A front hydraulic lifting device for a heavy truck dump truck

A lifting device and dump truck technology, which is applied in the direction of tilting bearing motion vehicles, etc., can solve the problems of high overall rigidity requirements of the floor of the carriage, difficulty in ensuring the synchronization of two hydraulic cylinders, poor lifting stability, etc., so as to prevent hydraulic clamping. , The structure is simple, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

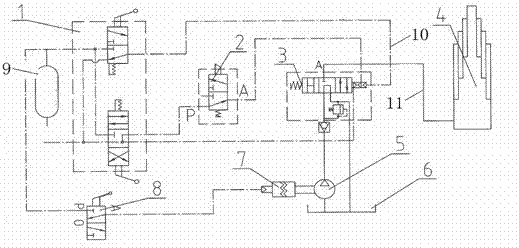

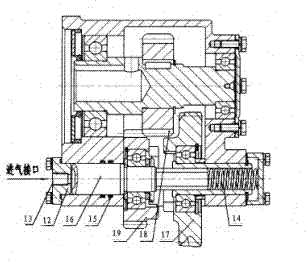

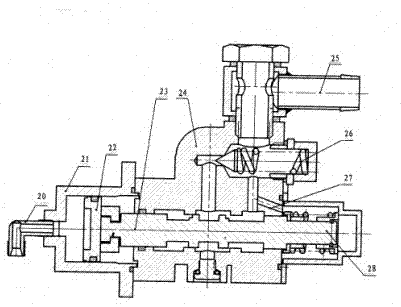

[0010] Example 1, such as figure 1 As shown in -4, the present invention includes an air storage tank 9, a control air valve 8, a power take-off 7, a gear oil pump 5, a hydraulic oil tank 6, a hydraulic oil cylinder 4, an oil line pipe 11, and an air line pipe 10. The lowering combination control air valve 1 is connected to the control air valve, and then the control air valve is connected to the power take-off to control the work of the power take-off, and the power take-off is connected to the gear oil pump, which is fixed on the frame, and the air is slowly lowered. The control reversing valve 3 is connected with the hydraulic oil tank, the limit air valve 2 and the slow-down combined control air valve. Gear 19, O-shaped sealing ring 15, clutch shaft 16, return spring 14, and an end cover 12 is added to the power take-off, and the end cover is fixedly connected to the end of the clutch shaft cylinder of the power take-off box through bolts, and the middle part of the end co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com