Patents

Literature

257results about How to "Reduce coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

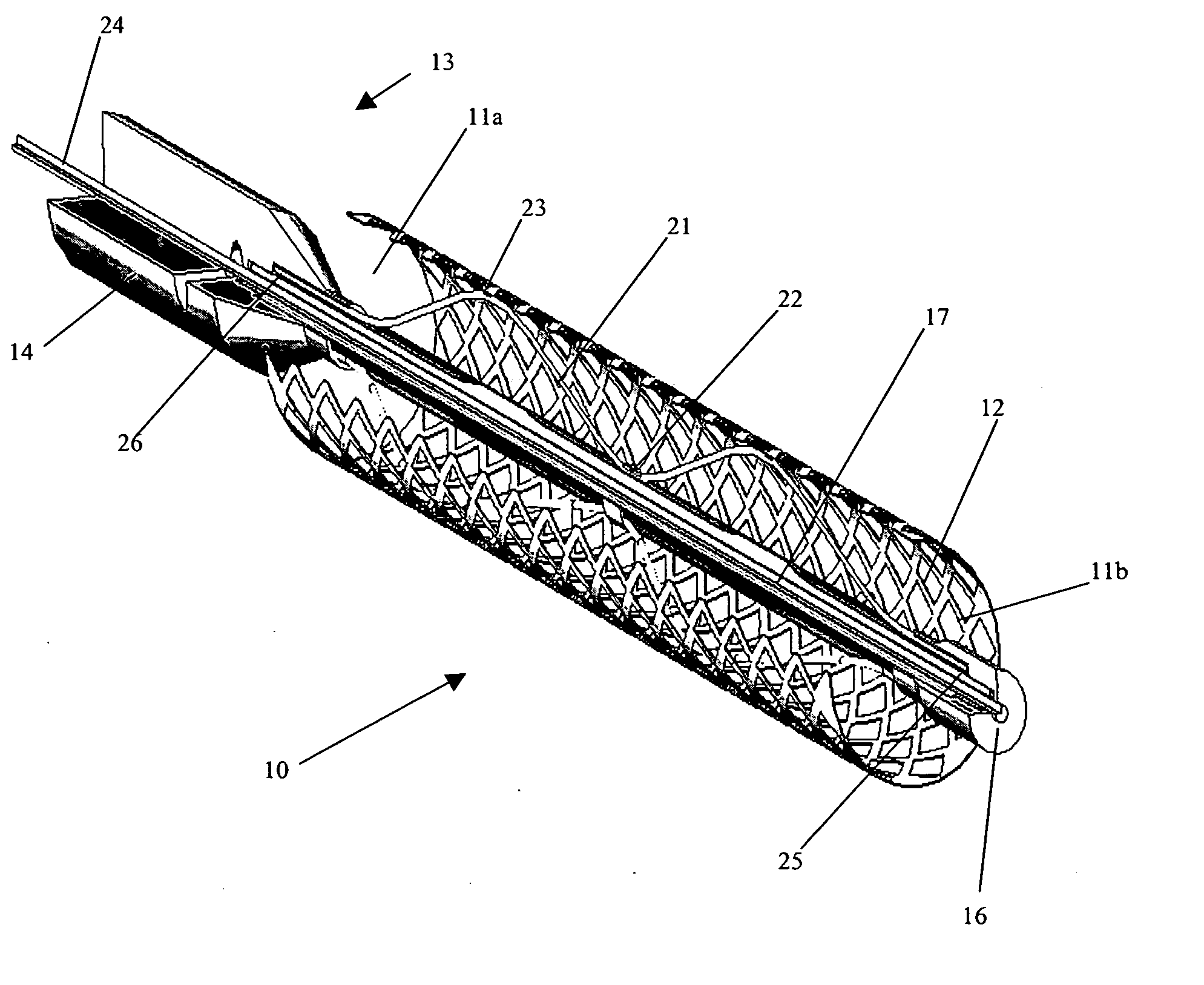

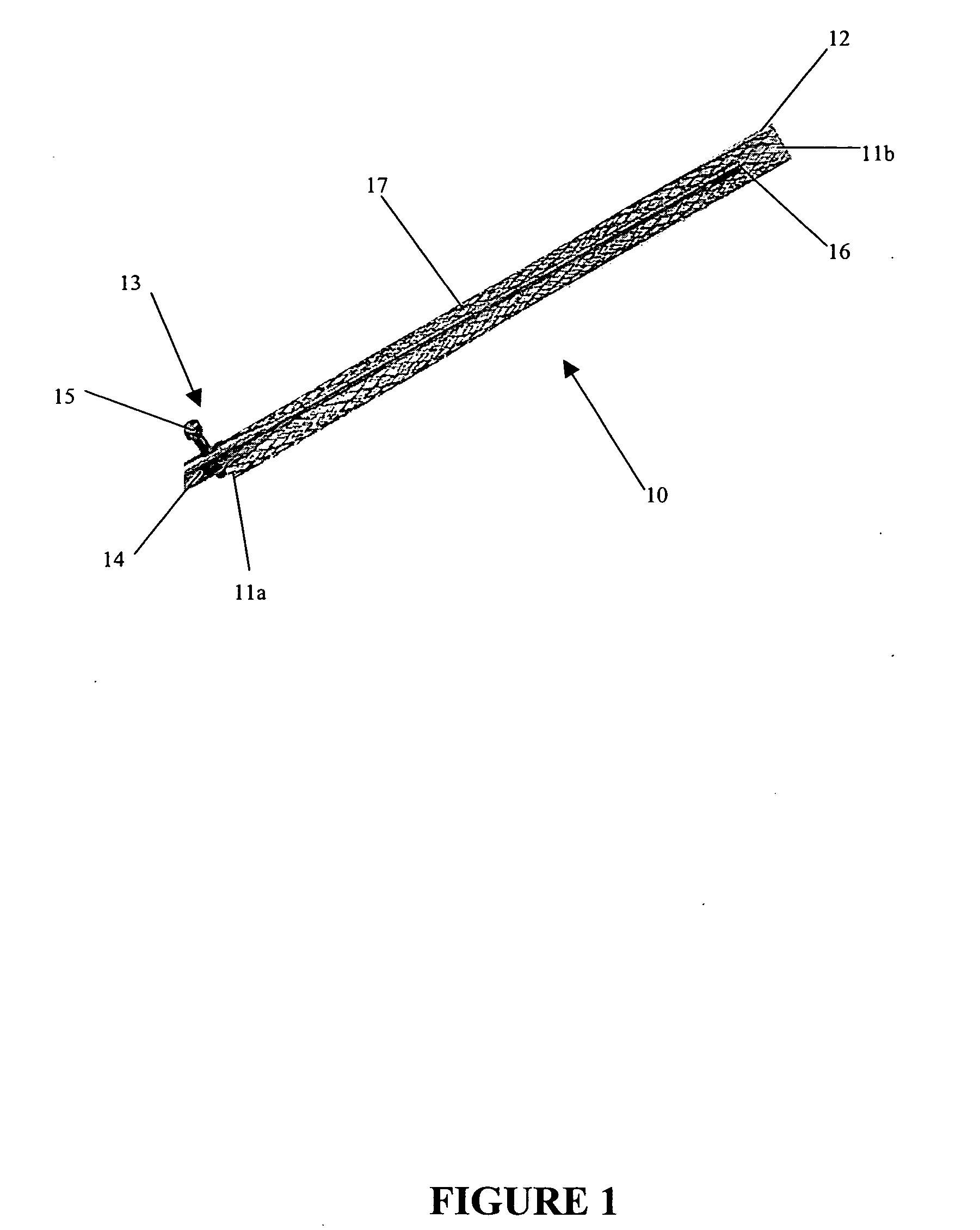

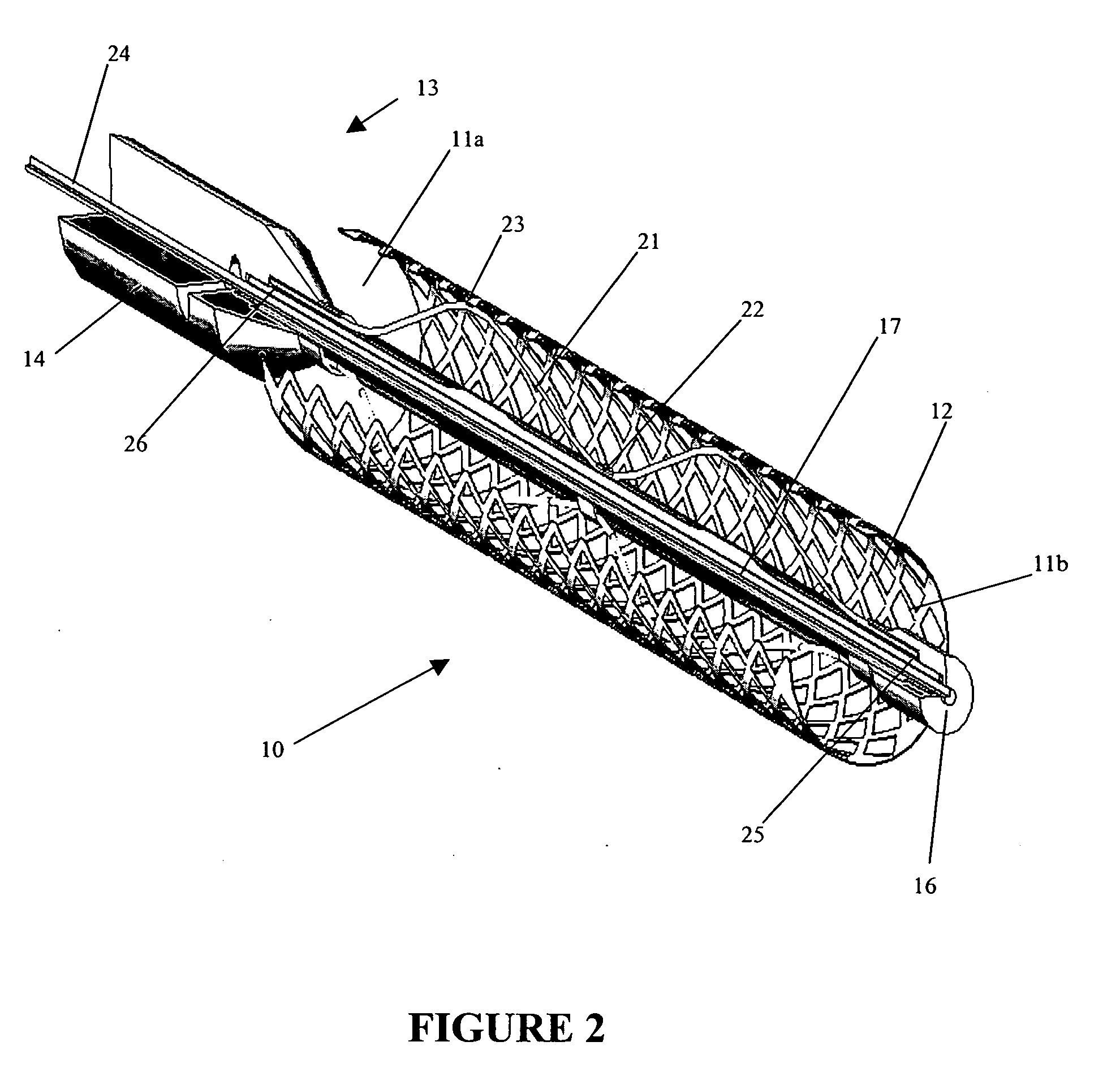

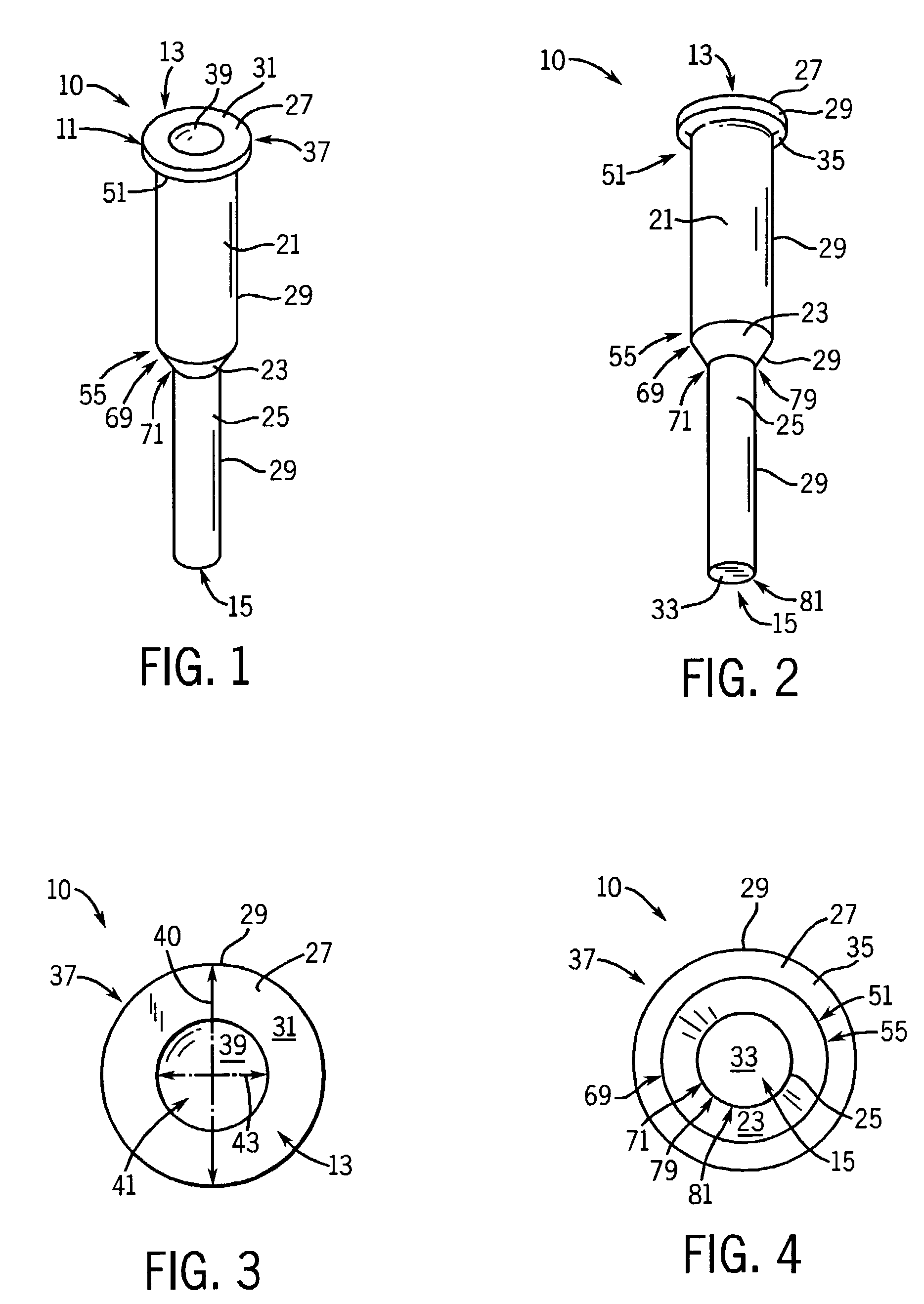

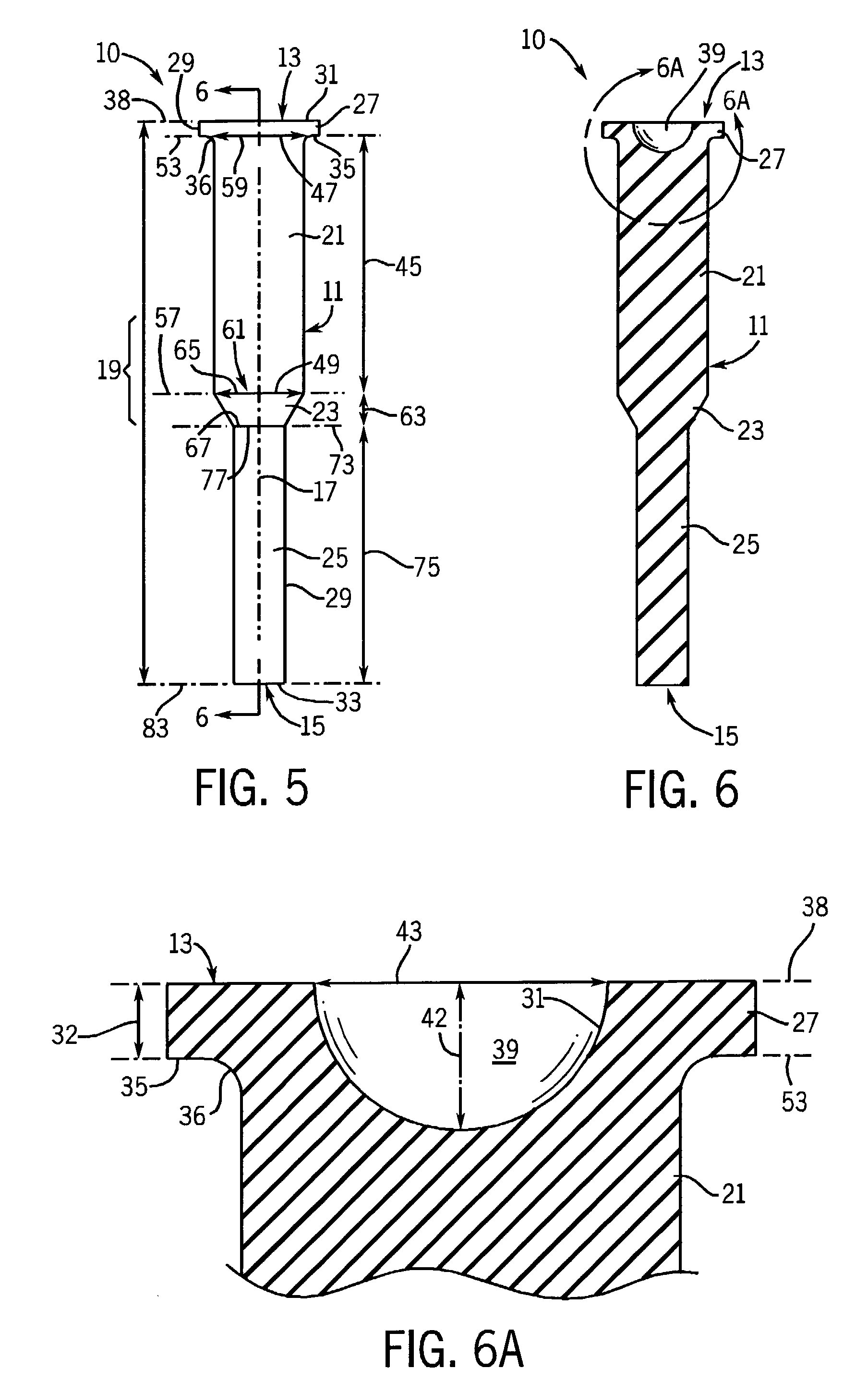

Orthopedic surgery access devices

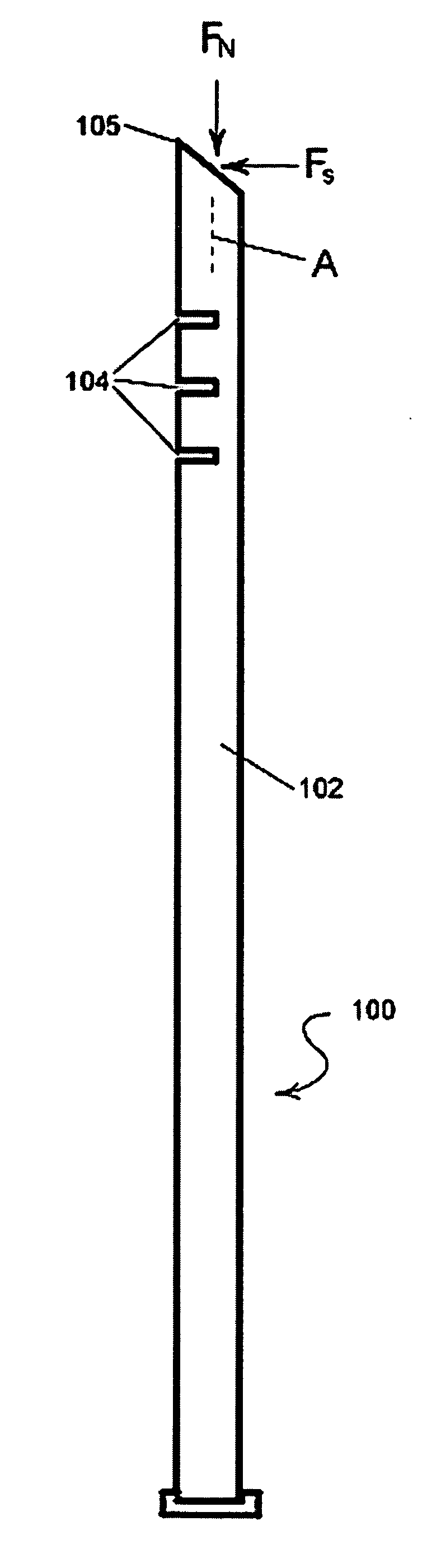

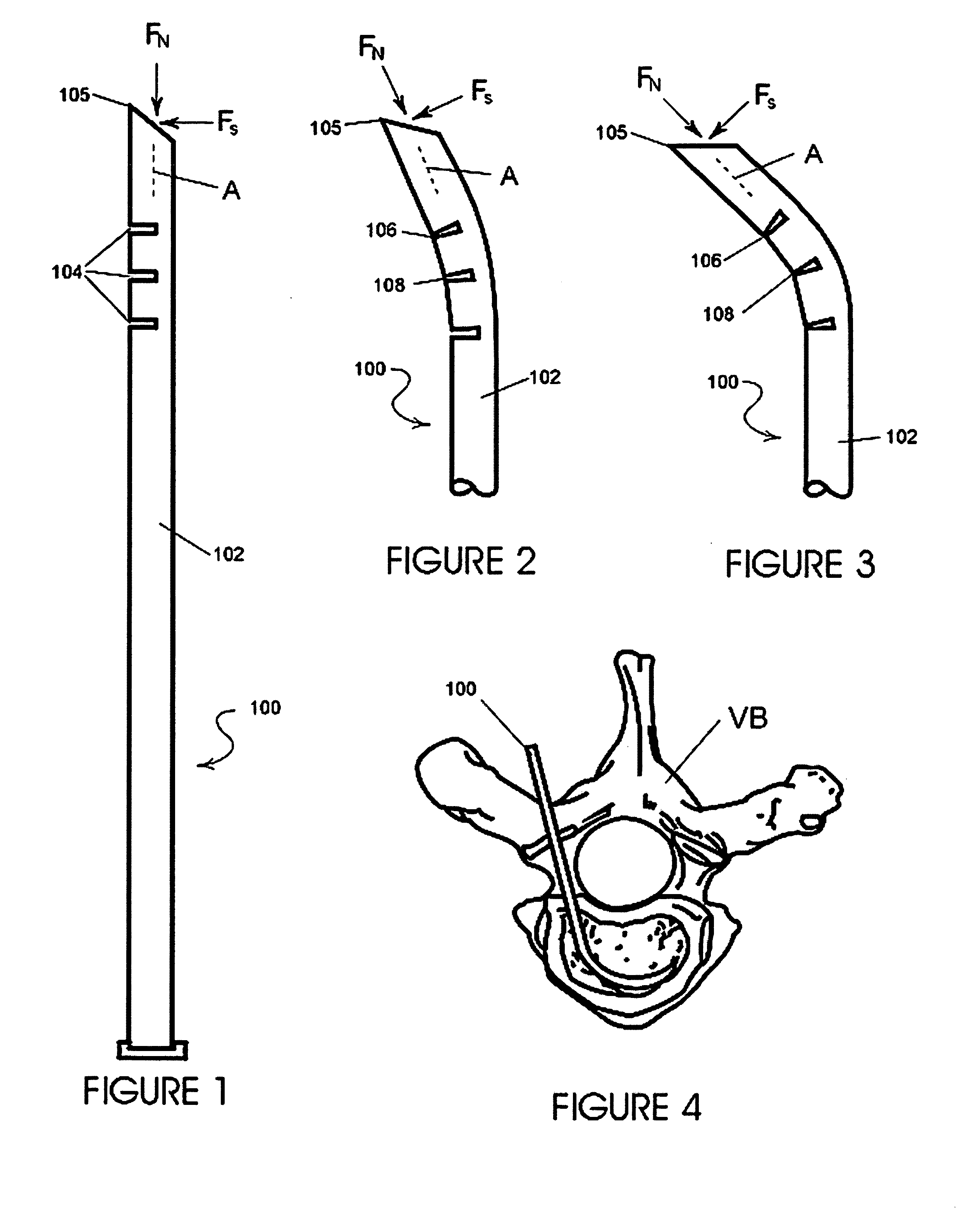

InactiveUS20050216018A1Easy accessLow bending stiffnessCannulasOsteosynthesis devicesCancellous boneBending stiffness

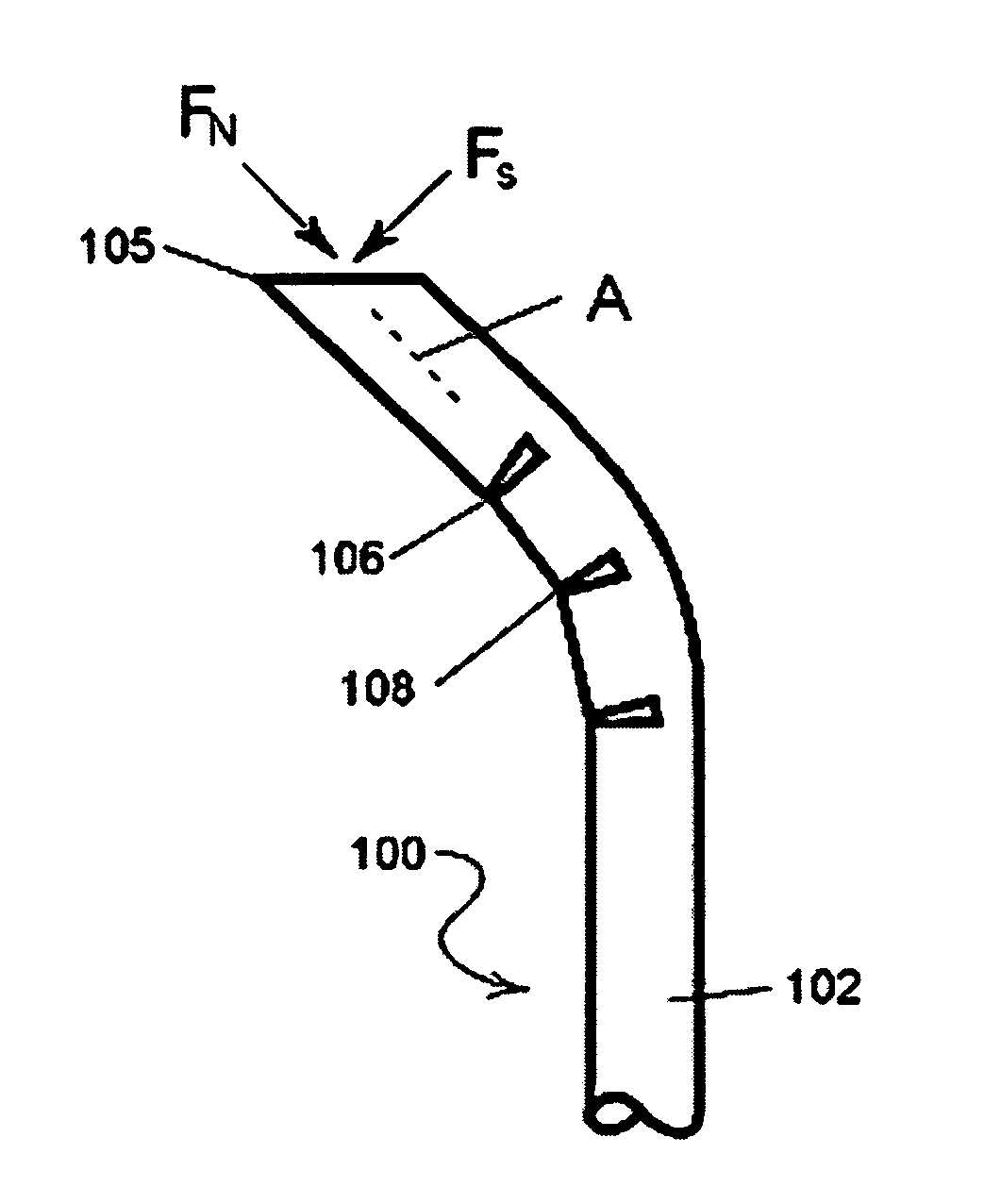

The present invention provides instrumentation that facilitates access to both sides of the vertebral body from a single access point. More particularly, the present invention provides bendable access devices that can be steered so as to traverse the vertebral body from the point of entry into the vertebral body, through the cancellous bone within the vertebral body, and to the contralateral side of the vertebral body. This steerability is provided by forming the access device with a series of slots, grooves, or notches in the side of the access device near the distal end of the access device, which slots, grooves, or notches reduce the bending stiffness of the access device. As a result, the distal end of the access device bends as it is being advanced into the vertebral body.

Owner:GLOBUS MEDICAL INC

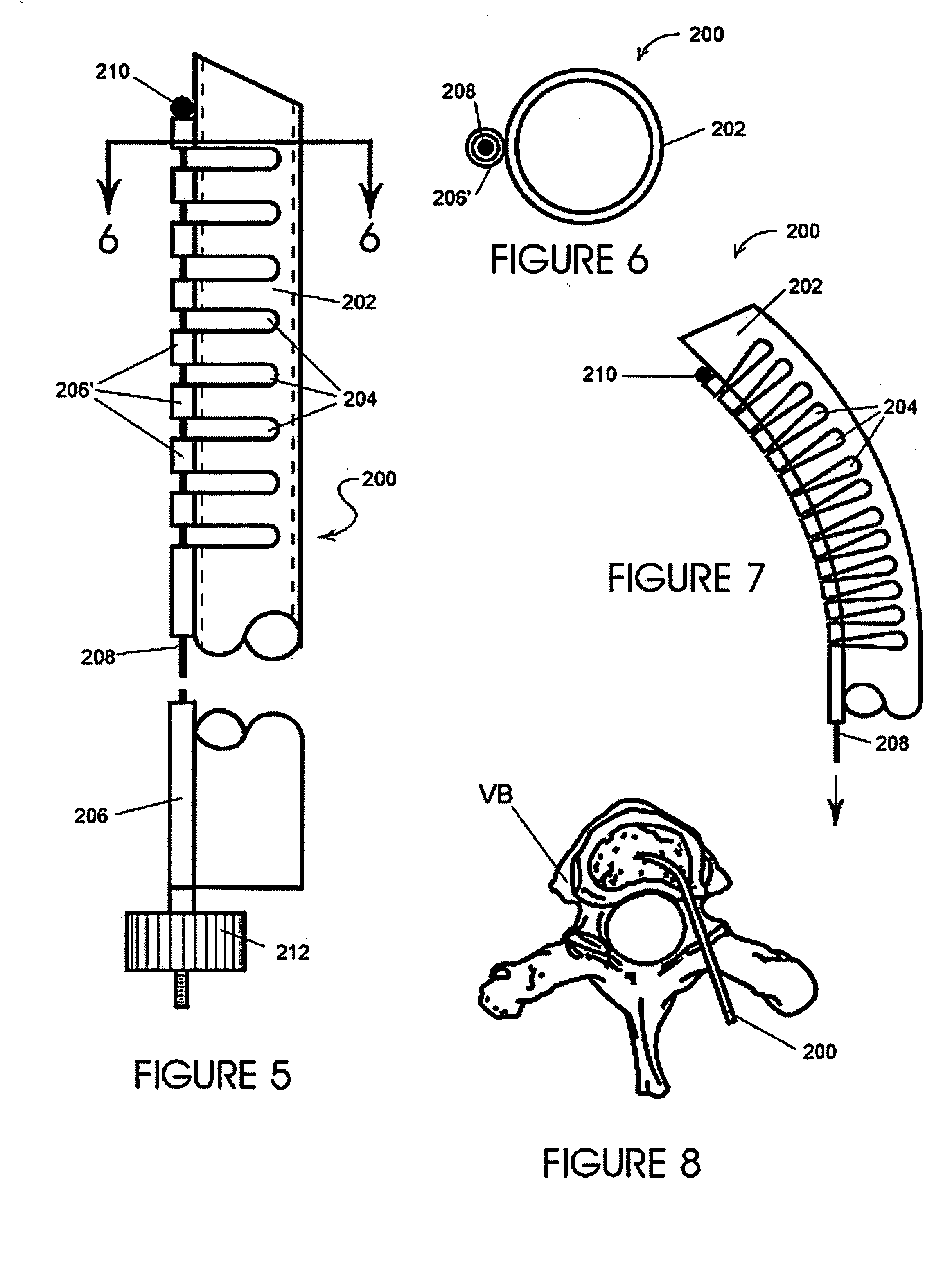

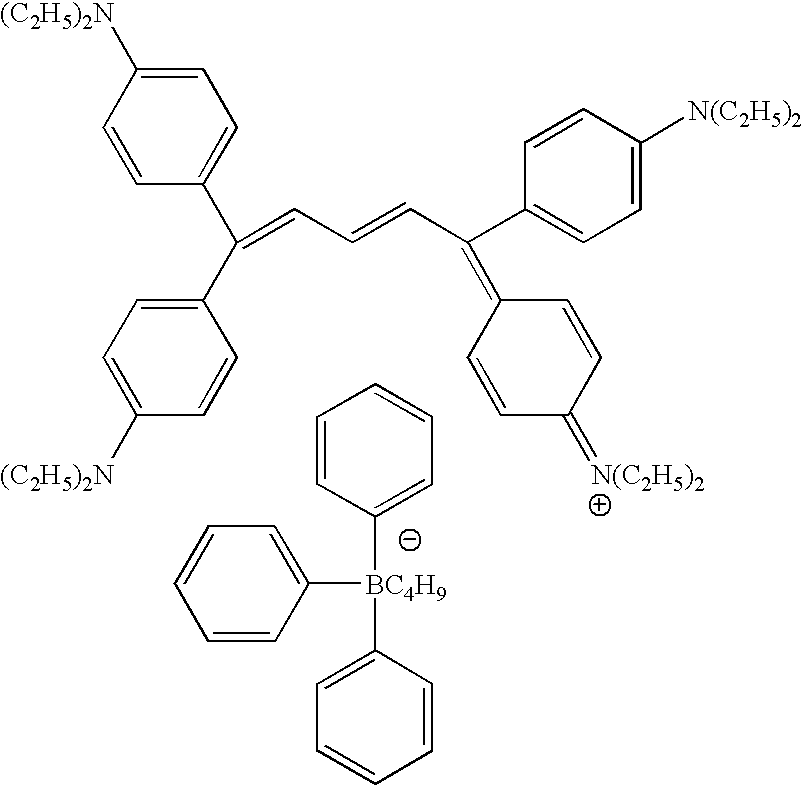

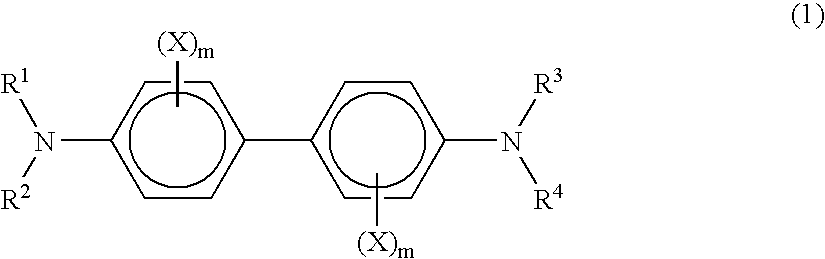

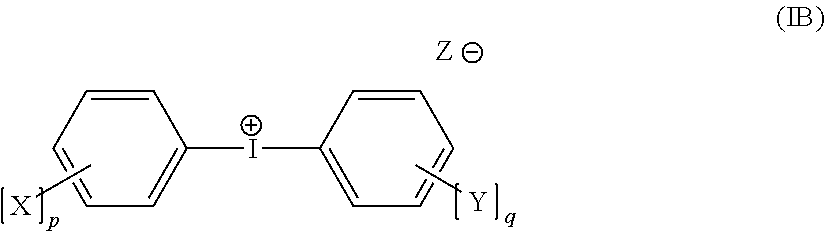

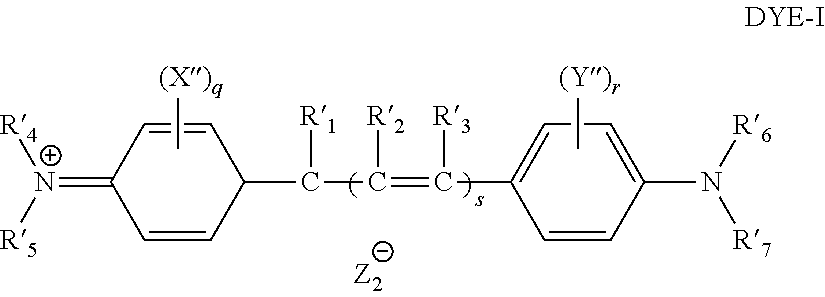

Radiation-sensitive compositions and imageable materials

InactiveUS7153632B1Maintaining photo speedMaintaining visible print outPhotosensitive materialsRadiation applicationsPolymer sciencePolymer

A radiation-sensitive composition includes a radically polymerizable component that comprises carboxy groups, an initiator composition to generate radicals, and a polymeric binder comprising poly(alkylene oxide) segments and optionally pendant cyano groups. This composition can be used to prepare imageable elements such as negative-working, on-press developable printing plate precursors.

