Motor vehicle brake fluid and preparation method thereof

A technology for motor vehicles and brake fluids, which is applied in the field of brake fluids and can solve problems such as inability to meet higher-level requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

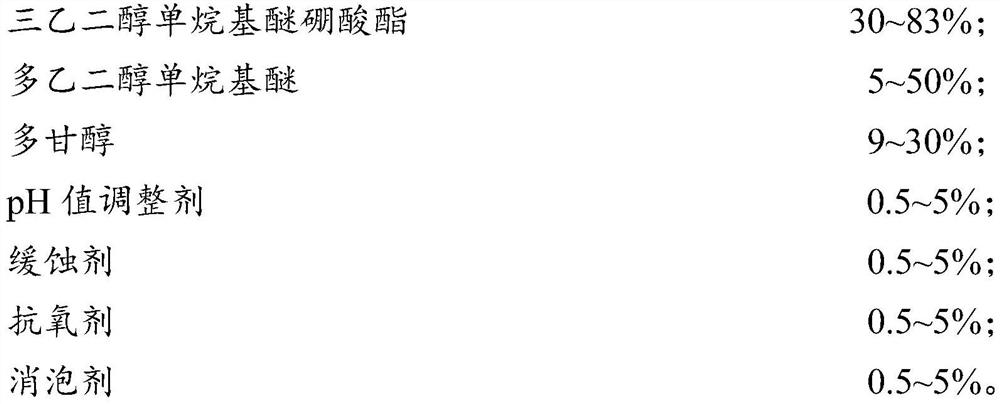

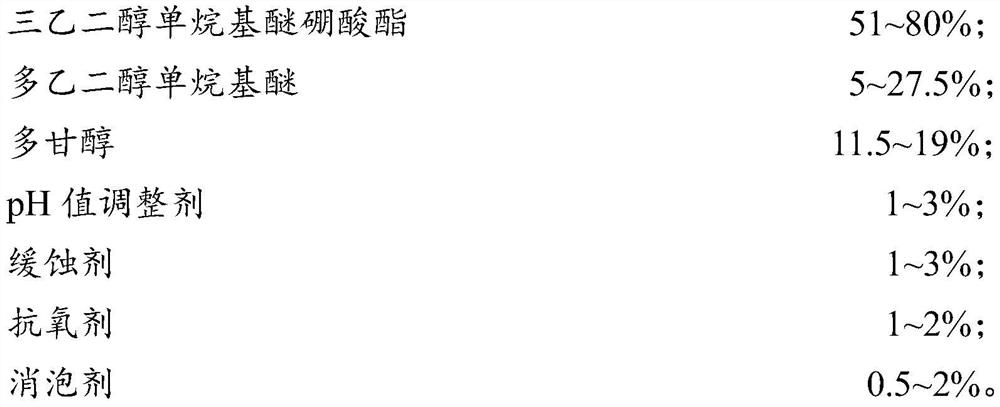

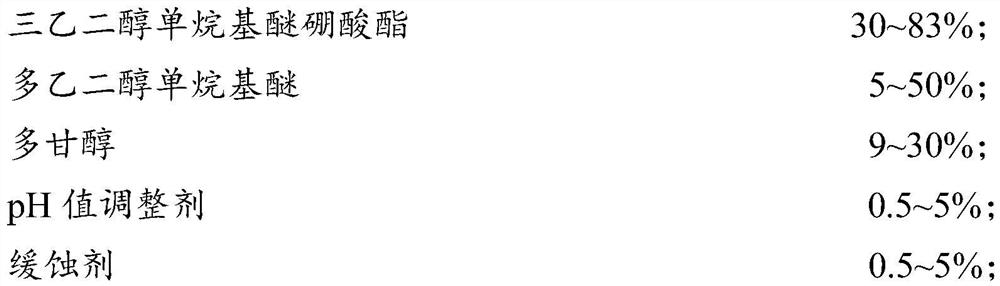

[0034] The present invention also provides a preparation method of the motor vehicle brake fluid described in the above technical solution, comprising the following steps:

[0035] Mix and dissolve triethylene glycol monoalkyl ether borate, polyethylene glycol monoalkyl ether, polyglycol, pH regulator, corrosion inhibitor, antioxidant and defoamer to obtain the motor vehicle brake fluid.

[0036] In the present invention, there is no special limitation on the order of mixing, as long as it can be mixed evenly. In the present invention, the mixing temperature is preferably 60-120°C, more preferably 65-110°C, and most preferably 70-100°C. In the present invention, the mixing is preferably carried out under stirring conditions, and the stirring speed is preferably not lower than 100r / min, more preferably 110-200r / min, most preferably 120-160r / min; the stirring The time is preferably 4 to 6 hours, more preferably 4.5 to 5.5 hours, and most preferably 5 hours.

[0037] After the m...

Embodiment 1

[0040] 800kg triethylene glycol methyl ether borate, 50kg triethylene glycol monomethyl ether, 60kg diethylene glycol, 55kg triethylene glycol, 10kg triethanolamine, 10kg benzotriazole, 10kg bisphenol A and 5kg methyl Silicone oil is mixed; the mixed solution is heated to 70° C. and then stirred for 5 hours at a rotation speed of 120 r / min to dissolve; the stirred solution is filtered, and the obtained filtrate is motor vehicle brake fluid.

Embodiment 2

[0042] 700kg triethylene glycol methyl ether borate, 50kg triethylene glycol monomethyl ether, 50kg triethylene glycol monoethyl ether, 35kg triethylene glycol monobutyl ether, 130kg diethylene glycol, 5kg triethanolamine, 5kg butylamine Mix ether, 5kg benzotriazole, 5kg borax, 10kg bisphenol A and 5kg methyl silicone oil; heat the mixture to 65°C and stir for 4.5h at a speed of 160r / min to dissolve; The solution is filtered, and the obtained filtrate is motor vehicle brake fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com