Hub motor integrated system

An in-wheel motor and integrated system technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of not being suitable for heavy-duty vehicles, insufficient braking force, replacement of friction plates, etc., to achieve improved braking stability, braking Powerful, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

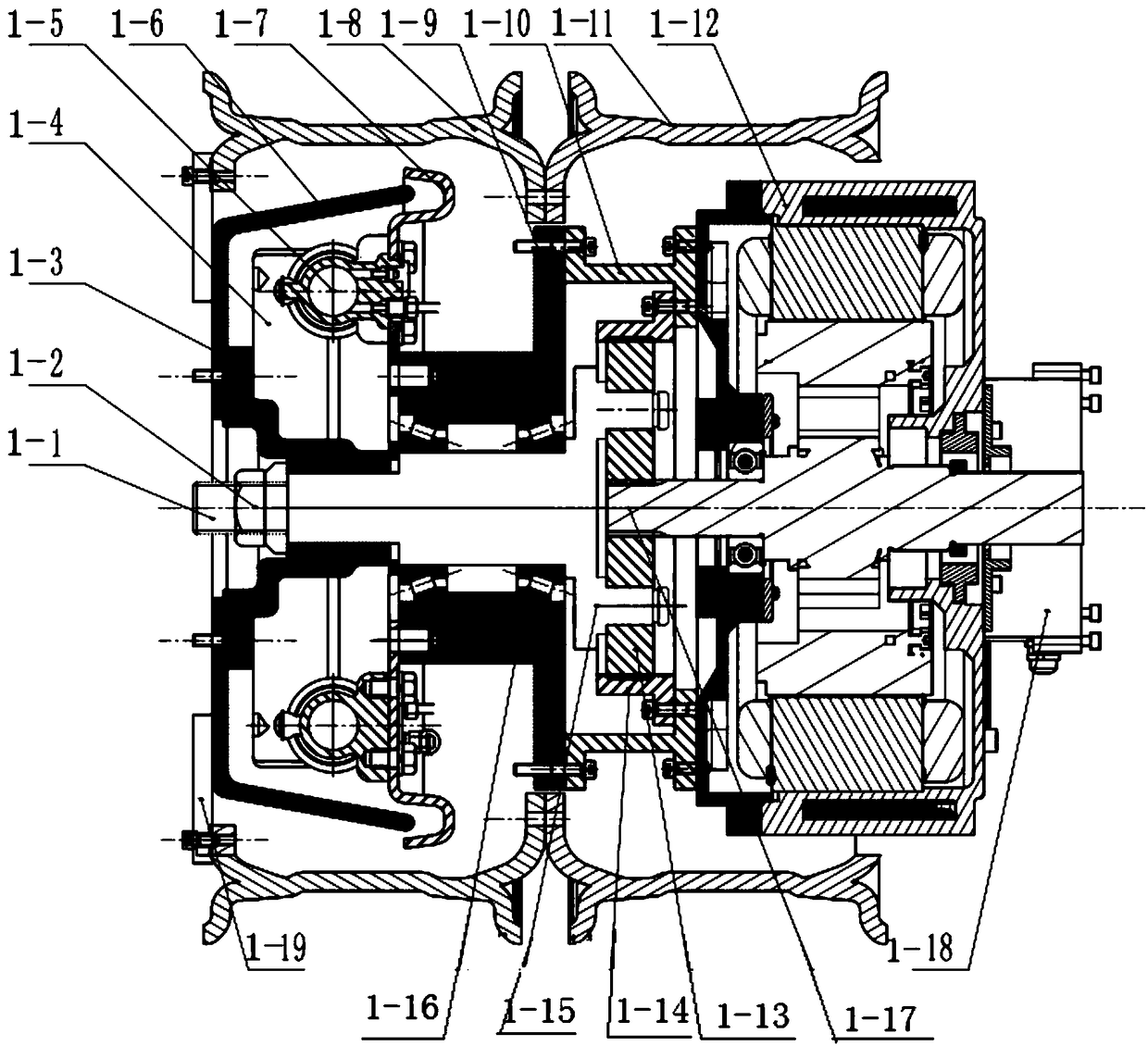

[0029] like figure 1 As shown, a hub motor integrated system is arranged in a double wheel, including a hub motor 1-12, a reducer and a brake, the hub motor 1-12 is arranged in the inner rim 1-11, and the reducer and brake are arranged on the outside In the rim 1-8, the reducer is a planetary gear reducer, and the hub motor output shaft 1-17 meshes with the planetary gear 1-13 of the reducer; the brake is a drum brake, including brake drum connectors 1-3, brake Shoe 1-4, brake wheel cylinder 1-5, brake drum 1-6 and brake base plate 1-7; the middle part of the brake drum connector 1-3 is socketed and fixed on the planetary gear output shaft of the reducer 1-1, the outside of the brake drum connector 1-3 is connected to the brake drum 1-6, the outside of the brake drum 1-6 is fixed to the spoke 1-19, and the inside of the brake drum passes through the brake base plate 1- 7 is connected to the brake support member 1-9; the brake wheel cylinder 1-5 is connected to the vehicle bra...

