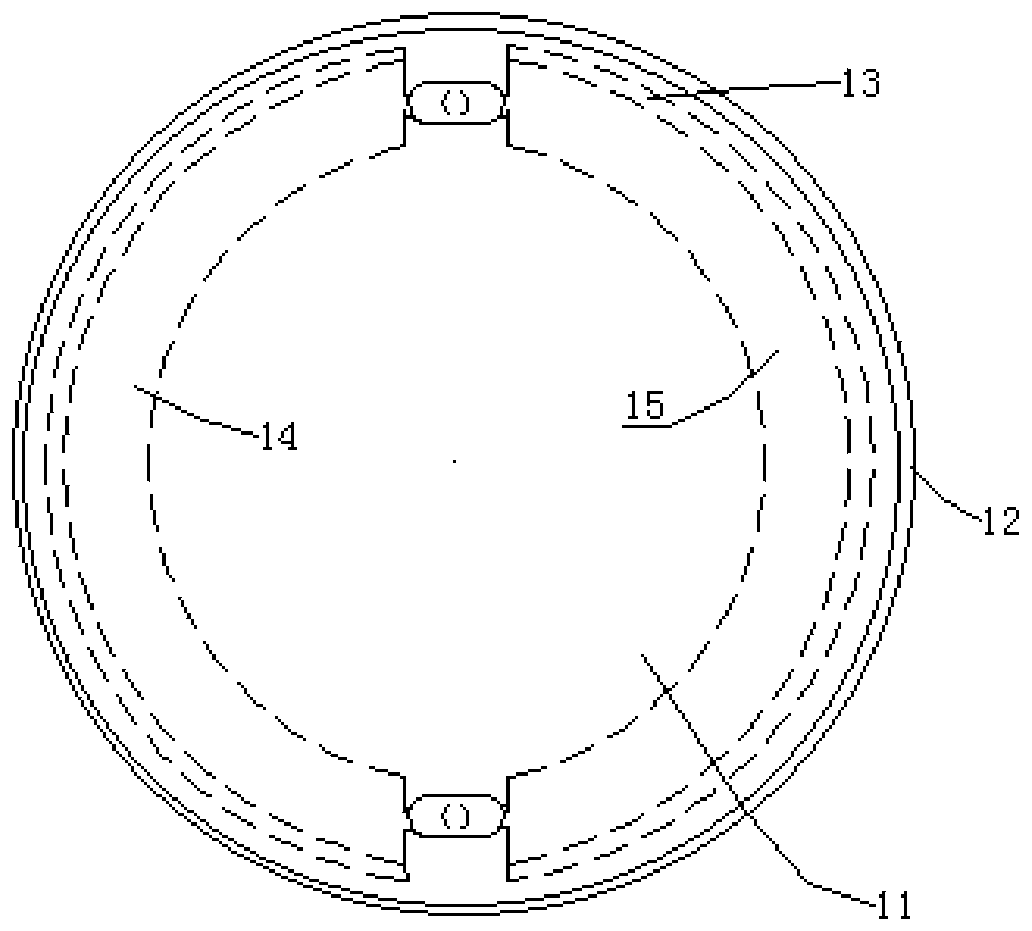

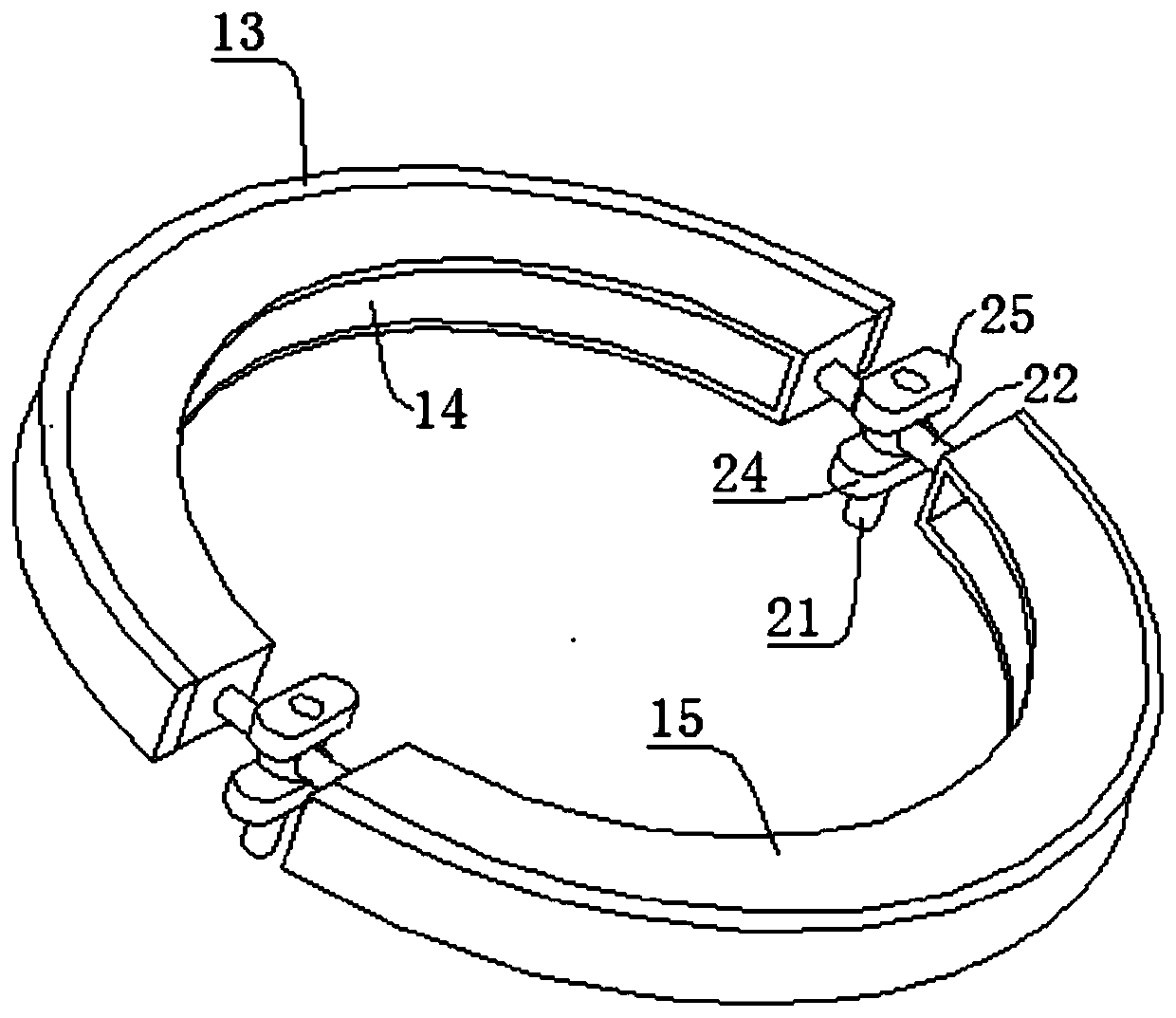

Belt type braking device for anchor machine

InactiveCN104196921AImprove securityBraking force is strongWaterborne vesselsFluid actuated drum brakesEngineeringMechanical engineering

The invention discloses a belt type braking device for an anchor machine. The belt type braking device comprises a left braking belt and a right braking belt which are hinged together and are arranged on an anchor machine braking hub in an embracing mode. One end of the left braking belt is fixedly connected with an anchor machine frame through a pin shaft group. The other end of the left braking belt is connected with one end of the right braking belt through a second pin shaft group. The tail end of the right braking belt is fixedly connected with a crank assembly through a third pin shaft group. The crank assembly is in transmission connection with a piston rod of a braking oil cylinder. According to the device, the shortcoming that manual locking is needed in traditional belt type braking is overcome, and the safety of the anchor machine braking device is improved.

Owner:BAOJI PETROLEUM MASCH CO LTD

Vertical servo hydraulic tool rest

The invention discloses a vertical servo hydraulic tool rest, which comprises a base, cylindrical vertical shafts, a drive system, inner gear rings, tool stages and a braking and loosening component, wherein the inner sides of the lower ends of the tool stages are fixedly with a movable fluted disc respectively, while upper ends are fixedly connected with the inner gear rings; fixed fluted discs are arranged on the upper end face of the base between the movable fluted discs and the vertical shafts; meshing teeth are arranged on the upper end faces of the movable fluted discs and the fixed fluted discs; the inner gear rings and the tool stages are driven by the drive system to rotate; the drive system comprises a speed reducer, a servo motor, a drive gear and a transmission gear; the speed reducer and the servo motor are connected with each other and are arranged below a bearing block; the drive gear is arranged above the bearing block, and is connected with an output shaft of the speed reducer; and the transmission gear is arranged on the bearing block, is externally meshed with the drive gear and is internally meshed with the inner gear rings. The vertical servo hydraulic tool rest has the characteristics of small moment of inertia, stable rotation, large output torque and relatively larger braking torque.

Owner:烟台环球机床装备股份有限公司

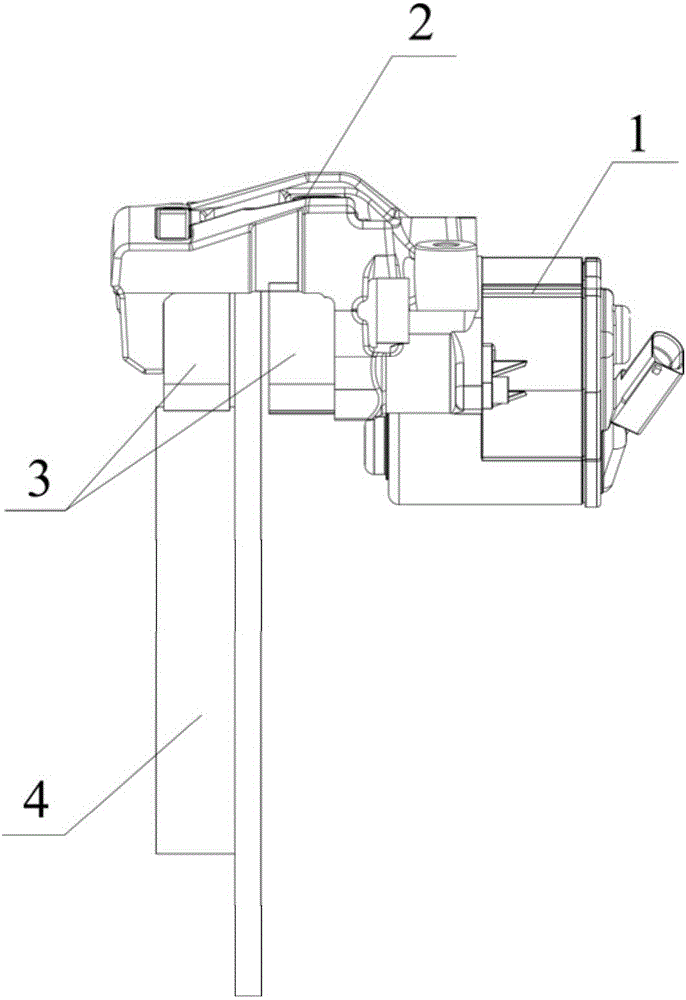

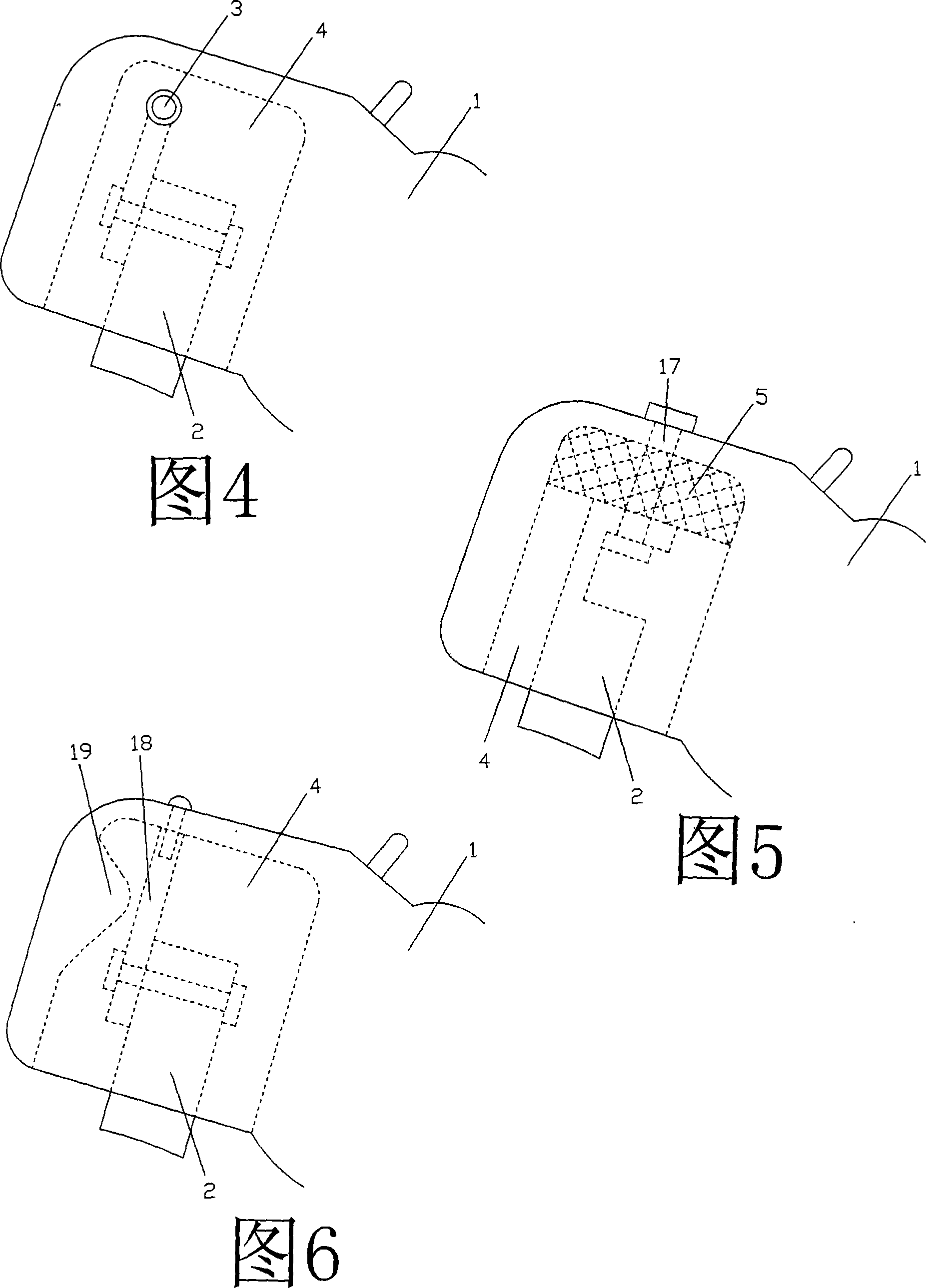

Electronic parking braking system with double-piston callipers

InactiveCN105799685ABroaden the field of applicationIncrease the scope of applicationBraking element arrangementsBraking action transmissionElectric machineryActuator

The invention relates to an electronic parking braking system with double-piston calipers. The electronic parking braking system comprises an EPB actuator and the double-piston calipers, and the EPB actuator is used for driving the double-piston calipers. The system further comprises an electronic control unit used for controlling the current direction and intensity of a motor in the EPB actuator. The electronic parking braking system which is of the structure and is provided with the double-piston calipers is adopted, as the calipers used are double-piston calipers and are different from single-piston calipers used in the current market, the double-piston calipers can provide larger brake force in the same hydraulic system, and therefore the double-piston calipers are used in medium and large vehicles and other vehicles high in requirement for brake performance more frequently. By means of the provided EPB actuator and the double-piston caliper parking mode, the application field and range of novel EPB are enlarged.

Owner:GELUBO TECH CO LTD

Piston rod brake device

InactiveCN104315047AExtended service lifeEasy interchangeFluid-pressure actuatorsBrake actuating mechanismsEngineeringMechanical engineering

The invention relates to a brake device which maintains extension and retraction positions of a piston rod, in particular to a piston rod brake device which is needed by sudden stop of a cylinder during the moving process of the cylinder, and uses a pneumatic element as a power source, can lock moving positions of an air cylinder, the piston rod of a hydraulic rod and other cylindrical guide pillars, and belongs to the pneumatic hydraulic technology field. The piston rod brake device comprises a cylinder barrel, wherein a plurality of locking blocks are arranged in the cylinder barrel, and a plurality of brake pads are arranged on the inner side of each locking block, an air sac is arranged on the inner wall of the cylinder barrel and each locking block, and inflation inlets communicated with the air sacs are formed in the side wall of the cylinder barrel. When the air sacs are inflated through the inflation inlets, the air sacs swell and compress the locking blocks towards the inner side of the cylinder barrel, and therefore the brake pads at the front ends of the locking blocks are driven to tightly hold the piston rod installed at the central position of the piston rod brake device. The piston rod brake device swells the air sacs by supplying air to the air sacs so as to push the locking blocks, provides stable clamping force, rapidly and reliably brakes the piston rod, and is large in brake force and reliable in reset ability.

Owner:WUXI YAZHONG PNEUMATIC HYDRAULIC

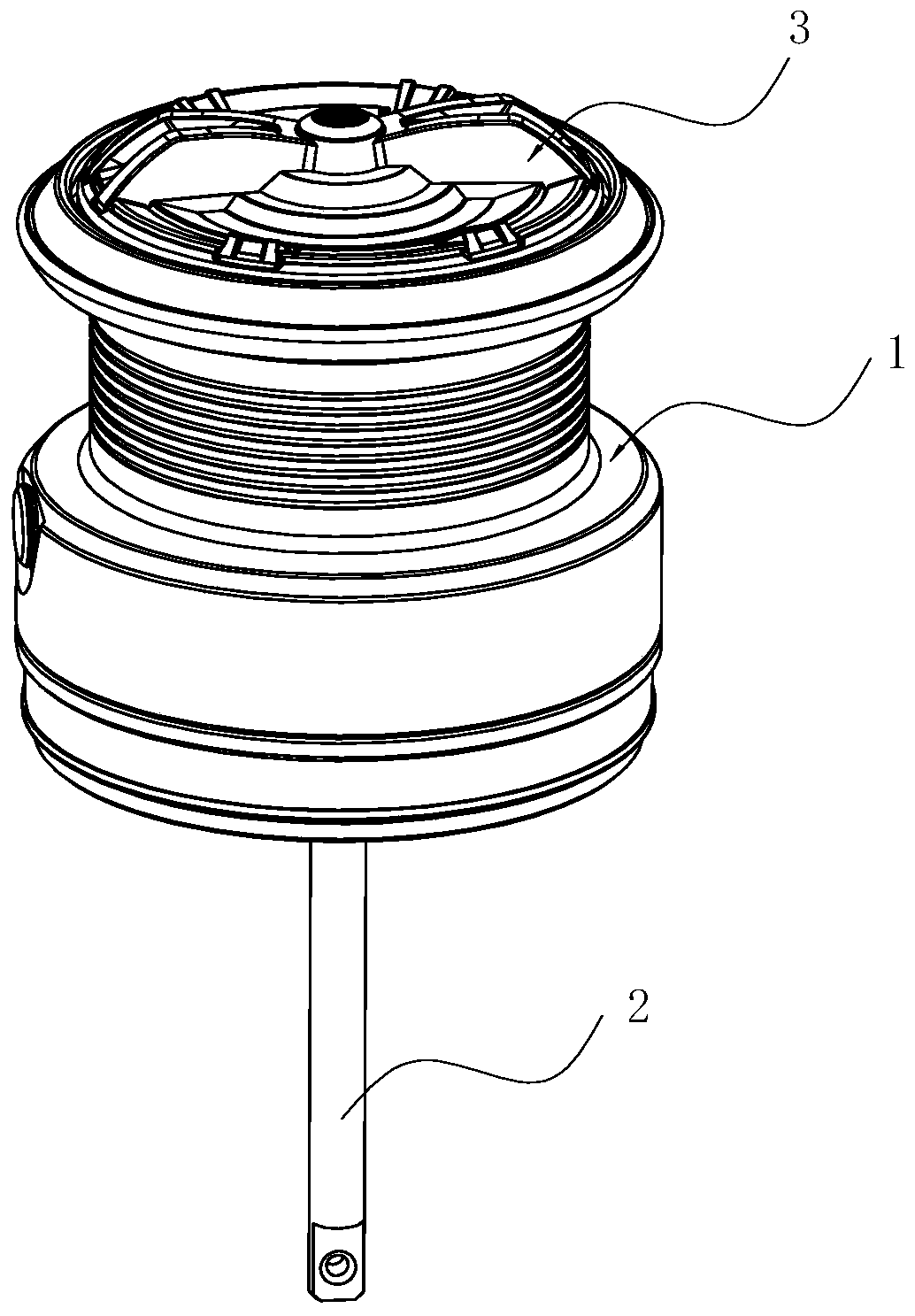

Novel line wheel structure

The invention relates to a novel line wheel structure. The structure comprises a line wheel supported on a main shaft through a front bearing and a rear bearing, a brake pad assembly located in an inner cavity of the line wheel and an adjusting button assembly and is characterized in that a partition board for dividing the inner cavity into a front cavity and a rear cavity is arranged in the innercavity of the line wheel, a shaft hole allowing the main shaft to penetrate through is formed in the middle of the partition board, a front shaft sleeve and a rear shaft sleeve axially extend out ofthe front and rear cavity sides of the partition board along the shaft hole, and the front bearing and the rear bearing are mounted in the front and rear shaft sleeves; besides, the brake pad assemblycomprises a front brake pad assembly mounted in the front cavity and a rear brake pad assembly mounted in the rear cavity, and the adjusting button assembly is abutted against the front brake pad assembly. With the adoption of the structure, the front brake pad assembly is mounted in the front cavity, the rear cavity extends to the non-winding area of the line wheel, so that more rear brake pad assemblies can be mounted in the rear cavity, and higher brake force can be obtained. Meanwhile, the front and rear bearings are mounted in the front and rear shaft sleeves, the coaxiality of the two bearings can be ensured, and the brake stability of the line wheel is better.

