Rotating mechanism

A technology of rotating mechanism and rotating shaft, which is applied in the field of sapphire single crystal production, can solve the problems of inconvenient use, large size and high cost, and achieve the effect of simplifying equipment structure, reducing space size and no jamming phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

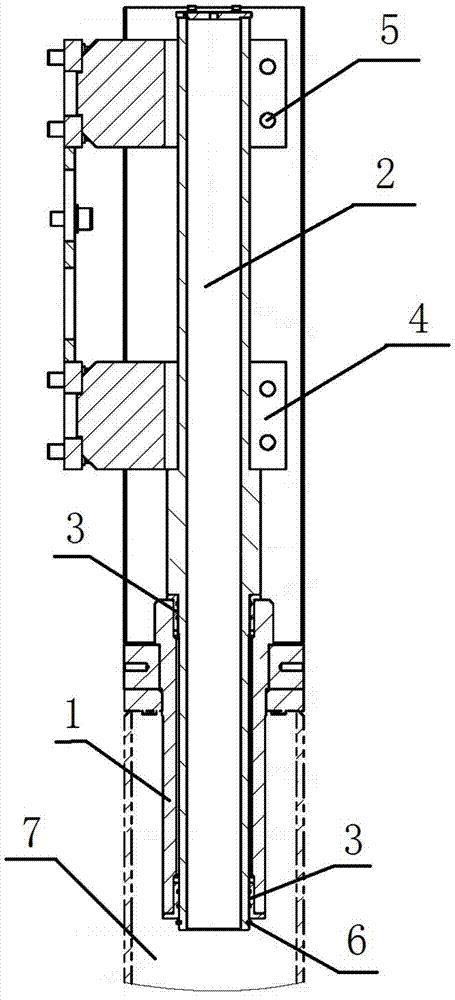

[0015] The rotating mechanism of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] like figure 1 As shown, the rotating mechanism of the present invention includes: a base 1 in the shape of a through cylinder, and one end of the base 1 is inserted into the column 7 . Insert sliding bushings 3 into the openings at both ends of the base 1 respectively, and apply a small amount of grease in the semicircular annular oil groove (not shown in the figure) of the sliding bushing 3 . Then the rotating shaft 2 is installed into two sliding bushes 3 and runs through the entire base 1 . At the same time, a stop ring 6 is provided at the end of one end of the rotating shaft 2 inserted into the column 7 . At this time, the base 1 and the bush 3 on it can ensure that the rotation shaft 2 rotates smoothly without jamming. And have enough resistance to deformation.

[0017] Then. Install the support 4 on the upper part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com