Patents

Literature

111 results about "Rubber Cup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cup used for polishing teeth.

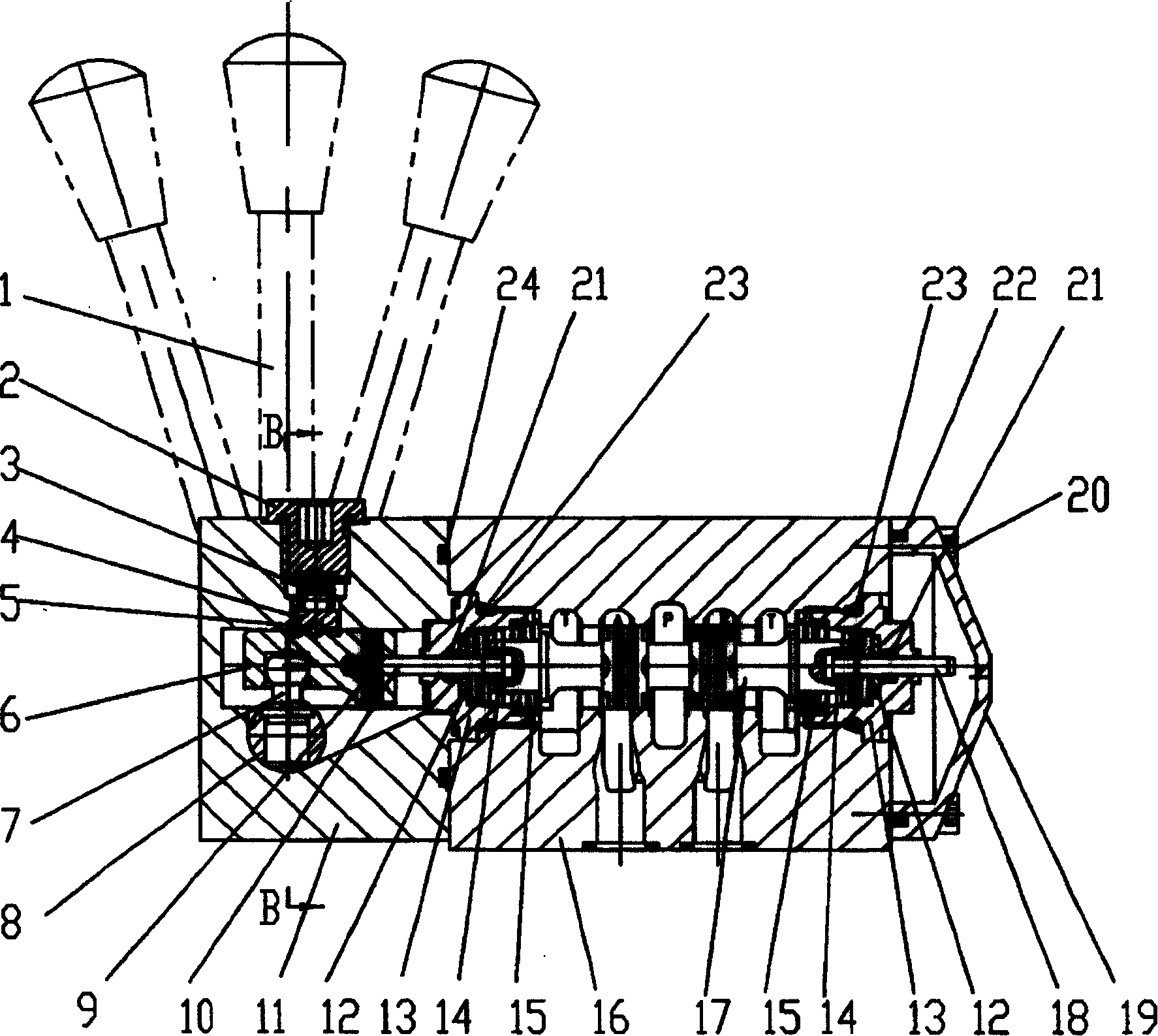

Automatic nozzle bottle cap assembling machine

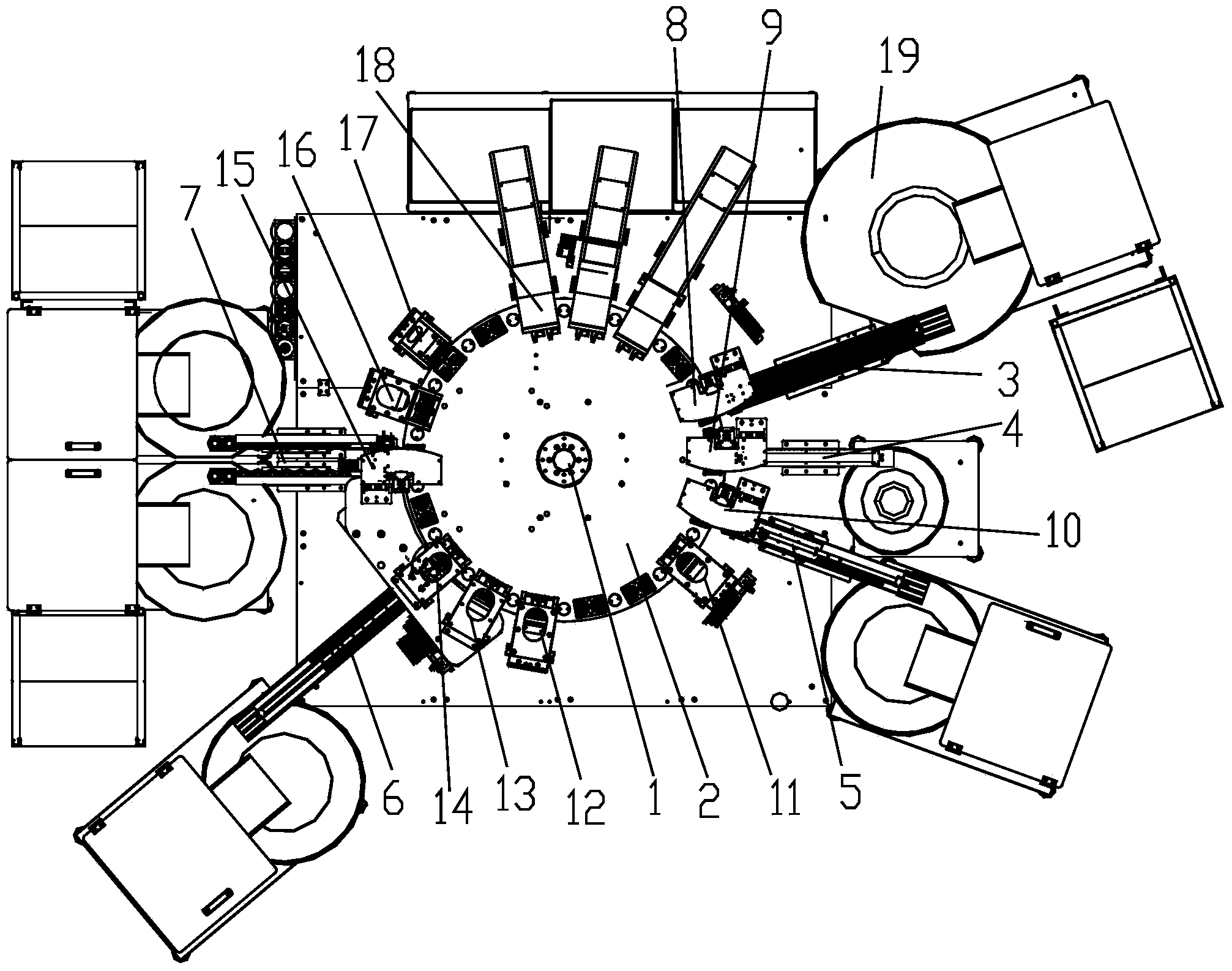

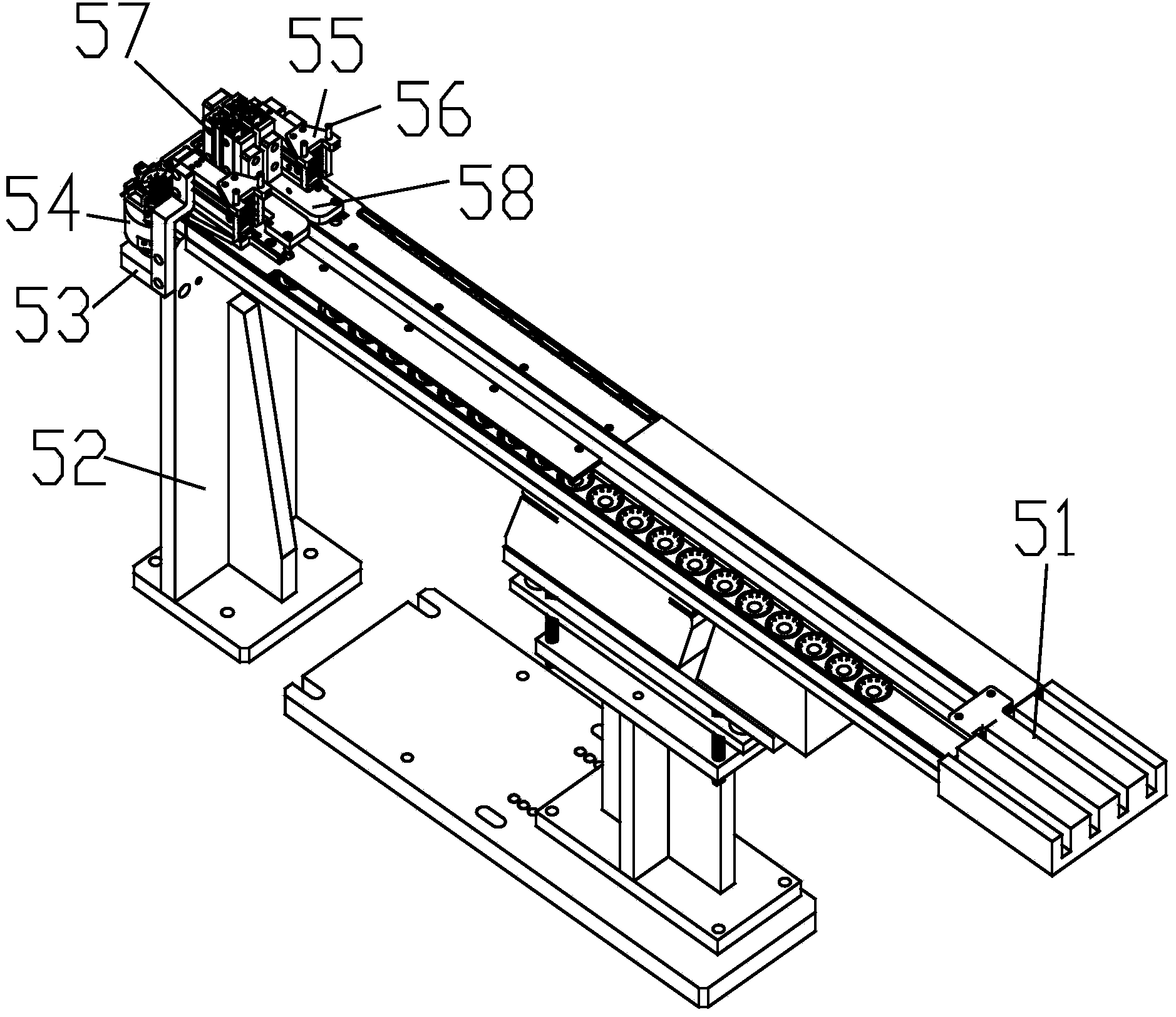

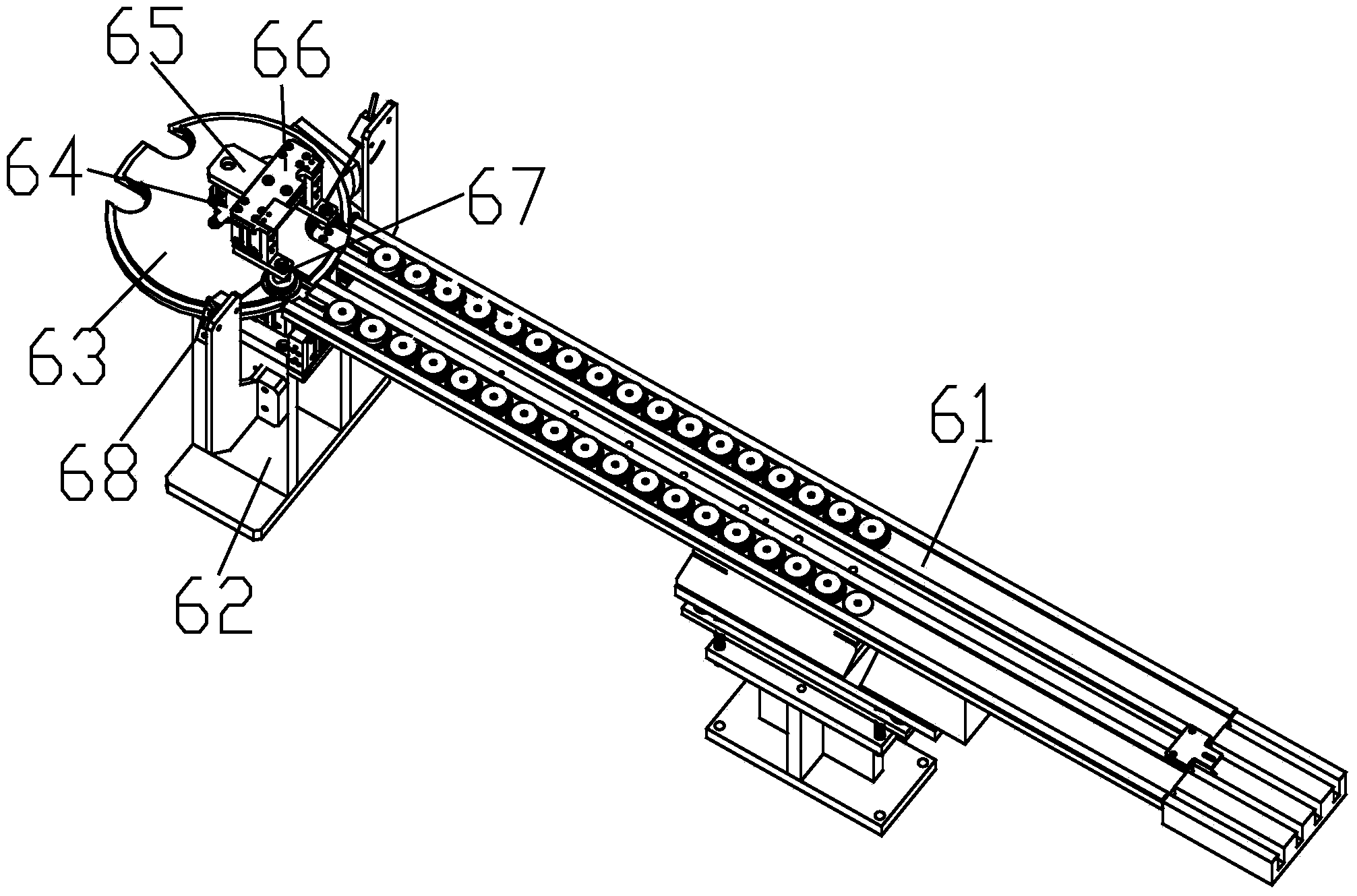

The invention discloses an automatic nozzle bottle cap assembling machine which comprises a working platform and a station cam graduator fixed on the working platform, wherein the station cam graduator is provided with a station dividing plate, a locating jig is fixed on the station dividing plate, an automatic bottle cap base shell feeding mechanism, an automatic valve core feeding mechanism, an automatic sealing rubber cup feeding mechanism, an automatic dustproof cover feeding mechanism, an automatic bottle cap connector feeding mechanism and a discharge station are sequentially arranged corresponding to the station dividing plate, and a detection mechanism is further arranged on the position corresponding to the station dividing plate of the working platform. Through the above method, the processing efficiency is improved, the labor force is saved, and the processing cost is lowered.