Owner:NINGBO HAIBO GRP CO LTD

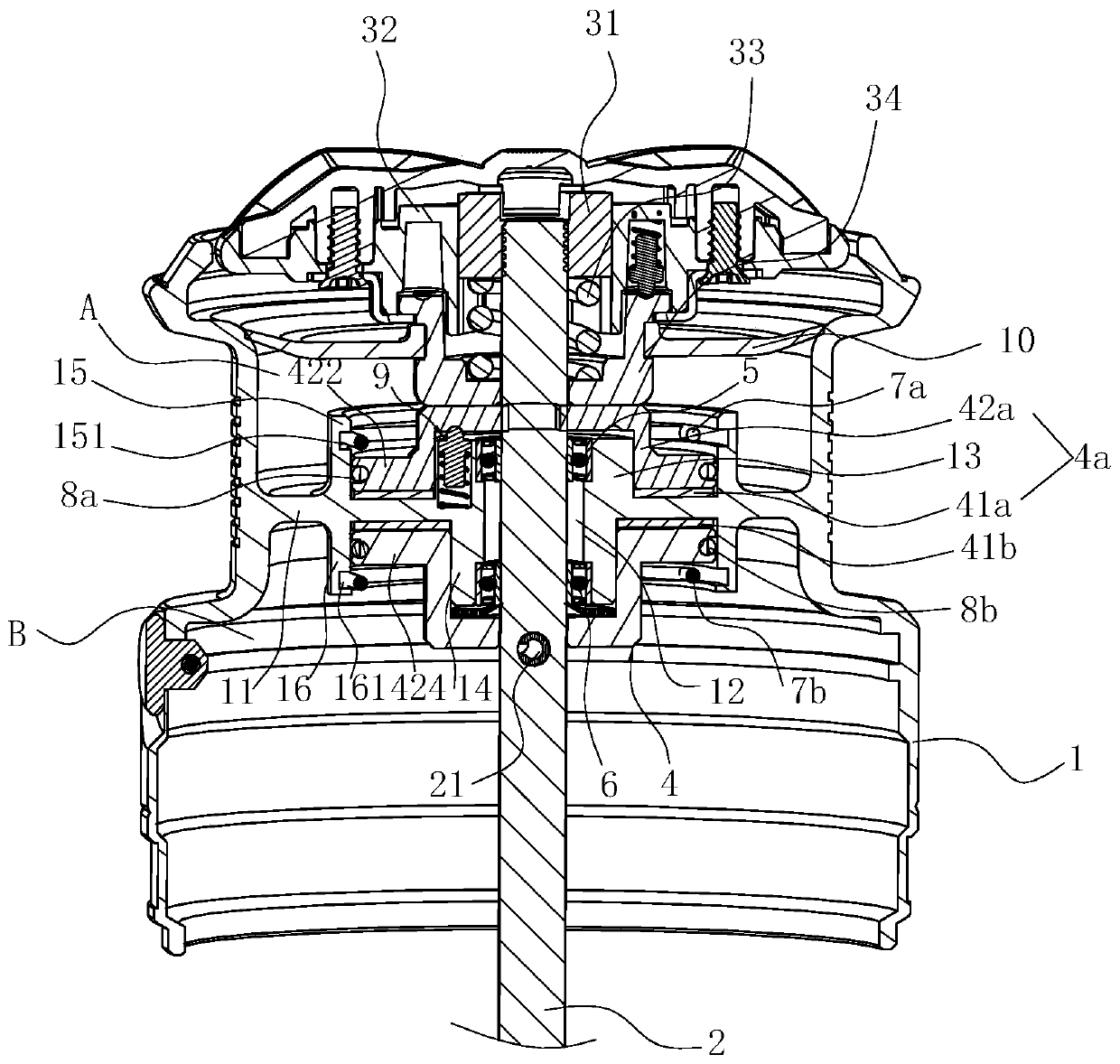

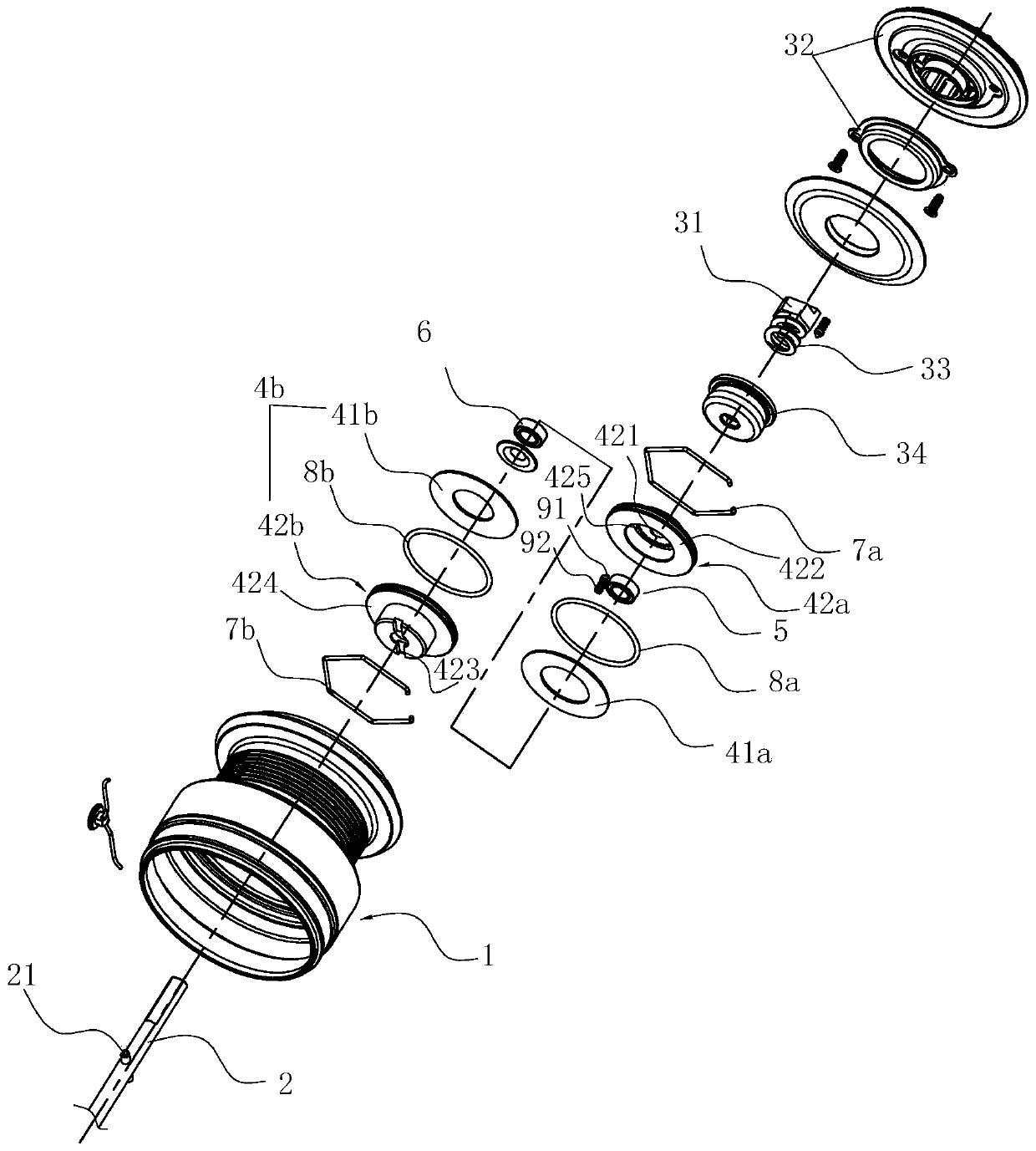

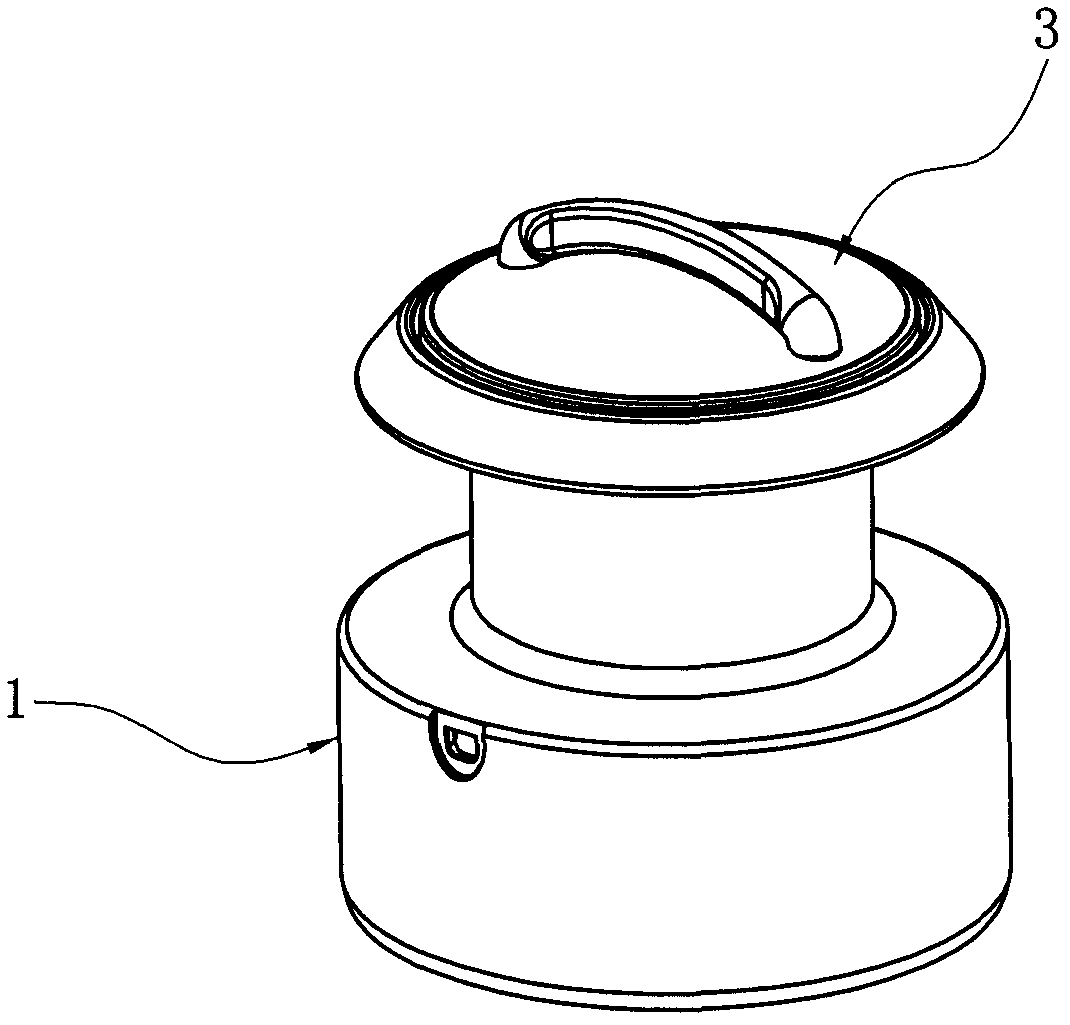

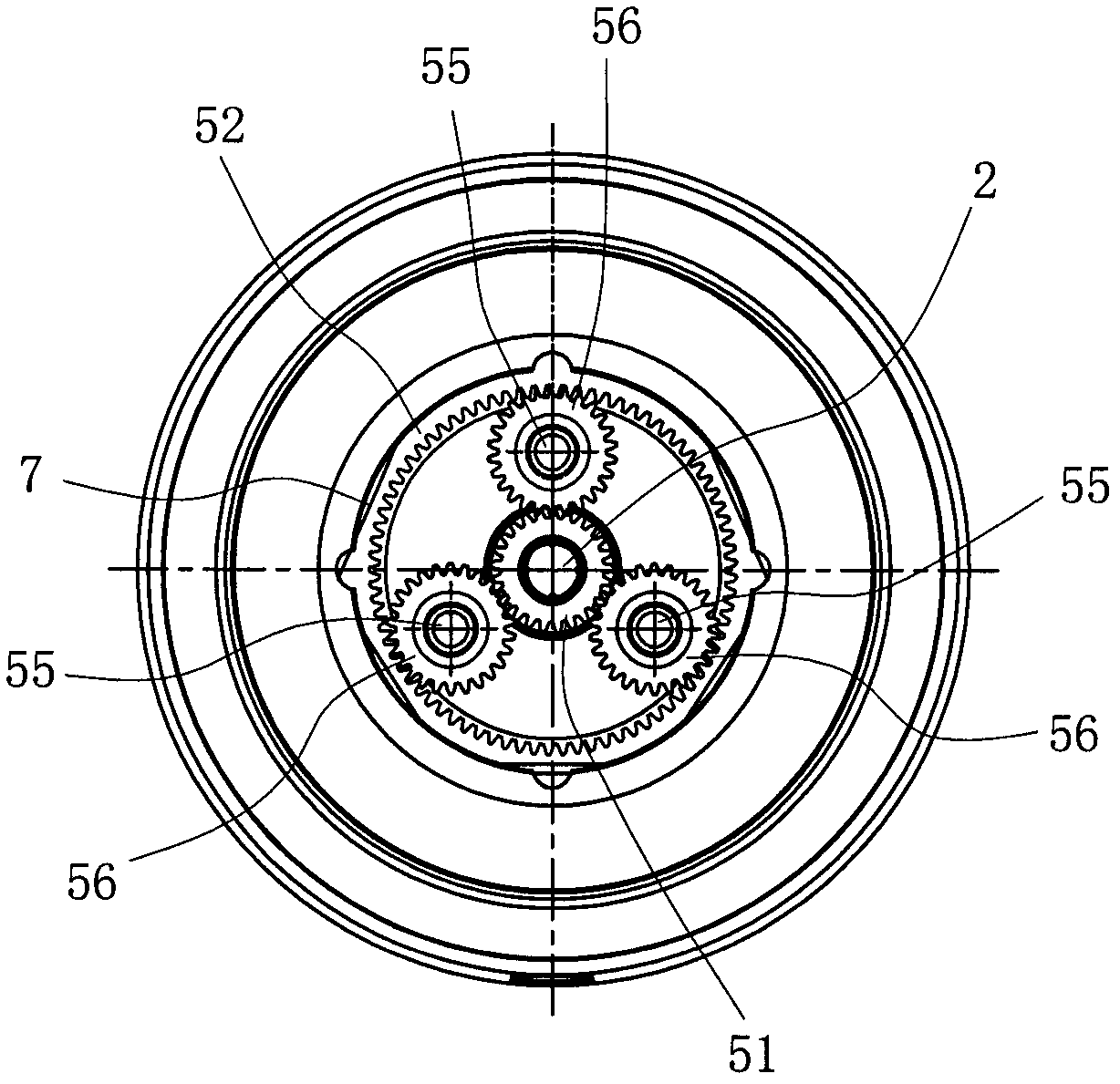

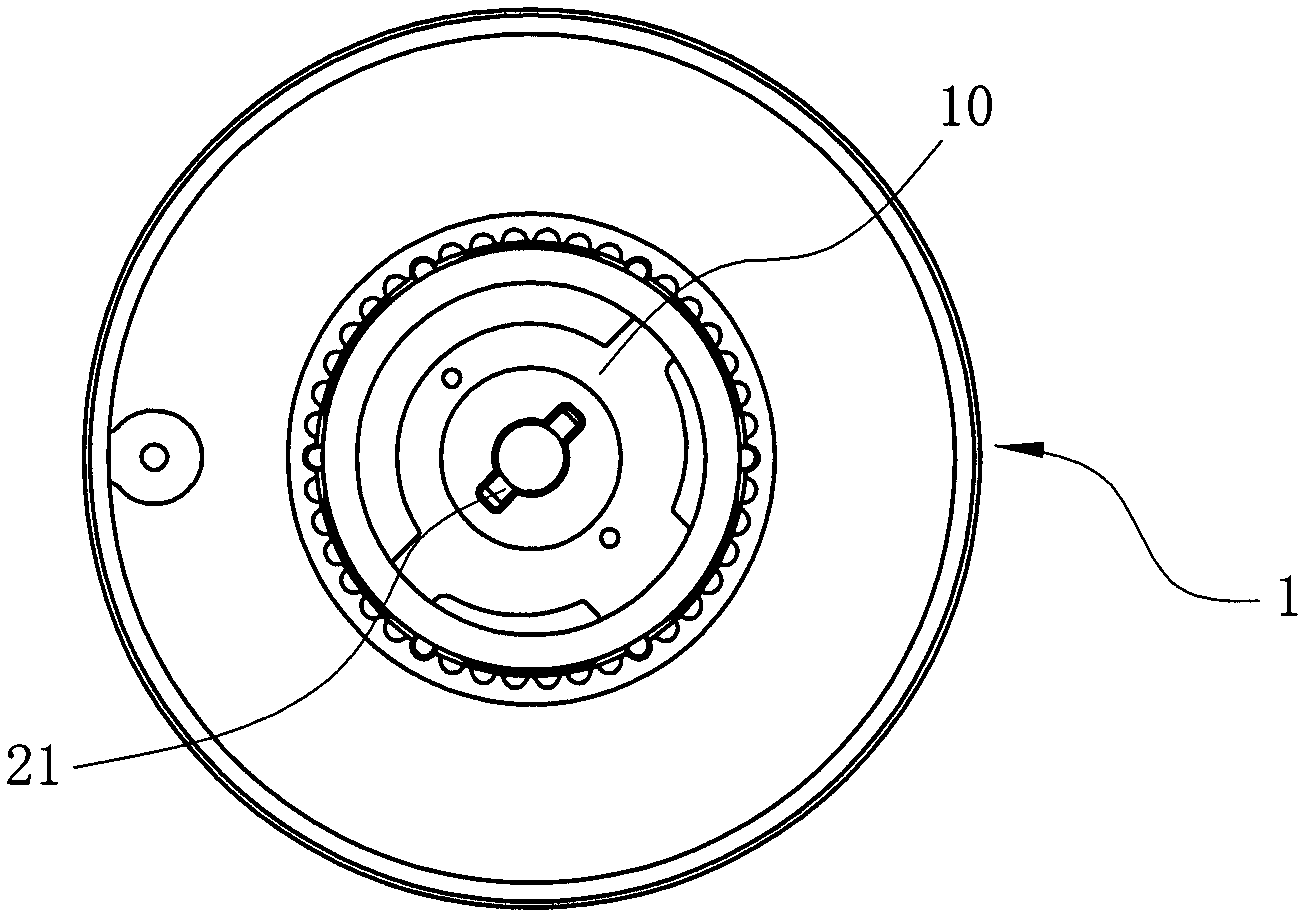

Brake mechanism of fishing line wheel

The invention relates to a brake mechanism of a fishing line wheel. The brake mechanism is improved on the basis of a conventional adjusting button assembly and a brake pad set positioned in the upper cavity of the line wheel, namely a planet gear mechanism positioned between the adjusting button assembly and the brake pad set is also arranged in the upper cavity; the planet gear mechanism comprises a sun gear, an inner gear, a planet gear and upper and lower cover plates; the inner gear is axially limited on the inner wall of the upper cavity and linked with the line wheel; the sun gear is sleeved on a main shaft in a loose manner, and a sun gear seat is fixed on the sun gear; one of the upper and lower cover plates is linked with the main shaft, and the other cover plate is opposite to the sun gear seat; and meanwhile, the main shaft above the sun gear seat and the main shaft below the sun gear seat are respectively sleeved with a first brake washer in a loose manner. By means of the planet gear mechanism, the friction force which acts on the line wheel is amplified exponentially, so in a limited space, a high braking force can be obtained without excessive increase in the brakepad set, and a big brake of the fishing line wheel is obtained.

Owner:NINGBO HAIBO GRP CO LTD

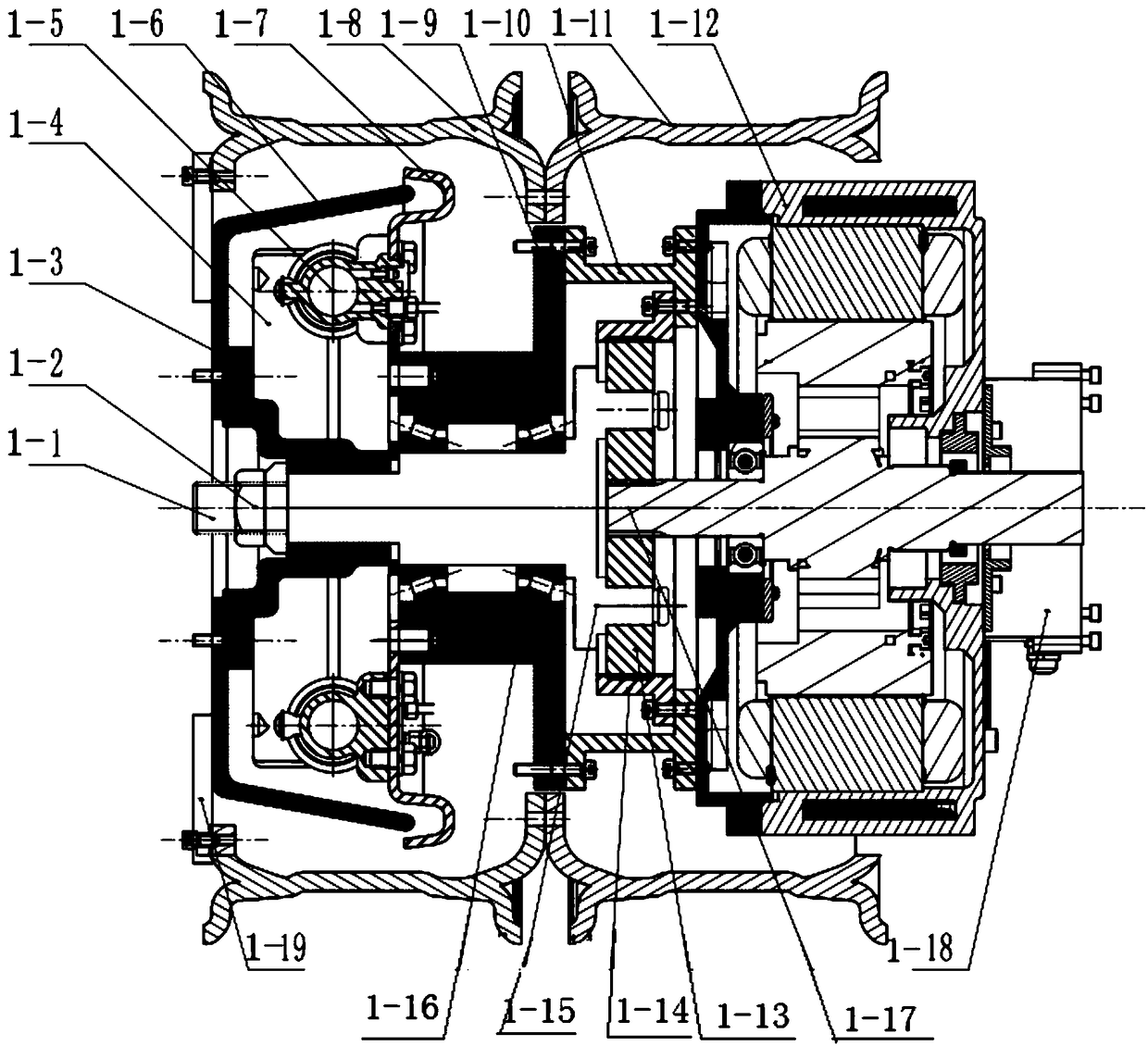

Hub motor integrated system

InactiveCN108749556ABraking force is strongExpand the scope of applicationBraking element arrangementsMotor depositionDrum brakeDisc brake

The invention provides a hub motor integrated system which is arranged in a dual wheel. The system comprises a hub motor, a speed reducer and a brake. The brake is a drum brake and comprises a brake drum connecting piece, a brake shoe, brake wheel cylinders, a brake drum and a brake bottom board. The specially-manufactured drum brake is adopted for substituting an existing disc brake of a heavy load vehicle, brake force is large, the drum brake is more suitable for braking a rear wheel of the heavy load vehicle, and the application range of the hub motor technology is enlarged; and for the heavy load vehicle, the vehicle traveling speed is low, the required brake force is large, under the condition, the durability of the drum brake is higher than that of the disc brake, the brake stabilityof the heavy load vehicle can be improved, and cost is saved as well.

