Cam-type pedal lock braking mechanism

A cam-type, pedal-operated technology, which is applied to metal processing machinery parts, driving devices, metal processing equipment, etc., can solve the problem of large structure of the spring return part, and achieve the effects of fast braking speed, low cost and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

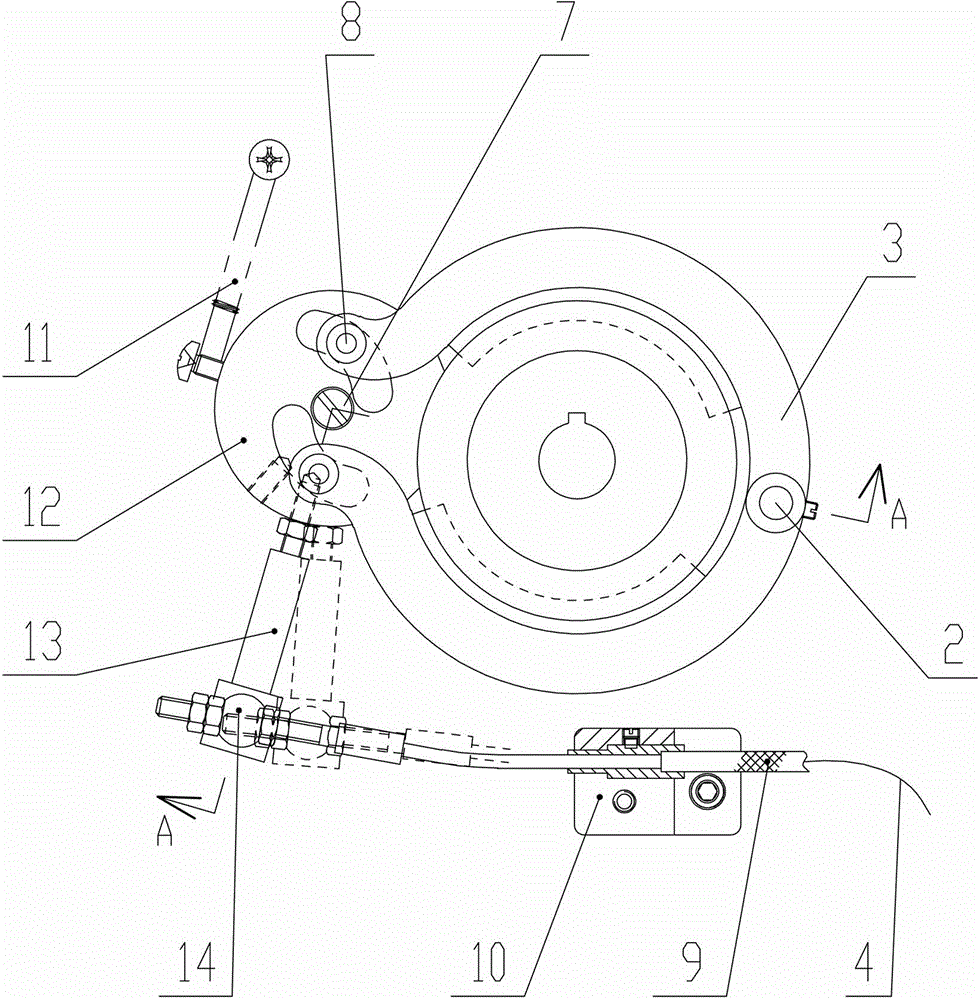

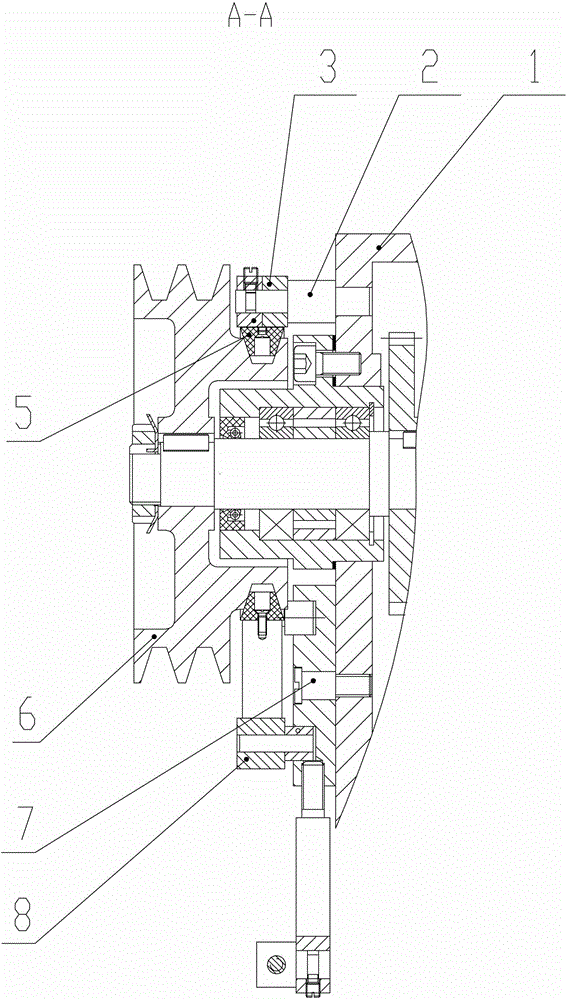

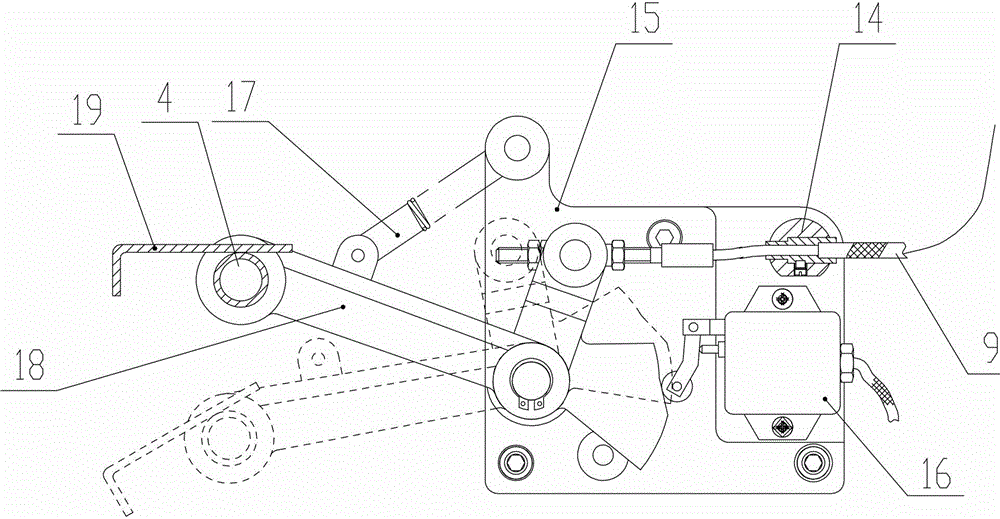

[0016] A cam-type pedal brake mechanism, comprising a pedal part, a brake cable 9, and a brake brake part, characterized in that the pedal part includes a support plate 15, a pedal 19, and a brake limit block 14. Cam lever 18 and travel switch 16, the brake brake part includes brake runner 12, brake block 3 and brake pad, brake cable 9 and cable support seat 10;

[0017] The support plate 15 is vertically fixed on the side of the front leg of the lathe, the cam end of the cam lever 18 is arranged on the support plate 15 through a pin shaft, and the middle position of the cam lever 18 is provided with a pedal extension spring 17, and the pedal extension spring 17 The other end is connected on the support plate 15, the travel switch 16 is fixed on the support plate 15, the contact of the travel switch 16 is located within the range of the cam rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com