Double-pipe line hydraulic brake main cylinder

A technology of hydraulic braking and dual pipelines, which is applied in the field of improvement of existing automobile braking systems, can solve problems such as poor corrosion resistance, increased production costs, and reduced service life, and achieve weight reduction, cost reduction, and price reduction. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

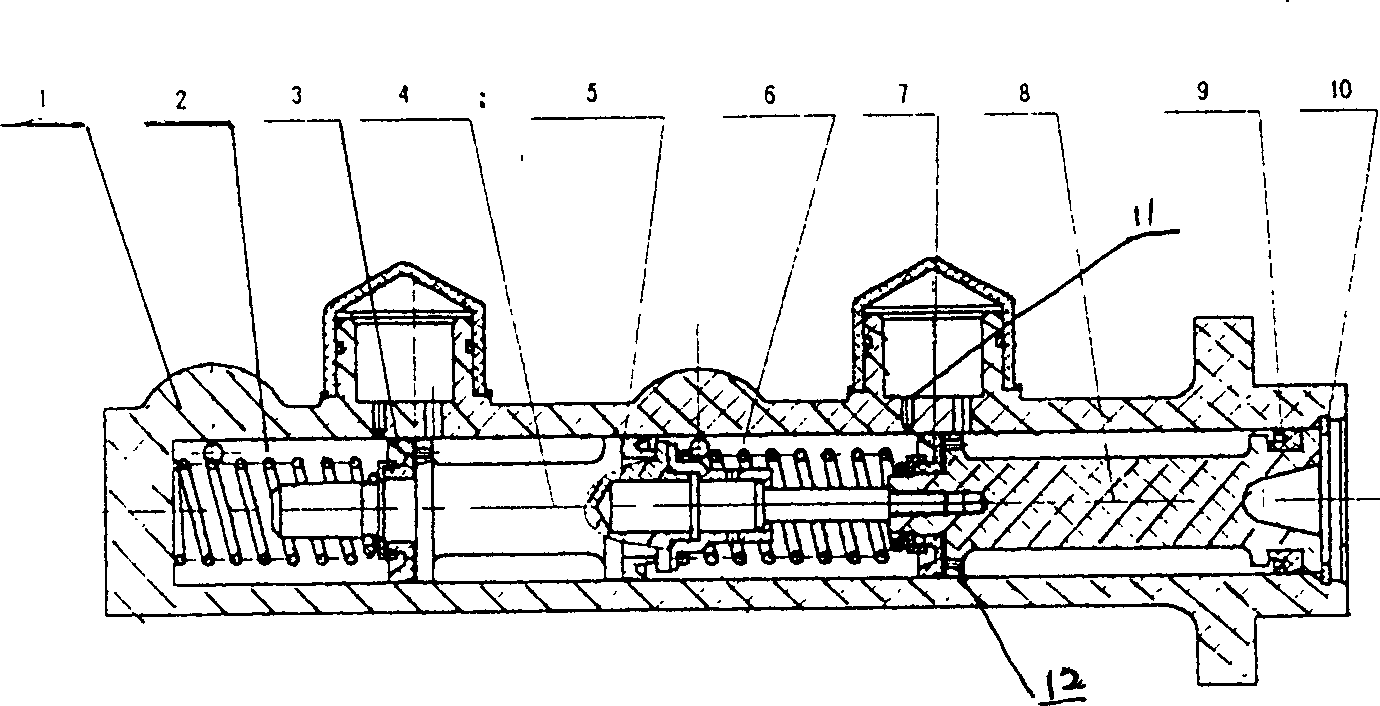

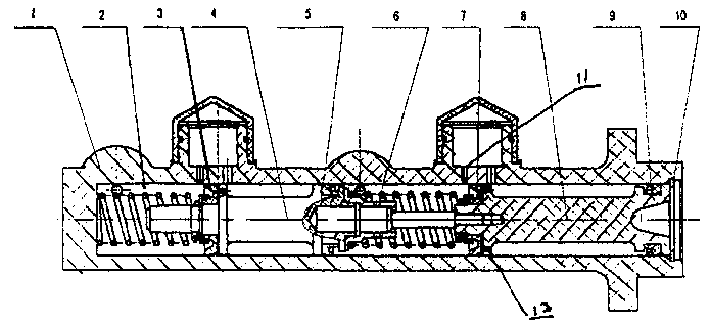

[0007] As shown in the figure, the dual-pipeline hydraulic brake master cylinder provided by the present invention mainly includes a cylinder block, a first piston, a second piston, a first spring, a second spring, a main cup, and an auxiliary cup , spring retaining ring and compensation hole, etc., the improvement is that the piston is provided with an axial ¢1 oil hole, and the master cylinder body and piston are composite reinforced, wear-resistant and heat-resistant , modified nylon material, and one-time die-casting molding, wherein the composition of the modified nylon material is: nylon 80-85%, glass fiber 2-3%, carbon fiber 6-7%, and the rest is NBR; Die-casting molding process The parameters are: the pressure required for injection molding is 5000MPa, the temperature required for injection molding is 250-260°C, the pressure-holding time for injection molding is 10-15 seconds, and the cooling method is air cooling.

[0008] The present invention is to the performance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com