Toroidal and thrust bearing assembly

A bearing assembly and thrust bearing technology, applied in the field of rolling element bearing devices, can solve the problems of rotational inertia limiting operating efficiency, occupying large bearings, high material costs, etc., to improve internal force transmission/distribution and load carrying capacity, compact cross-section , space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In the various figures, similar or identical elements are denoted by the same reference numerals. If not described or otherwise shown, the described embodiments are arranged in a similar or corresponding manner.

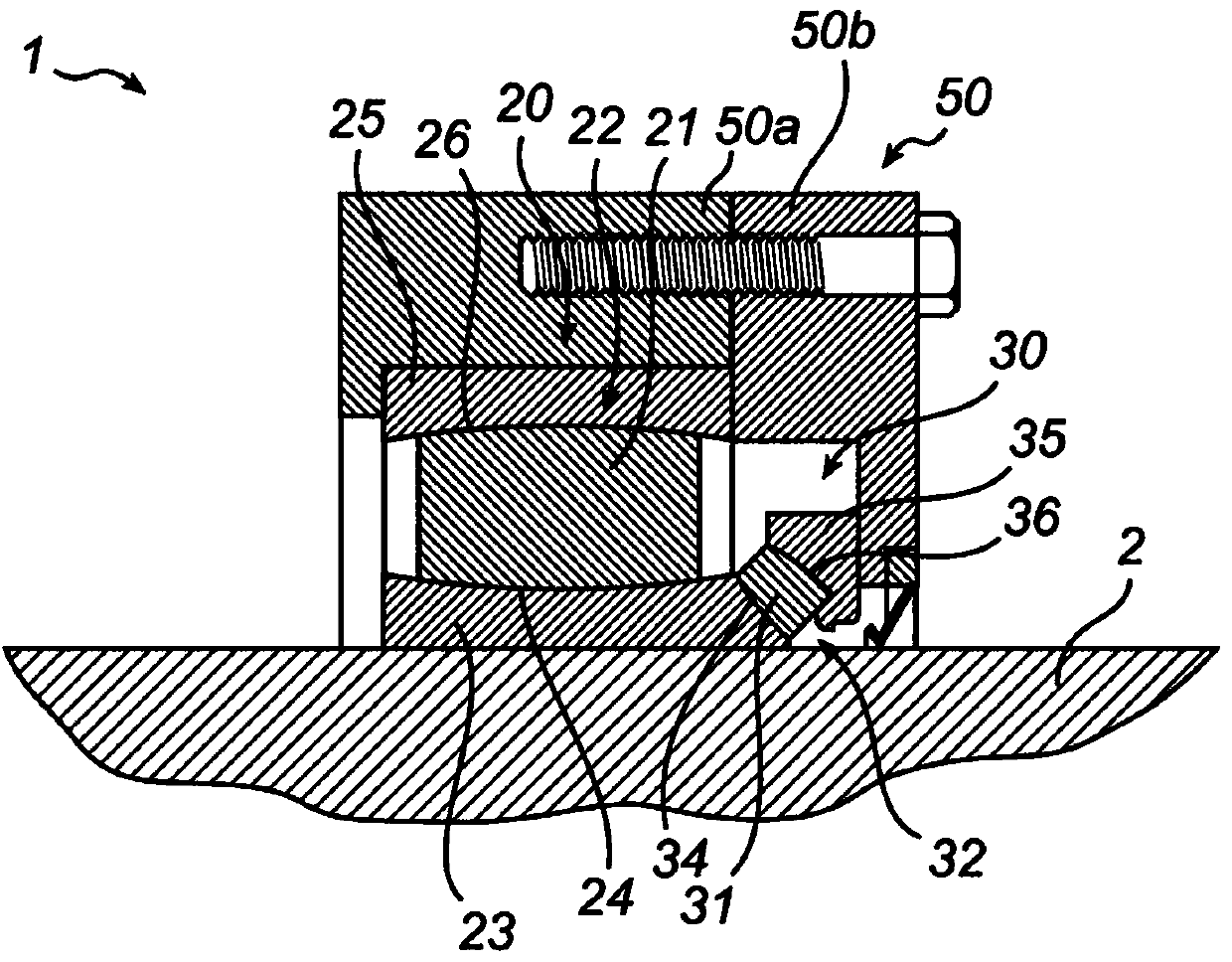

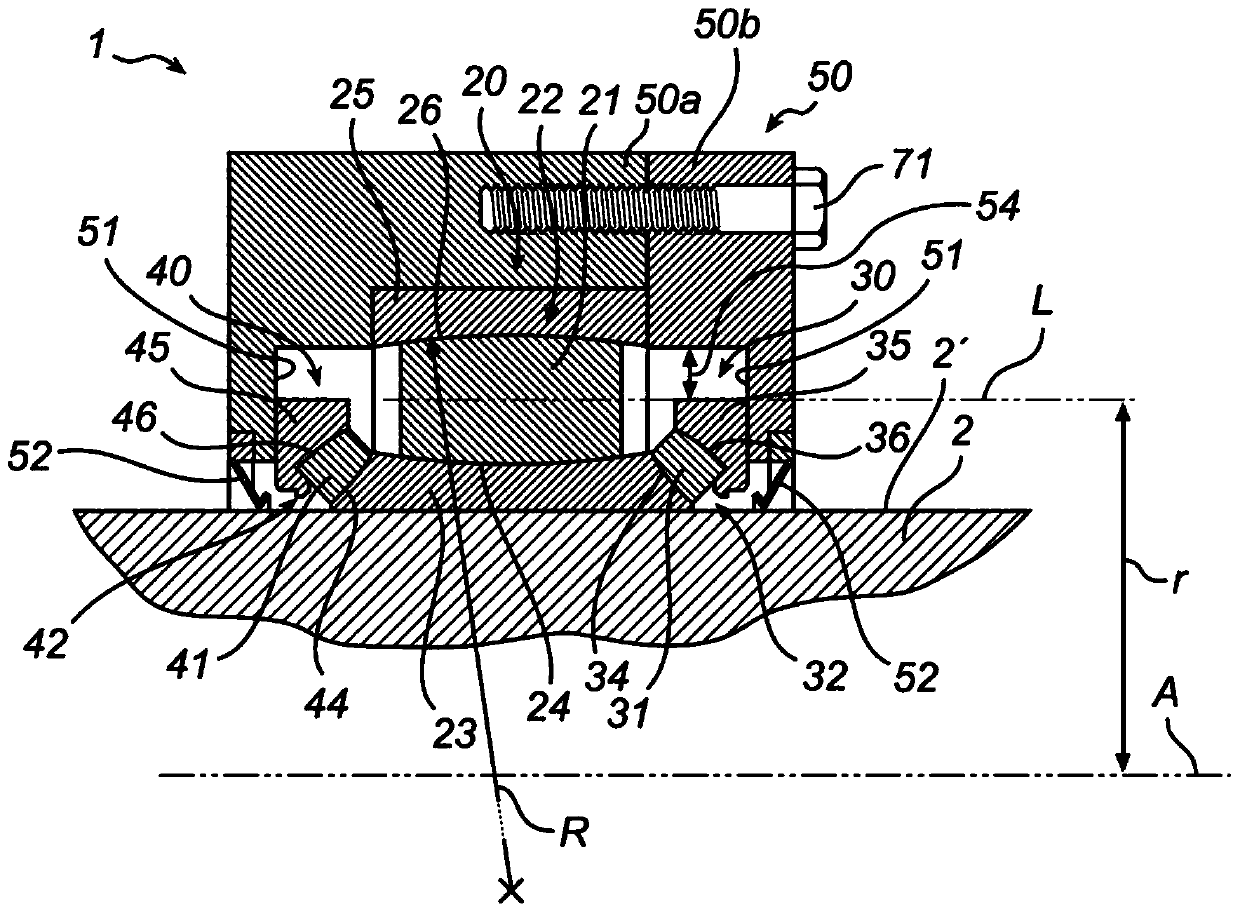

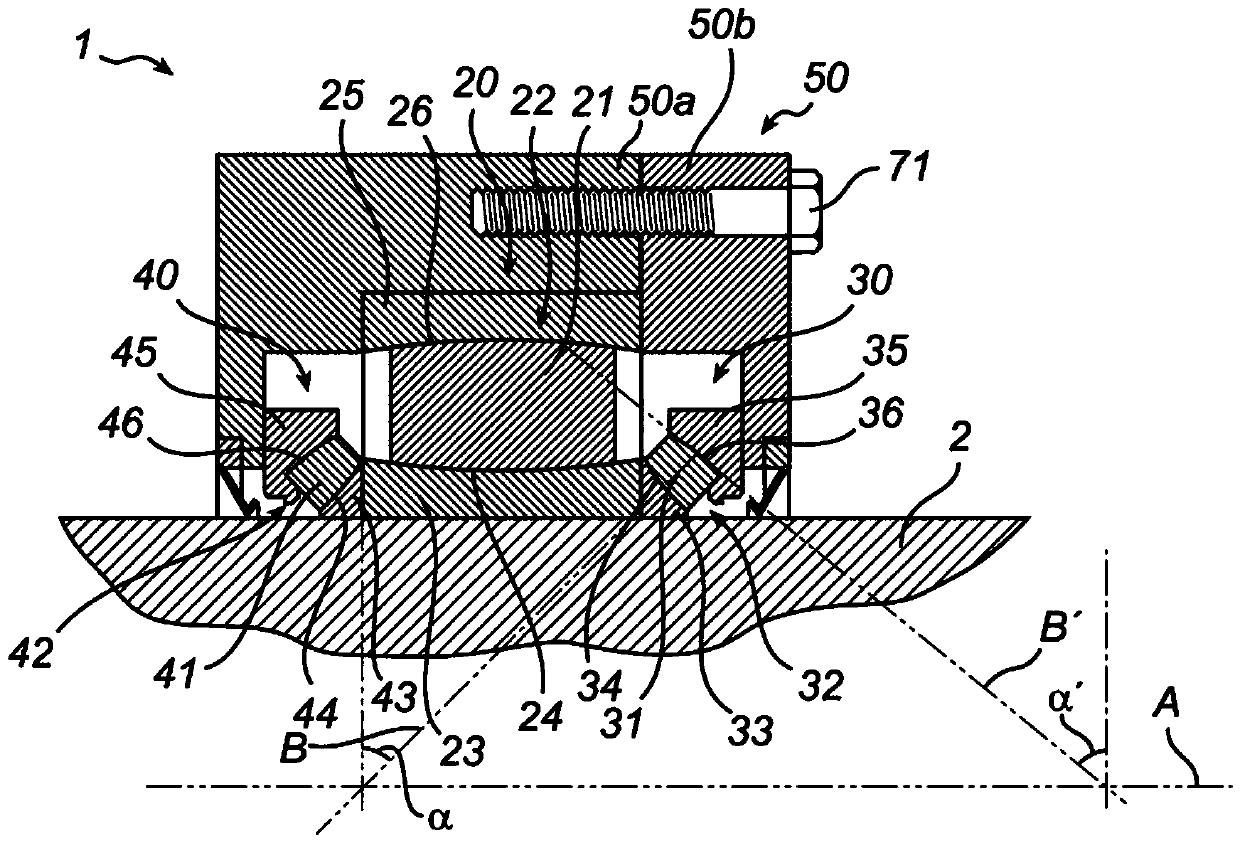

[0046] exist Figure 1-5 , a schematic cross-sectional view of an exemplary embodiment of a bearing assembly 1 for supporting a shaft 2 is shown. The assembly 1 comprises a toroidal roller bearing arrangement 20 comprising a first set of rolling elements formed by toroidal roller elements 21 arranged in a first toroidal circumferential row 22 around the axis of the shaft A and between Between the inner ring 23 including the first inner raceway 24 and the first outer ring 25 including the first outer raceway 26 . The first inner and outer raceways 24, 26 are in contact with the roller elements 21 and are arranged to cooperate with said roller elements, wherein said roller elements roll relative to and against the raceways to allow Axial and angular displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com