Large turning angle positioning vacuum chuck

A technology of vacuum suction cups and large rotation angles, which is applied to suction cups, suction cup devices with large rotation angles and high-precision positioning requirements, and the field of vacuum suction cups with large rotation angles, which can solve the problems of unusable positioning, large number of mold tires, and long preparation period, etc., to achieve The effects of ensuring positioning accuracy, expanding the scope of use, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

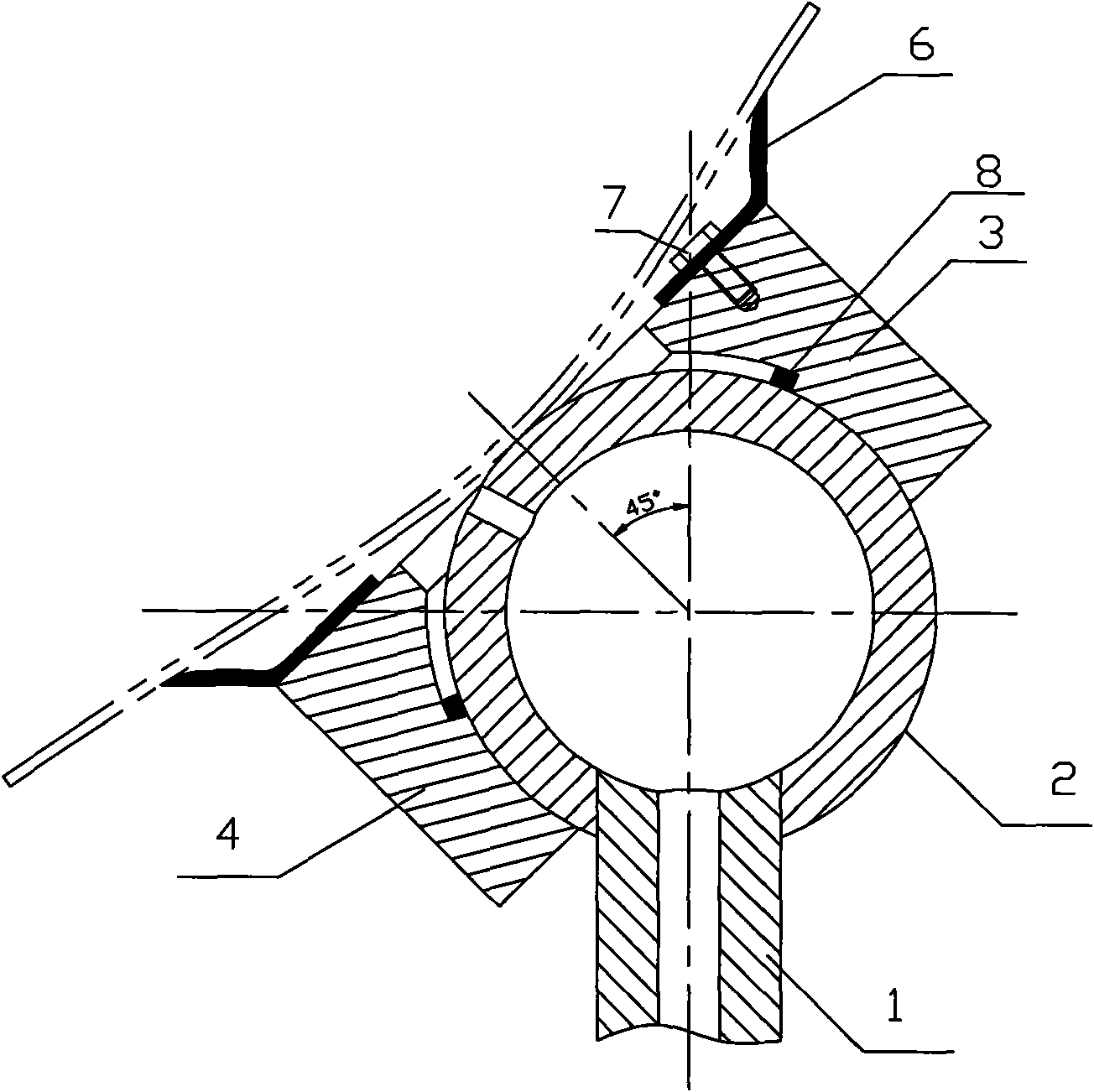

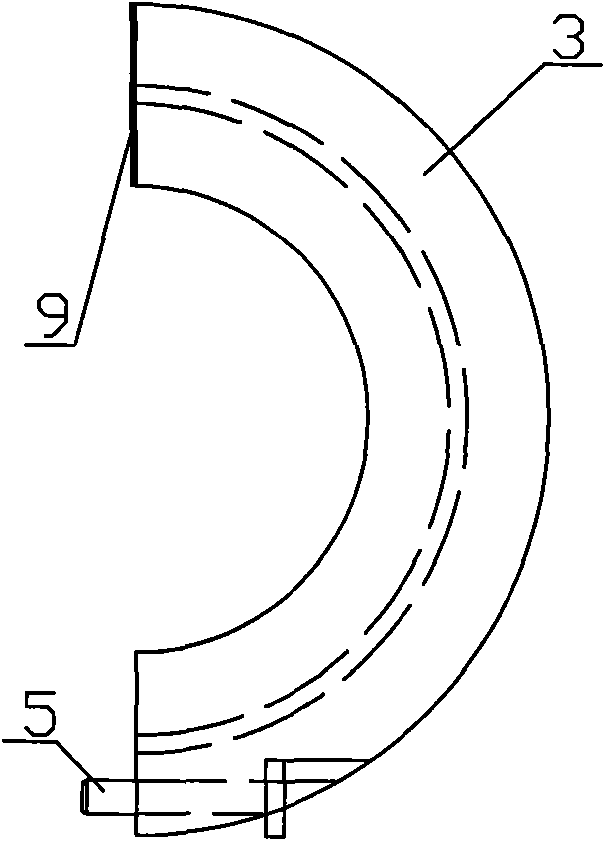

[0008] Such as Figure 1-Figure 2 As shown, the large rotation angle positioning vacuum suction cup includes a suction cup seat 1, a positioning ball 2, a rotating block A3, a rotating block B4, a bolt A5, a sealant bowl 6, a bolt B7, a sealing strip A8 and a sealing strip B9. The suction cup seat 1 is connected with the positioning ball 2, and the rotating block A3 and the rotating block B4 are connected together by the bolt A5, and the inner surface forms a spherical surface to cooperate with the positioning ball to slide. The seal between the rotating block A3 and the rotating block B4 is sealed by the sealing strip B9, and the spherical sealing is realized between the sealing strip A8 and the positioning ball 2 . The sealant bowl 6 is connected with the rotating block 3A and the rotating block B4 through the bolt B7.

[0009] Working principle: The positioning ball 2 can support and accurately locate the sheet metal parts, and the holes in it are used for vacuuming. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com