Cable plug connector

A technology of cable plugs and connectors, applied in the direction of connection, two-part connection devices, circuits, etc., can solve the problems of restricting distribution frames, snap ring elastic failure, inconvenience, etc., achieve convenient installation and maintenance, improve connection efficiency, and improve The effect of electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

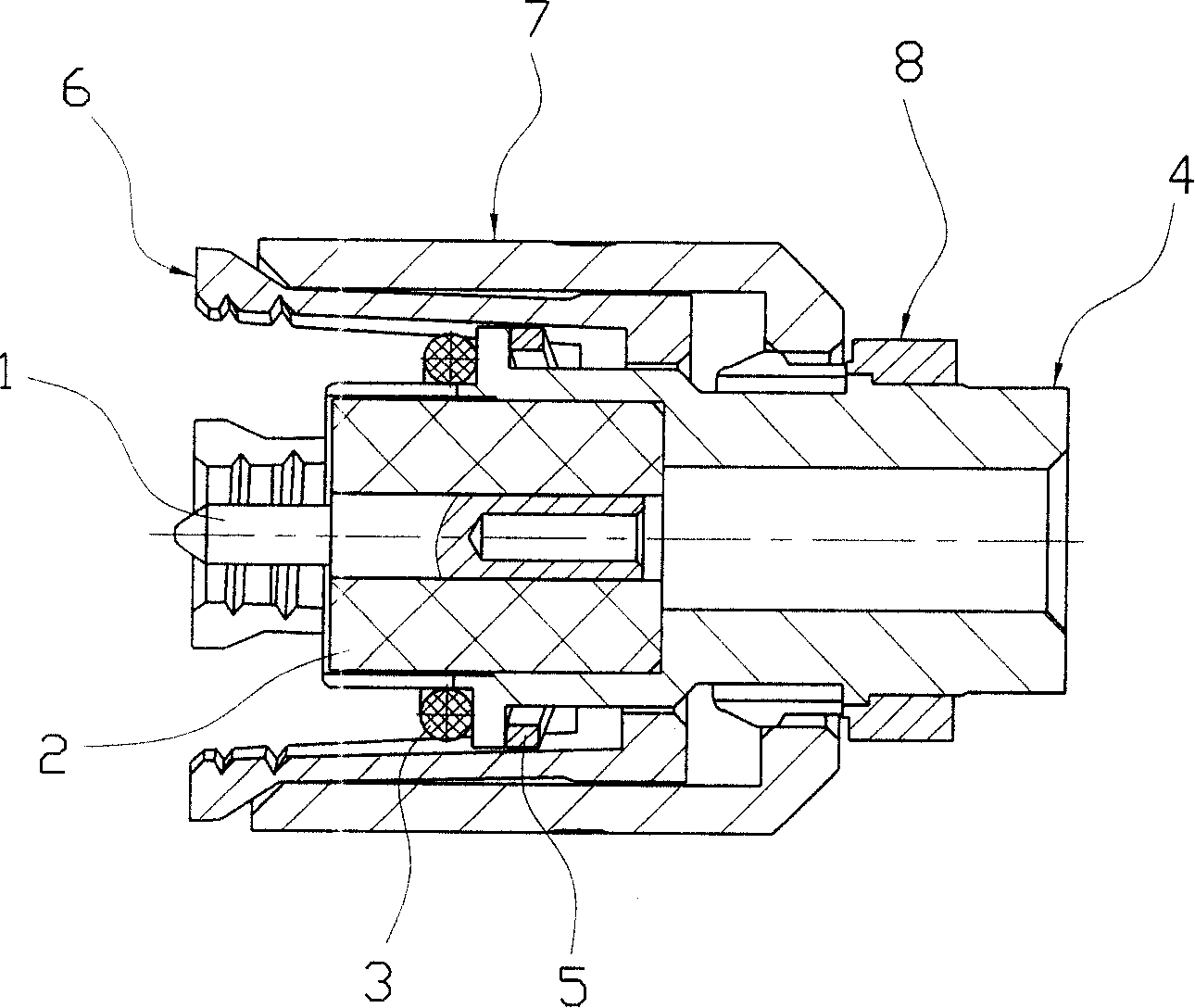

