A kind of rubber tree tapping method

A rubber tree and rubber tapping technology, which is applied in the field of rubber tree rubber mining, can solve the problems of high production cost of rubber tapping labor, shortage of skilled rubber workers, high labor intensity, etc., and achieve the effects of avoiding tree damage, expanding rubber tapping workers resources, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of rubber tree tapping method provided by the invention comprises the following steps:

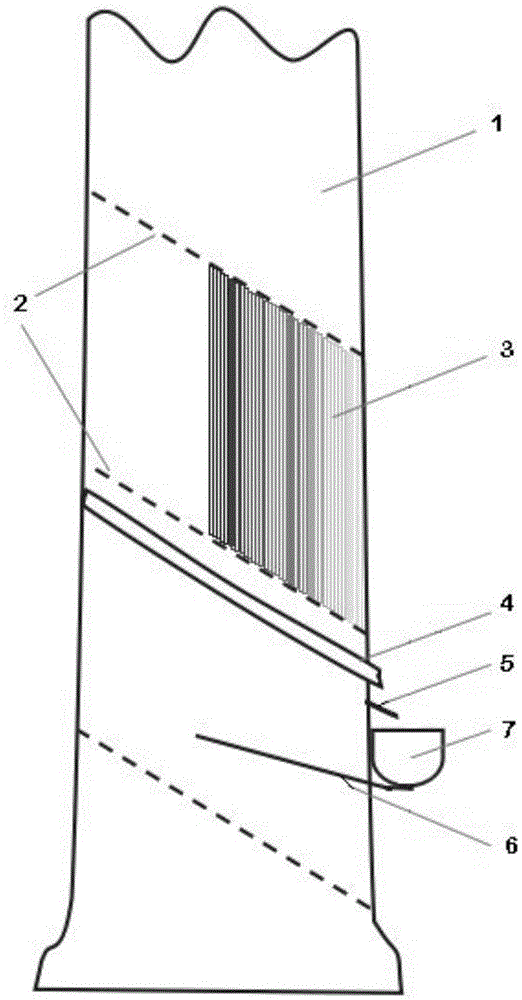

[0022] (1) The straight line that connects the direction central point between the rubber tree strains is the boundary line that the rubber tree trunk 1 is divided into two sides, and the intersection point of the bud joint junction of any side line and the rubber tree is the starting point, draw on the rubber tree trunk bark A slant line 2 with an upward angle of 20° to the circumference of the tree, ending at the other side line of the side, taking this slant line 2 as the baseline, above it, draw a parallel slash line 2 every 50cm, two adjacent The bark between the oblique lines 2 is a cut surface 3;

[0023] (2) the diversion groove 4 of about half a tree circumference is installed at the bottom 5-10cm place of the lowest cut surface 3, and the duck tongue 5 is installed at the 3-7cm place below the diversion groove 4 bottom, and the duck tongue 5 below 10 Install the pl...

Embodiment 2

[0028] A kind of rubber tree tapping method that present embodiment provides, comprises the steps:

[0029] (1) The straight line that connects the direction central point between the rubber tree strains is the boundary line that the rubber tree trunk 1 is divided into two sides, and the intersection point of the bud joint junction of any side line and the rubber tree is the starting point, draw on the rubber tree trunk bark A slant line 2 with an upward angle of 25° to the circumference of the tree, ending at the other side line of the side, taking this slant line 2 as the baseline, above it, draw a parallel slash line 2 every 60cm, two adjacent The bark between the oblique lines 2 is a cut surface 3;

[0030] (2) the diversion groove 4 of about half a tree circumference is installed at the bottom 5-10cm place of the lowest cut surface 3, and the duck tongue 5 is installed at the 3-7cm place below the diversion groove 4 bottom, and the duck tongue 5 below 10 Install the plas...

Embodiment 3

[0034] A kind of rubber tree tapping method that present embodiment provides, comprises the steps:

[0035] (1) Take the intersection point of the straight line formed by the direction center point between the rubber tree strains and the bud joint of the rubber tree as the starting point, draw a slant line 2 that is 20° with the upper angle of the tree circumference along the bark of the rubber tree trunk, and use this slant line 2 is the baseline, above it, draw a parallel oblique line 2 every 70cm, and the bark between two adjacent oblique lines 2 is a cut surface 3;

[0036] (2) Install a diversion groove 4 with a length of about 25cm at the place 25-30cm below the cutting surface 3, and install a duck tongue 5 at 3-7cm below the bottom of the diversion groove 4, 10-10cm below the duck tongue 5. A plastic cup holder 6 capable of fixing the plastic cup 7 is installed at 20 cm, and the mouth of the plastic cup 7 is located directly below the lower end of the duck tongue 5;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com