Polishing pad finishing head

A polishing pad, an integrated technology, applied in the direction of grinding/polishing equipment, abrasive surface adjustment devices, grinding machine parts, etc., can solve problems such as unstable air pressure, rubber bowl 1 fatigue damage, easy to break, etc., to achieve guaranteed repair effect, increase service life, improve the effect of dressing wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

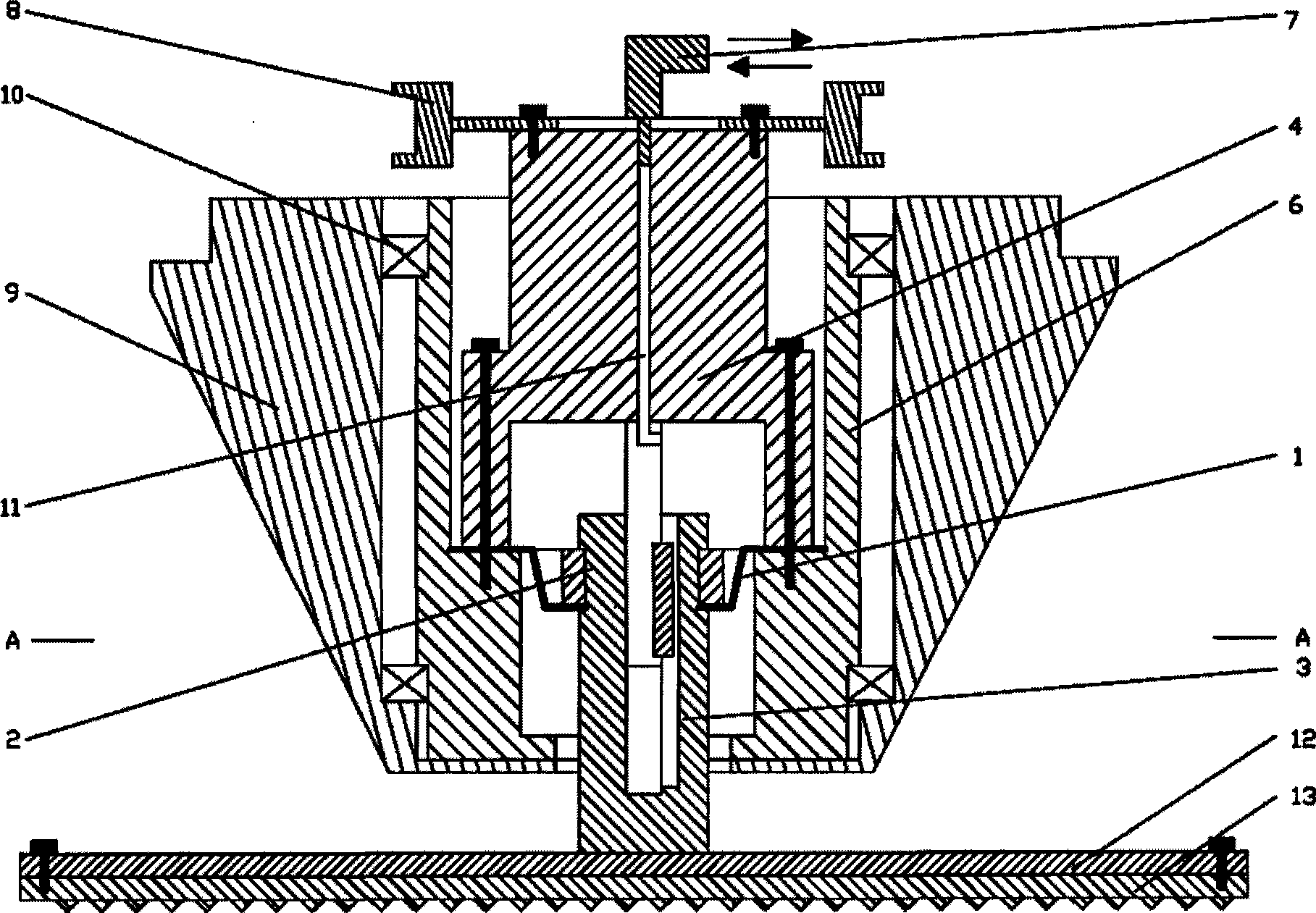

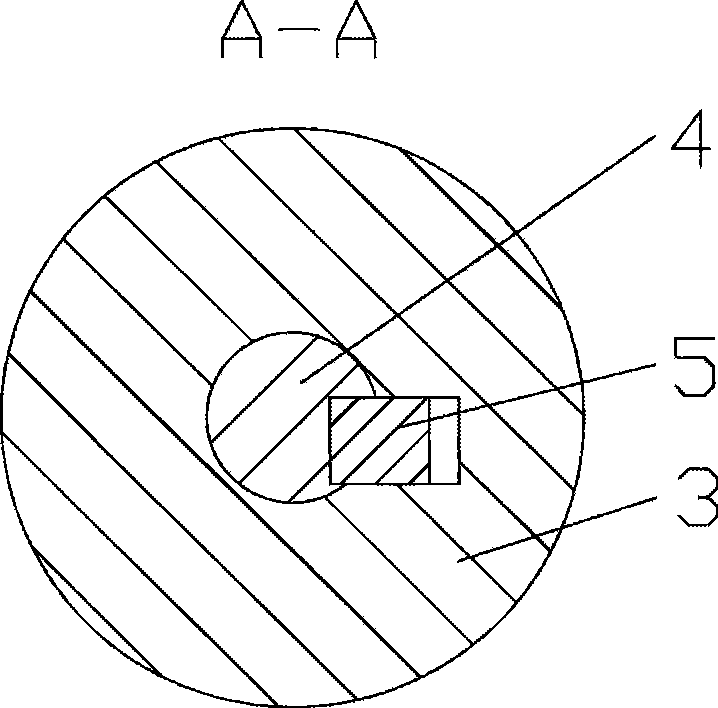

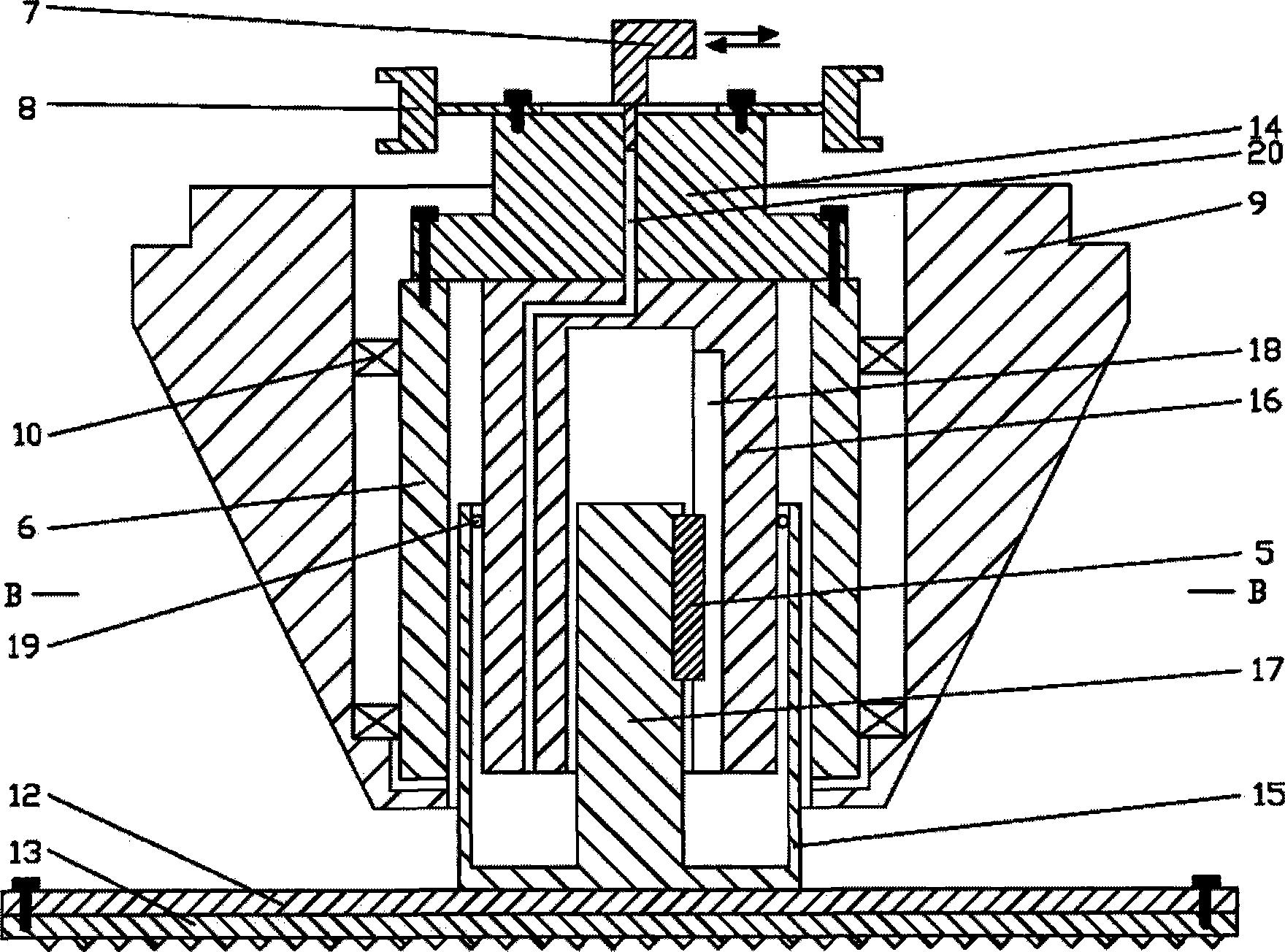

[0036] Such as image 3 and Figure 4 As shown, the polishing pad dressing head of the first specific embodiment of the present invention includes a rotatable air pipe joint 7, a synchronous pulley 8, a second rotating block 14, a key 5, a support body 9, a bearing 10, a first cylinder Body 15, first cylinder piston 16, two rotating rings 6. Described synchronous pulley 8, the second rotating block 14, the first cylinder piston 16, and the rotating ring 6 are connected as one; 2 bearings 10 are installed on each rotating ring 6, therefore, the rotating ring 6 and the first cylinder piston 16 It can rotate under the drive of the synchronous pulley 8; the inside of the second rotating block (14) and the first cylinder piston (16) has a second air pipe passage (20); the key 5 is fixed on the core of the first cylinder body On the shaft 17, the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com