Sealing apparatus

A technology of sealing device and sealing components, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of pressure rise, pressure leakage, bad sealing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

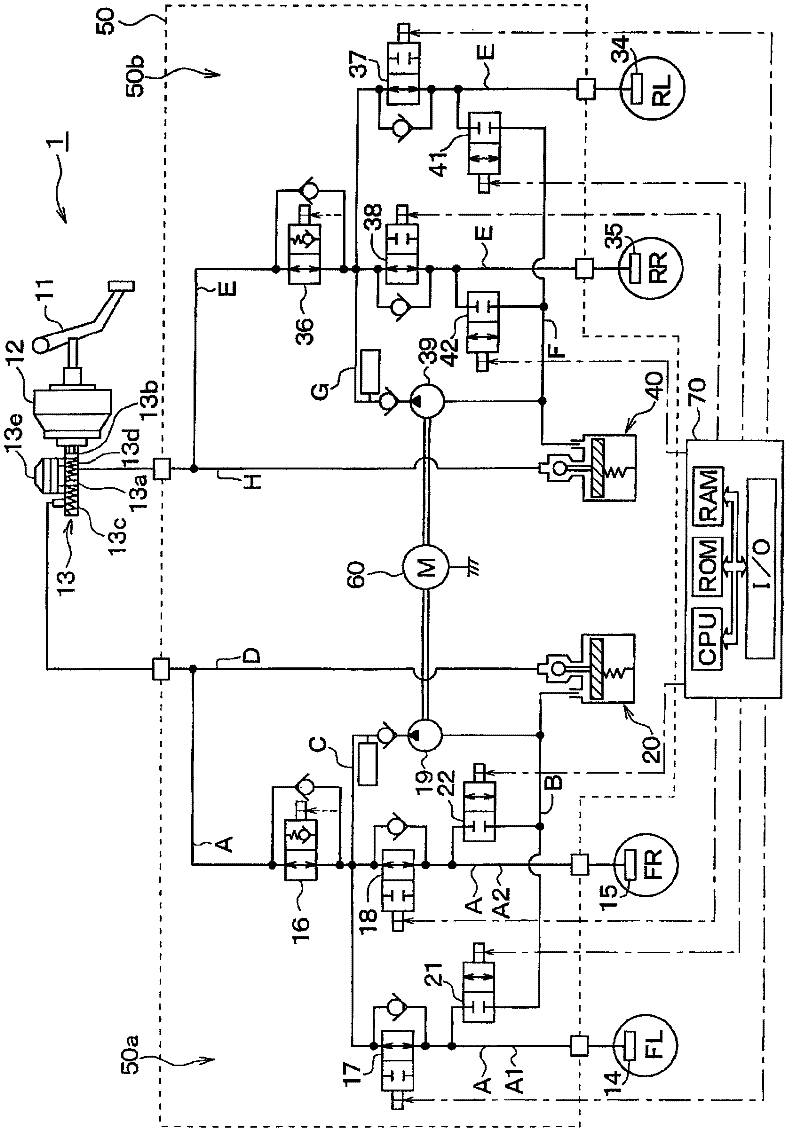

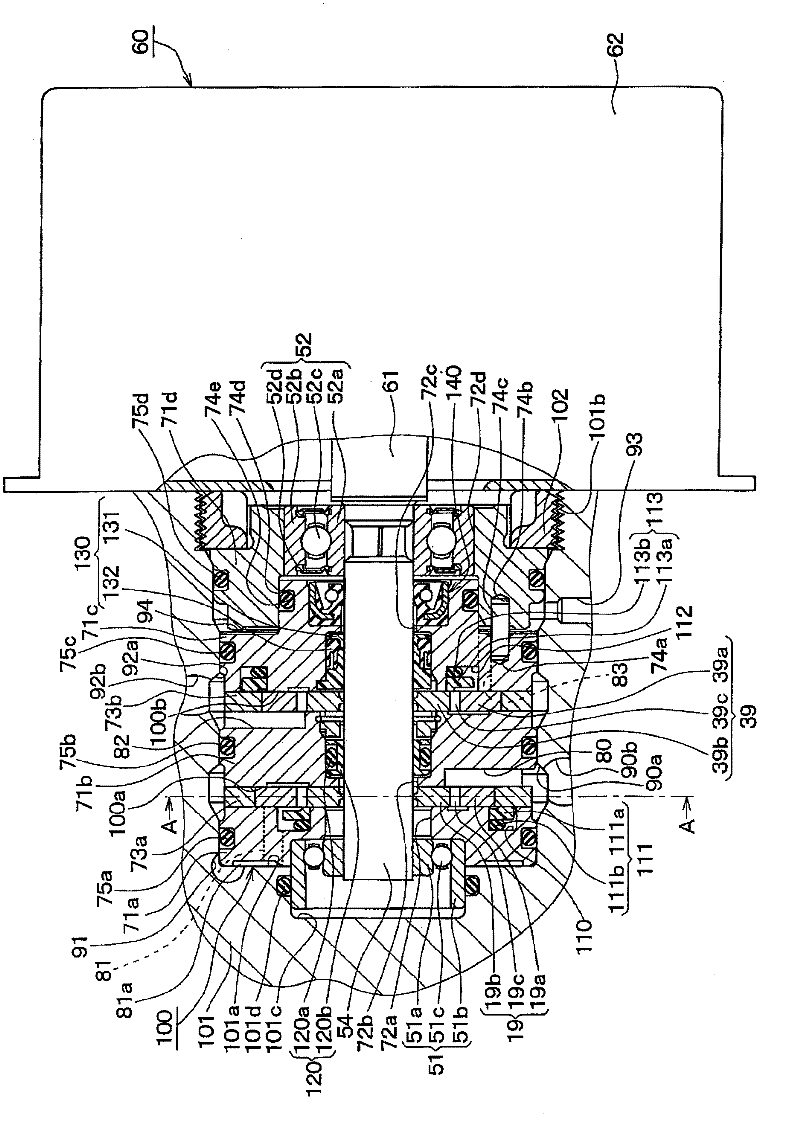

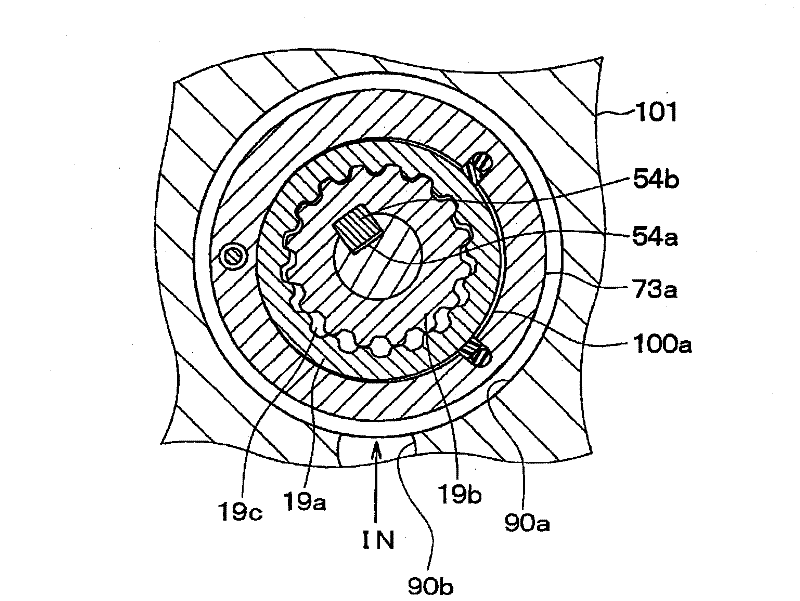

[0036] Hereinafter, the present invention will be described with reference to the embodiments shown in the drawings. figure 1 A schematic diagram of brake piping of a vehicle brake device to which a rotary pump device according to an embodiment of the present invention is applied is shown in . Below, based on figure 1 The basic configuration of a vehicle brake device will be described. Here, an example in which the brake device for a vehicle according to the present invention is applied to a vehicle constituting a hydraulic circuit of front and rear piping in a front-wheel drive four-wheeled vehicle will be described, but it can also be applied to a vehicle equipped with a right front X piping of each piping system of wheel-left rear wheel, left front wheel-right rear wheel, etc.

[0037] exist figure 1 Among them, when the driver steps on the brake pedal 11 , the stepping force is boosted by the booster 12 to push master pistons 13 a , 13 b arranged in a master cylinder (h...

no. 2 approach

[0109]A second embodiment of the present invention will be described. In this embodiment, the structure of the sealing member 130 is changed from that of the first embodiment, and other than that, it is the same as the first embodiment, so only the parts different from the first embodiment will be described.