Owner:SUZHOU LING AUTOMATION EQUIP

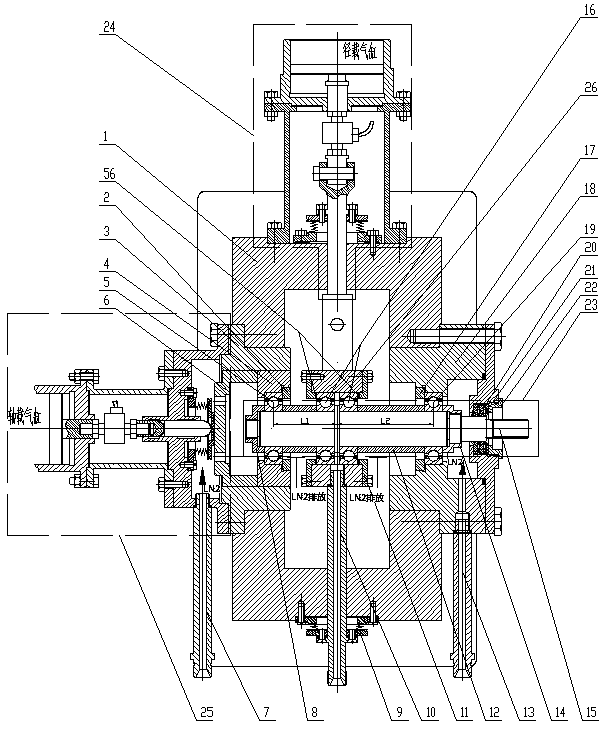

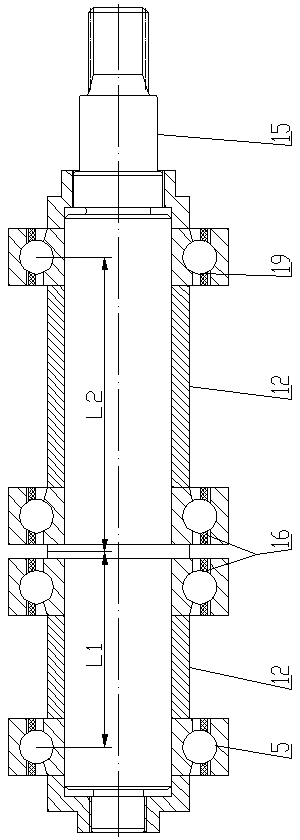

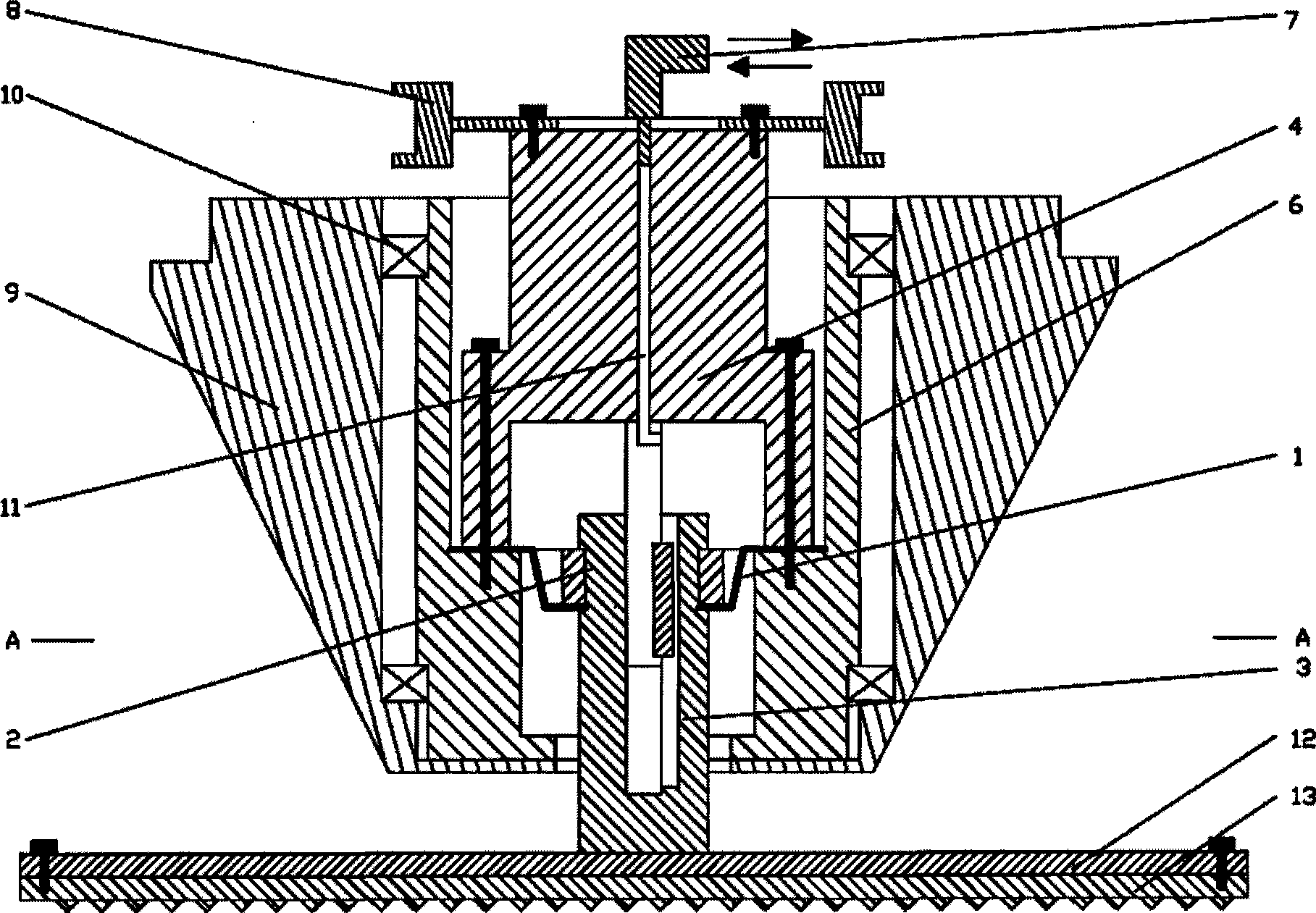

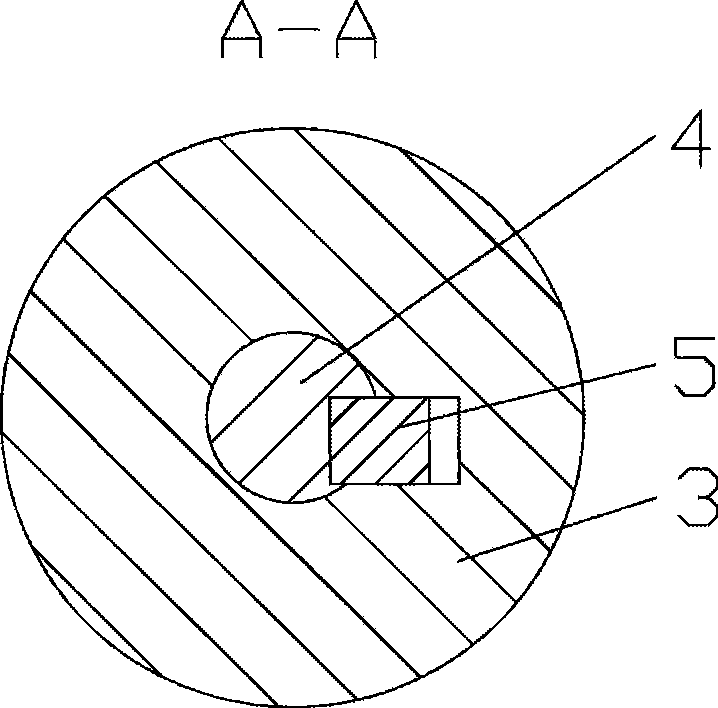

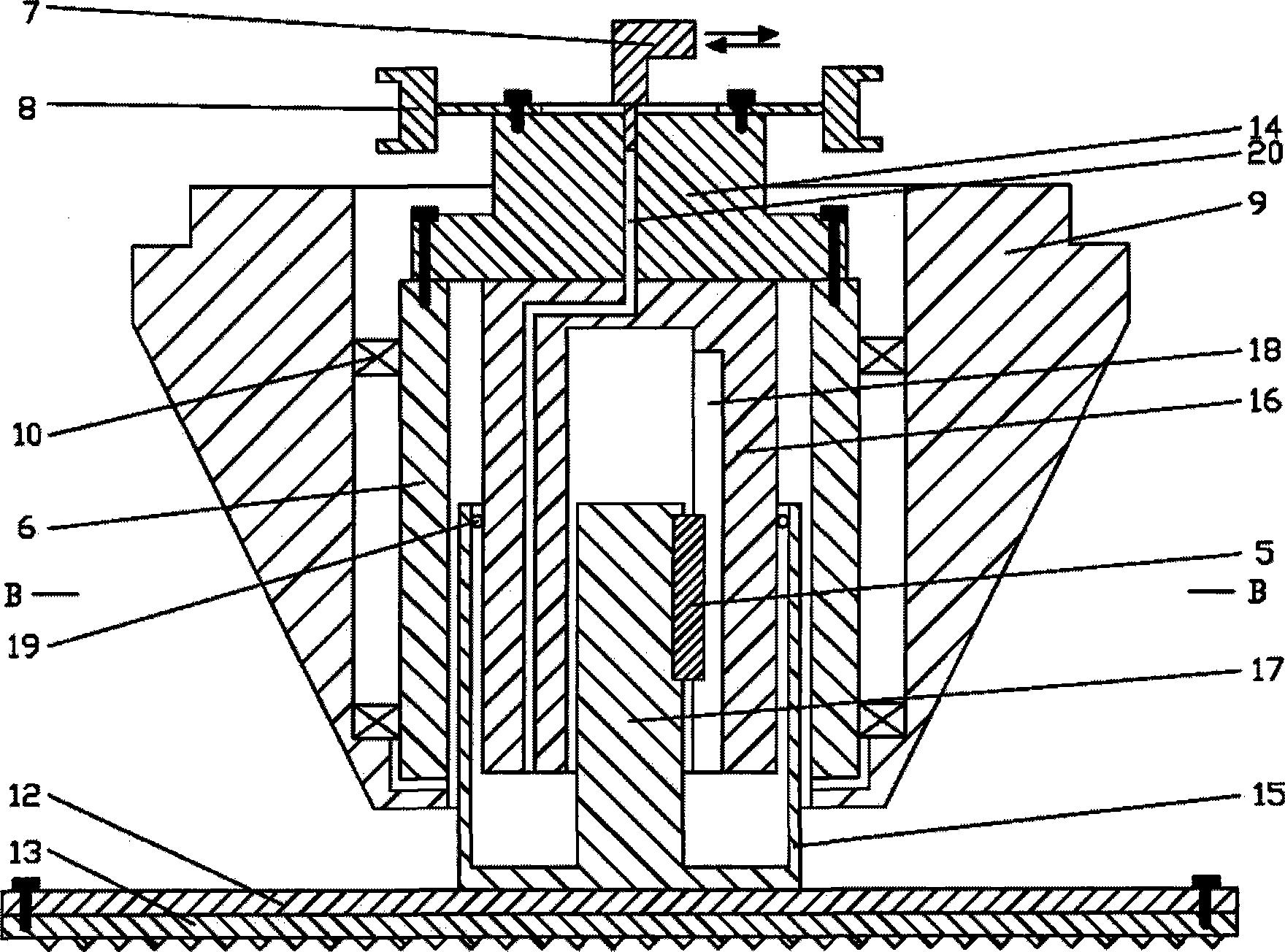

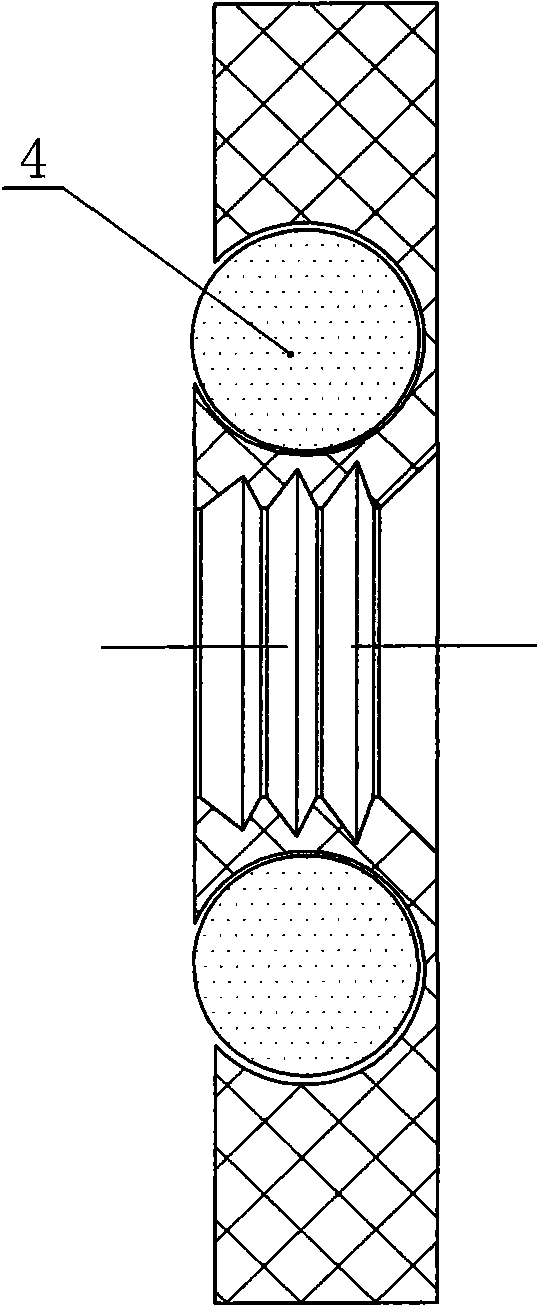

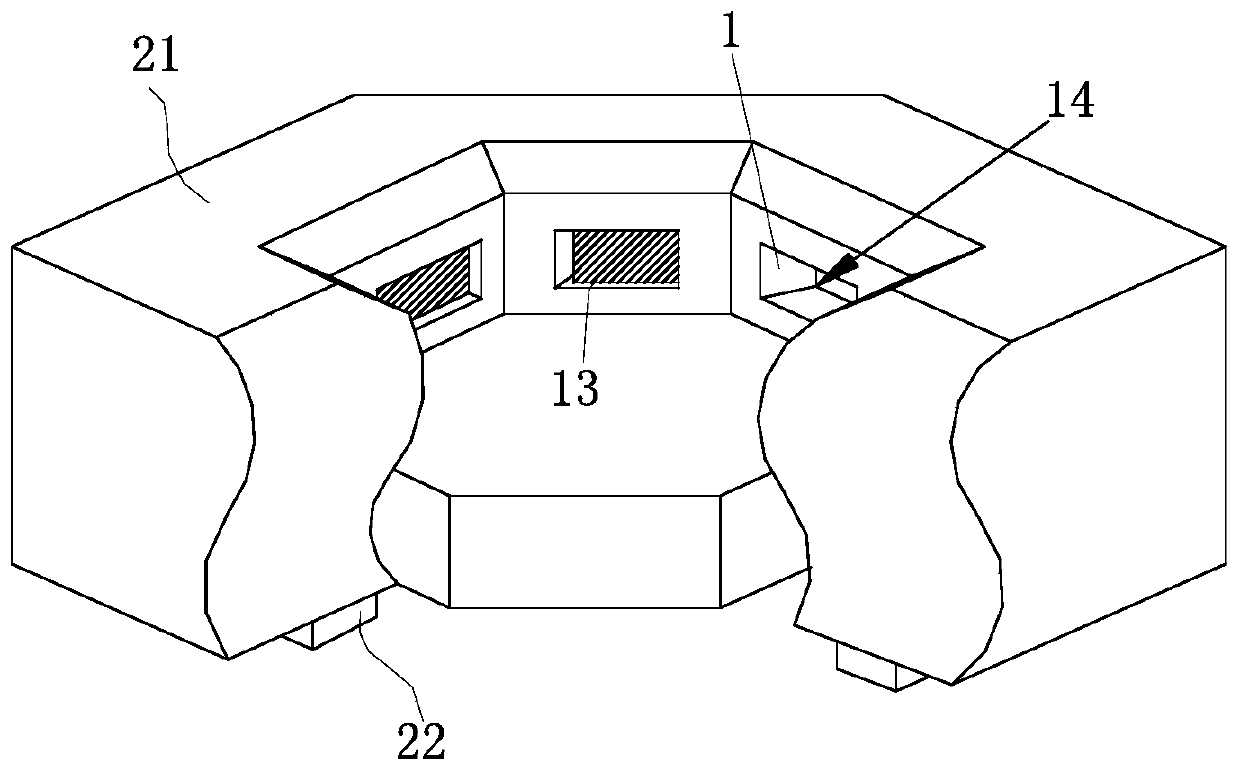

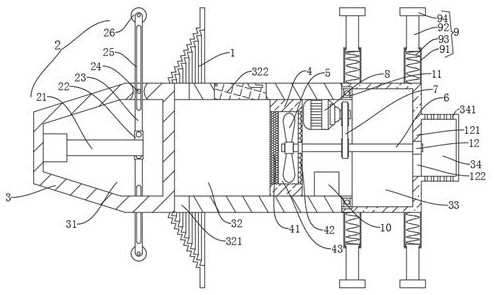

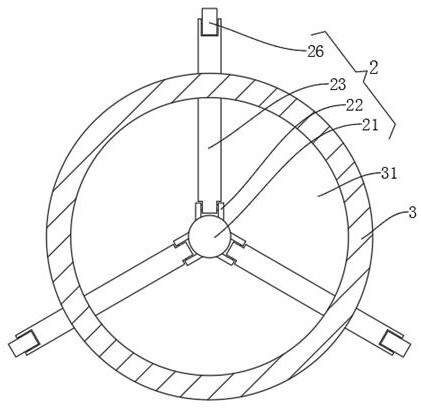

Test device and test method for fatigue life of bearing with ultra-low temperature and high DN value

PendingCN109975022AImprove cooling effectReduce vibrationMachine bearings testingRubber CupEngineering

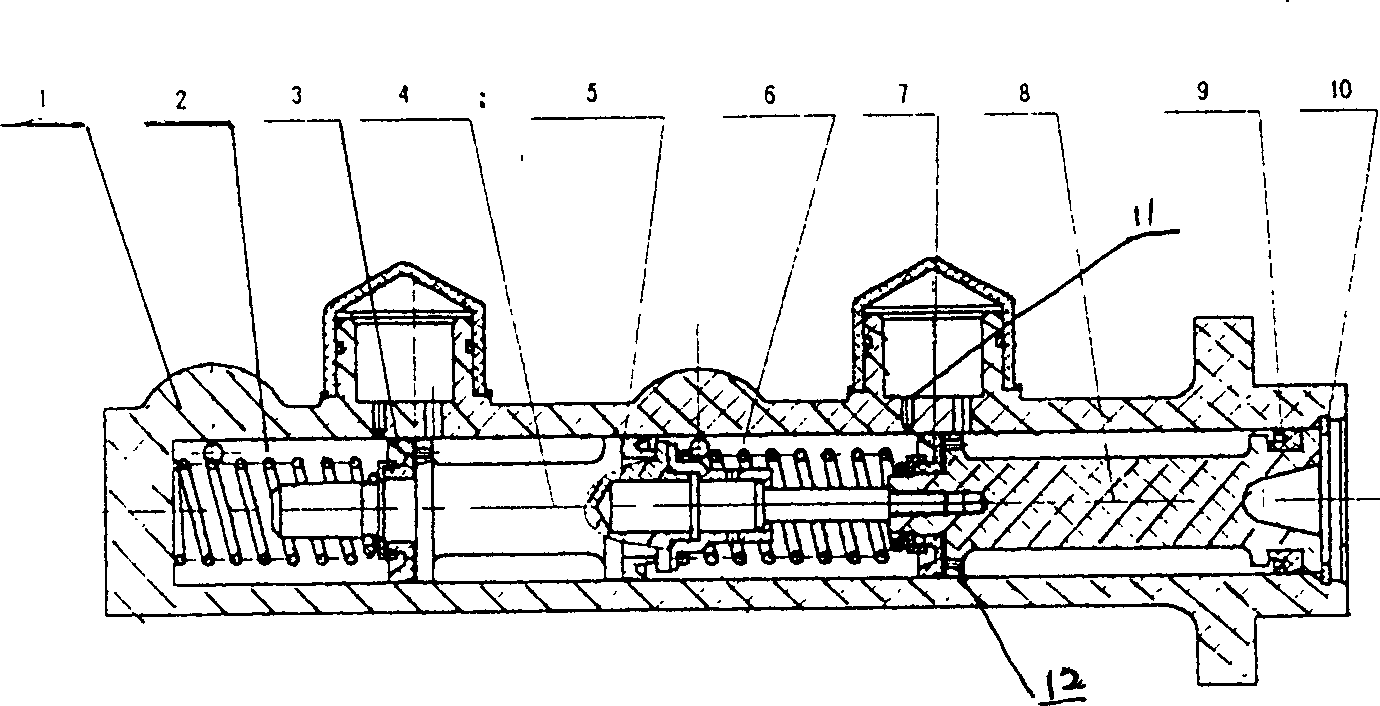

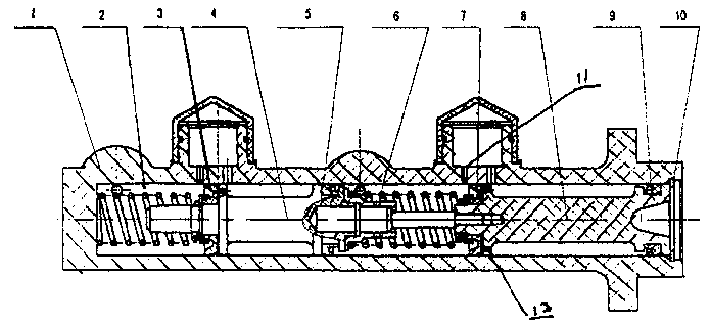

The invention discloses a test device and a test method for fatigue life of a bearing with ultra-low temperature and a high DN value. The test device comprises a device housing, wherein the device housing is connected with an axial flexible loading device and a radial flexible loading device; the axial flexible loading device and the radial flexible loading device are connected with a test rotor respectively; the test rotor comprises a main shaft; a tested bearing, a supporting process bearing, two loading process bearings and a shaft sleeve are installed on the main shaft; the main shaft andend covers are sealed by means of rubber cup sealing pieces; a force transmission sleeve having a through hole is installed between the axial flexible loading device and the radial flexible loading device; and a tested bearing outer sleeve and a front pressing cover fix a tested bearing outer ring through threaded connection, the tested bearing outer sleeve is connected with a front intermediate sleeve, and the front intermediate sleeve is connected with a front positioning cover. The test device and the test method realize the simulation of actual operating conditions of a low-temperature bearing in a turbopump of a low-temperature liquid rocket engine, including the ambient temperature, load, rotational speed and cooling flow rate being consistent or approximated to the actual operatingconditions.

Owner:北京宇航推进科技有限公司

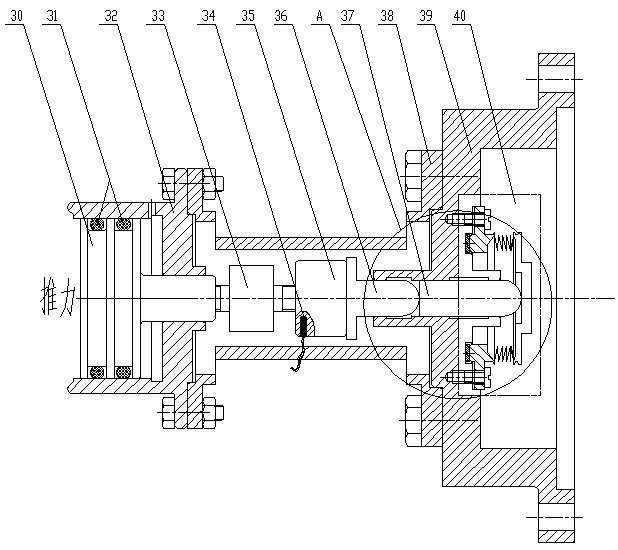

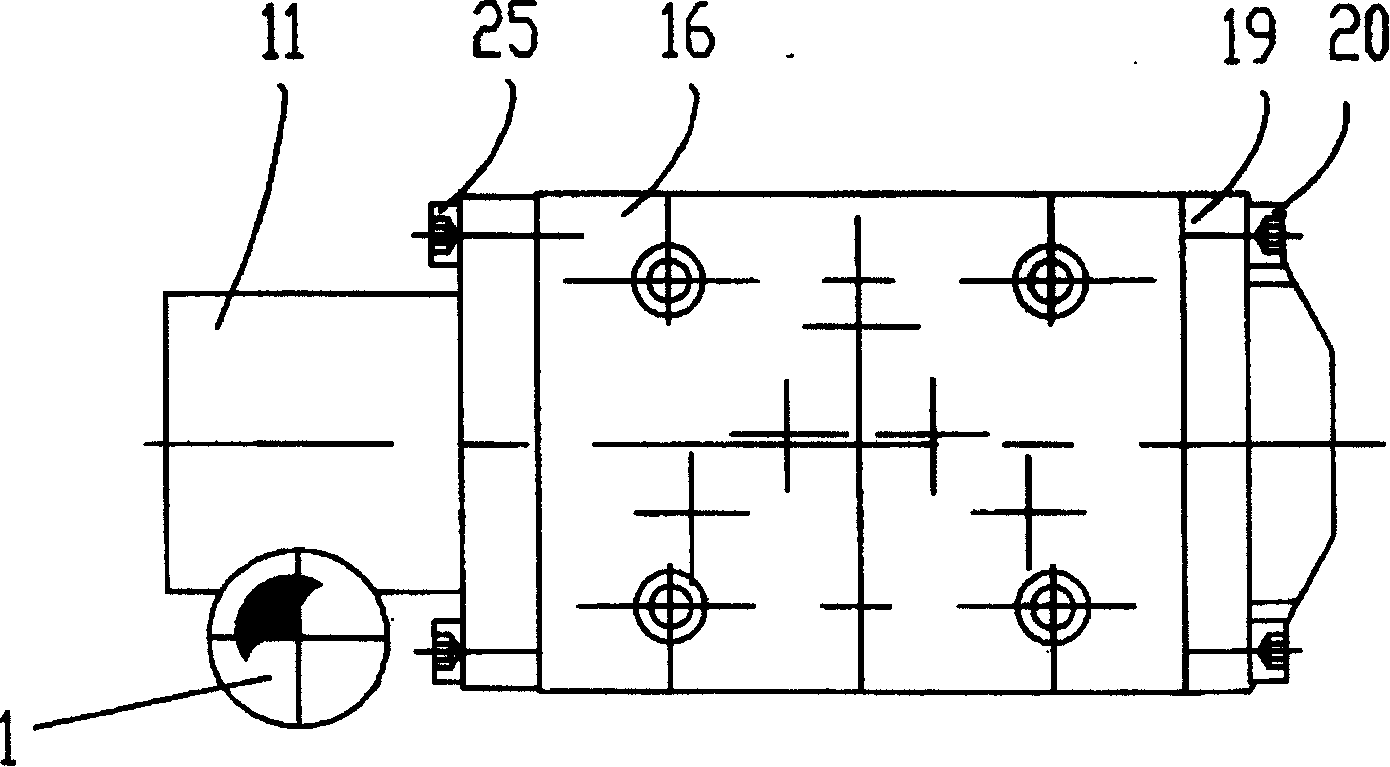

Hand-driven change valve

InactiveCN101235832AReduce commutation resistanceImprove reset effectServomotor componentsRubber CupWorking environment

The invention relates to a manual directional valve, which comprises a valve body, a front and a back covers, a valve plug assembly and a handle, wherein the front cover and the back cover are arranged on the front side and the back side of the valve body, the valve plug assembly is arranged in the inner portion of the valve body, the handle drives a valve plug in the valve plug assembly, and the handle is arranged on the outer portion of the front cover and is connected with the valve plug in the valve plug assembly through a link gear which is arranged in the front cover. The link gear comprises a push rod which is connected with a pin in the valve plug assembly, the push rod is vertically crossly connected with a handle shaft, and the handle is connected with one end of one side of the handle shaft, which is extended from the front cover. Because the handle is arranged outside the front cover by the manual directional valve, dust does not enter into the front cover, a prior rubber cup is capable of being cancelled, and the production and installment cost are reduced. When the rubber cup is cancelled, the reversing resistance of the handle is capable of being reduced, and the reduction effect is excellent. The manual directional valve of the invention has high flexibility and strong generality, and is capable of being suitable for wicked working environment. The pins which are arranged on the two ends of the valve plug have a same diameter, and pressure oil is not escaped through a seal ring which is arranged between the pin and a blind nut.

