Manufacturing method of shallow groove isolation structure

A technology of isolation structure and manufacturing method is applied in the manufacturing field of shallow trench isolation structure, which can solve problems such as application scope limitation, and achieve the effects of saving manufacturing cost, simplifying process and improving integration degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

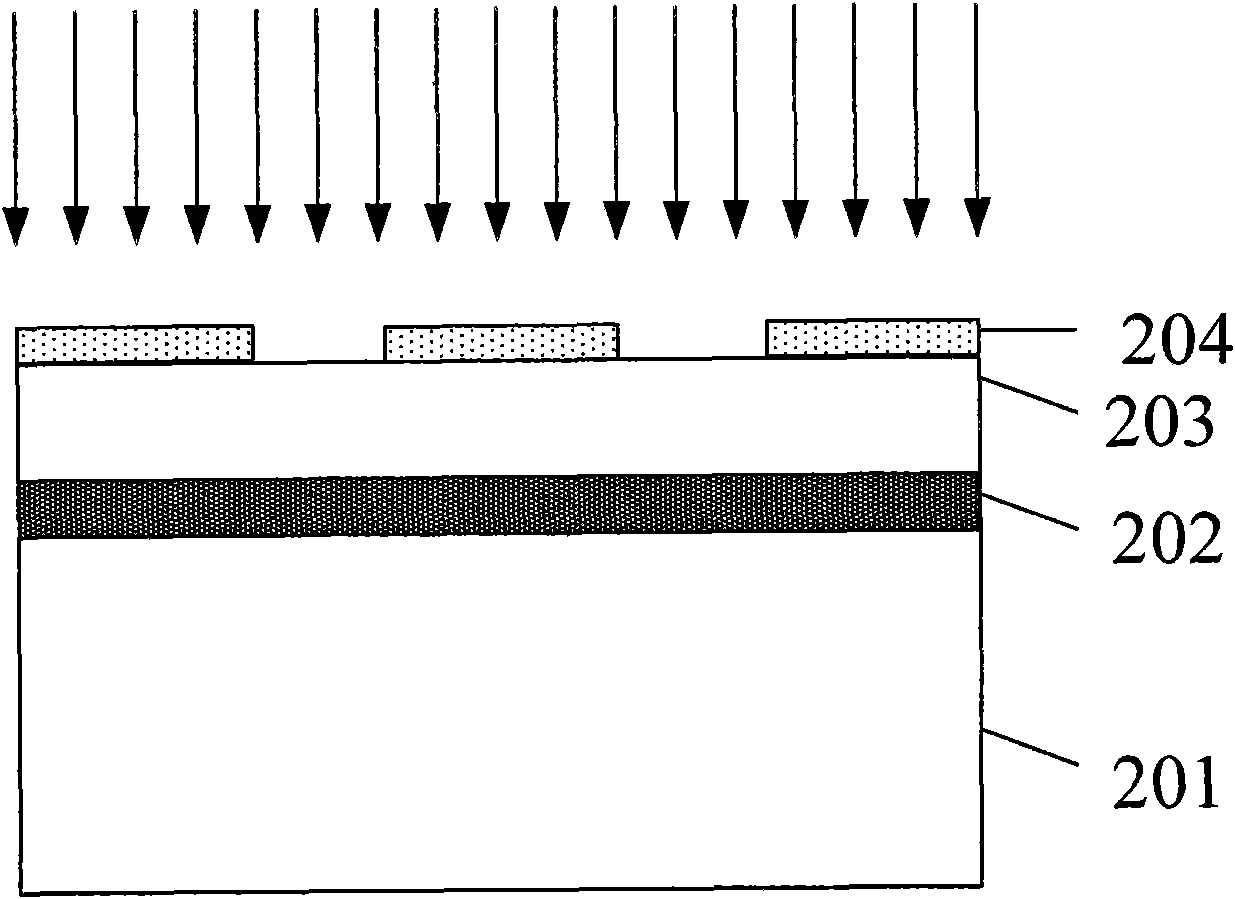

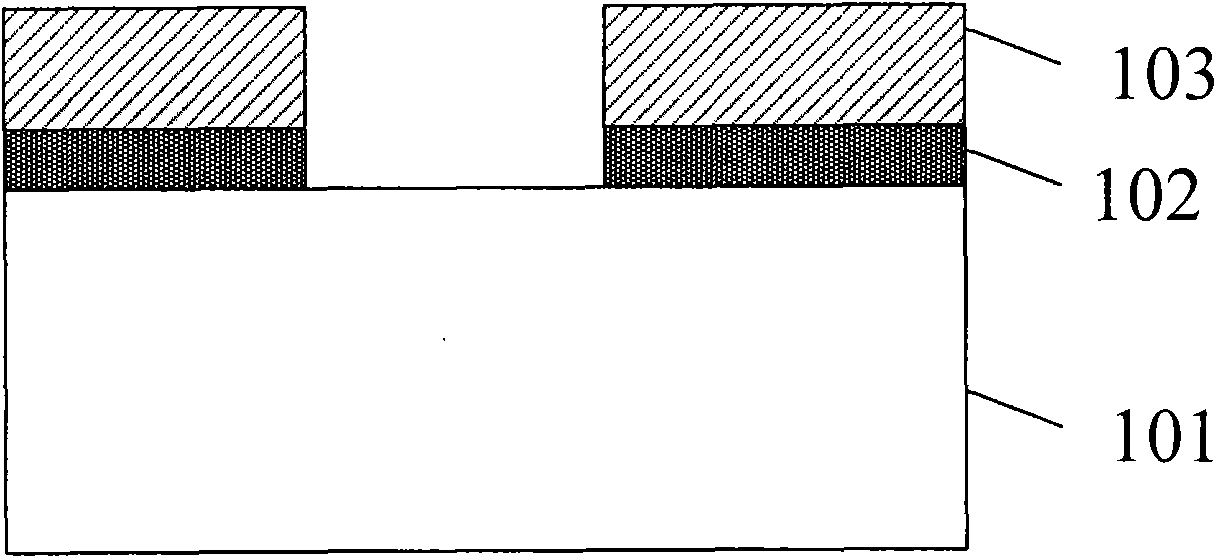

[0029] figure 2 Shown is a flow chart of a method for fabricating a shallow trench isolation structure in a preferred embodiment of the present invention; Figure 3a-3e shown in figure 2 Schematic diagrams of device structures in each process shown.

