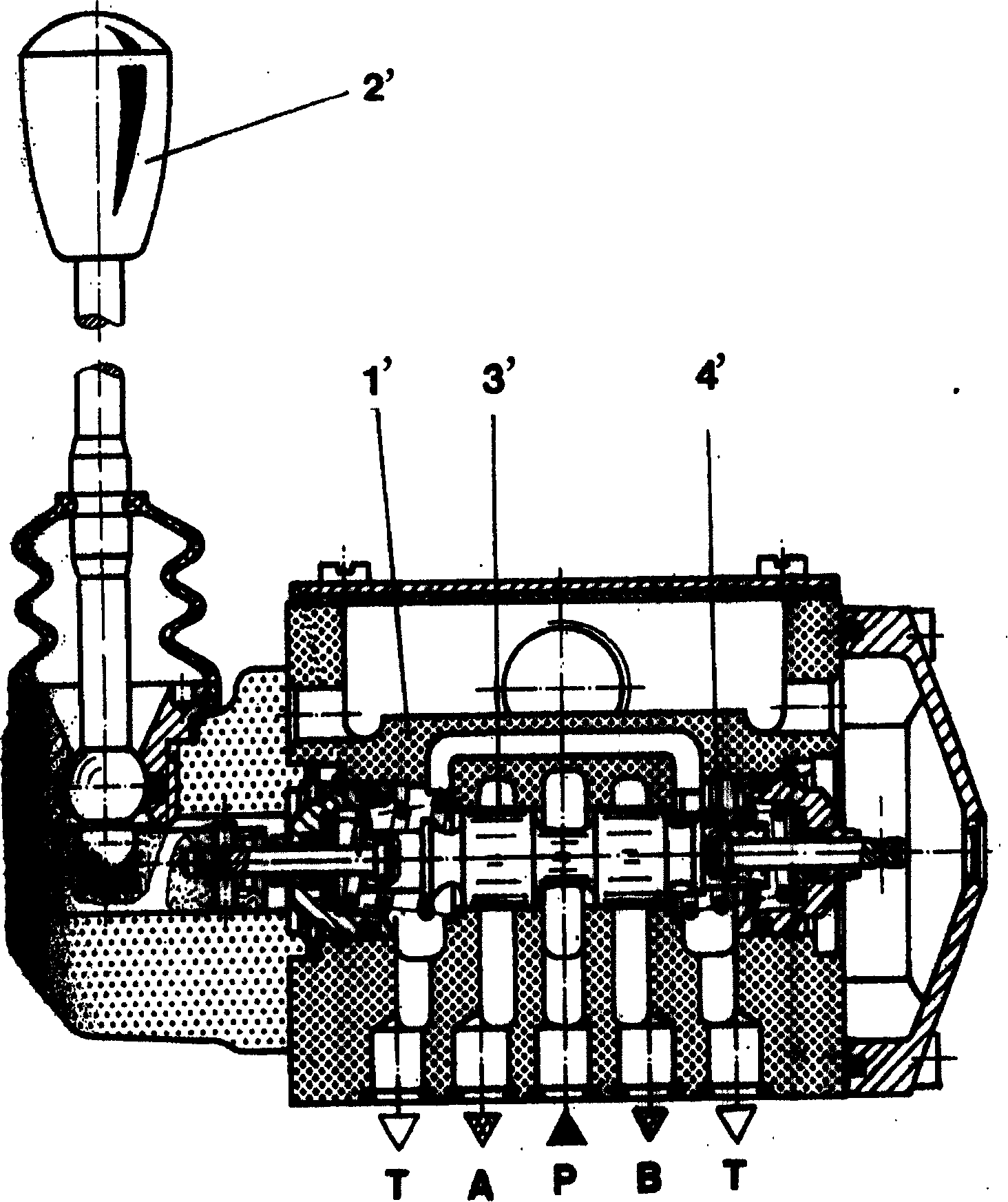

Hand-driven change valve

A manual reversing valve, valve core technology, applied in the direction of fluid pressure actuating device, servo motor assembly, mechanical equipment, etc., can solve the problems of affecting the normal operation of the hydraulic system, affecting the dustproof effect, and the leather cup being easily disengaged, etc. Achieve the effect of reducing production and installation costs, good reset effect, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

