Brake block mechanism for dry skating boot deflection brake

A technology for brake pads and roller skates, which is applied to roller skates, ice skating, and skateboards. It can solve the problems of not having a unidirectional braking function, affecting the safety of roller skates, and insufficient braking force, so as to achieve reliable braking action. Easy installation and simple brake mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

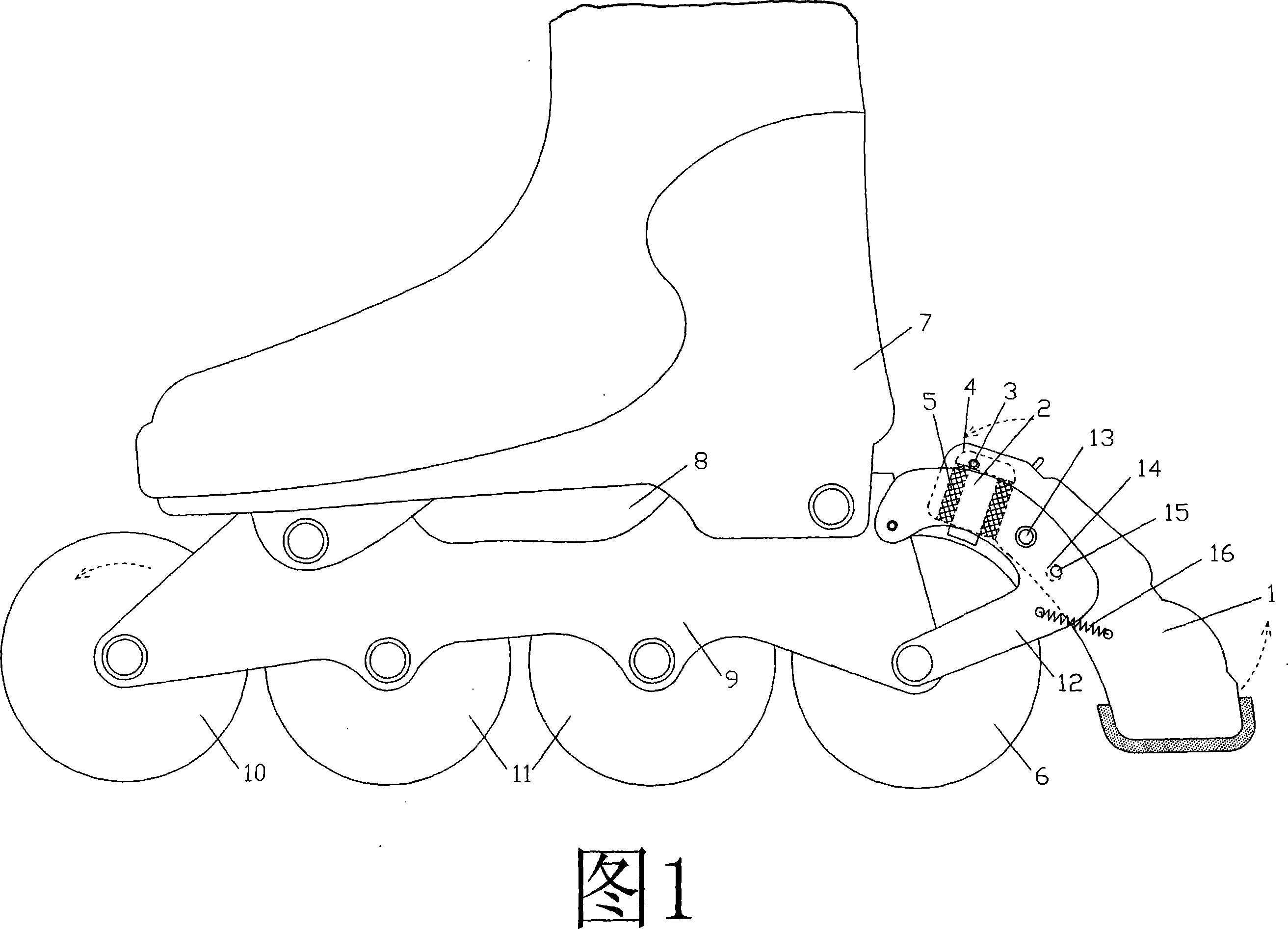

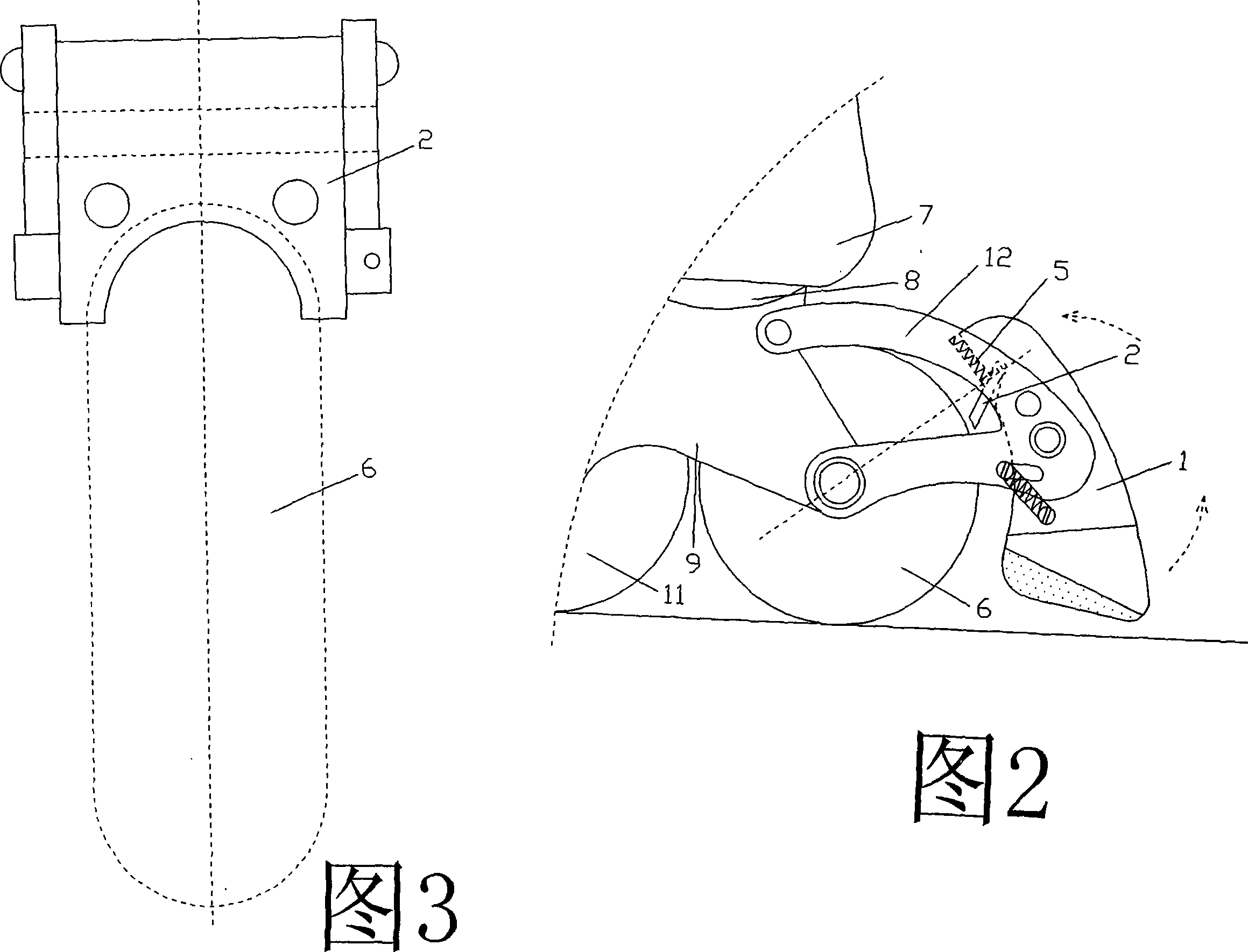

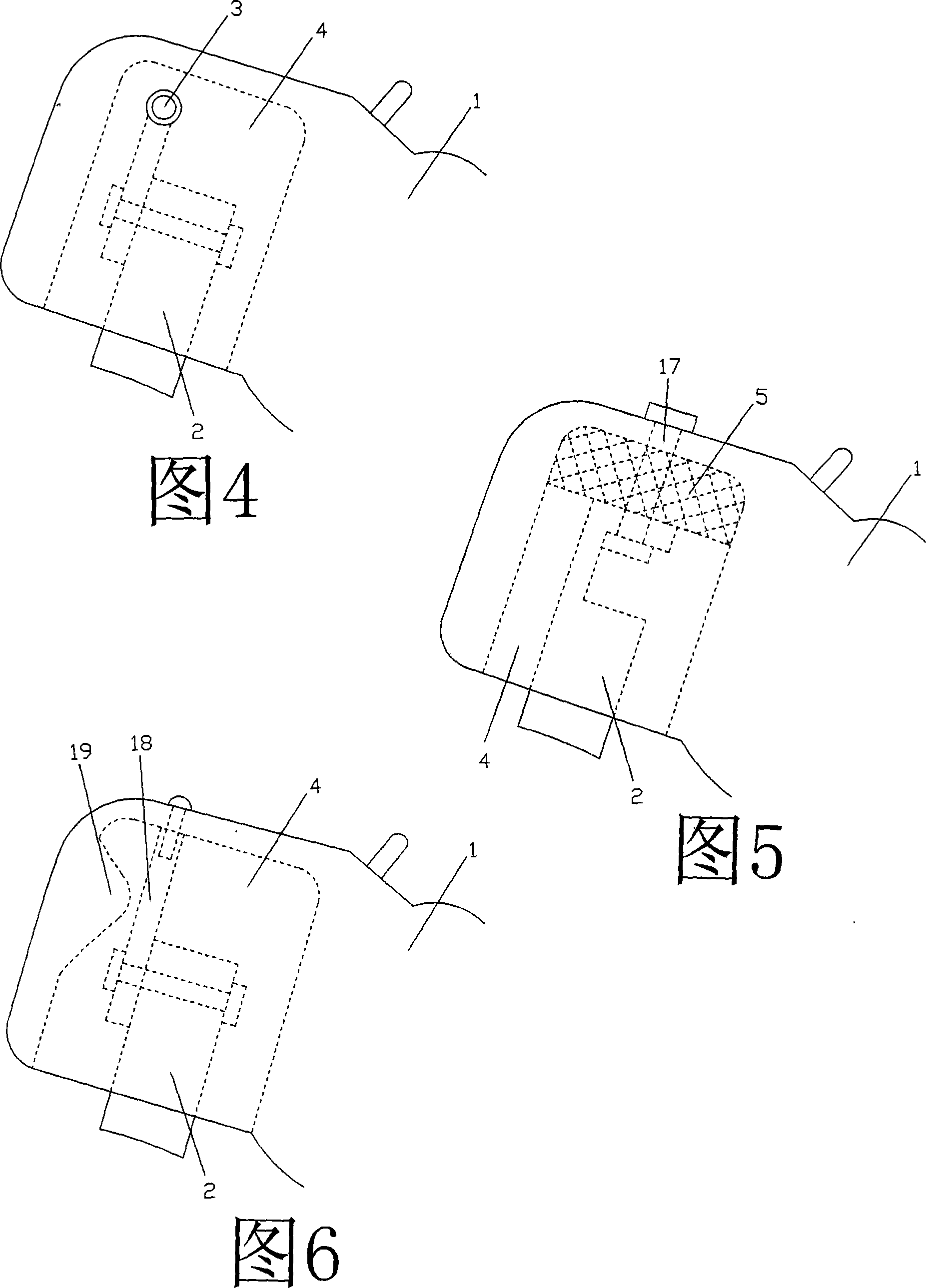

[0025] Example 1. The structure of the brake pad of this embodiment is shown in FIG. 1 , which has a brake pad 2 connected to the rear brake swing block 1 that can be contacted and deflected. Specifically, the brake pad 2 is movably connected to the groove on the brake swing block through the connecting shaft 3 4, the left and right sides of the brake pad are embedded with elastic bodies 5 that can limit the swing of the brake pad in the groove; the elastic body 5 can also be one, located on the left side of the brake pad (see Figure 2); The