Owner:EASTMAN KODAK CO

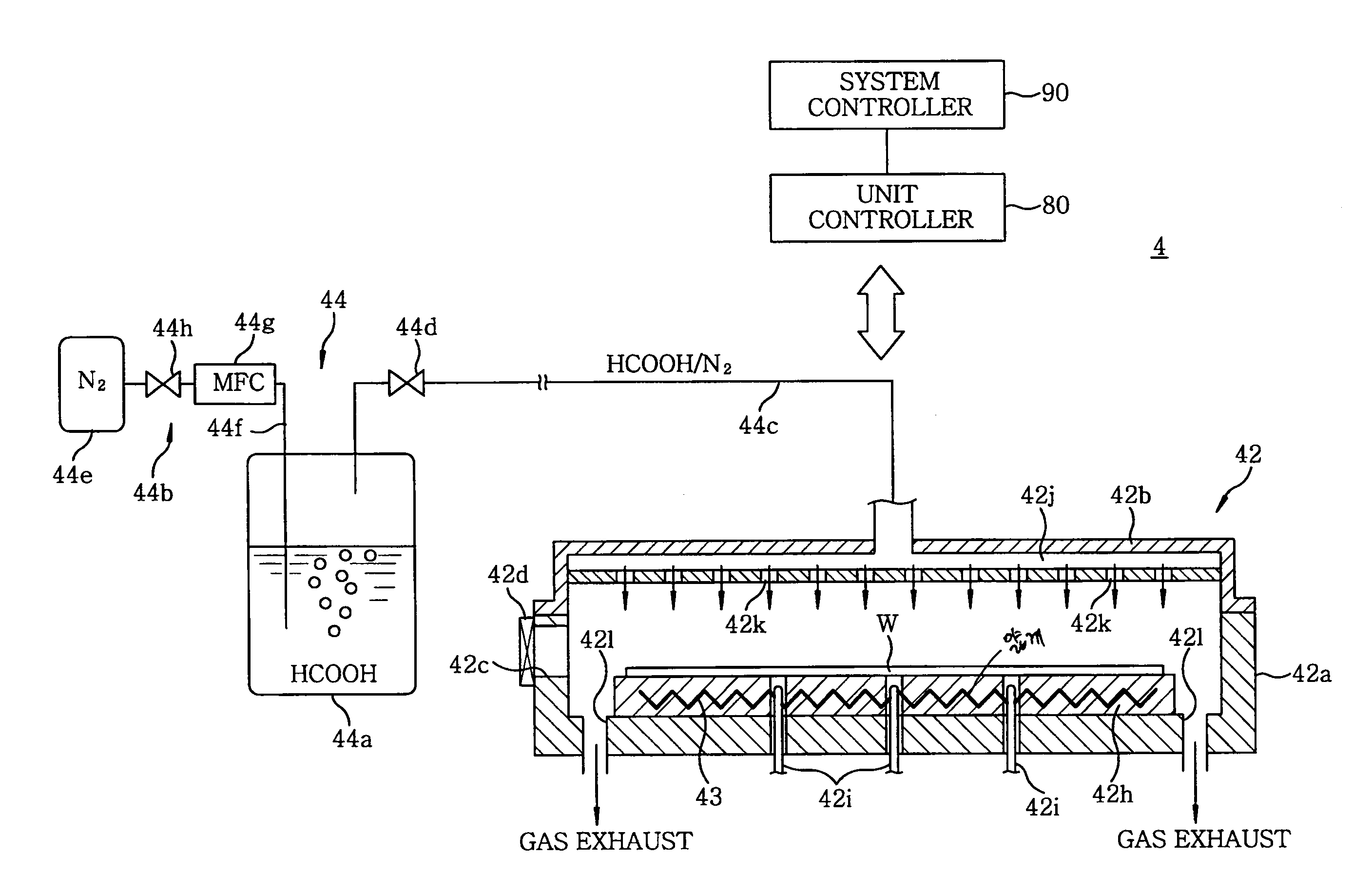

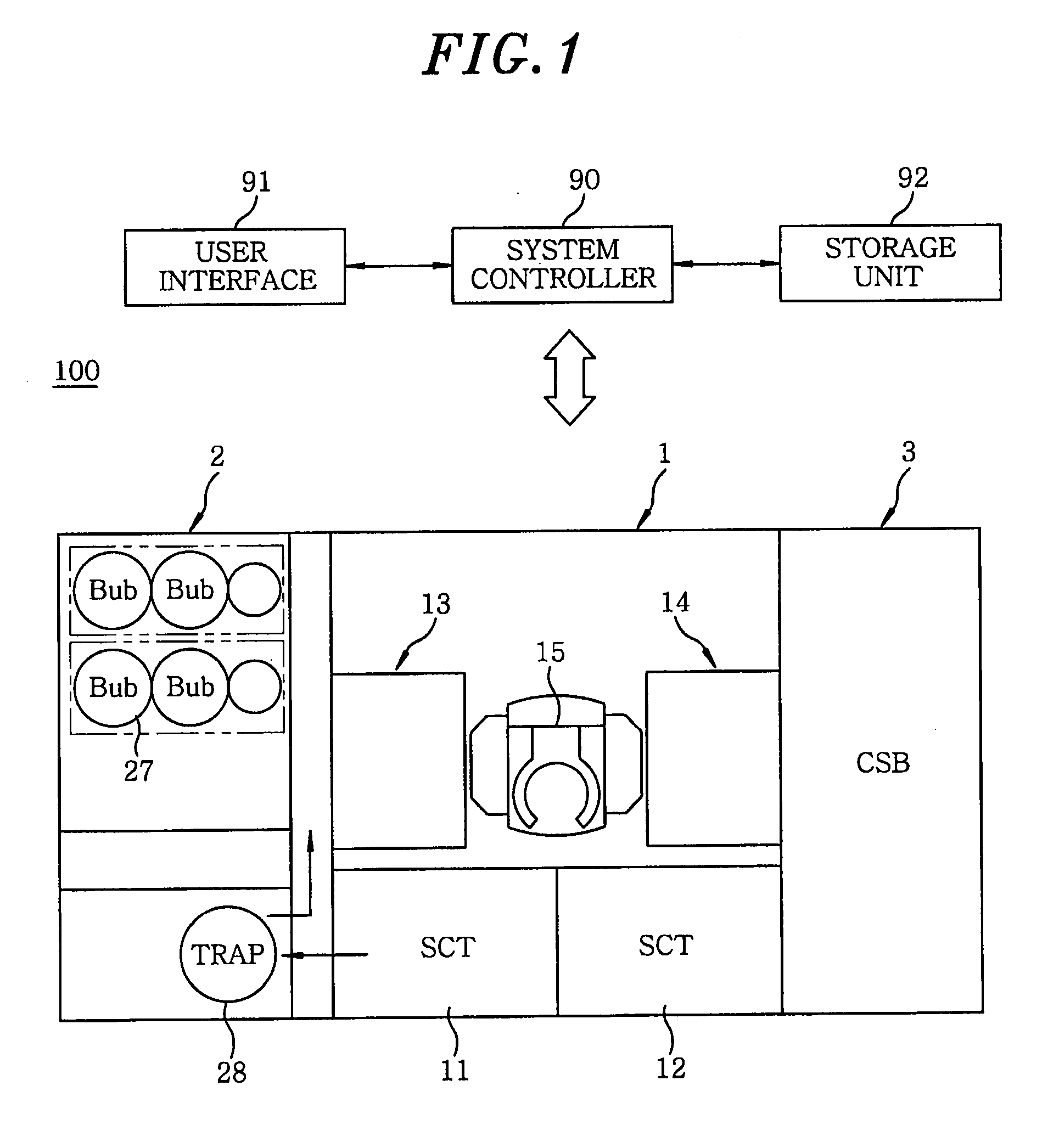

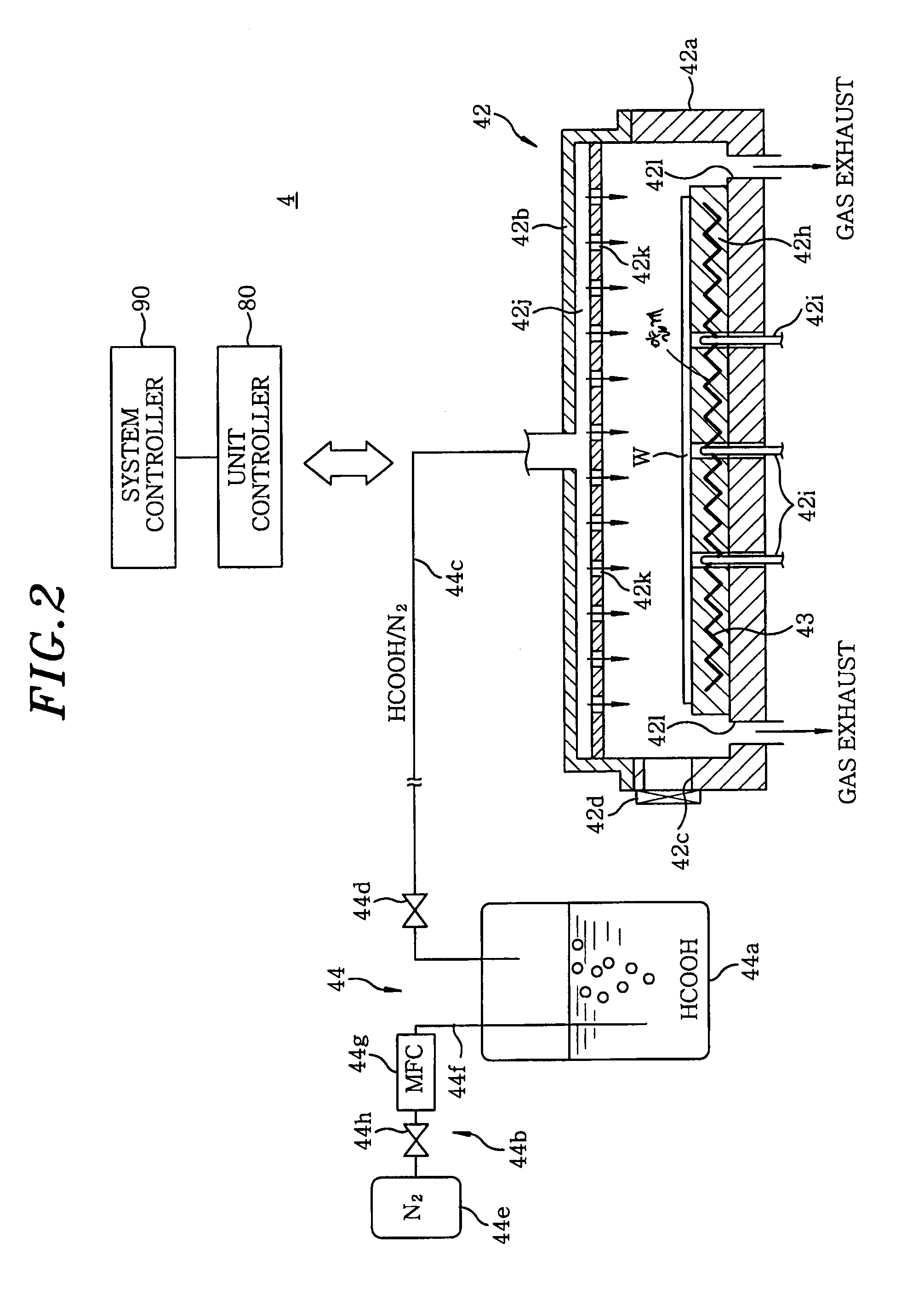

Heat treatment method, heat treatment apparatus and substrate processing apparatus

InactiveUS20090163038A1Improve reducibilityEfficient removalSemiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingEngineeringHeat treated

Disclosed is a heat treatment unit 4 serving as a heat treatment apparatus, which includes a chamber 42 for containing a wafer W on which a low dielectric constant interlayer insulating film is formed, a formic acid supply device 44 for supplying gaseous formic acid into the chamber 42, and a heater 43 for heating the wafer W in the chamber 42 which is supplied with formic acid by the formic acid supply device 44.