Owner:WUHAN UNIV OF TECH

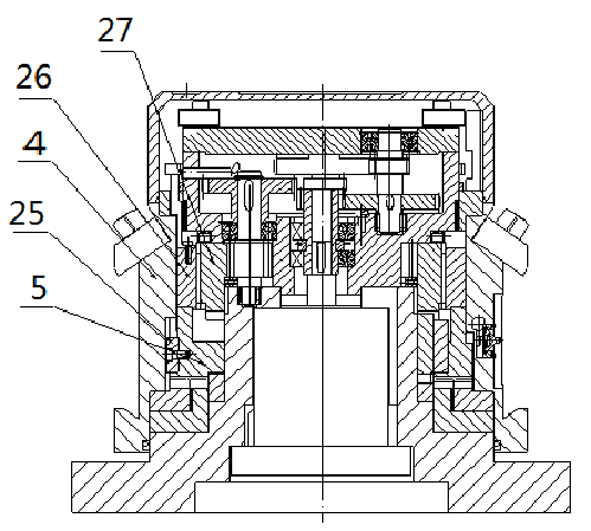

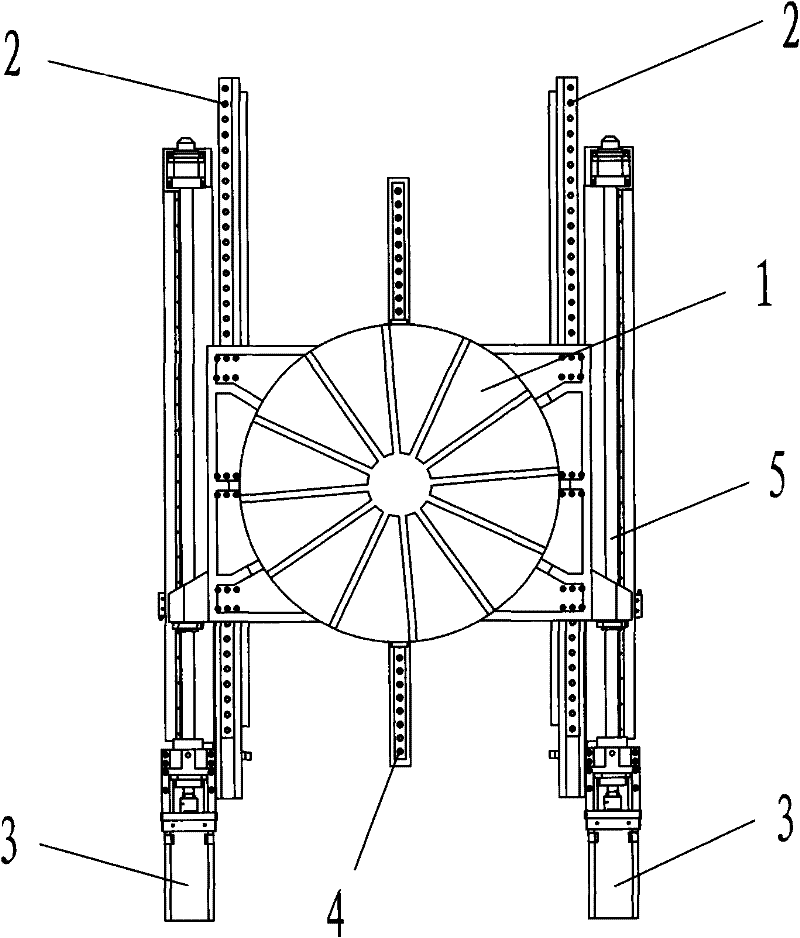

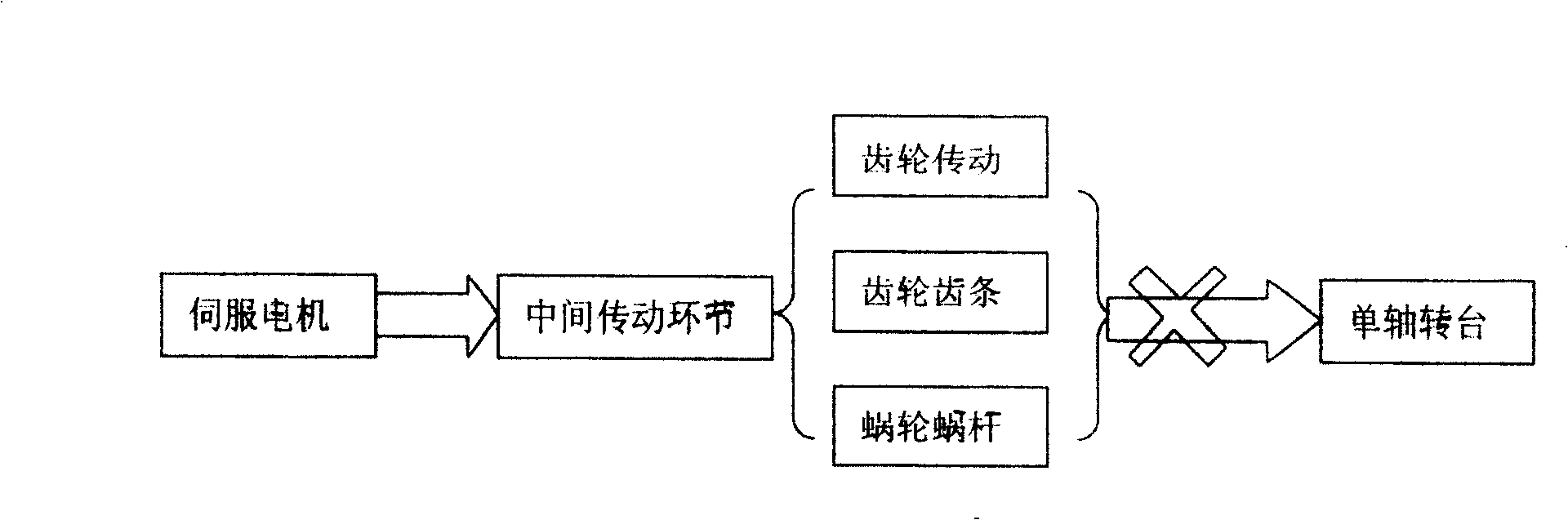

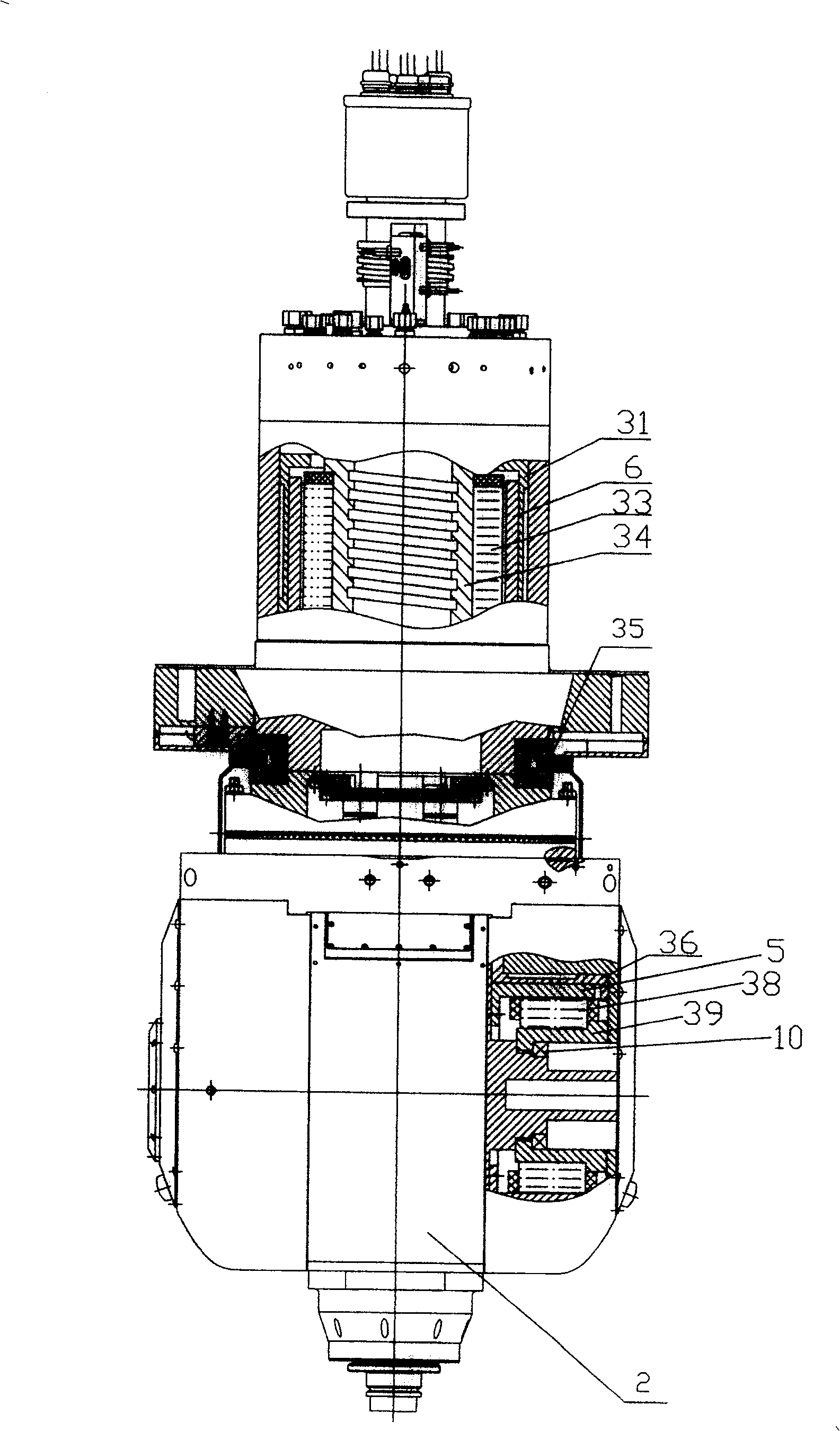

Vertical milling lathe complex machining center

ActiveCN101722419BIncrease productivityReduce wearOther manufacturing equipments/toolsLarge fixed membersTorque motorElectric machinery

The invention discloses a vertical milling lathe complex machining center which comprises a horizontally arranged lathe body (6) and a vertically arranged upright post (7). The lathe body (6) is provided with an X-axis lateral supporting line track (2) and an X-axis guide screw (5) and configured with a uniaxial rotating table (1) which reciprocates and is driven by a first outer rotor torque motor in a direct driven mode. The upright post (7) is vertically provided with a Z-axis lateral supporting line track (10) and a Z-axis guide screw (9) and configured with a crossbeam which reciprocatesup and down. The crossbeam (11) is provided with a transverse Y-axis line track (13) and a Y-axis guide screw (12) and configured with a single pendulum milling head seat frame which can reciprocate along the Y-axis guide screw (12); and a single pendulum milling head is driven by a second outer rotor torque motor at the rear part in the direct driven mode. Since a direct driven technology is applied to a B axis and a C axis, the motor torque is greatly increased and a functional part can stably operate; therefore the integral rigidity and the stability of a lathe are improved.

Owner:KEDE NUMERICAL CONTROL CO LTD

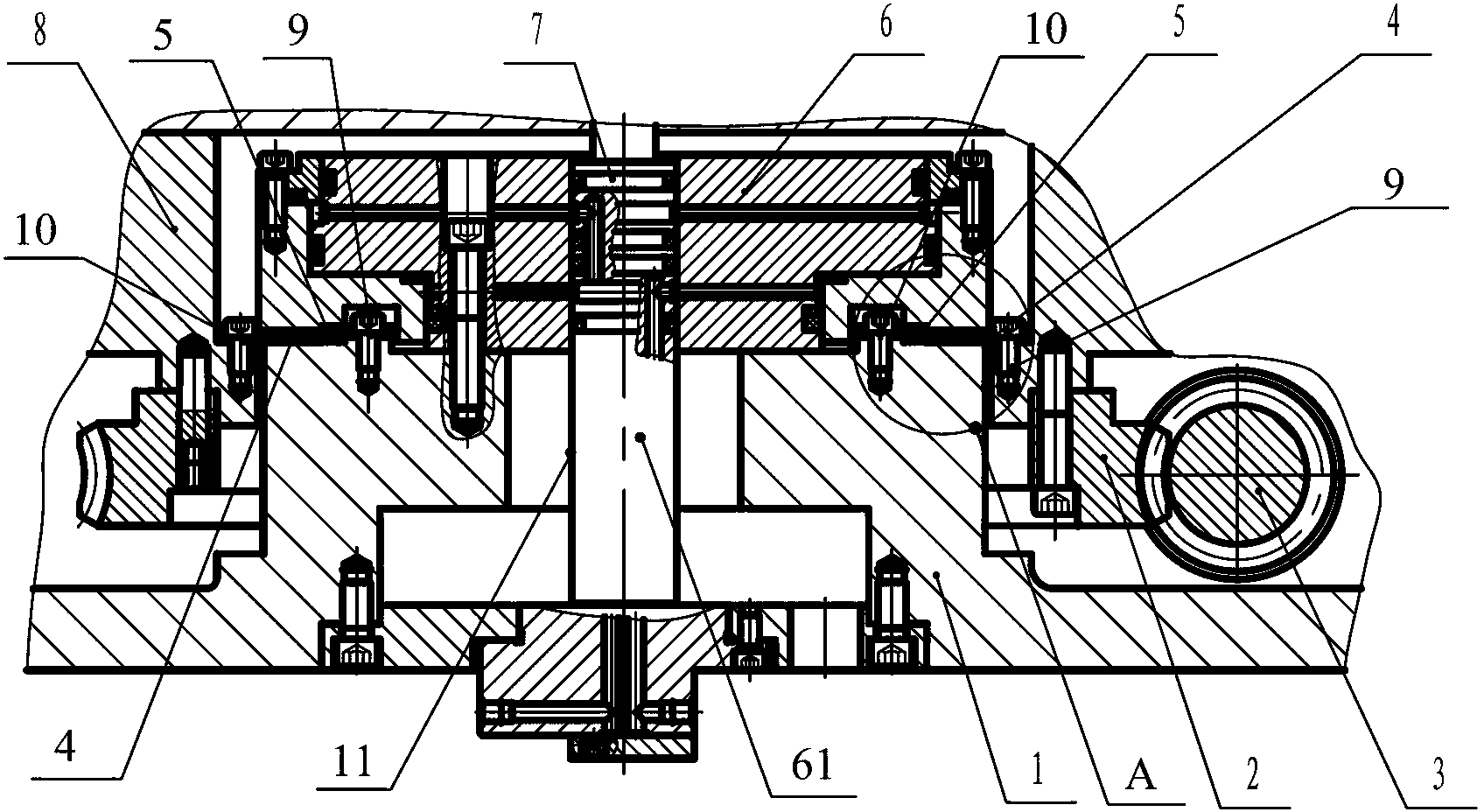

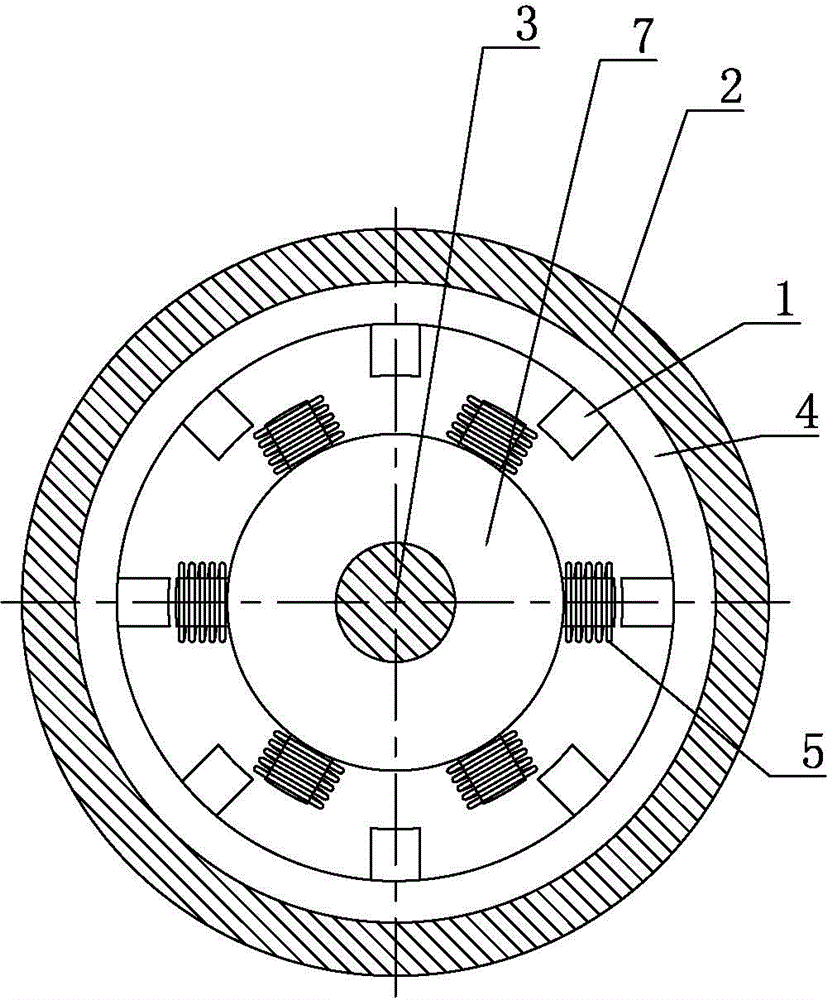

Switch reluctance machine applied to elevator traction machine

InactiveCN103151894AReduce torque rippleReduce volumeMagnetic circuit stationary partsWindings conductor shape/form/constructionPhase differenceEngineering

The invention discloses a switch reluctance machine applied to an elevator traction machine in the technical field of motors. The switch reluctance machine comprises a rotor and a stator, wherein the rotor and the stator are coaxially arranged and can relatively rotate, the rotor is arranged on the outer circumference of the stator, four tooth poles with inward radial directions are uniformly distributed on the front end and the back end of the rotor, six tooth poles with outward radial directions are correspondingly and uniformly distributed on the front end and the back end of the stator, the phase difference of the tooth poles of the front end and the back end of the stator are 45 degrees in the circumference direction, the tooth poles of the front end and the back end of the stator are in same-phase arrangement in the circumference direction, a coil is wound around each tooth pole of the stator, and the coils of the two tooth poles with the opposite radial directions are in serial arrangement. When the switch reluctance machine works, each phase coil is sequentially communicated with a power supply to generate the magnetic flux, a magnetic line of force passes through an iron core of the rotor from the nearest tooth pole of the rotor, and the rotor can rotate in one direction under the traction of the magnetic force. The switch reluctance machine disclosed by the invention can reduce the torque ripple of the rotor so that the rotor stably operates and the noise and the vibration of the rotor during operation are greatly reduced; and the switch reluctance machine can be served as the elevator traction machine.

Owner:JIANGSU GENERAL ELEVATOR

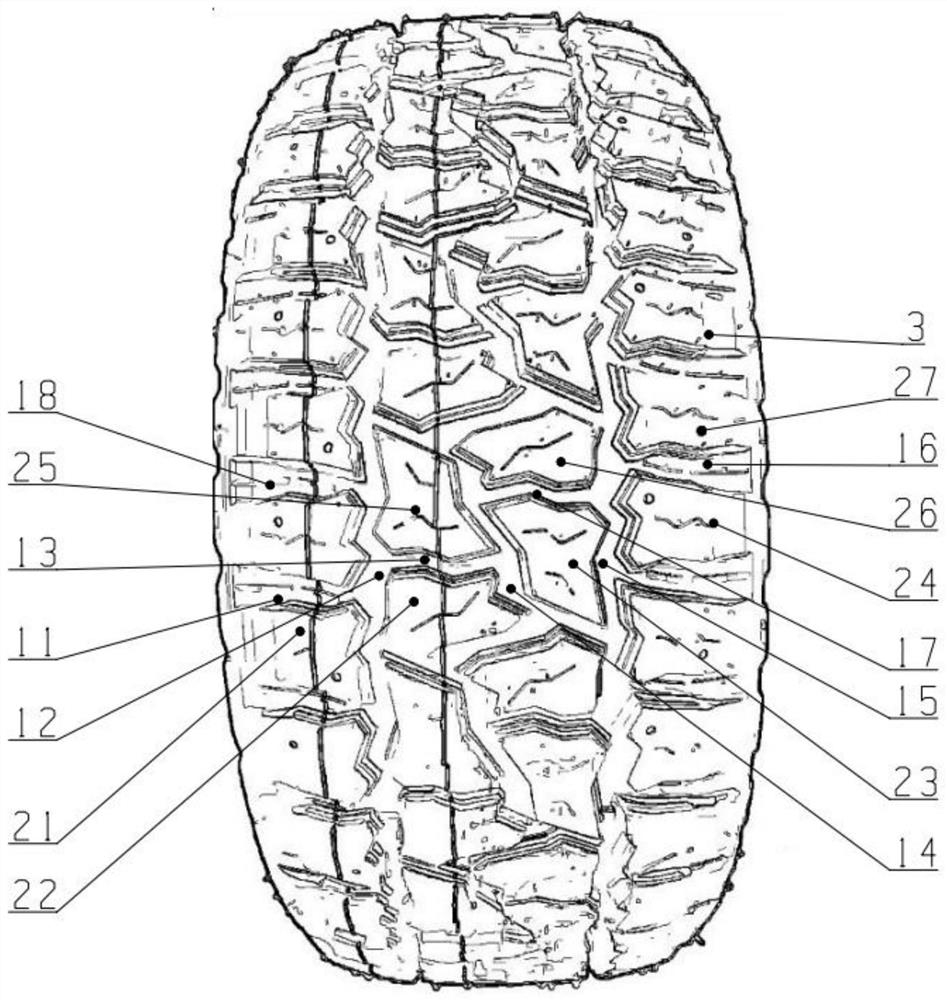

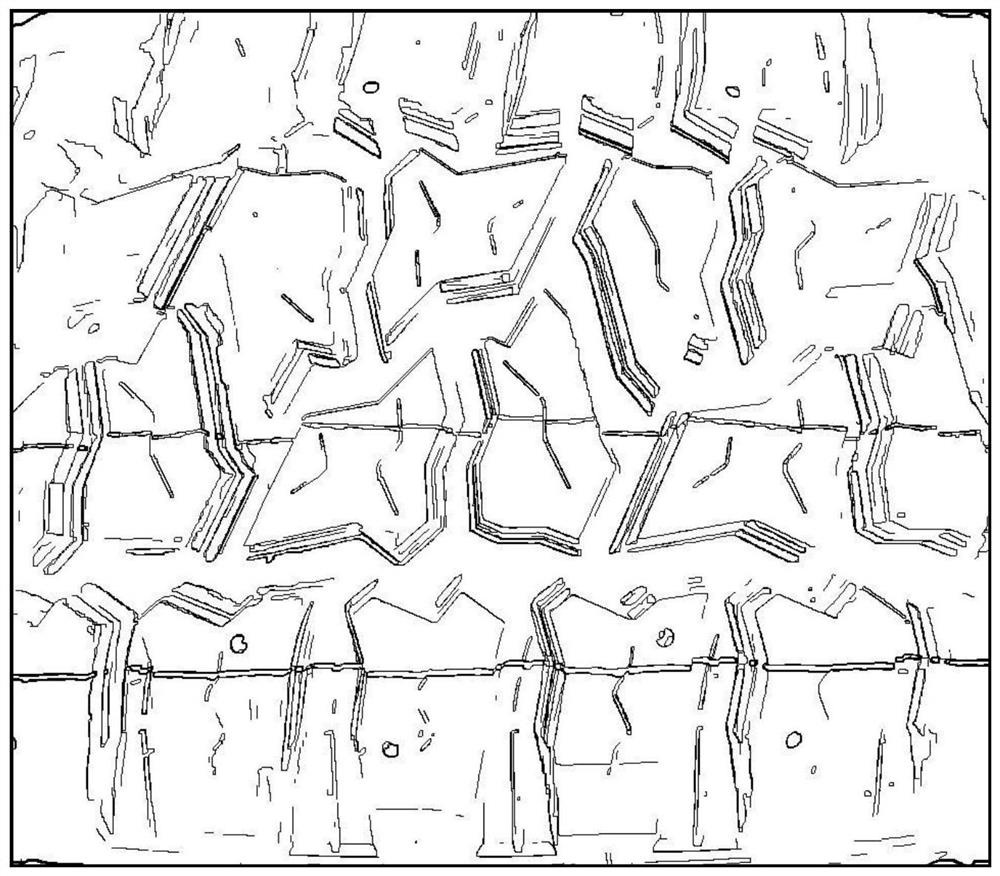

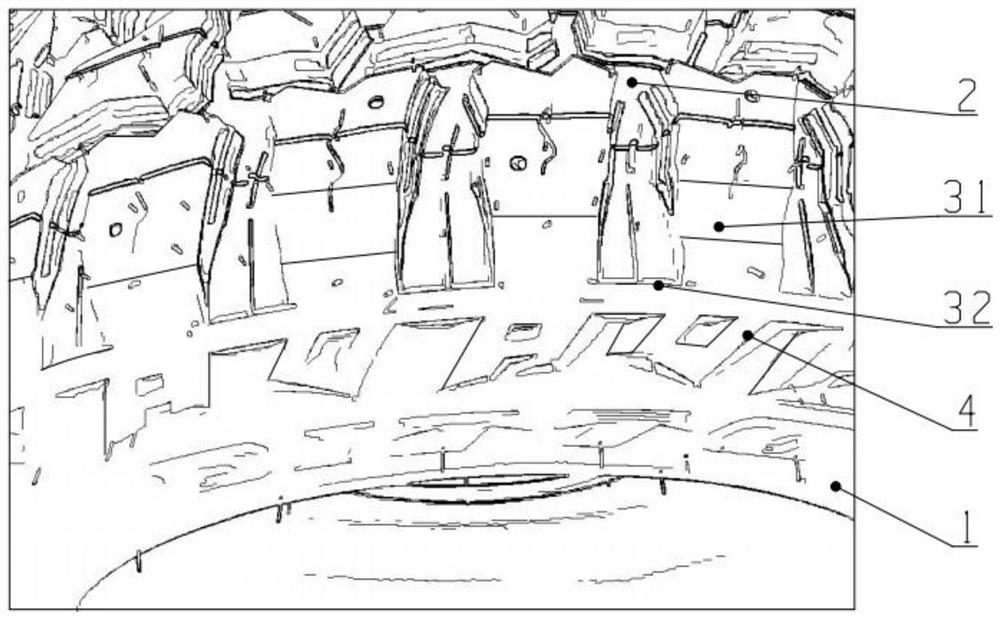

Special sand tire and wear resistance detection device thereof

ActiveCN112277533AImprove steering performanceImprove rigidityTyre tread bands/patternsVehicle tyre testingRoad surfaceMechanical engineering

The invention discloses a special sand tire and wear resistance detection device thereof. The special sand tire comprises a tire body, wherein a tire tread is formed on an outer ring of the tire body,a tire shoulder is formed on an edge of the tire tread, a plurality of pattern blocks are arranged on the tire tread and the tire shoulder, and the pattern blocks are symmetrically arranged on the left side and the right side of the circumferential axis of the tire tread in a staggered mode; each pattern block comprises a tread pattern block group arranged on the tread and distributed along the circumferential direction of the tire, and a tire shoulder pattern block group arranged on the tire shoulder and distributed along the circumferential direction of the tire, and the tail end of the tire shoulder pattern block group extends towards the tire side to form an under-shoulder pattern block. According to the special sand tire, a computer model is established to simulate the size and shapeof a grounding mark, the grounding pressure and distribution condition, and the contact condition of a pattern and a soft pavement of a tire in soft lands such as deserts, sand lands, beaches and thelike so as to design a pattern groove with a U-shaped structure and an undirected blocky pattern block; the passing rate of the special sand tire on a soft road surface is increased, the functions ofwater drainage, mud discharge, sand discharge and the like are improved, stability and the quick turning performance of a vehicle are improved, and meanwhile the control performance of the tire is improved.

