Powerful double-pipeline brake cylinder

A technology of brake cylinder and dual pipelines, which is applied in the direction of brake cylinder, etc., can solve the problems of poor braking performance and small jacking force, and achieve the effects of long service life, improved braking force and reduced maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

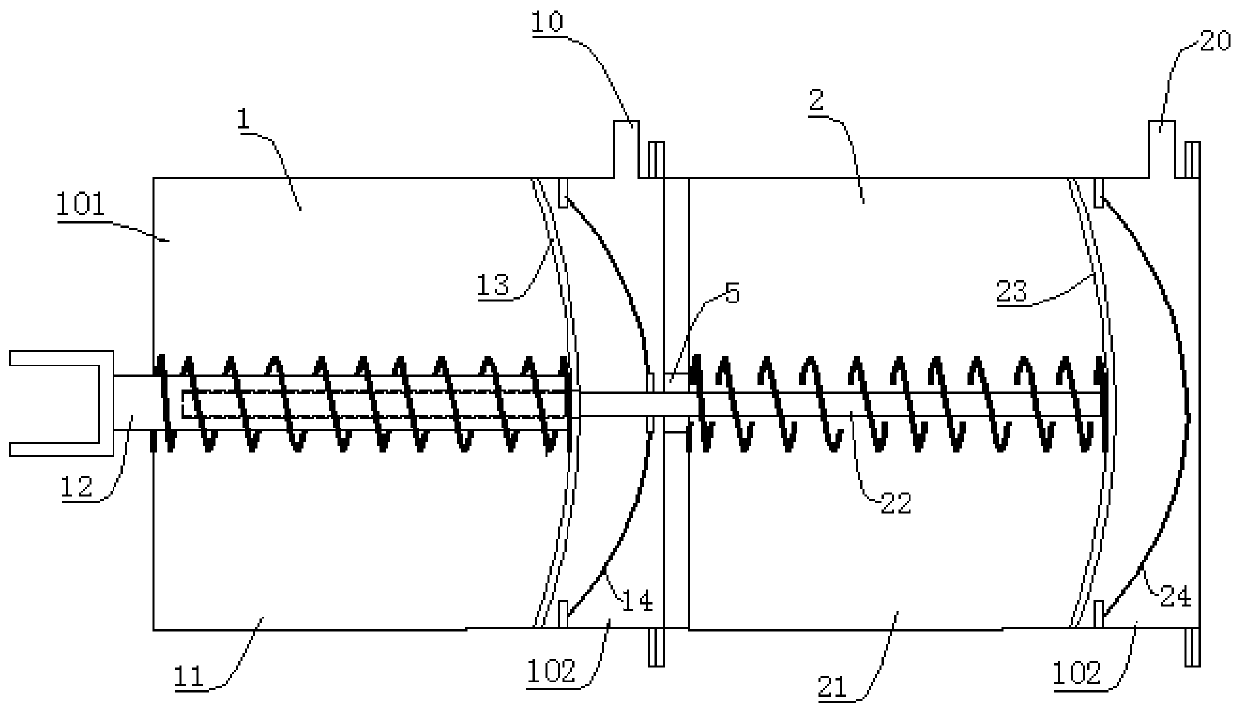

[0026] A powerful dual-pipeline brake cylinder, including an output pump 1 and a booster pump 2, the output pump 1 includes a first pump body 11, a first push rod 12 and a first piston 13, and the first piston 13 is located in the first pump body 11 Inside, the first push rod 12 is fixedly connected with the first piston 13; the booster pump 2 includes a second pump body 21, a second push rod 22 and a second piston 23, the second piston 23 is located in the second pump body 21, and the second The push rod 22 is fixedly connected with the second piston 23; the second pump body 21 is fixedly arranged at the rear part of the first pump body 11, and a through hole is provided between the first pump body 11 and the second pump body 21, and the second push rod 22 One end passes through the through hole and leans against the first push rod 12 .