[0110] Figure 7 It is a partially enlarged view of the sealing member 130 according to this embodiment. In this figure, the resin ring 131 and the rubber cup 132 are shown in a separated state.

[0111] Such as Figure 7 As shown, in the present embodiment, the holding portion 132c included in the base portion 132a is not formed in a cross-sectional arc shape, but is formed in a cross-sectional triangular shape. Moreover, the shape of the holding part accommodation part 131g formed in the resin ring 131 is also formed in the cross-sectional triangle shape corresponding to the holding part 132c.

[0112] In this way, even when the holding portion 132c is formed in a ...

no. 3 approach

[0116] A third embodiment of the present invention will be described. This embodiment is also obtained by changing the structure of the sealing member 130 from the first embodiment, and is the same as the first embodiment except for that, so only the parts different from the first embodiment will be described.

[0117] Figure 9 It is a partially enlarged view of the sealing member 130 according to this embodiment. In this figure, the resin ring 131 and the rubber cup 132 are shown in a separated state.

[0118] Such as Figure 9 As shown, in this embodiment, like the second embodiment, the holding portion 132c included in the base portion 132a is formed in a triangular cross-sectional shape, but the portion of the holding portion 132c on the oil seal 140 side is formed into a tapered surface. The groove slope 131e formed in the holding portion housing portion 131g of the resin ring 131 is also formed in a portion of the bottom surface 131d continuous with the wall surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com