Owner:TOKYO ELECTRON LTD

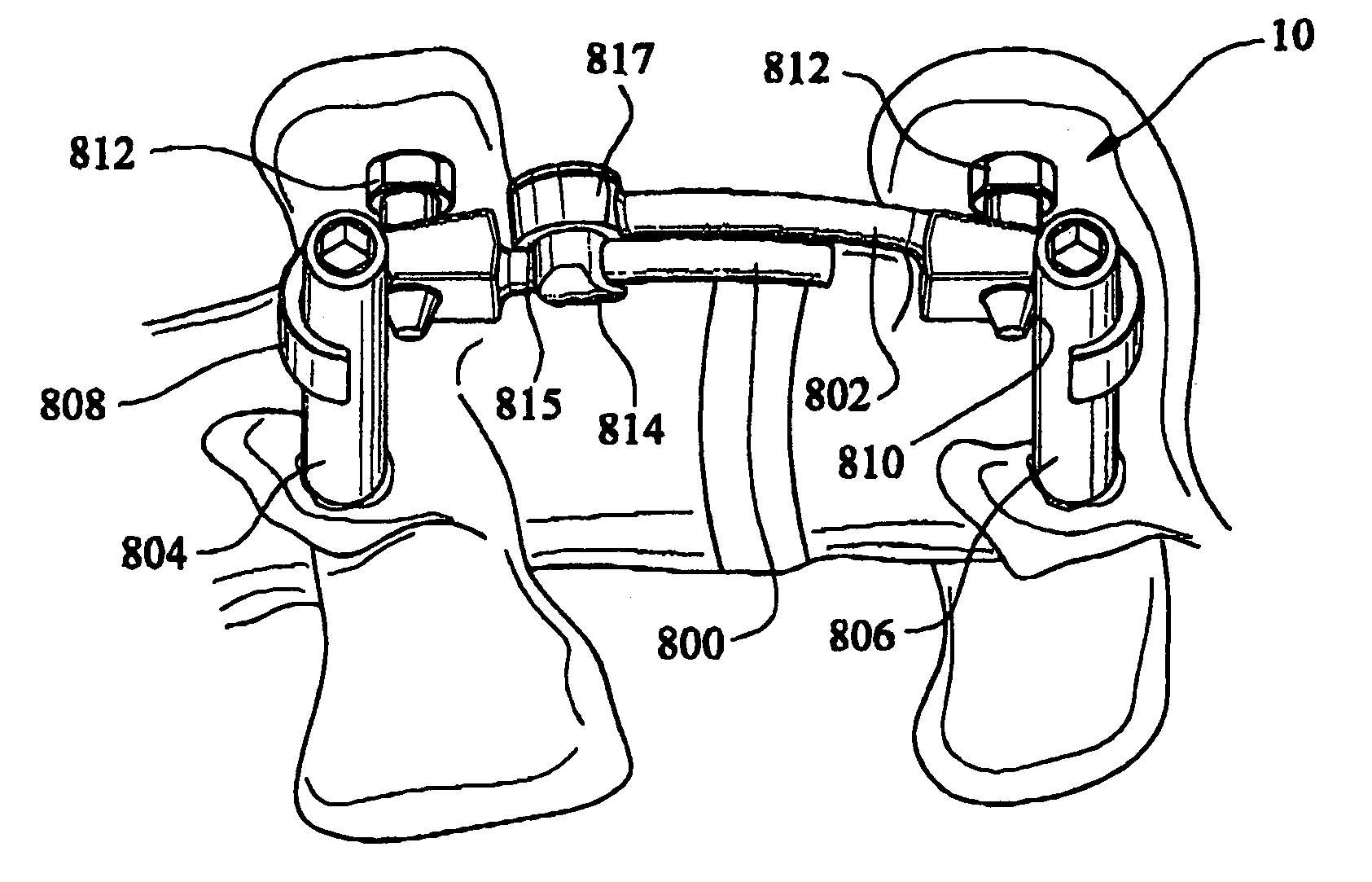

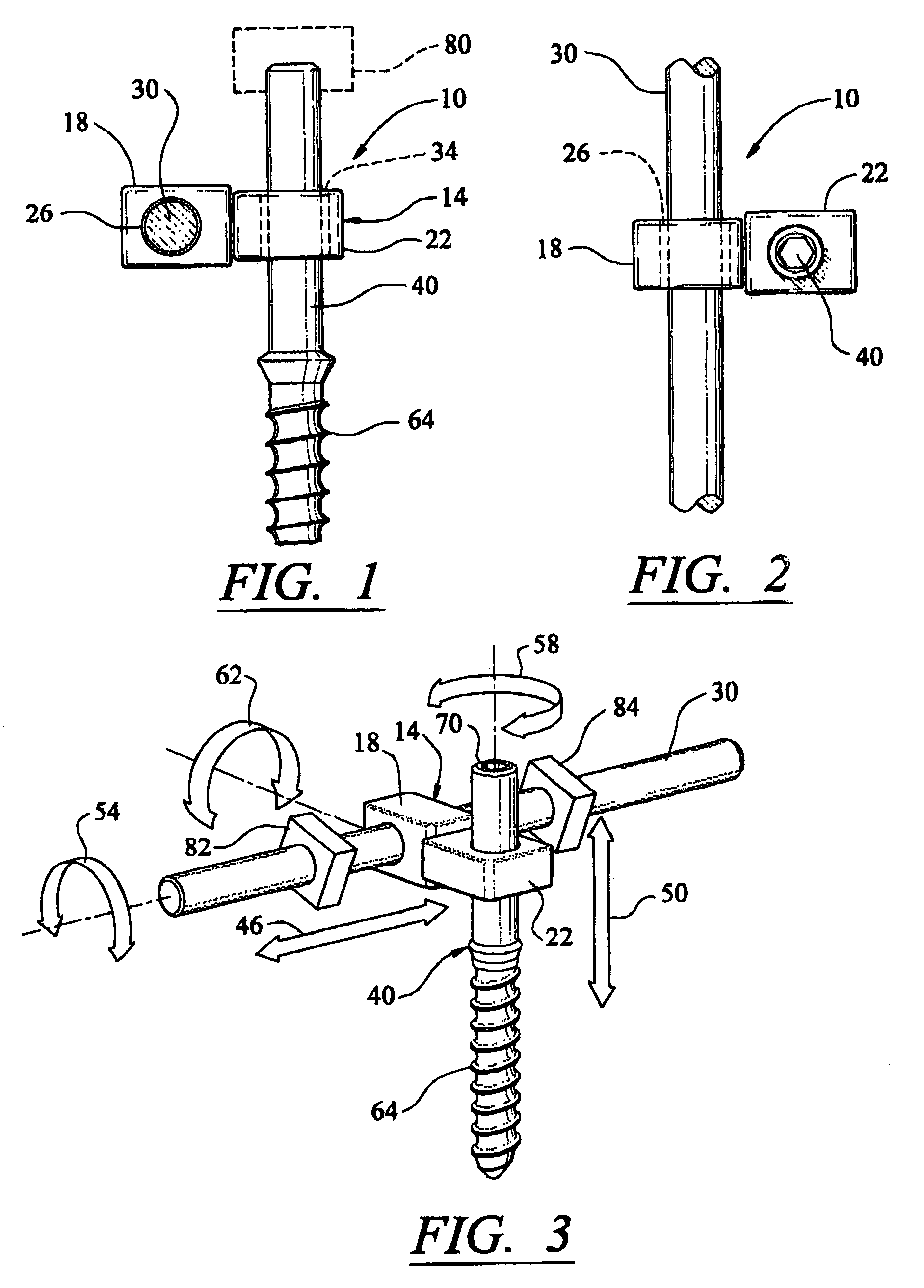

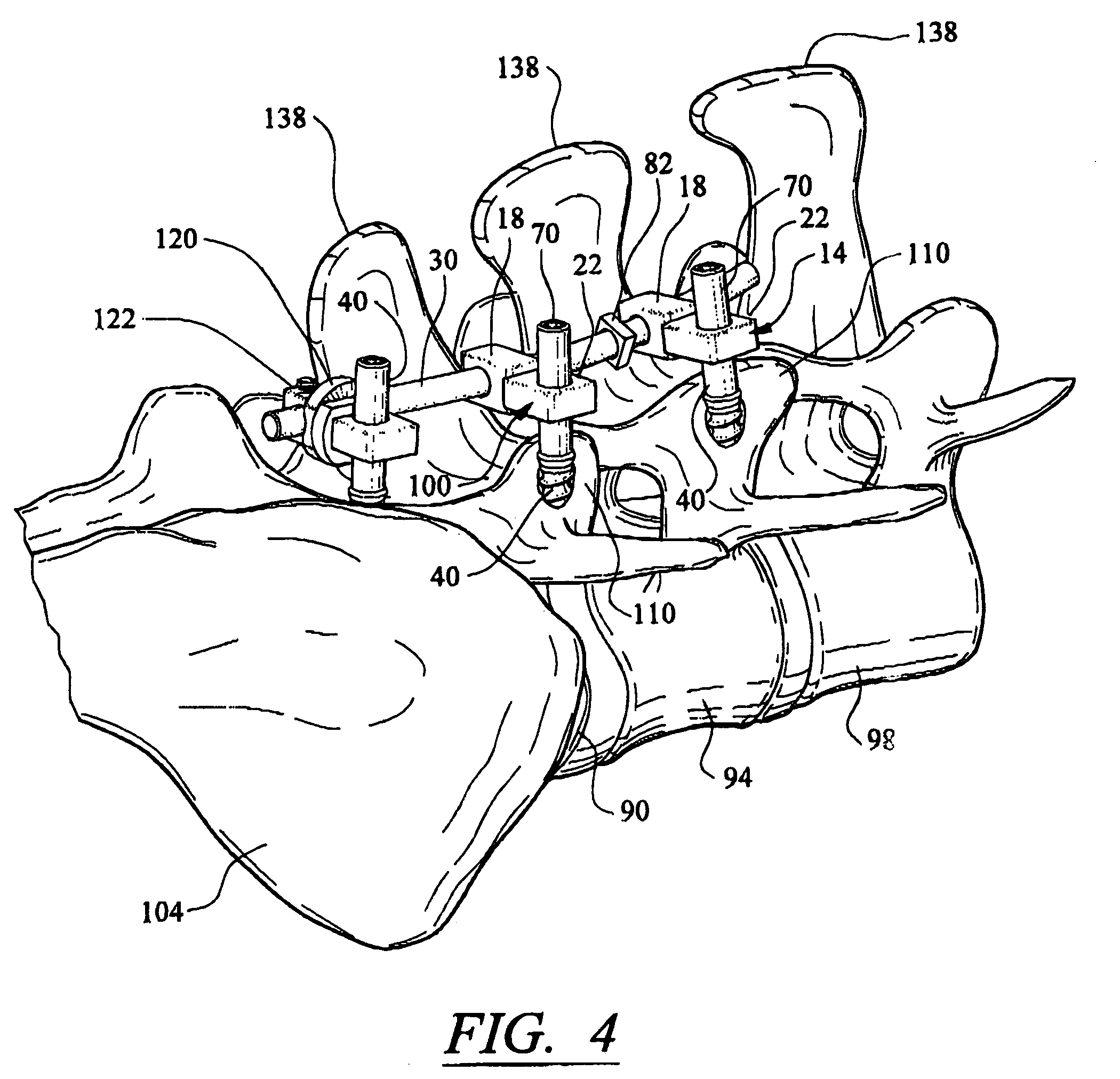

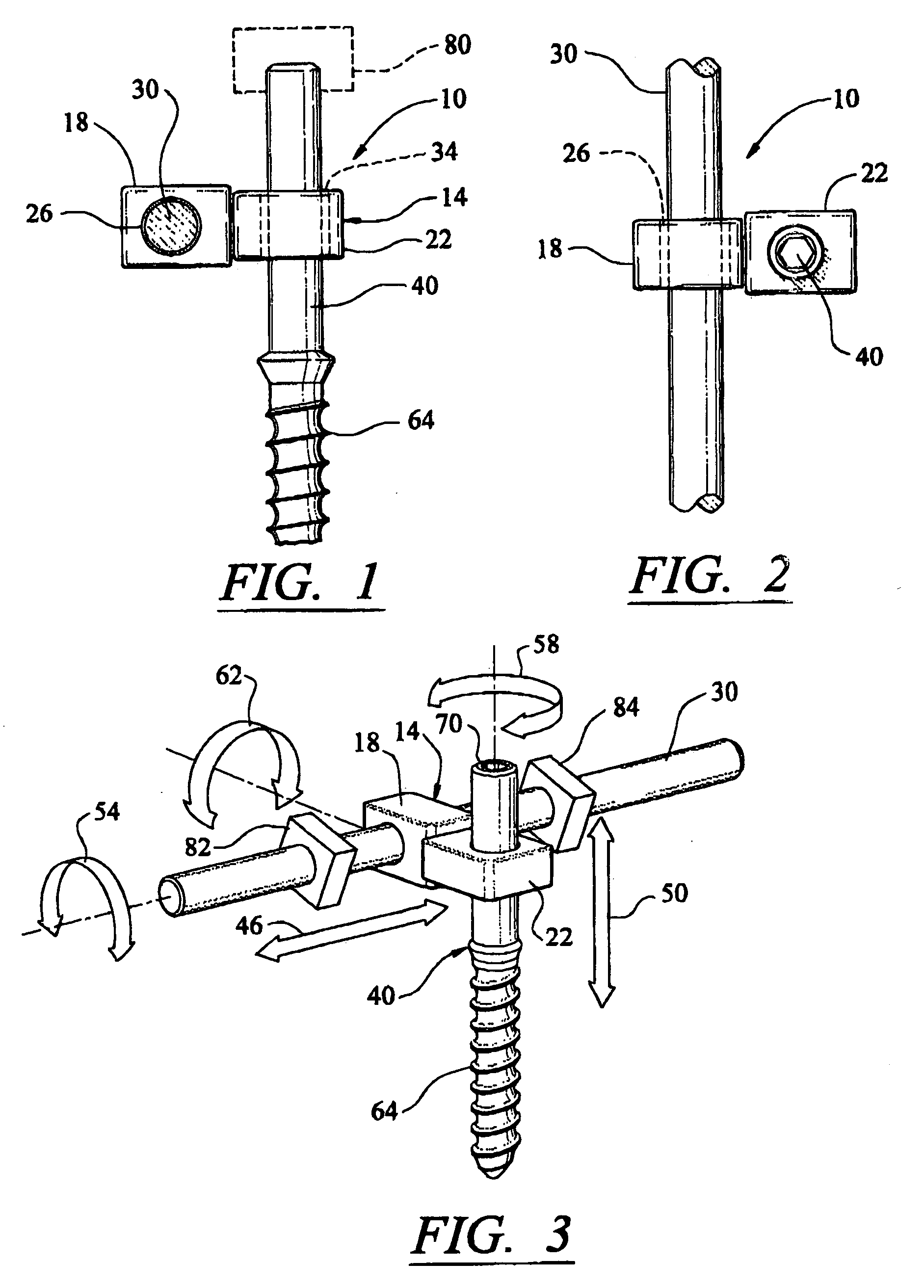

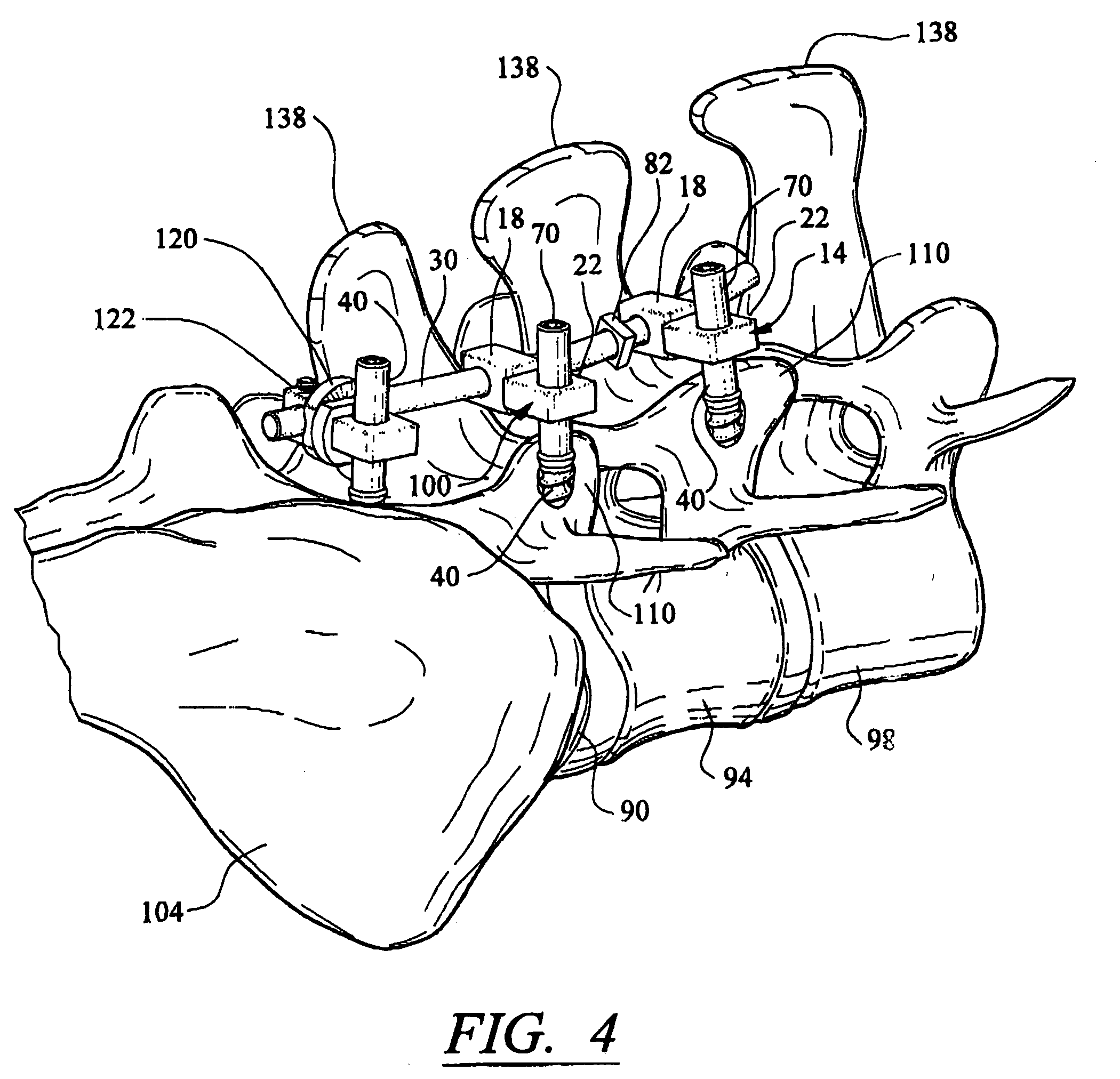

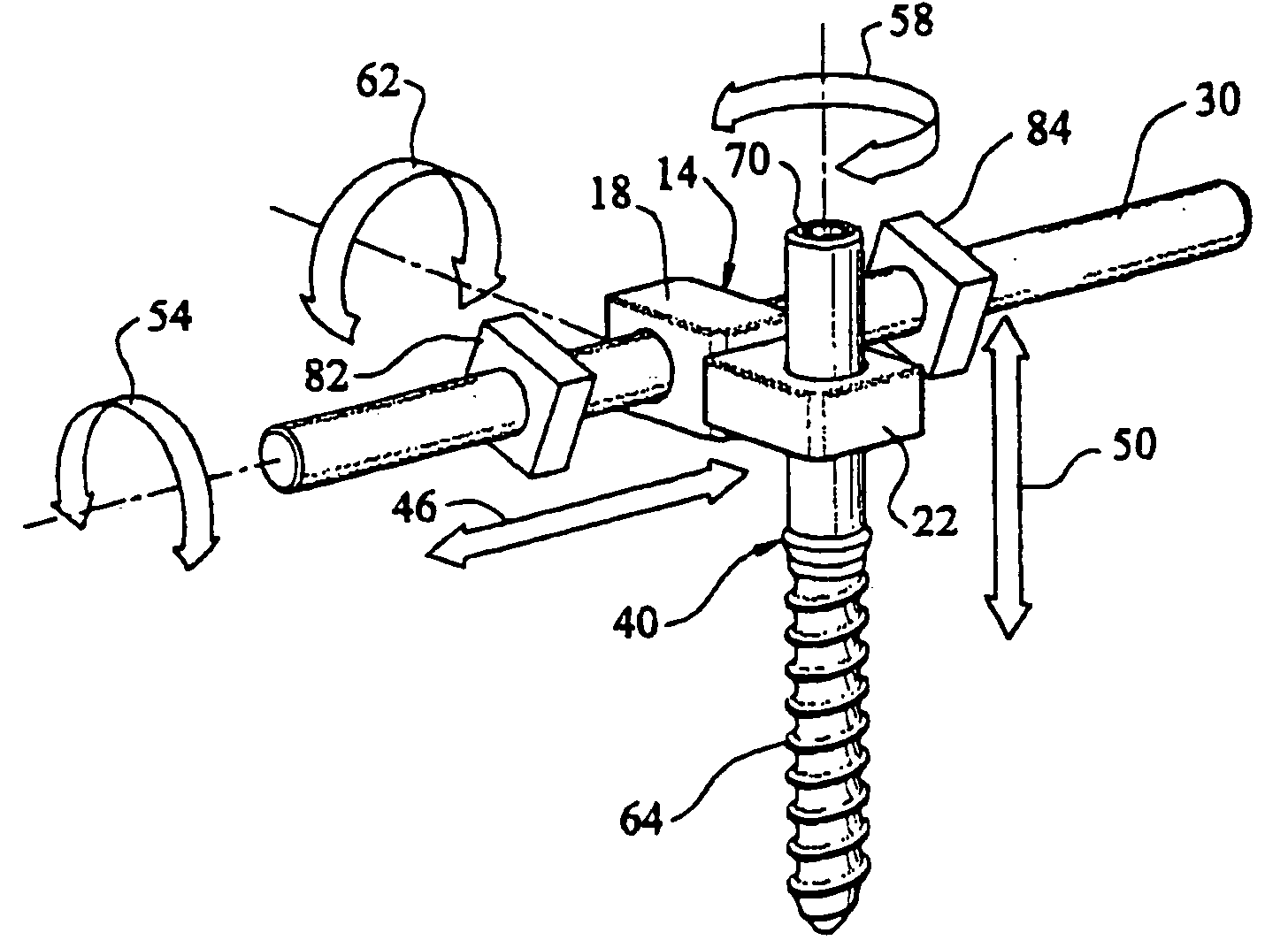

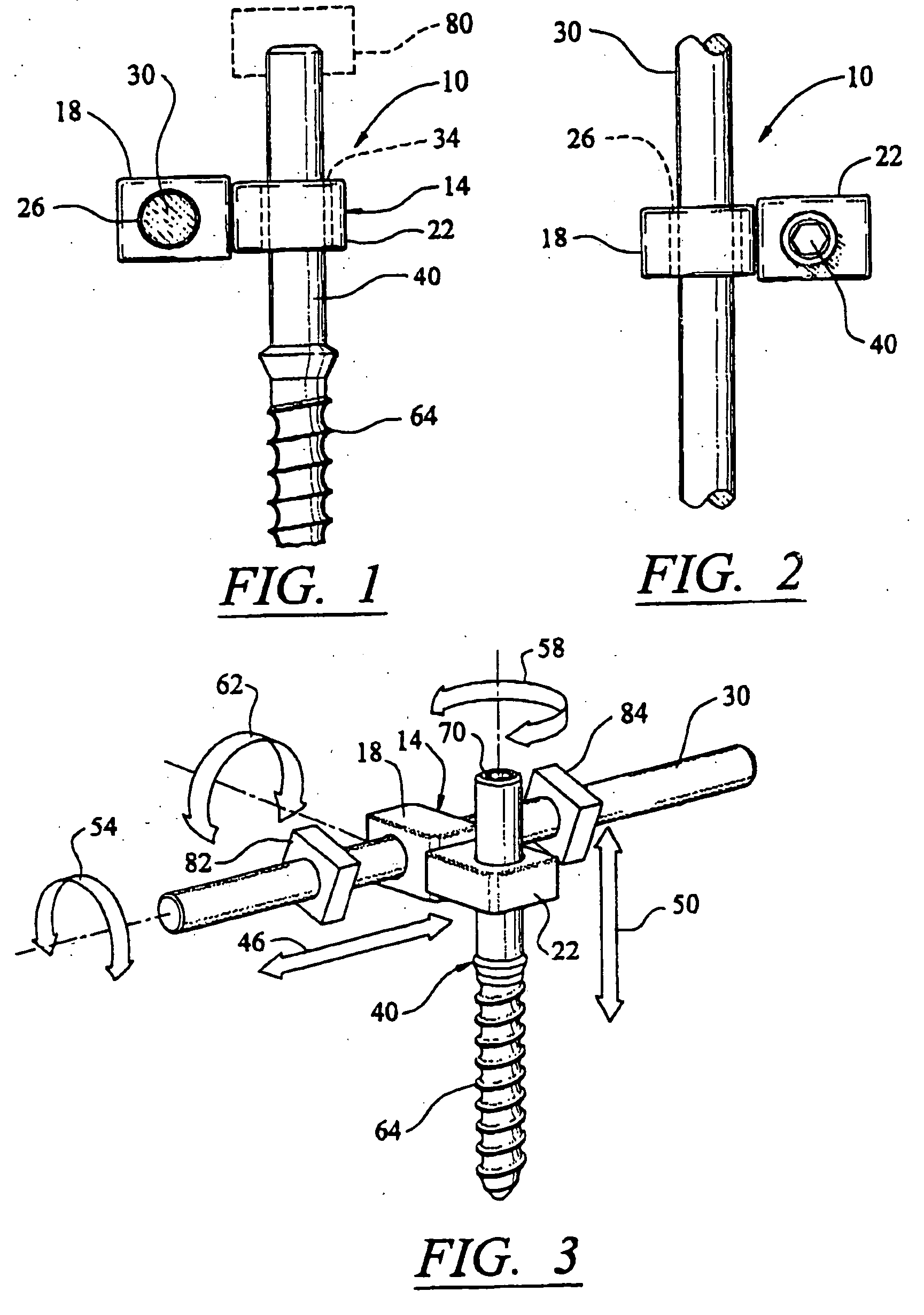

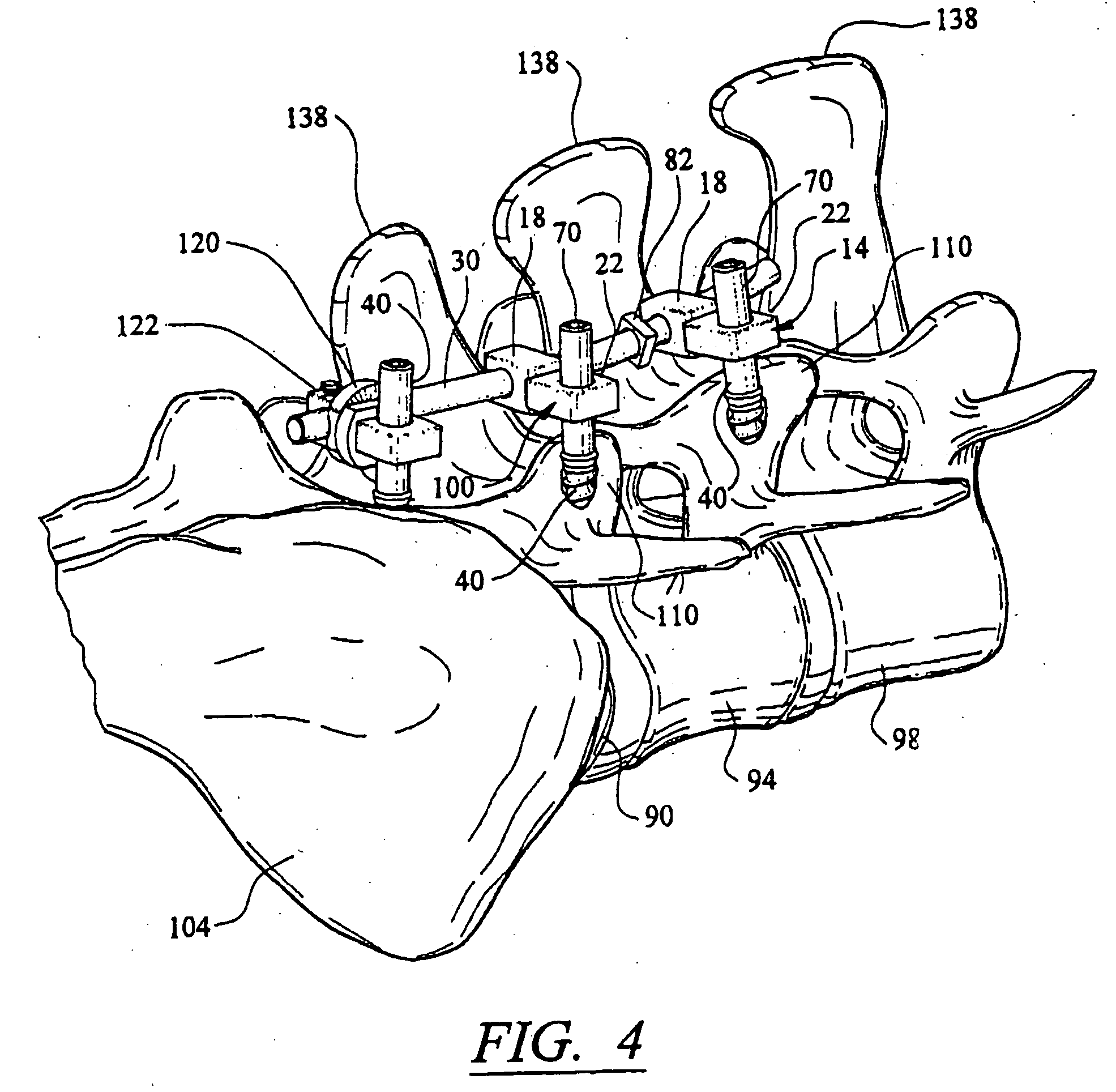

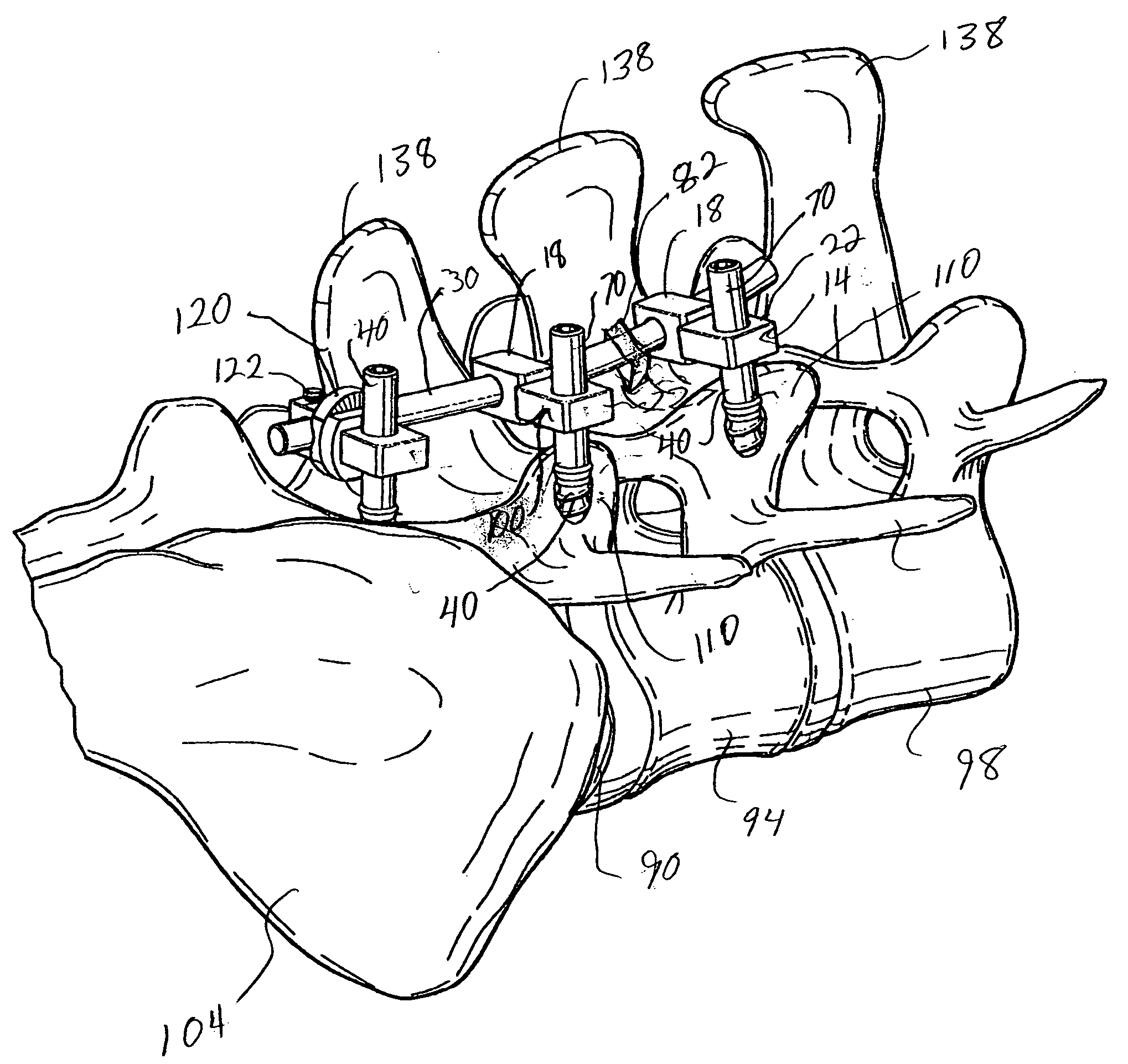

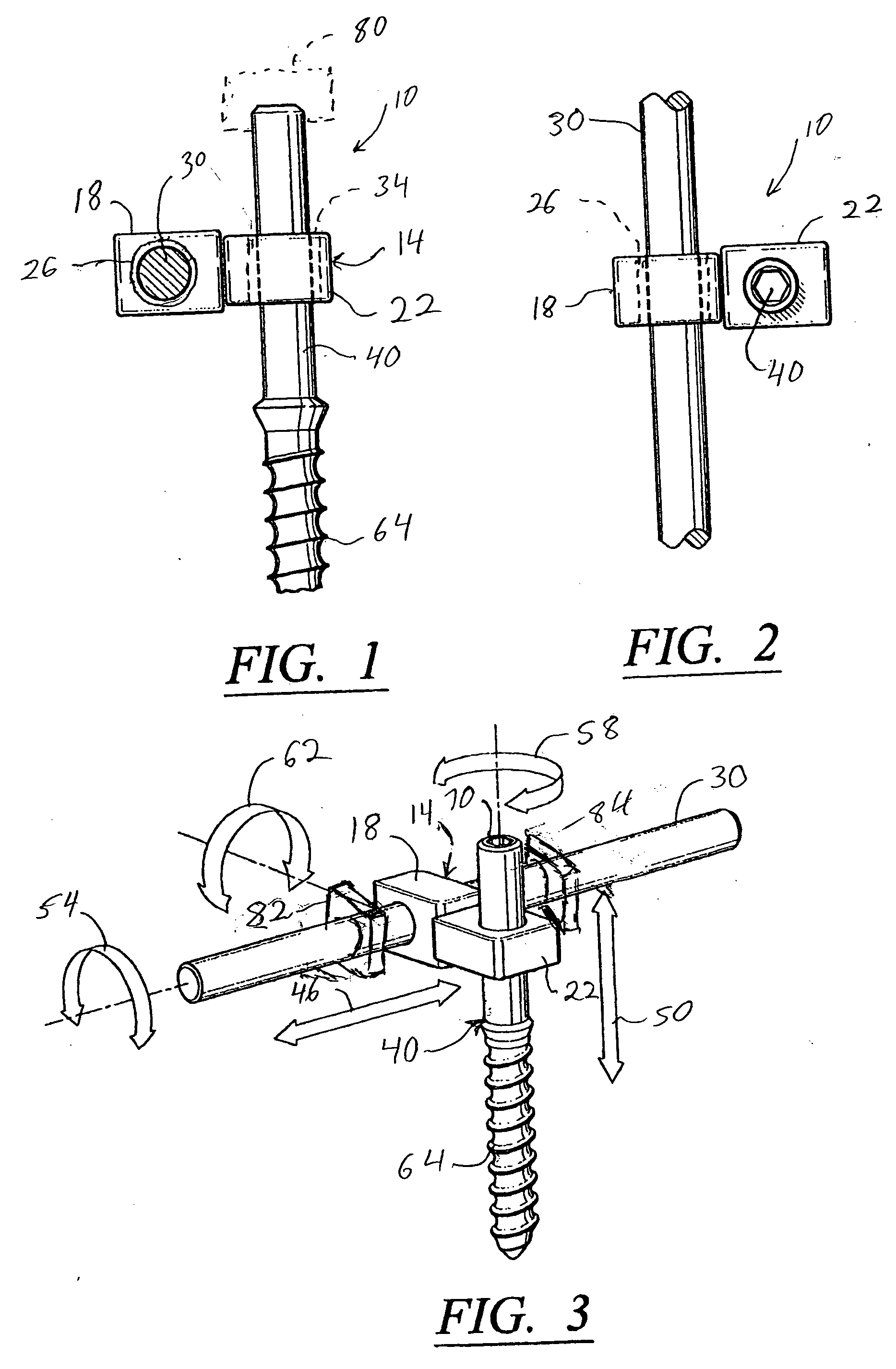

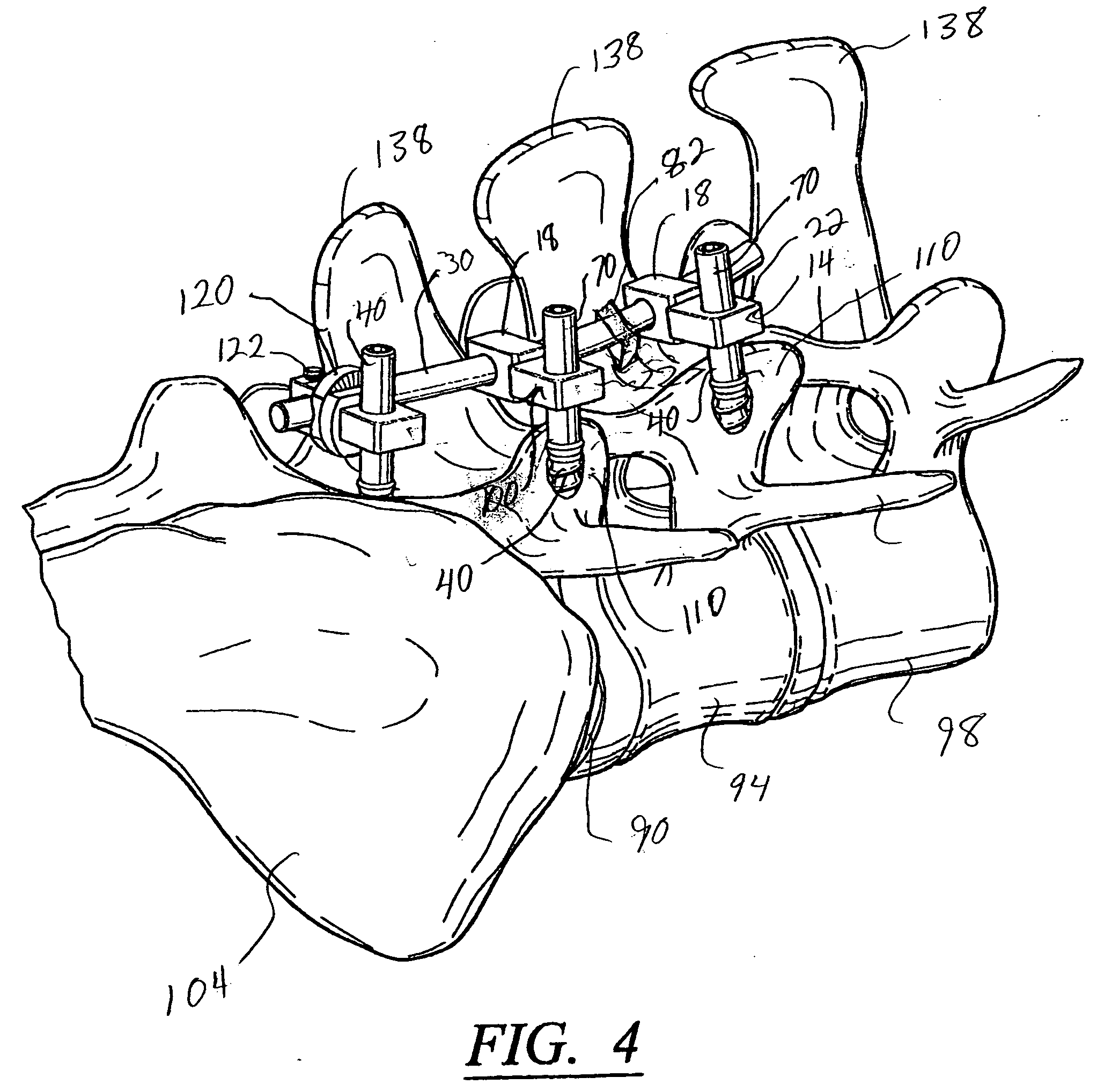

Artificial facet joint and method

InactiveUS7083622B2Limit movement of jointReduce coatingInternal osteosythesisJoint implantsEngineeringSacroiliac joint

An artificial facet joint includes a spinal implant rod and a connector. The connector includes a screw and a rod connecting member having structure for engagement of the rod. The rod connecting member is pivotally engaged to the screw. The rod may also be held slideably within the connector enabling the rod to be moved relative to the connector.

Owner:SIMONSON PETER M

Artificial facet joint and method

InactiveUS20050101956A1Limit movement of jointReduced friction coatingInternal osteosythesisJoint implantsSacroiliac jointSpinal implant

An artificial facet joint includes a spinal implant rod and a connector. The connector includes a screw and a rod connecting member having structure for engagement of the rod. The rod connecting member is pivotally engaged to the screw. The rod may also be held slideably within the connector enabling the rod to be moved relative to the connector.

Owner:SIMONSON PETER M

Artificial facet joint and method

InactiveUS20050101954A1Limit movement of jointReduced friction coatingInternal osteosythesisJoint implantsEngineeringSacroiliac joint

An artificial facet joint includes a spinal implant rod and a connector. The connector includes a screw and a rod connecting member having structure for engagement of the rod. The rod connecting member is pivotally engaged to the screw.