Owner:SHANGHAI LIXIN HYDRAULIC

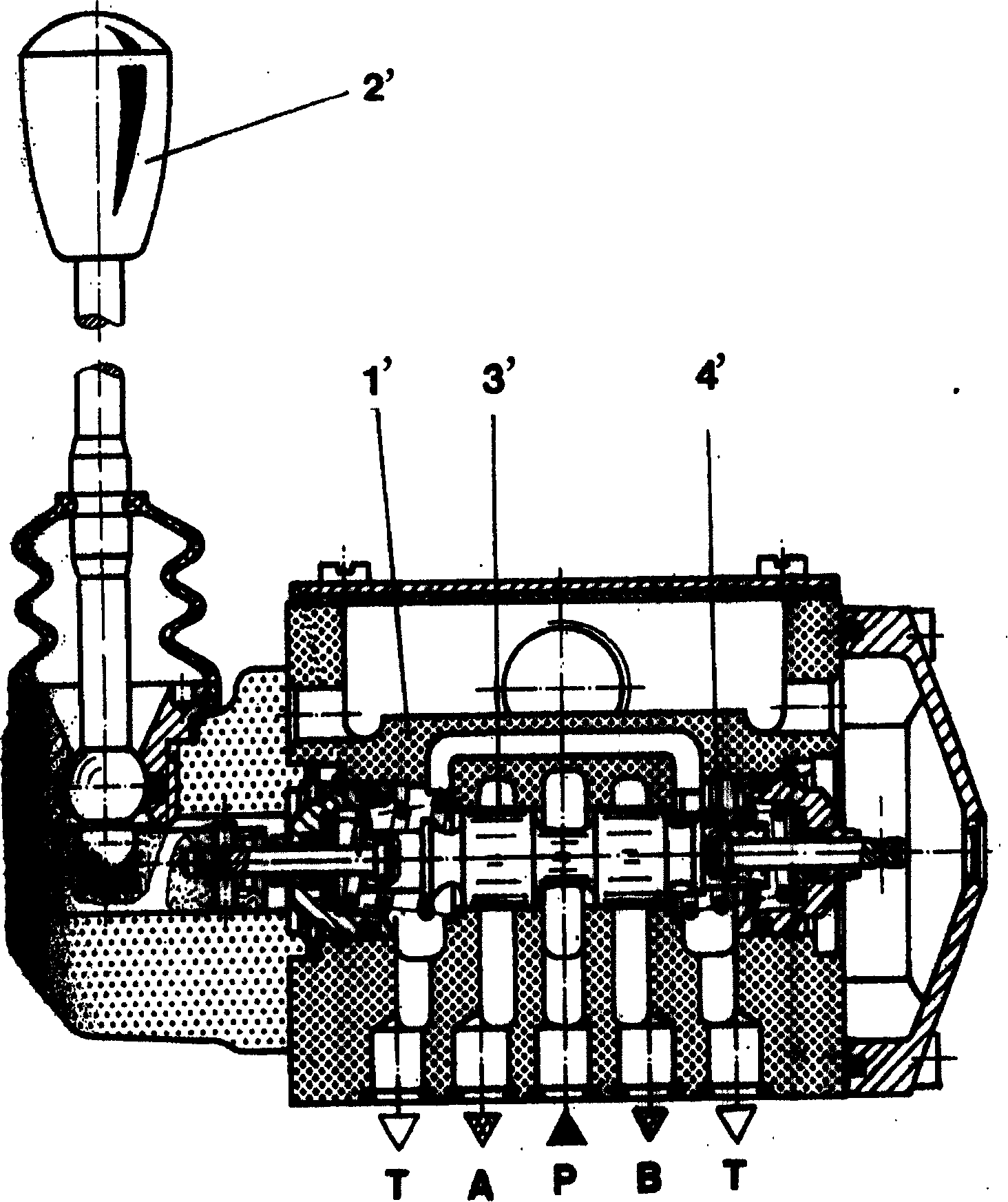

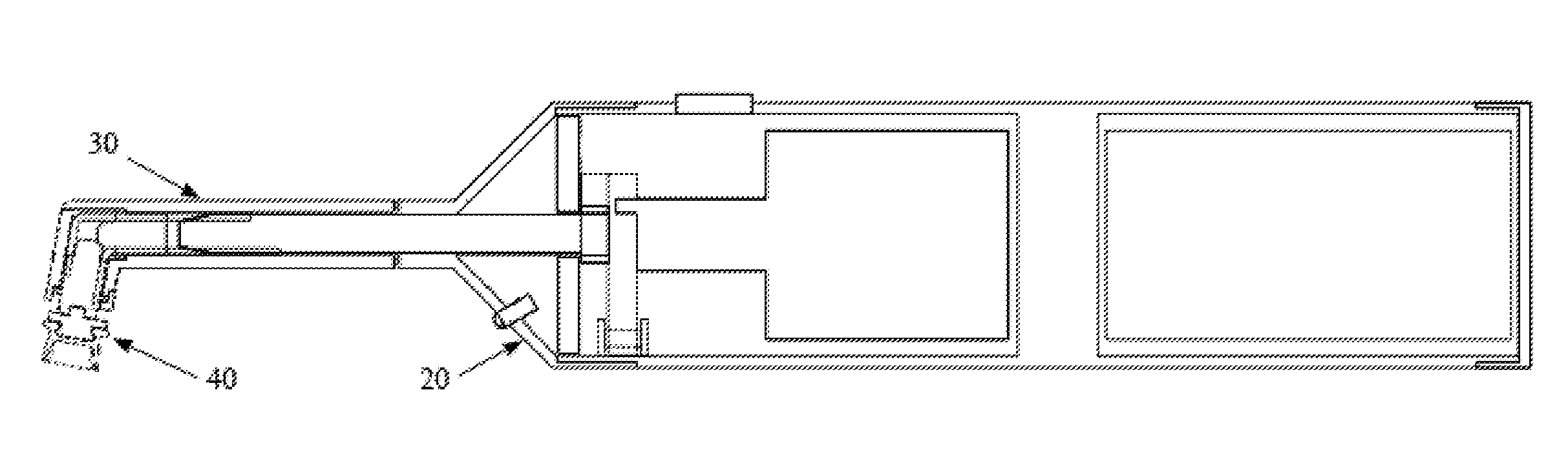

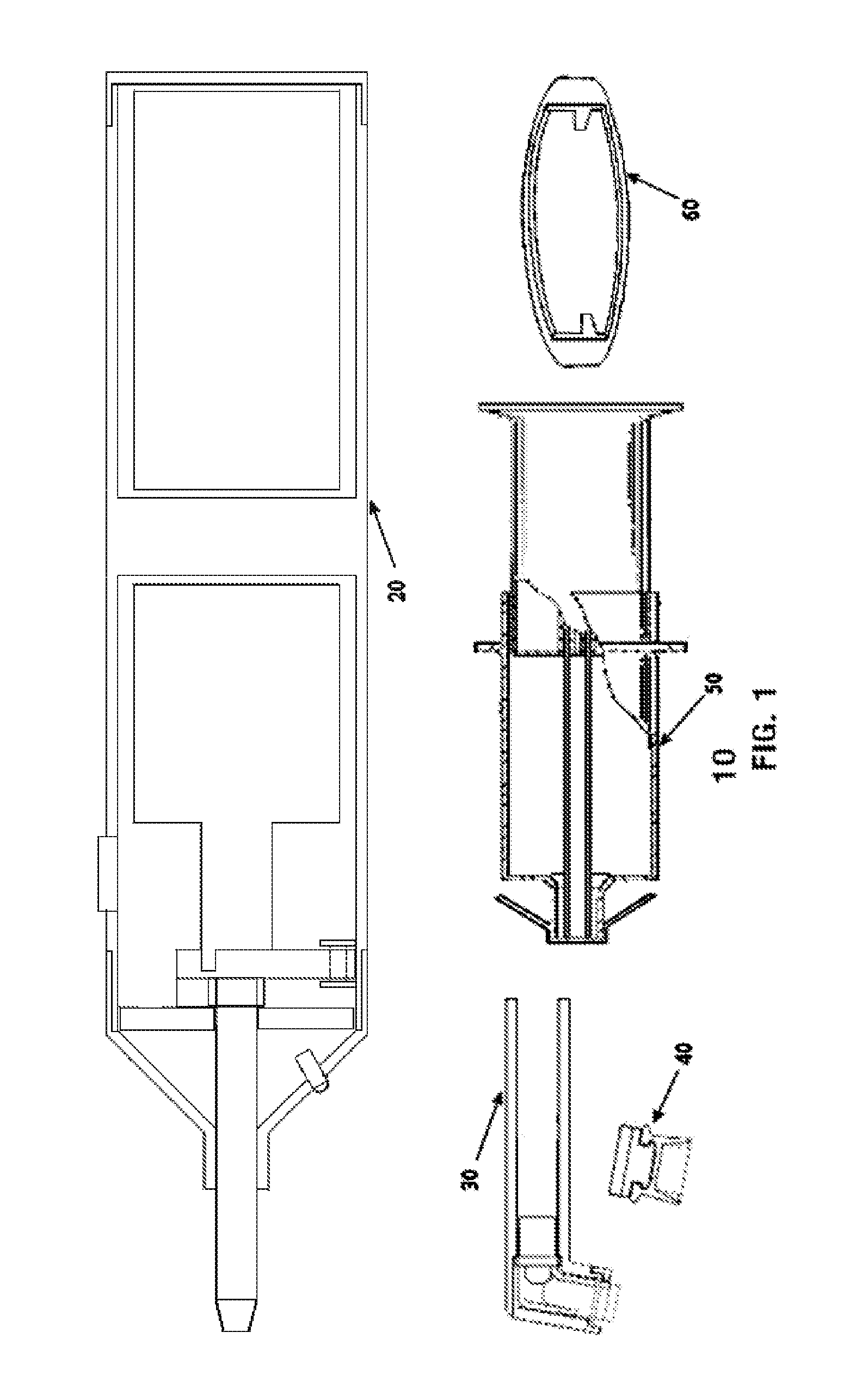

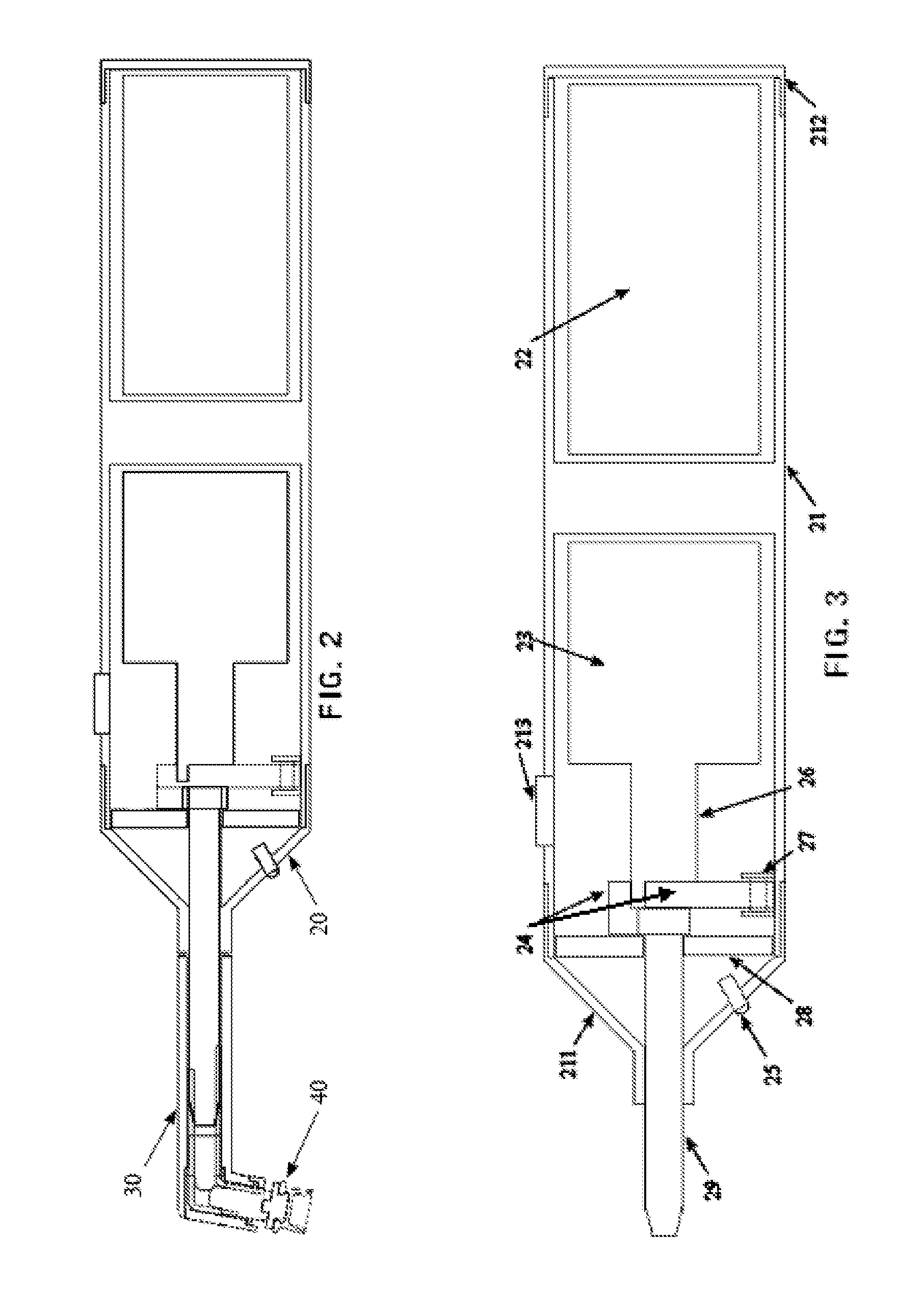

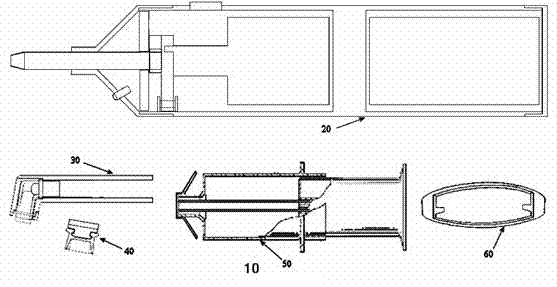

Portable Simultaneous Tooth Prophylaxis And Bleaching System

InactiveUS20120258418A1Reduce paste splatterExtend working lifeTooth pluggers/hammersSomatoscopeRubber CupTooth polishing

A portable dental prophylaxis and bleaching system is provided for simultaneous tooth polishing and bleaching. It includes an oscillatory driving handpiece, a dental angle with a disposable rubber cup assembly, a dual-component dispenser, and a disposable mouthpiece. The battery-powered handpiece transforms a continuous rotation through a driving cam into a rotary oscillation which is then transferred through the attached dental angle to the rubber cup with an obtuse angle at its distal output end. The dispenser is operated manually to correctly apportion and mix the dual treatment materials into the rubber cup. In order to provide longer shelf life and effective bleaching action, the treatment materials are maintained at optimal pH values in separate compartments within the dispenser before use. The disposable mouthpiece is shaped for easy access to the user's teeth while protecting the gum surfaces. The system can be used both in dental clinics and at home.

Owner:SHEN FEIMO

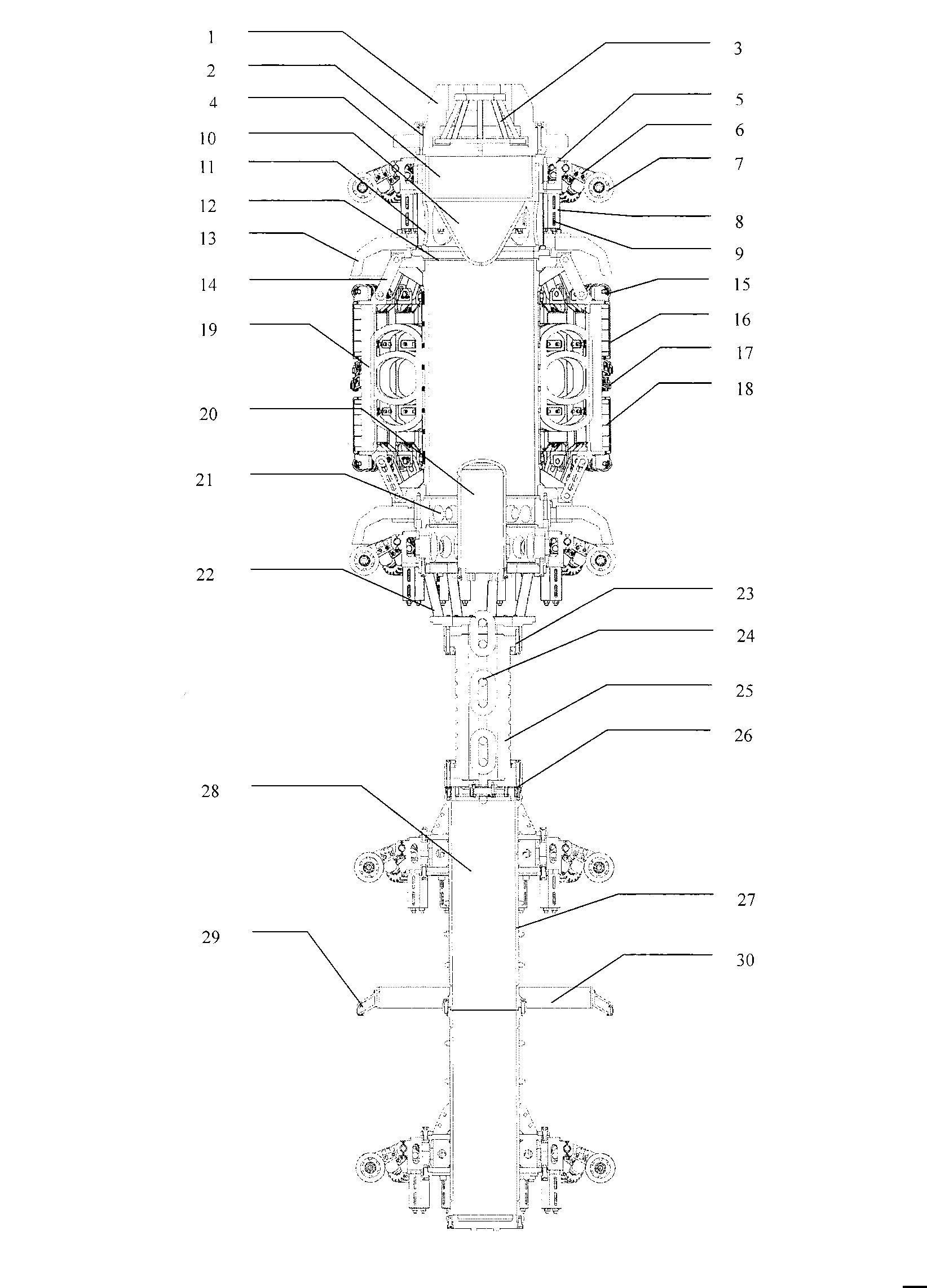

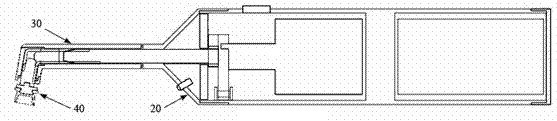

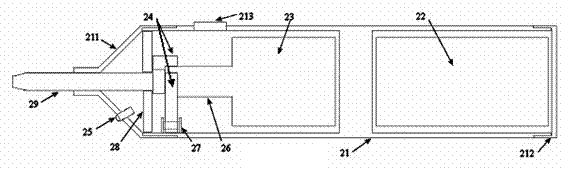

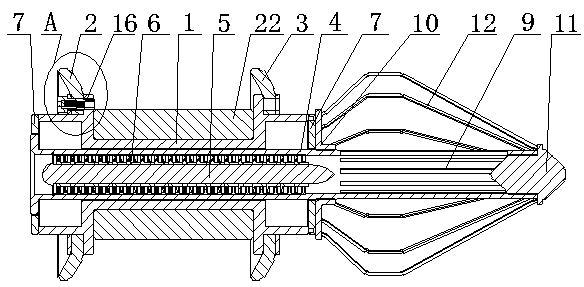

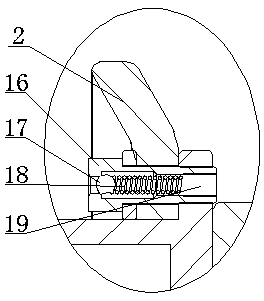

Natural gas long-distance pipeline three-dimensional high-definition magnetic leakage internal detection apparatus

InactiveCN103235034ARealize acquisitionImplement storageMaterial magnetic variablesMagnetizationMeasurement precision

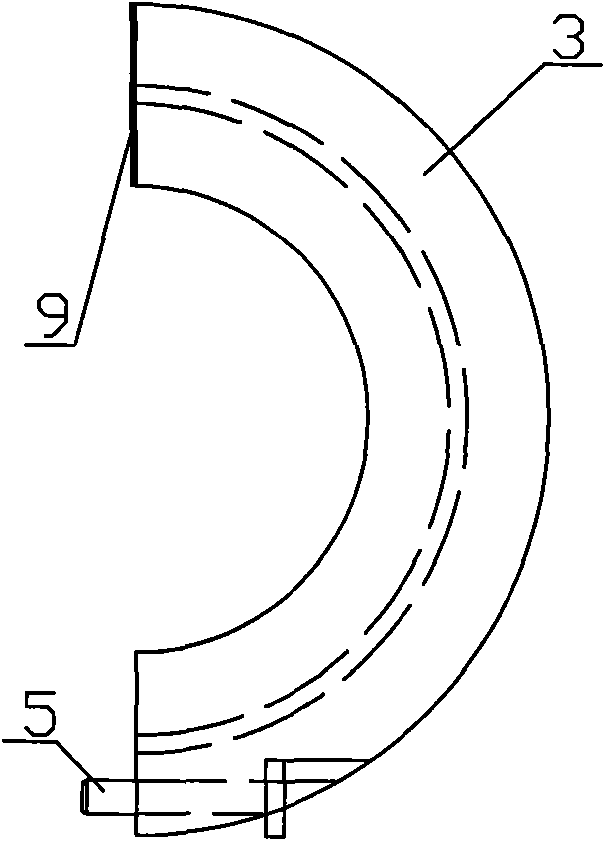

The invention relates to a natural gas long-distance pipeline three-dimensional high-definition magnetic leakage internal detection apparatus. The apparatus is composed of upper and lower frames, a venting bypass valve system, odometer wheel systems, an exciting detection unit, a main probe, a universal joint, a sealing rubber cup, a battery cavity, a universal coupling, and internal and external distinguishing probes. When the apparatus is used, the venting bypass valve system is mainly used for completing the adjustment of the travelling speed of the apparatus in a pipeline during the running of a detector in the gas convey pipeline in order to realize the transient speed control and the speed control under stationary running; the odometer wheel systems are used for realizing the gravity support of the internal detector in order to guarantee the positioning of the apparatus in the center of the pipeline; the sealing rubber cup guarantees the close contact of the internal detector and the inner wall of the gas convey pipeline to block the flow of a natural gas fluid and generate the travel thrust of the internal detector in order to drive the whole apparatus to forward; the exciting detection unit realizes the magnetization of the wall of the pipeline and the measurement through utilizing the above probes; and a movement contains a acquisition system to realize the acquisition and storage of flaw detection data. The apparatus has the advantages of simple structure, convenient installation and use, and high measure precision.