[0030] In this embodiment, an STI is formed on a silicon-on-insulator (SOI) structure by implanting oxygen (Separation by Implanted Oxygen, SIMOX) as an example. In practical applications, silicon-on-insulator (SOI) produced by other processes can also be used, such as the Smart Cut method.

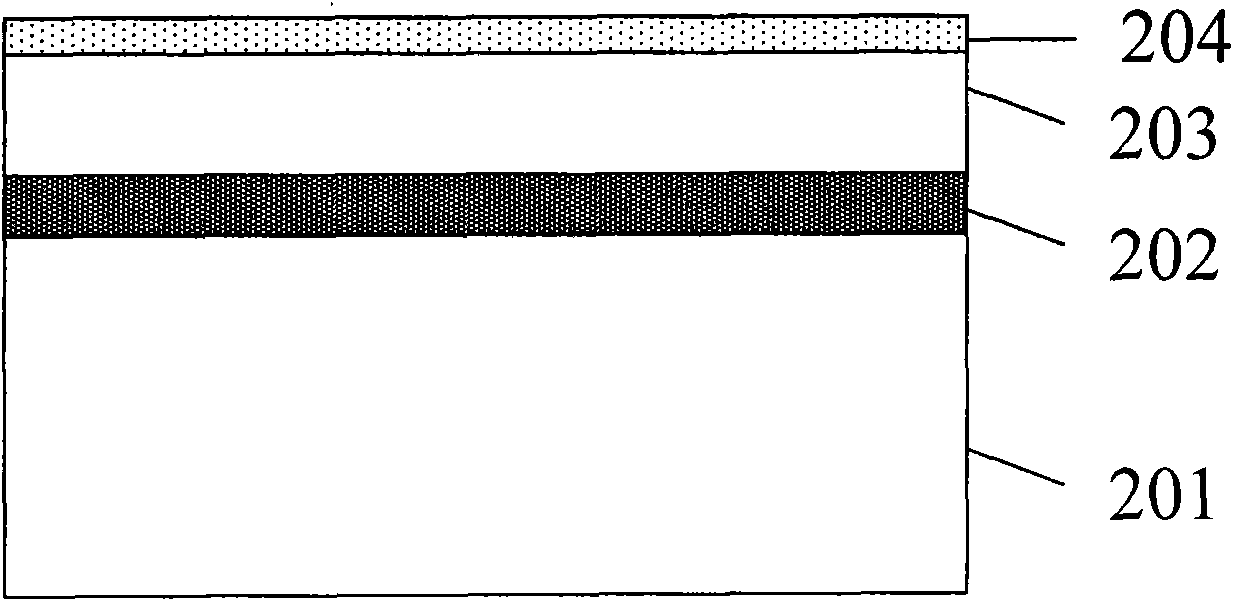

[0031] The SOI structure in this embodiment includes a substrate layer 201, an oxide buried layer 202, and a single crystal silicon top layer 203 in sequence, (such as Figure 3a The structure shown) the manufacturing method provided in this embodiment comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com