Malaysian squid processing apparatus

A processing device and squid technology, applied in food science and other directions, can solve the problems of reducing production efficiency, unfavorable automatic production, shutdown, etc., and achieve the effect of improving labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

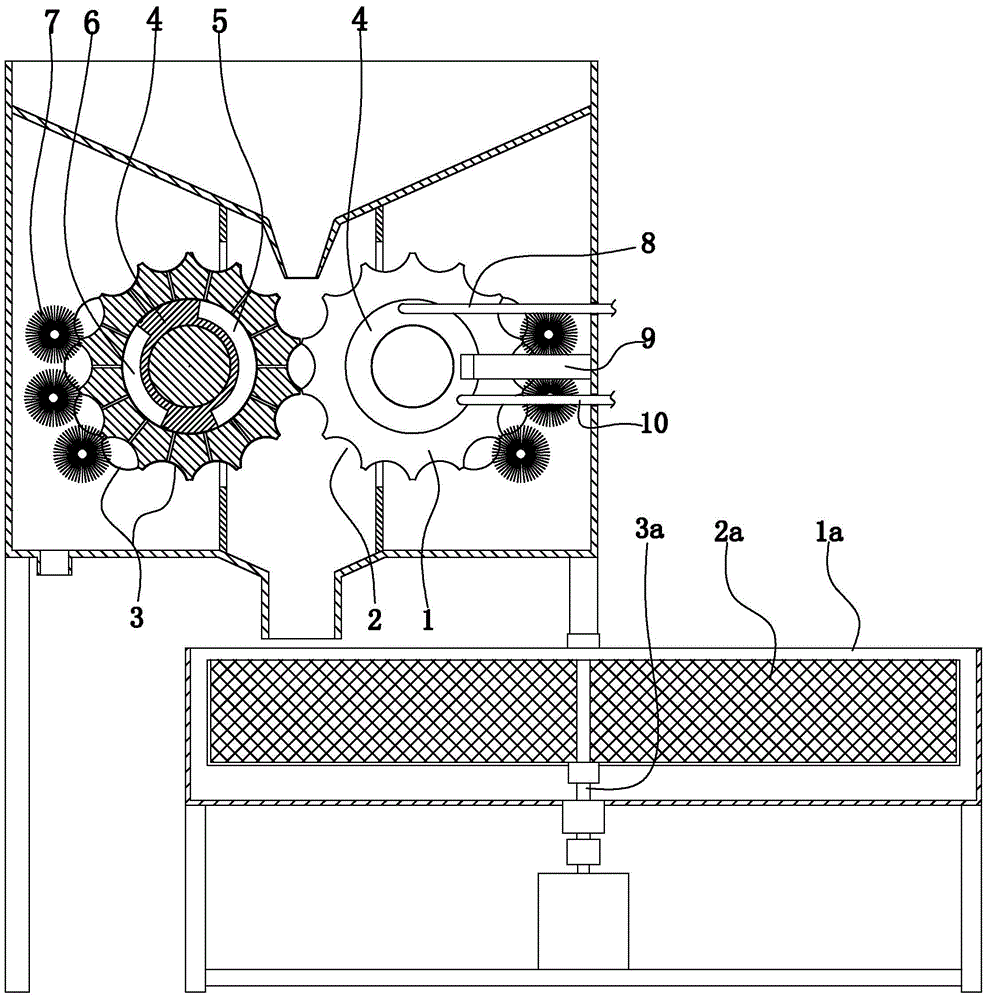

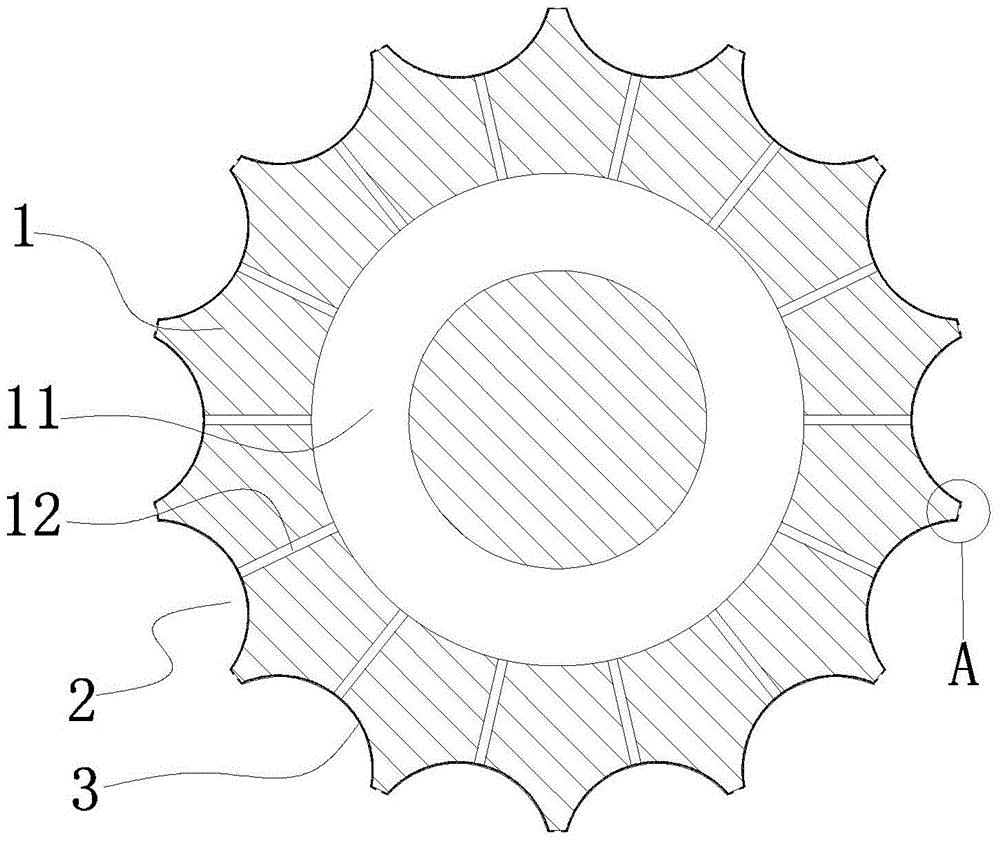

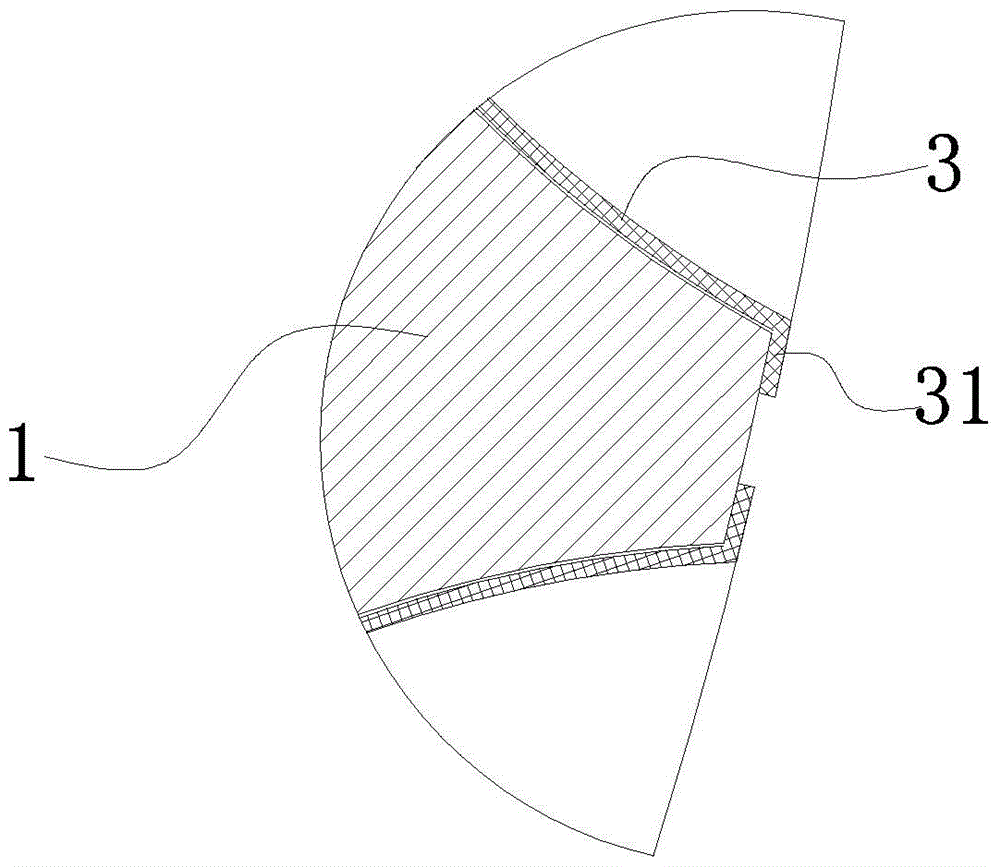

[0028] Such as figure 1 , image 3 As shown, a Malaysian squid processing device includes an air supply chamber, a negative pressure chamber, a frame, two left and right synchronously rotating turntables 1 and a cooking device arranged on the frame. The two turntables have the same diameter. A number of forming grooves 2 corresponding to each other for forming fish balls are provided on the outer peripheral surfaces of the two rotating disks. The forming grooves are uniformly distributed around the turntable. The forming groove is hemispherical. Rubber cups 3 are arranged in each molding groove. The rubber cup is hemispherical corresponding to the molded groove. The edge of the port of the rubber cup is sealed and connected with the edge of the port of the forming groove; specifically, the edge of the port of the rubber cup is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com