Owner:ZHAOQING JUNHONG CO LTD

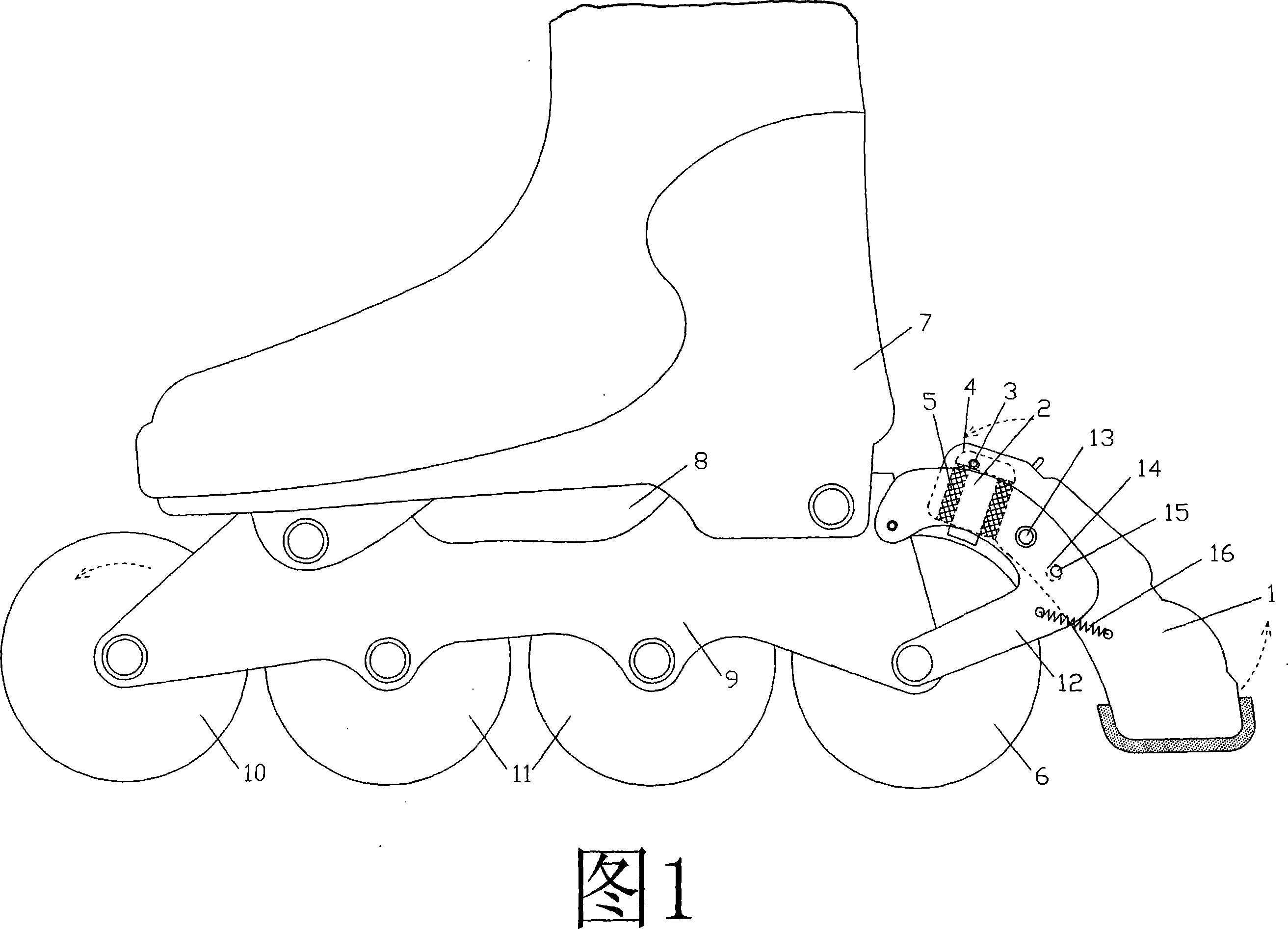

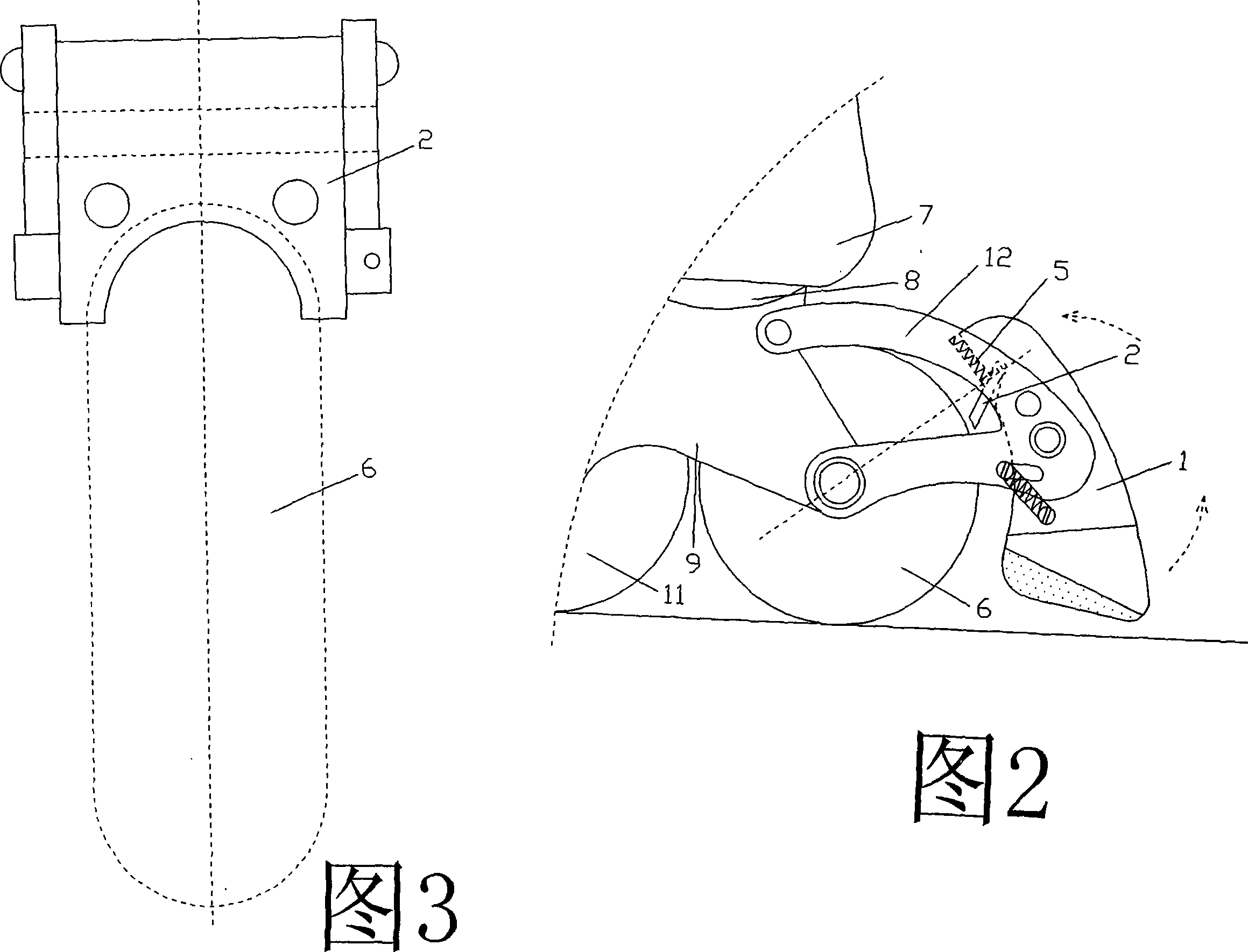

Brake block mechanism for dry skating boot deflection brake

InactiveCN101104108AImprove securityBraking force is strongSkate-boardsRoller skatesInsertion stentEngineering

The invention discloses a brake block mechanism used for the deviated brake of the roller skates, which has a brake block that can be connected to the brake swing block which can deviate when touching the ground, the invention is characterized in that the brake swing block is provided with a brake block swing-limit member, the brake block can deviate following the brake swing block or the wheel stent to touch the shoe wheel; the brake surface of the brake block is a wheel-touching surface with a basic smooth surface that can couple with the surface of the wheel at the outer upper half part of the shoe wheel, the brake block can rotate following the shoe wheel after touching the wheel to do deviated brake. The brake block of the invention directly enforce unidirectional brake to the soft surface of the shoe wheel, such effect is favorable for improving the safety of the sliding, and the roller skates can play the role of anti-falling forward and backward, and is particularly suitable for beginners to use for learning sliding.

Owner:林苏钦

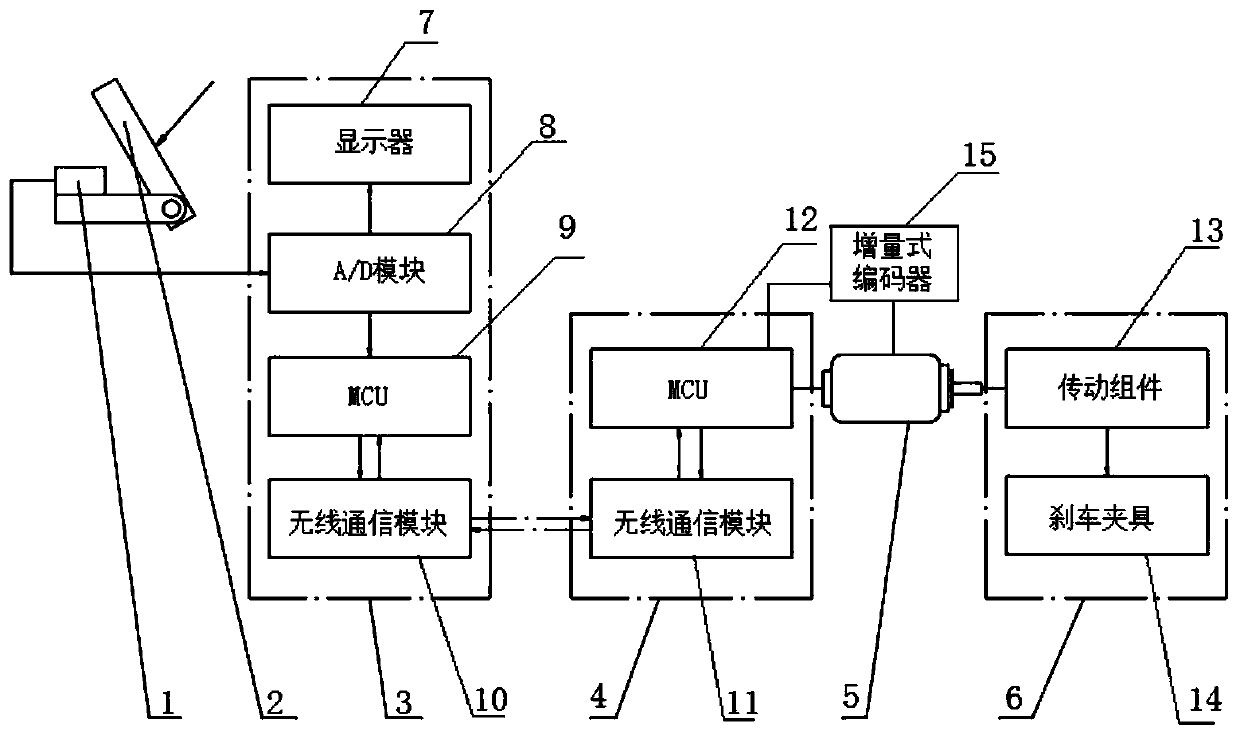

Wireless braking system

The invention relates to a wireless braking system. The wireless braking system comprises a braking control module and a braking realizing module which are connected with each other through a wirelessmode; the braking control module comprises a pedal plate and a first control module; an angle sensor used for detecting a steering angle and an angular acceleration of the pedal plate is arranged onthe pedal plate; the angle sensor is connected with the first control module; the first control module comprises a first micro-control unit and a first wireless communication module connected with thefirst micro-control unit; the braking realizing module comprises a second control module, a motor and a mechanical brake unit which are connected with each other in sequence; the second control module comprises a second micro-control unit and a second wireless communication module connected with the second micro-control unit; and the first wireless communication module is connected with the second wireless communication module. Compared with the prior art, the wireless braking system has the advantages that the oil leaking phenomenon of an oil braking system is avoided and the wiring harnessarranging space of a vehicle compartment is also saved by using an electronic control and mechanical structure combined method.

Owner:TONGJI UNIV

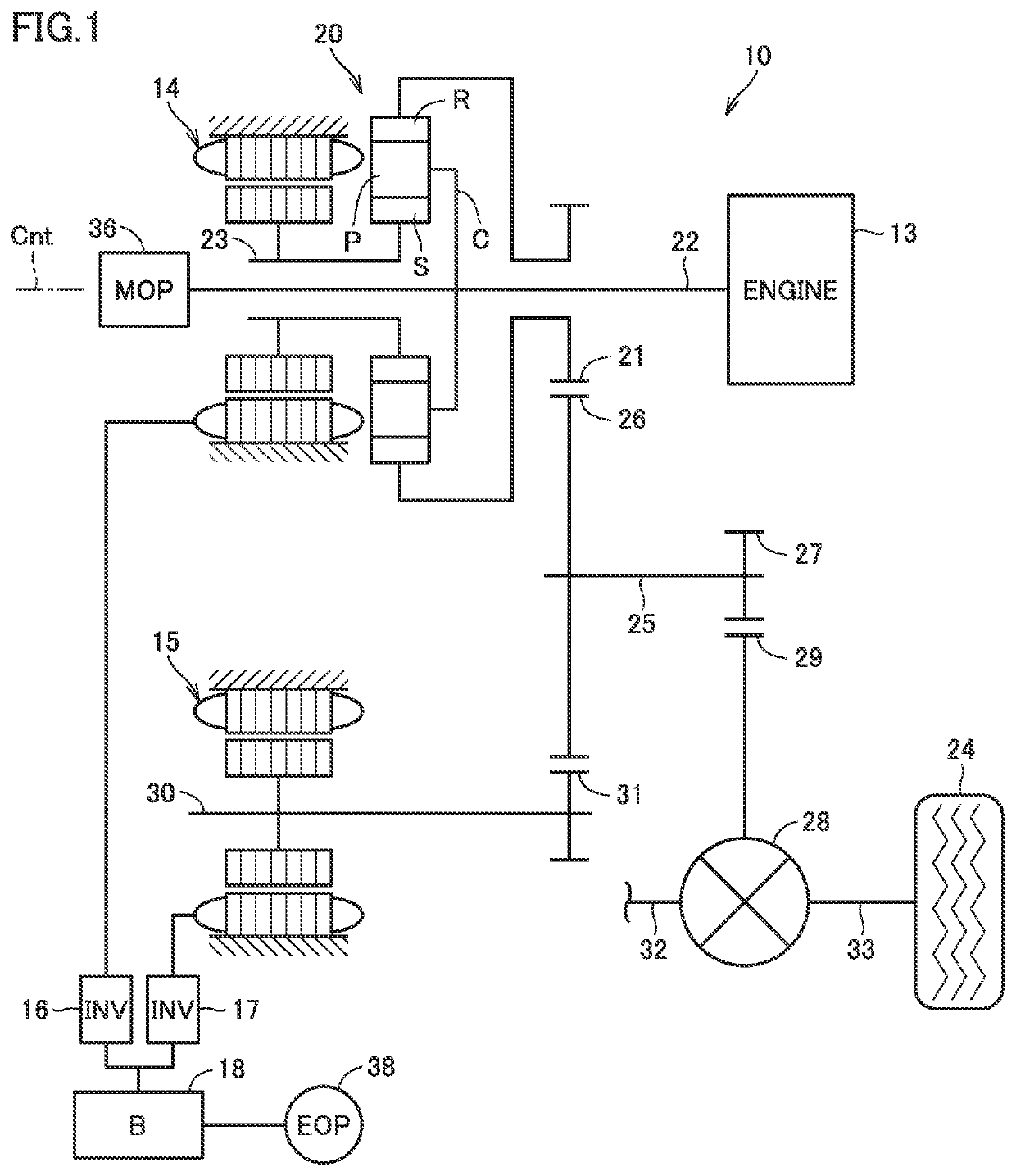

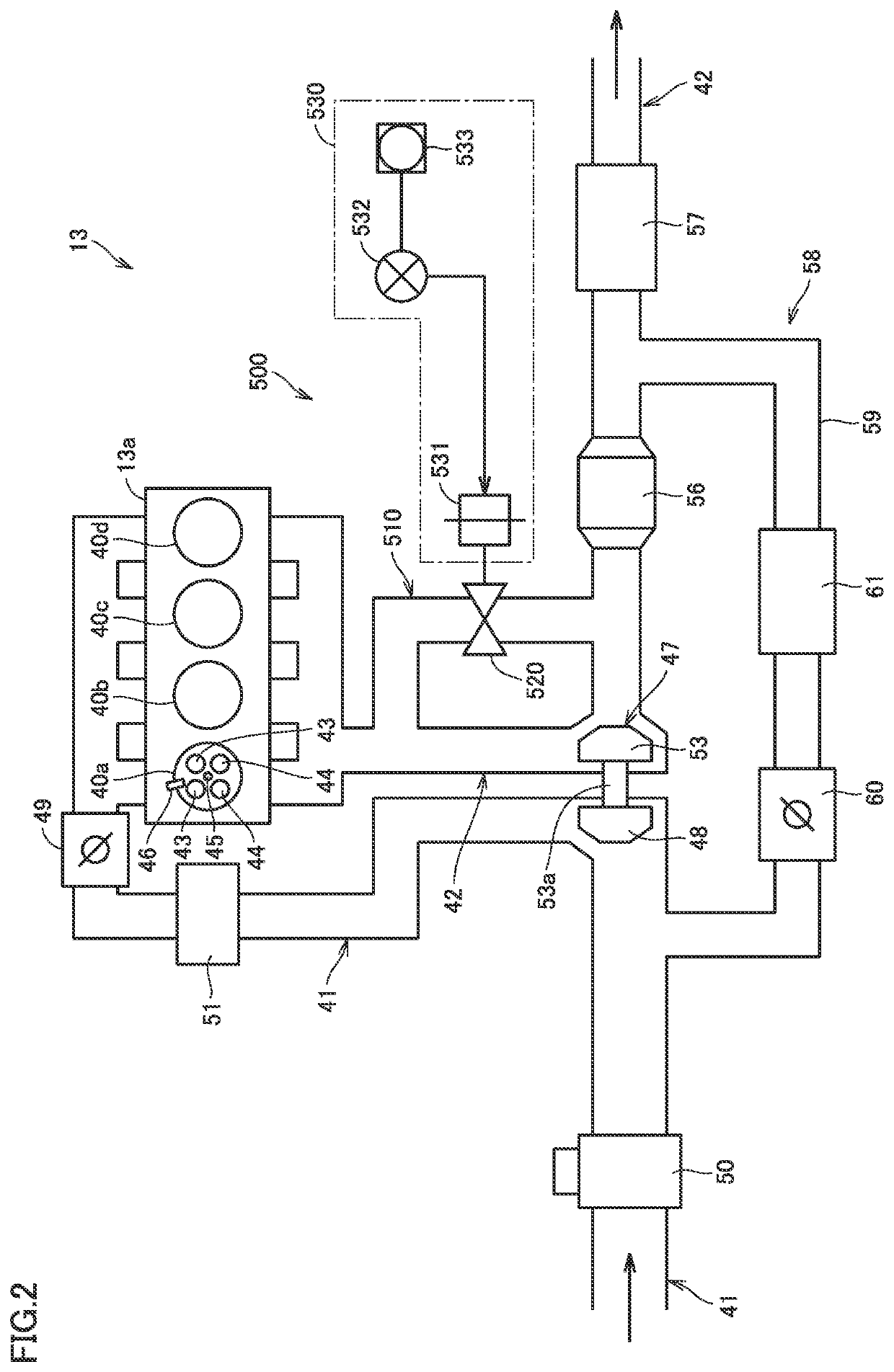

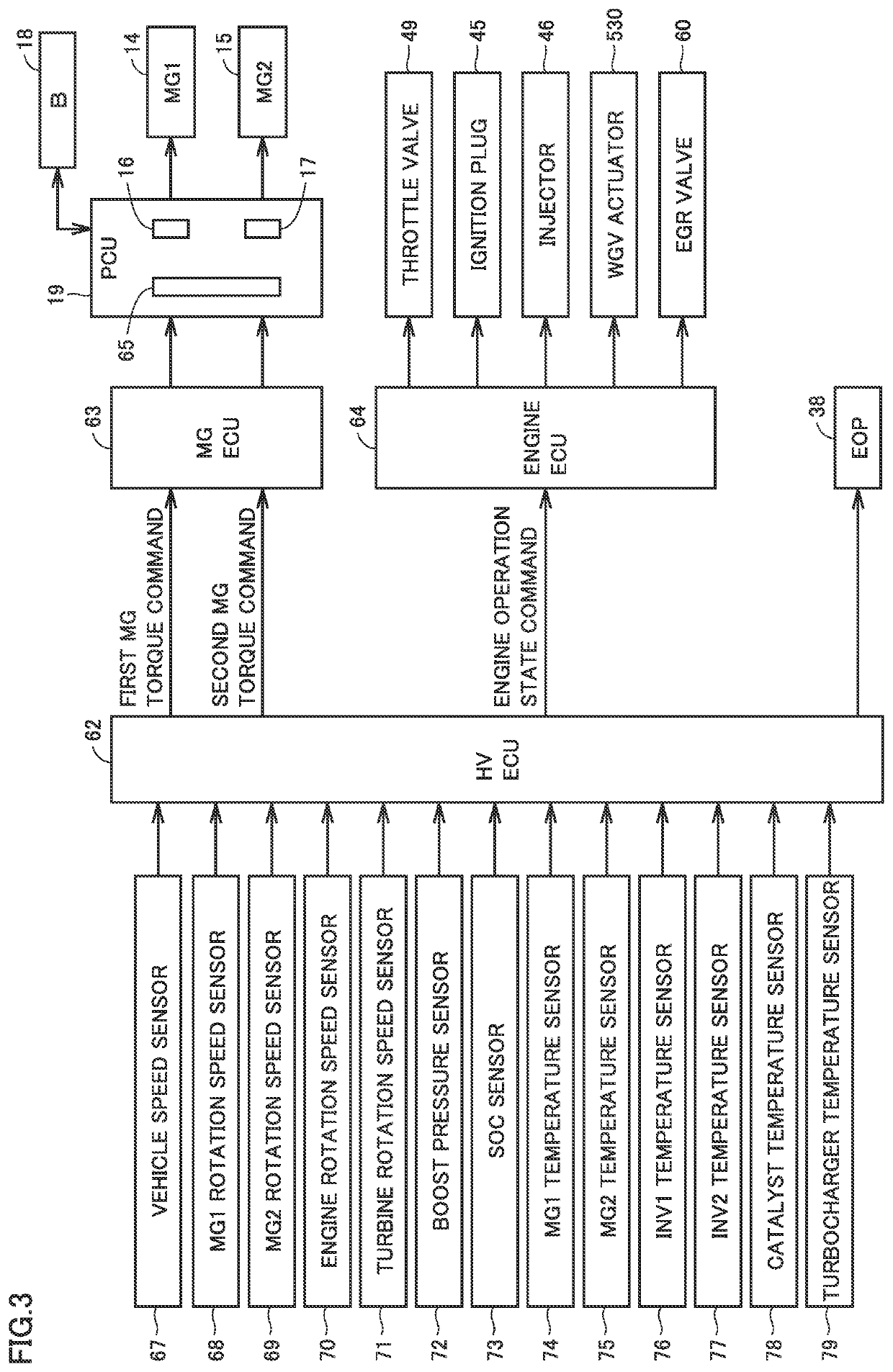

Hybrid vehicle and method of braking hybrid vehicle

ActiveUS20200298857A1Electric power input to power is reducedPower storage is suppressedHybrid vehiclesElectrical controlDrive wheelGear wheel

In a hybrid vehicle, each of an engine and an MG1 is mechanically coupled to a drive wheel with a planetary gear being interposed. The planetary gear and an MG2 are configured such that motive power output from the planetary gear and motive power output from the MG2 are transmitted to the drive wheel as being combined. When a first condition is satisfied during traveling of the vehicle, a controller stops combustion in the engine and performs motoring by the MG1 such that the planetary gear outputs deceleration torque. When a second condition in addition to the first condition is satisfied (YES in S20) during deceleration of the hybrid vehicle with deceleration torque, the controller performs motoring with throttle opening being set to first opening or larger and WGV opening being set to second opening or smaller.

Owner:TOYOTA JIDOSHA KK

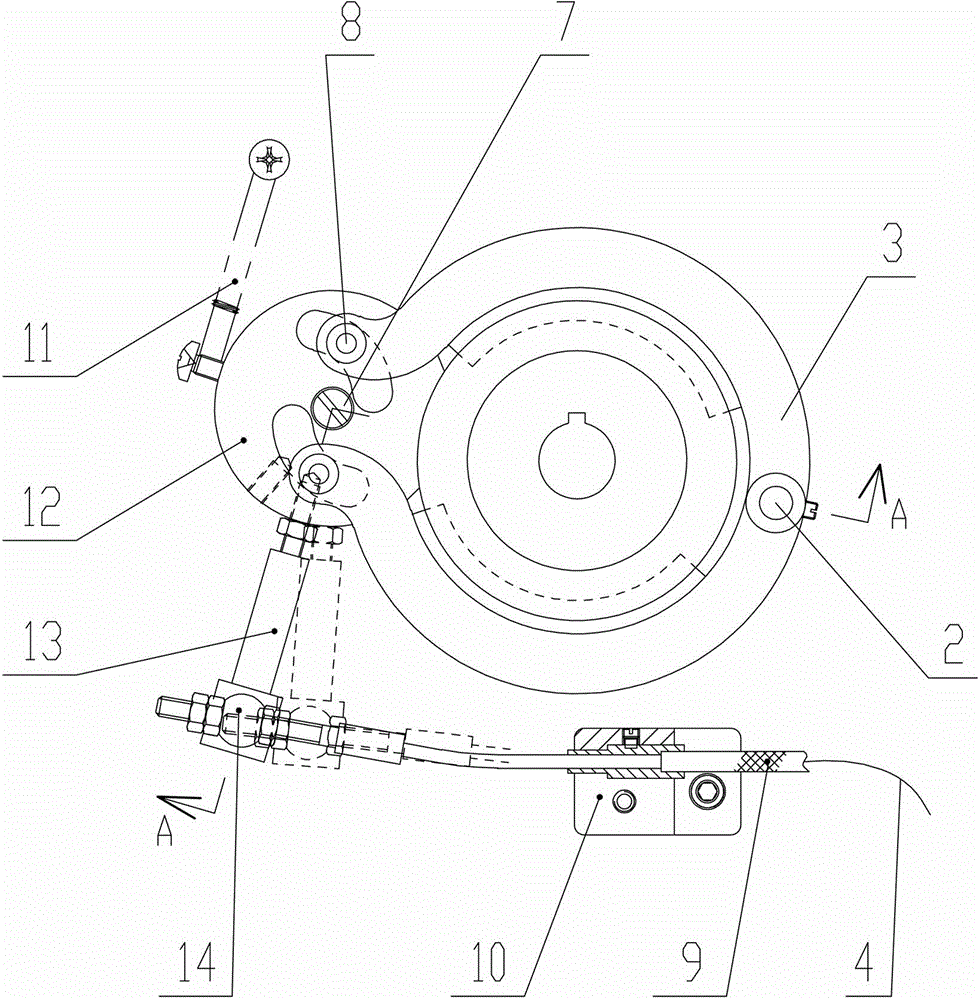

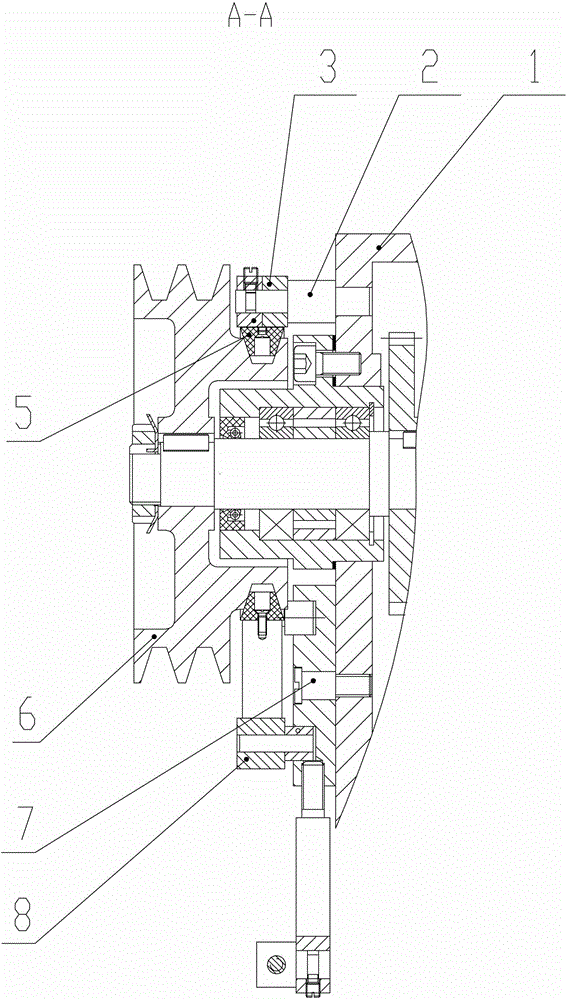

Cam-type pedal lock braking mechanism

The invention relates to a braking mechanism, in particular to a cam-type pedal lock braking mechanism. According to the adopted technical scheme, the cam-type pedal lock braking mechanism comprises a pedal part, a braking connecting line and a braking part, and is characterized in that the pedal part comprises a support plate, a pedal plate, a braking line limiting block, a limiting brake rod, a cam rod and a travel switch; the braking part comprises a brake runner, a brake cable, a brake block and a brake pad. The cam-type pedal lock braking mechanism has the advantages that the friction force between the brake pad and a moving part is used for braking, and rotation or rotation trend is stopped by means of mutual friction between a non-rotating element and a rotating element. The cam-type pedal lock braking mechanism has the characteristics of flexibility in braking, simple structure, convenience in adjustment, low cost, high suitability and the like, and a belt axle in a headstock of a machine tool can be used for braking. The cam-type pedal lock braking mechanism has the advantages of compact structure, flexibility in action, convenience in adjustment, great braking force, high braking speed, adjustable braking time, automatic compensation after wear of the brake pad, and the like.