Embodiment 2

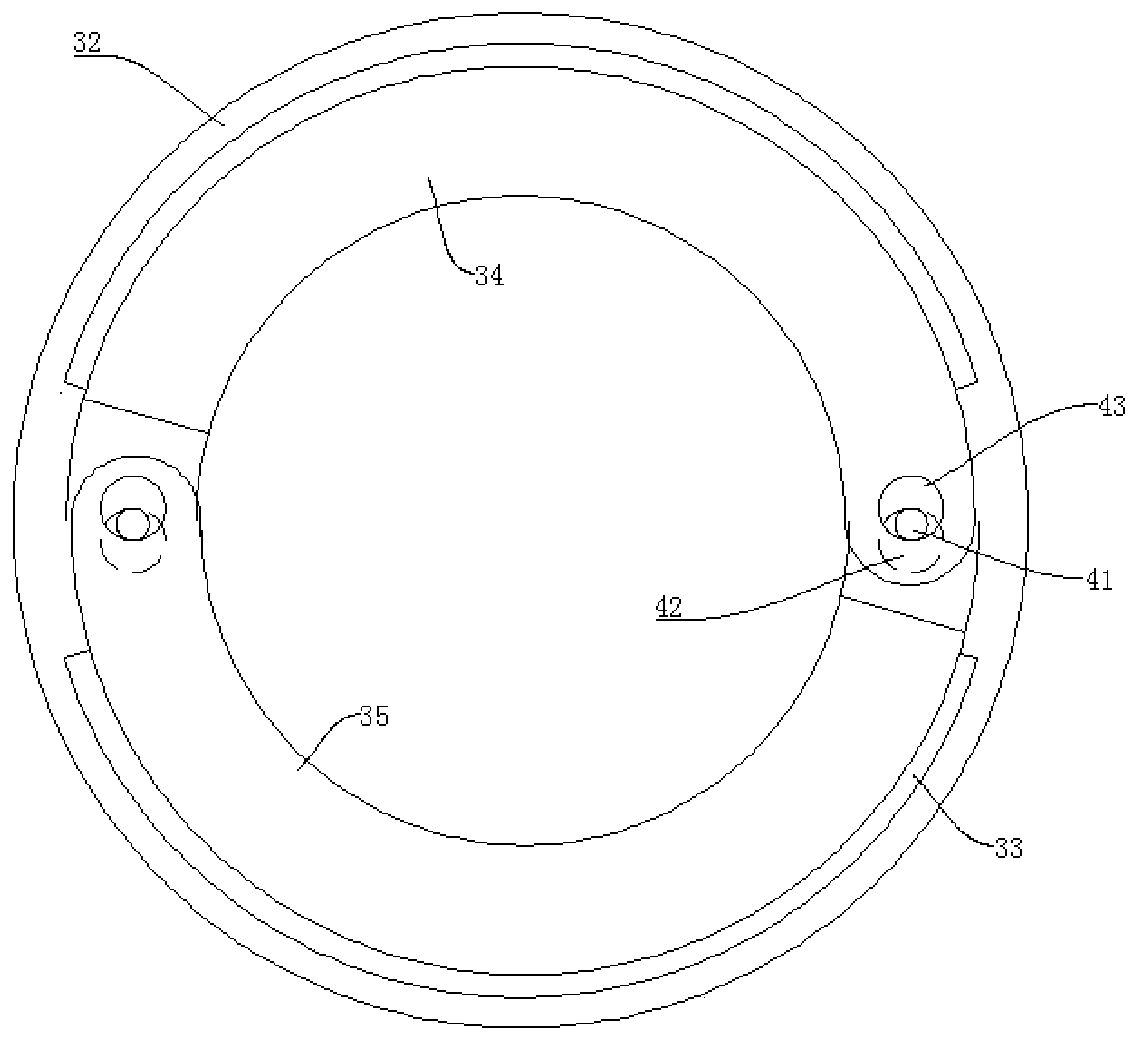

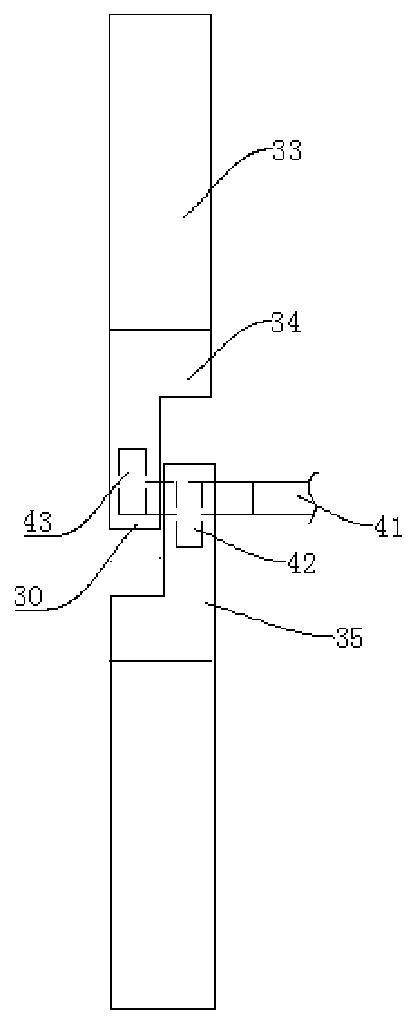

[0028] Such as Figure 1 to Figure 4As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the output pump 1 and the booster pump 2 are both pneumatic brake pumps, and the output pump 1 includes a first pump body 11, a first push rod 12, a second A piston 13, a first rubber cup 14, and the first pump body 11 are provided with an inner chamber, and the first rubber cup 14 is arranged in the inner chamber, and the first rubber cup 14 divides the inner chamber into a piston chamber 101 and a blower chamber. cavity 102, the first piston 13 is slidably installed in the piston cavity 101, one end of the first push rod 12 extends into the piston cavity 101 and is fixedly connected with the first piston 13, and the other end of the first push rod 12 is located outside the first pump body 11 , the first piston 13 is laterally slidingly connected to the first pump body 11, the first pump body 11 is provided with a first air inlet...

Embodiment 3

[0035] Such as Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that both the output pump 1 and the booster pump 2 are hydraulically driven brake pumps, the first piston 13 is slidingly connected with the first pump body 11, and the first piston The outer wall of 11 is provided with a first oil storage groove 71, the piston ring 9 is installed in the first oil storage groove 71, the rear part of the first pump body 11 is provided with a first oil inlet 81; the second piston 23 Slidingly connected with the second pump body 21, the outer wall of the second piston 23 is provided with a second oil storage groove 72, the piston ring 9 is installed in the second oil storage groove 72, and the rear part of the second pump body 21 is provided with There is a second oil inlet 82, and the brake pump of this structure is suitable for vehicles with hydraulically driven brakes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com