Slurry pump bionic piston casting forming method and device

A casting molding, mud pump technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of piston failure and affecting the service life of the piston, and achieve the effect of simple principle, simple structure and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

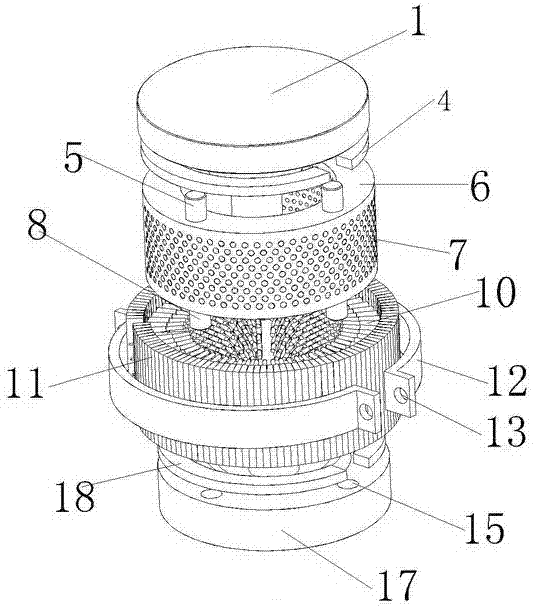

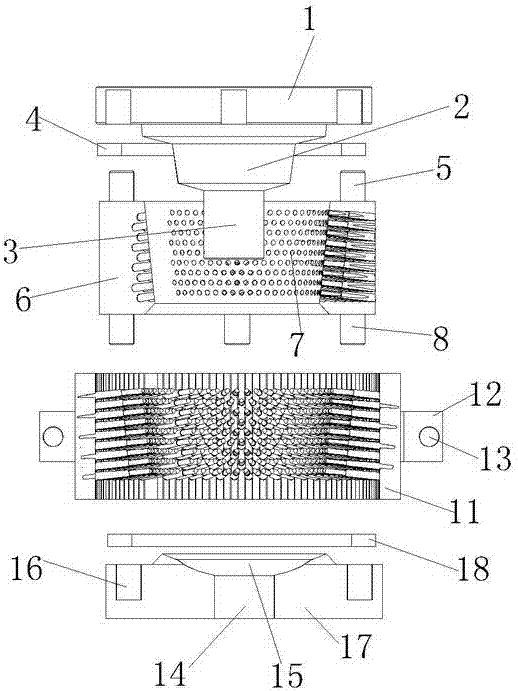

[0028] Such as figure 1 and figure 2 As shown, the mud pump imitation piston casting molding method of the present invention comprises the following steps:

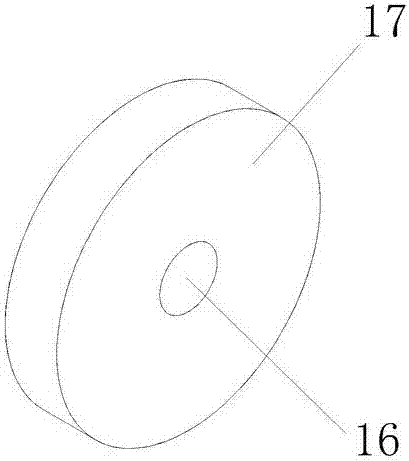

[0029] The first step: the lower positioning hole 16 faces upward, and the bottom mold base 17 is fixed on the processing platform; the high-styrene-butadiene-styrene skeleton primer is fixed on the die 15 of the bottom mold base 17;

[0030] Step 2: After the high styrene-butadiene-styrene skeleton primer is fixed, place the lower sealing gasket 18 on the upper edge of the bottom mold base 17;

[0031] Step 3: After the lower sealing gasket 18 is placed, install the central support 6 on the bottom mold base 17; Reasonably coordinate with the positioning;

[0032] Step 4: apply a uniform downward force on the center support 6; clamp the middle mold 11 and the center support 6, and match the positioning pins 10 of the middle mold 11 with the through holes 7 on the center support 6;

[0033] Step 5: use the fastening c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com