Owner:国家管网集团西部管道有限责任公司

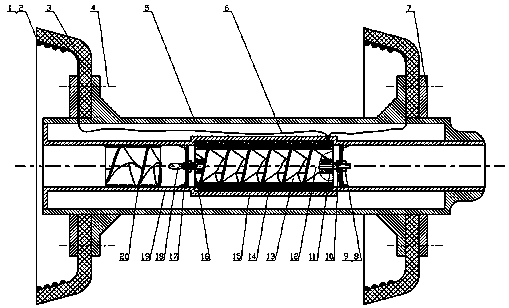

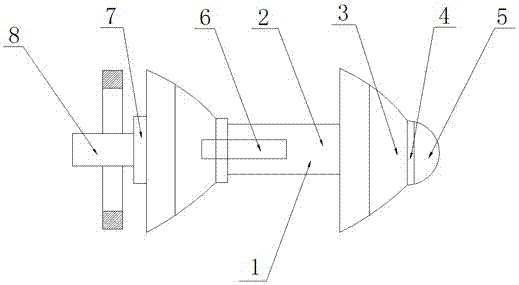

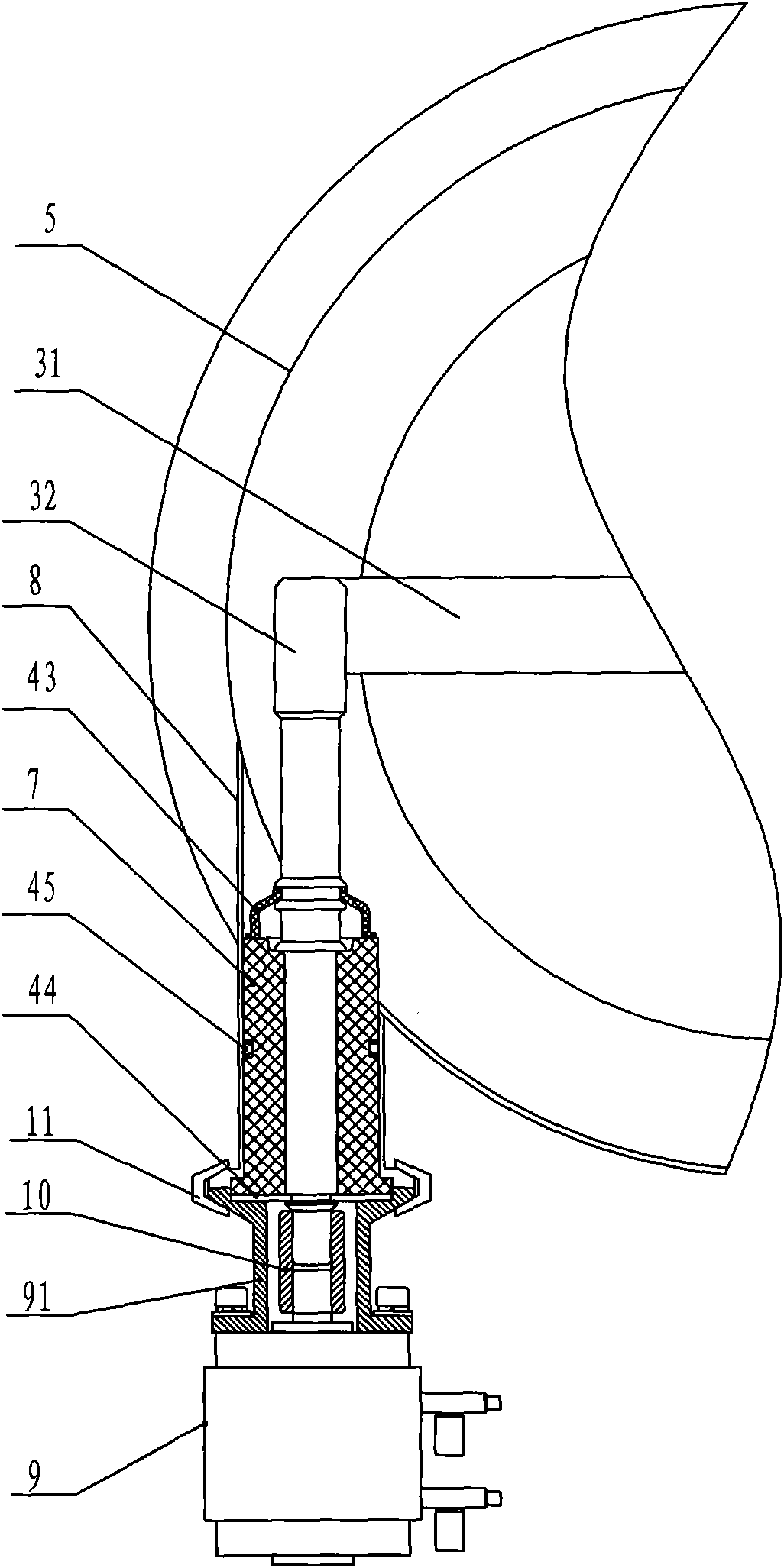

Polishing pad finishing head

InactiveCN101367200AAvoid breakingNot easy to ageAbrasive surface conditioning devicesRubber CupPiston

The invention discloses a finishing head of a polishing pad, which comprises a rotatable gas pipe connector (7), a synchronous pulley (8), a key (5), a supporting body (9), bearings (10) and a rotating ring (6), wherein the rotating ring (6) is provided with two bearings (10); and the finishing head also comprises a second turning block (14), a first cylinder body (15), a first cylinder piston (16) and a sealing ring (19). The finishing head of the polishing pad solves the problems of poor reliability and poor stability of the prior finishing head due to the damage of a rubber cup, improves the reliability and stability, and prolongs the service life of the finishing head.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

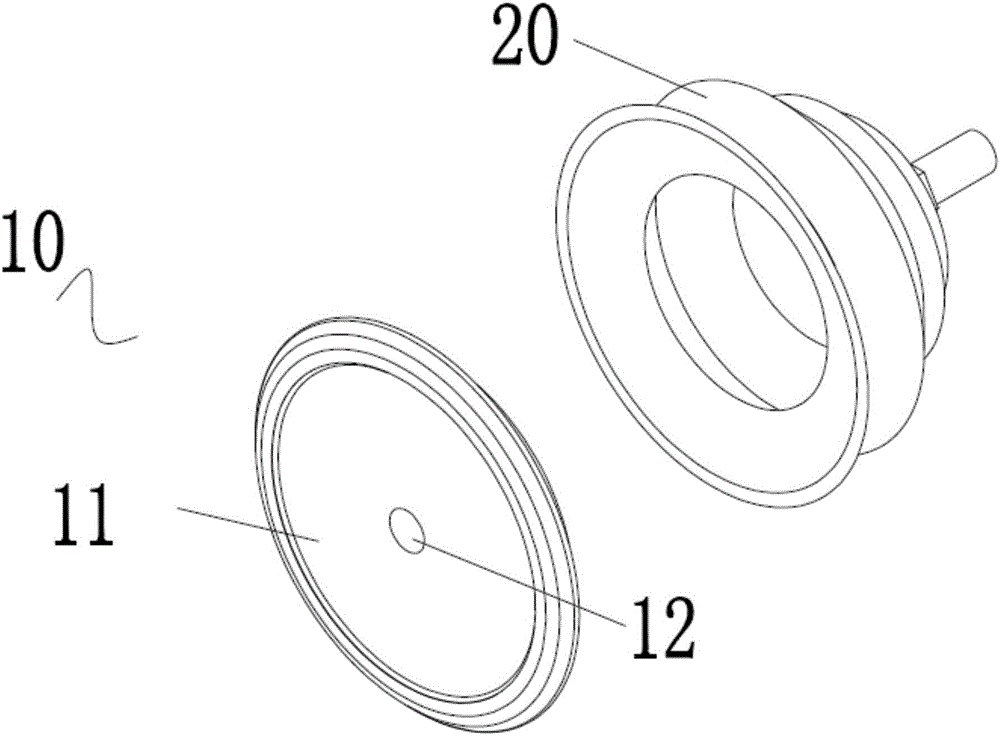

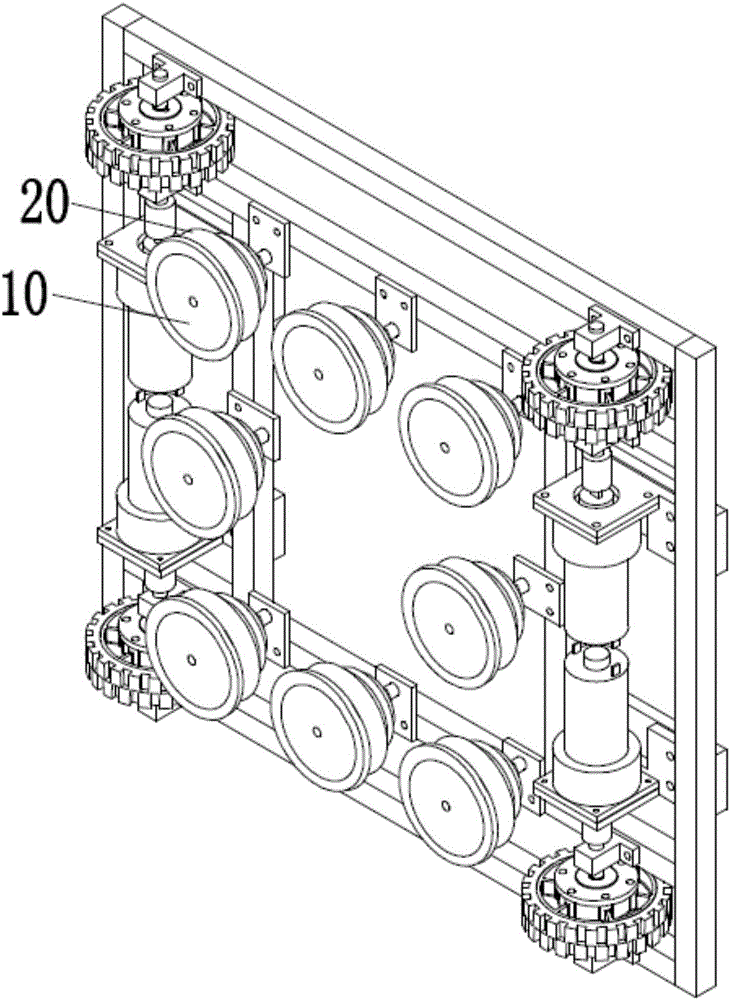

Sliding-type sucker

The invention discloses a sliding-type sucker comprising a sliding disk and an elastic rubber cup which are in seal fit; the surface of the sliding disk is smooth and a surface which fits with an adsorption plane is concave inwards to form a recess; the recess is provided with an air suction hole therein which is communicated with the elastic rubber cup; one end of the elastic rubber cup is connected with the sliding disk and the other end is connected with a vacuum generator. The sliding-type sucker of the invention can directly slide on an adsorption plane with good adsorption performance and can smoothly pass through unevenness places on the adsorption plane.

Owner:HUAWAY IOT TECH

Large turning angle positioning vacuum chuck

InactiveCN101549485ARealize large angle rotationImprove flexibilityWork holdersPositioning apparatusTurn angleRubber Cup

The invention discloses a large turning angle positioning vacuum chuck which comprises a chuck base, a positioning ball, a turning block A, a turning block B, a bolt A, a sealing rubber cup, a bolt B, a sealing strip A and a sealing strip B. The chuck base is connected with the positioning ball, the turning block A and the turning block B are connected together by the bolt A, the inner surfaces thereof form a spherical surface which slide coordinately with the positioning ball. The turning block A and the turning block B are sealed by the sealing strip B, the turning block A, the turning block B and the positioning ball are spherically sealed by the sealing strip A. The sealing rubber cup is connected with the turning block A and the turning block B by the bolt B. The chuck adopts the positioning ball to carry out point positioning so as to ensure positioning accuracy, thereby realizing large angle turning of the chuck, being suitable for the process of sheet metal parts with different curvatures, enlarging the serviceable range of machine tools, solving the problem of numerous tooling during process of edge trimming of the sheet metal parts and the like, increasing the flexibility of tooling, and improving the production efficiency.

Owner:SHENYANG AEROSPACE UNIVERSITY

Double-pipe line hydraulic brake main cylinder

InactiveCN1483620ALow priceGood formabilityFluid braking transmissionBraking componentsRubber CupWear resistant

The present invention relates to a double-pipeline hydraulic brake main cylinder, betonging to automobile fitting, and it mainly includes cylinder body, first piston, second piston, first spring, second sping, main rubber cup, auxiliary rubber cup, spring retainer ring and compensation hole, and its improvement lies in that on the piston an axial oil hole is set, and the described main cylinder body and pistons are made of composite reinforced wear-resistant heat-resistant modified nylon material whose composition is composed of 80-85% of nylon, 2-3% of glass fibre, 6-7% of carbon fibre and the rest butyronitrile through the process of die-casting forming treatment. Its injection forming pressure is 5000 MPa, temp. is 250-260 deg.C and pressure-retaining time is 10-15 sec. and its cooling mode is air cooling.

Owner:徐瑞祥

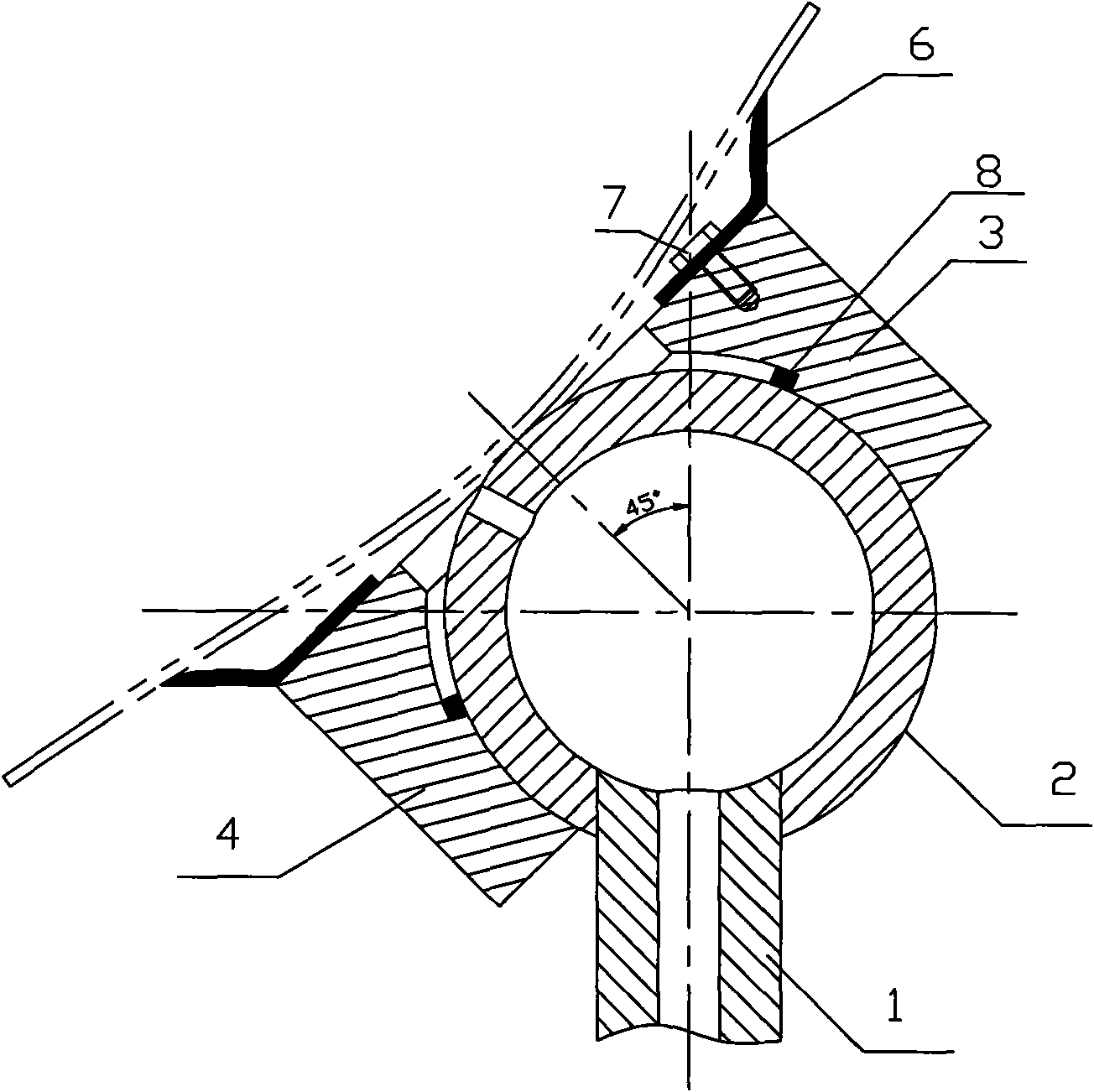

Self-compensation sealing device

The invention relates to a self-compensation sealing device which is suitable for rotary devices in industrial and mining enterprises, in particular to carrier rollers and the like. The self-compensation sealing device comprises a sealing ring, wherein the sealing ring is a C-groove sealing ring with a V-shaped rubbing surface; a C-shaped groove is formed on the circumference of the sealing ring; an O-shaped rubber cup ring is arranged in the C-shaped groove; the V-shaped rubbing surface is arranged at the aperture position of the sealing ring; an antiwear plastic sleeve is arranged in the aperture of the C-groove sealing ring with the V-shaped rubbing surface; the antiwear plastic sleeve is fixedly sleeved on a shaft; the C-groove sealing ring with the V-shaped rubbing surface is in rotary frictional connection with the antiwear plastic sleeve; the C-groove sealing ring with the V-shaped rubbing surface is prepared from an ultrahigh molecular weight polyethylene material with the molecular weight less than 3,000,000; and the antiwear plastic sleeve is prepared from an ultrahigh molecular weight polyethylene material with the molecular weight more than 5,000,000. The self-compensation sealing device has the advantages of wear resistance, self-compensation, corrosion resistance, high sealing property, impact resistance, long-time wear resistance and long service life.

Owner:山东太极龙塑胶科技有限公司

Rice automatic vending machine

InactiveCN106408767AHigh nutritional valueReduce mildewApparatus for dispensing fluids/granular materialsGrain treatmentsRubber CupEngineering

The invention discloses a rice automatic vending machine comprising a grain hopper, a feed valve, a rice mill, a weighing hopper, a motor, a cup type automatic packing machine, a rubber cup, a fetch port, an automatic cup distributer, a slide way, and a rice bran hopper; the grain hopper is connected with the feed valve; the rice mill is arranged below the feed valve, and connected with the motor; the weighing hopper is arranged below the rice mill, and arranged on the left side of the automatic cup distributer; the rubber cup is arranged between the fetch port and the slide way; the slide way is arranged below the weighting hopper; the cup type automatic packing machine is connected with one end of the rubber cup; the rice bran hopper is arranged below a bran discharge port of the rice mill. The rice automatic vending machine can realize all-weather unmanned on duty purpose, can realize automatic management, production and sales, thus saving labor cost, realizing accurate metering, reducing nutrition loss, improving rice nutrition value, saving operation management cost, and ensuring foodstuff safety health, internet of things high efficiency management, and excellent consumption experience.

Owner:日照先农氏物联网科技有限公司

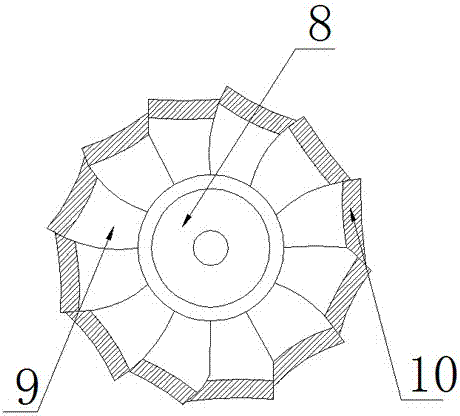

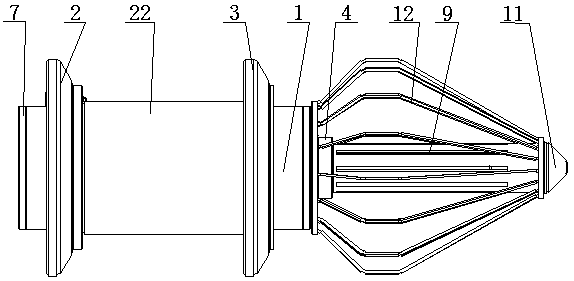

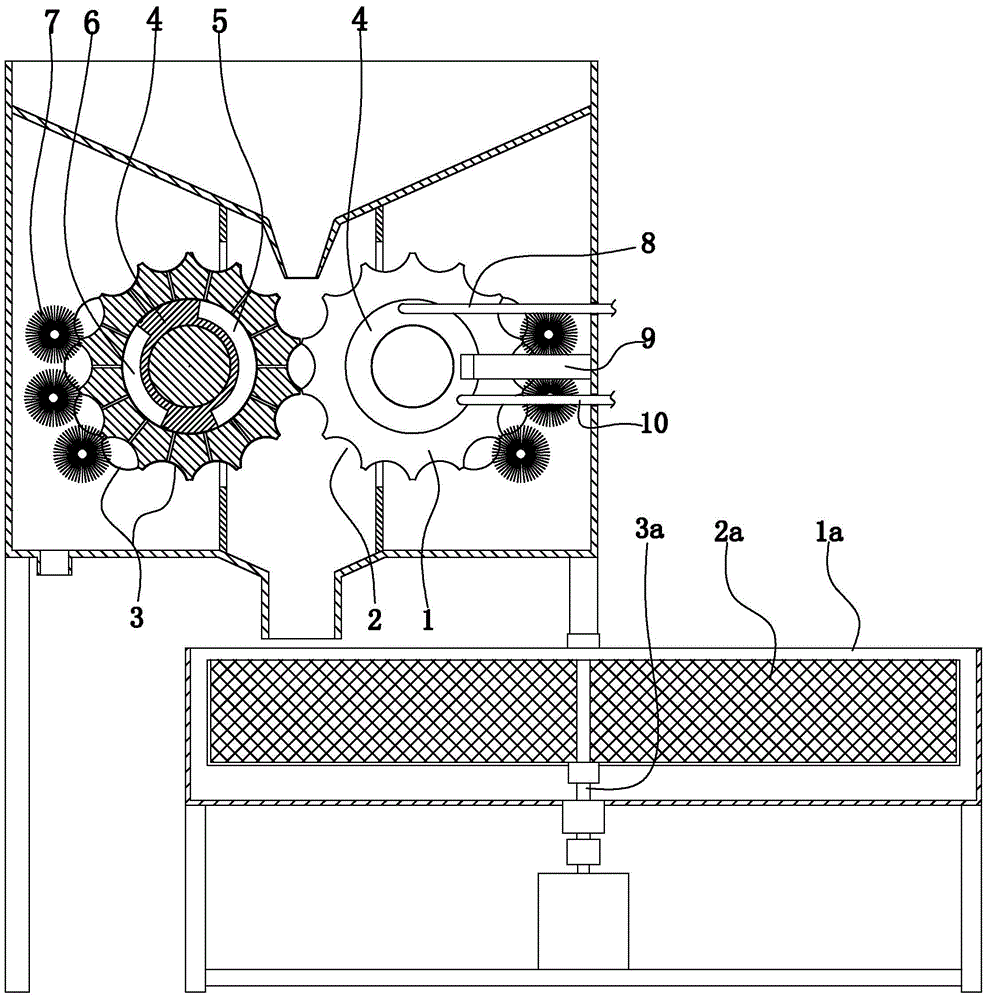

Self-blockage-removing speed-regulating pipe cleaner

PendingCN111036627AAutomatic speed adjustmentRealize automatic adjustmentHollow article cleaningRubber CupImpeller

The invention provides a self-blockage-removing speed-regulating pipe cleaner, which comprises actuators, actuator protective sleeves, rubber cups, a pipe cleaner outer body, lead wires, a distance adjusting ring, a bearing, a mandrel, an impeller, magnetic poles, a coil, a supporting ring, a pipe cleaner inner body and a guide wheel, wherein the rubber cups are arranged at the two ends of the pipe cleaner outer body, the pipe cleaner inner body is arranged in the pipe cleaner outer body, and the pipe cleaner inner body, the pipe cleaner outer body and the rubber cups form a hollow structure;and the coil is fixed in an annular groove of the pipe cleaner inner body, the impeller is arranged in the coil, and the magnetic poles are arranged on the outer circumferential surface of the impeller. Electric energy generated by rotation of the impeller is converted into heat energy by means of an electric heating wire on the artificial muscle, crude oil can be heated when the pipe cleaner works normally, wax on a pipeline can be removed conveniently, and the actuators drive the rubber cups to deform to a certain degree due to temperature changes, so as to control a friction force between the pipe cleaner and the pipeline, and achieve the purpose of adjusting the speed of the pipe cleaner.