Embodiment 2

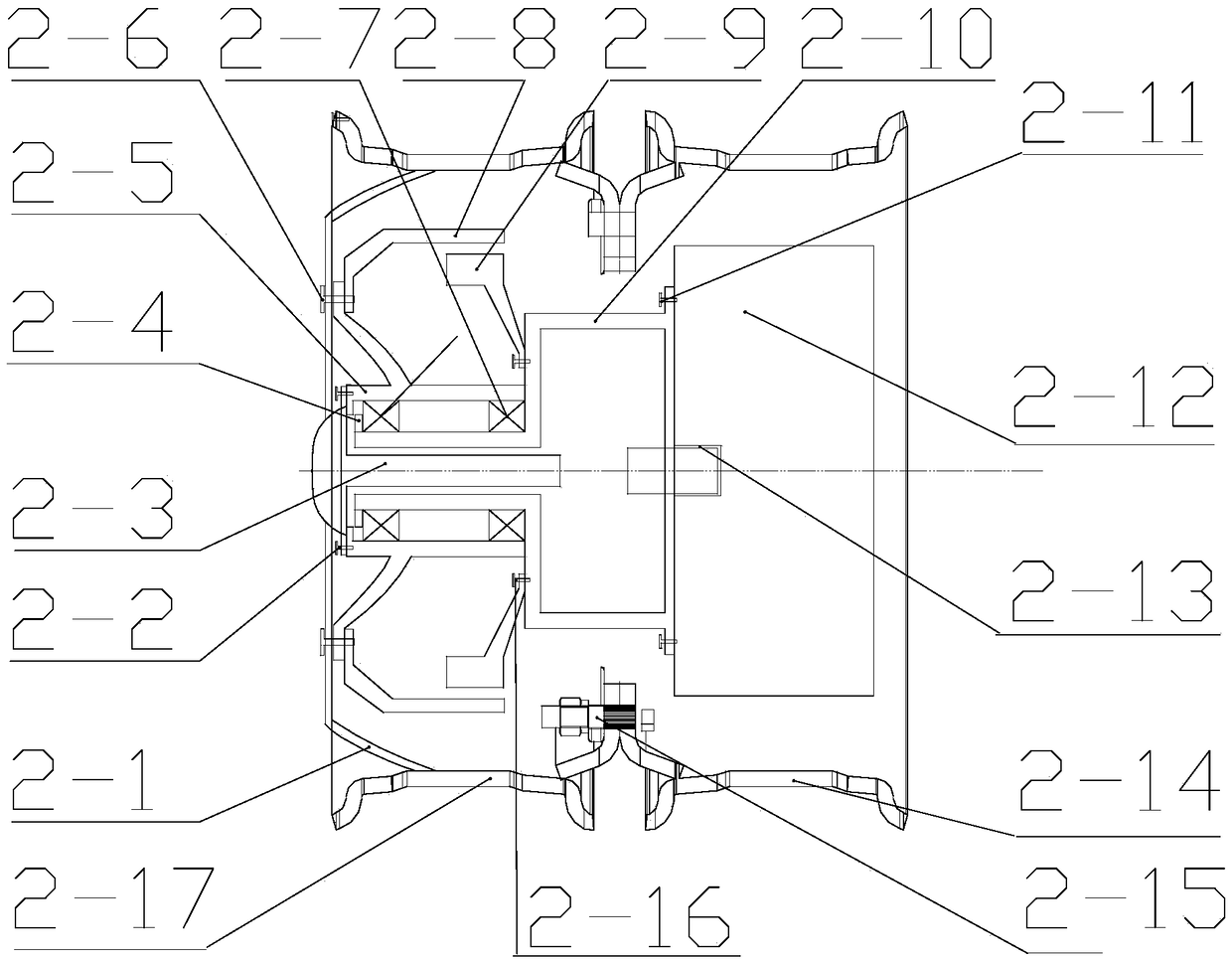

[0039] like figure 2 As shown, a dual wheel hub motor integrated system is arranged in a dual wheel, including a hub motor, a reducer and a brake. The hub motor is arranged in the inner rim 2-14, and the reducer and brake are arranged in the outer rim 2-14. In 17, the reducer is a planetary gear reducer, the output shaft of the hub motor meshes with the planetary gear of the reducer, and the planet carrier output shaft 2-3 of the reducer is connected to the hub 2-5; the inner rim 2-14 is connected to the outer rim 2- The two end faces of the rim spoke plate 2-1 of 17 are made into tapered surfaces, in order to be convenient to the bolt connection with brake. The inner rim 2-14 and the outer rim 2-17 are connected by bolts 2-15.

[0040] The brake is a drum brake, the brake base plate 2-9 of the drum brake is connected to the planetary gear reducer housing 2-10 through bolts 2-16, and the brake drum 2-8 of the drum brake is connected to the wheel hub 2-10. 5. The rim webs 2-...

