High-precision rotary working-table driven by moment motor

A technology of rotary table and torque motor, used in manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of complex braking structure and poor braking effect, and achieve good braking effect, compact structure and large braking effect. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

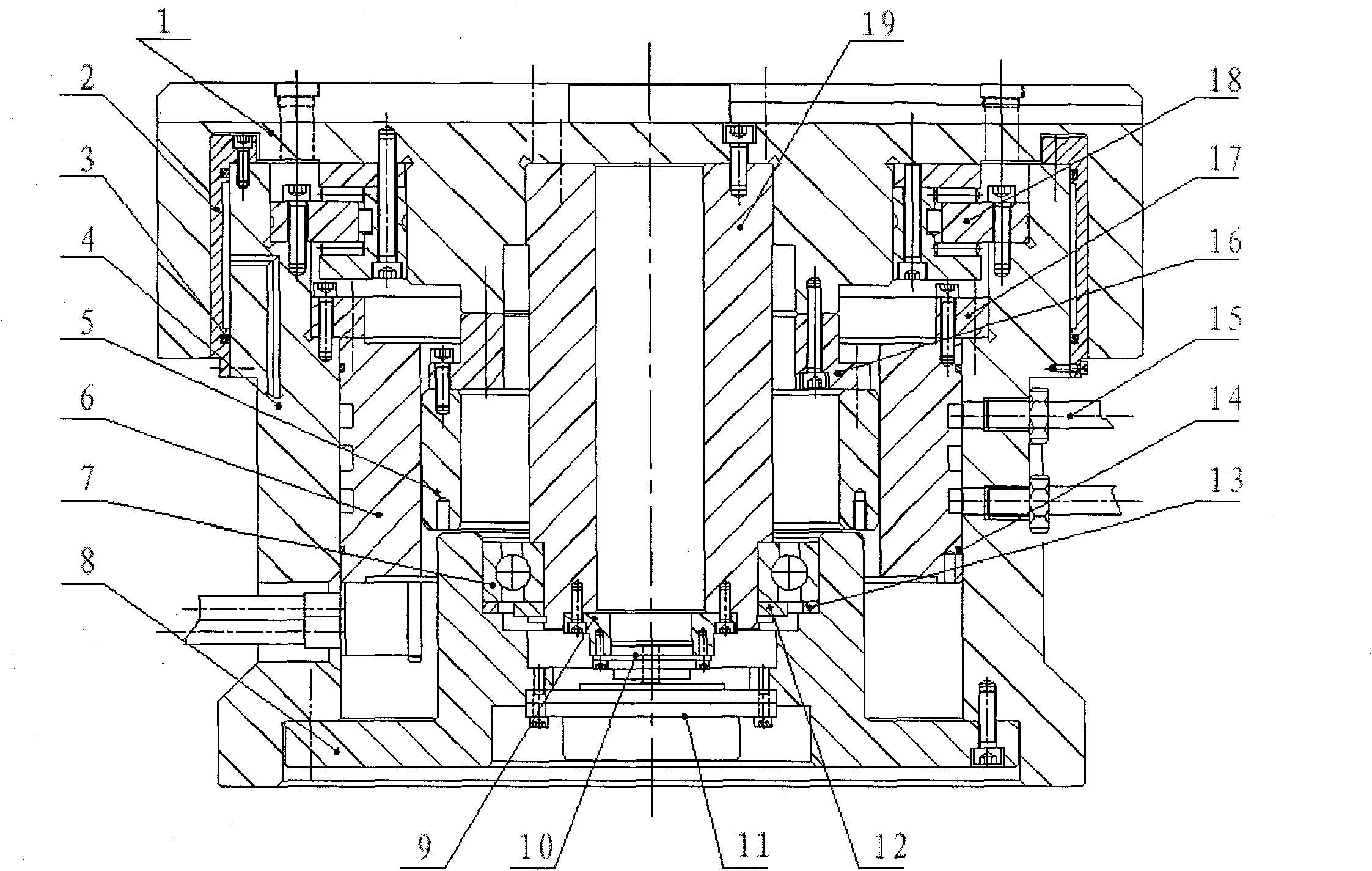

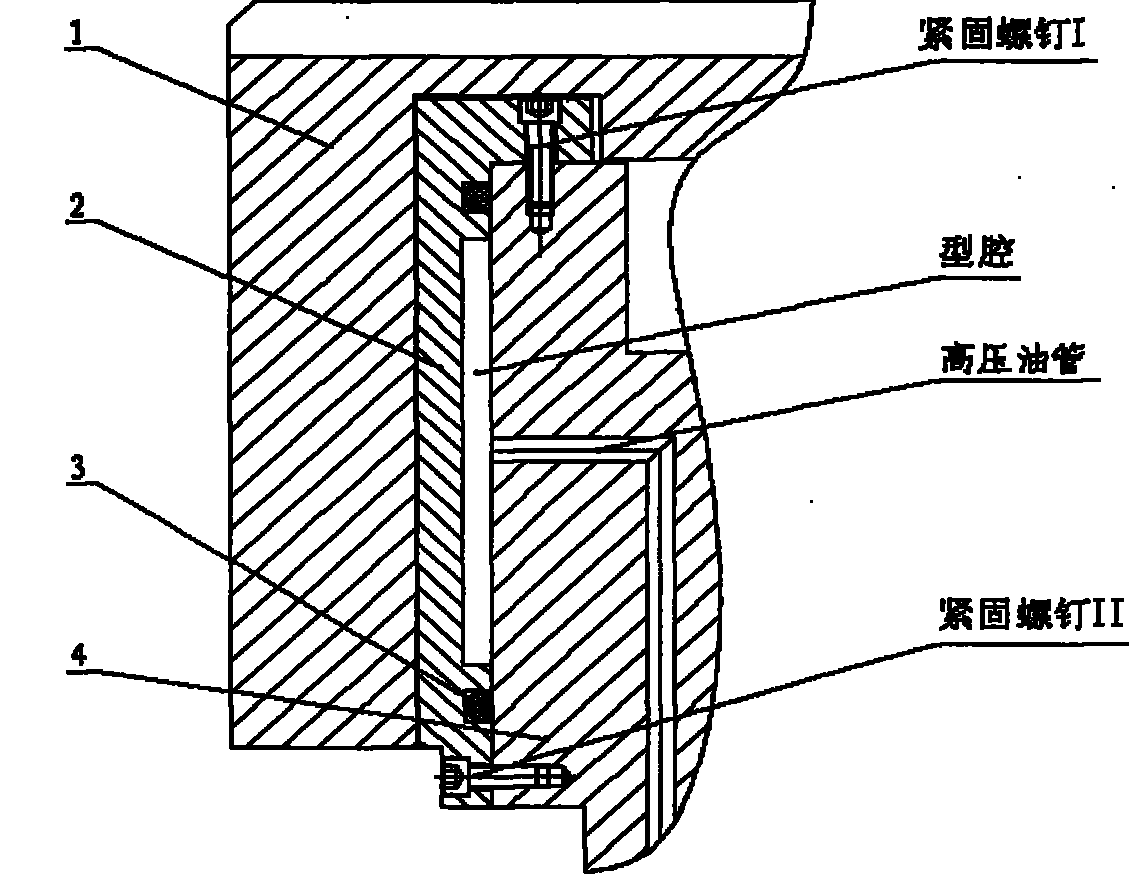

[0019] Such as figure 1 As shown, a high-precision rotary table driven by a torque motor includes a turntable 1, a clamping mechanism 2, a box seat 4, and a central shaft 19. The clamping mechanism 2 is installed on the inner surface of the outer ring of the turntable 1 and the box Between the outer surfaces of the seat 4, between the brake mechanism 2 and the box seat 4, an oil pressure sealing ring 3 is provided for sealing the brake oil. The seat 4 is connected to the stator 6 of the torque motor by connecting the stator flange 17, and the turntable 1 and the rotor 5 of the torque motor are connected to form an assembly through an axial radial bearing 18, and the outer ring of the axial radial bearing 18 is fixed by a hexagon socket head cap screw. On the box base 4, the torque motor stator 6 is connected to the box base 4 through the stator flange 17 to form a whole. The first adjusting washer 12 is installed in between, and the flat coupling 10 is connected with the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com