Owner:XIAN CHANGQING TECH ENG +1

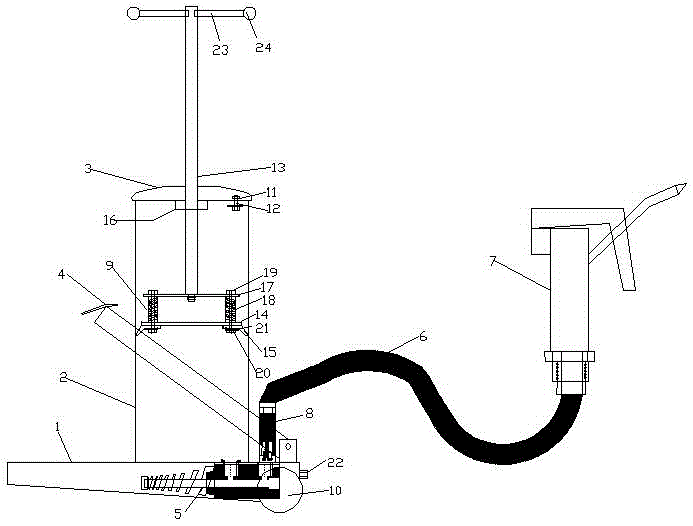

Novel high efficiency high pressure foot-operated oil injector

InactiveCN105090720ASolve the situation of poor oil outputSimple structureManual lubricationRubber CupPump chamber

A novel high efficiency high pressure foot-operated oil injector belongs to the oil injection tool technical field, and comprises a pedestal, a barrel body, an oil injector cover, a pedal connecting plate, an oil pump, a high pressure soft pipe, an oil gun, an oil injection non-return mechanism, and an oil pressing; one end of the oil injection non-return mechanism is connected with a pump chamber of the oil pump, and the other end is connected with the oil gun through the high pressure soft pipe; a piston is connected with the pedal connecting plate; a middle hole of the oil injector cover is provided with a screw rod; an oil pressing substrate of the oil pressing is fixedly connected with the upper portion of an oil pressing cup so as to form a rubber cup piston; the features are that the oil pressing also comprises a bottom plate and a cylinder spring; the screw rod extends into the barrel body and is fixedly connected with the center of the bottom plate; the cylinder spring is arranged between the bottom plate and the rubber cup piston; the screw rod inserts into a hole of the cylinder spring; two ends of the screw rod are respectively connected with the bottom plate and the rubber cup piston through a nut. The novel high efficiency high pressure foot-operated oil injector is simple in structure, strong in practicality, and can improve product performance, quality and life.

Owner:扬州市琼花工具有限公司

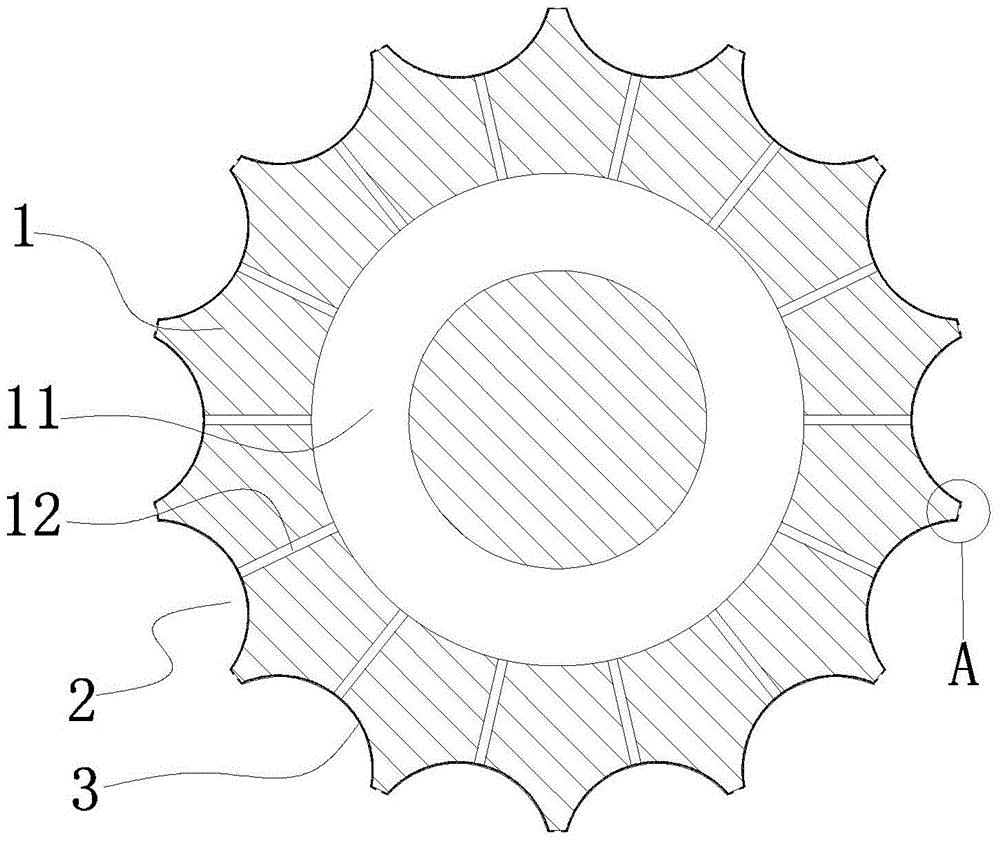

Rubber cup type pipe cleaner with high cleaning efficiency

InactiveCN107138486AImprove cleaning efficiencyReasonable designHollow article cleaningRubber CupProduct gas

The invention discloses a pipe cleaner with a leather bowl with high cleaning efficiency, which comprises a pipe cleaner body. Pressing plate, one side of the pressing plate is provided with a guide, the inside of the skeleton is provided with a signal transmitter, the bottom of the cup is provided with a fixed block, one side of the fixed block is provided with a threaded rod, and several fan blades are evenly provided around the threaded rod , brushes are arranged on the tops of several fan blades. The device solves the problem that the existing leather bowl pigs often use gas or liquid as the driving force when cleaning the pipeline. The oil stains on the pipe wall are too thick, which causes the pig to work in the pipeline. Incomplete, leading to the problem of unsmooth pipelines.

Owner:盐城瑞峰石材有限公司

Portable system capable of simultaneously polishing and bleaching tooth surface

The invention discloses a portable system capable of simultaneously polishing and bleaching tooth surface. The system comprises an oscillation type drive handle, a dental bend attached with a disposable rubber cup assembly, a double-material paste agent distributor and a disposable mouth propping sheet. The handle driven by a battery converts subsequent rotation into oscillation rotation by driving a cam and transmits the oscillation rotation to a rubber cup in a manner of obtuse angle outputting through the attached dental bend; the double-material paste agent distributor mixes two working materials in accurate proportion in the rubber cup by using a hand-operated manner; and the rubber cup carries out oscillation friction on tooth surface so as to finish polishing as well as bleaching of teeth. To prolong the storage life and bleaching effects of the working materials, the working materials with different pH values are respectively stored in independent cavities of the distributor before usage and are mixed to obtain a bleaching agent with an optimal pH value during usage. The disposable mouth propping sheet can be conveniently placed in a mouth behind lips so as to expose teeth and protect gums.

Owner:沈非默

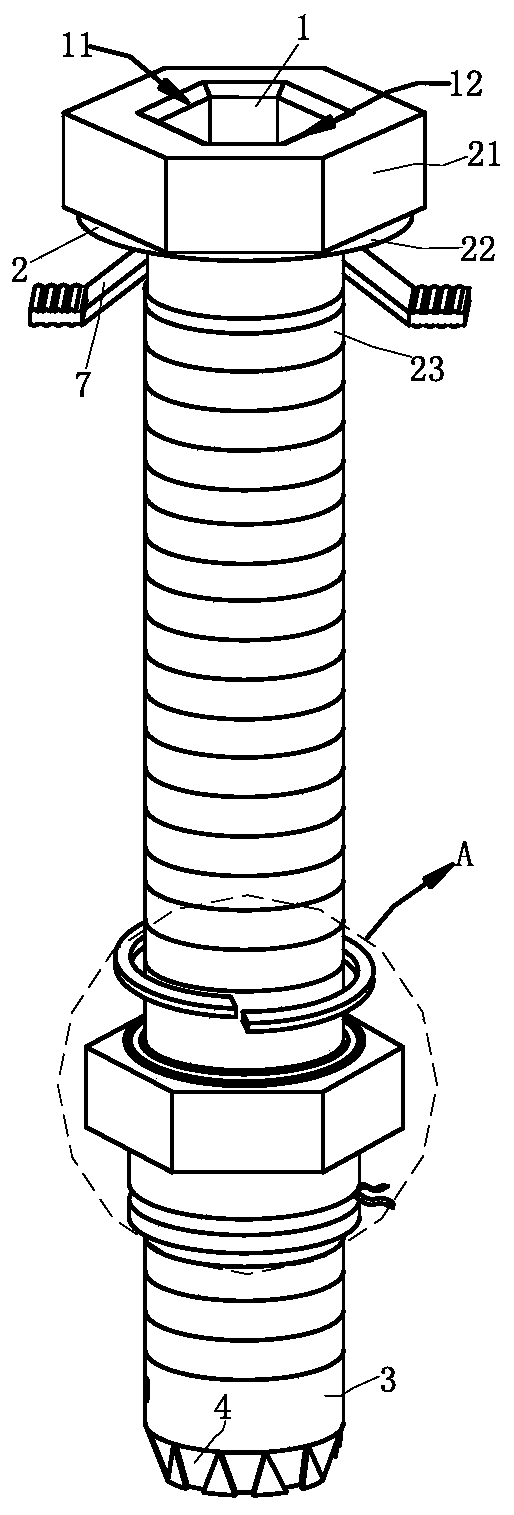

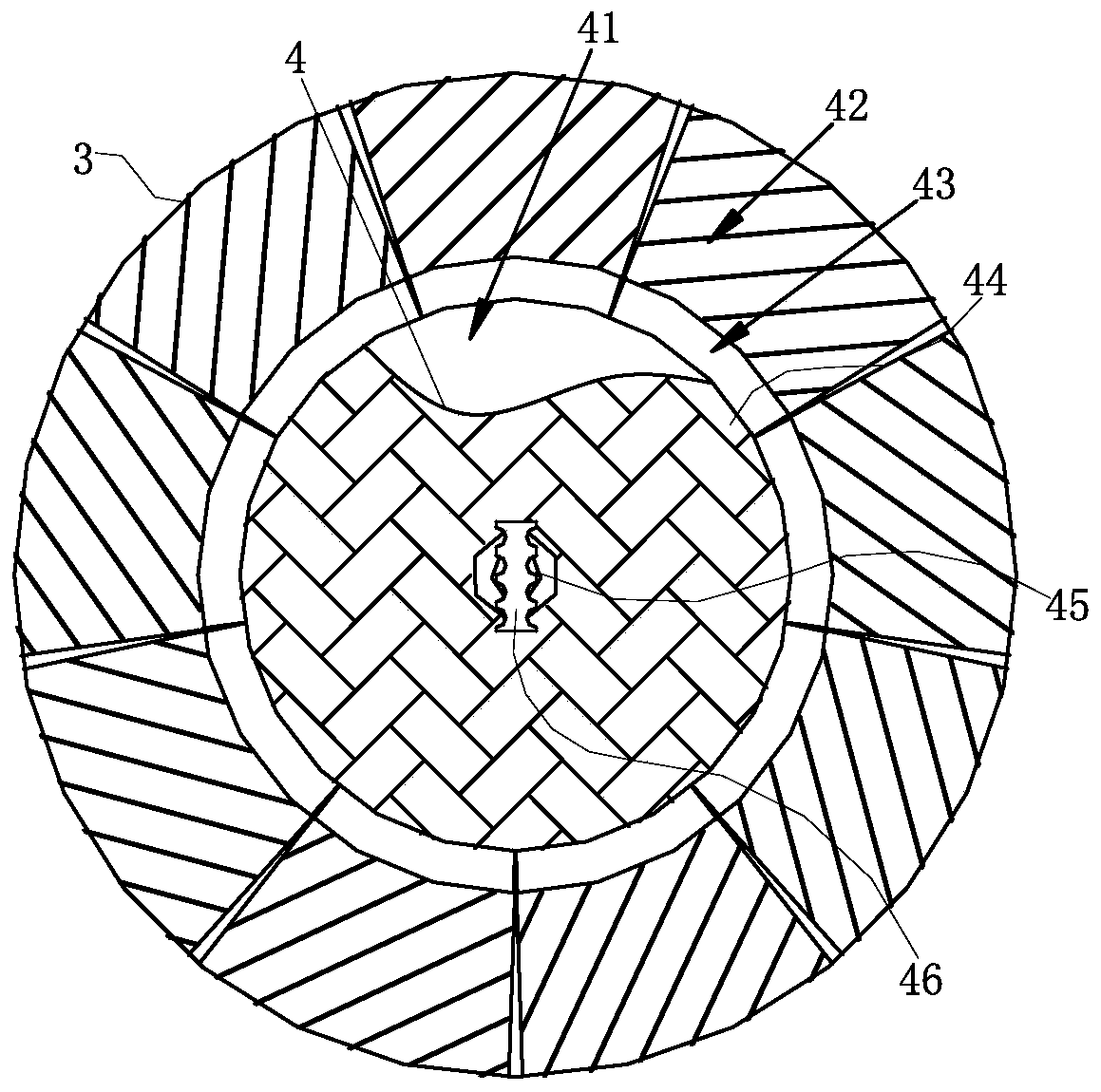

Inner-hexagon screw fastener

The present invention relates to the field of fasteners, in particularly to an inner-hexagon screw fastener, comprising: a disassembling mechanism, a connecting mechanism, a guide post, a lubricatingmechanism, a protection mechanism, a water-proofing mechanism, a pushing mechanism and an oiling mechanism; the pushing mechanism is installed inside a screw rod; when a fixing hole of a plate is toolarge to affect the stability of fixing, the screw rod is used to pass through the plate to make a platen in contact with the plate; when two connecting plates are opened from each other, a push rod is pushed towards a rubber cup to jack up the rubber cup, thereby making lubricating oil flow out from the rubber cup so as to lubricate a screw rod and facilitate installation; when flowing out from the rubber cup, the lubricating oil can flow from an oil inlet in the sidewall of the screw rod and into an oil chamber; when disassembled, a nut is loosened to make the platen and the plate separate from each other, thus the angle between the two connecting plates becomes smaller; and the push rod moves towards a fixed block, the rubber cup restores, and a press rod extrudes oil from the oil chamber to the sidewall of the screw rod for lubrication, so it is convenient to unscrew the nut.

Owner:山东九佳紧固件股份有限公司

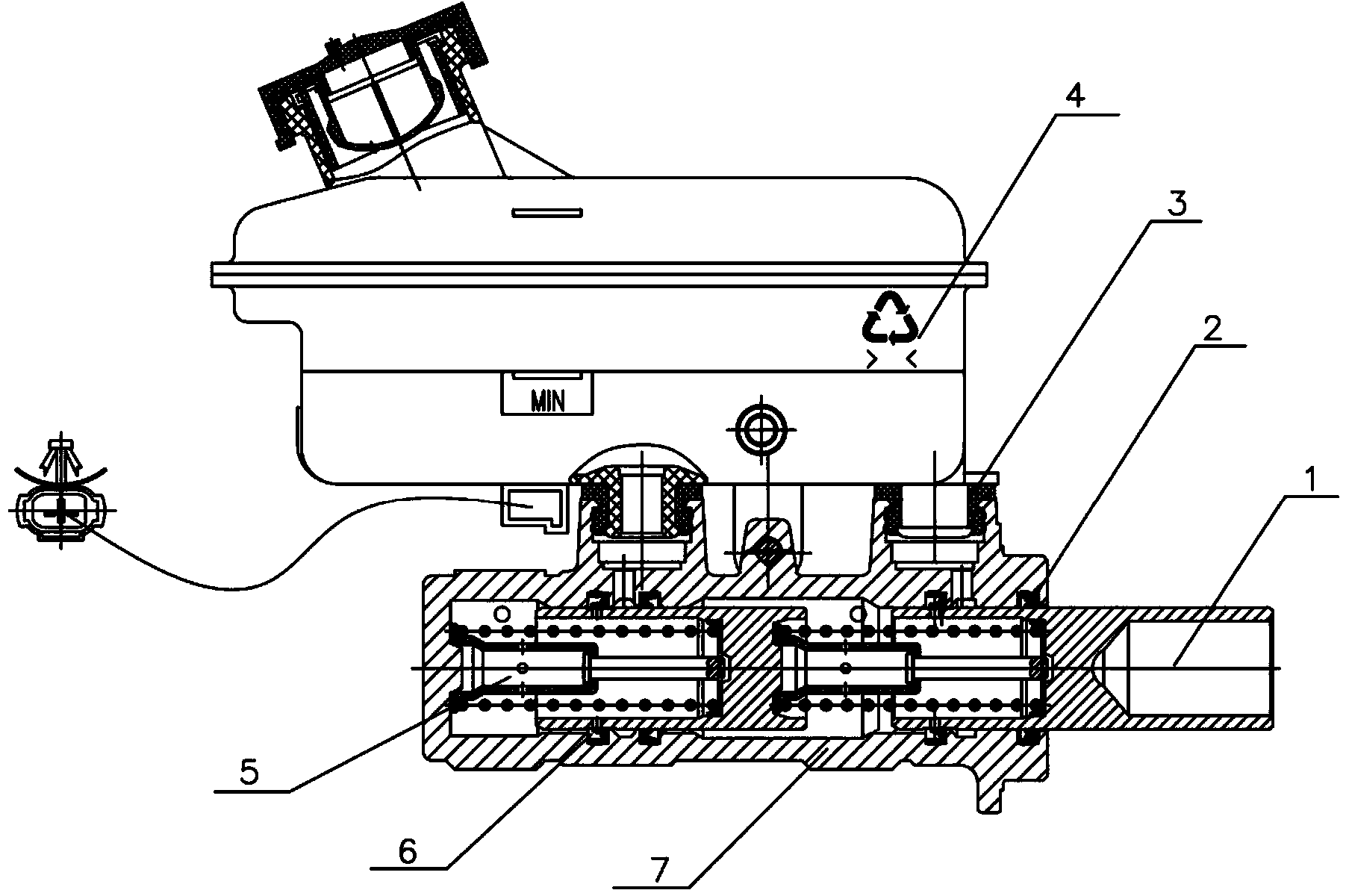

Brake master cylinder assembly

InactiveCN103448705AShorten the lengthOptimize space layoutFluid braking transmissionRubber CupMaster cylinder

The invention relates to a brake master cylinder assembly, which mainly comprises a brake oil storage cup, a master cylinder body, a first piston assembly and a second piston assembly, wherein the brake oil storage cup is fixed on the upper part of the master cylinder body; an oil outlet of the brake oil storage cup is mutually matched with an oil inlet of the master cylinder body; a sealing rubber cup is arranged at a connector; the first piston assembly and the second piston assembly are arranged in the master cylinder body, and are mutually connected in series. The brake master cylinder assembly has the beneficial effect that the working stroke is increased, meanwhile, the length of the cylinder body can be shortened as soon as possible, the spatial arrangement of a vehicle is favored, after the working stroke of the brake master cylinder is lengthened, the volume of liquid provided when the vehicle is braked can be increased, the braking force is increased, and the safety of the vehicle is enhanced.