Owner:SHANDONG LUNAN MACHINE TOOL

Automatic anti-pinch door

InactiveCN104675234BBraking force is strongAvoid pinchingBuilding braking devicesWing fastenersTrap doorMechanical engineering

The invention relates to a door capable of automatically preventing clamping. The door comprises a door frame, a movable door and a clamping preventing device, wherein the clamping preventing device comprises a housing, a swinging device, a lever device and a door brake device; the clamping preventing device is mounted at the bottom end of the movable door; the swinging device comprises a swinging hammer, a driving piece and a first guide cover; the door brake device comprises a brake piece, a first spring and a second guide cover; the lever device comprises a first lever, a first supporting piece, a second lever and a second supporting piece; the swinging device is connected with the lever device; the lever device is connected with the door brake device; during use, the swinging hammer is driven to swing by virtue of inertia caused by fast swing of the movable door, the first and second levers are driven to swing by using the swinging hammer, and the brake piece is driven by virtue of swinging of the second lever to overcome downward movement of elastic force of the first spring, so that the brake piece declines to be contacted and fractioned with the ground to prevent the movable door from fast swinging, so that the movable door is prevented from fast swinging to hurt children.

Owner:梁家平

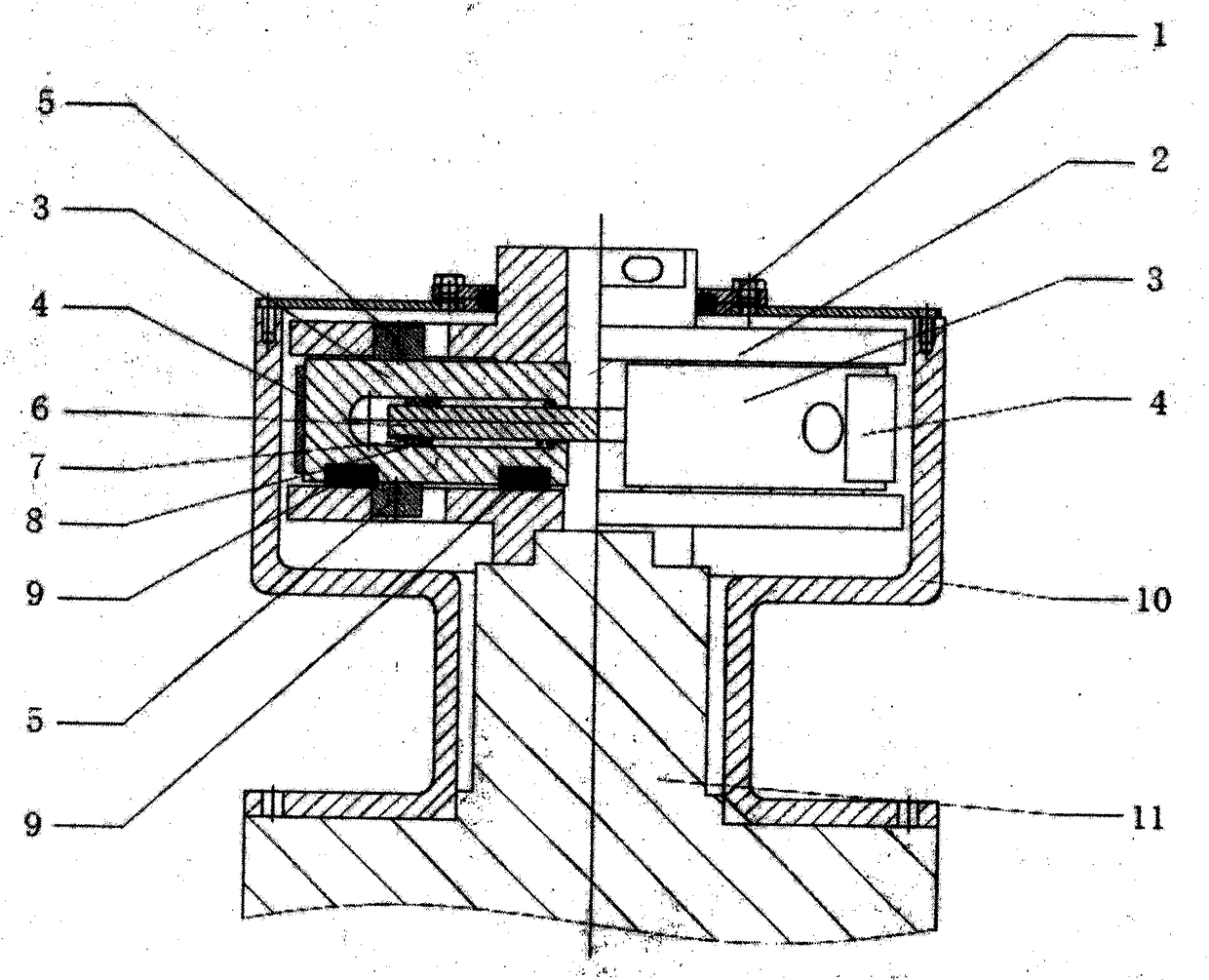

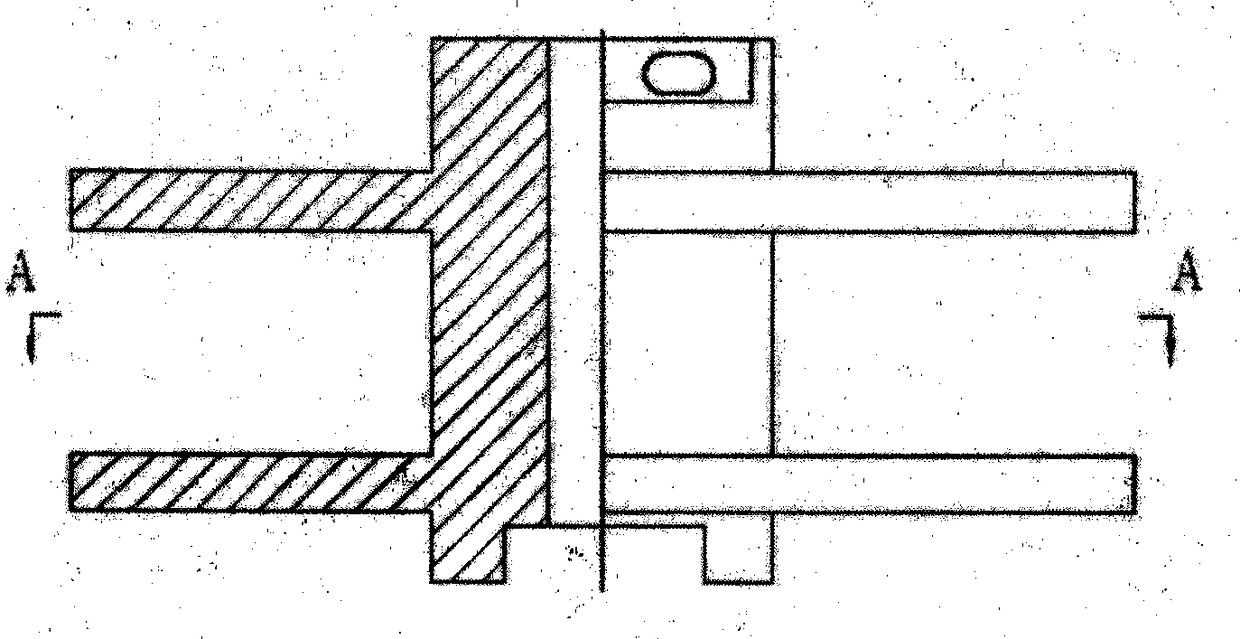

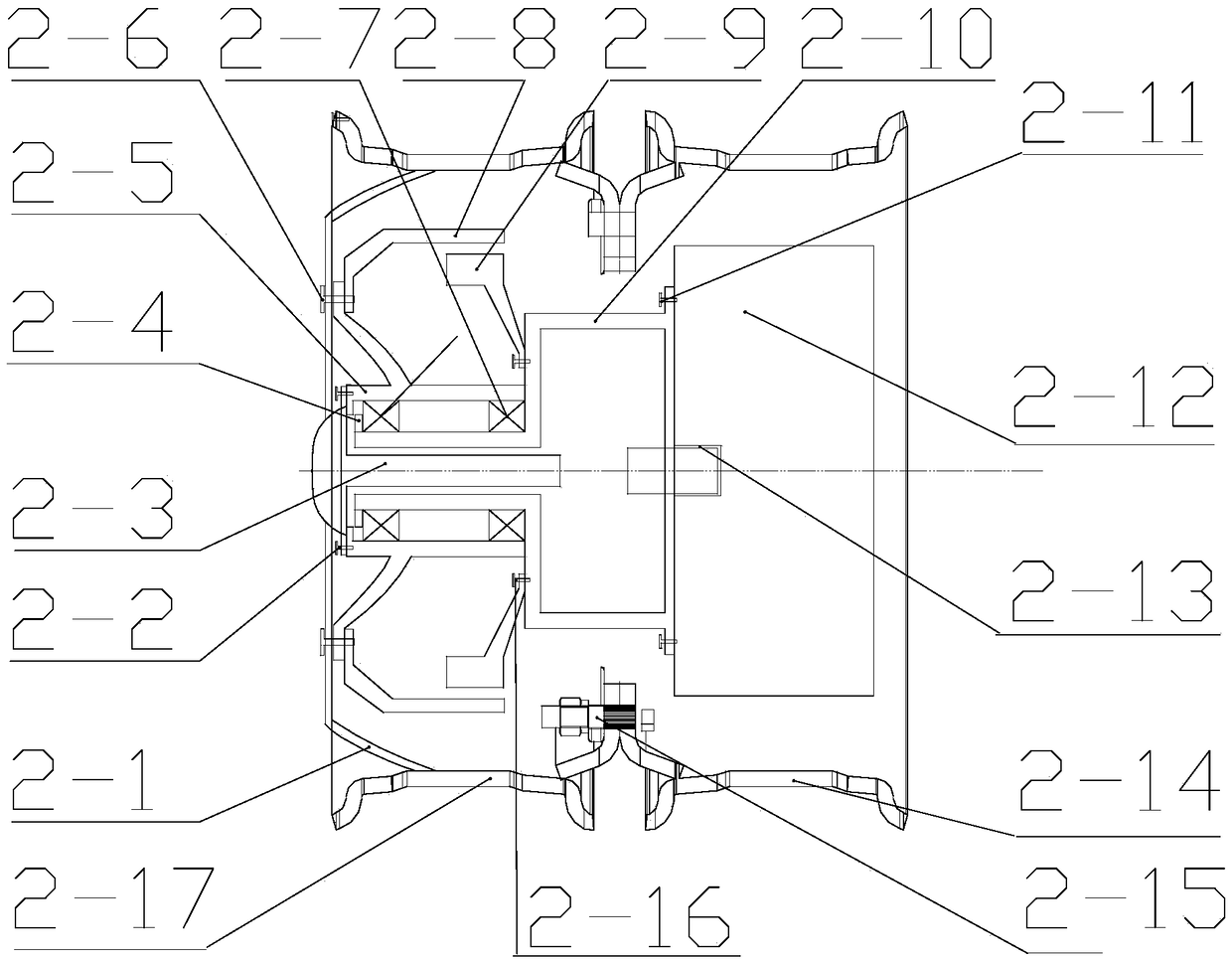

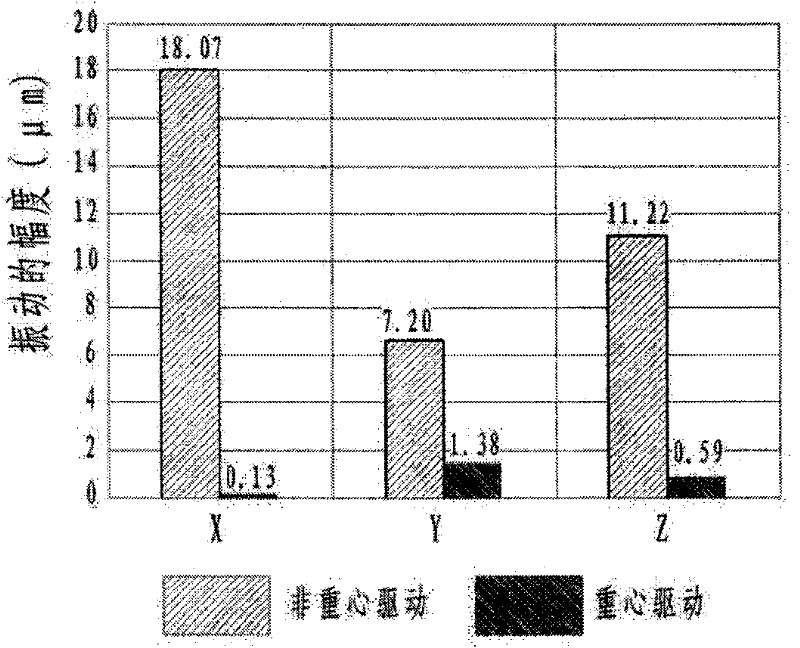

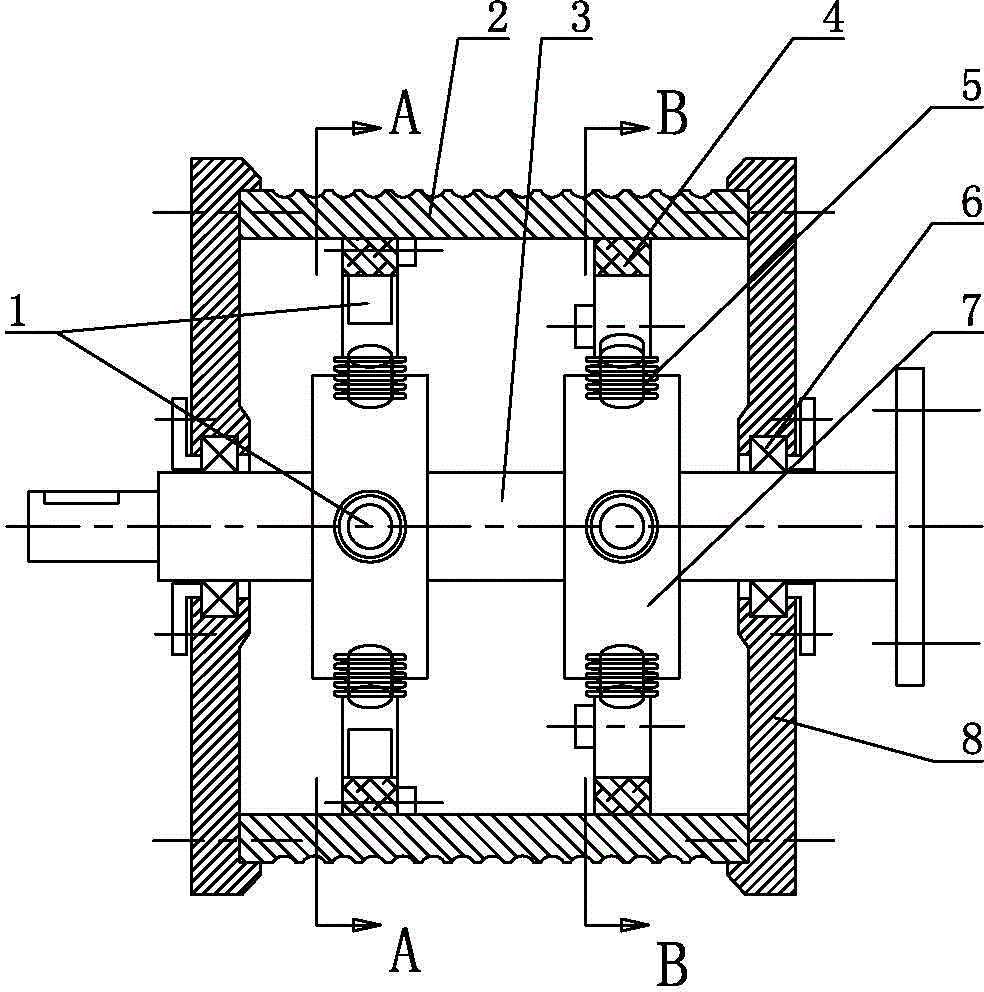

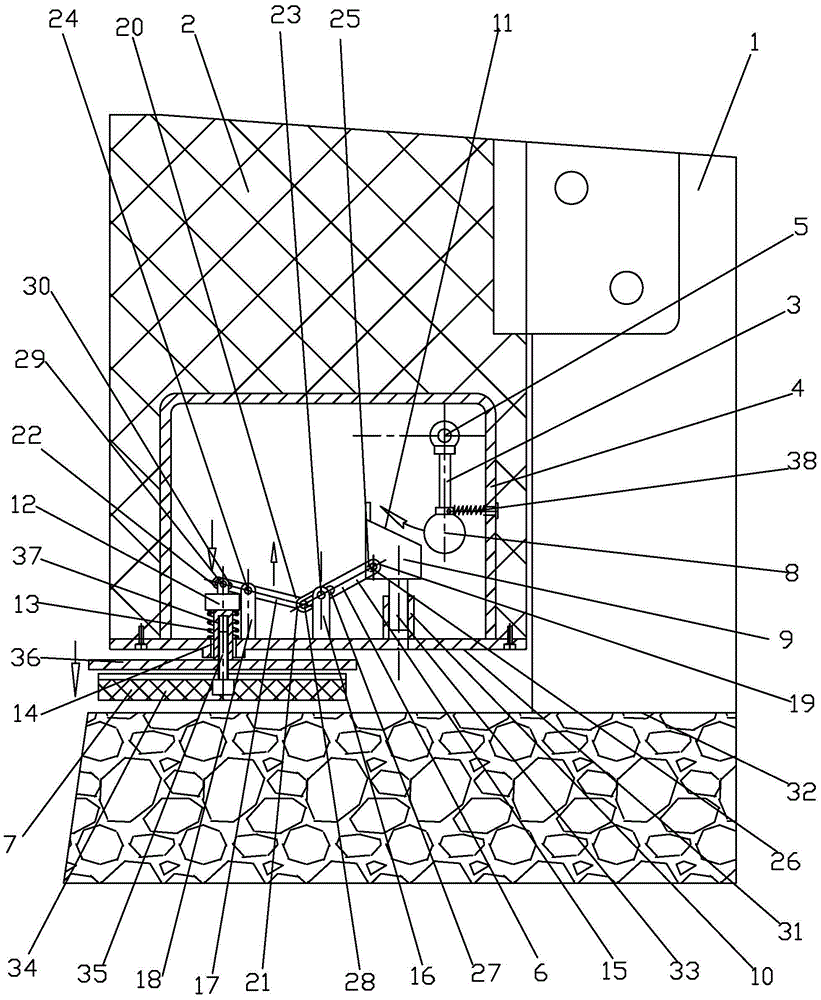

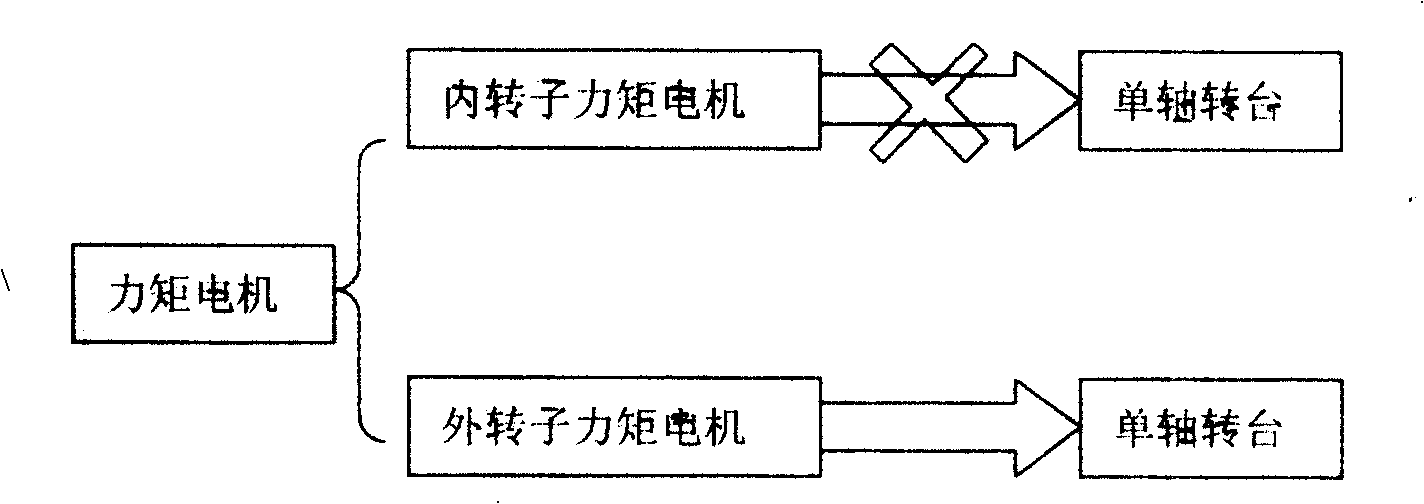

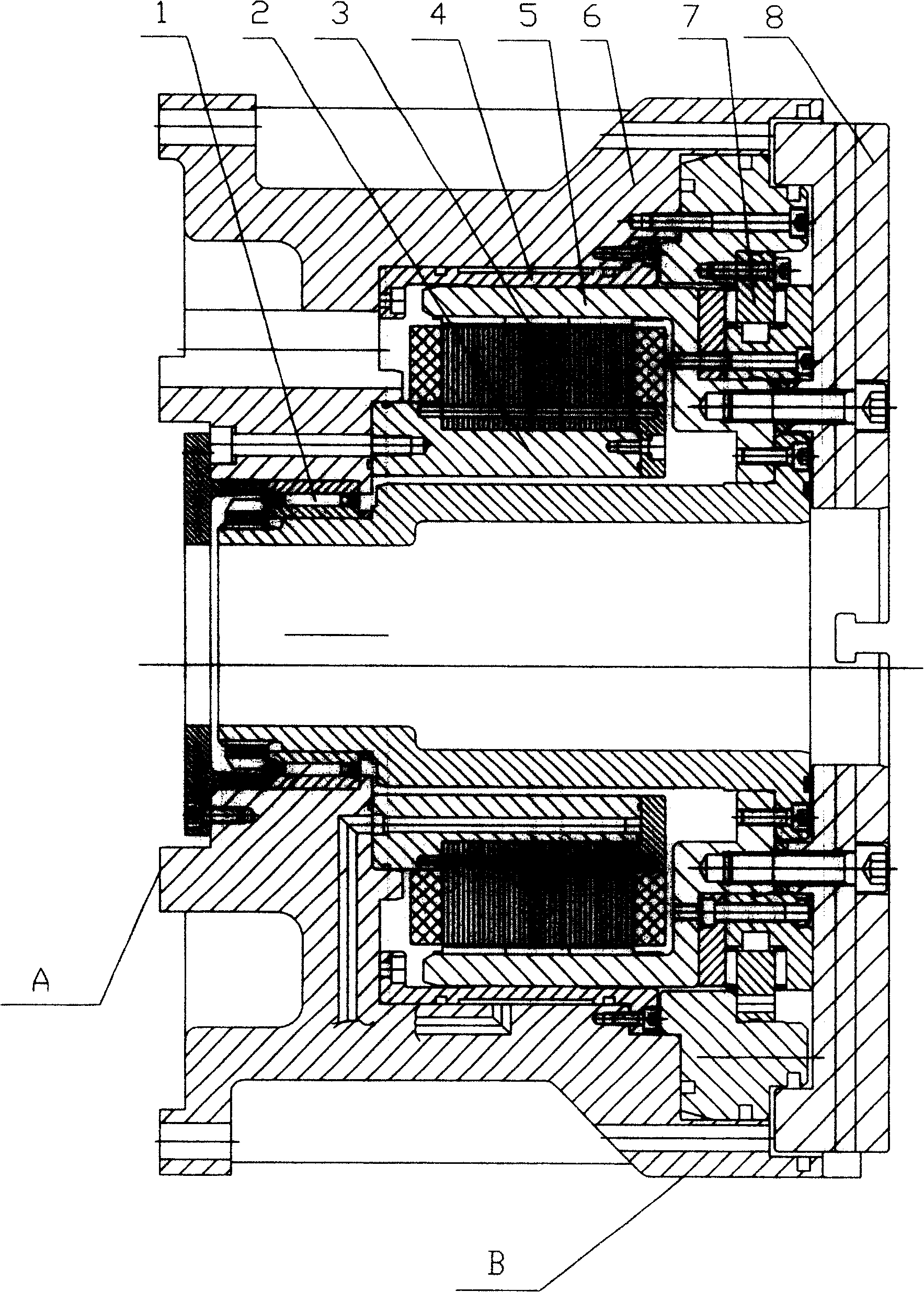

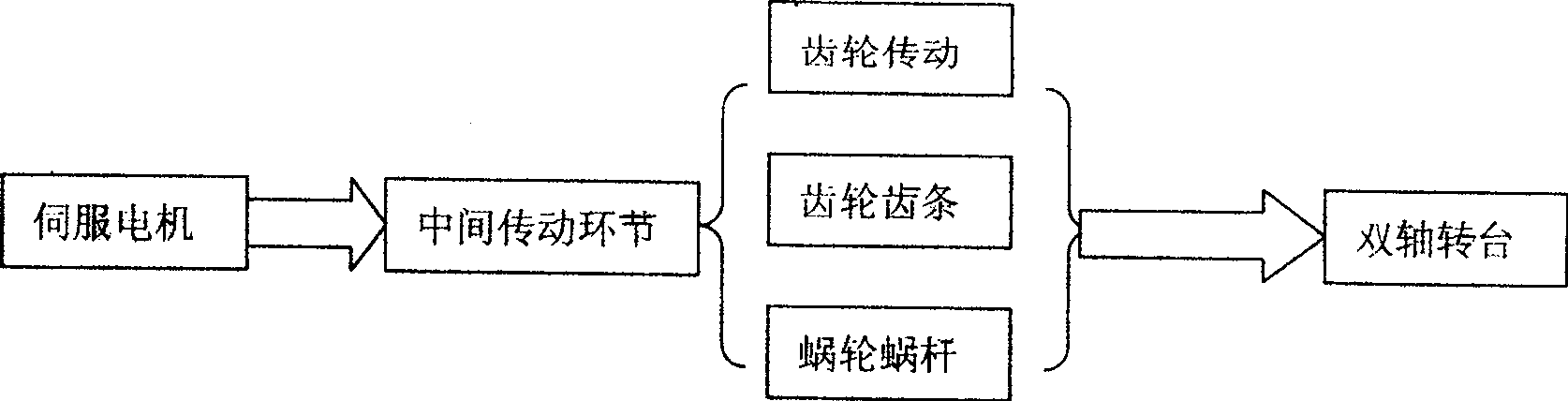

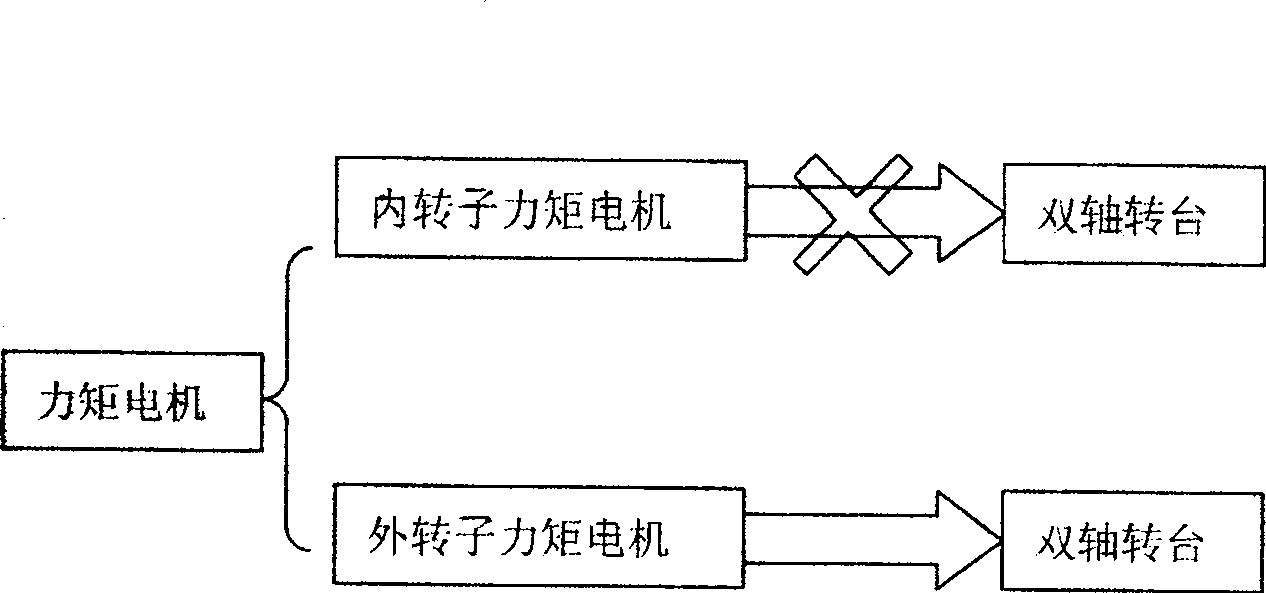

