Tight braking device for numeric control rotary table

A technology of numerical control turntable and rotary table, which is applied in the direction of large-scale fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of reduced precision of processed workpieces, deviation in the circumferential direction of oil cylinders, and low reliability of brake tightness, etc., to achieve Improved rigidity, high braking force, and high braking reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

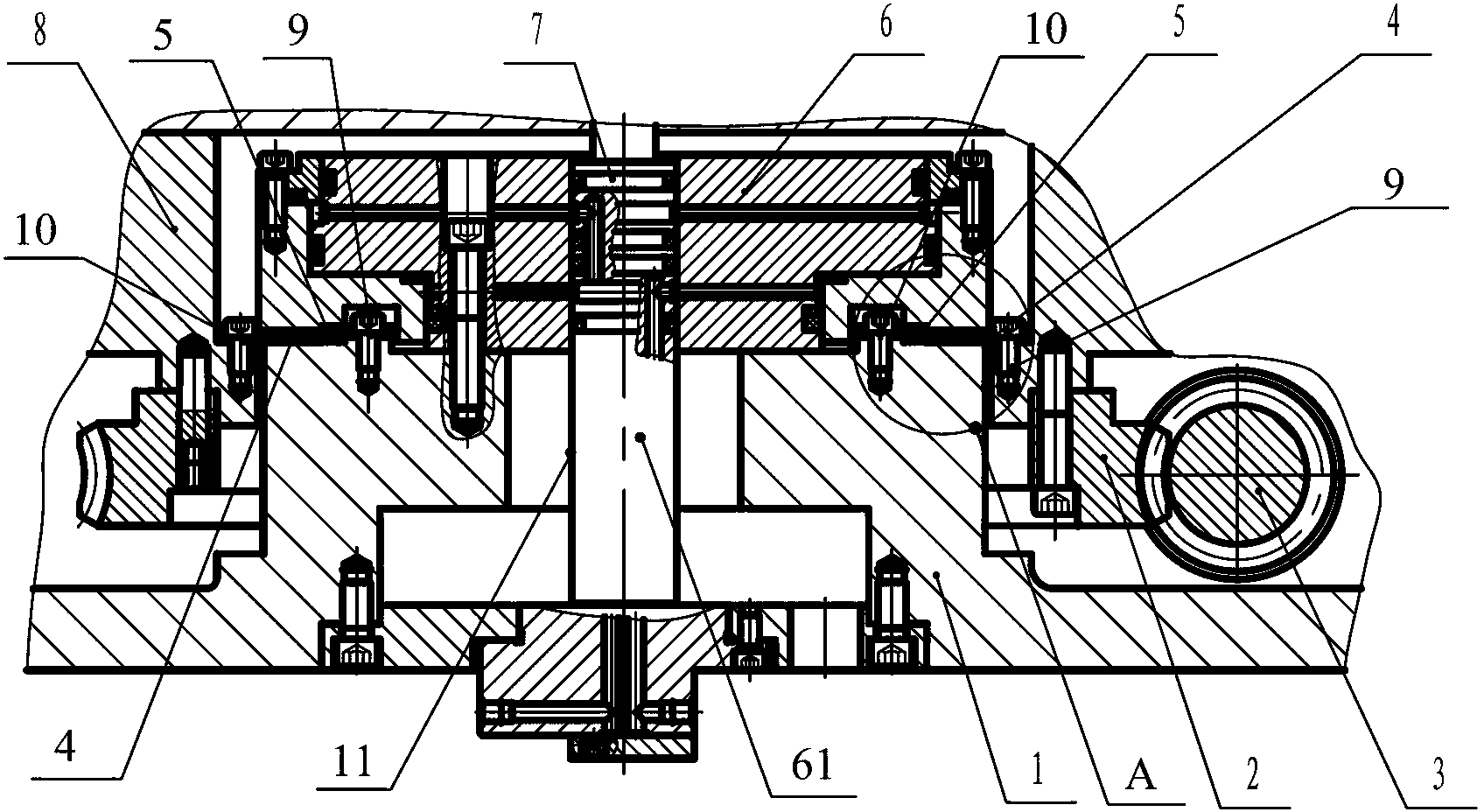

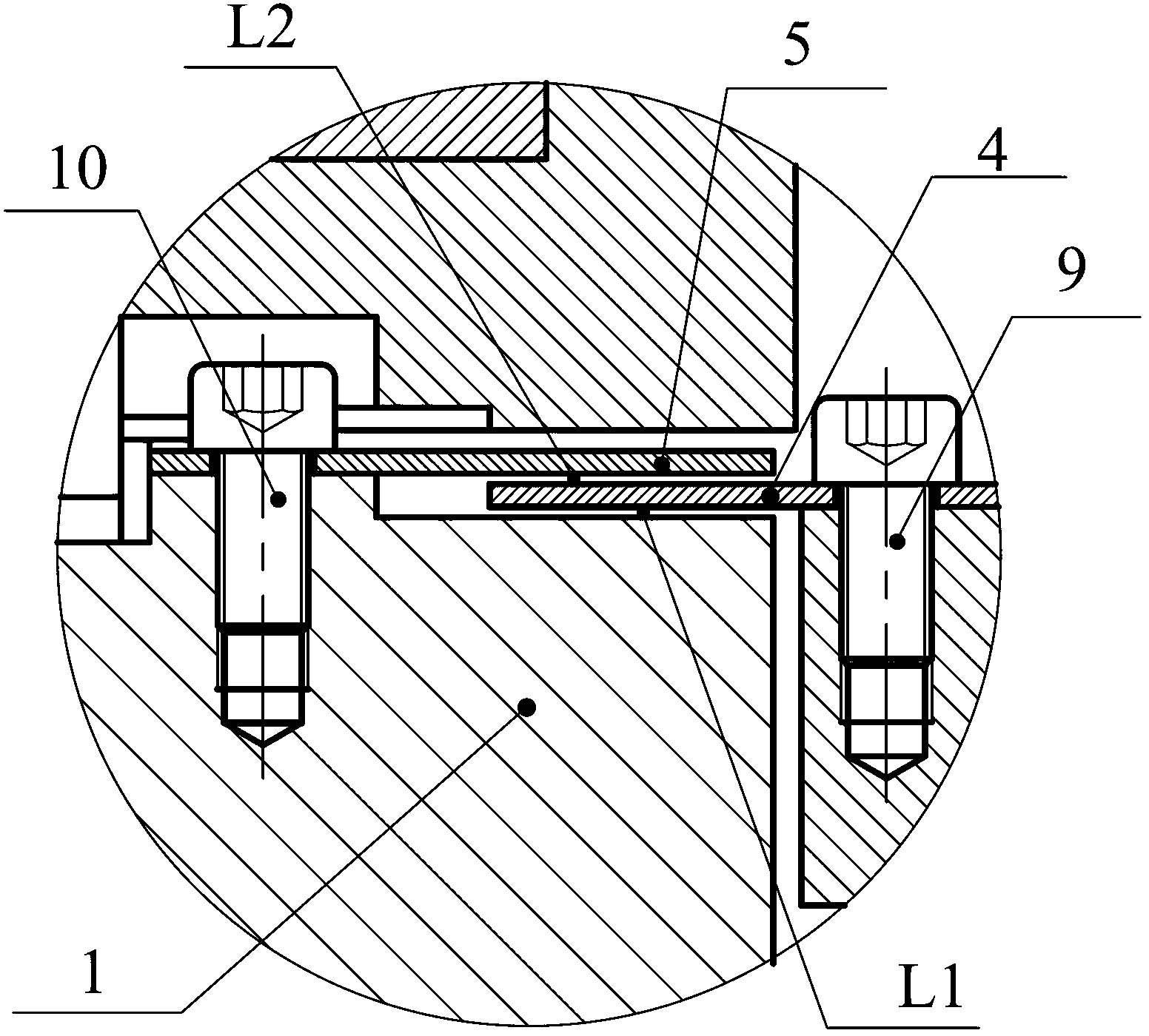

[0016] Embodiment 1: As shown in the figure, a braking device for a numerically controlled turntable includes a base 1, an oil cylinder 6, an oil separator 7 and a first annular friction plate 4 fixedly arranged on a rotary disc 8. The base 1 is provided with Piston hole 11, the piston 61 of the oil cylinder 6 extends into the piston hole 11, the oil cylinder 6 is connected with the oil separator 7, the first annular friction plate 4 is located between the base 1 and the oil cylinder 6, the first annular friction plate 4 and the oil cylinder 6 A second annular friction plate 5 is arranged between them, and the second annular friction plate 5 is fixedly arranged on the base 1 .

[0017] In this embodiment, a first gap L1 is provided between the first annular friction plate 4 and the base 1, a second gap L2 is provided between the first annular friction plate 4 and the second annular friction plate 5, and the first gap L1 is 0.05mm, and the second gap L2 is 0.05mm.

[0018] In ...

Embodiment 2

