Rice automatic vending machine

A technology of automatic vending machines and automatic packaging machines, which is applied in the direction of instruments, coin-operated equipment for distributing discrete items, grain processing, etc. It can solve the problems of rice spillage, decentralized management of terminals, and high cost of packaging equipment, so as to save space rental cost, save operation and management cost, and save human resource cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, preferred embodiments of the present invention are given in conjunction with the drawings to illustrate the technical solutions of the present invention in detail.

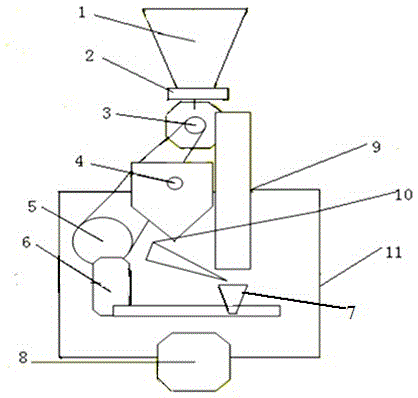

[0020] Such as figure 1 As shown, the automatic rice vending machine of the present invention includes a grain hopper 1, a feeding valve 2, a rice mill 3, a weighing hopper 4, a motor 5, a cup-type automatic packaging machine 6, a plastic cup 7, a take-out port 8, and an automatic sorting machine. Cup 9, slide 10, grain hopper 11, grain hopper 1 is connected to feed valve 2, rice mill 3 is located below feed valve 2, rice mill 3 is connected to motor 5, weighing hopper 4 is located in the mill Below the rice machine 3, the weighing bucket 4 is located at the left end of the automatic cup divider 9, the glue cup 7 is located between the picking port 8 and the slide 10, and the slide 10 is located below the weighing bucket 4. The cup type automatic packaging machine 6 is connected to one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com