Owner:SIMONSON PETER M

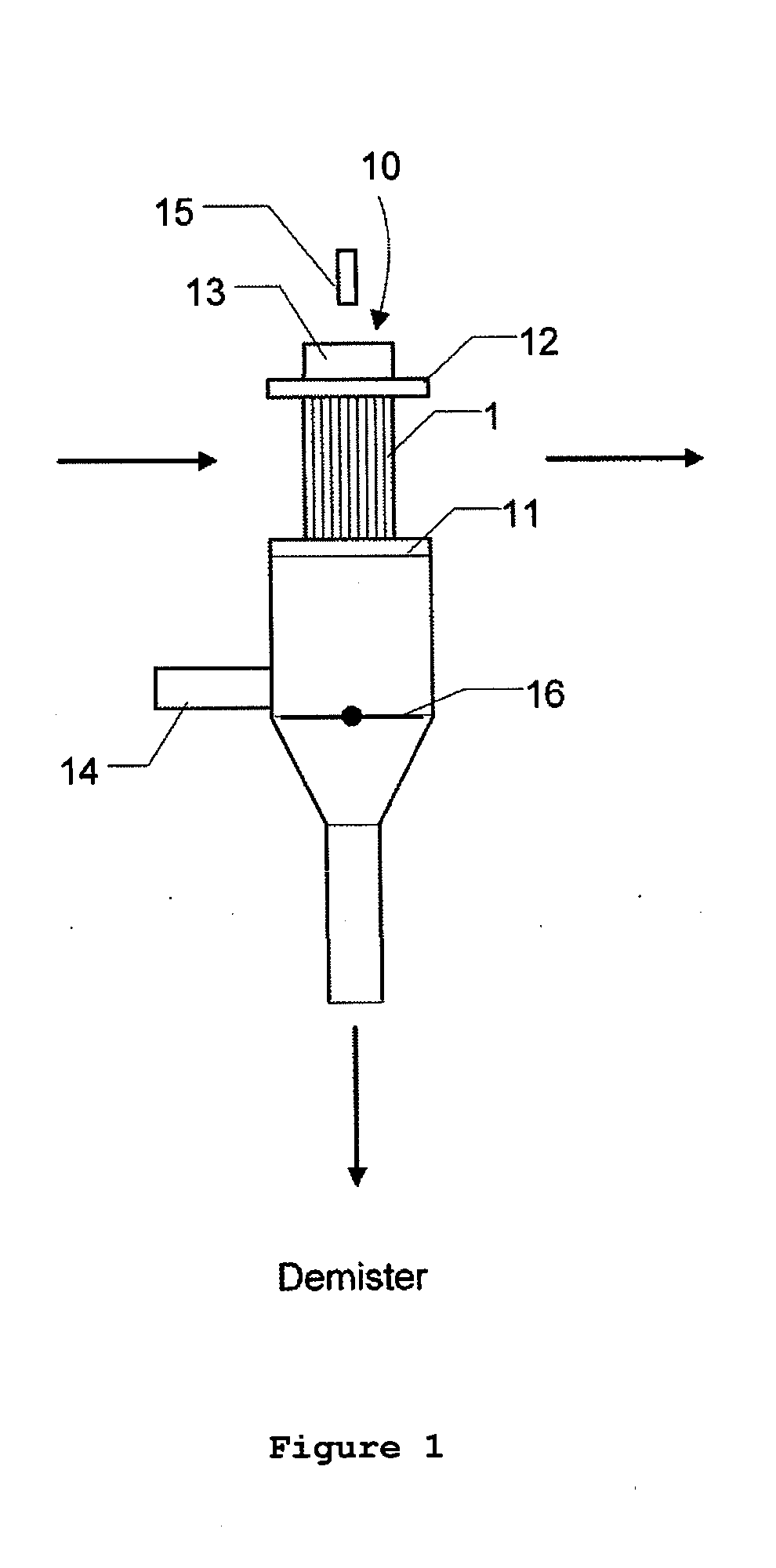

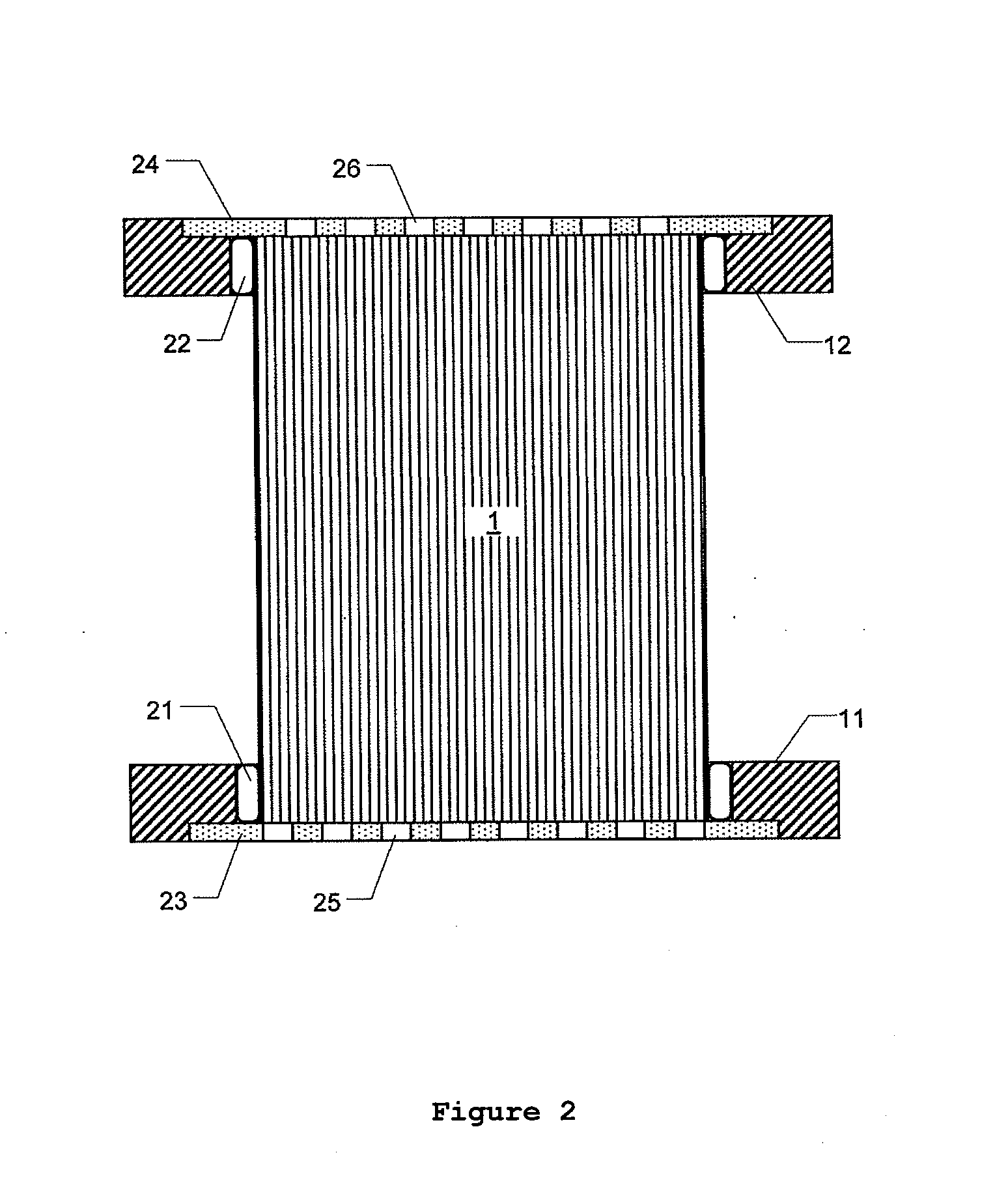

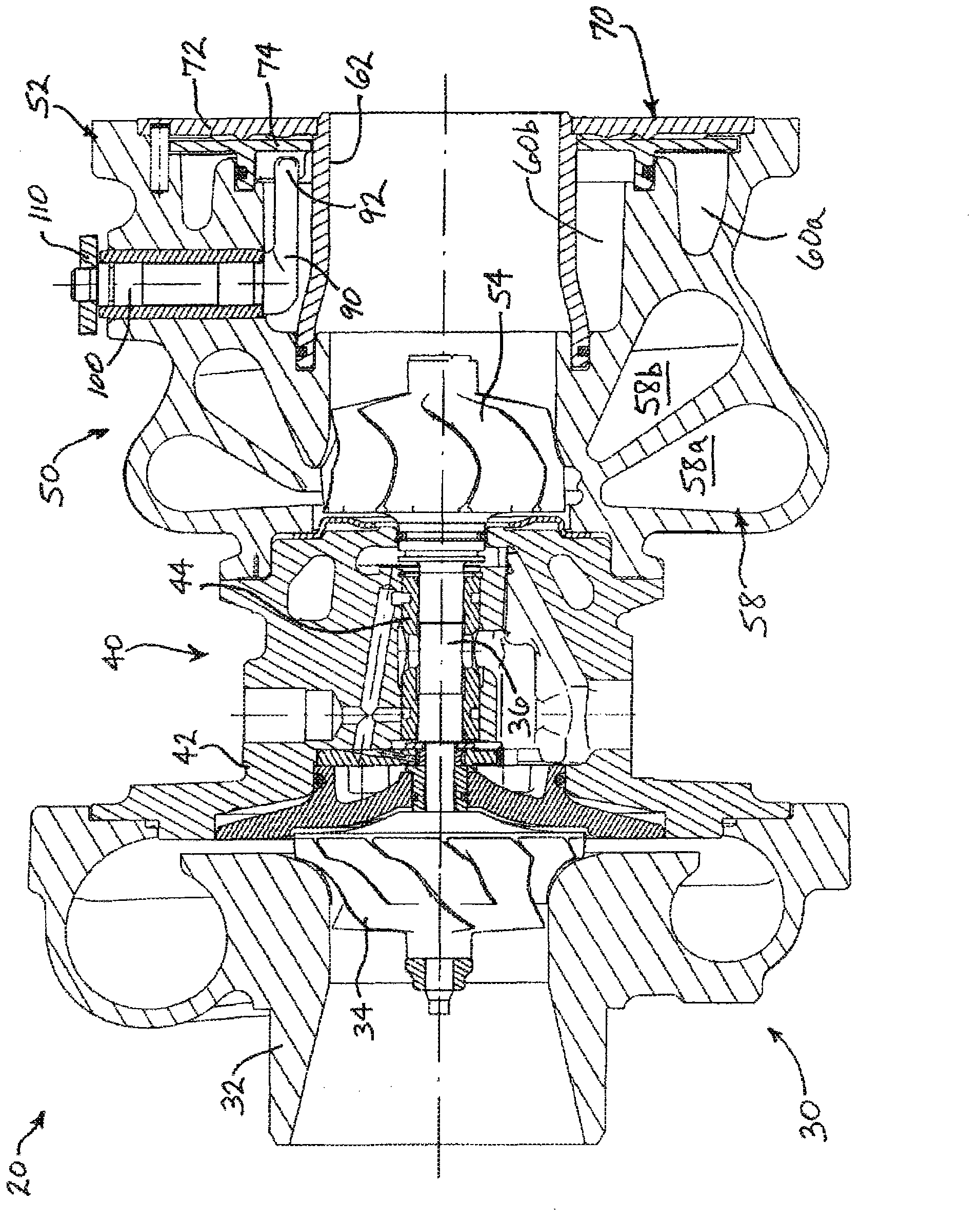

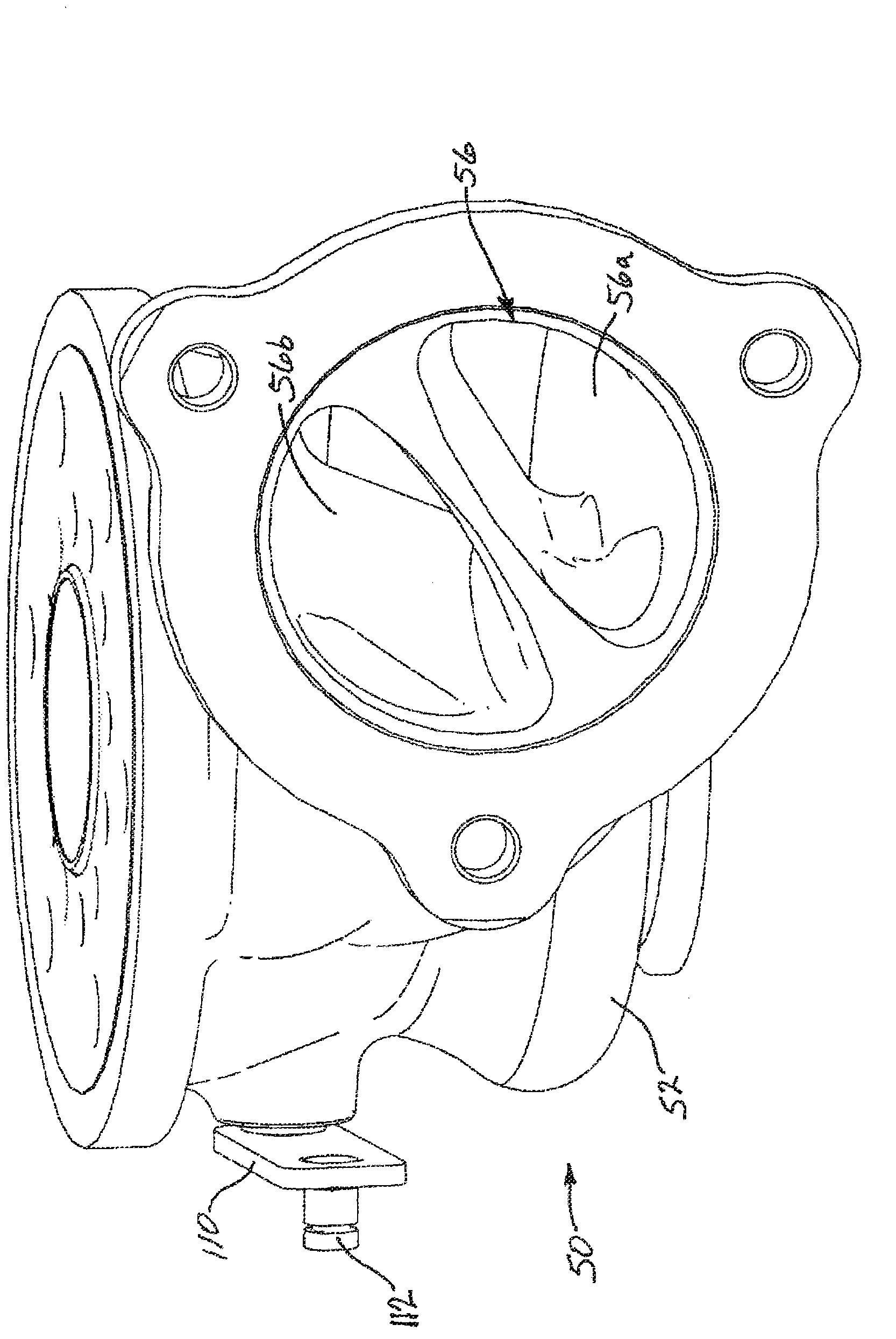

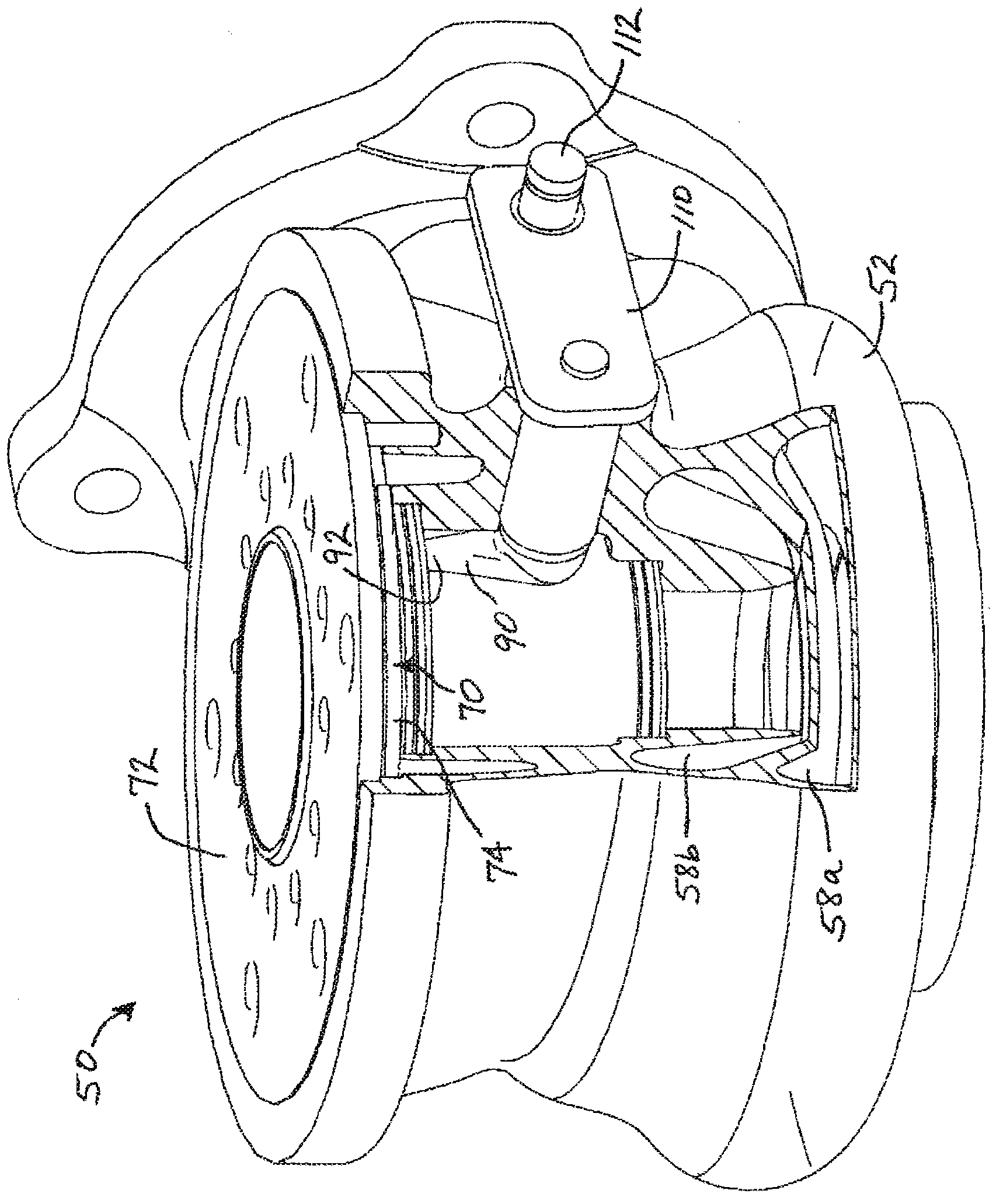

Clamping fixture for coating stents, system using the fixture, and method of using the fixture

InactiveUS20050166841A1Reduce distanceIncrease the cross-sectional areaStentsLiquid surface applicatorsInsertion stentEngineering

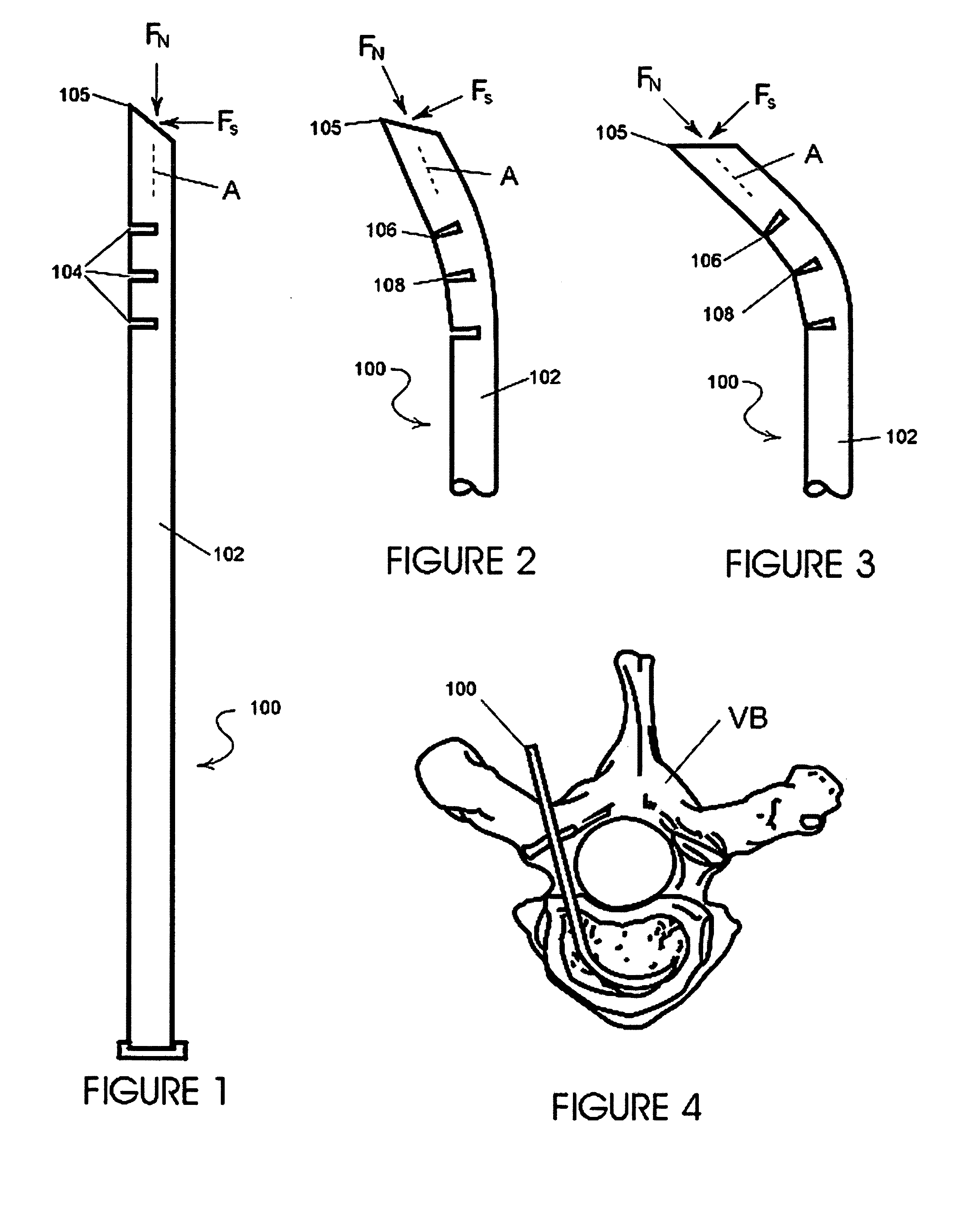

A device is provided for holding an appliance from an interior that may include a center support shaft, two arbors arranged on the center support shaft in a spaced apart position, a plurality of springs coupled to the two arbors, and an actuator coupled to the center support shaft and adapted to decrease the distance between the two arbors. The device may be adapted to support a hollow cylindrical object from an inside of the hollow cylindrical object. The hollow cylindrical object may include a stent. When the actuator is actuated, the plurality of springs may be compressed and each spring may buckle in at least one buckle region. Actuating the actuator may cause the plurality of springs to expand and to clamp a stent. Deactuating the actuator may cause the plurality of springs to retract and to release a stent. A system for coating a medical appliance is provided. A method for coating a medical appliance is provided.

Owner:BOSTON SCI SCIMED INC

Orthopedic surgery access devices

InactiveUS7959634B2Easy accessLow bending stiffnessCannulasOsteosynthesis devicesCancellous boneBending stiffness

The present invention provides instrumentation that facilitates access to both sides of the vertebral body from a single access point. More particularly, the present invention provides bendable access devices that can be steered so as to traverse the vertebral body from the point of entry into the vertebral body, through the cancellous bone within the vertebral body, and to the contralateral side of the vertebral body. This steerability is provided by forming the access device with a series of slots, grooves, or notches in the side of the access device near the distal end of the access device, which slots, grooves, or notches reduce the bending stiffness of the access device. As a result, the distal end of the access device bends as it is being advanced into the vertebral body.

Owner:GLOBUS MEDICAL INC

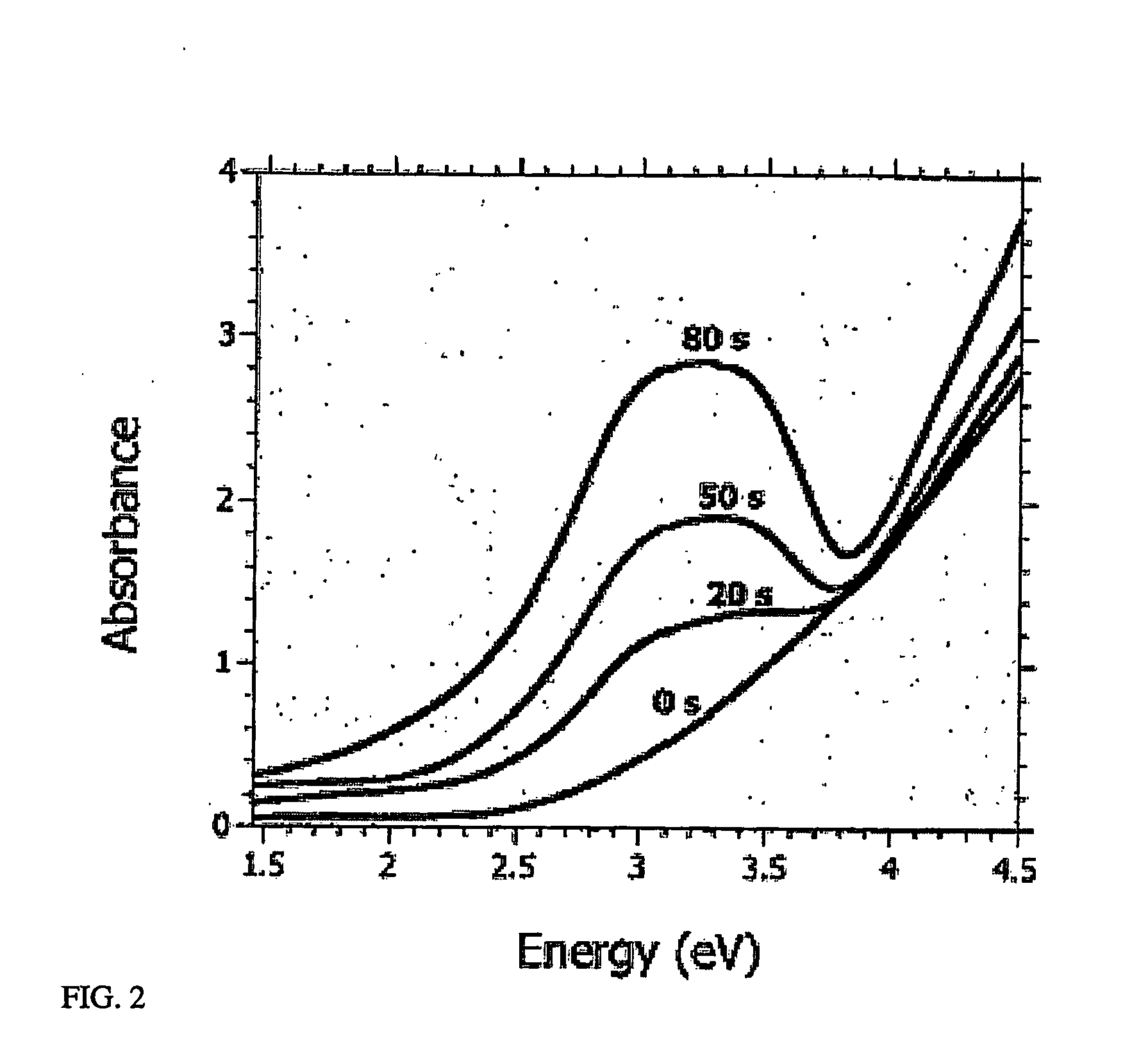

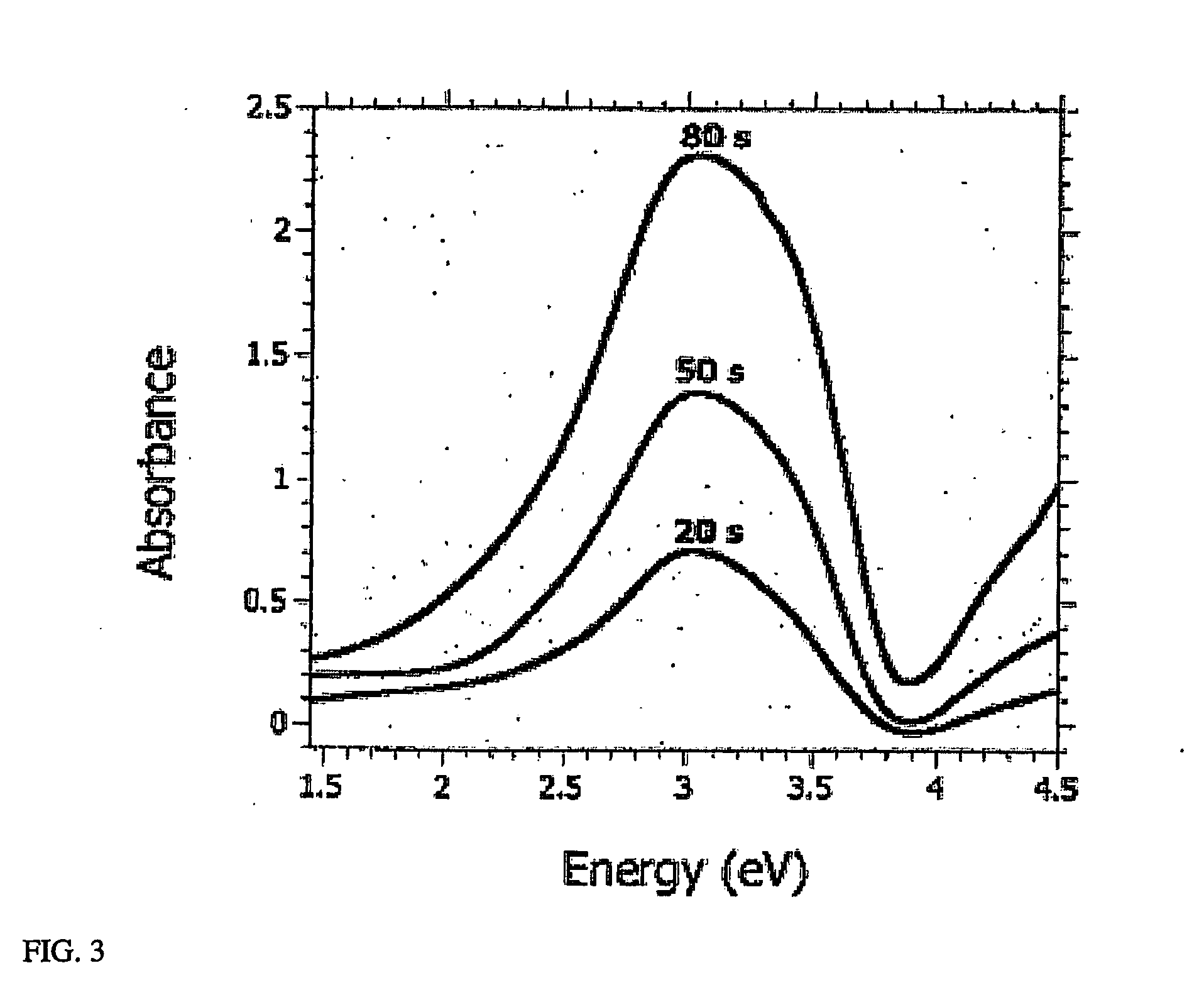

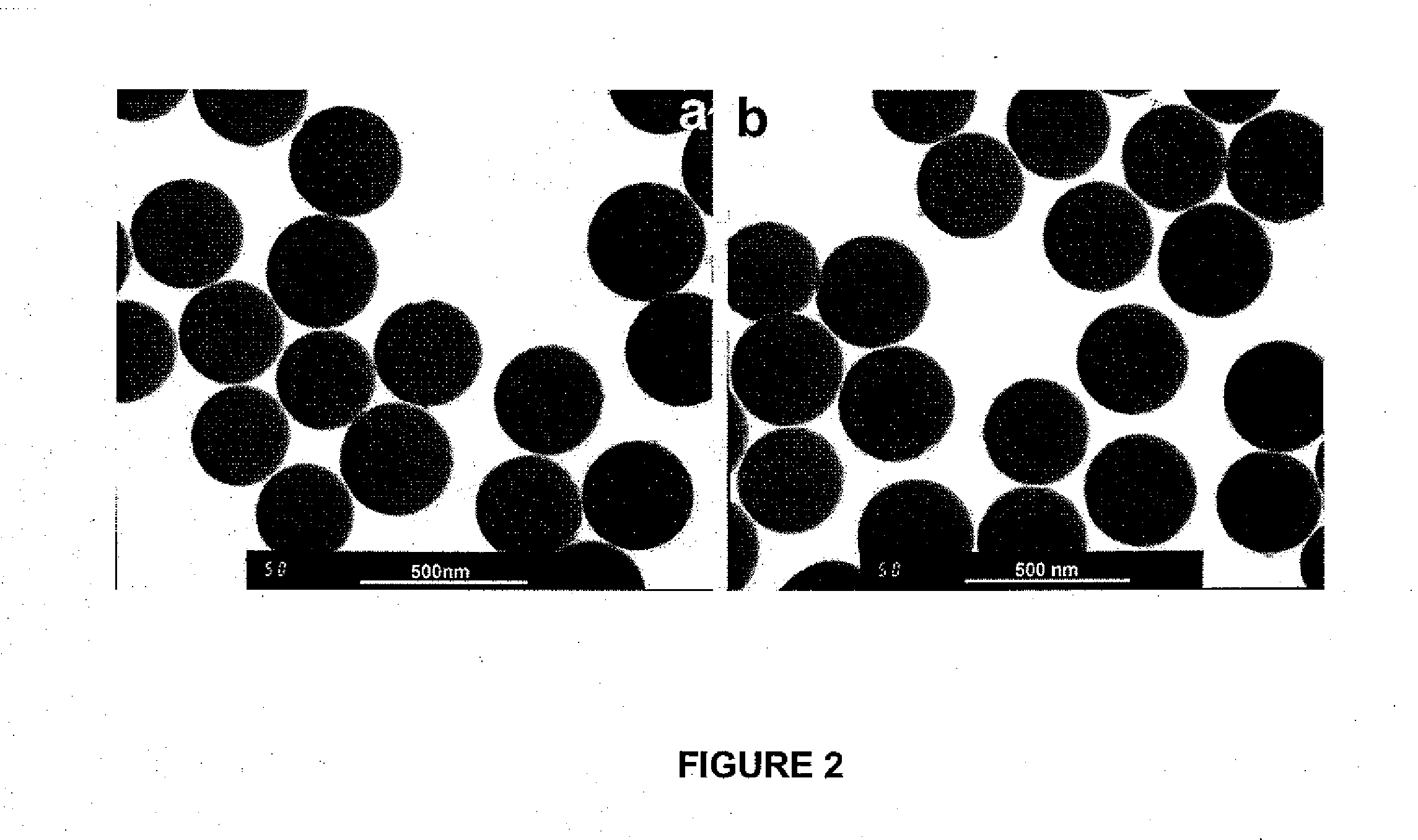

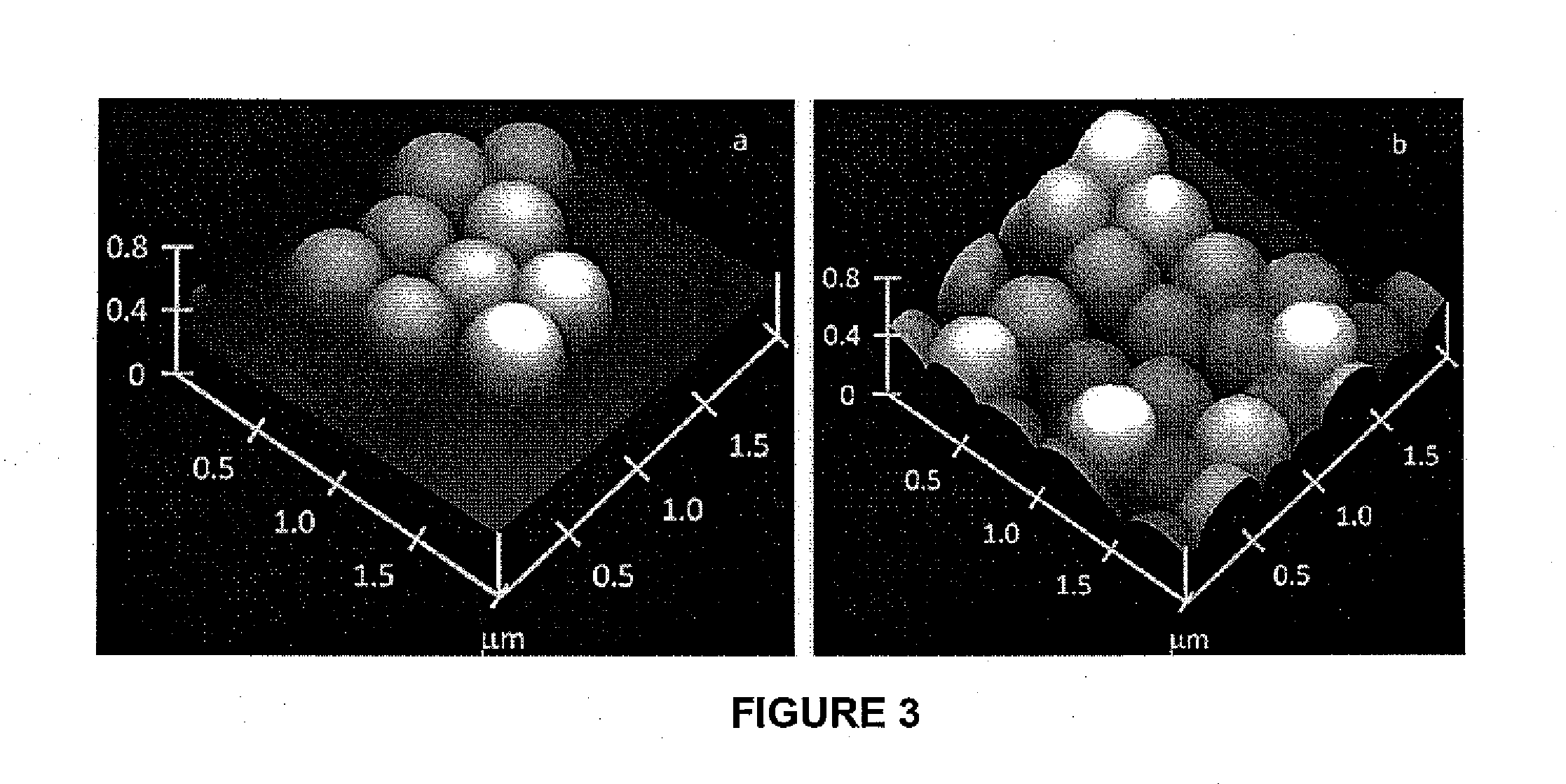

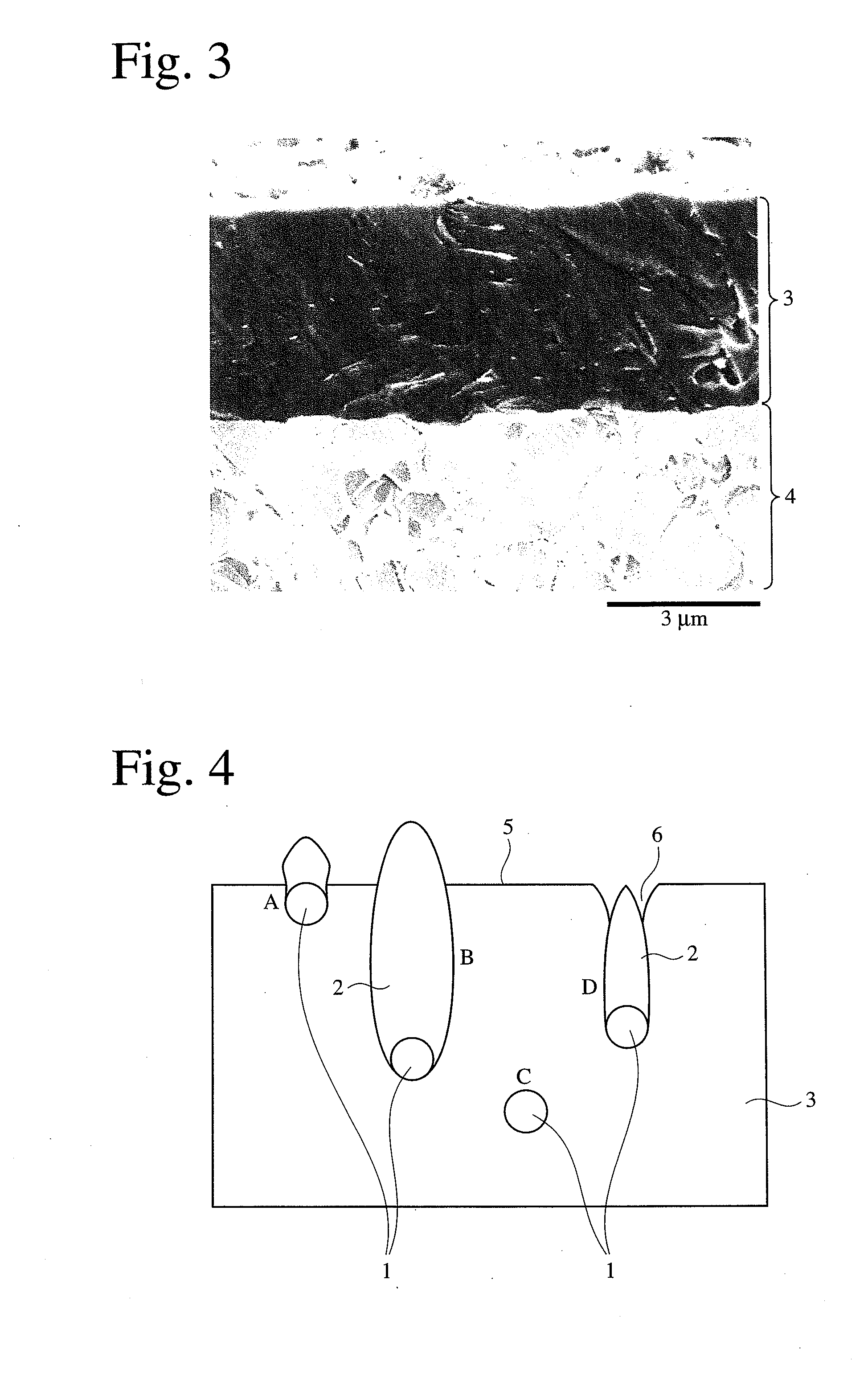

Nanoparticle coated nanostructured surfaces for detection, catalysis and device applications

InactiveUS20060141268A1Strong surface plasmon optical absorptionFine surfaceMaterial nanotechnologyNanomagnetismNano catalystNanostructured materials

A non-vacuum-based, non-collodial chemistry-based method of synthesizing metal nanoparticles and nanoparticle-nanostructured material composites obtained by that method. An embodiment of the method of this invention for fabricating a nanoparticle-nanostructured material composite and synthesizing nanoparticles includes preparing a nanostructured / nanotextured material, and, contacting the nanostructured / nanotextured material with a solution. Nanoparticles are synthesized on the nanostructured / nanotextured material as a result of the contact. The method of the present invention can be utilized to fabricate SPR and SERS substrates for sensing and detection. Additional systems based on this approach (e.g., surface plasmon resonance absorption and alloying sensors and nanocatalysts) are described.