body 5 constitutes the swing restricting member of the brake pad, and the elastic body can also adopt a spring structure; the braking surface of the brake pad is a contact wheel surface with a substantially smooth surface and can fit the surface of the outer upper half of the wheel of the shoe wheel 6 (see Figure 3), the brake pad 2 is in contact with the shoe wheel 6 as the brake swing block 1 touches the ground and deflects; the brake pa...

Embodiment 2

[0027] Example 2. The structure of the brake pad of this embodiment is shown in FIG. 7 , with the brake pad 2 connected to the front and rear extension brake brackets 21 of the sole shell 8 and / or the sole center column 20. The brake pad 2 is long and has a certain elasticity. The plate can be deflected with the front and rear shoe wheel brackets 9a, 9b to contact with the front and rear shoe wheels 10, 6; (i.e. front) upper part of the wheel surface or the outer (i.e. rear) upper part of the wheel surface of the rear shoe wheel 6 fits the contact wheel surface (refer to FIG. 3), the front wheel 10 alone pushes hard on the ground to cause the front shoe wheel bracket After the deflection, the brake pad 2 is in contact with the surface of the front wheel. At this time, when the front wheel 10 touches the ground and rotates backward (clockwise), the brake pad is driven to shift backward, and the braking surface will directly sink into the soft surface of the shoe wheel. , And t...

Embodiment 3

[0030] Example 3. This embodiment is shown in Fig. 8. The biggest difference between the structure shown in Fig. 8 and Fig. 7 is: the shoe wheel bracket 9 in Fig. 8 is a whole, and the shoe wheel bracket 9 is movably connected to the sole shell through the front and rear connecting pieces 22. On the corresponding central column 20 above, the connecting piece 22 is composed of a connecting shaft, a sleeve sleeved outside the connecting shaft and a connecting nut. The left and right two pieces are fixedly locked at the two ends of the sleeve, and the shoe wheel bracket 9 can be rotated; 34 in the figure is a locking rod. Of course, the same brake pad mechanism as in Embodiment 2 can be used completely in FIG. 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com