Through shaft tapered-tooth planet wheel side reducer with brake

A wheel-side reducer and through-shaft technology, which is applied in the direction of brake types, belts/chains/gears, transmission parts, etc., can solve the problems of large vehicle width and large space occupation of the support truck, and achieve compact structure and manufacturing Effect of high dynamic torque and reduced width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

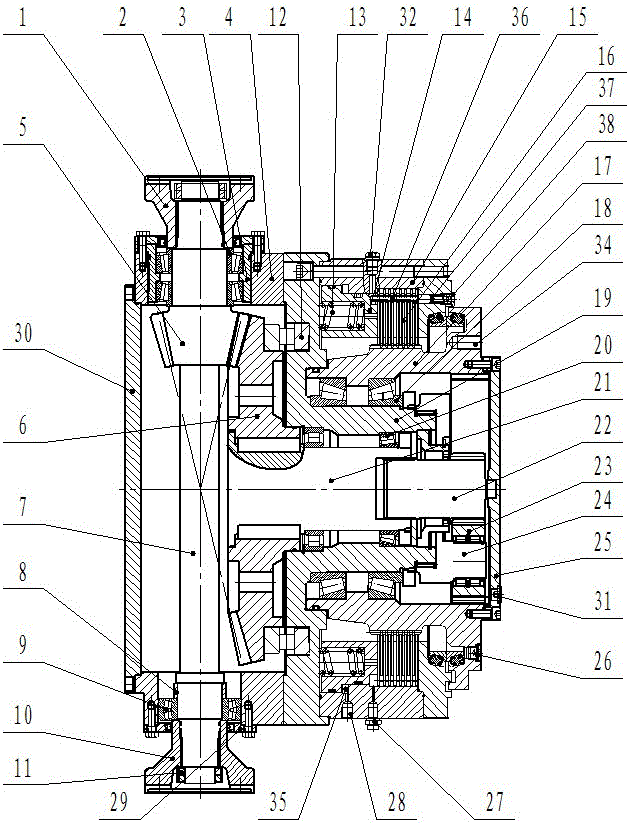

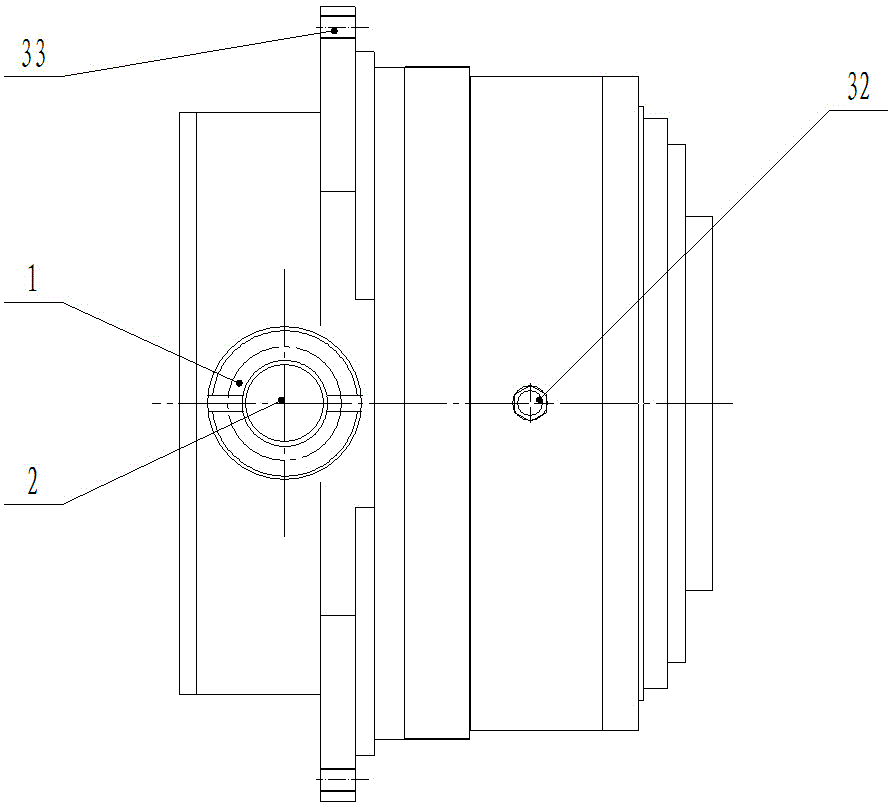

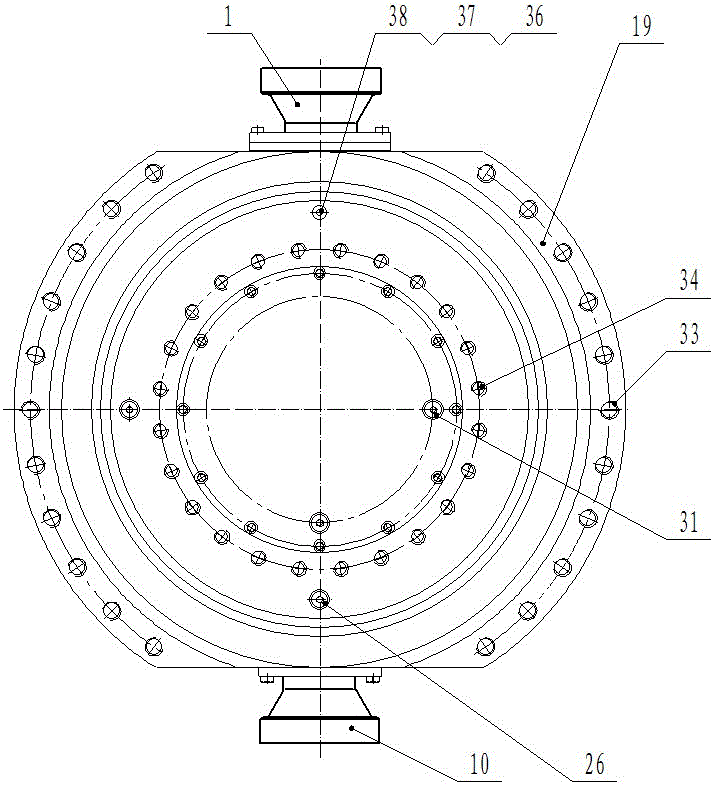

[0015] Such as figure 1 As shown, a penetrating shaft bevel gear planetary reducer with a brake includes an input fork I1, a first rolling bearing 2, an inner bracket 3, an input housing 4, a small bevel gear 5, a large bevel gear 6, a through Shaft 7, shaft sleeve 8, radial bearing 9, output fork frame II10, lock nut 11, brake spring 13, brake block 14, brake sleeve 15, friction plate group 16, inner gear frame 17, second Rolling bearing 18, bearing sleeve 19, third rolling bearing 20, main drive shaft 21, sun gear shaft 22, planetary gear 23, planet carrier 24, right end cover 25, vent plug 27, high pressure oil filling port 28, small end cover 29, left end Cover 30, frame mounting hole 33, wheel mounting screw hole 34 and high-pressure oil chamber 35, the input fork I1 is connected to the external universal joint transmission shaft, the input f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com