High abrasion-proof PU printing ink for silicon rubber surface

A technology of silicone rubber and ink, applied in the field of ink, can solve the problems of weak adhesion, poor ink wear resistance, inconvenient construction, etc., and achieve the effect of good adhesion, convenient construction, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

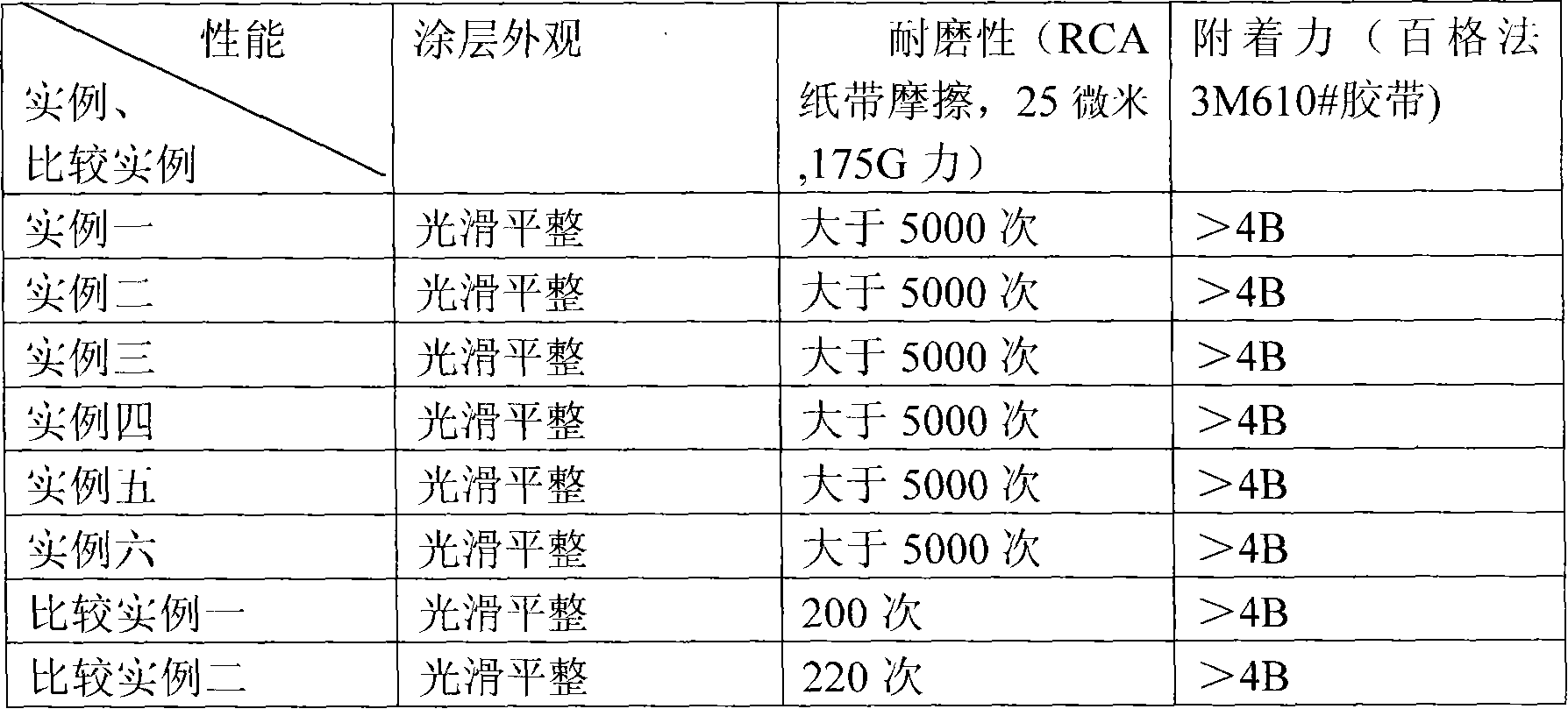

[0013] The present invention will be further described below in conjunction with specific examples.

[0014] Each embodiment raw material and percentage by weight are shown in the table below:

[0015]

components

Example one

Example two

Example three

Example four

Example five

Example six

Compare

Example one

Compare

Example two

Hydroxy Polyurethane Tree

Lipid (hydroxyl value

50MMOL / MG)

135

135

140

140

200

300

135

140

blocked diisocyanate

ester trimer

70

70

0

0

100

0

70

0

diisocyanate

0

0

55

60

0

200

0

60

Zinc oxide

3

0

0

2

0

0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com