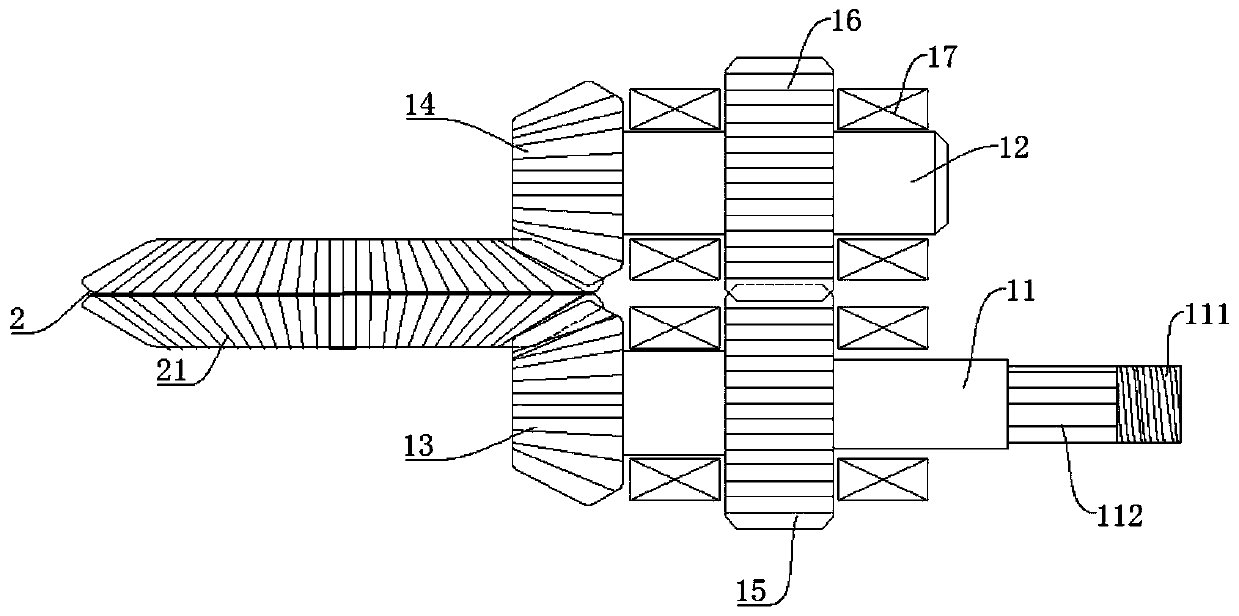

Vertical and horizontal dual-purpose single axle table of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN100421874CImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsMotor driveTorque motor

The invention relates to the vertical and horizontal single shaft rotary bench driven by an alternate permanent syntactic outside rotor torque motor. It directly fixes the bench on the end of the said torque motor rotor, connecting the shell with the inner cold bushing of the stator and the stator of the torque motor, with reduced middle drive linkages, improves the running precision and stability of the rotary bench, with bigger output torque and improved mechanical effect. It simplifies the braking mechanism with bigger clamping area, less drive effect with less size of the outside rotor torque motor under same performance conditions.

Owner:KEDE NUMERICAL CONTROL CO LTD

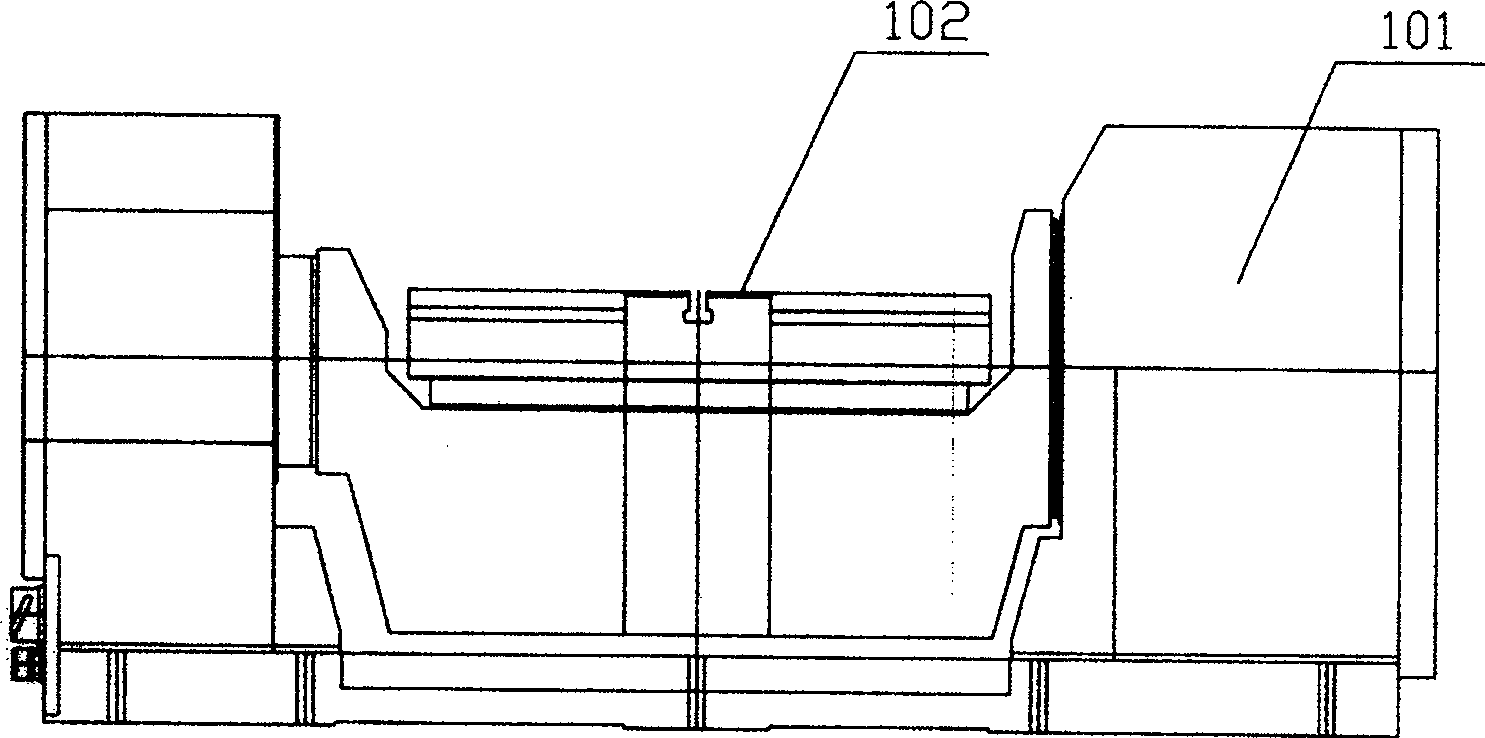

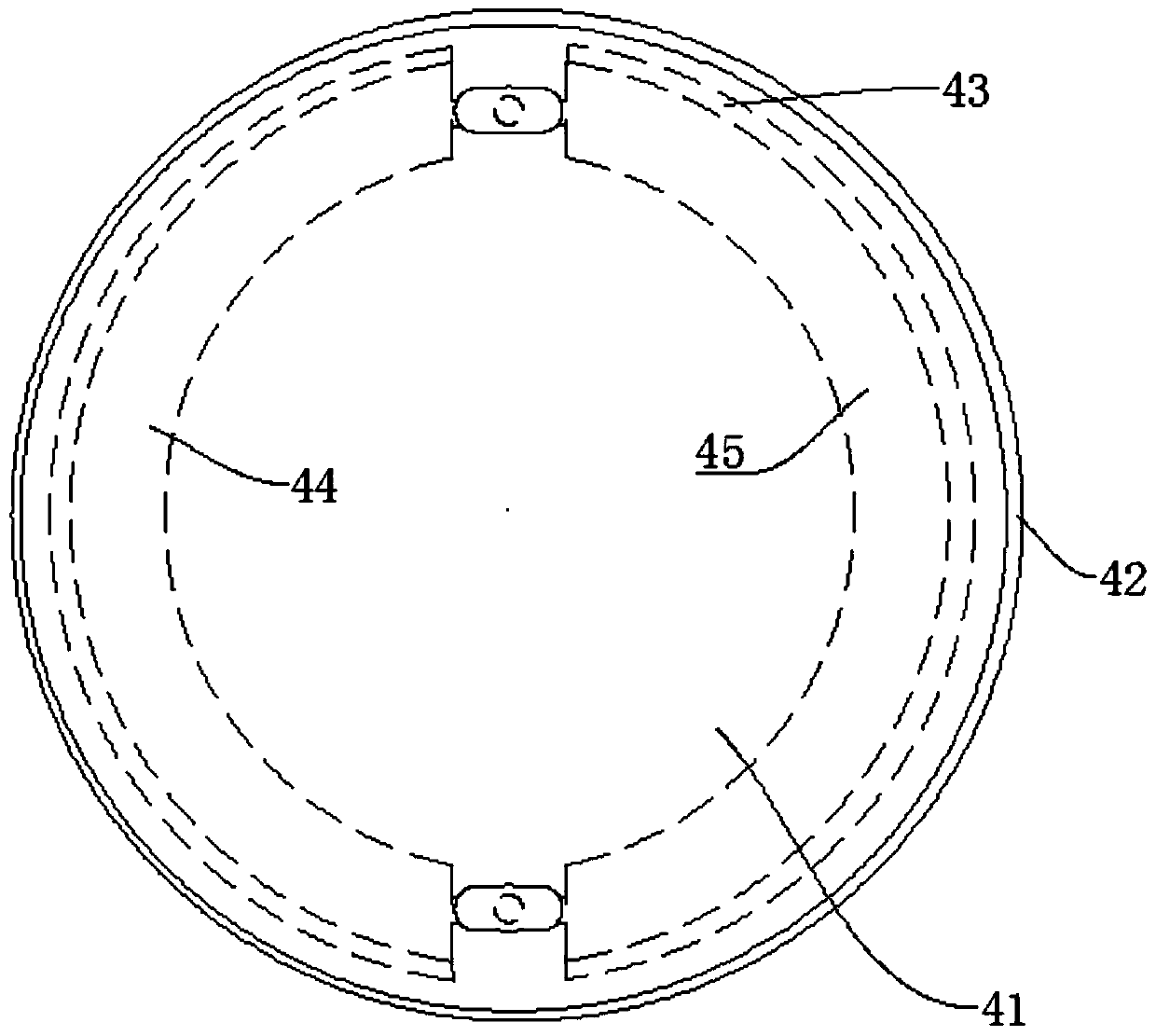

Double axle table driven by AC permanent magnetic synchronization external-rotor-type force moment motor

ActiveCN100467208CImprove running accuracyImprove stabilityEngine sealsMagnetic circuit stationary partsTorque motorEngineering

The biax turntable of an AC permanent magnet syntactic outside rotor torque motor comprises a turntable in the middle with vertical main shaft, turntable at one side of the said turntable with horizontal main shaft connecting with horizontal torque motor and vertical torque motor, oscillating driven by the horizontal torque motor, rotating driven the vertical motor. Saving a lot of middle drive linkage, it improves the running precision and stability of the turntable, with bigger output torque, and improved mechanical returns. It simplifies the braking structure with enlarged clamping area, less effect to the drive and system, smaller size of the outside rotor torque motor.