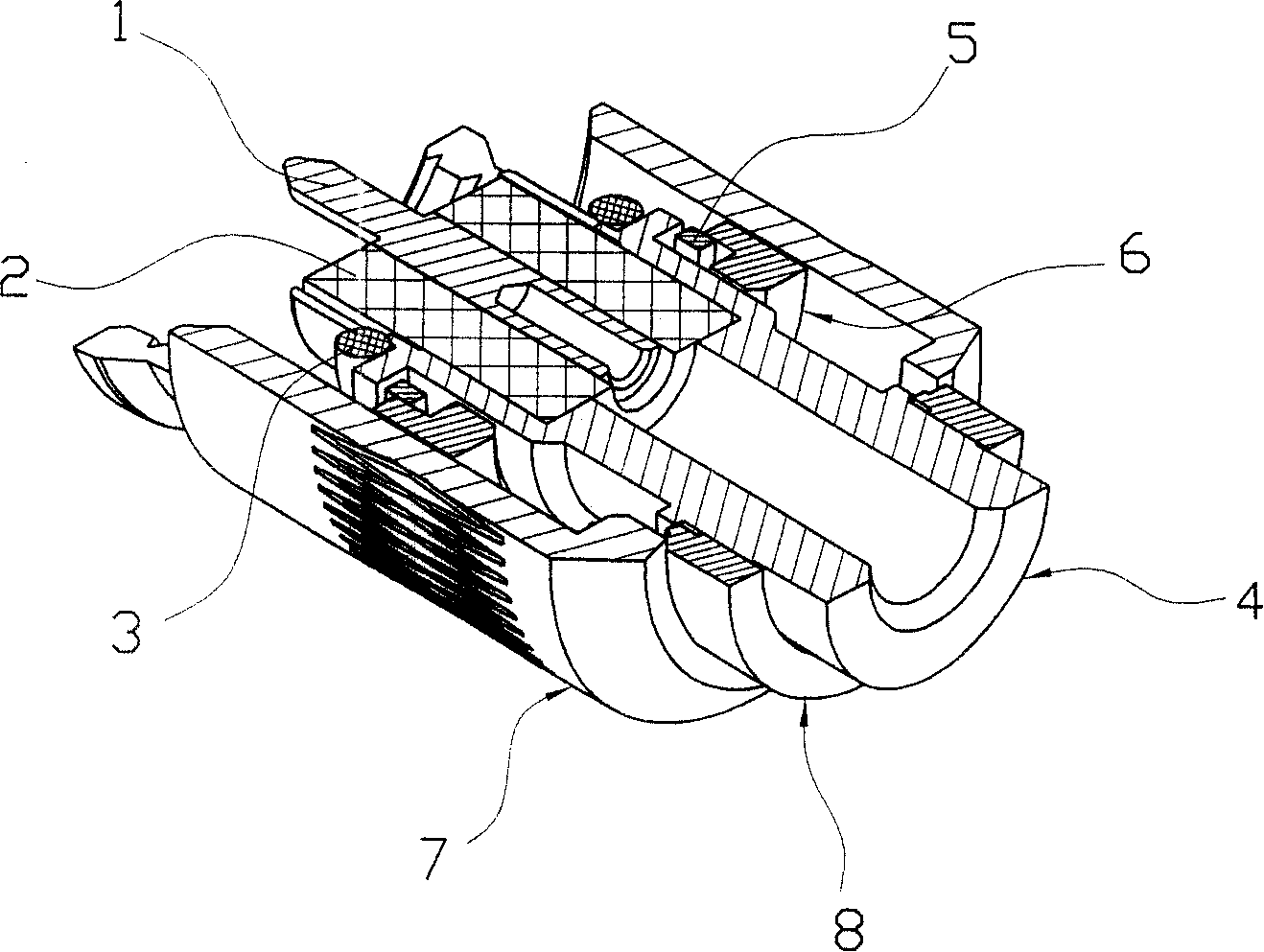

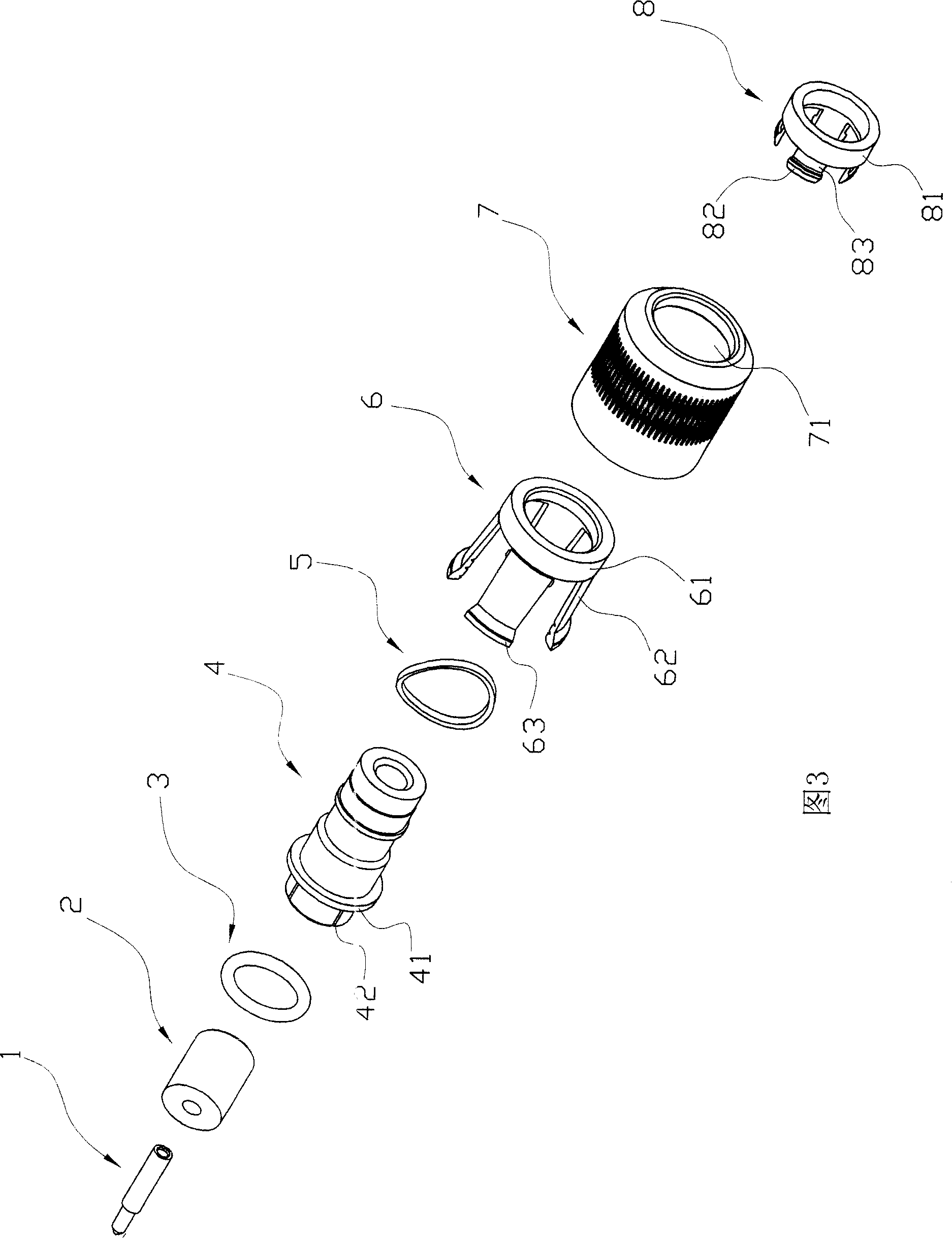

[0019] Such as figure 1 As shown in Figure 3, the structure of the cable plug connector includes a pin 1, an insulator 2, a housing 4, a connecting sleeve 6 and a jacket 7 that are coaxially assembled sequentially from the inside to the outside, wherein the jacket 7 is in the shape of a cylinder, and its opening The place is used for inserting into the socket, and a through hole 71 is provided at the bottom thereof for passing through the shell 4 . And described casing 4 is hollow tubular body shape, and above-mentioned pin 1 and insulator 2 are conventionally installed in the thinner end of its tube wall, and the other end of its tube wall is thicker with coaxial cable (in the figure) (not shown) are fixedly connected, and at the same time, the outer peripheral surface of the housing 4 is provided with an integral shaft shoulder 41 and a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com