Owner:PENN STATE RES FOUND

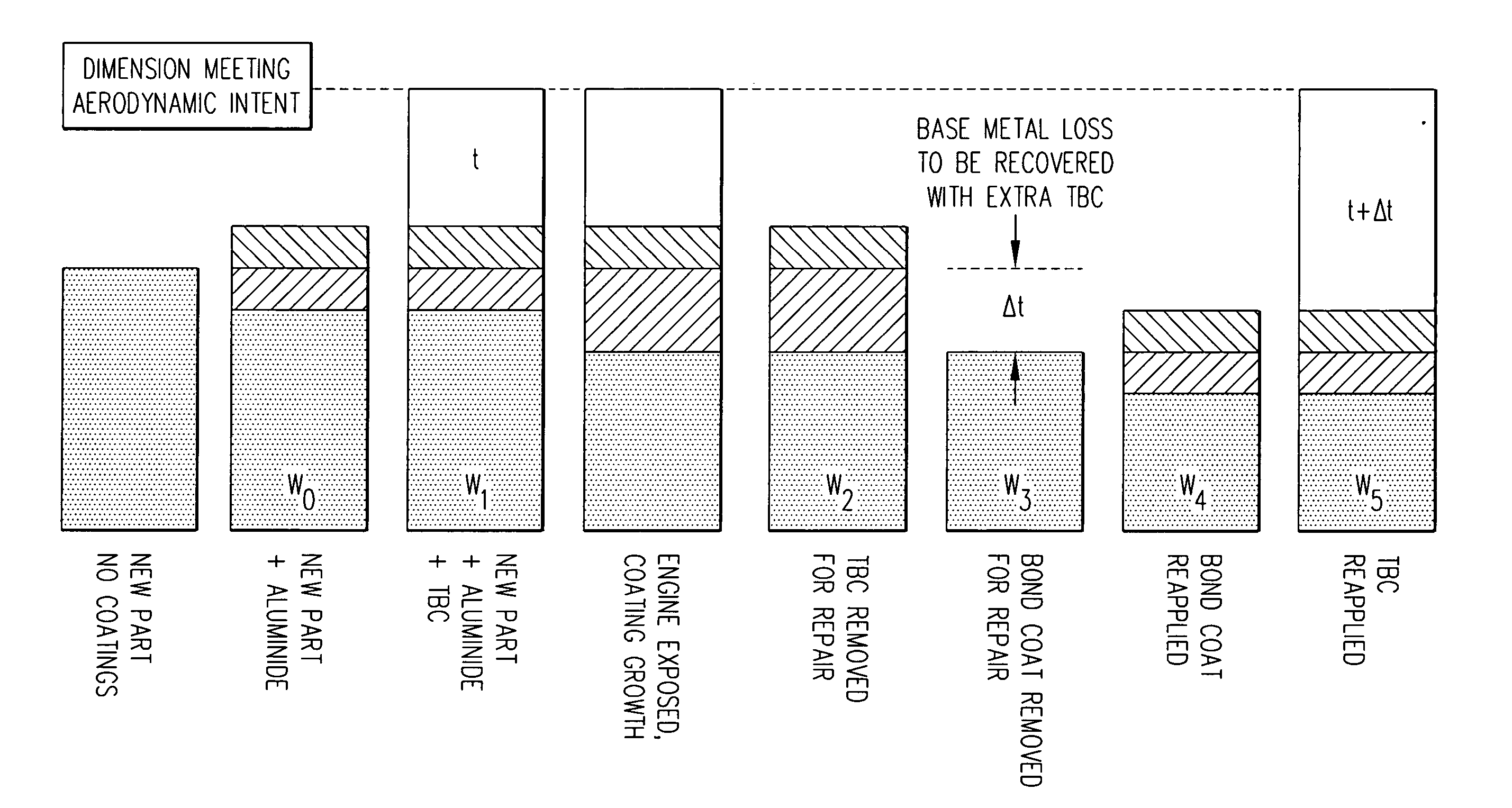

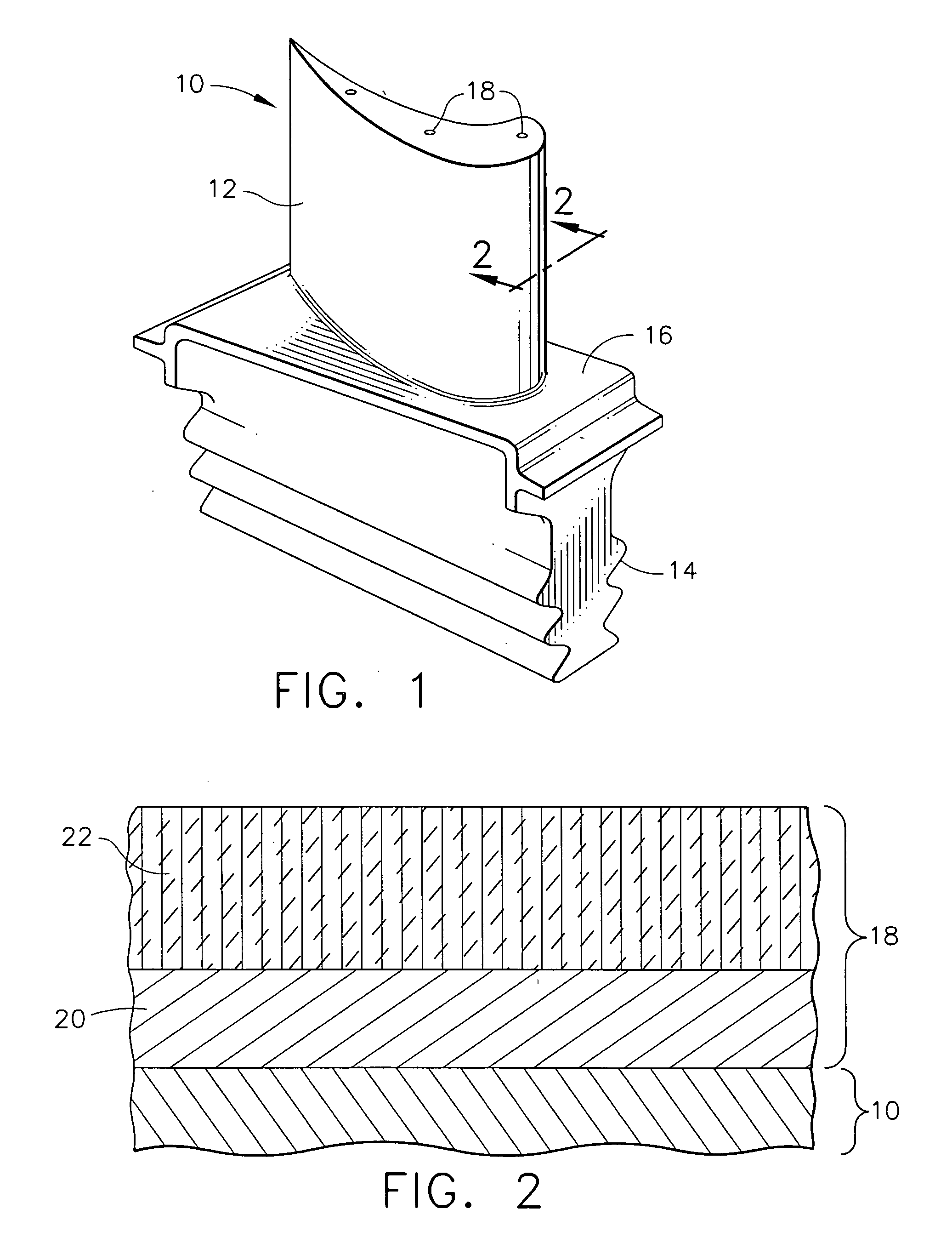

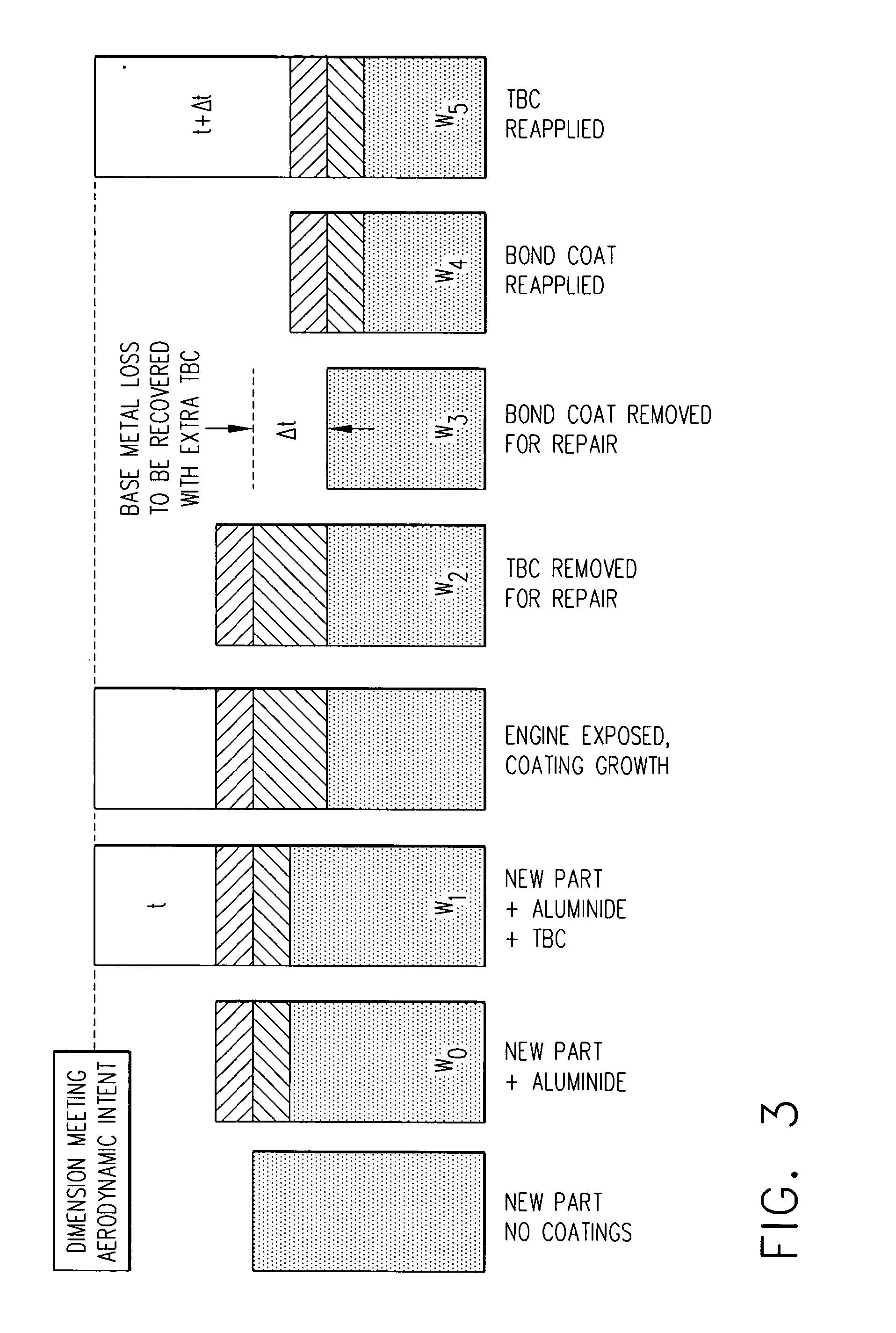

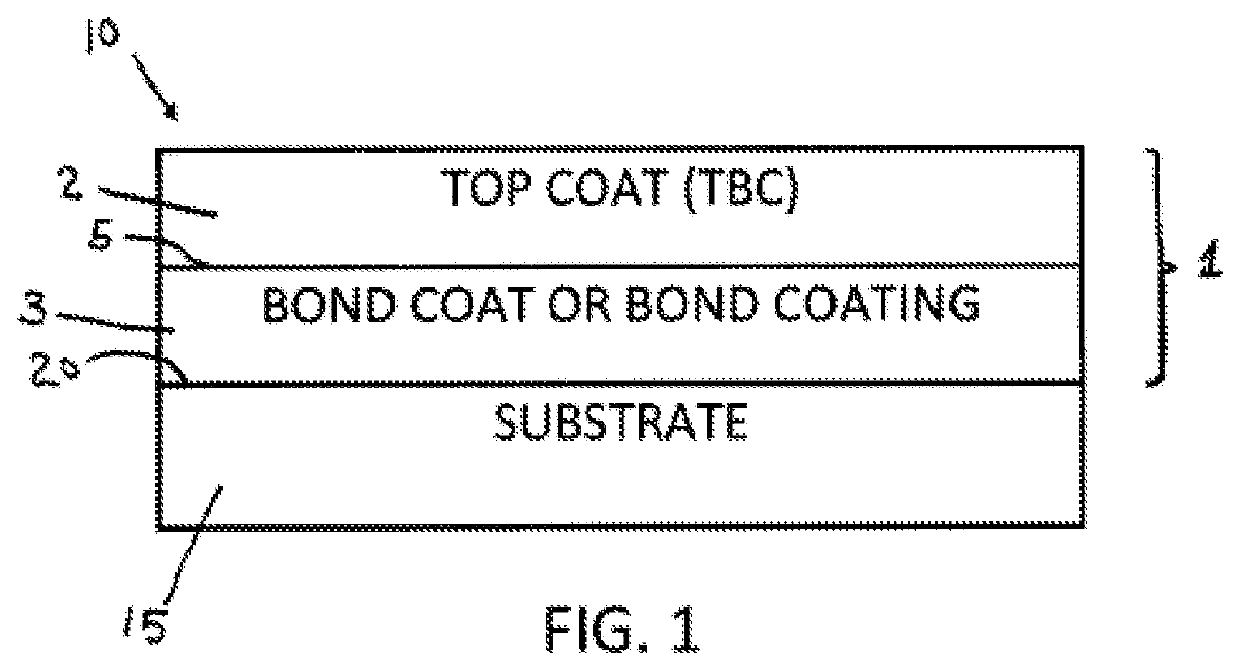

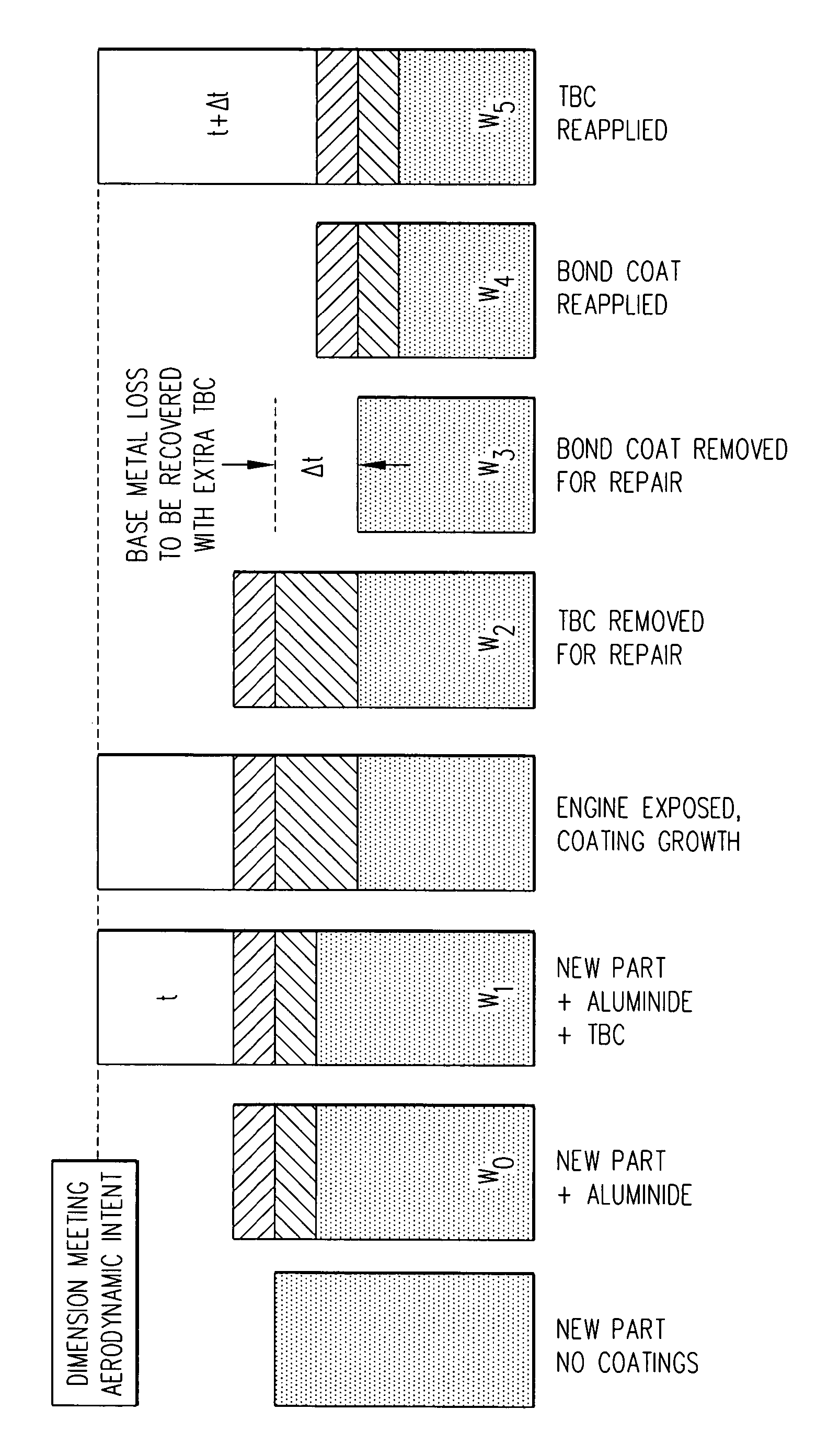

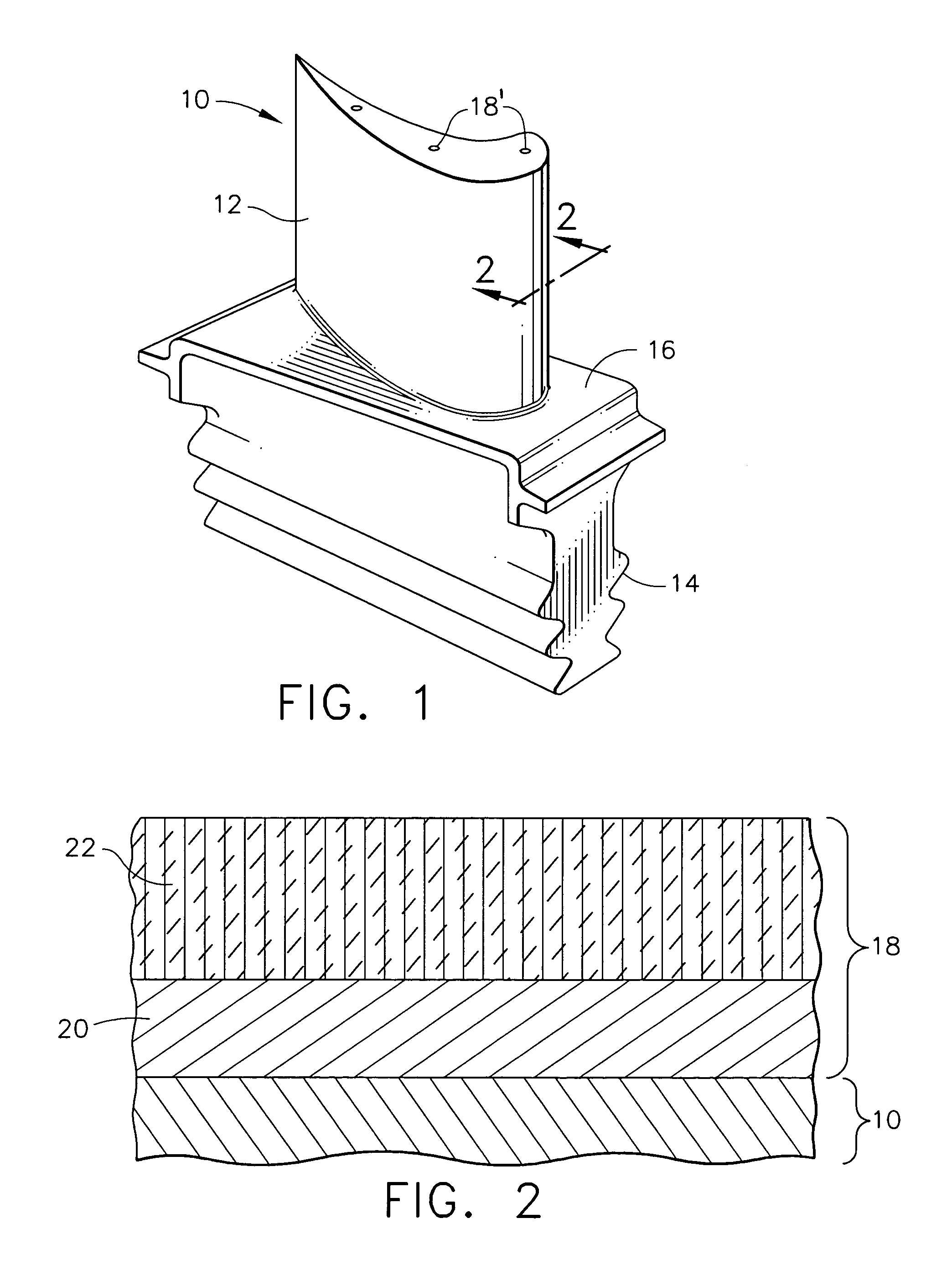

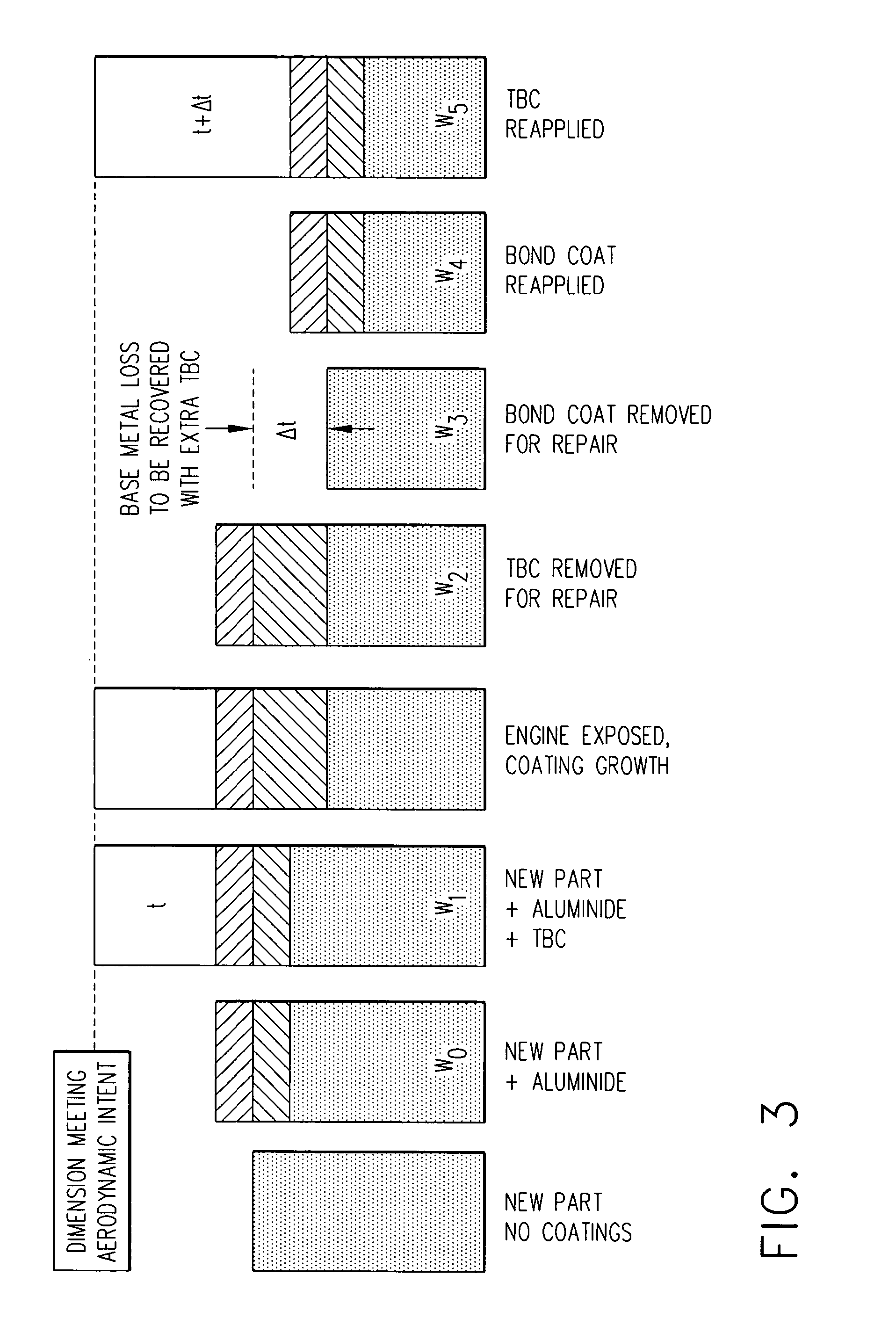

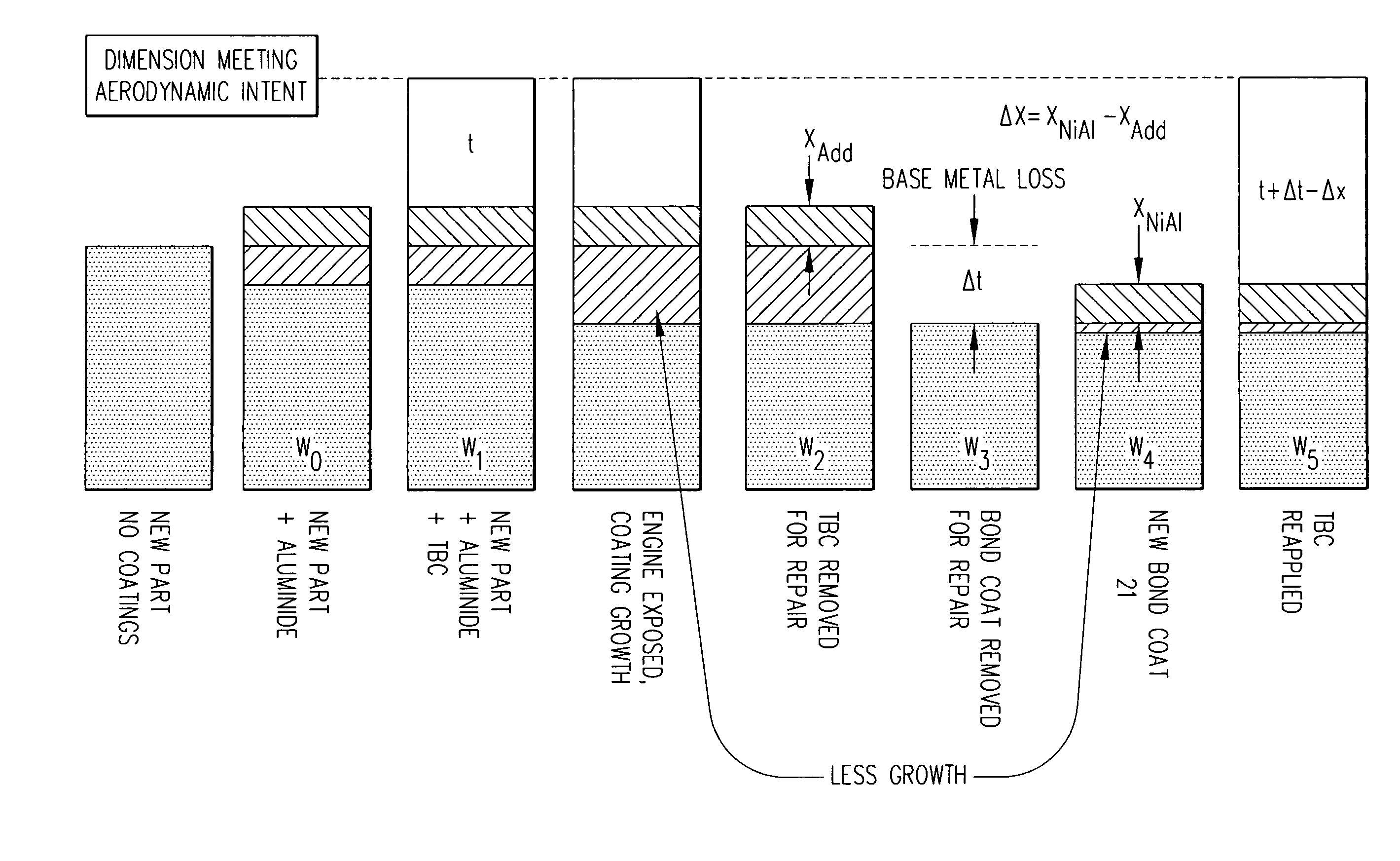

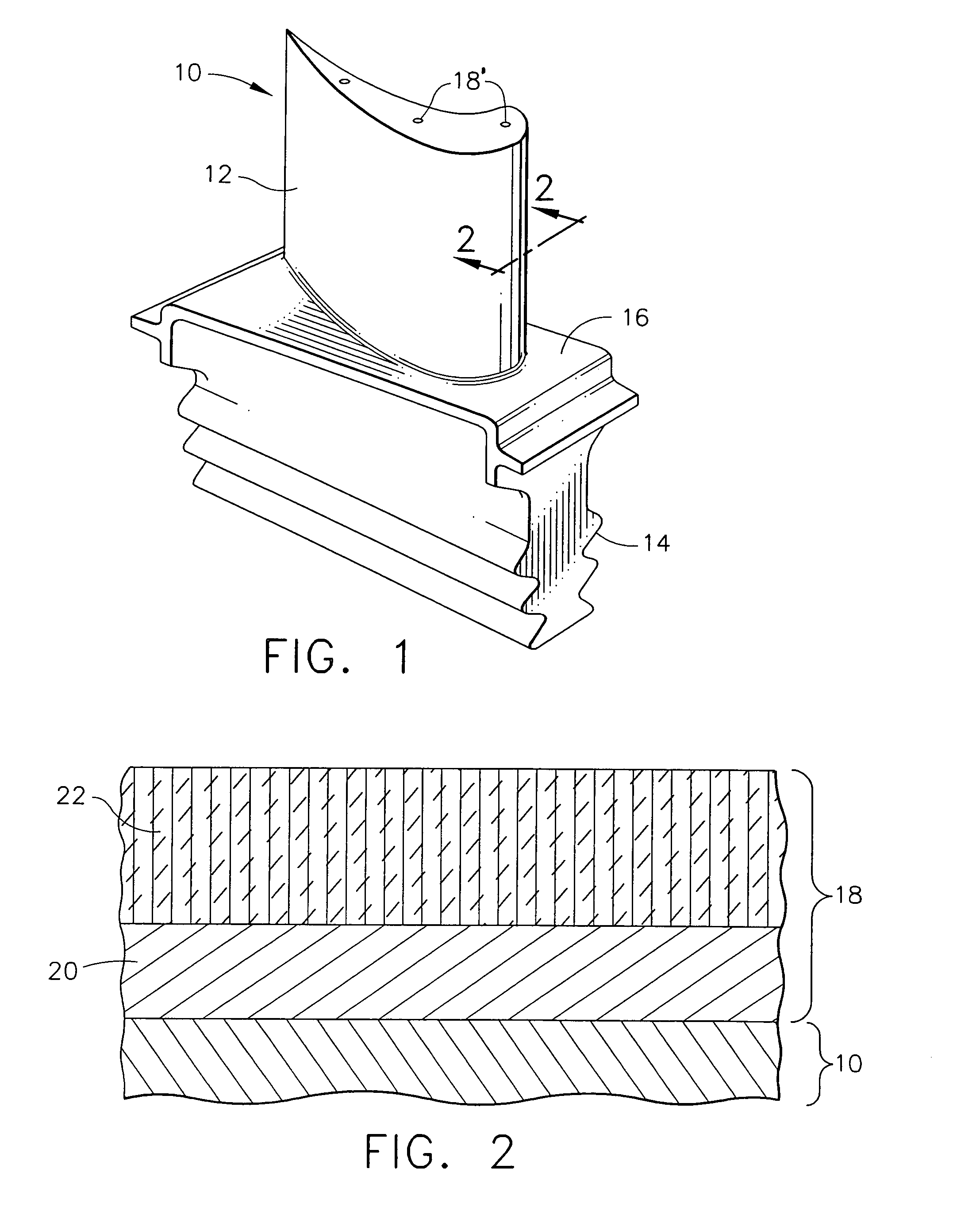

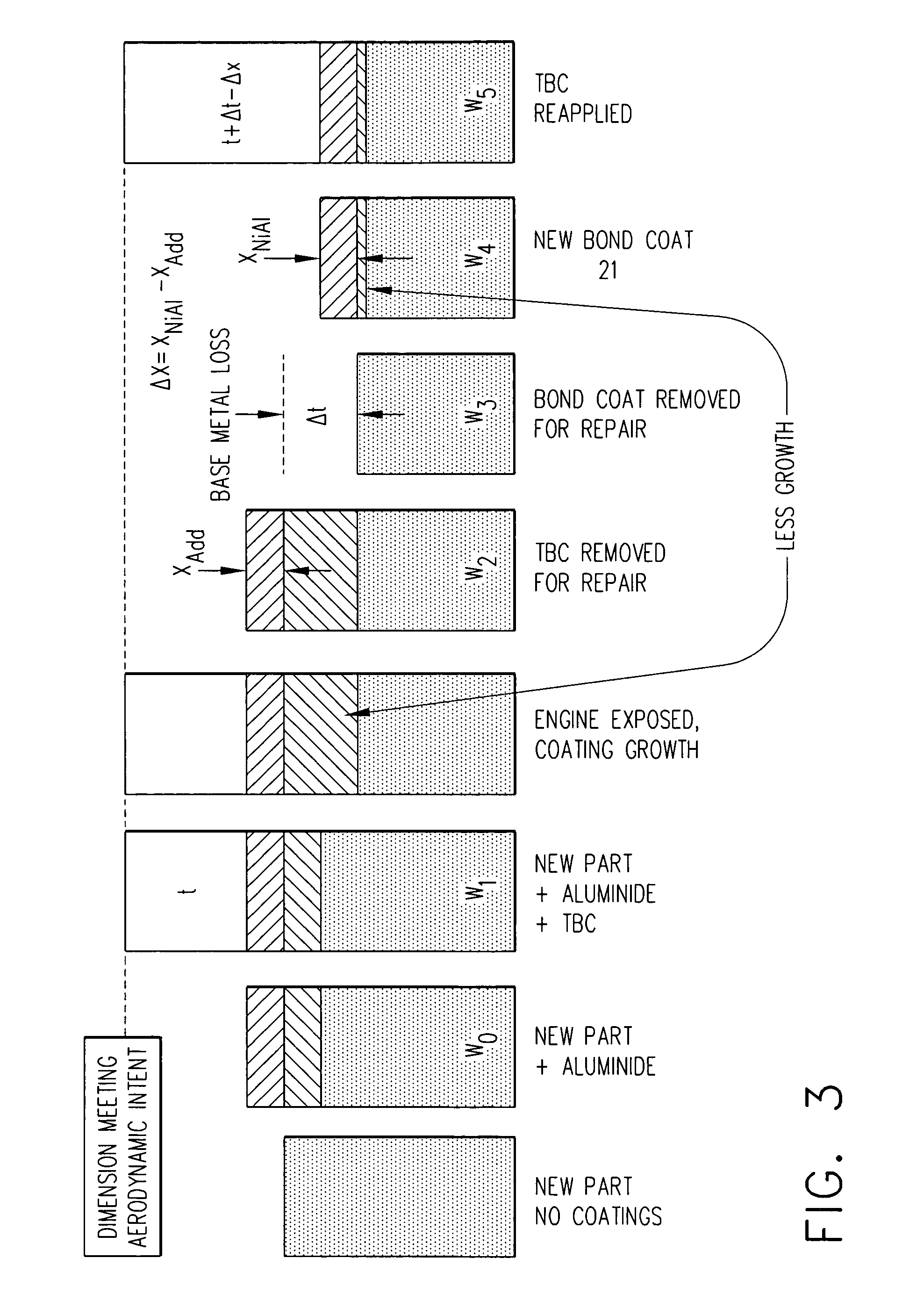

Method for repairing coated components

ActiveUS20050106316A1Increase ceramic spallation lifeReduce coatingMolten spray coatingLayered productsTurbine bladeAlloy

According to an embodiment of the invention, a method for repairing a coated high pressure turbine blade, which has been exposed to engine operation, to restore coated airfoil contour dimensions of the blade, is disclosed. The method comprises providing an engine run high pressure turbine blade including a base metal substrate made of a nickel-based alloy and having thereon a thermal barrier coating system. The thermal barrier coating system comprises a diffusion bond coat on the base metal substrate and a top ceramic thermal barrier coating comprising a yttria stabilized zirconia material. The top ceramic thermal barrier coating has a nominal thickness t. The method further comprises removing the thermal barrier coating system, wherein a portion of the base metal substrate also is removed, and determining the thickness of the base metal substrate removed. The portion of the base metal substrate removed has a thickness, Δt. The method also comprises reapplying the diffusion bond coat to the substrate, wherein the bond coat is reapplied to a thickness, which is about the same as applied prior to the engine operation; and reapplying the top ceramic thermal barrier coating to a nominal thickness of t+Δt, wherein Δt compensates for the portion of removed base metal substrate. Advantageously, the coated airfoil contour dimensions of the high pressure turbine blade are restored to about the coated dimensions preceding the engine run.