Owner:ZHEJIANG WANXIANG SYST +1

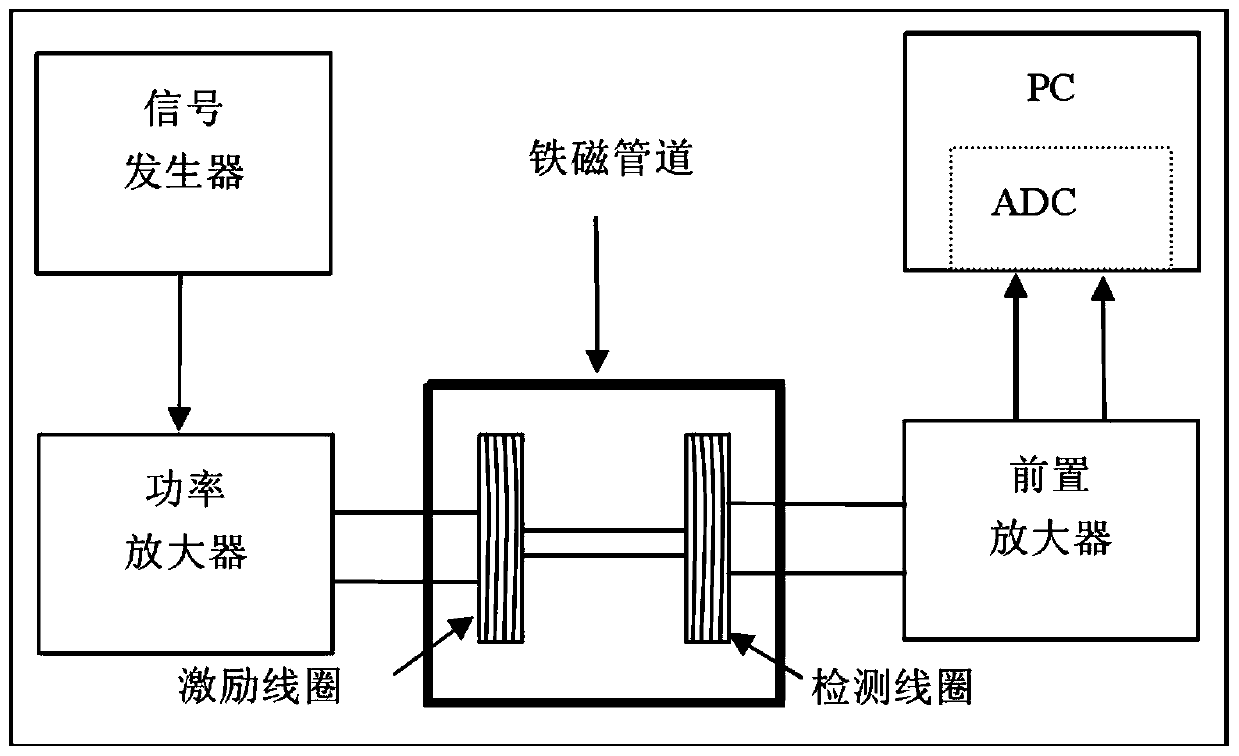

Crude oil conveying pipeline inside corrosion detection device and method thereof

PendingCN109932419AEarly detection of corrosionFew missing defectsMaterial magnetic variablesRubber CupEngineering

The invention discloses a crude oil conveying pipeline inside corrosion detection device and a method thereof. A mileage counting wheel is attached onto the inner wall of a pipeline; a circuit controland data storage device is provided with a speed controller; pressure difference generated on the surface of a driving rubber cup through a liquid forms a driving force, so that the detection devicecan be made to move forward in the pipeline; a driving area and the number of installations can be changed, so that the driving force can be stabilized, and the moving speed of the detection device can be controlled; the circuit control and data storage device is connected with a data analysis unit; and corrosion conditions inside the pipeline can be analyzed through detection electromagnetic signals stored in the circuit control and data storage device. The crude oil conveying pipeline inside corrosion detection device and the method thereof of the invention have the advantages of suitabilityfor the detection of small-diameter pipelines, stable detection signals, easiness in corrosion defect quantification, and high applicability for pipelines with many elbows.

Owner:PETROCHINA CO LTD

Discharge gate mechanism

ActiveCN101555946AGood retention propertiesMaintain propertiesOperating means/releasing devices for valvesLift valveRubber CupEngineering

The invention relates to a discharge gate mechanism. The mechanism comprises a discharge gate which rests against a discharge hopper port inside a discharge bin, a coupler, an L-shaped connecting lever, an axial supporting device of the L-shaped connecting lever, a drive unit of the L-shaped connecting lever and a sealing member for sealing a connecting part of the parts; the coupler consists of a pin boss and a pin inserted into the same, and is externally provided with a matching sealing rubber sleeve; one arm of the L-shaped connecting lever is connected with the discharge gate by the coupler, and the other arm is provided with a stepped section which hermetically passes through a discharge bin shell and is connected with the drive unit, and the stepped section is sequentially sheathed with a sealing rubber cup, a supporting casing and a retaining ring of the axial supporting device; the sealing rubber cup, the supporting casing and the retaining ring are arranged inside a supporting sleeve, one end of the supporting sleeve is fixedly arranged outside the discharge bin shell, and the other end of the supporting sleeve is fixedly connected with the drive unit; and a sealing ring is arranged between the supporting casing and the supporting sleeve. The discharge gate mechanism has the advantages of good tightness, convenient opening and closing and easy assembly and disassembly for cleaning.