Embodiment 3

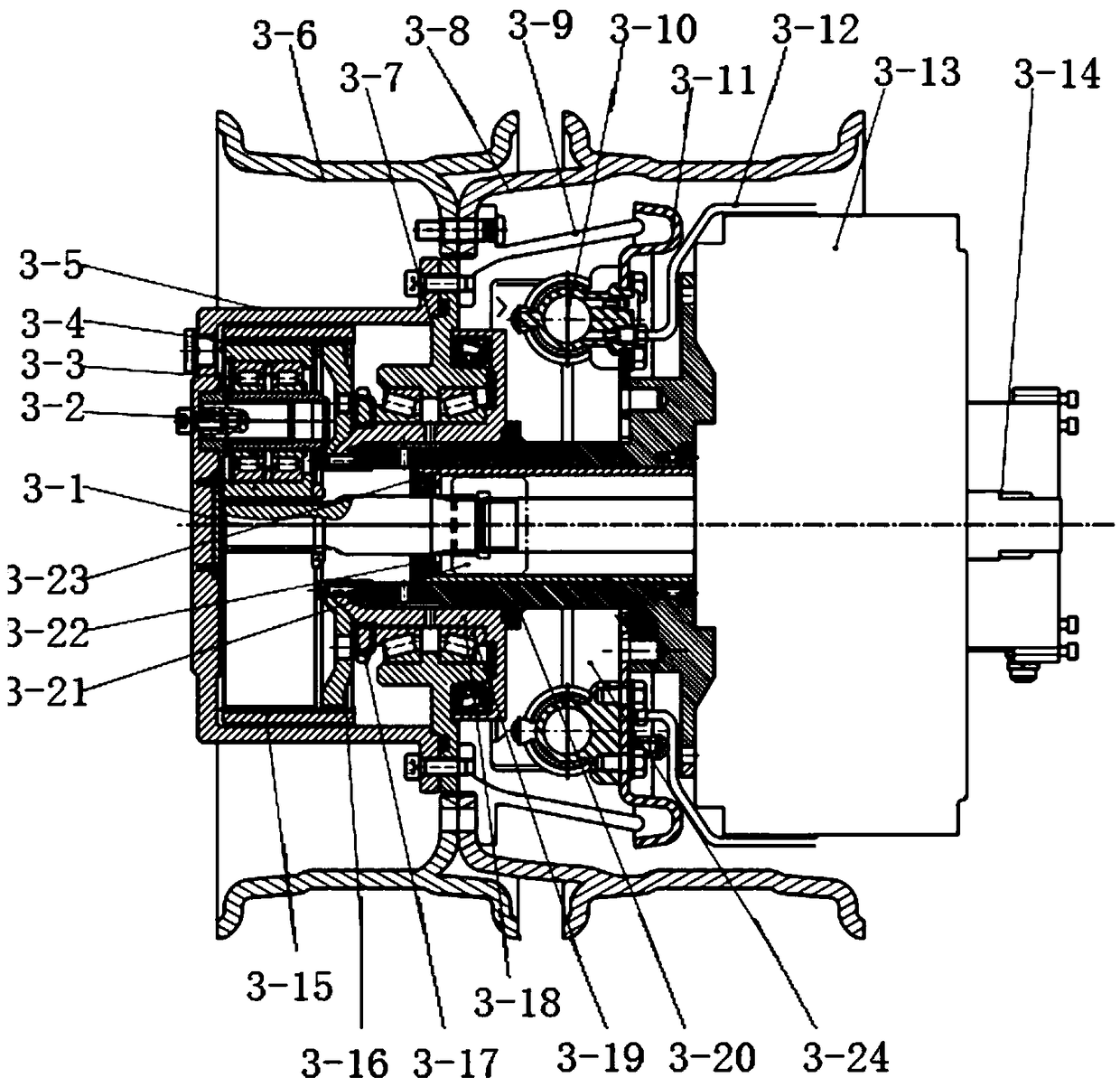

[0055] like image 3 As shown, a dual-type tire hub motor assembly is arranged in a dual-type wheel, including a hub motor 3-13, a reducer and a brake, the hub motor 3-13 is arranged in the inner rim 3-8, and the reducer is arranged on In the outer rim 3-6, the brake is set between the hub motor 3-13 and the reducer; the reducer is a planetary gear reducer, and the output shaft of the hub motor meshes with the sun gear 3-1 of the reducer through the coupling 21 to reduce the speed. The small planetary gear shaft 3-2 of the gear unit is connected with the output member 3-5 of the speed reducer.

[0056]The brake is a drum brake, and the drum brake includes a brake drum 3-9, a brake wheel cylinder 3-10, a brake shoe 3-24, a brake bottom plate 3-11 and a brake pipeline 3-12; Wherein the reducer output part 3-5 is connected with the left side of the brake drum 3-9, the top of the brake drum is connected with the spokes of the inner rim 3-8 and the outer rim 3-6, and the brake whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com