Self-compensation sealing device

A sealing device and self-compensating technology, which is applied in the direction of transportation and packaging, conveyor objects, rollers, etc., can solve the problems of inconvenient inspection and maintenance, short service life of idlers, and short service life, so as to reduce the number of inspection and maintenance personnel Quantity, high operational reliability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

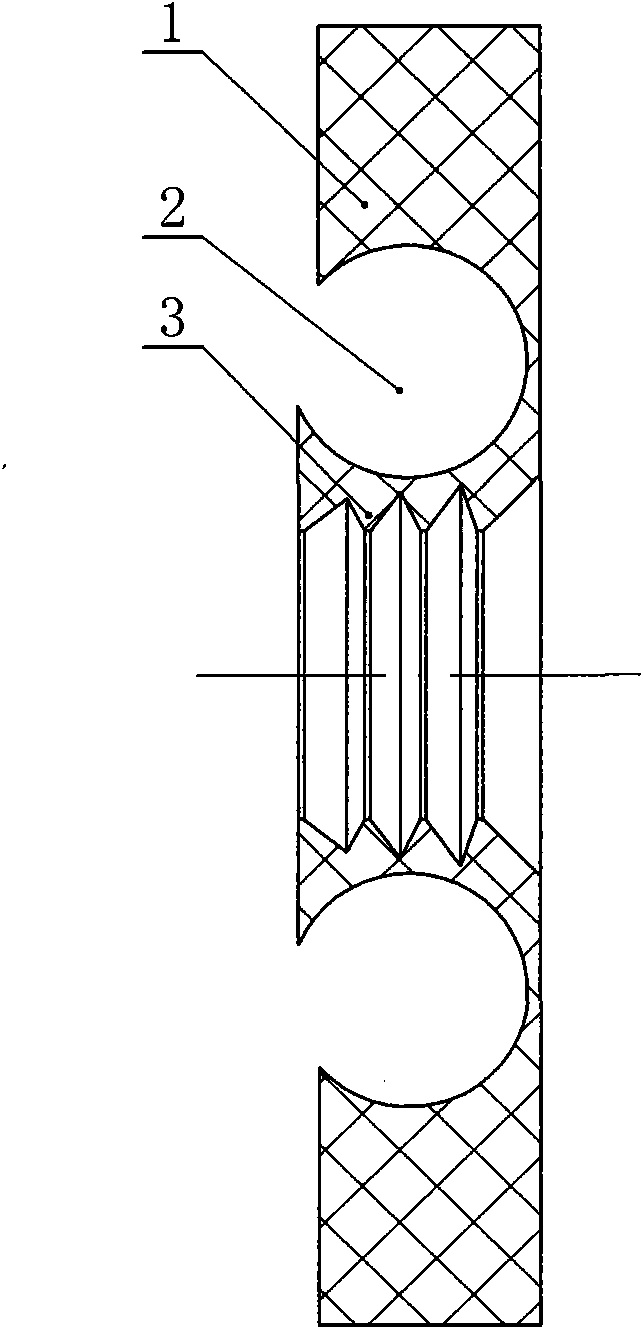

[0021] The self-compensating sealing device of the present invention such as figure 1 As shown, it includes: sealing ring, which is characterized in that: the sealing ring is a sealing ring 1 with a C groove and a V-shaped friction surface, the circumferential direction of the sealing ring has a C-shaped groove 2, and the aperture of the sealing ring has a V-shaped friction Surface 3. The C-shaped groove structure of the sealing ring is elastic and can play a self-compensating role. The V-shaped friction surface 3 of the sealing ring can reduce the relative friction with the wear-resistant plastic sleeve 5. When the V-shaped friction surface rubs against the wear-resistant plastic sleeve, the V-shaped friction surface is elastically deformed to increase its sealing effect and life.

