Low-energy-consumption and high-frequency-response control valve and control method

A high-frequency response, low-energy-consumption technology, applied in the valve device for absorbing fluid energy, multi-port valve, valve device, etc., can solve the problems of local oil circuit pressure rise, spool movement disorder, spool movement late, etc. , to achieve the effect of reducing fluid pressure loss, reducing fluid flow resistance, and low commutation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

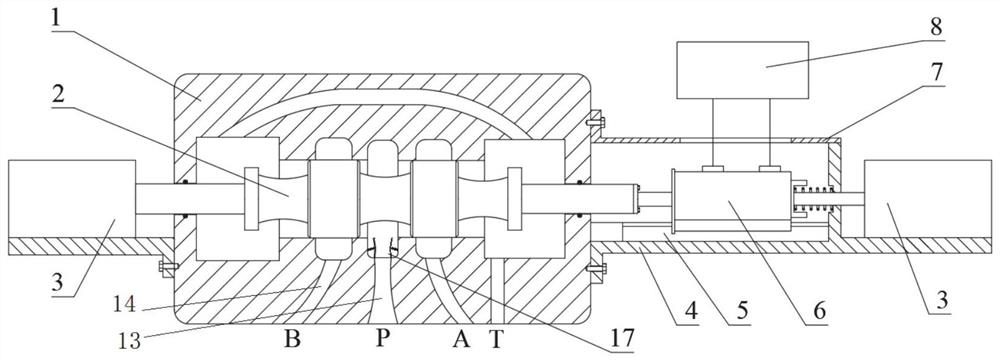

[0041] See how Figure 1-6 , the invention discloses a control valve with low energy consumption and high frequency response, comprising a valve body 1, a valve core 2 is arranged in the valve body 1, one end of the valve core 2 is connected with a first valve core control mechanism 9, and the other end is connected with a rotating motor 6 connections.

[0042] The left and right sides of the valve body 1 are respectively provided with through holes, and the through hole on the left side is used to connect one end of the first spool control mechanism 9 with one end of the spool 2 located in the valve body 1, and the first spool 2 control mechanism 9 Used to control the left and right movement of the spool 2.

[0043] The bottom of the first spool control mechanism 9 is installed on the base 3 , and one end of the base 3 is connected to the side of the valve body 1 . The frame 3 is used to support the first spool control mechanism 9 .

[0044] Such as figure 1 As shown, one...

Embodiment 2

[0067] In the second aspect, the present application also discloses a method for controlling a control valve with low energy consumption and high response, and the specific steps are as follows:

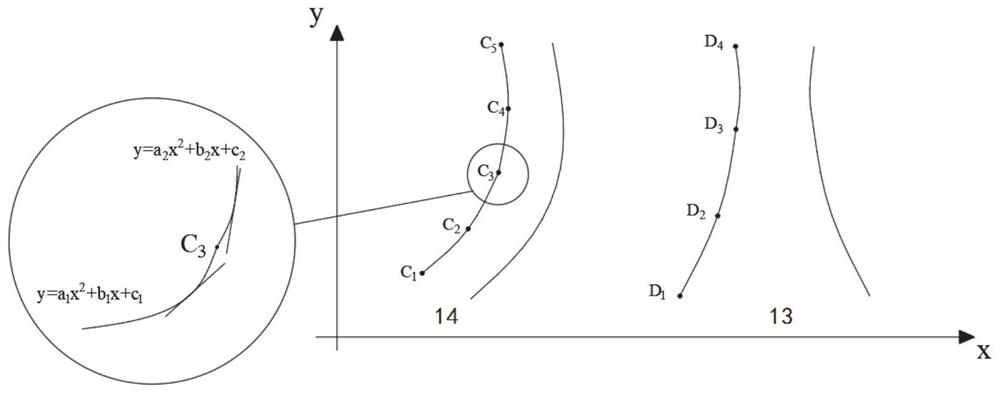

[0068] S1: input the oil into the cavity of the valve body 1 through the first curved channel 13 of the valve body 1;

[0069] S2: The rotary motor 6 drives the spool 2 to rotate;

[0070] S3: The second spool control mechanism 10 moves to the side where the first spool control mechanism 9 is connected to the spool 2 by pushing the rotating motor 6; the first spool control mechanism 9 pushes the spool 2 to the second spool control mechanism The side where 10 is located moves; the oil passes through the second curved channel 14 on the side of the spool 2 close to the first spool control mechanism 9 to control the movement of the actuator connected to the second curved channel 14;

[0071] S3: The first spool control mechanism 9 moves to the side where the second spool control mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com