Owner:KEDE NUMERICAL CONTROL CO LTD

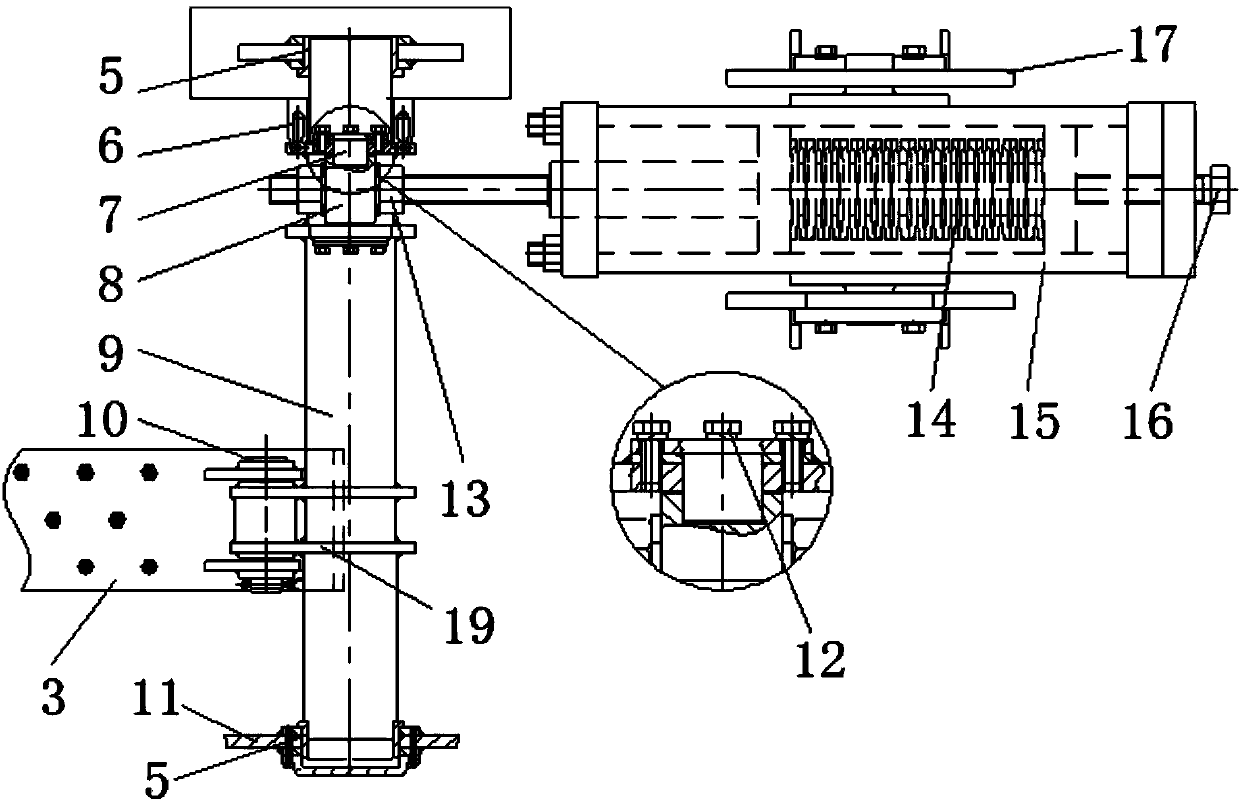

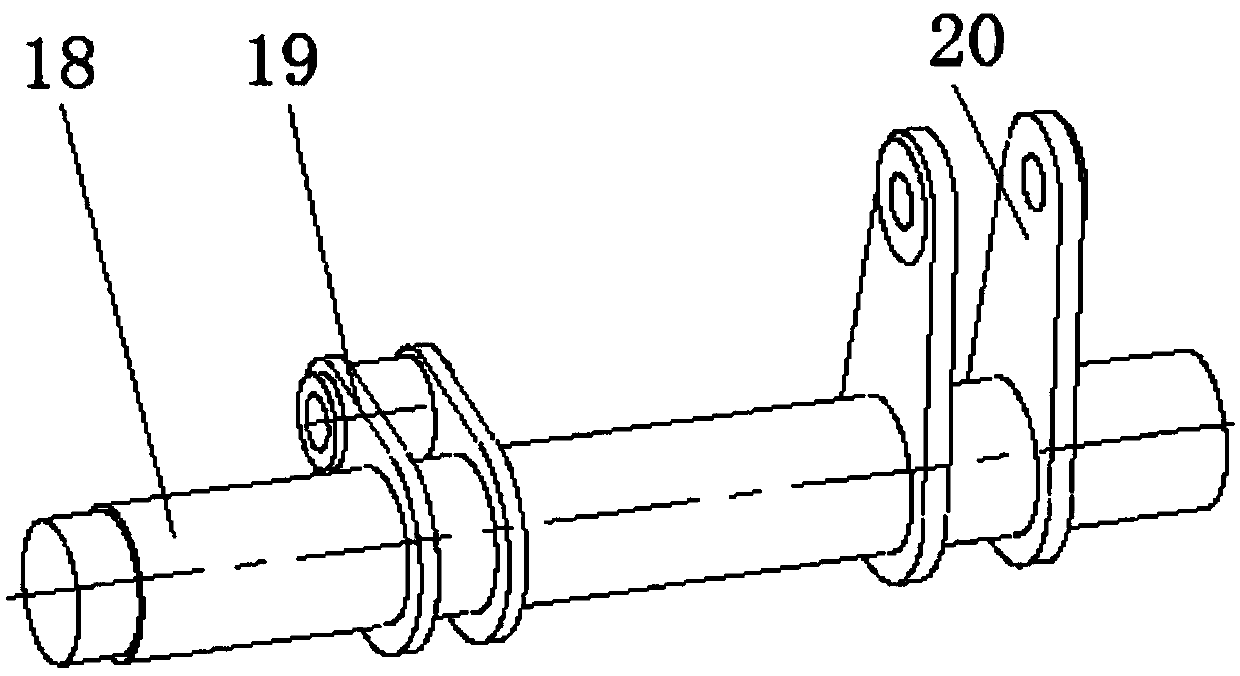

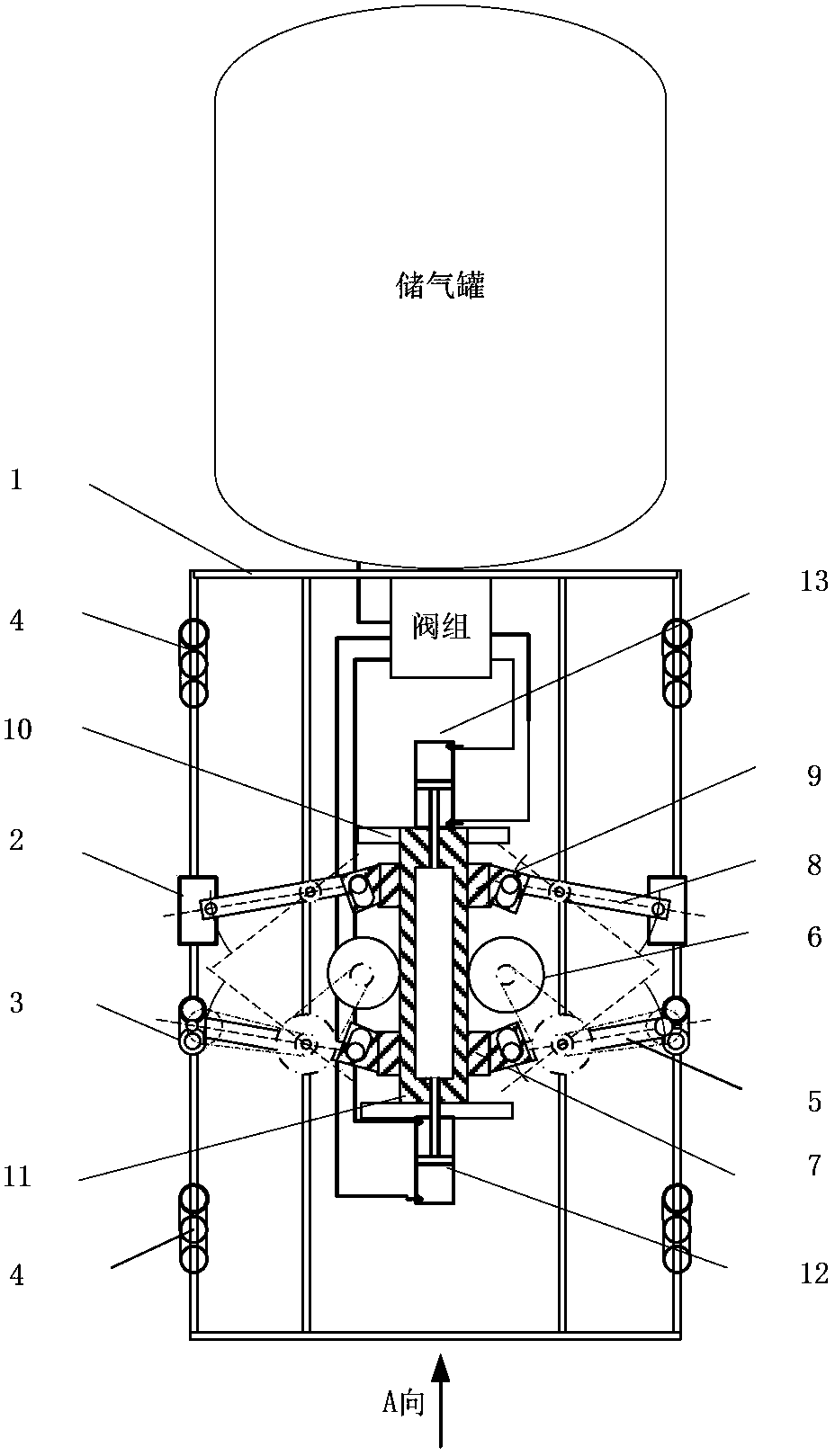

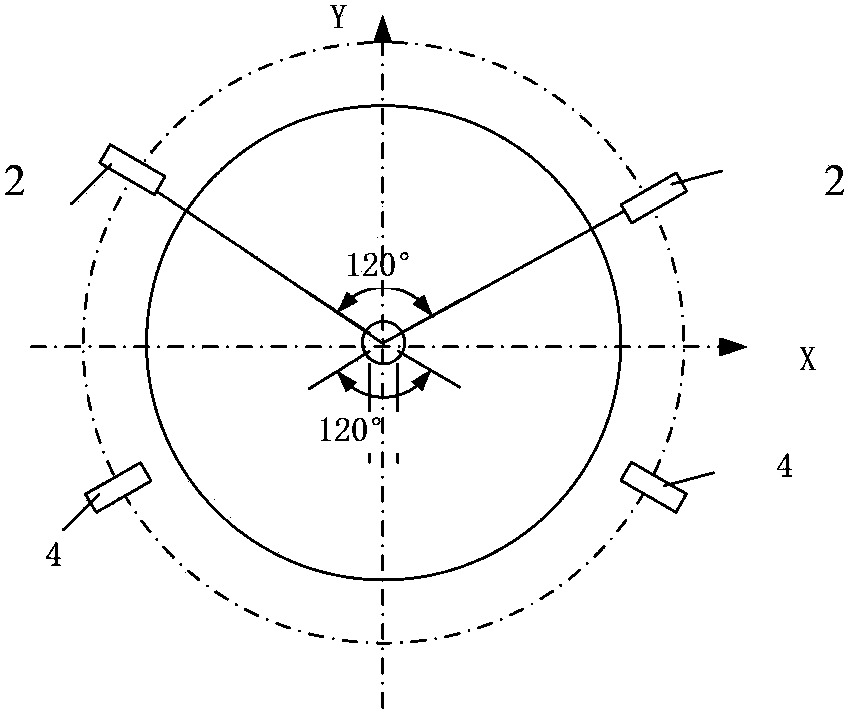

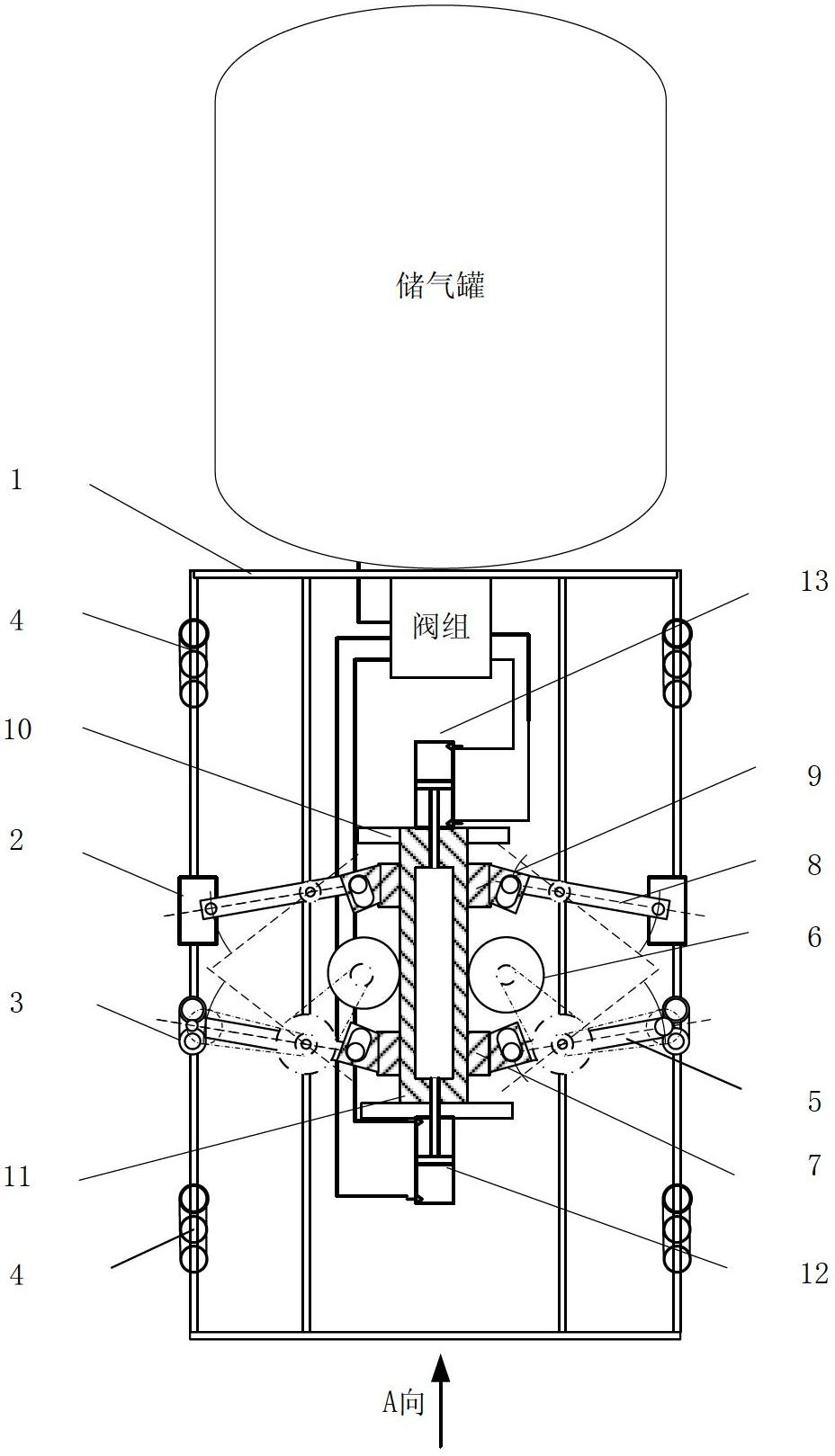

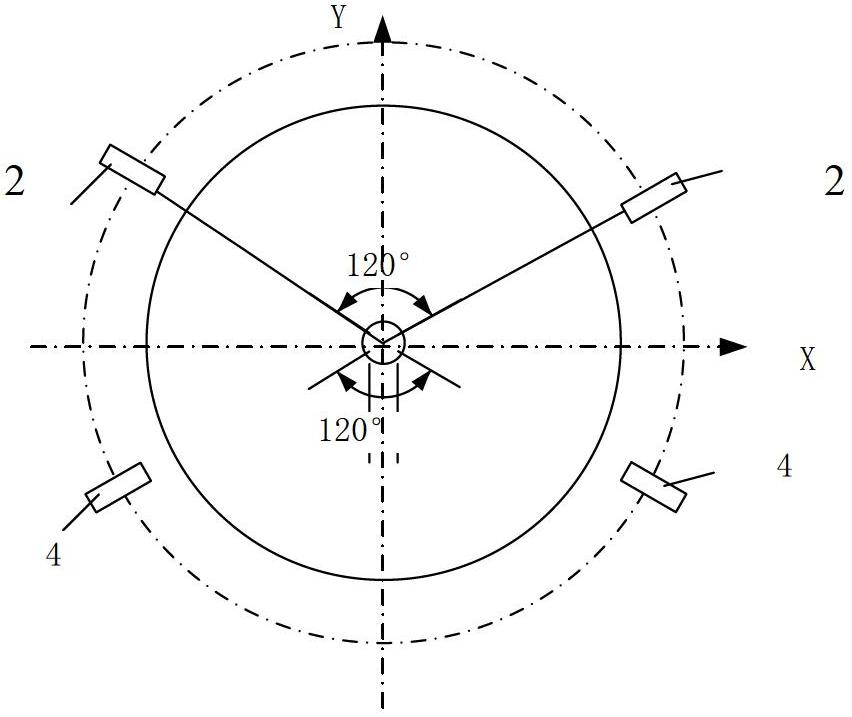

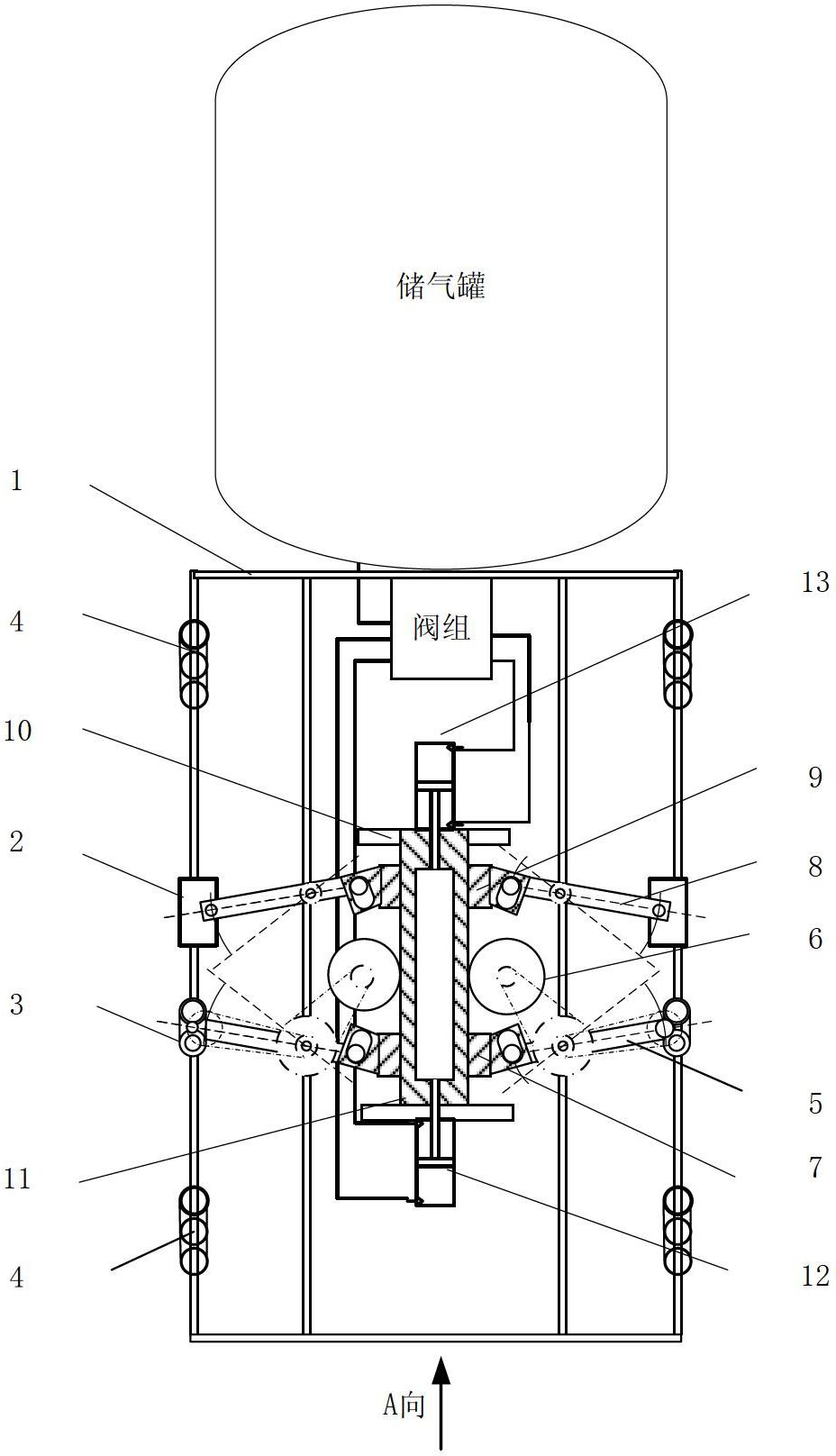

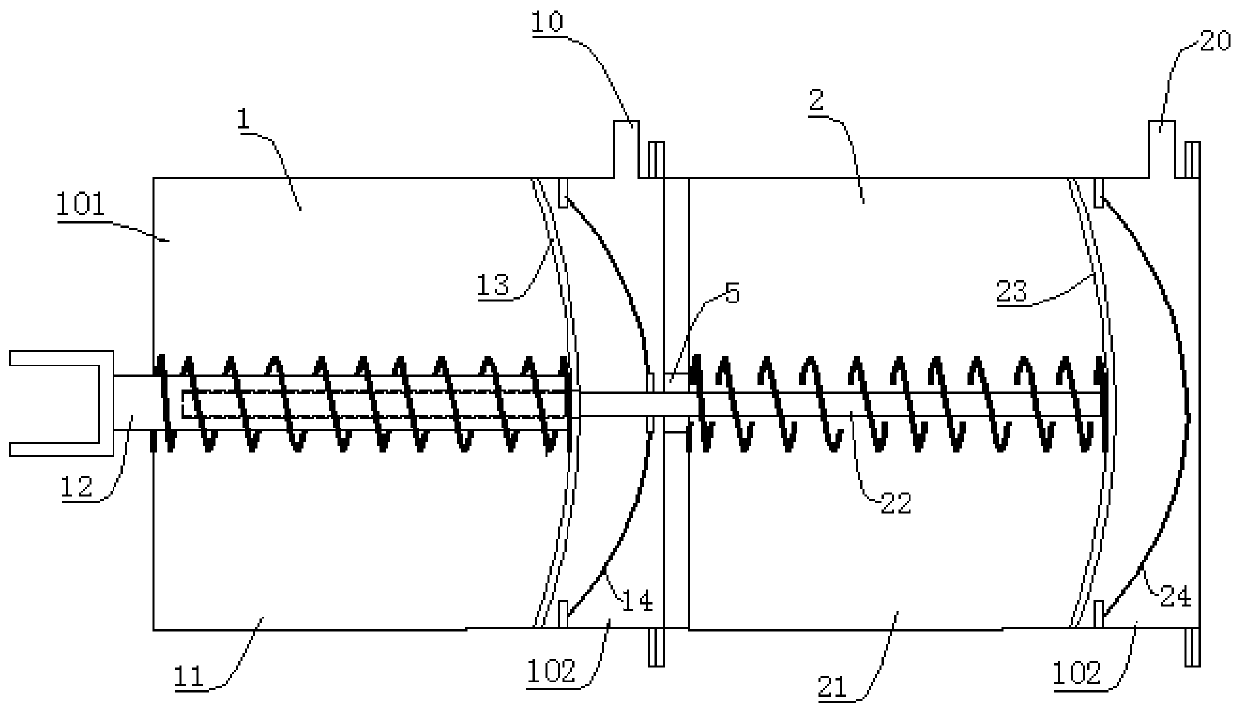

Pneumatic pipeline internal traveling device capable of braking quickly and reliably

InactiveCN102691854BComply with construction management requirementsIncrease positive pressurePipe elementsDrive wheelTransmitted power

The invention discloses a pneumatic pipeline internal traveling device capable of braking reliably, which comprises a frame, a shoe brake, driving wheels and traveling wheels. The frame is provided with two traveling wheels, the shoe brake, the driving wheels and two traveling wheels arranged sequentially in the direction of a central shaft of the frame, wherein seen from the axial direction, the traveling wheels are located at the lower semicircle of the frame, and the shoe brake and the driving wheels are located at the upper semicircle of the frame; on the radial distribution, the two traveling wheels are symmetric around an axis Y and mounted on the frame; the driving wheels are connected with a driving transmission mechanism; the shoe brake is connected with a brake transmission mechanism; a central shaft seat is fixedly connected with the frame central shaft; the frame central shaft is glidingly sleeved with an upper sliding sleeve and a lower sliding sleeve; the lower end of the lower sliding sleeve is fixedly connected with a telescopic rod of a driving cylinder; and the upper end of the upper sliding sleeve is fixedly connected with the telescopic rod of a brake cylinder. A pneumatic motor comprises a pneumatic motor shaft, wherein the pneumatic motor shaft, a rotating shaft and a driving wheel shaft are equipped with chain wheels to transmit power from the pneumatic motor to the driving wheel. The pneumatic pipeline internal traveling device can be used for braking reliably and safely.

Owner:吉林艾瑞环保技术有限公司

Strength enhancing structure of double-face basin angle gear

PendingCN110094477AReduce wearReduce feverDifferential gearingsBrake actuating mechanismsGear wheelUltimate tensile strength

The invention provides a strength enhancing structure of a double-face basin angle gear. The strength enhancing structure of the double-face basin angle gear comprises a power input shaft, a reinforcing shaft, a first bevel gear, a second bevel gear, a driving gear, a driven gear and the double-face basin angle gear. The first bevel gear is arranged at the front end of the power input shaft, the second bevel gear is arranged at the front end of the reinforcing shaft, the driving gear is arranged on the power input shaft, the driven gear is arranged on the reinforcing shaft, the driving gear isengaged with the driven gear, basin angle teeth are arranged on the two faces of the double-face basin angle gear separately and oppositely arranged, the double-face basin angle gear is arranged between the first bevel gear and the second bevel gear, the first bevel gear is engaged with the basin angle tooth on one face of the double-face basin angle gear, and the second bevel gear is engaged with the basin angle tooth on the other face of the double-face basin angle gear. The technical problems that a power input shaft of a differential mechanism of a vehicle is seriously abraded, tooth jumping of a driving bevel gear is likely to happen under the heavy-load condition, and the service life of the differential mechanism is affected can be solved.