Owner:GENERAL ELECTRIC CO

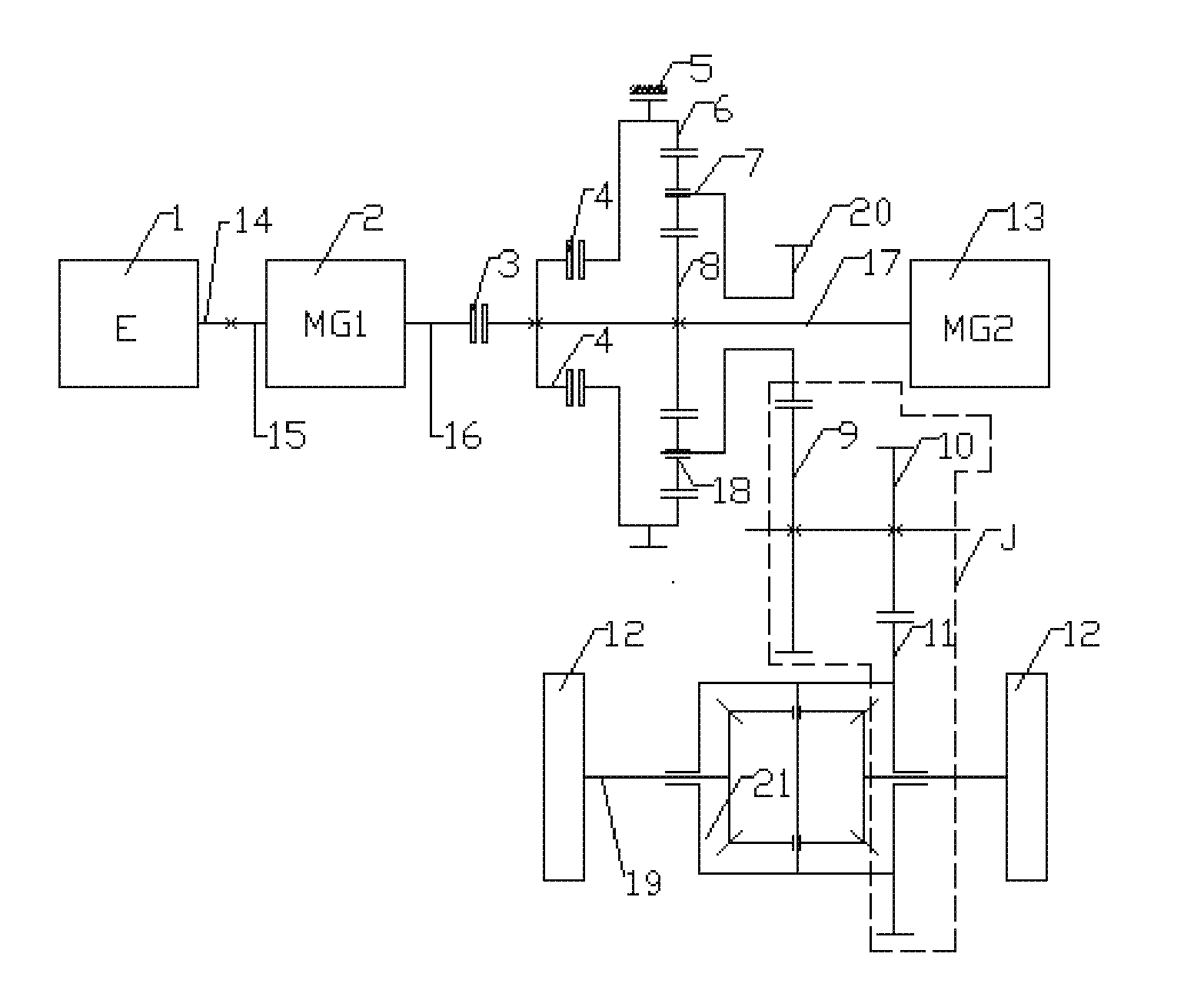

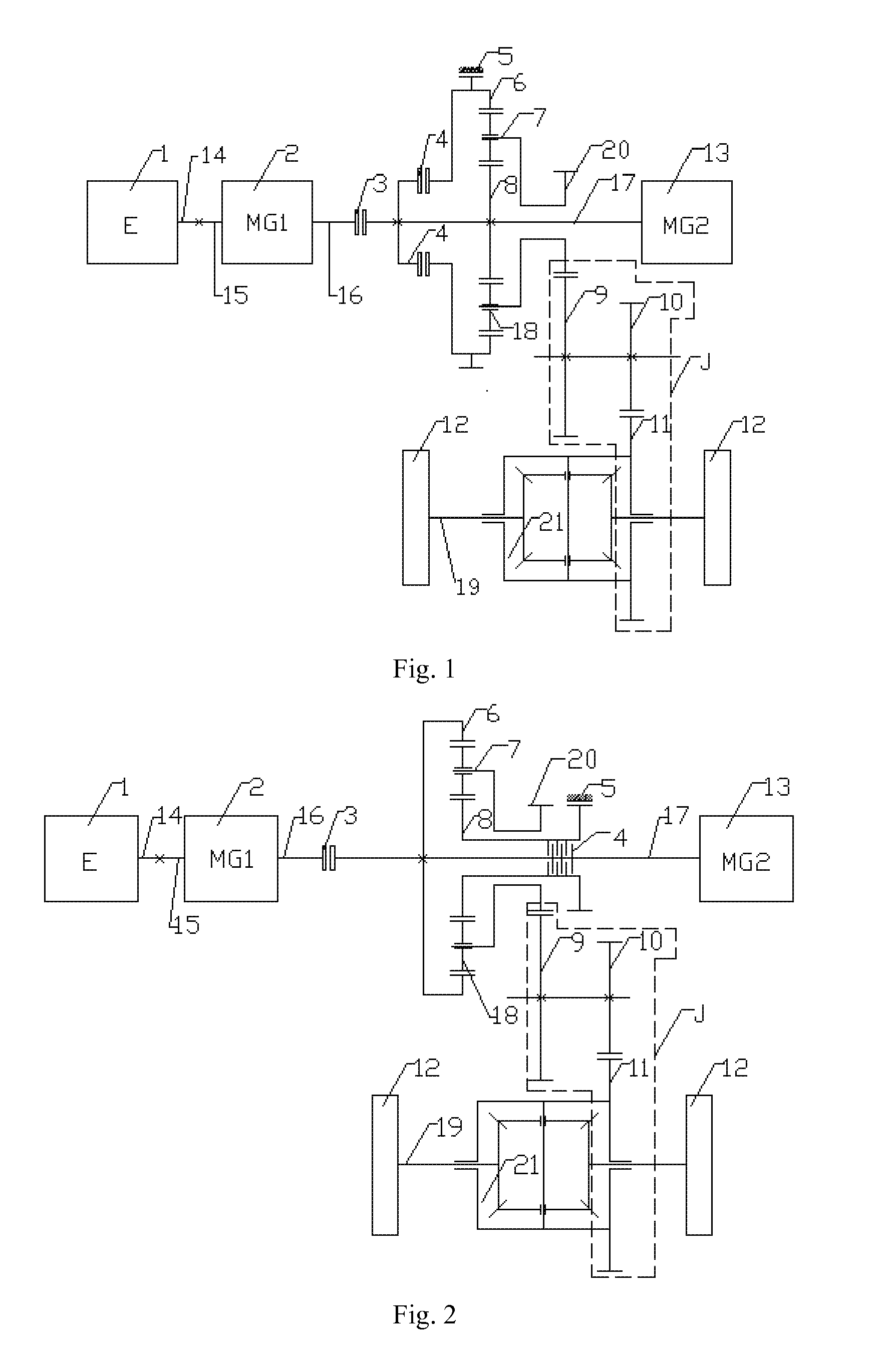

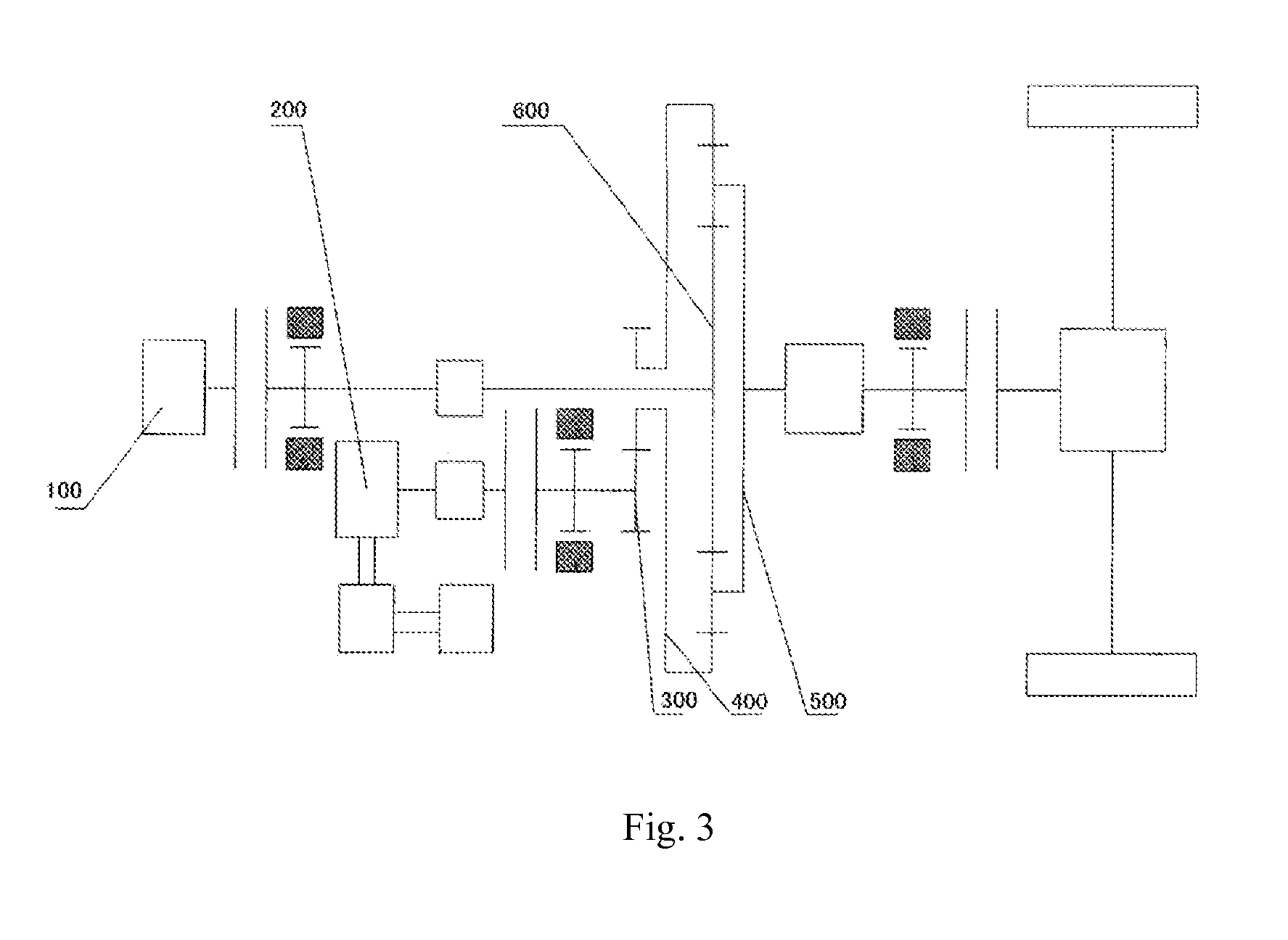

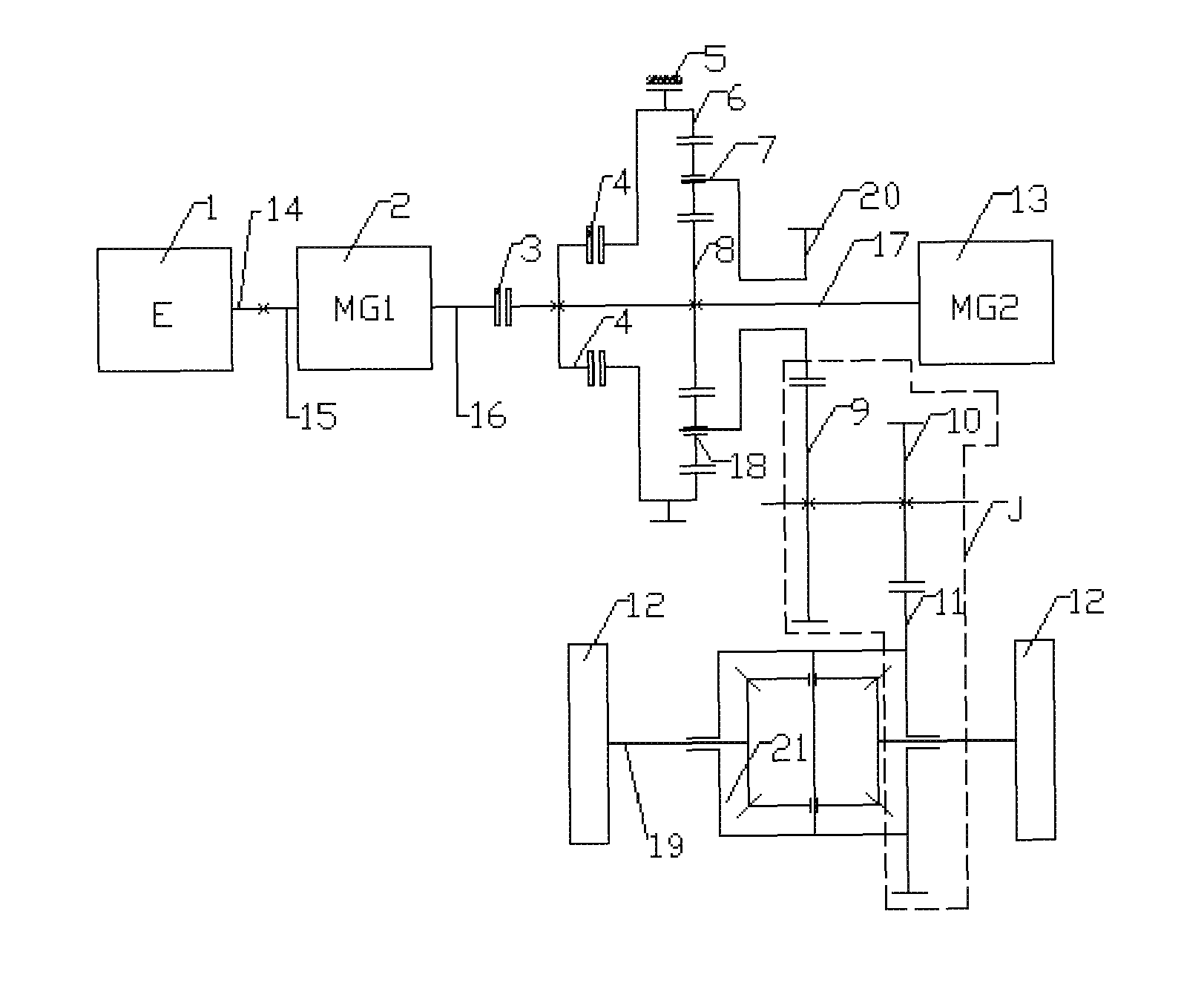

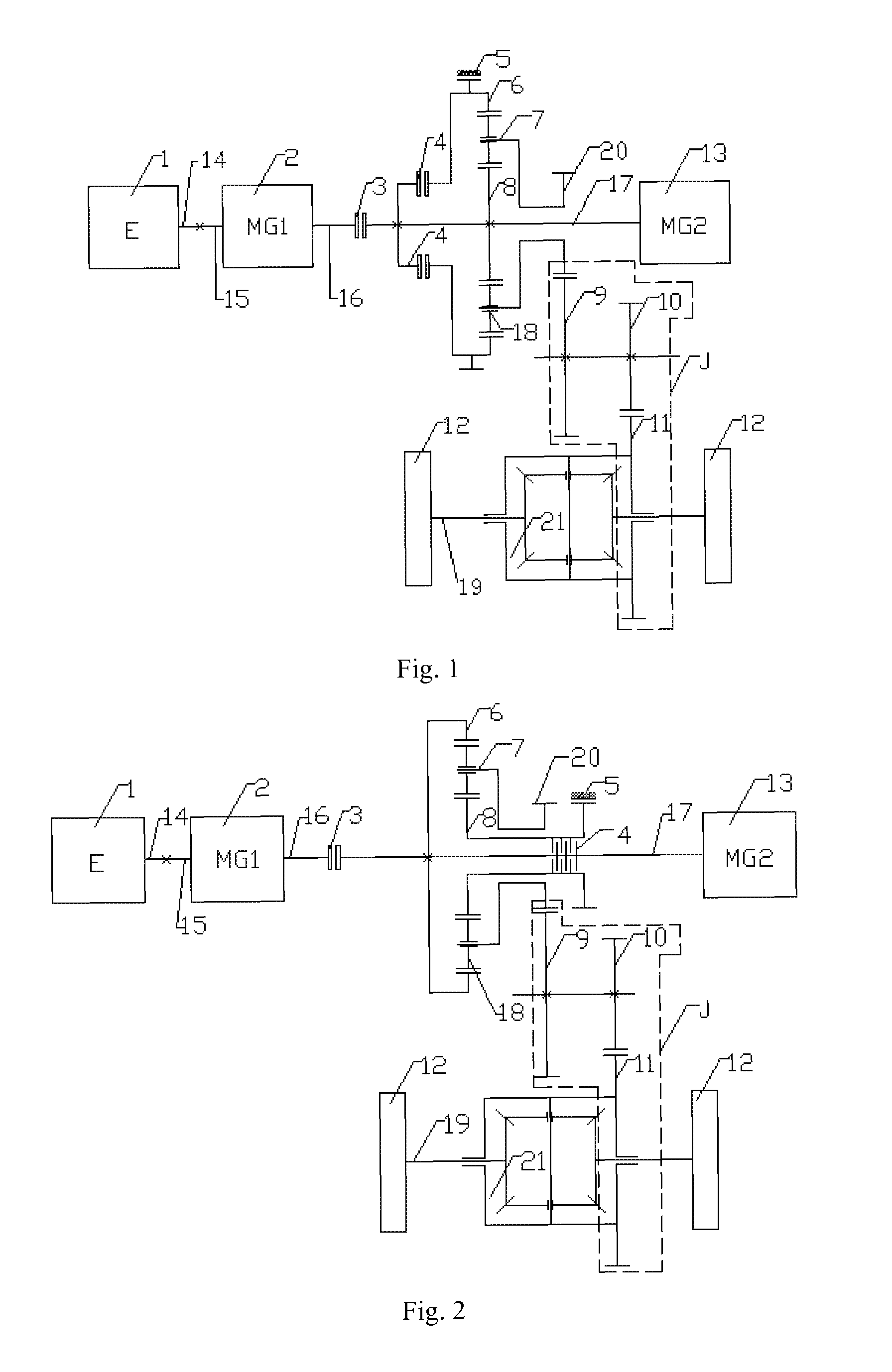

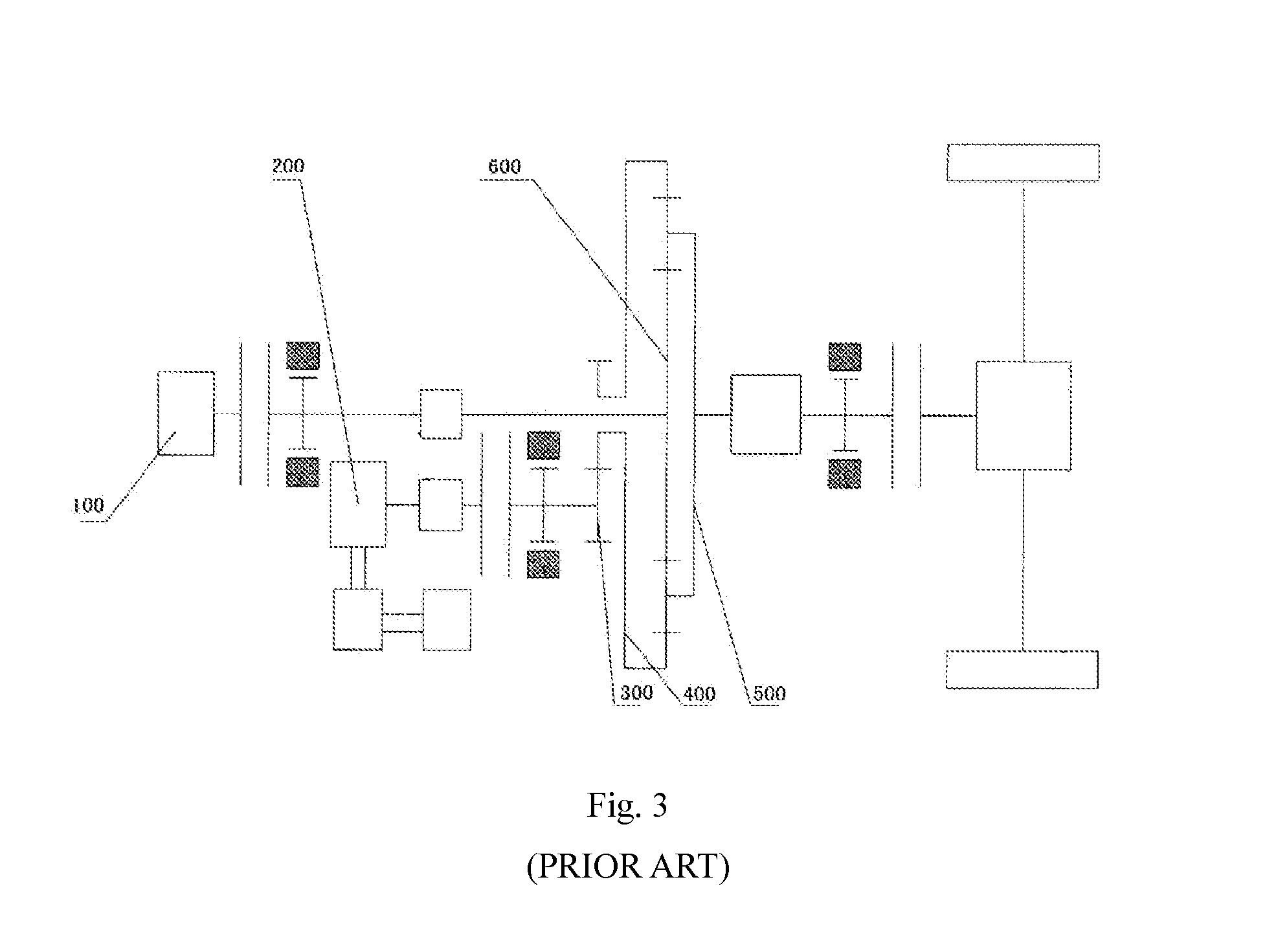

Hybrid power driving system and gear position operation method thereof

ActiveUS20110160015A1Reduce rateIncrease torqueHybrid vehiclesGas pressure propulsion mountingCouplingInternal combustion engine

A hybrid power driving system for a vehicle comprises an internal-combustion engine, a first electric motor, a second electric motor, a planetary coupling mechanism, a speed-reduction mechanism and a differential mechanism. An output shaft of the internal-combustion engine is connected with an input shaft of the first electric motor, and an output shaft of the first electric motor is connected with an output shaft of the second electric motor via a first clutch. The output shaft of the second electric motor is connected with one of a sun gear and a ring gear of the planetary coupling mechanism at a position of the output shaft along its axial direction. And the output shaft of the second electric motor is connected with the other one of a sun gear and a ring gear at another position of the output shaft along the axial direction via a second clutch.

Owner:BYD CO LTD

Antimicrobial medical gloves

InactiveUS20050186258A1Readily understoodExpand coverageGarment special featuresBiocideDamp environmentGram-positive bacterium

The invention disclosed herein relates to elastomeric articles such as medical or industrial gloves coated by antimicrobial compositions and protected by water-resistant packaging. Antimicrobial gloves are useful in methods for reducing nosocomial infection by Gram positive bacteria, Gram negative bacteria, fungi, and viruses. Packaged gloves maintain quick-kill activity against microbes, even after extended storage. In a preferred embodiment, the present invention provides a method of packaging which protects the antimicrobial activity of a glove during storage and transportation by shielding the glove from warm and / or humid environments. Alternatively, the present invention provides a system comprising an antimicrobial glove and packaging as a means for maintaining a low level of humidity in the vicinity of the glove.

Owner:ALLEGIANCE CORP

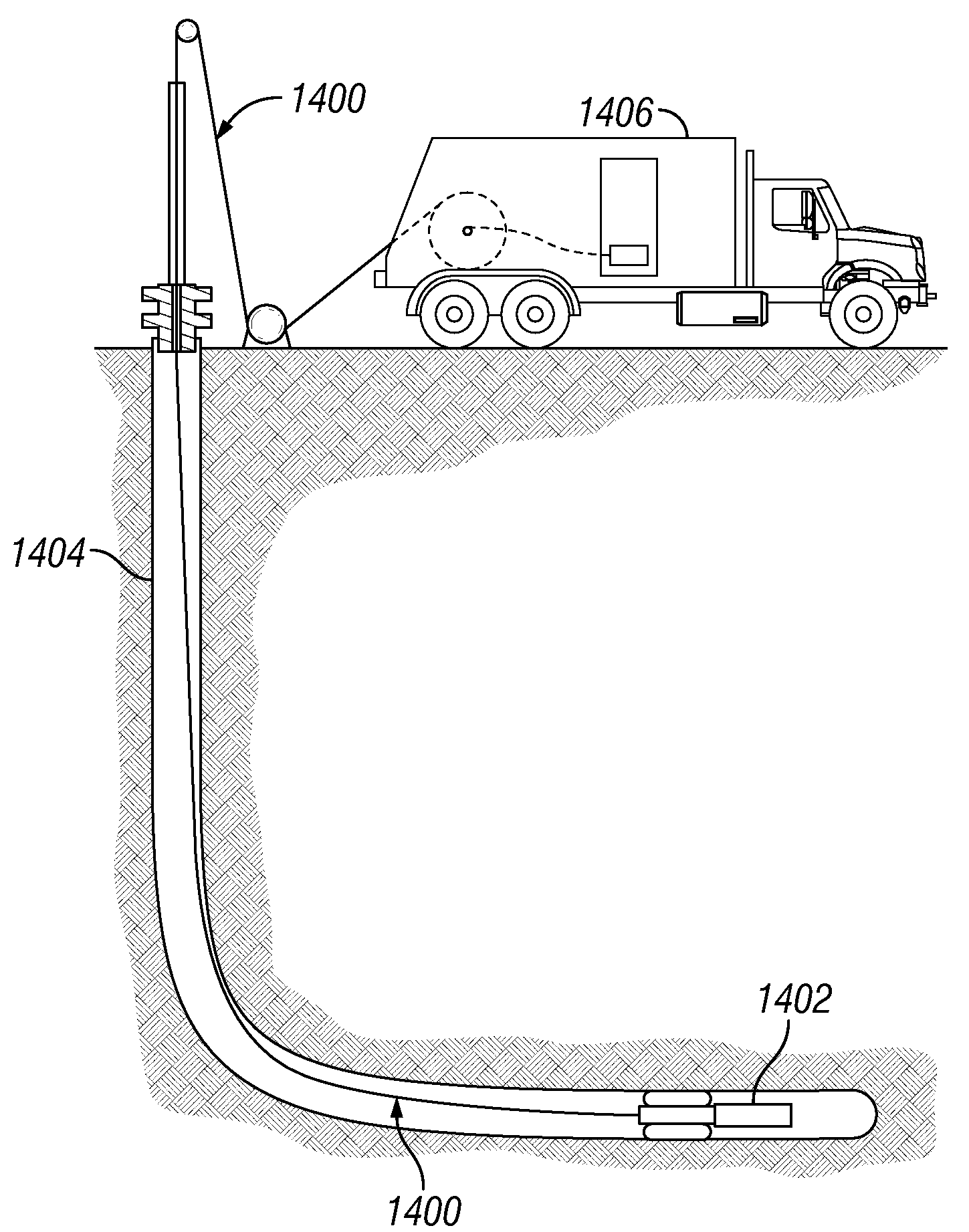

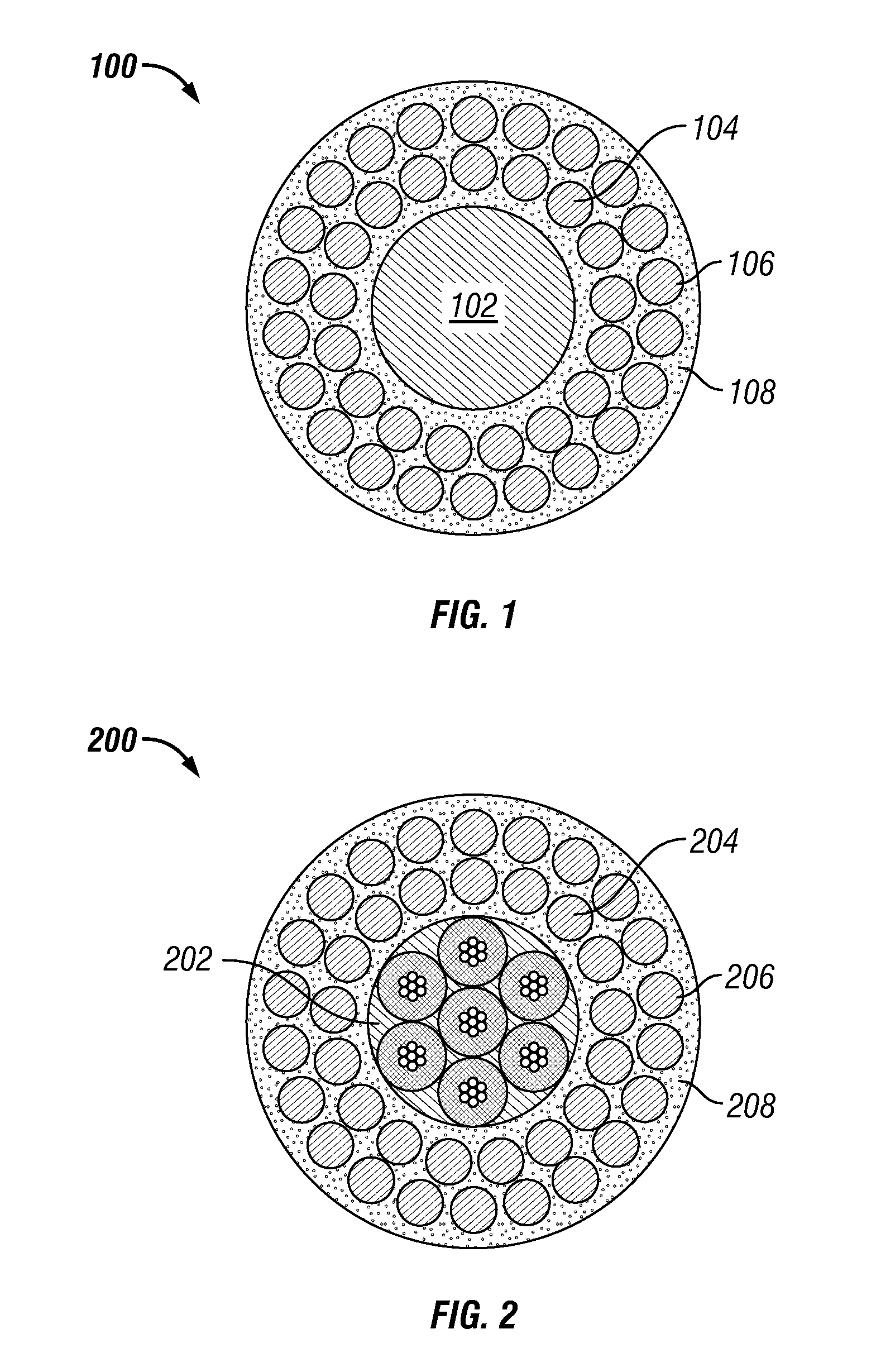

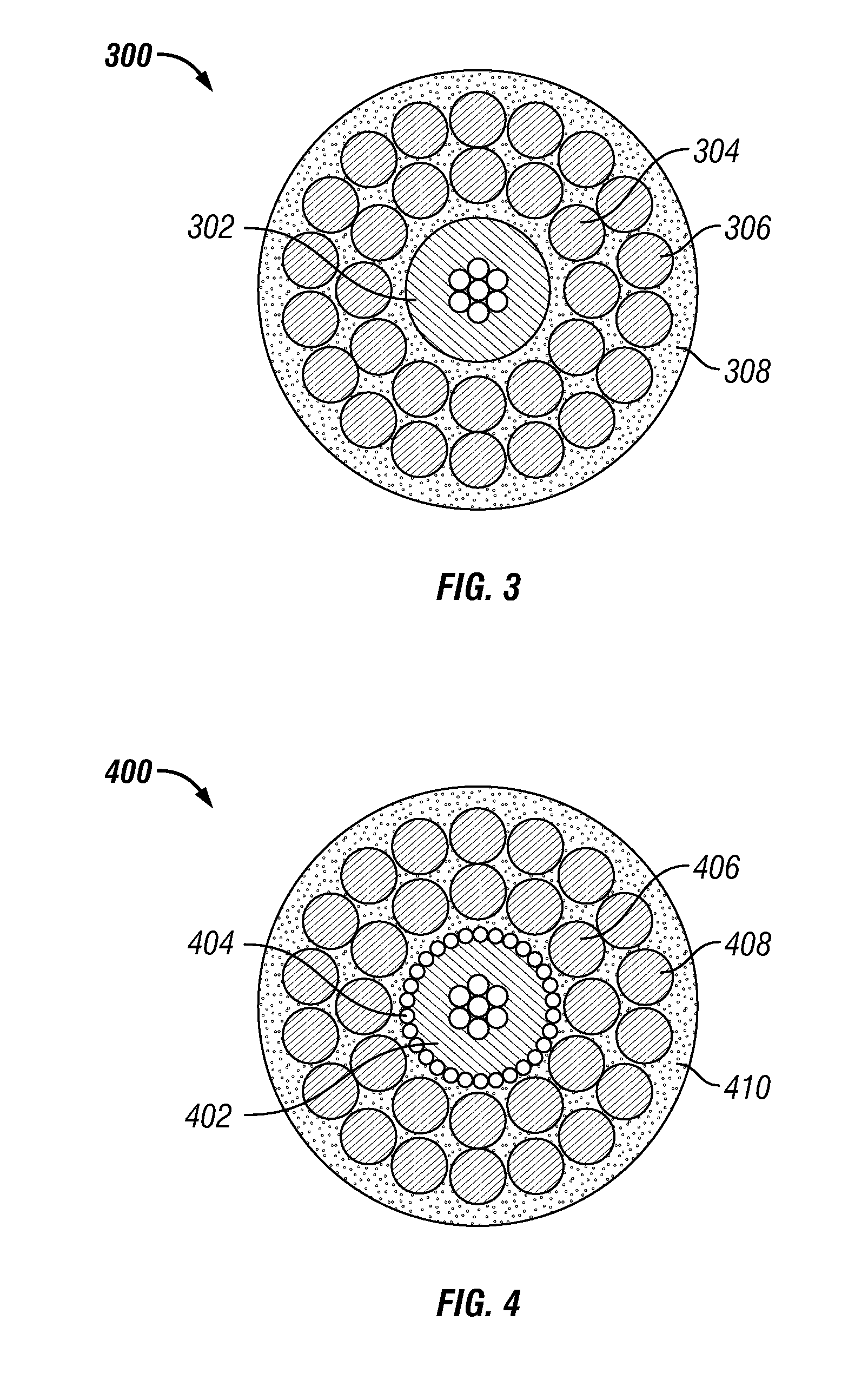

Methods of Using Enhanced Wellbore Electrical Cables

ActiveUS20090145610A1Reduce frictionReduce coatingDrilling rodsConstructionsElectrical conductorEngineering

An embodiment of a method of deploying a cable into a wellbore penetrating a subterranean formation comprises providing a cable, wherein the cable comprises at least one insulated conductor, at least one armor wire layer surrounding the insulated conductor, a polymeric material disposed in interstitial spaces formed between armor wires forming the at least one armor wire layer, and interstitial spaces formed between the at least one armor wire layer and insulated conductor, the polymeric material forming a continuously bonded layer which separates and encapsulates the armor wires forming the at least one armor wire layer, and whereby the polymeric material is extended to form a smooth polymeric jacket around the at least one armor wire layer, introducing the cable into a wellbore and performing at least one operation in the wellbore utilizing the cable.

