Switch reluctance machine applied to elevator traction machine

A technology of switched reluctance motor and elevator traction machine, which is applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of poor running stability, large torque ripple, large noise and vibration, etc. Stabilization, reduced torque ripple, noise and vibration reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

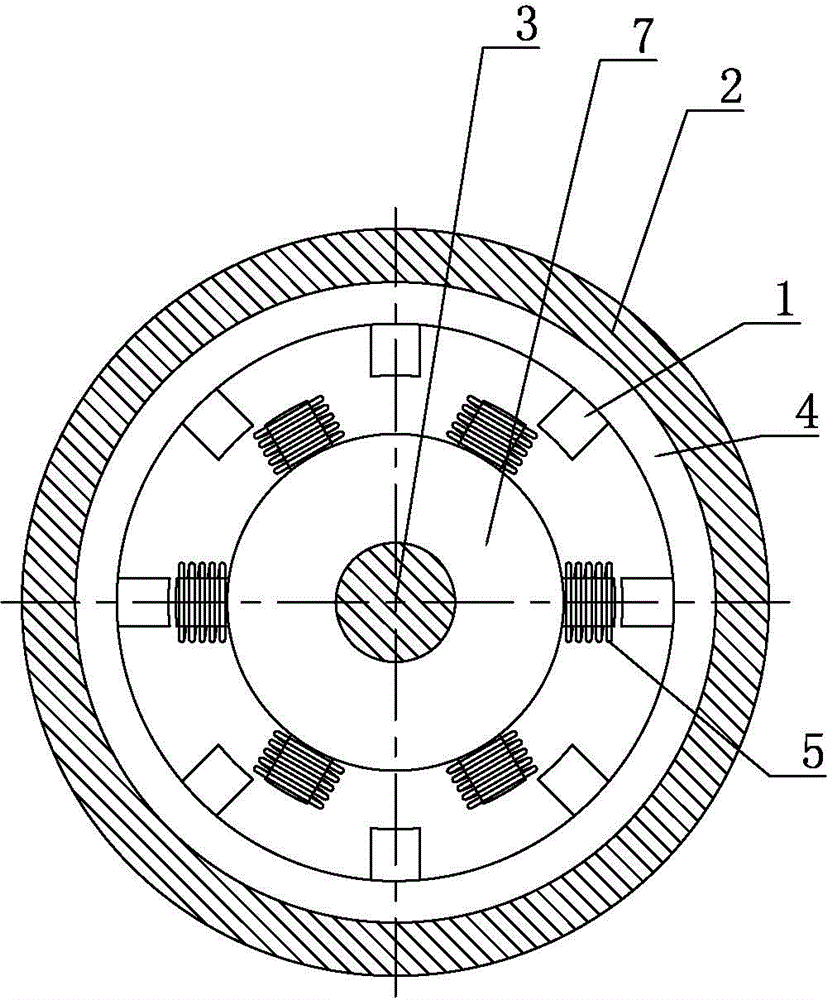

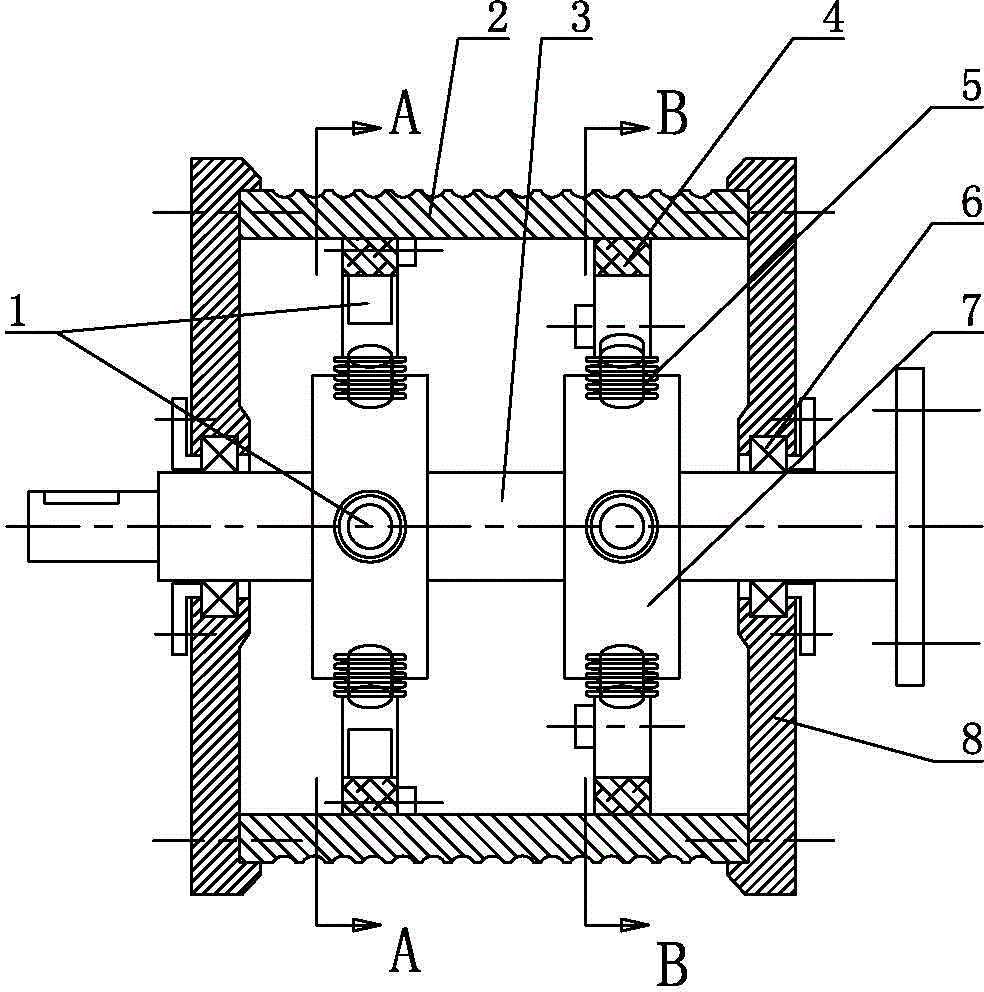

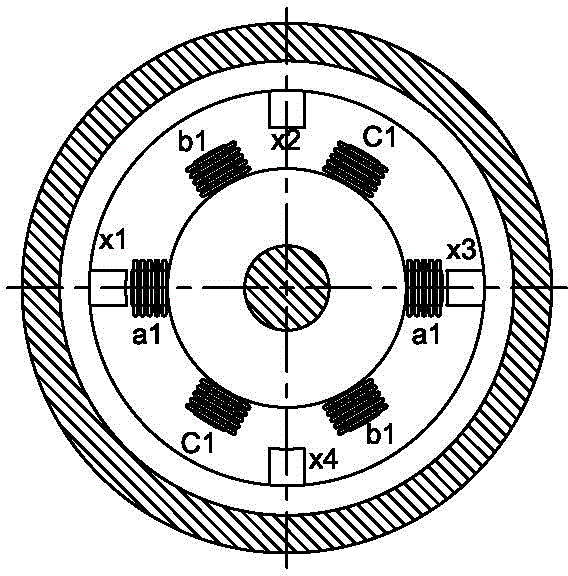

[0016] As shown in the figure, it is a switched reluctance motor for elevator traction machine, including a rotor 4 and a stator 7 which are coaxially arranged and can rotate relatively. The rotor 2 is located on the outer periphery of the stator 7, and the front and rear ends of the rotor 2 are respectively There are four radially inward tooth poles 1 uniformly distributed. The front and rear ends of the stator 7 are respectively distributed with six radially outward tooth poles 1. The front and rear ends of the stator are connected by a fixed shaft 3. The tooth poles 1 at the front and rear ends of the rotor are arranged with a phase difference of 45° in the circumferential direction. The tooth poles 1 at the front and rear ends of the stator are arranged in the same phase in the circumferential direction. The stator teeth are wound with coils 5, which are diametrically opposed. The coils 5 on the two tooth poles are arranged in series; the rotor 4 is provided with a steel wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com