Reversing device

A technology of reversing device and driving handle, which is applied to valve device, fluid pressure actuating device, valve operation/release device, etc., can solve the problem of affecting the normal operation of the hydraulic system, affecting the dust-proof effect, and easy disengagement of the leather cup, etc. problems, to achieve the effect of reducing production and installation costs, good reset effect, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

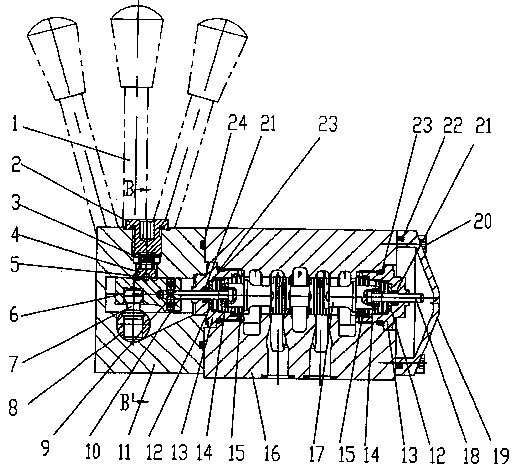

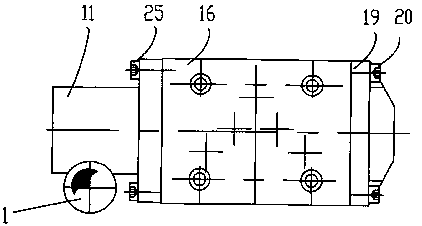

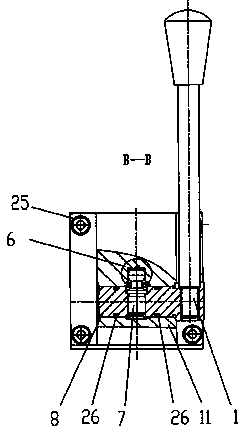

[0020] Such as Figure 1-Figure 6 As shown, the present invention schematically shows a reversing device.

[0021] The invention discloses a reversing device, such as figure 1 As shown, it includes a body 16, a front cover 11, a rear cover 19, a core assembly and a drive handle 1. The front cover 11 and the rear cover 19 are installed on the front and rear sides of the body 16, the core assembly is located inside the body 16, and the drive handle 1 The spool 17 in the driving core body assembly moves, and the spool 17 is installed in the main hole in the body 16; the two ends of the main hole of the body are equipped with screw caps 13; 25 is fixed; the right end of the body is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com