Owner:SCHLUMBERGER TECH CORP

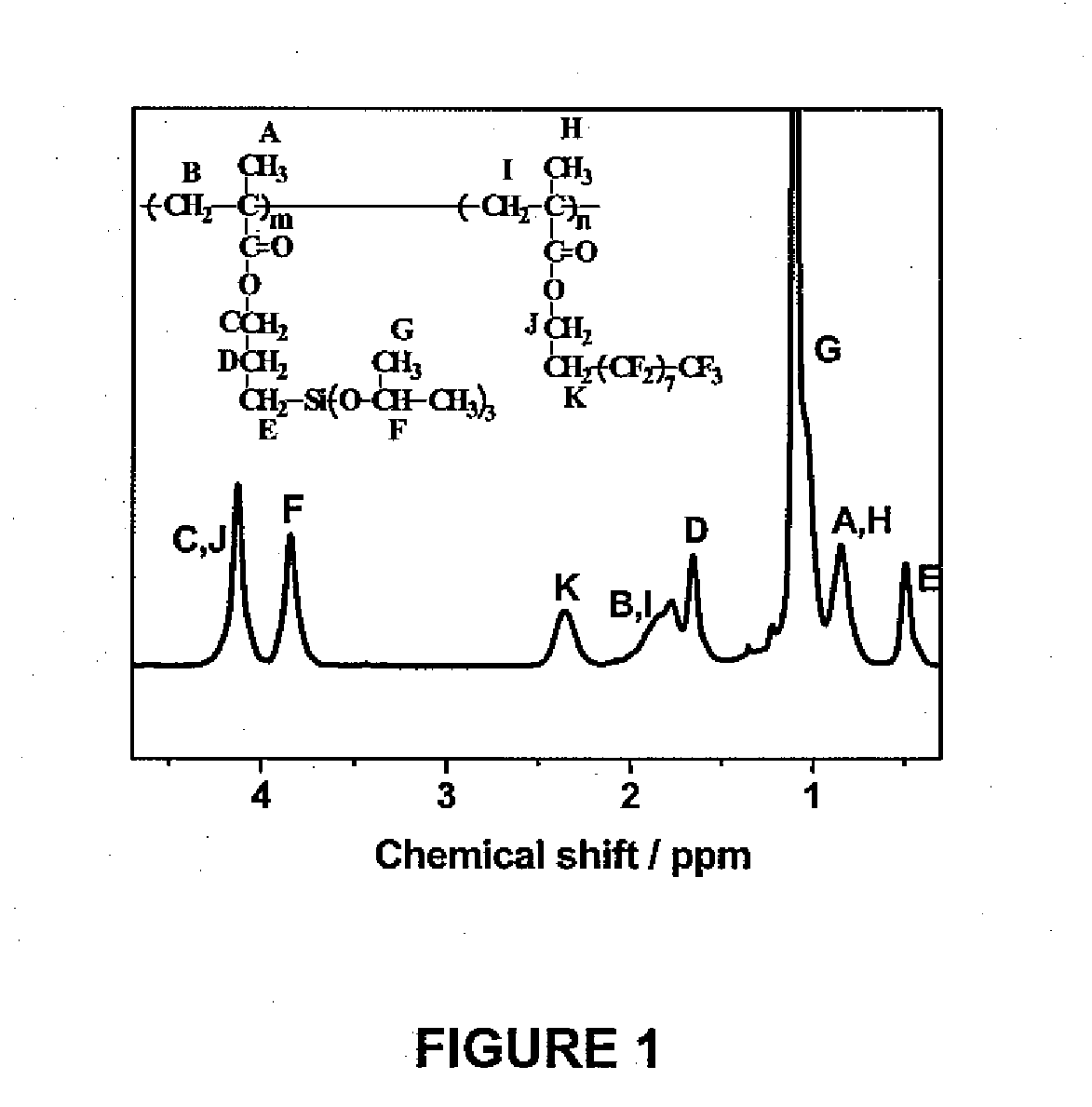

Amphiphobic Surfaces from Block Copolymers

InactiveUS20120264884A1Surface energy is lowEnhanced interactionLiquid repellent fibresCoatingsSilica nanoparticlesPolymer science

Provided are amphiphobic block copolymers, methods for preparing amphiphobic block copolymers, and applications thereof. Amphiphobic block copolymers can be used to prepare amphiphobic coatings on material surfaces, such as glass, printing paper or fabric. Amphiphobic block copolymers can also be used to coat particles, e.g., silica nanoparticles, which are then used to coat material surfaces. Such coated particles and uses thereof are also provided herein.

Owner:QUEENS UNIV OF KINGSTON

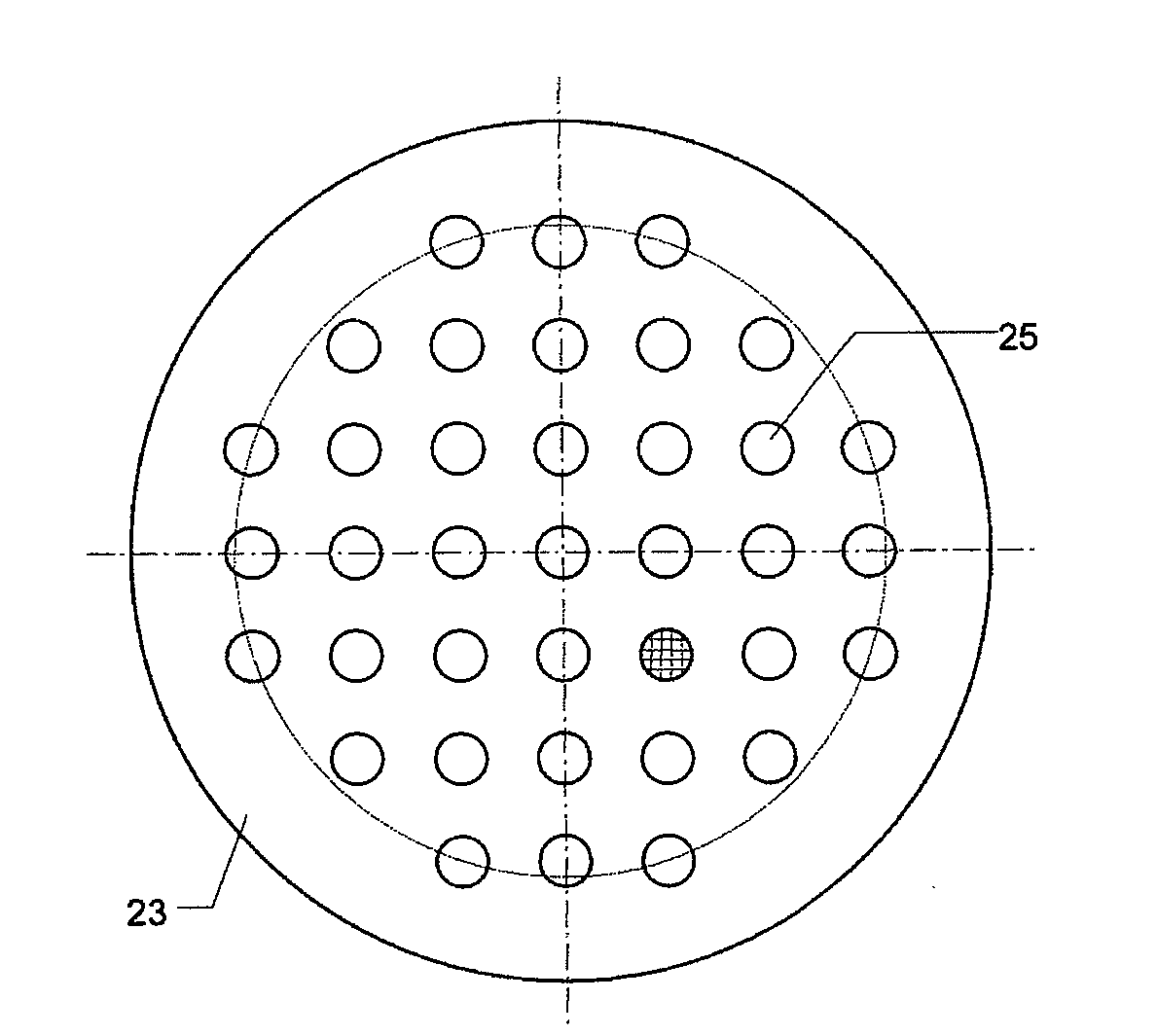

Method for introducing a catalytic coating into the pores of a ceramic honeycomb flow body

ActiveUS20100093527A1Increase pressureA large amountDispersed particle filtrationPretreated surfacesMaterials scienceBlow out

The invention relates to a process for coating ceramic honeycomb bodies with a catalyst suspension comprising catalyst components as solids and / or in dissolved form in a carrier liquid. Parallel flow channels run through the honeycomb bodies. The walls of the flow channels have an open pore structure. To coat the channel walls and in particular also the interior surfaces of the pores with the catalyst suspension, the entry and exit end faces of the vertically aligned honeycomb bodies are each brought into contact with a perforated mask, with the perforated masks being arranged so that the open regions of the perforated mask on the one end face are opposite the closed regions of the perforated mask on the other end face and vice versa. The catalyst suspension is then pumped or sucked from below into the honeycomb bodies until it exits at the upper end face. Excess suspension is then removed by blowing-out or sucking-out, the contact with the perforated masks is released and the honeycomb body is calcined to fix the coating.

Owner:UMICORE AG & CO KG

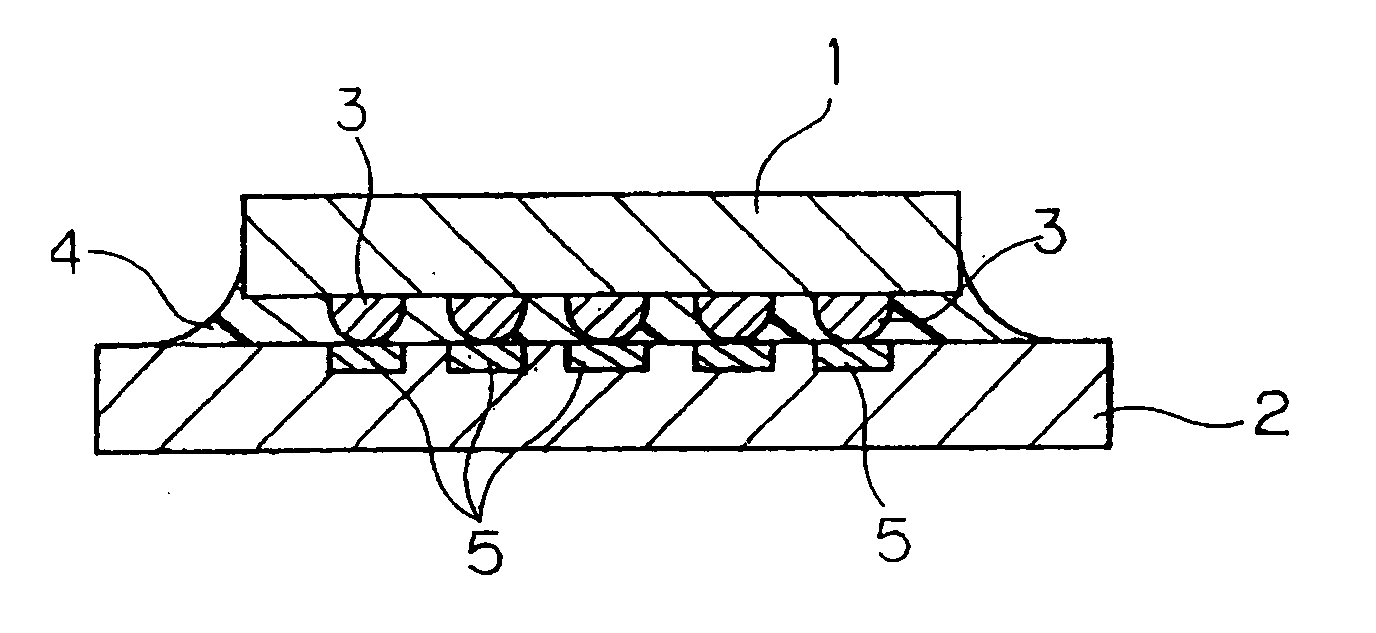

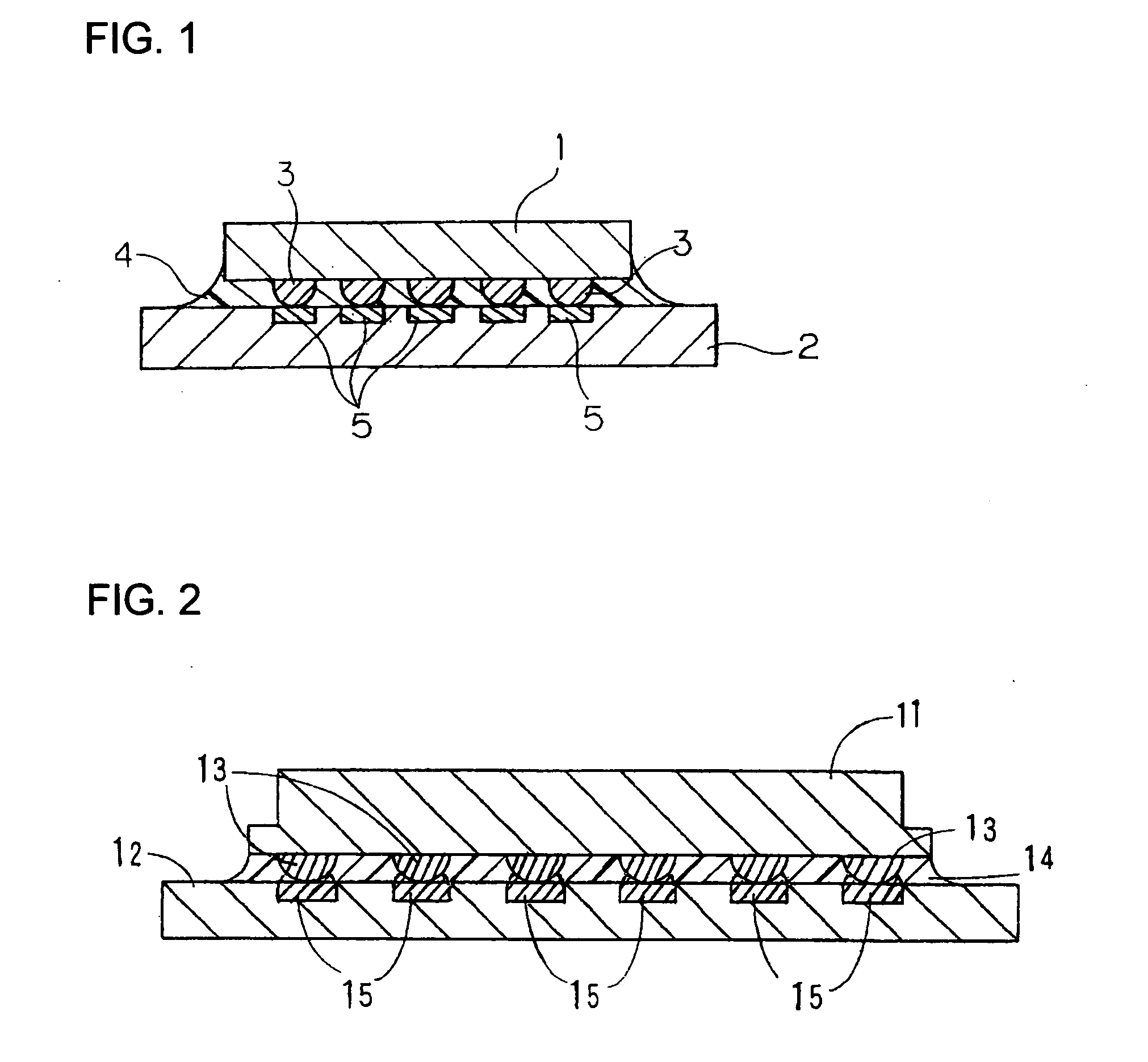

Liquid epoxy resin composition

InactiveUS20070196612A1Low viscosityEasily show solvation and swellingLayered productsSemiconductor/solid-state device detailsPolymer scienceElectrical connection

There is provided a low viscosity liquid epoxy resin composition which has excellent repairability because of the capability to remove residues at around room temperature even in the case of an electronic part device having a deficiency in the electric connection after once carrying out underfill, and what is more, wherein an electric parts device having a connected mounted structure shows high reliability. The liquid epoxy resin composition is used for resin-filling the gap between a circuit substrate and a semiconductor part on an electronic part device, wherein said electronic part device comprises a circuit substrate having an electrode part for connection and a semiconductor part having an electrode part for connection and being mounted on the circuit substrate in such a way that the electrode part of the circuit substrate and the electrode part of the semiconductor part are facing each other. In addition, the liquid epoxy resin composition comprises the following components (A) to (C) together with the following component (D). (A) A liquid epoxy resin. (B) An aromatic diamine curing agent. (C) An inorganic filler. (D) An organic additive.

Owner:NITTO DENKO CORP

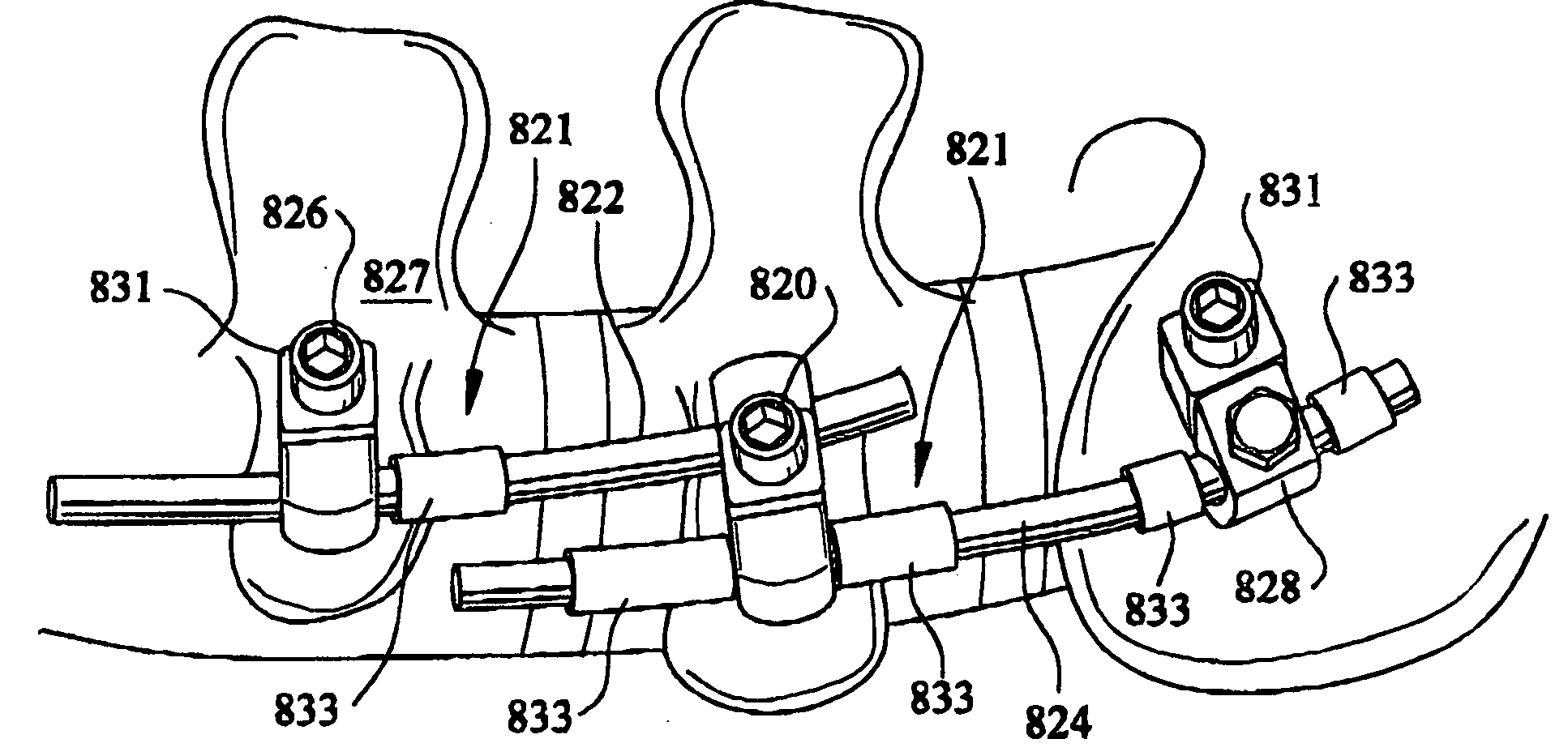

Artificial facet joint and method

InactiveUS20050101953A1Limit movement of jointReduced friction coatingSuture equipmentsInternal osteosythesisSacroiliac jointSpinal implant

An artificial facet joint includes a pair of connectors, each having a first device connecting member having structure for slidably engaging a rod, and a second device connecting member having an aperture for slidably engaging a screw. The first and second device connecting members are rotatably engaged to one another. A spinal implant and spinal implant screws are also provided. The first device connecting member of each connector is slidably engaged to the rod and the second device connecting member of each connector is slidably engaged to a respective one of the pair of spinal implant screws, whereby the screws can be engaged to the pedicles on one lateral side of adjacent vertebrae and the rod and connectors will limit movement of the joint. Another artificial facet joint can be provided on another lateral side of the adjacent vertebrae. A transverse member can be connected between the rods on each lateral side of the vertebrae.

Owner:SIMONSON PETER M

High-entropy oxides for thermal barrier coating (TBC) top coats

PendingUS20210347699A1Reduce coatingReduce layeringMolten spray coatingSuperimposed coating processAlkaline earth metalLanthanide

A thermal barrier coating (TBC) top coat which is a high entropy oxide (HEO) having a high configurational entropy, contains at least 5 different oxide-forming metallic cations, is a single phase or single crystalline structure, such as tetragonal or cubic over unexpectedly wide temperature ranges up to and beyond top coat operating temperatures of preferably at least 2300° F. The TBC top coats exhibit low thermal conductivity, good sintering resistance, excellent phase stability and good thermal cycling performance. At least five of the different oxide-forming metallic cations include: a) at least one of the transition metals: Sc, Y, Ti, Zr, V, Nb, Ta, Cr, Mo, W, Mn, Re, Fe, Ru, Co, Ni, Cu, or Zn, and / or at least one of the lanthanides La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb. Dy, Ho, Er, Yb, or Lu. One of the at least five different oxide-forming metallic cations may also comprise at least one of the alkaline-earth metals: Be, Mg, Ca, Sr, or Ba.

Owner:SULZER METCO (US) INC

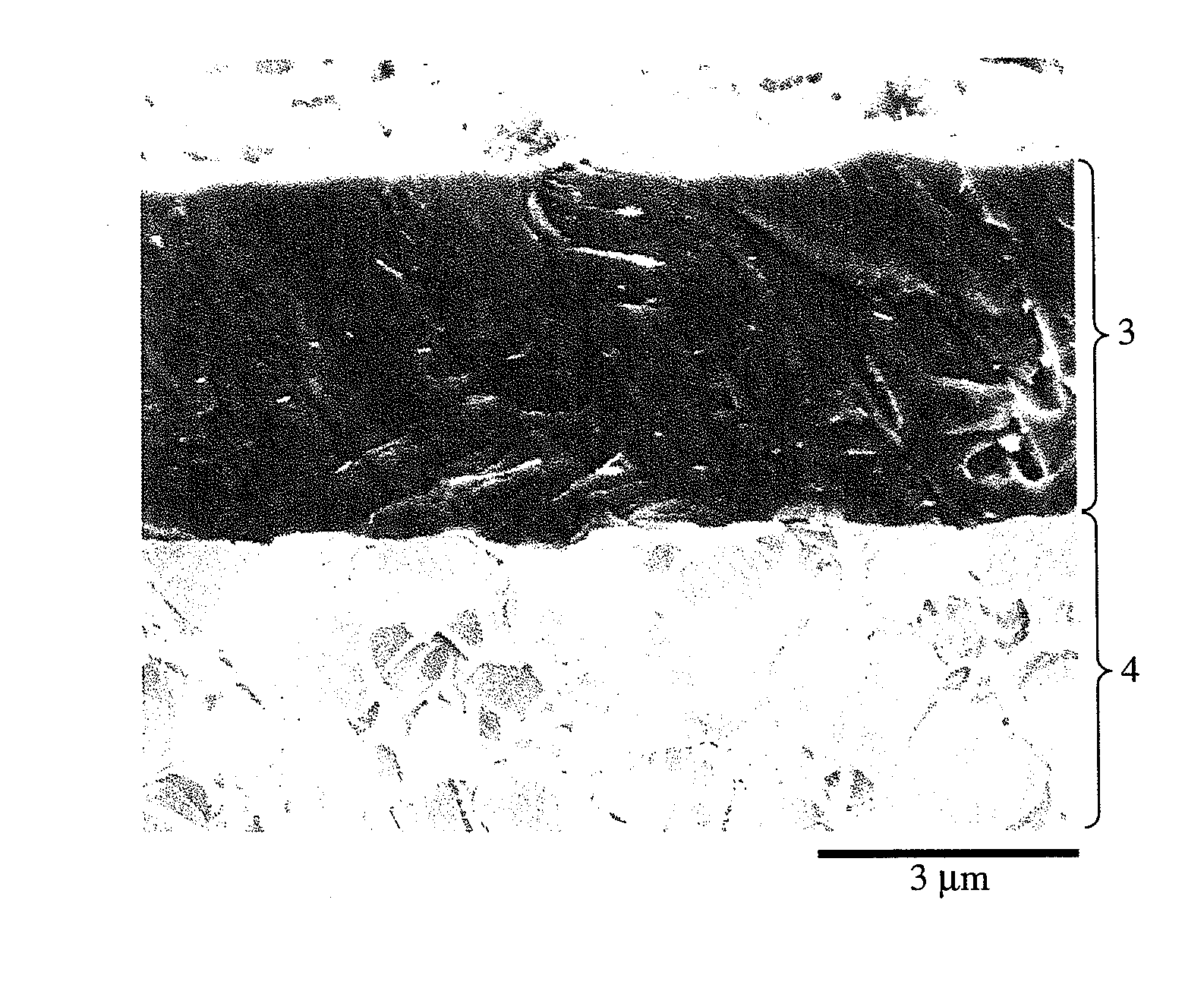

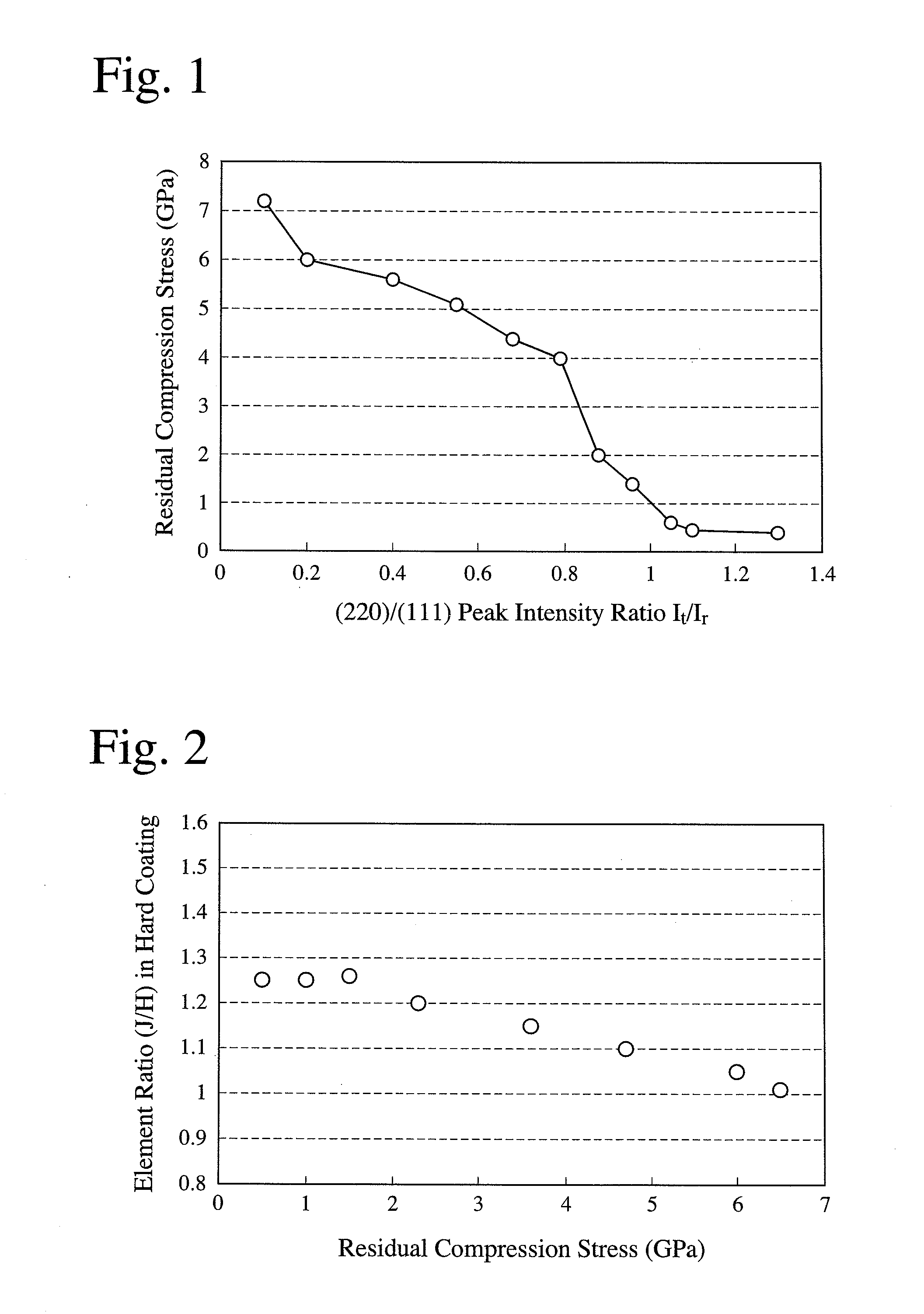

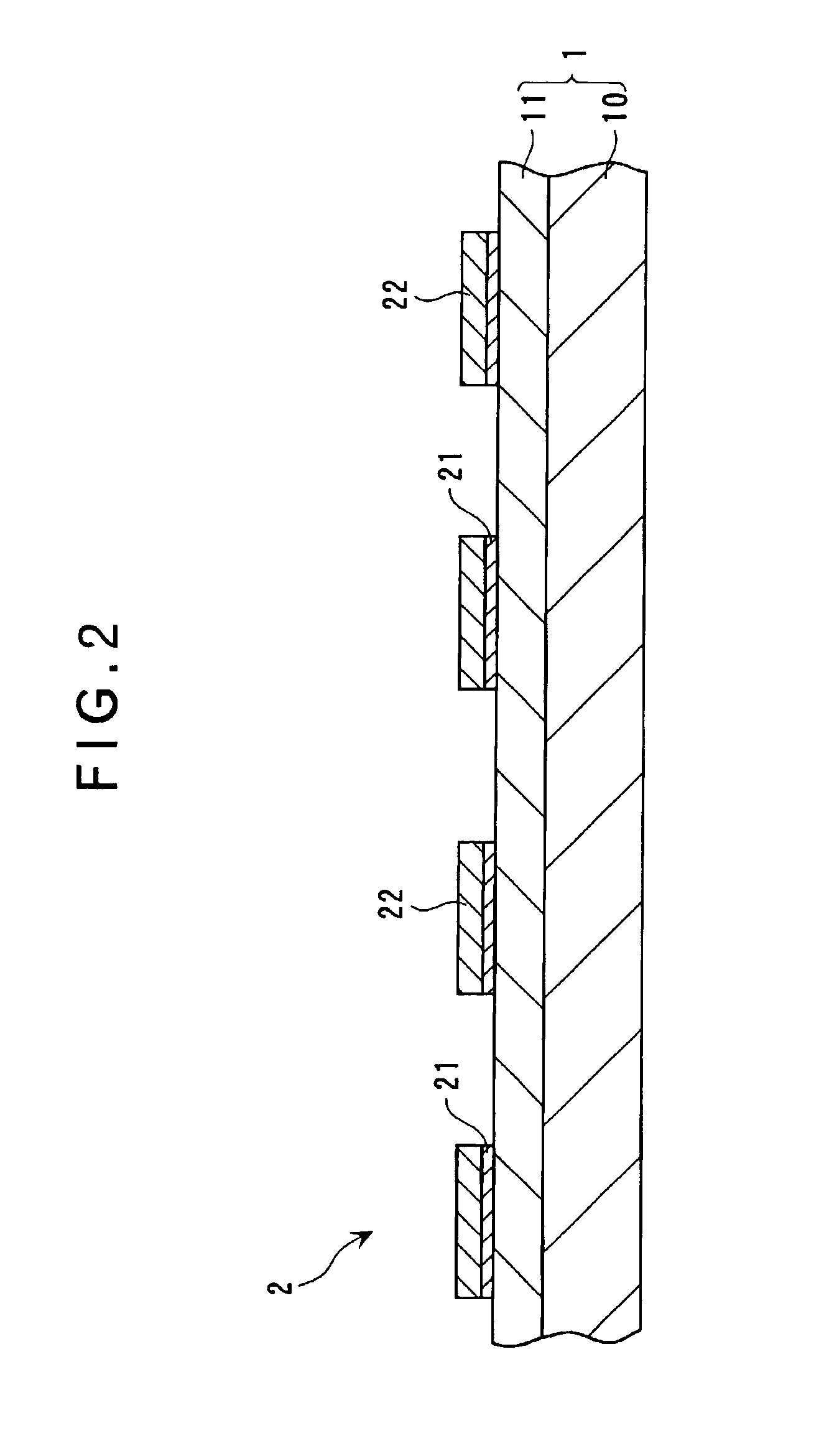

Hard-coated member, and its production method

ActiveUS20100215912A1Improve adhesionReduce coatingVacuum evaporation coatingSputtering coatingX-rayMaterials science