Owner:广西环江航舵汽车科技有限公司

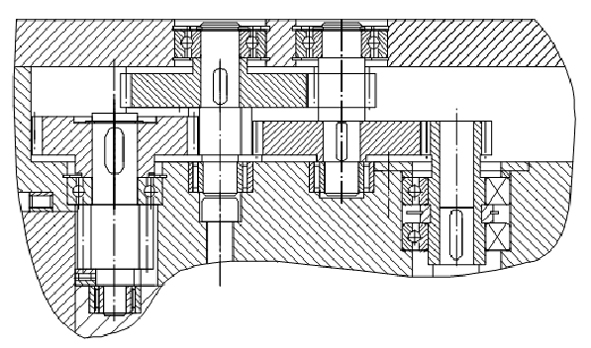

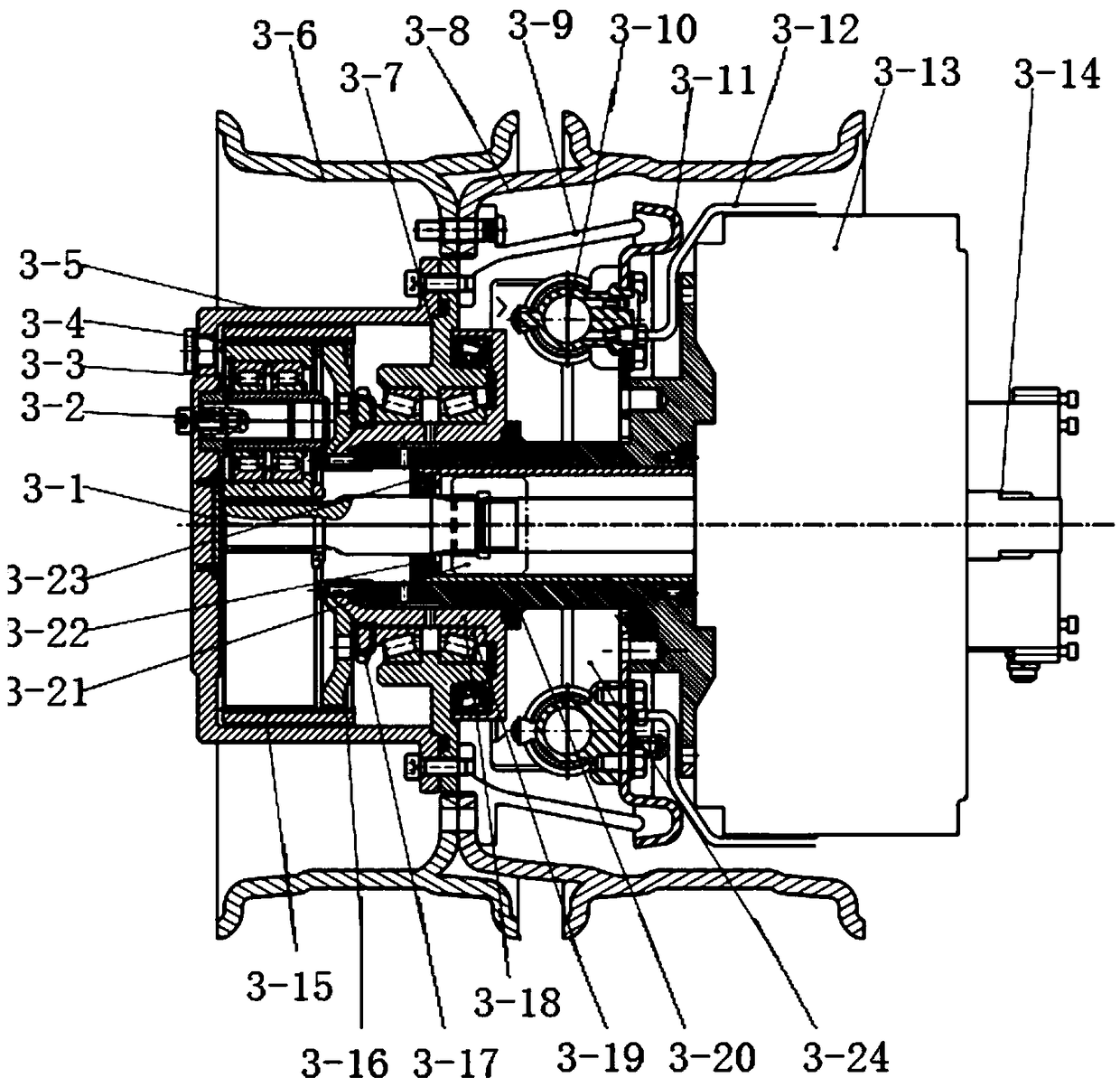

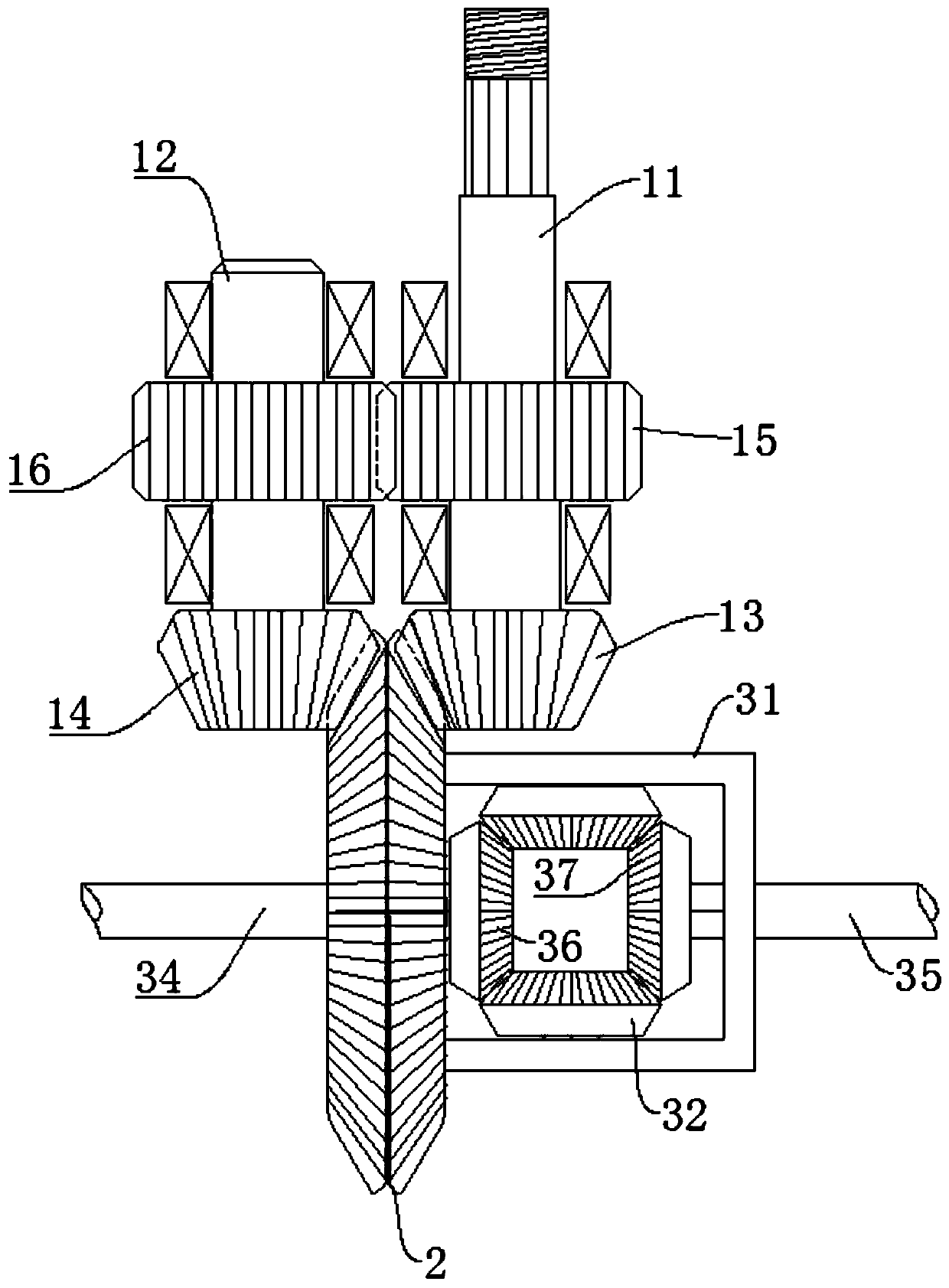

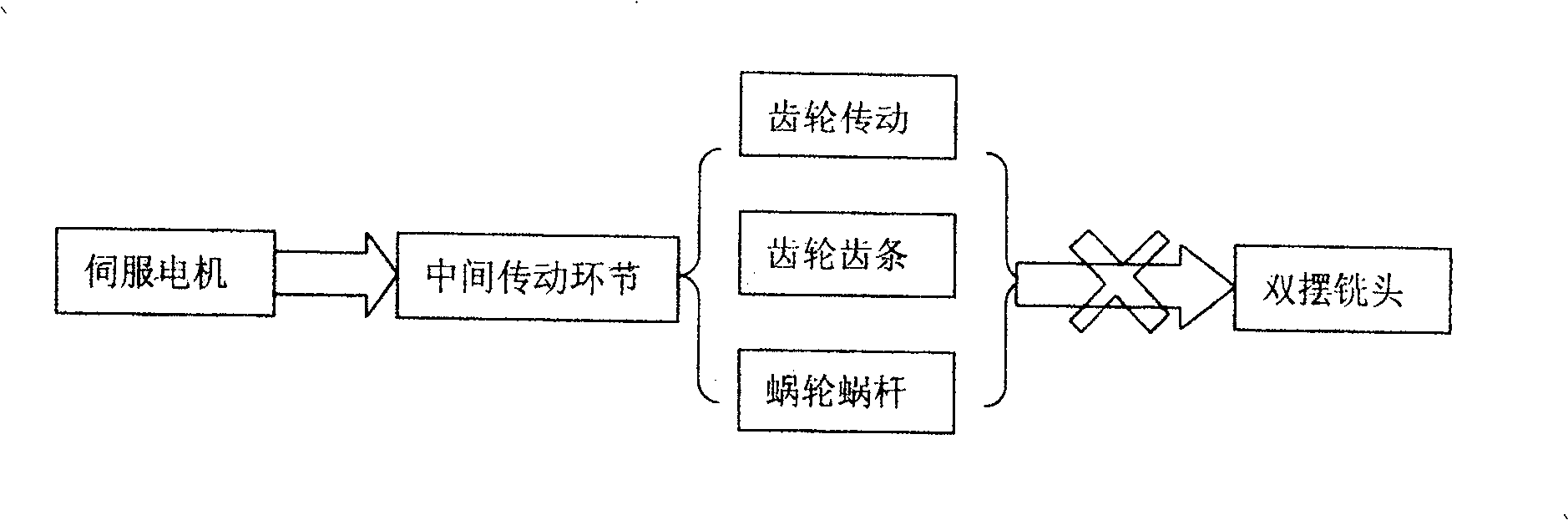

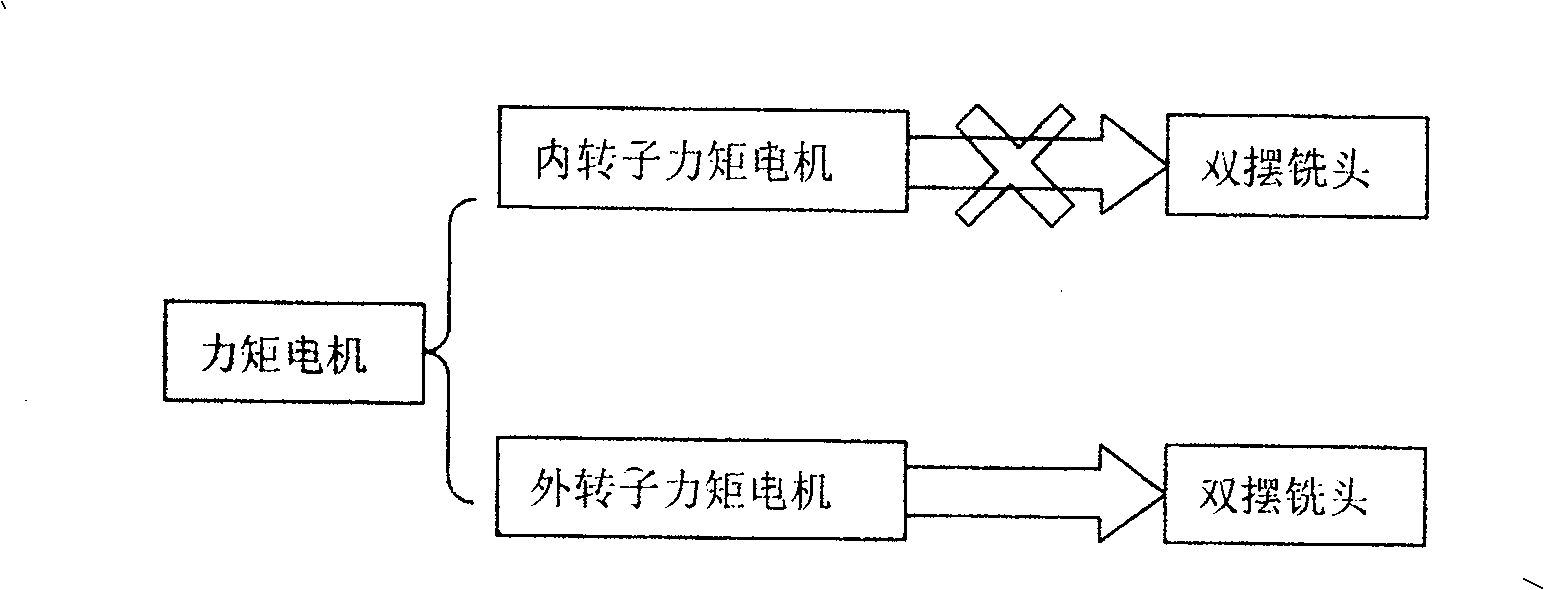

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN100475437CImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

Pneumatic pipeline internal traveling device capable of braking quickly and reliably

InactiveCN102691854AComply with construction management requirementsIncrease positive pressurePipe elementsVehicle frameDrive wheel

The invention discloses a pneumatic pipeline internal traveling device capable of braking reliably, which comprises a frame, a shoe brake, driving wheels and traveling wheels. The frame is provided with two traveling wheels, the shoe brake, the driving wheels and two traveling wheels arranged sequentially in the direction of a central shaft of the frame, wherein seen from the axial direction, the traveling wheels are located at the lower semicircle of the frame, and the shoe brake and the driving wheels are located at the upper semicircle of the frame; on the radial distribution, the two traveling wheels are symmetric around an axis Y and mounted on the frame; the driving wheels are connected with a driving transmission mechanism; the shoe brake is connected with a brake transmission mechanism; a central shaft seat is fixedly connected with the frame central shaft; the frame central shaft is glidingly sleeved with an upper sliding sleeve and a lower sliding sleeve; the lower end of the lower sliding sleeve is fixedly connected with a telescopic rod of a driving cylinder; and the upper end of the upper sliding sleeve is fixedly connected with the telescopic rod of a brake cylinder. A pneumatic motor comprises a pneumatic motor shaft, wherein the pneumatic motor shaft, a rotating shaft and a driving wheel shaft are equipped with chain wheels to transmit power from the pneumatic motor to the driving wheel. The pneumatic pipeline internal traveling device can be used for braking reliably and safely.

Owner:吉林艾瑞环保技术有限公司

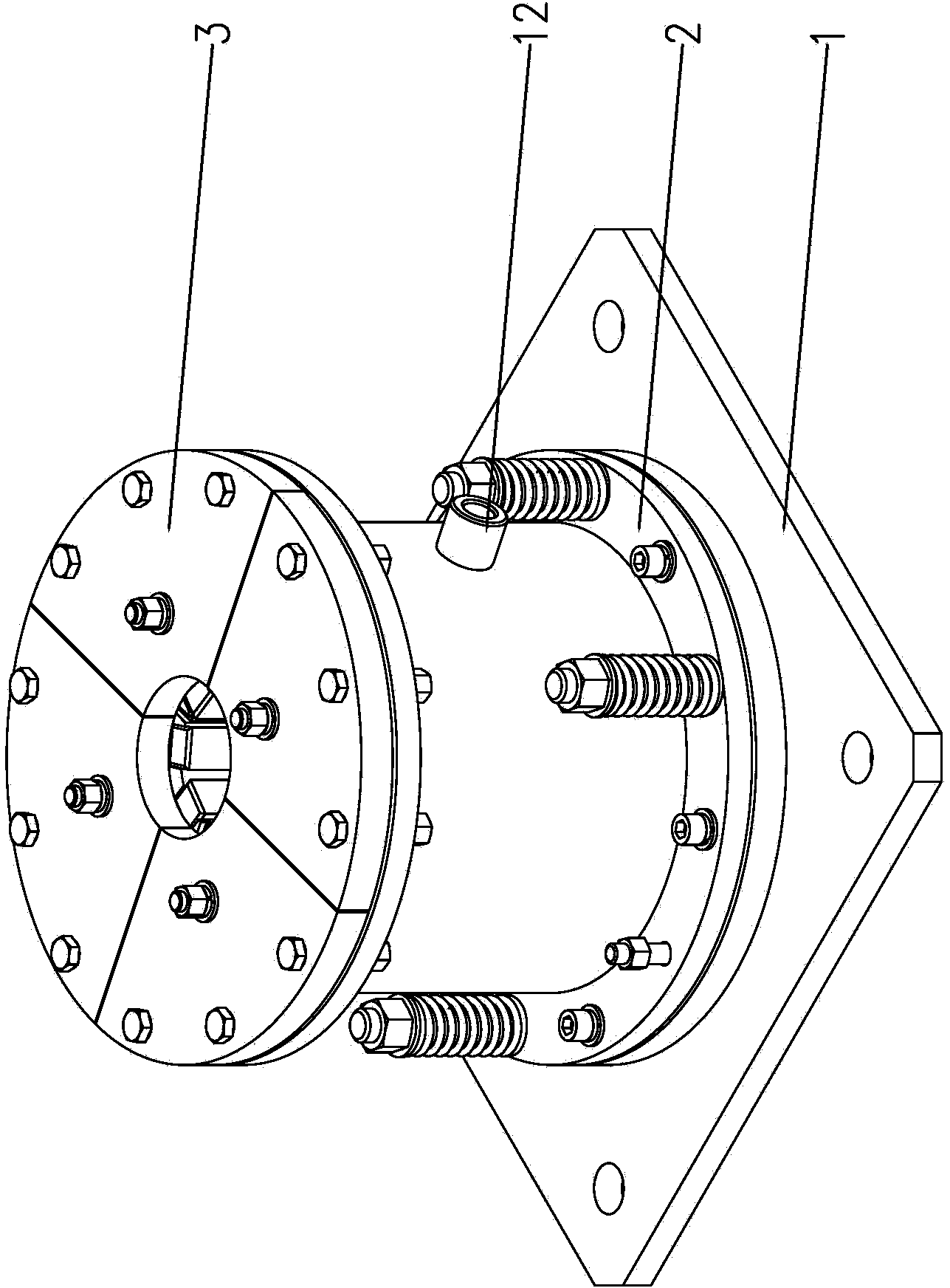

High-precision rotary working-table driven by moment motor

InactiveCN101596681BSimple structureIncrease the clamping areaLarge fixed membersNumerical controlElectric machinery

Owner:DONGHUA UNIV

Powerful balance brake device

PendingCN110067823APlay a guiding roleBraking force is strongBrake actuating mechanismsMechanically actuated drum brakesEngineeringCam

The invention provides a powerful balance brake device comprising a brake drum, a bottom plate, a left brake shoe, a right brake shoe and cam mechanisms. The left brake shoe and the right brake shoe are oppositely arranged to form two pairs of opposite end faces, guiding holes are formed in the two end faces of the left brake shoe and the two end faces of the right brake shoe, and one cam mechanism is arranged between each pair of opposite end faces of the left brake shoe and the right brake shoe; and each cam mechanism comprises a cam shaft, a guide shaft and a cam, the cams are arranged on the cam shafts, through holes are formed in the middle portions of the guide shafts, the cam shafts penetrate through the through holes, one end of each guide shaft is inserted into the corresponding guiding hole of the left brake shoe, and the other end of each guide shaft is inserted into the corresponding guiding hole of the right brake shoe. The technical problems that the braking force is small and braking is not sensitive are solved.

Owner:广西环江航舵汽车科技有限公司

Powerful double-pipeline brake cylinder

The invention provides a powerful double-pipeline brake cylinder which comprises an output pump and a reinforcement pump. The output pump comprises a first pump body, a first push rod and a first piston. The first piston is located in the first pump body. The first push rod is fixedly connected with the first piston. The reinforcement pump comprises a second pump body, a second push rod and a second piston. The second piston is located in the second pump body, and the second push rod is fixedly connected with the second piston. The second pump body is fixedly arranged on the rear portion of the first pump body, a through hole is formed between the first pump body and the second pump body, and one end of the second push rod penetrates through the through hole and abuts against the first push rod. The technical problem that the brake performance of a vehicle is poor due to the fact that the jacking force of an existing brake cylinder is small can be solved.

Owner:广西环江航舵汽车科技有限公司

Powerful cam brake balancing device

PendingCN110107619ABraking force is strongImprove stability and reliabilityBraking element arrangementsBraking action transmissionBrake shoeCam

The invention provides a powerful cam brake balancing device. The powerful cam brake balancing device comprises a brake drum, a bottom plate, friction plates, a left brake shoe, a right brake shoe andcam mechanisms, wherein the two ends of the left brake shoe and the right brake shoe are separately provided with butt blocks; the butt blocks are provided with cam holes; the left brake shoe is opposite to the right brake shoe to form two pairs of opposite ends; the butt blocks on each pair of opposite ends are arranged in an inner and outer staggered mode; each cam mechanism is arranged betweeneach pair of opposite ends; each cam mechanism comprises a camshaft, an inner cam and an outer cam, wherein the inner cam and the outer cam are separately fixed on the camshaft; the outer cams are eccentrically arranged relative to the inner cams; the outer cams are arranged in cam holes of the outer butt blocks; and the inner cams are arranged in the cam holes of the inner butt blocks. By meansof the powerful cam brake balancing device, the technical problems of low braking force and insensitive braking can be solved.

Owner:广西环江航舵汽车科技有限公司

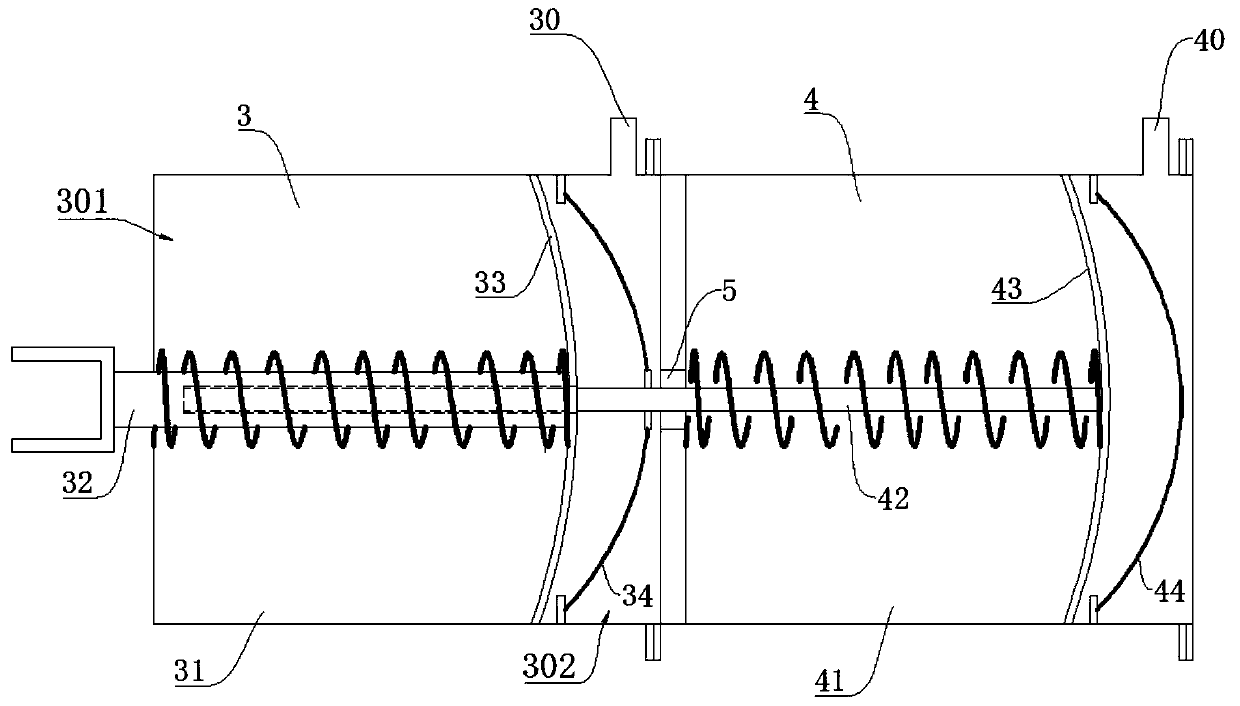

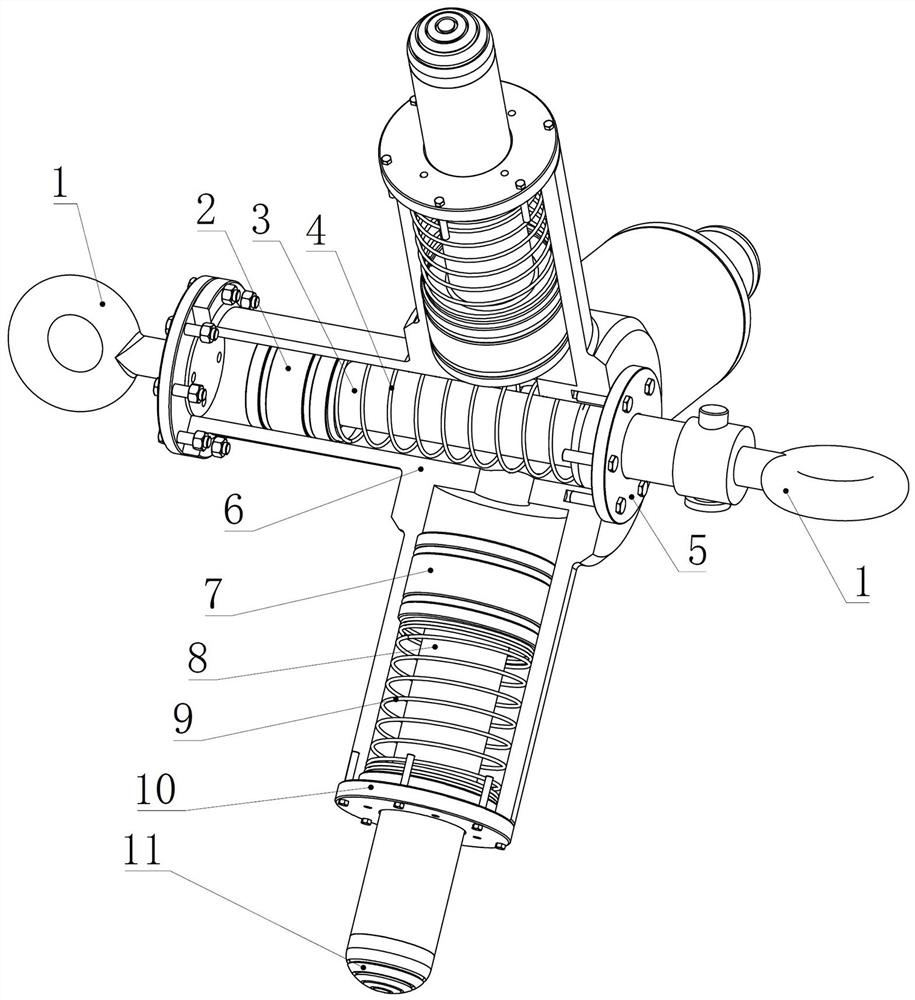

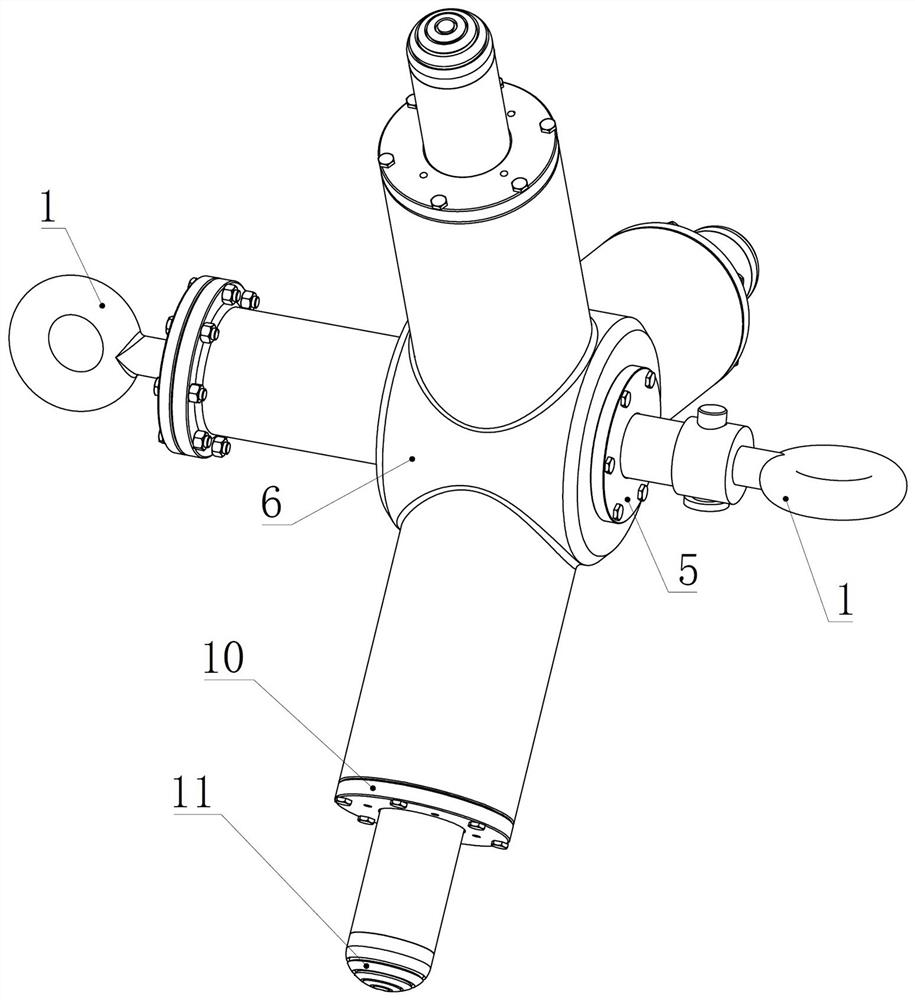

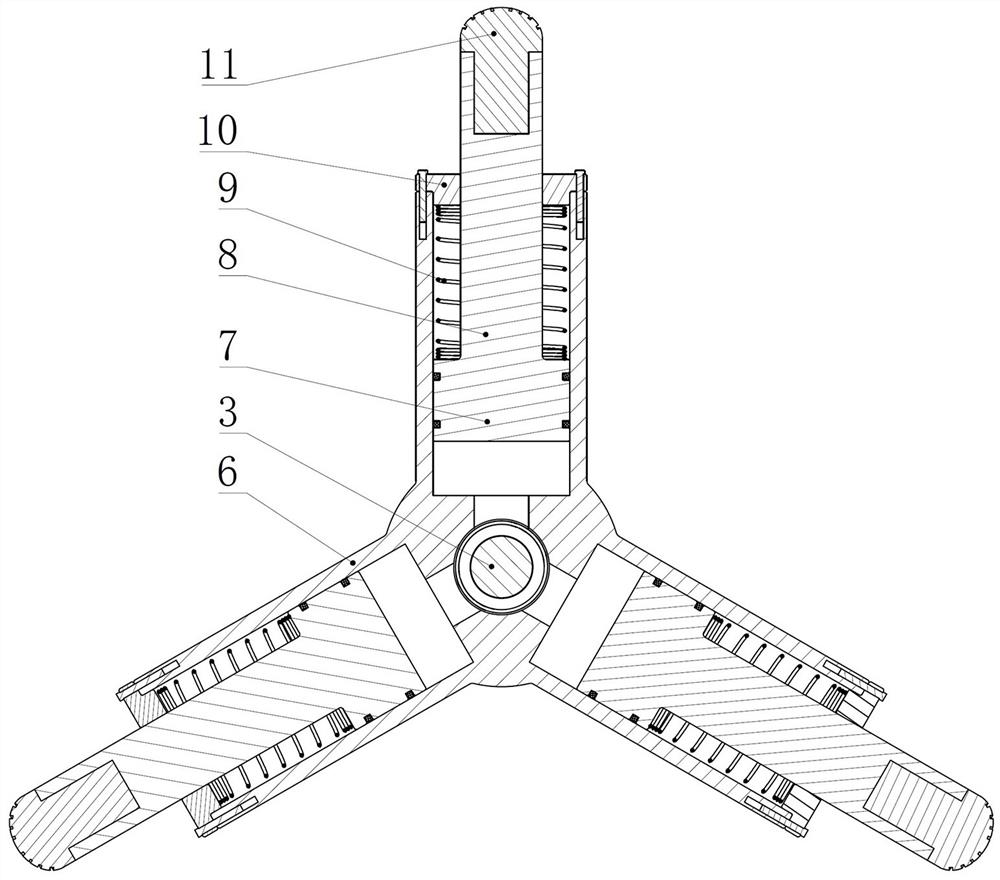

Hydraulic control acceleration controller of pipe cleaner

ActiveCN112170395ASuppression of speed shockEasy to send and receive the ballHollow article cleaningThermodynamicsEngineering

The invention relates to a hydraulic control acceleration controller of a pipe cleaner. The hydraulic control acceleration controller is used for pipe cleaning construction such as pipeline internal detection, liquid drainage and descaling. According to the technical scheme of the hydraulic control acceleration controller of the pipe cleaner, a radial oil cylinder is arranged at the radial position of a center oil cylinder, a piston rod of the radial oil cylinder extends outwards away from the center oil cylinder, and hydraulic oil is introduced into the side, close to the center oil cylinder,of the radial oil cylinder. A compression spring is arranged in a rod cavity of the center oil cylinder, the hydraulic oil is introduced into the rod cavity, the hydraulic oil of the center oil cylinder communicates with the hydraulic oil of the radial oil cylinder, and a piston rod of the center oil cylinder penetrates through a cylinder cover to extend outwards. A friction head is driven to work through the center oil cylinder and the radial oil cylinder, the acting force of the oil cylinders is amplified through cooperation of the large oil cylinder and the small oil cylinder, and the pipecleaner can be effectively prevented from generating speed impact.

Owner:大庆信海越石油科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com