Roadlouse drive front axle

A technology for small cars and front axles, applied in axles, wheels, brakes, etc., can solve problems such as large ball contact surface, limited ball space, easy to drop pins, etc., to achieve fast braking speed, large transmission torque, and flexible steering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

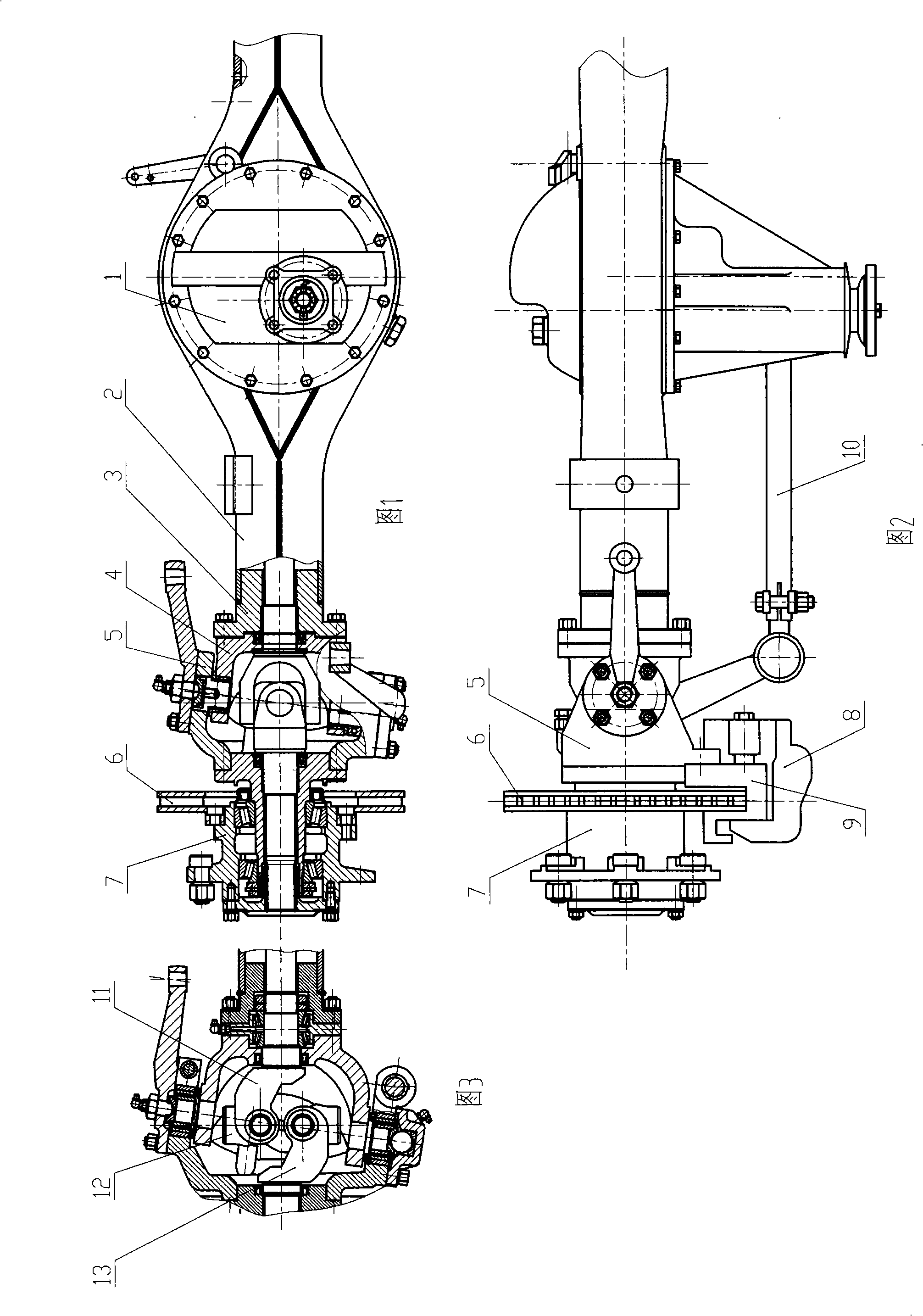

[0013] The structure of the present invention consists of a differential transmission assembly (1), an axle housing (2), an axle housing flange (3), a steering knuckle, a universal joint, an outer half shaft, a wheel hub (7), and a steering tie rod mechanism (10 )composition. The steering knuckle is a U-shaped structure, and the two U-shaped ports of the two U-shaped brackets are fitted with pin shafts. The bottom of the inner U-shaped bracket (4) is fixed on the axle housing flange (3), and the outer U-shaped bracket (4) is fixed on the axle housing flange (3). The bottom of the bracket (5) is fixed on the outer half shaft housing; the brake mechanism is a disc brake mechanism, and the U-shaped support seat (9) of the disc brake mechanism is fixed on the outer half shaft housing, and the disc (6) of the disc brake mechanism is fixed on the outer half shaft housing. On the rotating hub (7) seat of half shaft. It is to replace the ball steering knuckle of the driving front axl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com