[0019] Embodiment 2: As shown in the figure, a braking device for a numerically controlled turntable includes a base 1, an oil cylinder 6, an oil separator 7 and a first annular friction plate 4 fixedly arranged on a rotary disc 8. The base 1 is provided with Piston hole 11, the piston 61 of the oil cylinder 6 extends into the piston hole 11, the oil cylinder 6 is connected with the oil separator 7, the first annular friction plate 4 is located between the base 1 and the oil cylinder 6, the first annular friction plate 4 and the oil cylinder 6 A second annular friction plate 5 is arranged between them, and the second annular friction plate 5 is fixedly arranged on the base 1 .

[0020] In this embodiment, a first gap L1 is provided between the first annular friction plate 4 and the base 1, a second gap L2 is provided between the first annular friction plate 4 and the second annular friction plate 5, and the first gap L1 is 0.1 mm, and the second gap L2 is 0.1 mm.

[0021] In ...

Embodiment 3

[0022] Embodiment 3: As shown in the figure, a braking device for a numerically controlled turntable includes a base 1, an oil cylinder 6, an oil separator 7, and a first annular friction plate 4 fixedly arranged on a rotary disc 8. The base 1 is provided with Piston hole 11, the piston 61 of the oil cylinder 6 extends into the piston hole 11, the oil cylinder 6 is connected with the oil separator 7, the first annular friction plate 4 is located between the base 1 and the oil cylinder 6, the first annular friction plate 4 and the oil cylinder 6 A second annular friction plate 5 is arranged between them, and the second annular friction plate 5 is fixedly arranged on the base 1 .

[0023] In this embodiment, a first gap L1 is provided between the first annular friction plate 4 and the base 1, a second gap L2 is provided between the first annular friction plate 4 and the second annular friction plate 5, and the first gap L1 is 0.15mm, and the second gap L2 is 0.15mm.

[0024] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com