Oil pipeline cleaning device

A technology for oil pipelines and pigging, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as low efficiency, high pollution, easy jamming, etc., to ensure oil transportation efficiency, reduce loss, the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

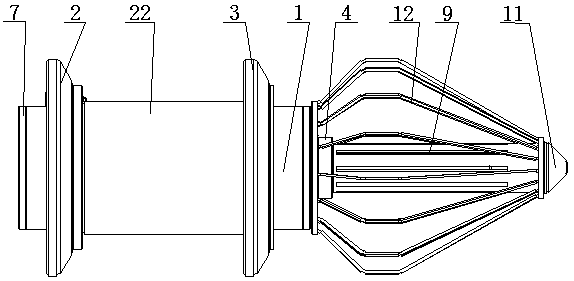

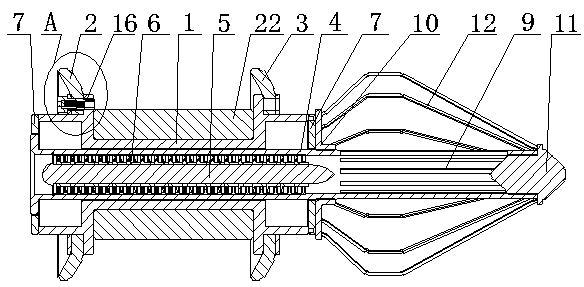

[0030] The oil pipeline pigging device consists of a stator body 1, a scrubber, a front cup 2, a rear cup 3, a rotor body 4, a mandrel 5 and a turbine 6: the stator body 1 is a cylindrical body with an annular space in the middle. The central annular part of the stator body 1 can be used to install the detection locator 22. When the pigging device is in operation, the detection locator 22 will be used to detect the thickness of the oil pipeline and to record the deformation of the pipeline and the position of the thin-walled part; and then It is convenient for people to understand the specific working condition of the pipeline.

[0031] A rotor body 4 is movable inside the stator body 1; the rotor body 4 is a cylinder; one end of the rotor body 4 is provided with an assembly flange 8;

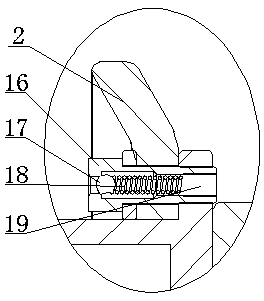

[0032] Both ends of the stator body 1 are fixedly equipped with sealing ring plates 7 , and the sealing ring plates 7 are slidably connected with the rotor body 4 . The purpose of setting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com