Brake master cylinder assembly

A technology of brake master cylinder and assembly, applied in the direction of hydraulic brake transmission, etc., can solve the problems of lengthening and easy wear and tear, and achieve the effect of enhancing safety, shortening the length of the cylinder block, and increasing the braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

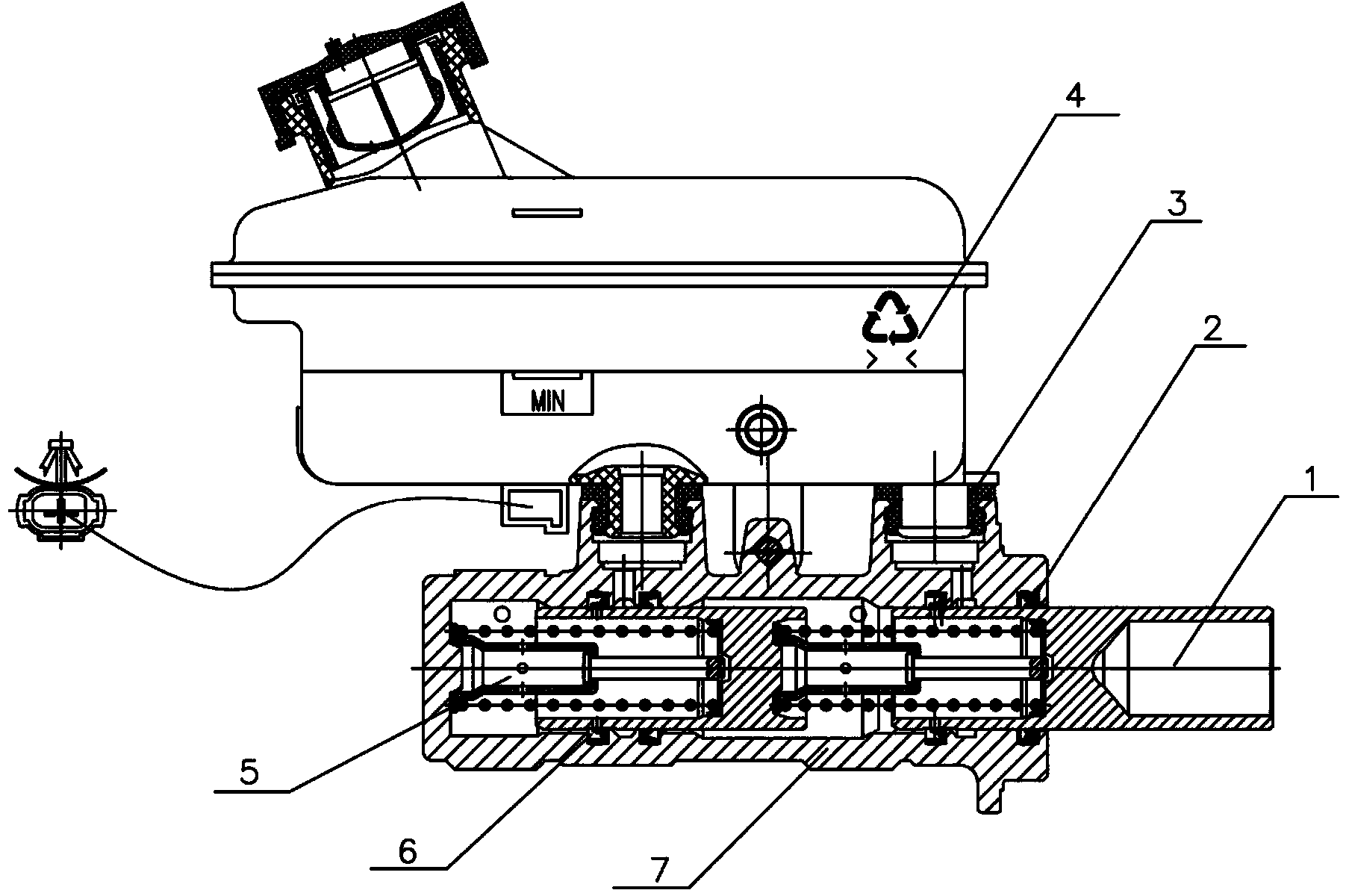

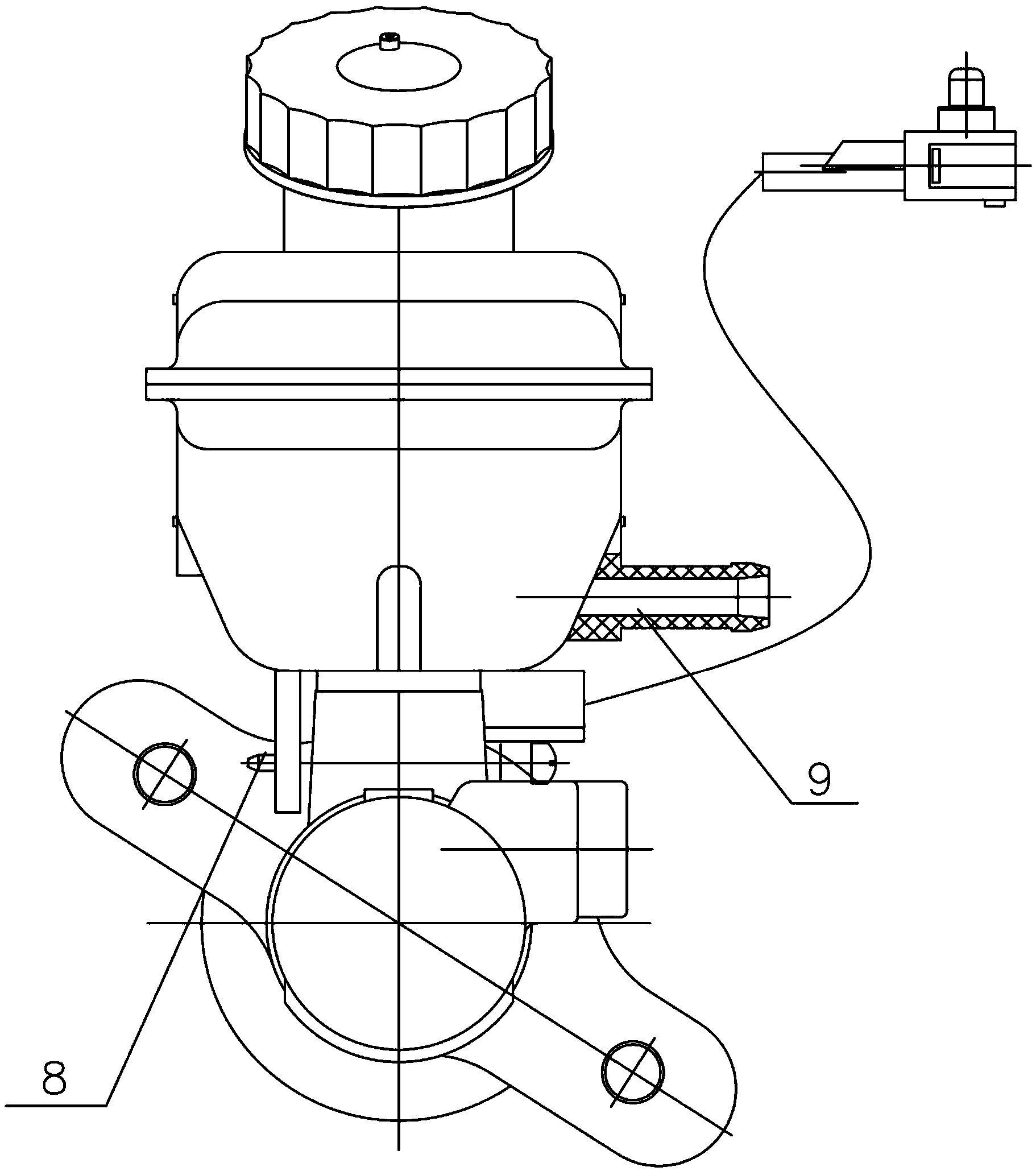

[0014] As shown in the figure, this brake master cylinder assembly mainly includes a brake oil storage cup 4, a master cylinder body 7, a first piston assembly 1 and a second piston assembly 5, and the brake oil storage cup 4 passes through The fixing bolt 8 is fixed on the upper part of the main cylinder body 7, the oil outlet of the brake oil storage cup 4 cooperates with the oil inlet of the main cylinder body 7, and a sealing cup 3 is provided at the interface, and the sealing cup 3 It is fixed on the main cylinder body 7, does not move with the movement of the piston, is not easy to wear, and prolongs the service life. The main cylinder body 7 is provided with a first piston assembly 1 and a second piston assembly 5, and the first piston The assembly 1 and the second piston assembly 5 are connected in series with each other. The outer cover of the first piston assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com