Owner:BEIJING GOLDENTEAM TECH

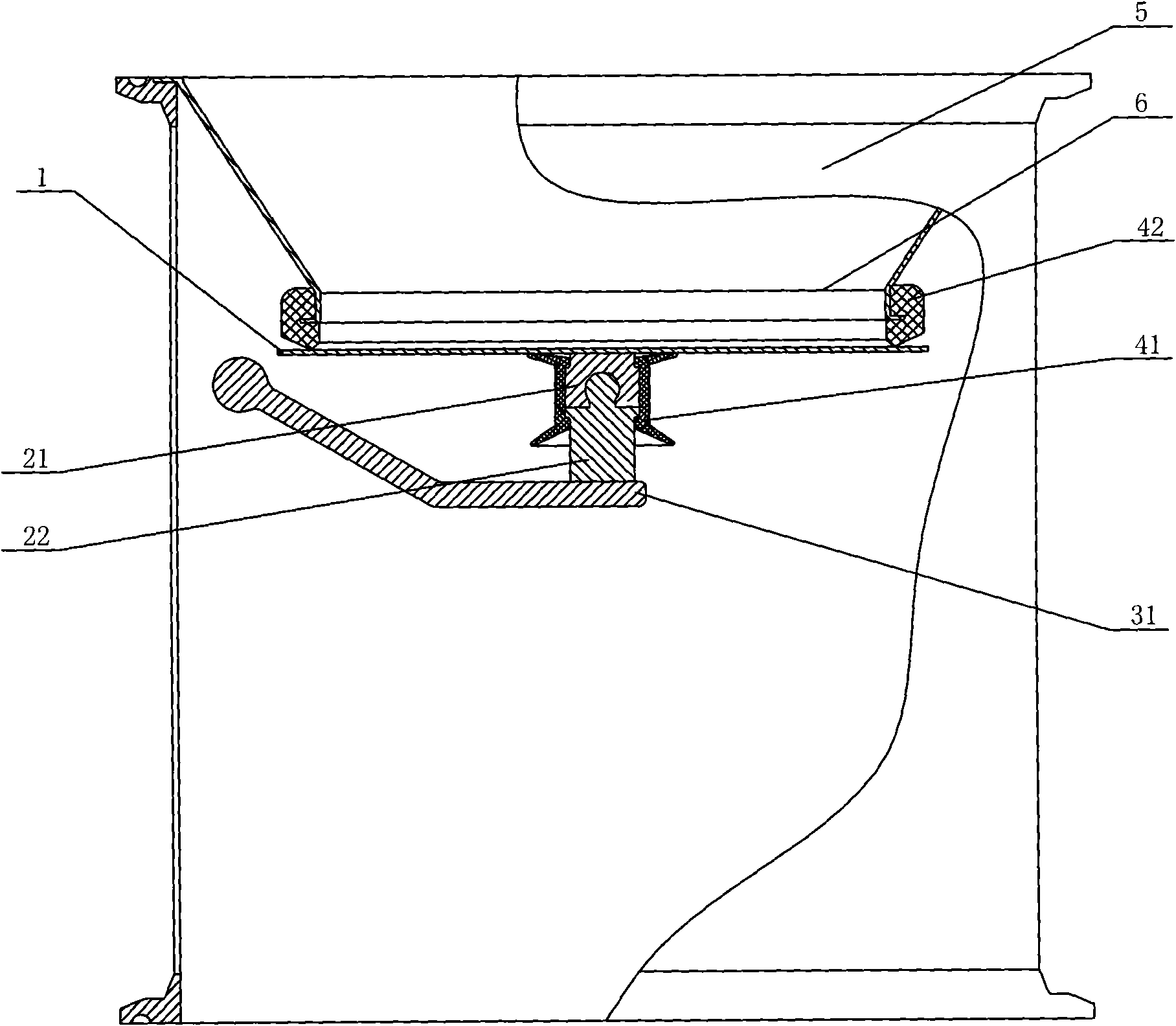

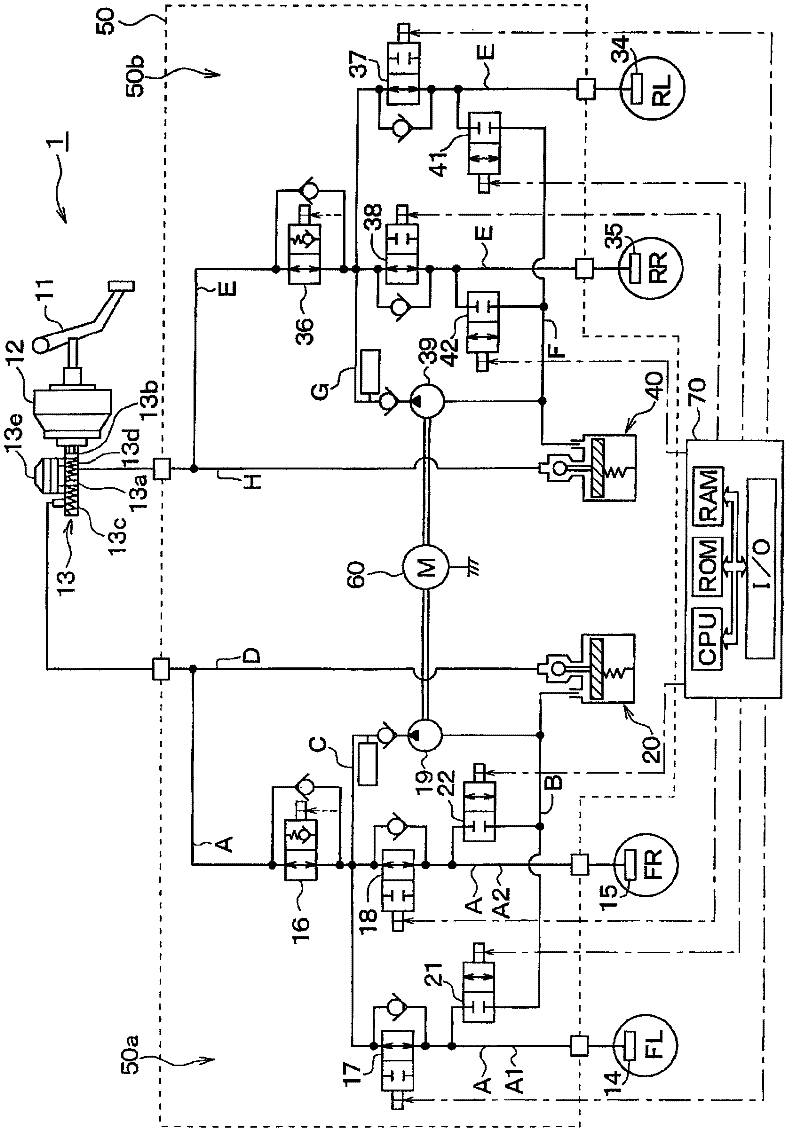

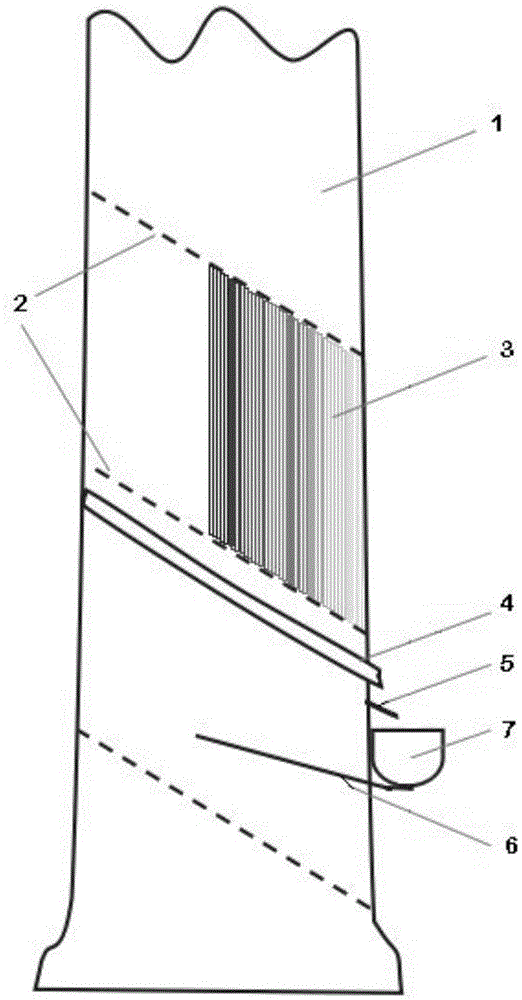

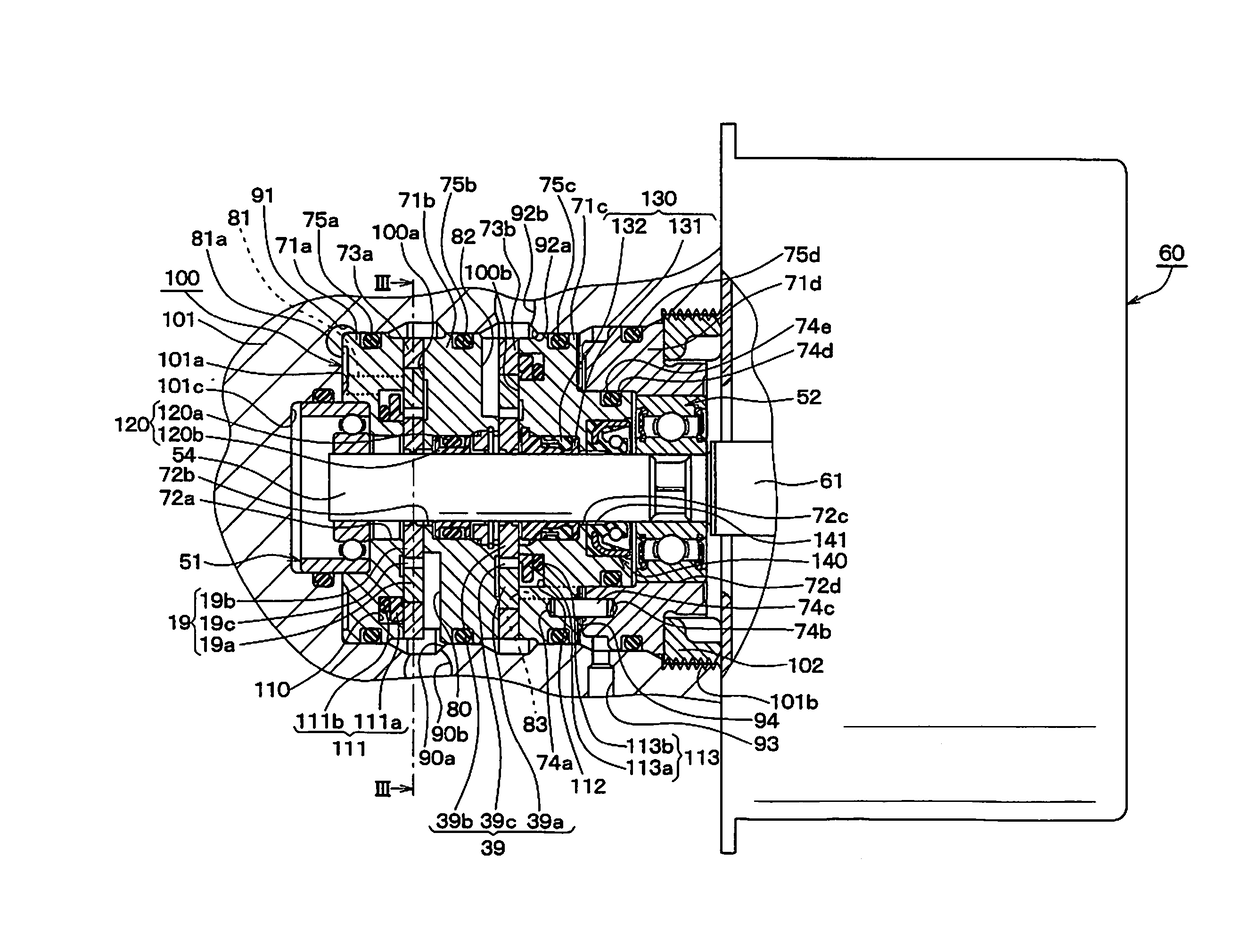

Sealing apparatus

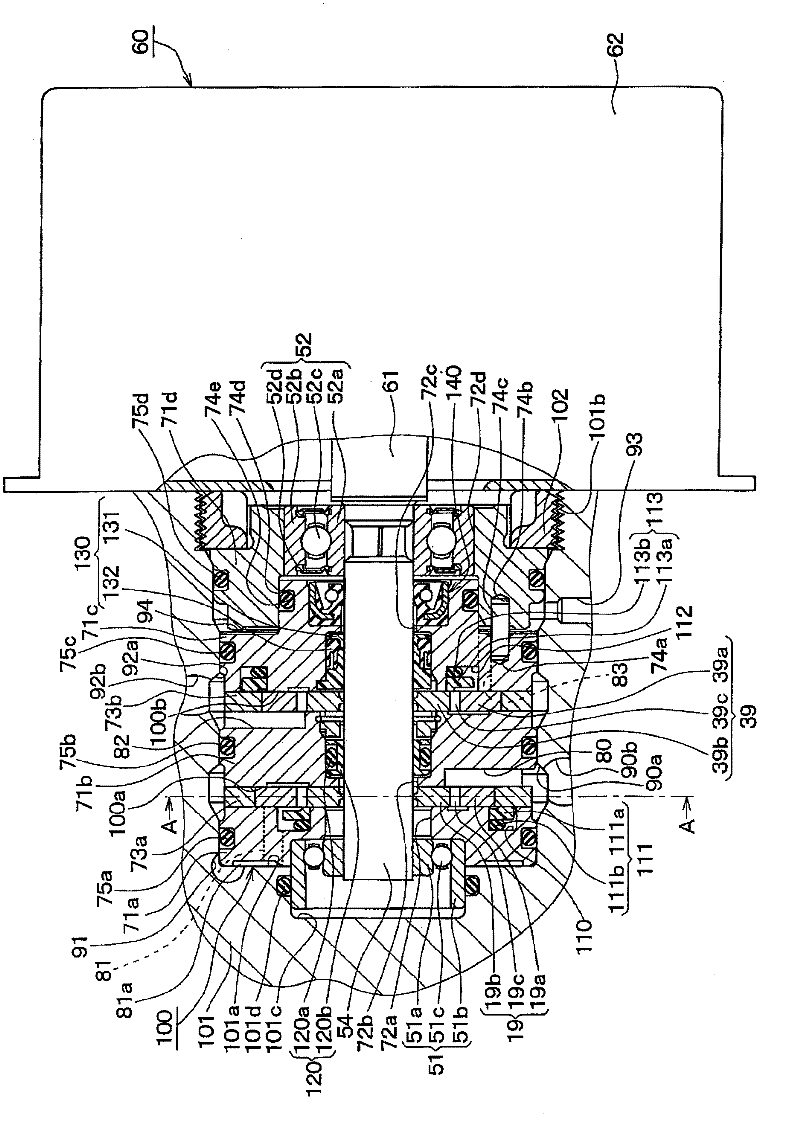

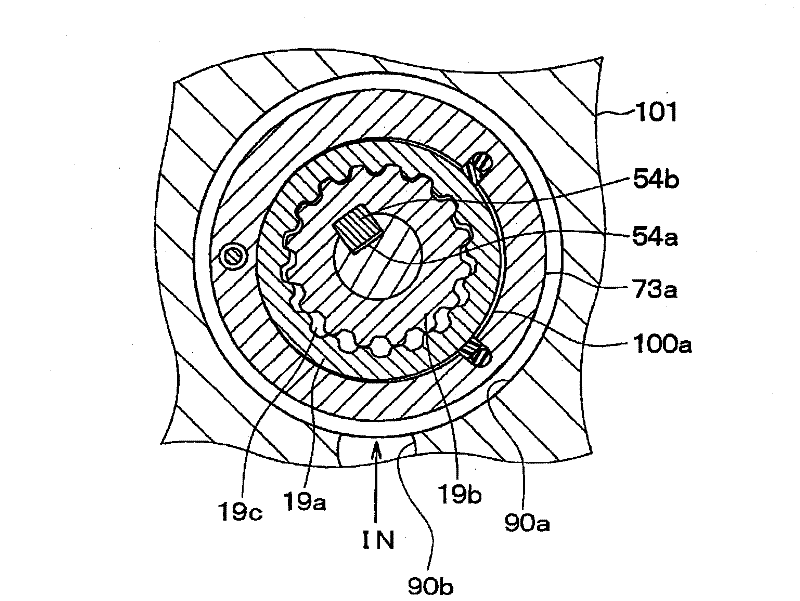

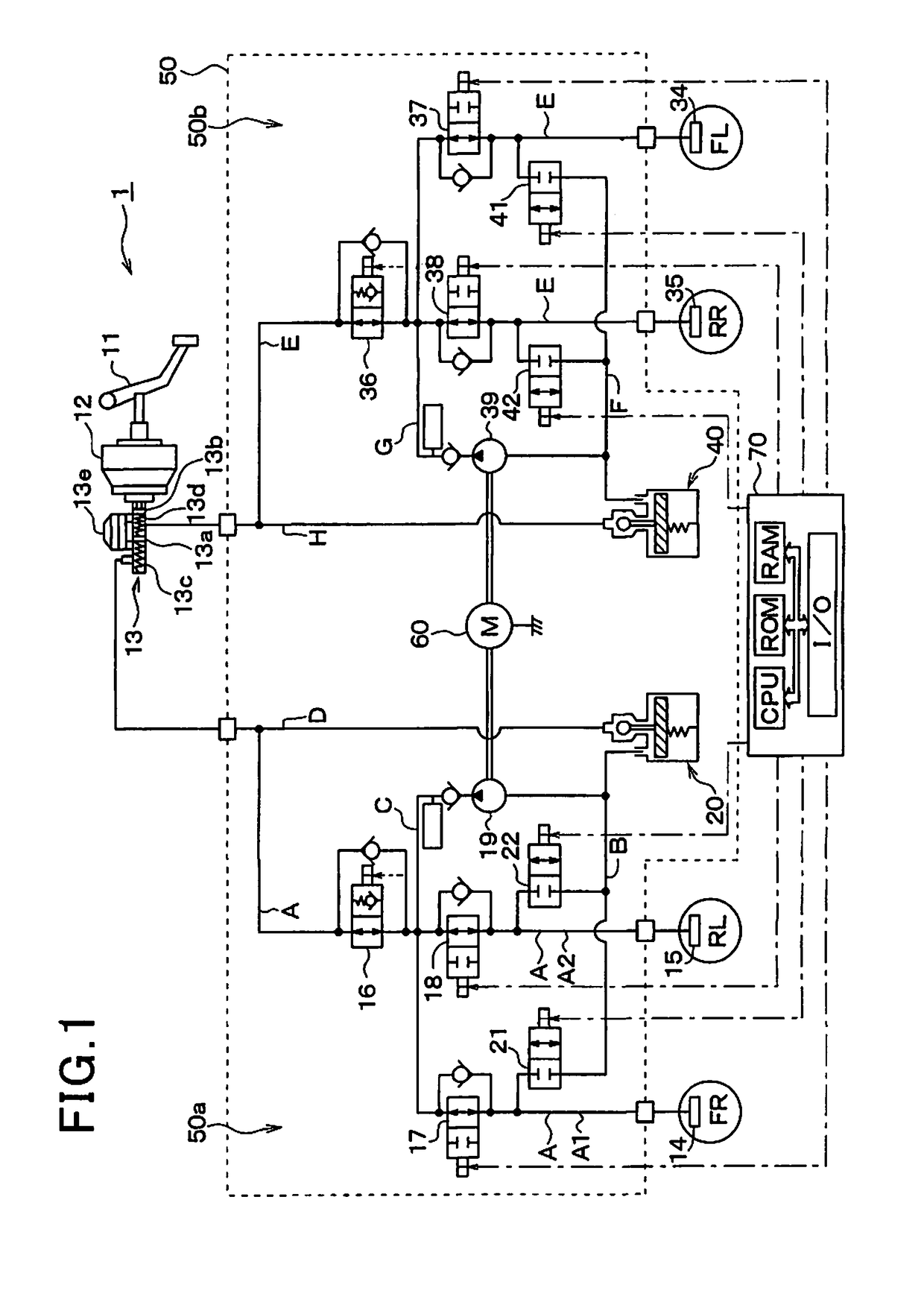

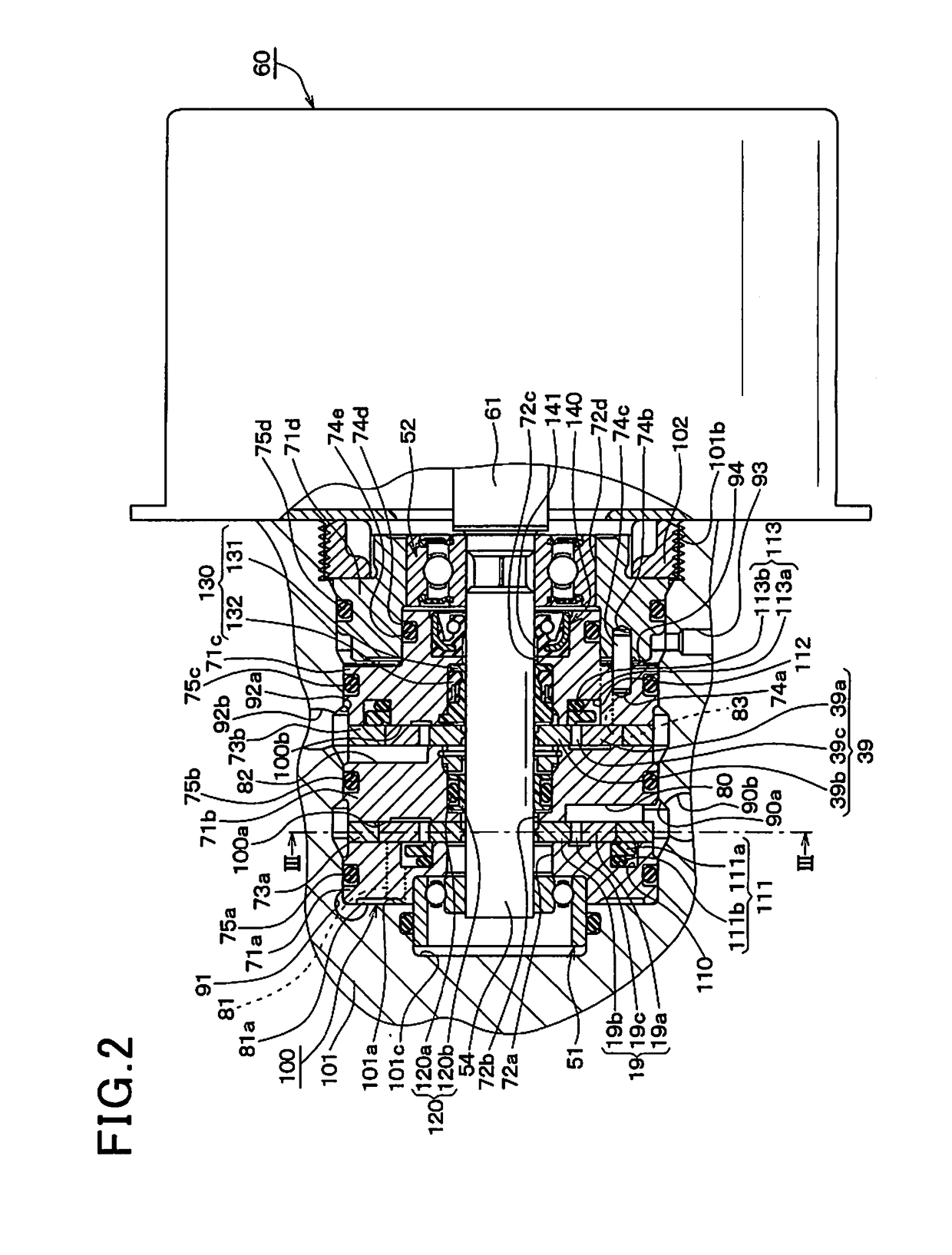

The invention provides a sealing apparatus capable of limiting axial movement of a sealing member disposed between a shaft and a housing. A rubber cup (132) of the sealing member (130) is configured to have a base portion (132a) and a lip portion (132b), wherein the lip portion (132b) is used for limiting flow of braking fluid from a first chamber to a second chamber; and the base portion (132a) is fixed to a prescribed position between a resin ring (131) and a third cylinder barrel (71c). Thus, the axial movement of the sealing member (130) between a driving shaft (54) serving as the shaft and the third cylinder barrel (71c) serving as one part of the housing can be limited. Therefore, the sealing apparatus is capable of preventing pumping caused by axial movement of the sealing member (130) on the driving shaft (54) and preventing pressure rise of the second chamber between the sealing member (130) and an oil seal (140), and pressure leakage and / or harmful effect on tightness following the pressure rise.

Owner:ADVICS CO LTD

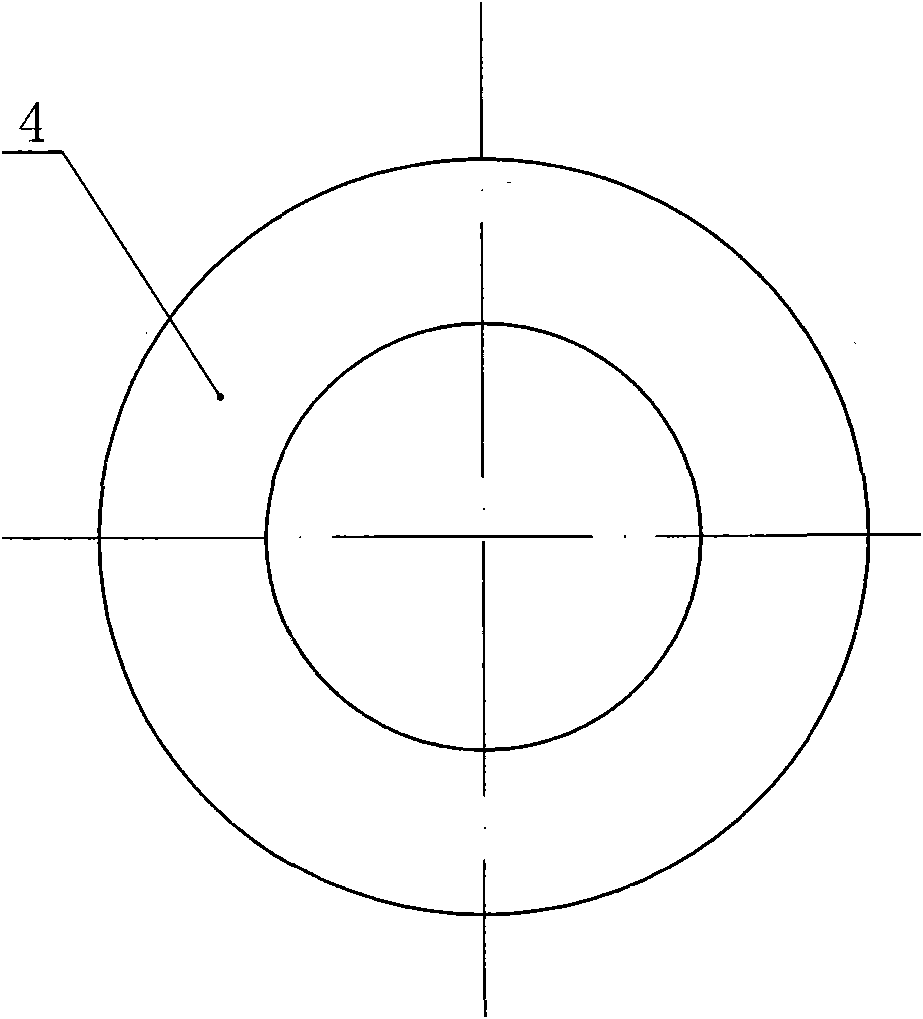

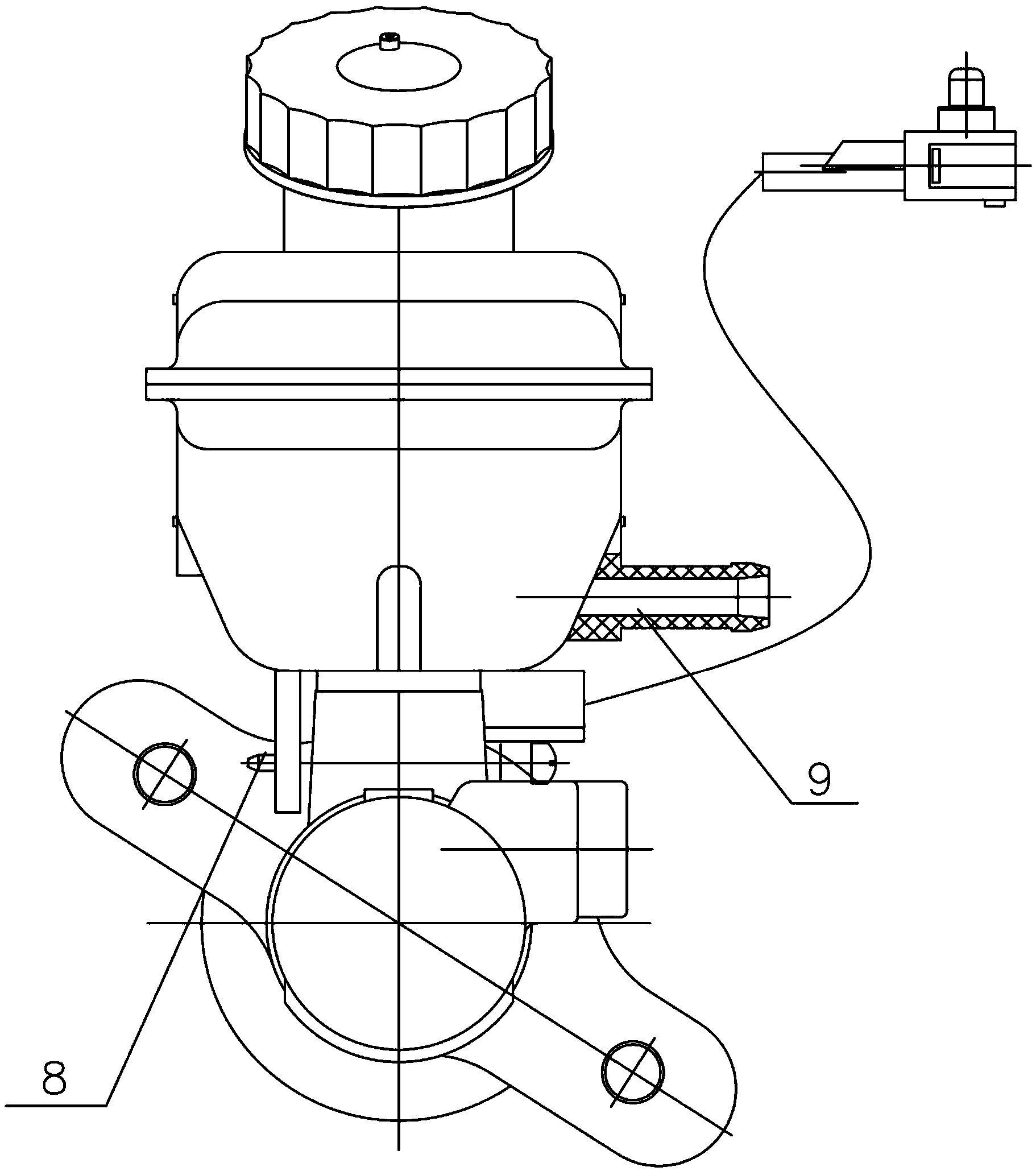

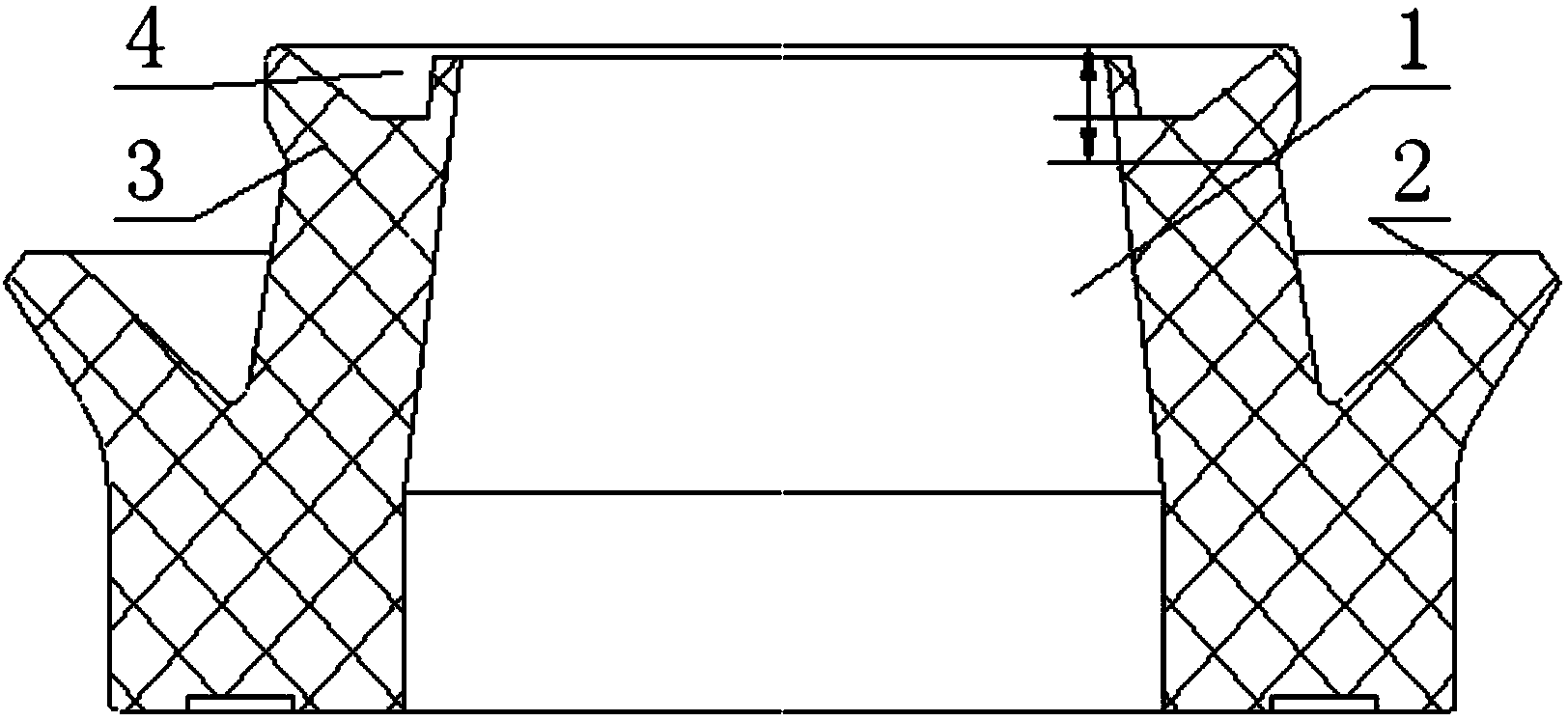

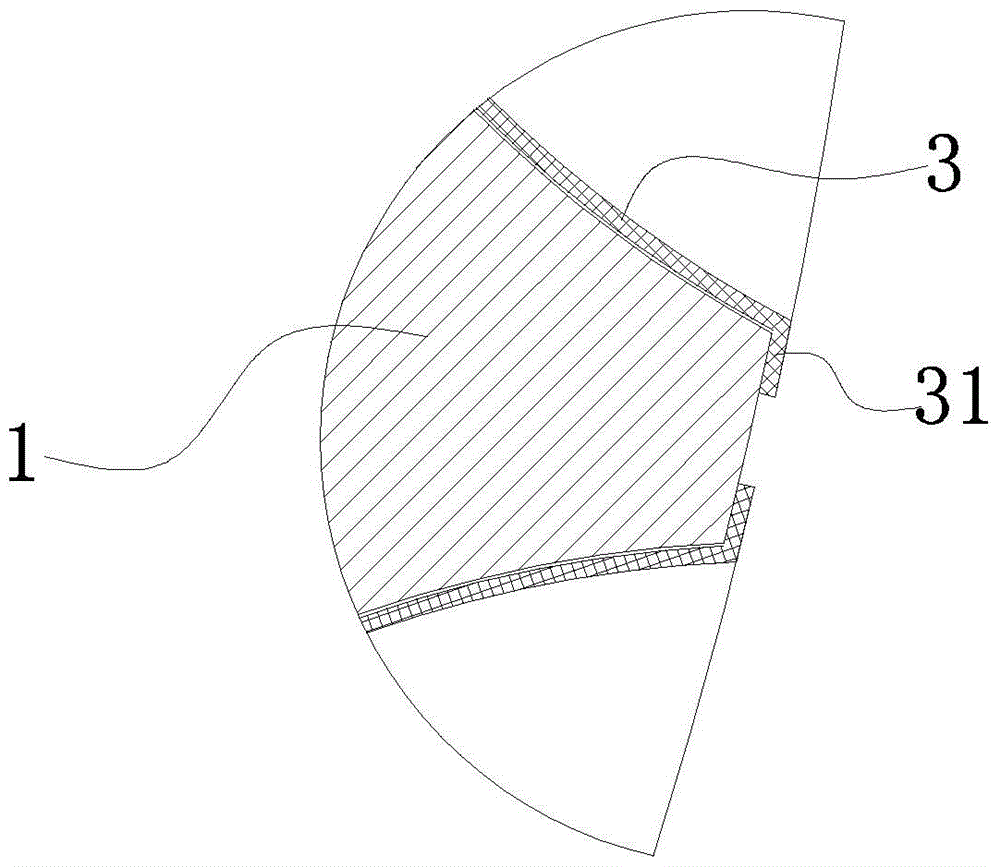

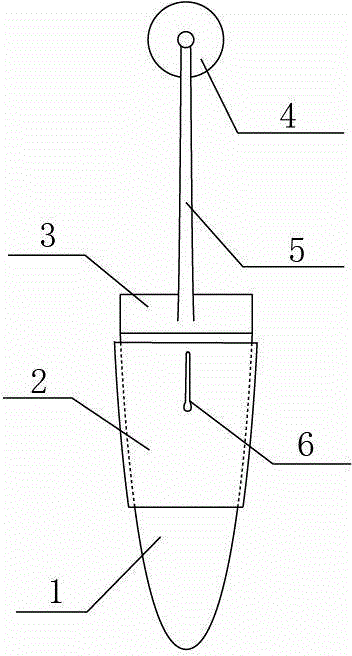

Rubber cup of automobile brake

InactiveCN103968075AManufacturing precision requirements are lowGuaranteed StrengthEngine sealsInterference fitRubber Cup

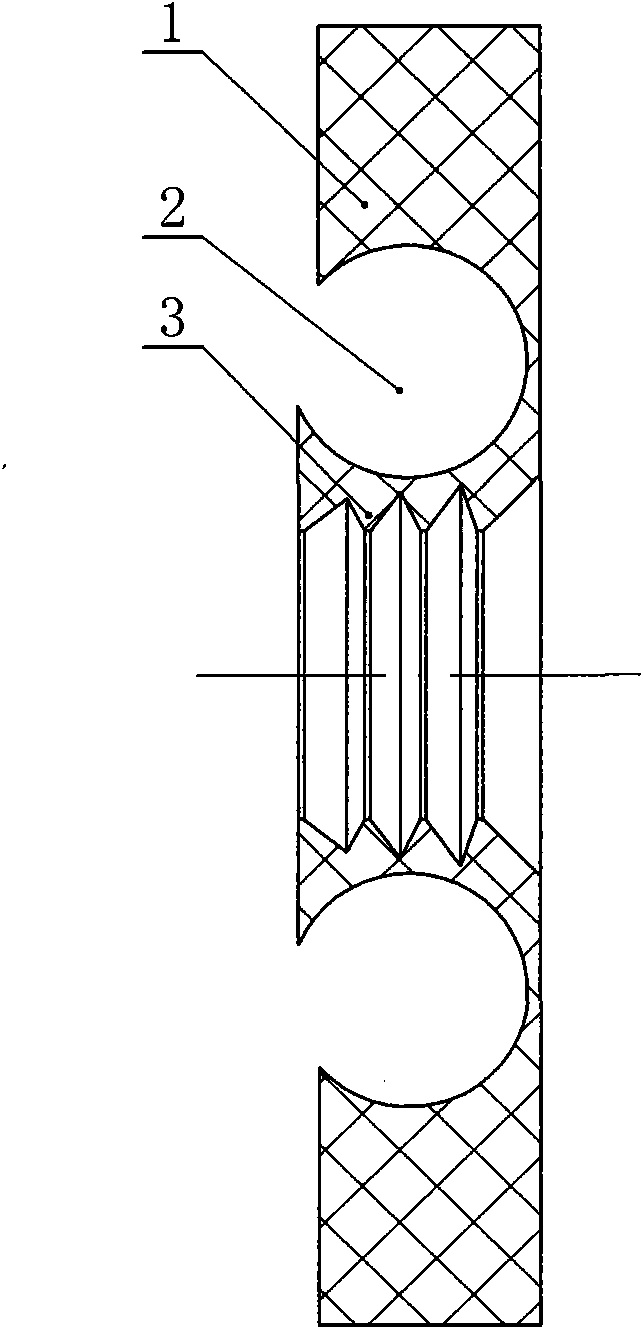

The invention discloses a rubber cup of an automobile brake. The rubber cup of the automobile brake comprises a cup body (1) and is characterized in that the cup body (1) is provided with an outer lip (2) and an inner lip (3), and the inner lip (3) is provided with a groove (4). According to the rubber cup of the automobile brake, the inner lip is provided with the groove, so the elasticity of the end of the inner lip can be lowered, and interference fit formed after the rubber cup is installed in a piston is mitigated. Compared with an existing cup, the rate of finished products can be increased by 10-20%. The rubber cup of the automobile brake has the advantages of being capable of mitigating the interference fit, good in sealing performance and not prone to damage.