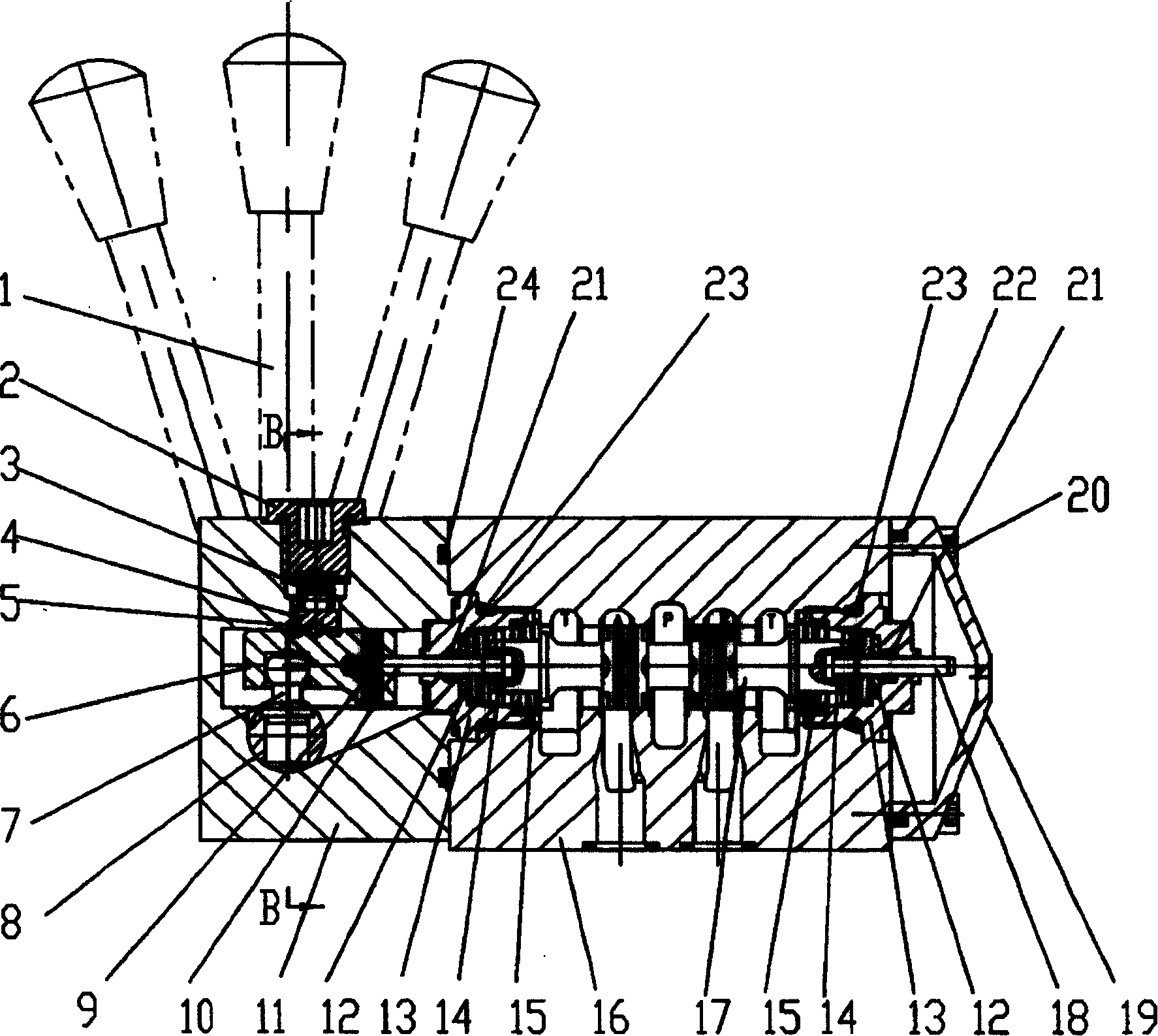

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

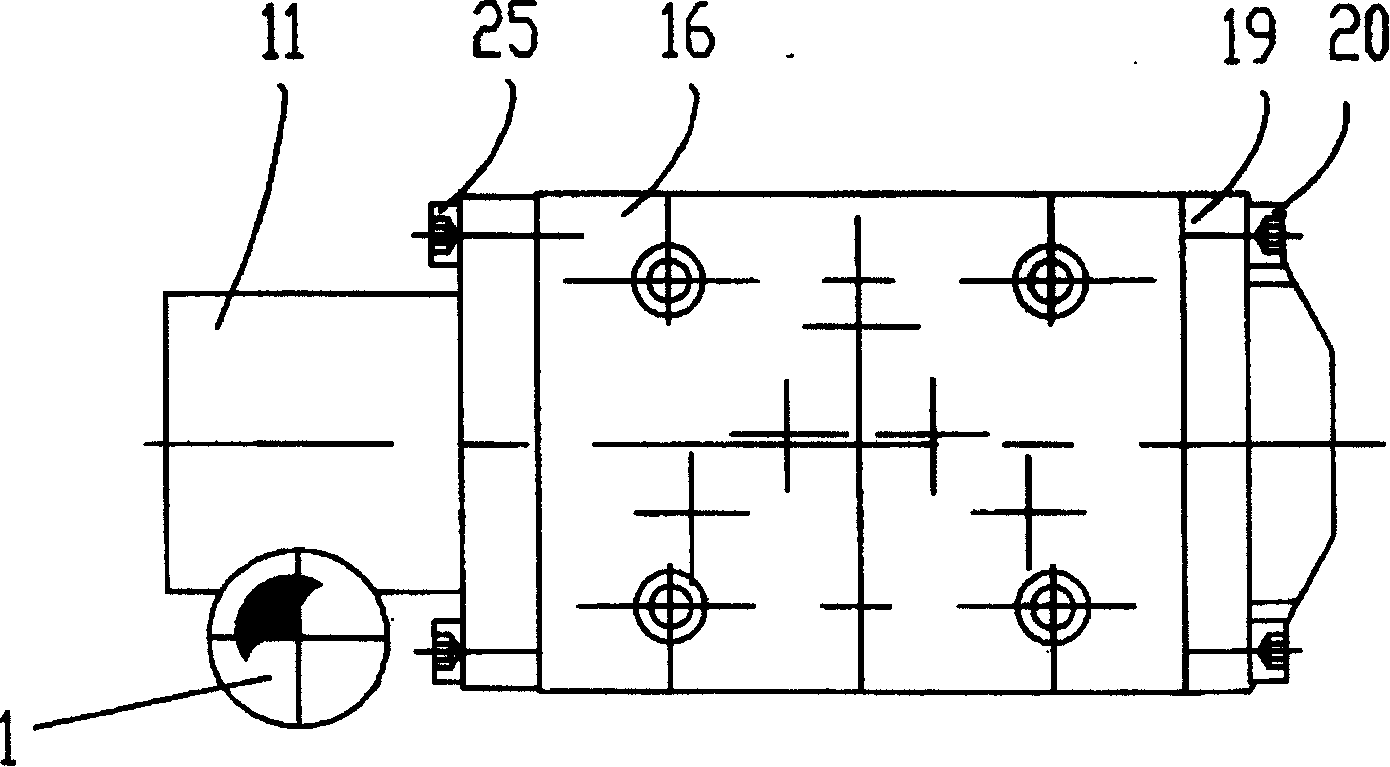

[0021] see figure 2 , the valve core 17 is installed in the main hole in the valve body 16; the two ends of the main hole of the valve body are equipped with screw caps 13; the left end of the valve body is equipped with a front cover 11 and a sealing ring 24, which are fixed by 4 screws 25; Cover 19 and sealing ring 22 are fixed by 4 screws 20 .

[0022] The back cover 19 material can be made of aluminum alloy die-casting or plastics, and there is sealing groove on the left side, and sealing ring 22 is placed in the groove, and this sealing ring is used for preventing dust from entering the inner cavity of back cover 19.

[0023] The screw caps 13 at the left and right ends of the main hole of the valve body 16 are connected with the valve bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com