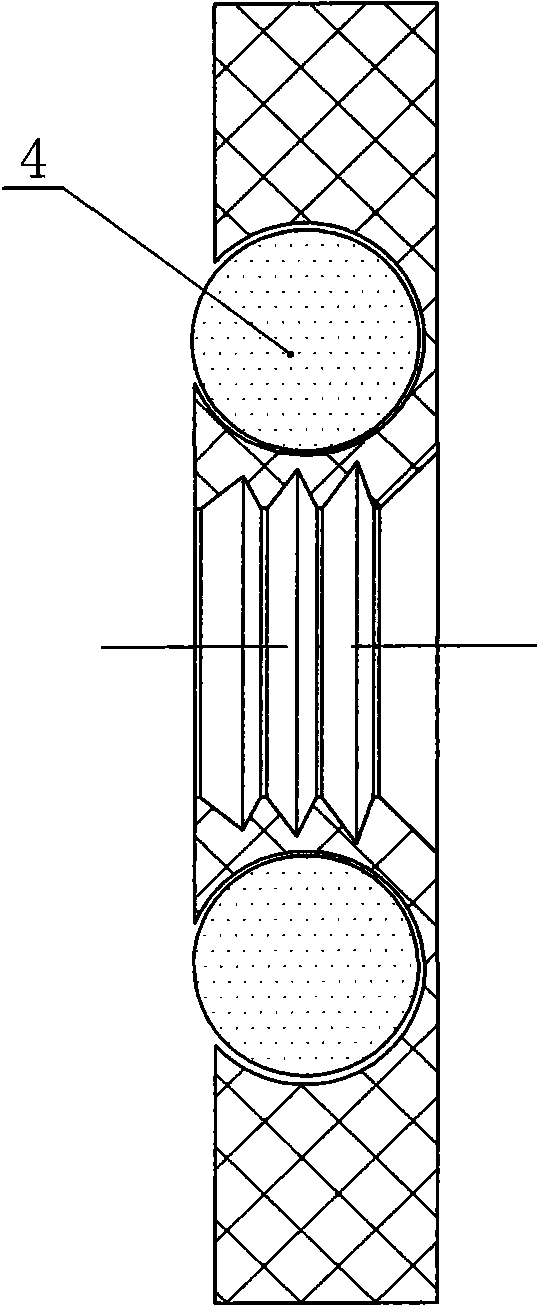

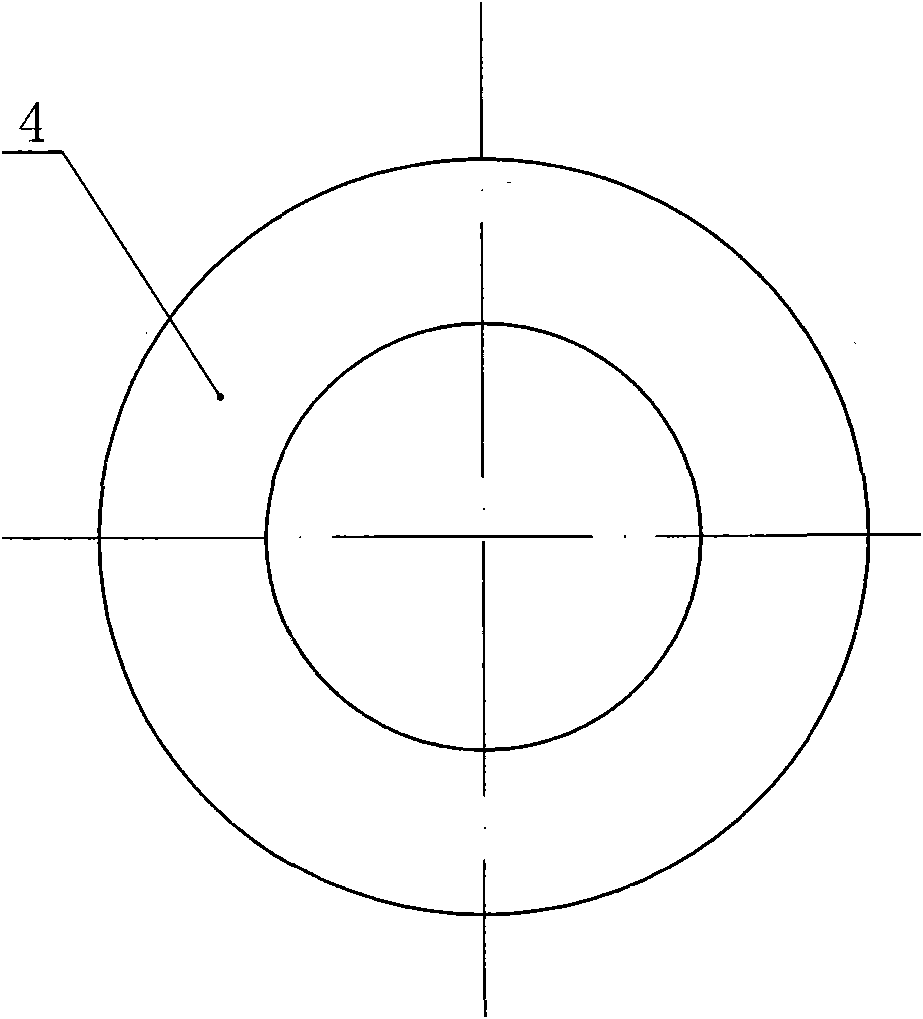

[0022] Such as figure 2 As shown, the C-groove seal ring 1 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com