Owner:HUZHOU QIANJIN BAOYUN MACHINERY CASTING

Oil pipeline cleaning device

The invention relates to an oil pipeline cleaning device, and belongs to the technical field of oil pipeline dredging equipment. The oil pipeline cleaning device consists of a stator body, a cleaningand brushing device, a front rubber cup, a rear rubber cup, a rotor body, a mandrel and a plurality of turbines; the rotor body is movably arranged in the stator body; one end of the rotor body extends to the outer side of the stator body; the cleaning and brushing device is arranged on the part, extending to the outer side of the stator body, of the rotor body; the turbines are arranged in the part, located in the stator body, of the rotor body through the mandrel; the turbines are fixedly connected with the rotor body; and the front rubber cup and the rear rubber cup are fixedly arranged atthe two ends of the outer side of the stator body correspondingly. The oil pipeline cleaning device is simple in structure and ingenious in design, energy is provided depending on crude oil conveyed in a pipeline without additional motive power, and cleaning on the pipeline is completed by scarping and extrusion drilling; and the oil pipeline cleaning device is especially suitable for oil pipelinecleaning and meets the use requirements of people.

Owner:YANGTZE UNIVERSITY

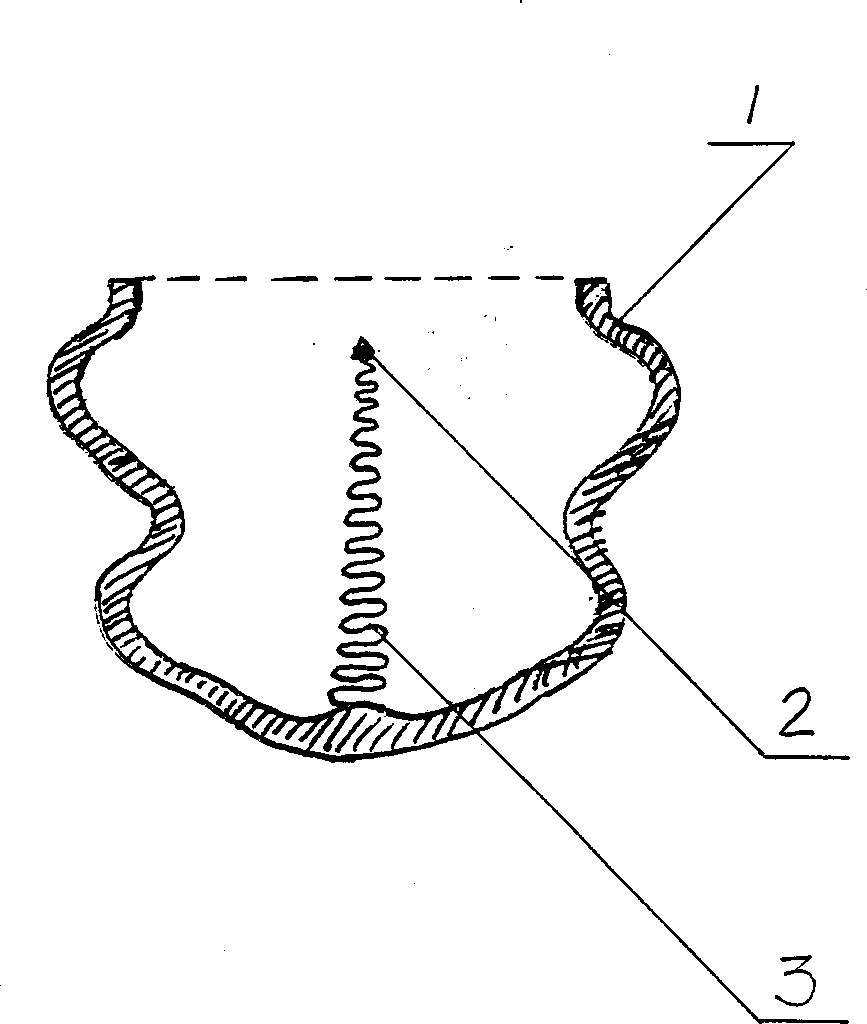

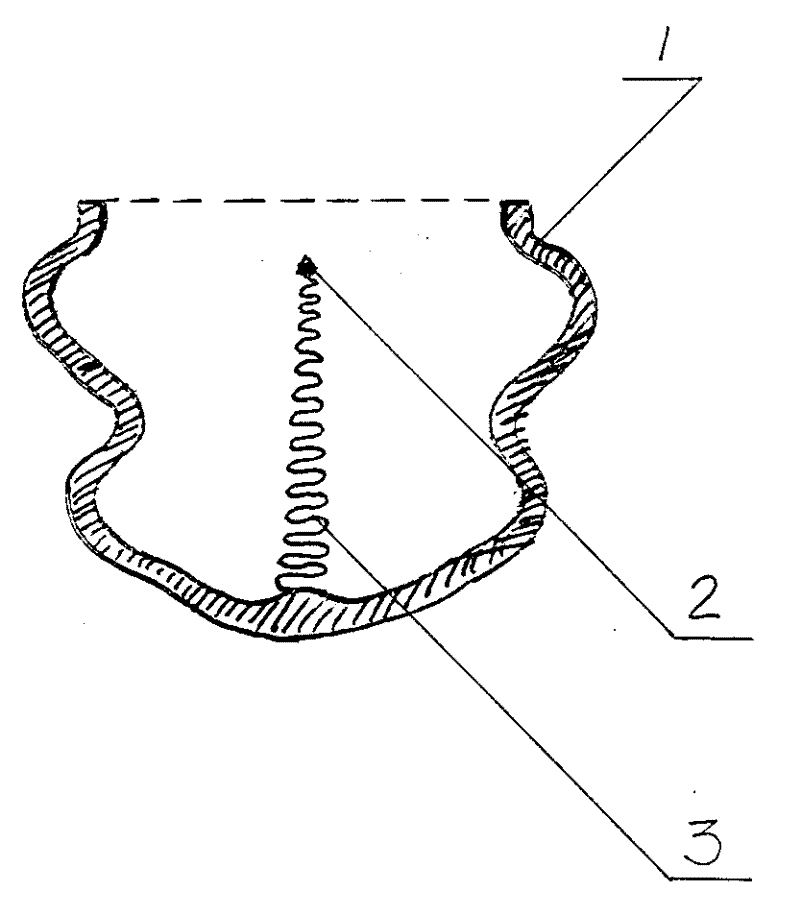

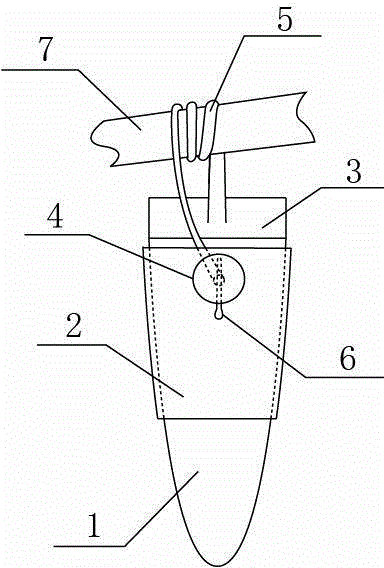

Magnetotherapeuitc rubber cup

The rubber magnetotherapeutic cup for traditional Chinese medicine cupping therapy is formed of rubber cup, spring and permanent magnet. Said rubber cup is a deformable one with several outside diameters, the spring is a compression spring, and hung from centre of cup bottom in the cup, and the permanent magnet is fixedly connected to the bottom end of said compression spring.

Owner:孙介义

Malaysian squid processing apparatus

The invention discloses a Malaysian squid processing apparatus, and aims to provide a processing apparatus capable of continuously producing fish balls and also capable of effectively clearing a fish ball pulp adhered to the inner walls of molding grooves for forming fish balls. The apparatus comprises a gas cavity, a negative pressure cavity, a frame, a left rotating disc and a right rotating disc arranged on the frame and synchronously relatively rotating, and a boiling device, the outer peripheral surfaces of the two rotating discs are respectively provided with a plurality of mutually corresponding molding grooves for forming the fish balls, the end surface of each of the rotating discs is provided with an annular slot coaxial to the corresponding rotating disc, and a gas guide sleeve is arranged in the annular slot; and the bottom surface of each of the molding grooves is provided with a gas guide through hole connected with the annular slot, a rubber cup is arranged in each of the molding grooves, and the port edge of the rubber cap is connected with the port edge of the corresponding molding grooves. The boiling device comprises a boiling box body with an open-ended upper end and a heating device arranged in the boiling box body, and the rotating discs are positioned above the boiling box body.

Owner:ZHEJIANG OCEAN UNIV

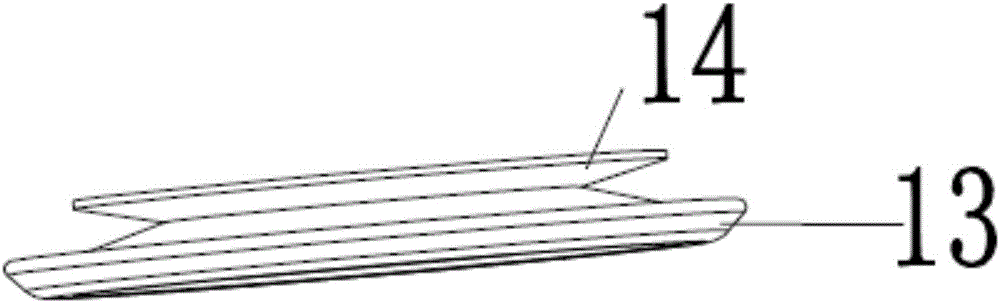

A kind of rubber tree tapping method

InactiveCN104604640BReduce labor intensityGood for up and down transportationForestryRubber CupEngineering

The invention relates to a rubber tree rubber tapping method. The method comprises the steps that 1, a plurality of non-intersecting oblique lines are scribed on the bark of a rubber tree, and a cutting plane is formed by the bark between every two adjacent oblique lines; 2, a flow guide chute is mounted below each cutting plane where rubber tapping will be conducted, and a duck tongue and a rubber cup are mounted at the bottom end of each flow guide chute; 3, a straight cutting line is cut in each cutting plane in the axial direction of the trunk of the rubber tree and vertically penetrates through the cutting plane; 4, the bark is cut leftwards or rightwards on the straight cutting lines along the straight cutting lines, after that, the bark continues to be cut along the straight cutting lines every time, rubber tree latex bursts out of the straight cutting lines, flows into the flow guide chutes and then flows into the rubber cups along the flow guide chutes. Bark cutting operation can be completed by workers or rubber tapping machines. By means of the method, original complex traditional rubber tapping operation is simplified, the rubber tapping speed is increased, and then the rubber tapping work efficiency is improved.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

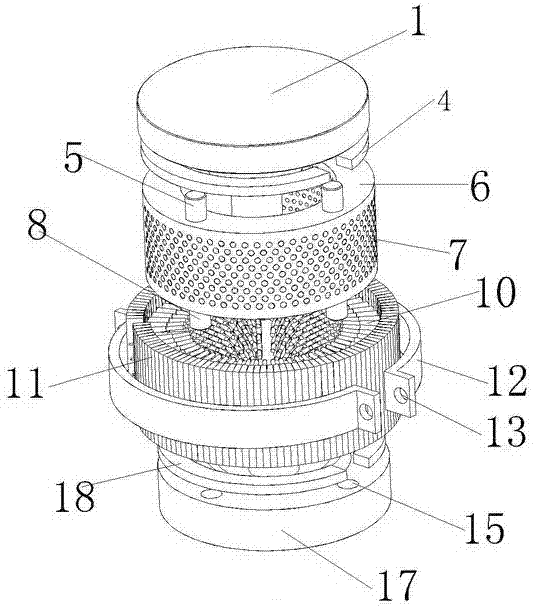

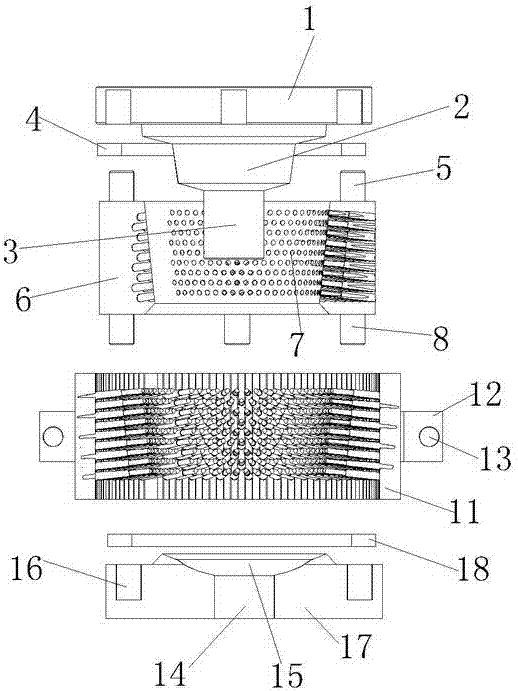

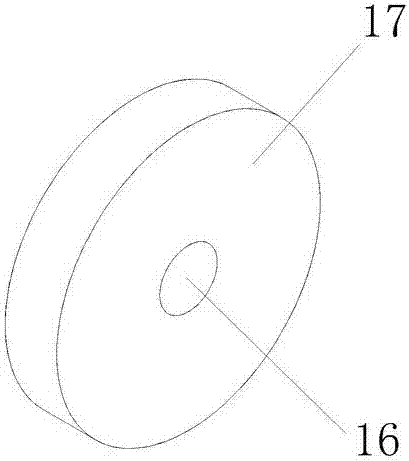

Slurry pump bionic piston casting forming method and device

The invention discloses a slurry pump bionic piston casting forming method and device. The slurry pump bionic piston casting forming device is mainly composed of an upper die cover, a middle support, a bottom die seat and a middle die. The upper die cover is provided with a male die, and a female die is arranged on the bottom die seat. A male die structure is used for forming a hollow part of a piston rubber cup, and a female die structure is used for fixing high-styrene butylbenzene framework base rubber. A middle shaft upper portion is used for forming a hollow part where a piston connecting rod is located, and a lower portion is matched with a positioning hole in the middle of the bottom die seat for achieving the centering effect. A bionic structure is designed on the middle die, and a bionic pit structure can be formed at a time after die assembling. By means of the method and device, the principle and the structure are simple, repeatability is high, and the method and device can be used for batched production of bionic pit-shaped pistons.

Owner:JILIN UNIV

Rotating pumping apparatus with seal mechanism

A rotating pumping apparatus is provided which may be employed in an automotive brake system. The rotating pumping apparatus includes a sealing member and an oil seal which are disposed around a pump drive shaft, and lubricating grease disposed between the oil seal and the pump drive shaft. The sealing member is made up of a resinous ring and a rubber cup. The sealing member has formed therein a labyrinthine flow path which extends from the resinous ring to the rubber cup. The labyrinthine flow path is designed to permit fluid to flow therethrough and create the resistance to flow of the lubricating grease to avoid leakage of the grease outside the sealing member.

Owner:ADVICS CO LTD

Automatic cleaning device for natural gas pipeline

PendingCN112958552AIncrease contactGuaranteed service lifeHollow article cleaningDirt cleaningRubber CupElectric machinery

The invention discloses an automatic cleaning device for a natural gas pipeline. The cleaning device comprises a device shell and a rubber cup coaxially and fixedly installed outside the device shell; the device shell is composed of a moving assembly cavity, a collecting bin, a rotating part and a gas injection part from left to right; a telescopic moving assembly is movably installed in the moving assembly cavity, a collecting bin is coaxially and fixedly connected to one side of the moving assembly cavity, a fixing cover is fixedly installed in the collecting bin, fan blades are coaxially and rotationally installed in the fixing cover, a rotating shaft is installed on a coaxial fixing rod of the fan blades, a shaft body of the rotating shaft is rotationally connected with a motor through a chain, the motor is fixedly installed on the inner wall of one side of the collecting bin, and a lithium battery is fixedly installed in the collecting bin; a rotating part is coaxially and rotationally installed at the end, away from the moving assembly cavity, of the collecting bin through a sealing bearing, a circular through opening penetrates through the side wall, away from the collecting bin, of the rotating part, a plurality of supporting columns are fixedly installed on the inner wall of the through opening, and fixing rings are fixedly installed at the ends of the supporting columns.

Owner:宁乡新奥燃气有限公司

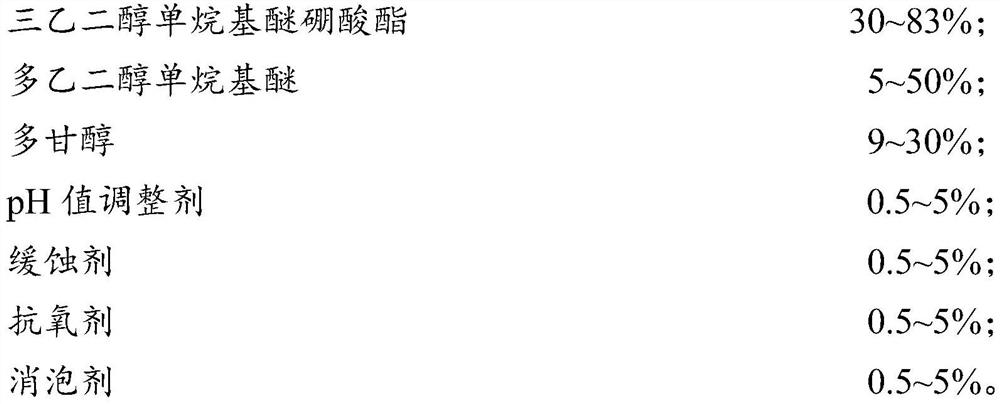

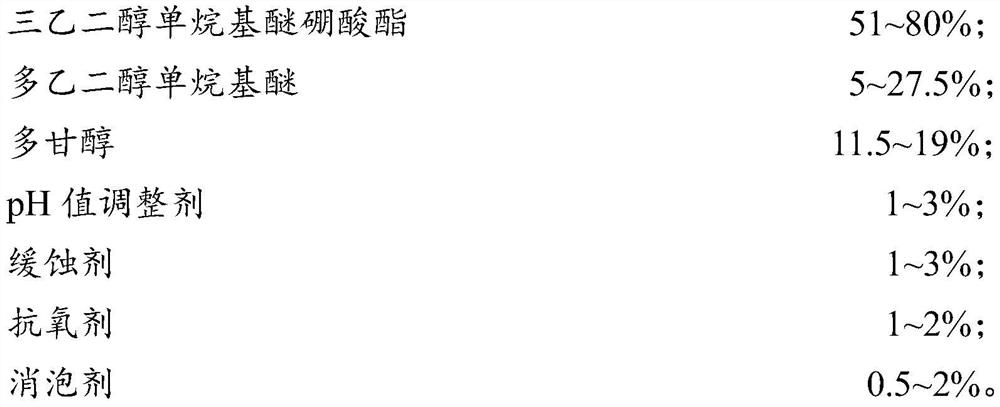

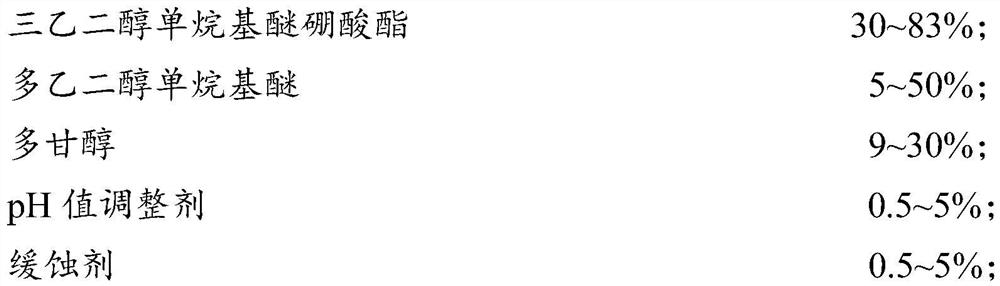

Motor vehicle brake fluid and preparation method thereof

The invention belongs to the technical field of brake fluids, and particularly relates to a motor vehicle brake fluid and a preparation method thereof. The invention provides motor vehicle brake fluid. The motor vehicle brake fluid comprises the following components in percentage by mass: 30-83% of triethylene glycol monoalkyl ether borate, 5-50% of polyethylene glycol monoalkyl ether, 9-30% of polyethylene glycol, 0.5-5% of a pH value regulator, 0.5-5% of a corrosion inhibitor, 0.5-5% of an antioxidant and 0.5-5% of a defoaming agent. The brake fluid provided by the invention has a relatively high dry-wet reflux boiling point and relatively low low-temperature viscosity under the combined action of triethylene glycol monoalkyl ether borate and polyethylene glycol monoalkyl ether with specific contents; meanwhile, under the combined action of the triethylene glycol monoalkyl ether borate, the polyethylene glycol monoalkyl ether and the polyethylene glycol with specific contents, the high adaptability to rubber is achieved, and the expansion effect on a rubber cup can meet the quality requirement of HZY5.

Owner:北京蓝星清洗有限公司

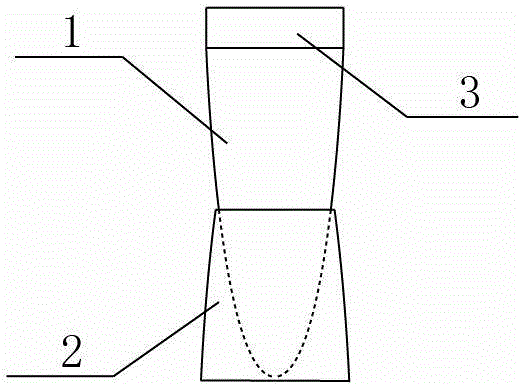

Portable cup

The invention discloses a portable cup. The portable cup comprises a cup body, a conical frustum shaped rubber cup sleeve, a cup cover, a sucker, a rubber cord and a gap. The portable cup is characterized in that the cup body is in a semi-elliptical shape integrally, the rubber cord is arranged on one side of the cup cover which is arranged at the upper end of the cup body, the sucker is arranged at the upper end of the rubber cord, and the gap is reserved in the conical frustum shaped rubber cup sleeve which is arranged on the outer side of the cup body. When hoping to put the cup on a table, a user can take off the conical frustum shaped rubber cup sleeve, put the conical frustum shaped rubber cup sleeve upside down on the table and put the cup body in the conical frustum shaped rubber cup sleeve; when hoping to hang the cup, the user can adhere the sucker onto a wall, and if the sucker cannot be used, the user can wind the rubber cord on the cup cover onto any transverse rod in surroundings and insert the sucker from one side of the gap to the other side of the gap to realize fixation. The portable cup has the advantages of simple design, reliability, durability and high practicality.

Owner:平邑经发科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com