The hard-coated member of the present invention having a compression-stress-loaded hard coating having a thickness of 5 μm or more, the hard coating having a face-centered cubic structure having a composition represented by (Me1-aXa)α(N1-x-yCxOy), wherein Me is at least one element selected from Groups 4a, 5a and 6a, X is at least one element selected from the group consisting of Al, Si, B and S, a, x and y are respectively the contents (atomic ratios) of X, C and O, and α is a ratio of (Me1-aXa) to (N1-x-yCxOy), meeting 0.1≦a≦0.65, 0≦x≦0.1, 0≦y≦0.1, and 0.85≦α≦1.25; and the X-ray diffraction of the hard coating having a peak intensity Ir of a (111) plane, a peak intensity Is of a (200) plane, and a peak intensity It of a (220) plane, meeting 2≦Is / Ir, and 0.2≦It / Ir≦1, and the (200) plane having a half-value W(°)≦0.7.

Owner:HITACHI TOOL ENG LTD

Deformable pull plug

InactiveUS20040056039A1Efficient use ofGood lookingClosure using stoppersSpraying apparatusEngineeringScrew thread

A reusable pull plug for masking part openings in parts to be coated or otherwise worked upon. The pull plug has particular utility in masking irregular surface portions about the part opening including, without limitation threaded, chamfered, stepped and spot faced surfaces. The pull plug is comprised of a deformable, segmented body including plug, transition and tail body segments. A flange and void volume, or "dimple," are formed in one plug body end adjacent the plug segment. The pull plug is pulled into the part opening by the tail segment and the plug segment forms a frictional fit with the deformable body tightly sealing the part opening. The flange covers the first thread in threaded part openings and further covers chamfered, stepped and spot faced surfaces protecting those surfaces from contact by the coating or other materials. The void volume facilitates deformation of the flange and plug segment permitting the flange to conform to the surface about the part opening and permitting the pull plug to be withdrawn through the part opening in the same direction as inserted thereby avoiding damage to the applied coating material. The novel design reduces stresses on the pull plug and enables the plug to be reused through repeated coating or operation cycles.

Owner:ENGINEERED PRODS & SERVICES

Method for repairing coated components

According to an embodiment of the invention, a method for repairing a coated high pressure turbine blade, which has been exposed to engine operation, to restore coated airfoil contour dimensions of the blade, is disclosed. The method comprises providing an engine run high pressure turbine blade including a base metal substrate made of a nickel-based alloy and having thereon a thermal barrier coating system. The thermal barrier coating system comprises a diffusion bond coat on the base metal substrate and a top ceramic thermal barrier coating comprising a yttria stabilized zirconia material. The top ceramic thermal barrier coating has a nominal thickness t. The method further comprises removing the thermal barrier coating system, wherein a portion of the base metal substrate also is removed, and determining the thickness of the base metal substrate removed. The portion of the base metal substrate removed has a thickness, Δt. The method also comprises reapplying the diffusion bond coat to the substrate, wherein the bond coat is reapplied to a thickness, which is about the same as applied prior to the engine operation; and reapplying the top ceramic thermal barrier coating to a nominal thickness of t+Δt, wherein Δt compensates for the portion of removed base metal substrate. Advantageously, the coated airfoil contour dimensions of the high pressure turbine blade are restored to about the coated dimensions preceding the engine run.

Owner:GENERAL ELECTRIC CO

Polyolefin-based sheet, display sheet comprising the same, package sheet, transparent recording sheet, cosmetic sheet, emblem sheet, decorative sheet, and coating material for polyolefin resin for use in these

InactiveUS6852407B2Adhesiveness is impairedHigh mechanical strengthLamination ancillary operationsLayered product treatmentPolyolefinAcrylic resin

A polyolefin-based sheet having a coating layer, which improves printability and does not impair adhesion, wherein the coating layer is one formed from a coating material comprising a water-soluble acrylic resin and polyalkylenimine.

Owner:IDEMITSU KOSAN CO LTD

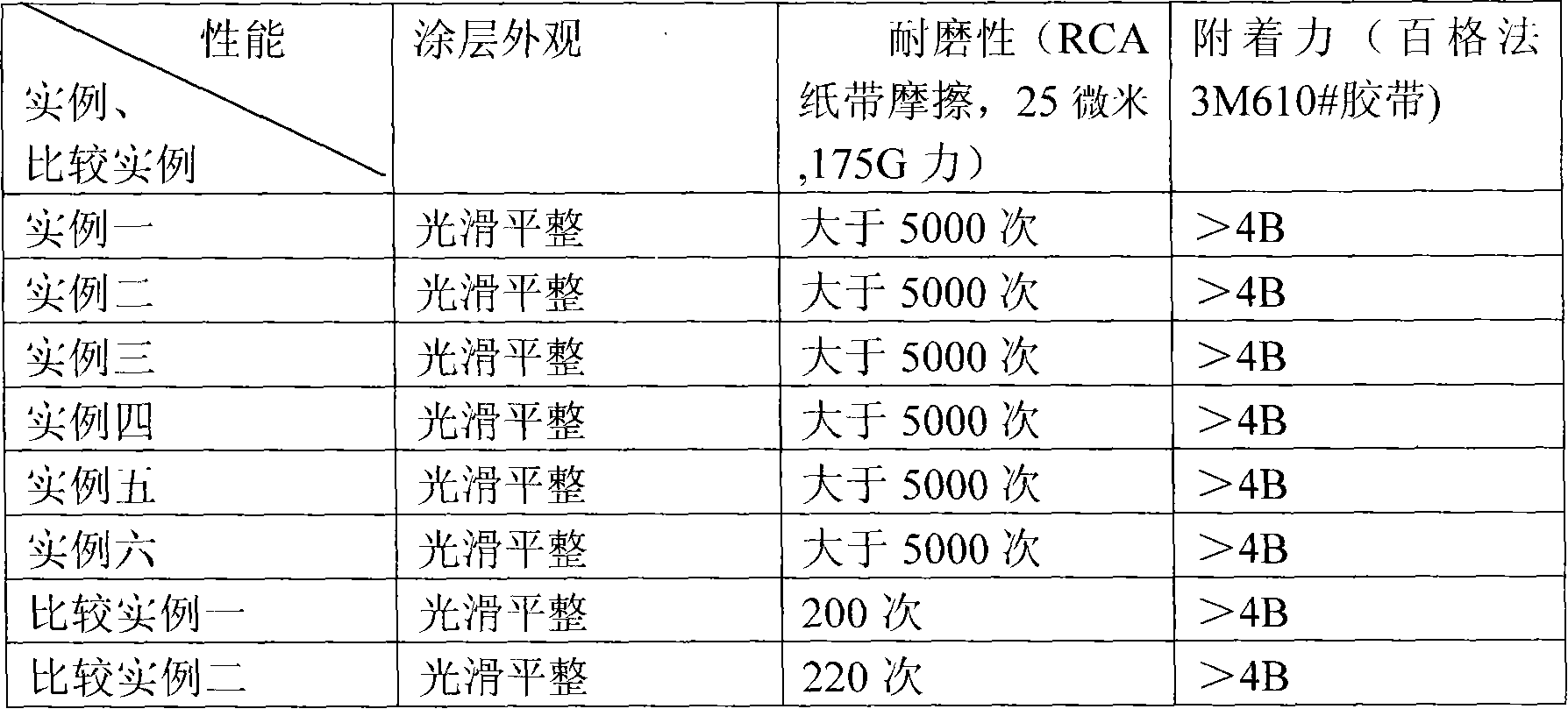

High abrasion-proof PU printing ink for silicon rubber surface

The present invention belongs to the field of ink, and in particular relates to highly wear-resistant PU ink for silicone rubber surface. The raw materials comprise hydroxyl-terminated polyurethane resin, curing agent, and mixed solvent. Moreover, the raw materials still comprise wear-resistant additives. The wear-resistant additives can be one of or the mixture of a plurality of polytetrafluoroethylene, polypropylene, polyethylene, polyethylene oxide, zinc oxide, alumina oxide, iron oxide, zirconium oxide, magnesium oxide, calcium carbonate, talc, silica aluminum, and magnesium silicate. With the proposal of the present invention, the suitable polyhydroxylated PU resin, curing agents and filler are used to prepare PU ink for silicone rubber of convenient construction, reduction of priming payer of middle coating, good adhesion and excellent wear resistance.

Owner:东莞市贝特利新材料有限公司

Coating for Improved Carbon Nanotube Conductivity

ActiveUS20110059317A1Great fiber fiber contactSuperior electrical propertySynthetic resin layered productsNon-conductive material with dispersed conductive materialCarbon nanotubePolymer coating

We discovered that the use of certain dopants or dopant moieties in polymeric coating formulations, that when applied over carbon nanotubes, unexpectedly decrease the measured electrical resistance of the coated carbon nanotubes (CNTs), when measured through the coating, even though the polymer coatings themselves do not have bulk conductivity. CNT compositions with enhanced electrical conductivity and methods of making such compositions are described. The CNTs are preferably coated with a dopant or dopant moiety having a HOMO energy of −7.0 eV or lower.

Owner:BATTELLE MEMORIAL INST

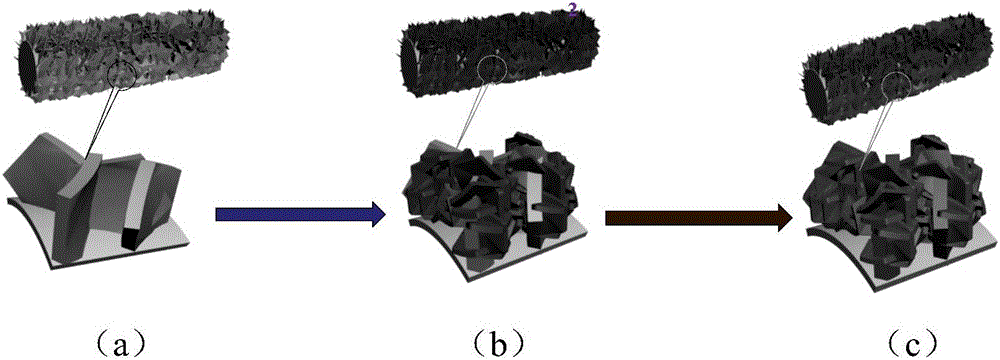

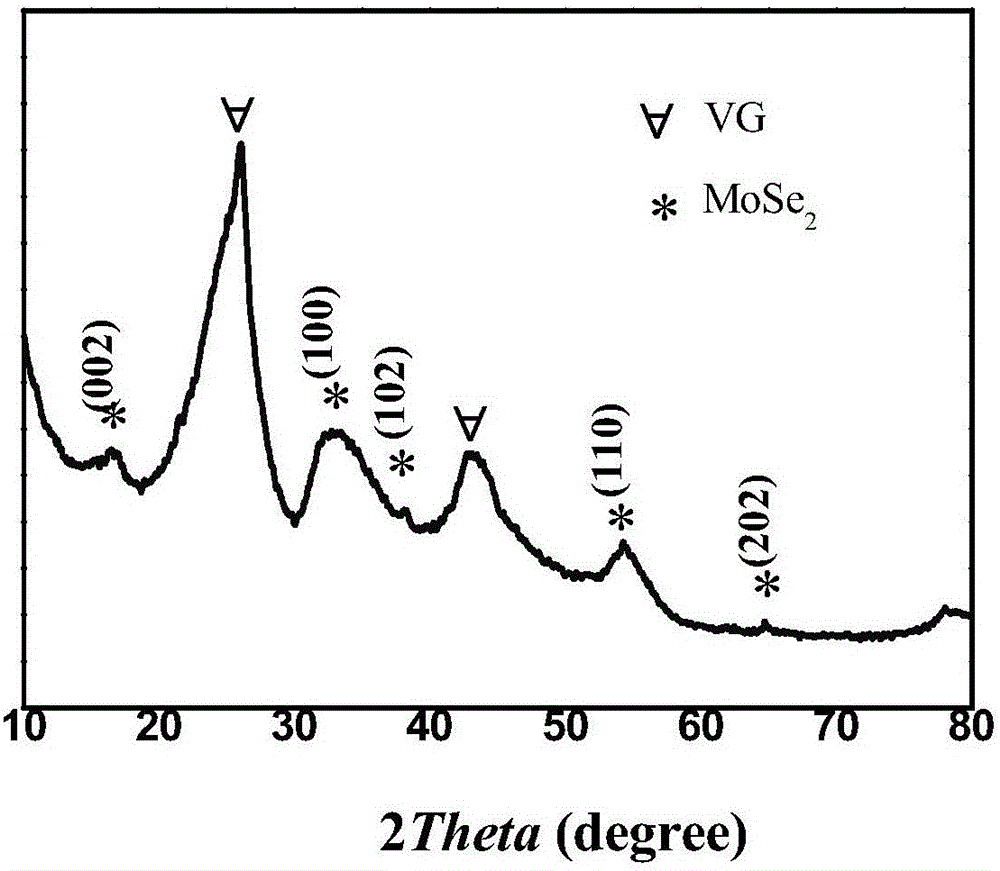

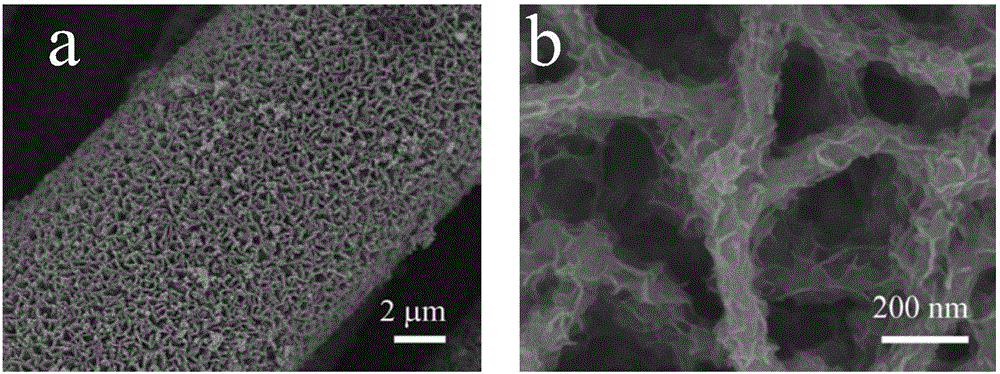

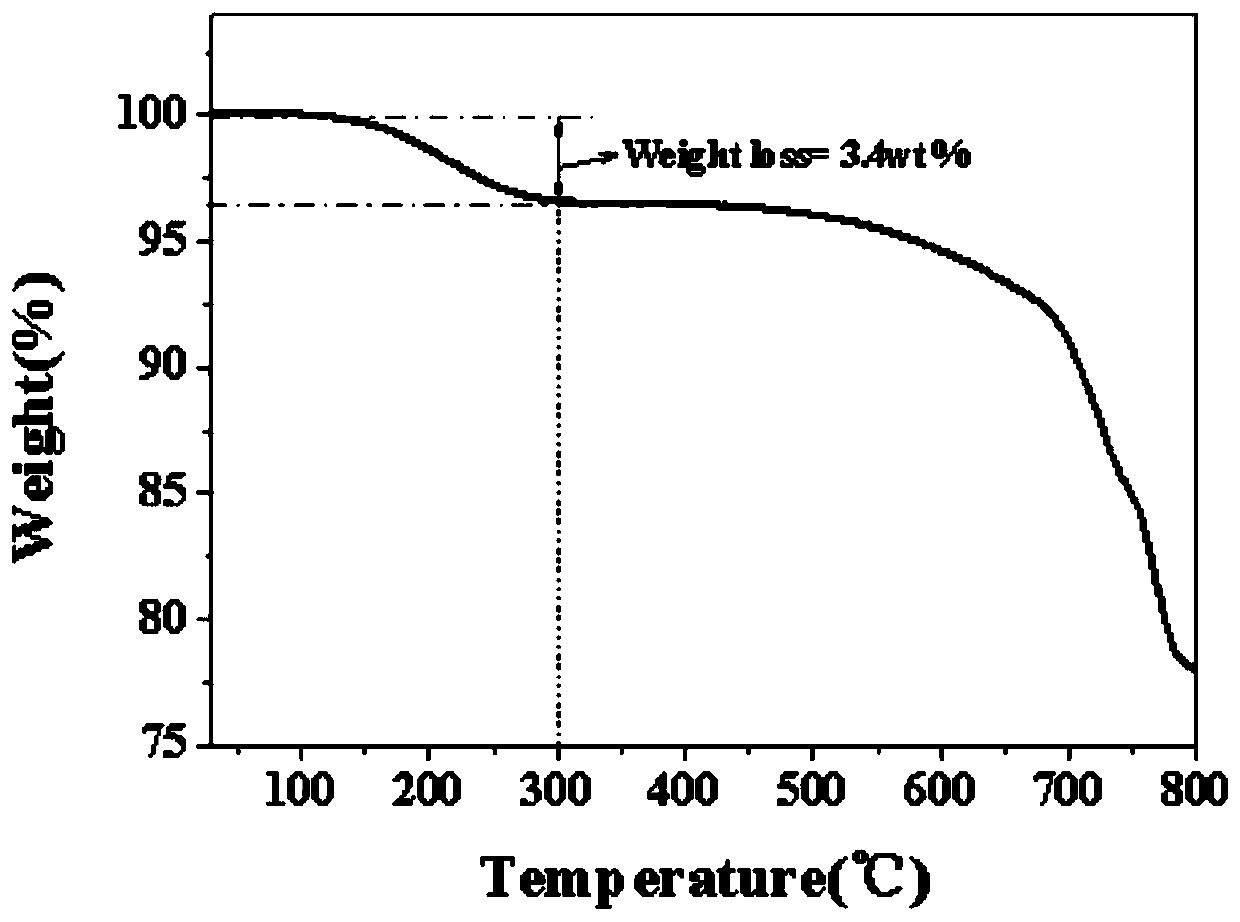

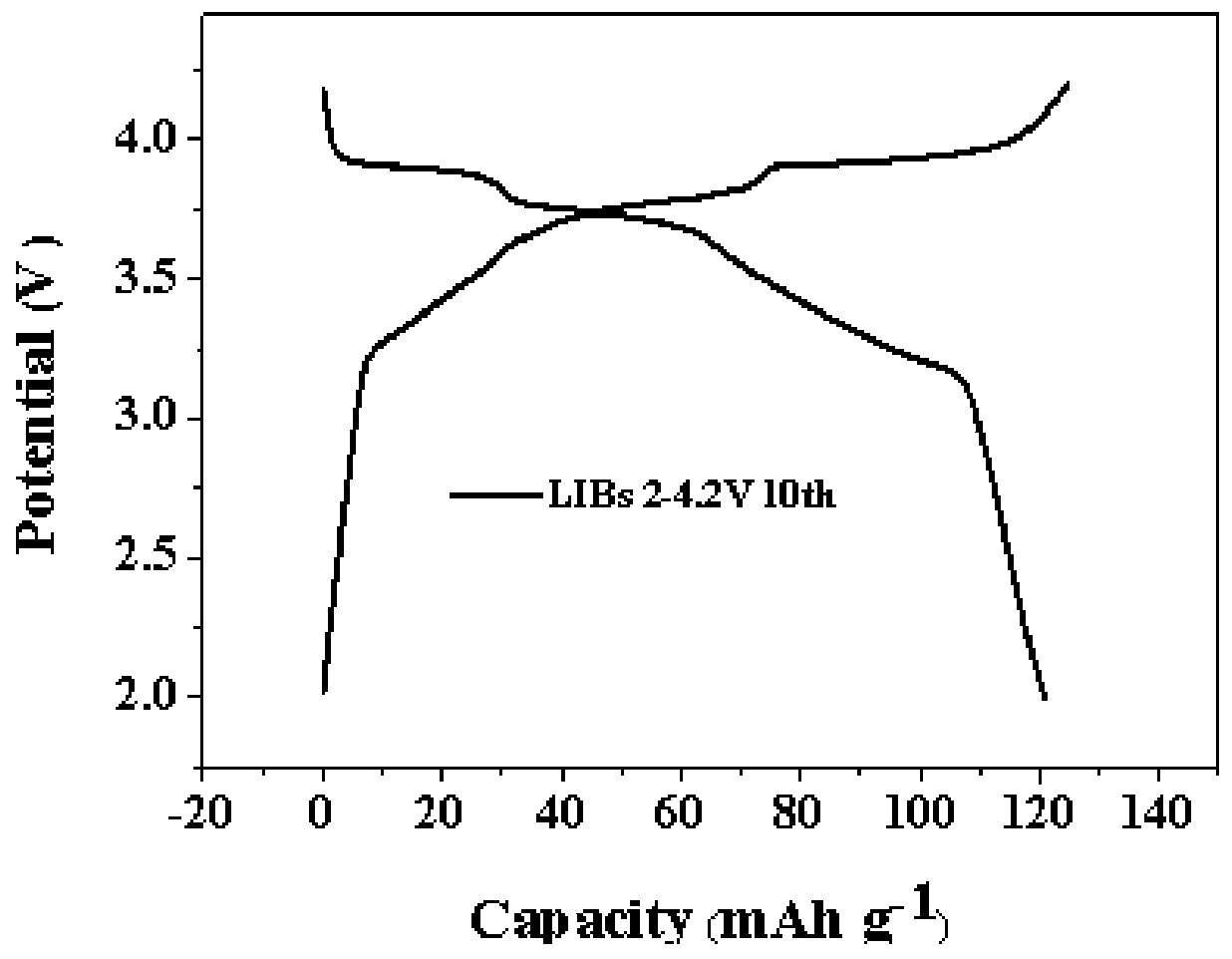

Nitrogen-doped carbon-coated molybdenum selenide/graphene core-shell array sandwich structure composite material, preparation method and application thereof

ActiveCN105914374AHigh reversible capacityImproved magnification performanceCell electrodesWater bathsCharge discharge

The invention discloses a nitrogen-doped carbon-coated molybdenum selenide / graphene core-shell array sandwich structure composite material, a preparation method and application thereof. The method includes: dissolving selenium powder in hydrazine hydrate to form a solution A; dissolving a sodium molybdate dehydrate solution in water to form a solution B; mixing the solutions to form a reaction solution, placing a vertical grapheme collector electrode material growing on a carbon cloth in the reaction solution to carry out hydrothermal reaction, and then conducting washing and drying to obtain a VG-MoSe2 core-shell array structure; dissolving dopamine hydrochloride in water, then soaking the VG-MoSe2 core-shell array structure in the dopamine hydrochloride aqueous solution, carrying out water bath polymerization, and performing washing drying; and carbonizing the dopamine polymerized core-shell array structure under high temperature condition in protective atmosphere, thus obtaining the nitrogen-doped carbon-coated molybdenum selenide / graphene core-shell array sandwich structure composite material. When used as a sodium ion negative electrode material, the constructed composite material has high reversible charge-discharge capacity, long cycle life and excellent rate performance.

Owner:ZHEJIANG UNIV

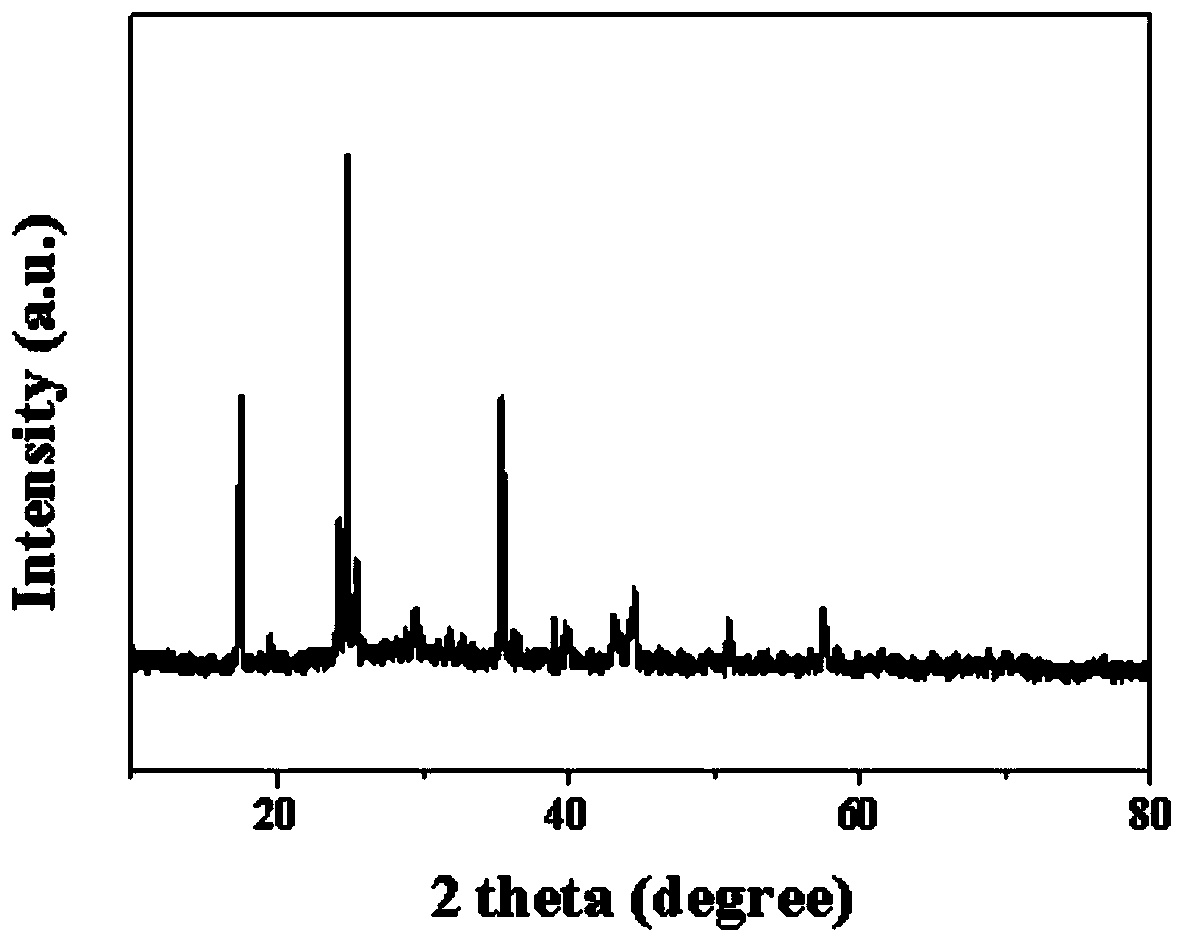

Prussian white analog cathode material and preparation method and application thereof

ActiveCN110002465AImprove crystal structureReduce defectsIron cyanidesSecondary cellsNew energyAqueous solution

The invention belongs to the field of new-energy batteries, and particularly relates to a Prussian white analog cathode material and a preparation method and application thereof. The preparation method of the Prussian white analog cathode material comprises the following steps: (1), acquiring an aqueous solution of K4Fe (CN)6, which is recorded as a solution A; (2), acquiring a mixed aqueous solution of a transition metal salt of Mn and potassium citrate, which is recorded as a solution B; and (3), dropwise adding the solution A into the solution B, continuing heating and stirring after completion of dropwise addition, aging for several hours, performing solid-liquid separation, collecting and washing a precipitate, and drying to obtain the Prussian white analog cathode material. The Prussian white analog cathode material adopts an open three-dimensional network frame structure, has a large gap position, and can guarantee free deintercalation of various ions such as Li<+>, Na<+> and K<+>.

Owner:HUAZHONG UNIV OF SCI & TECH

Hybrid power driving system and gear position operation method thereof

ActiveUS8475311B2Reduce rateIncrease torqueHybrid vehiclesToothed gearingsCouplingInternal combustion engine

A hybrid power driving system for a vehicle comprises an internal-combustion engine, a first electric motor, a second electric motor, a planetary coupling mechanism, a speed-reduction mechanism and a differential mechanism. An output shaft of the internal-combustion engine is connected with an input shaft of the first electric motor, and an output shaft of the first electric motor is connected with an output shaft of the second electric motor via a first clutch. The output shaft of the second electric motor is connected with one of a sun gear and a ring gear of the planetary coupling mechanism at a position of the output shaft along its axial direction. And the output shaft of the second electric motor is connected with the other one of a sun gear and a ring gear at another position of the output shaft along the axial direction via a second clutch.

Owner:BYD CO LTD

Method for repairing coated components using NiAl bond coats

InactiveUS7094444B2Guaranteed uptimeProlong lifeMolten spray coatingEngine manufactureBond coatingAlloy

Owner:GENERAL ELECTRIC CO

Negative-working imageable elements with improved abrasion resistance

InactiveUS8043787B2Increase resistanceReduce viscosityPhotosensitive materialsDuplicating/marking methodsSilica particleWear resistance

Owner:EASTMAN KODAK CO

Turbocharger with divided turbine housing and annular rotary bypass valve for the turbine

ActiveCN102536434AImprove controllabilityReduce coatingEngine manufactureInternal combustion piston enginesImpellerTurbine wheel

The invention provides a turbocharger with a divided turbine housing and an annular rotary bypass valve for a turbine. The turbocharger includes a turbine wheel mounted within a turbine housing and connected to a compressor wheel by a shaft. The turbine housing defines an exhaust gas inlet connected to a divided volute that surrounds the turbine wheel, and an axial bore through which exhaust gas that has passed through the turbine wheel is discharged from the turbine housing. The turbine housing further defines a pair of concentric annular bypass passages surrounding the bore and arranged to allow exhaust gas to bypass the turbine wheel as two separate bypass streams. An annular bypass valve is disposed in the bypass passage. The bypass valve comprises a fixed annular valve seat and a rotary annular valve member arranged coaxially with the valve seat. The valve member is disposed against the valve seat and is rotatable about the axis for selectively varying a degree of alignment between respective orifices in the valve seat and valve member.

Owner:GARRETT MOTION TECH (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com