Prussian white analog cathode material and preparation method and application thereof

A cathode material, Prussian white technology, applied in the field of Prussian white analog cathode materials, can solve problems such as defects, low water content, poor electrochemical performance, etc., achieve a perfect crystal structure, facilitate large-scale industrial production, and large particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of a kind of Prussian white analog cathode material provided by the present invention, the chemical formula of this cathode material is K x Mn[Fe(CN) 6 ] 1-y □ y .nH 2 O, where 0≤x≤2, 0≤y≤1, □ is [Fe(CN) 6 ] vacancies; the preparation method of the positive electrode material comprises the following steps:

[0040] (1) Get K 4 Fe(CN) 6 The aqueous solution, denoted as solution A;

[0041] (2) Obtain the mixed aqueous solution of the transition metal salt of Mn and potassium citrate, denoted as solution B;

[0042] (3) Add the solution A dropwise to the solution B, continue to heat and stir after the dropwise addition, and age for several hours, separate the solid from the liquid, collect and wash the precipitate, and dry to obtain the positive electrode of the Prussian white analog Material.

[0043] In some embodiments, the Mn transition metal salt is one or more of Mn chloride, sulfate, carbonate, nitrate and acetate.

[0044] In some ...

Embodiment 1

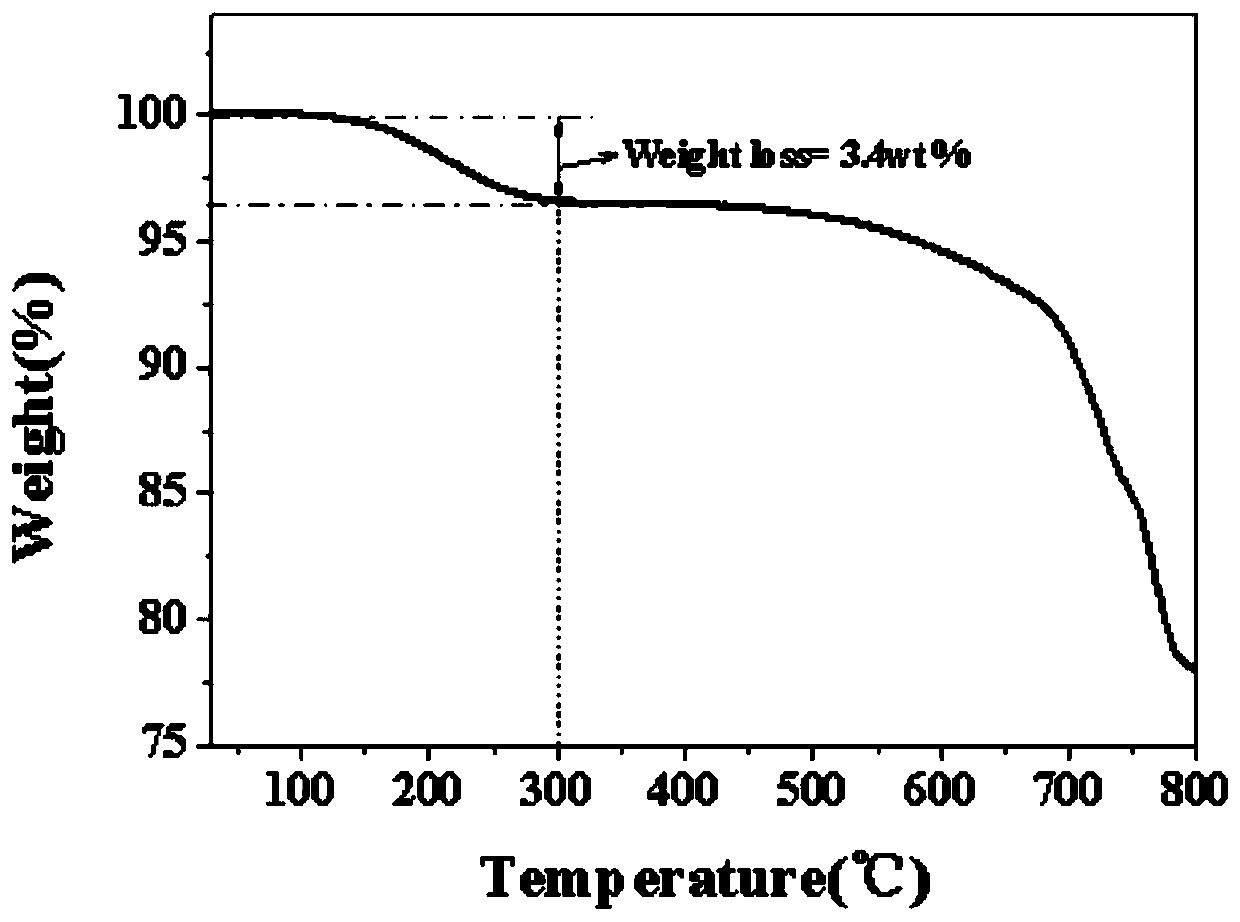

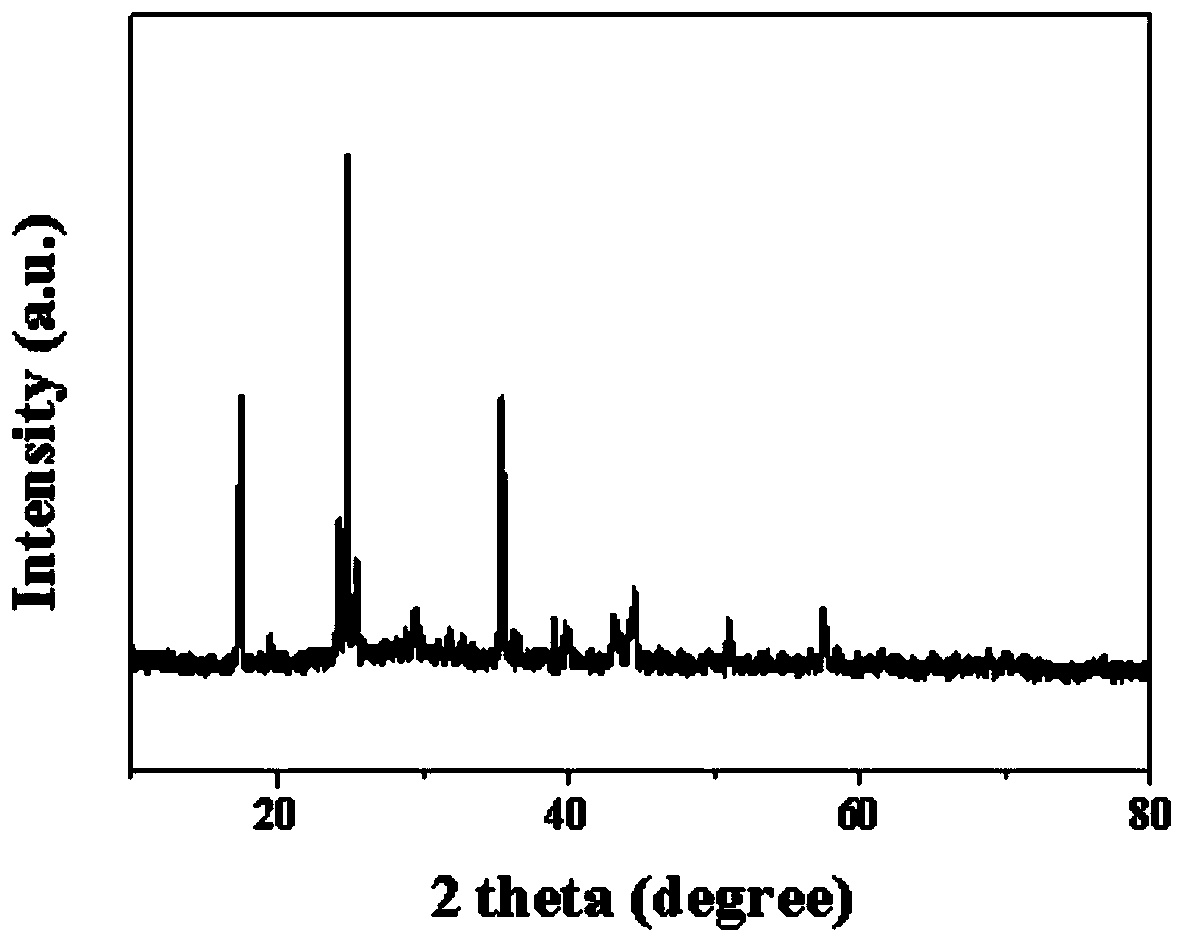

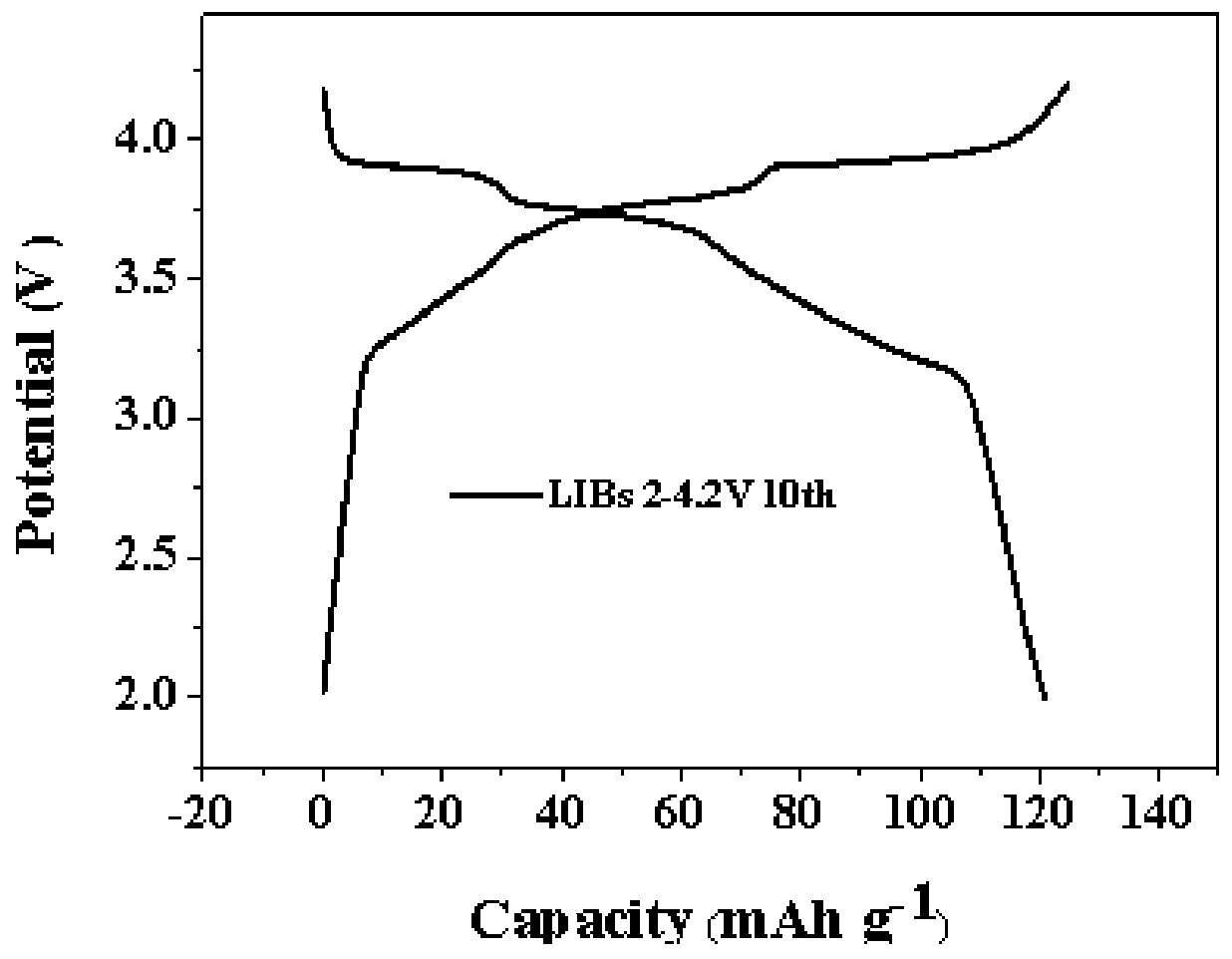

[0059] A kind of Prussian white analog cathode material, the chemical formula of this cathode material is expressed as K x Mn[Fe(CN) 6 ] 1-y □ y ·nH 2 O, where 0≤x≤2, 0≤y≤1, □ is [Fe(CN) 6 ] vacancies; the crystal water content of the material is 3.39 wt%. The preparation method of this cathode material comprises the steps:

[0060] 1) Weigh 4mmol of K 4 Fe(CN) 6 , dispersed in 200mL deionized water, stirred to form a uniform solution A;

[0061] 2) Weigh 6mmol of MnSO 4 and 15g of potassium citrate, dispersed in 200mL deionized water, stirred to form a uniform solution B;

[0062] 3) Use a peristaltic pump to add solution A to solution B at a rate of 5 mL / min, heat and stir at 60°C for 24 hours, and after aging for 20 hours, separate the precipitate from the product through a high-speed centrifuge, and use deionized water and ethanol for 3 times, and then vacuum-dried at a pressure of 20kPa and a temperature of 100°C for 24h to obtain the Prussian white analog catho...

Embodiment 2

[0065] A kind of Prussian white analog cathode material, the chemical formula of this cathode material is expressed as K x Mn[Fe(CN) 6 ] 1-y □ y ·nH 2 O, where 0≤x≤2, 0≤y≤1, □ is [Fe(CN) 6 ] vacancies; the crystal water content of this material is 3.54wt%, and the defect content is 10%, that is, y=0.1, and the molecular formula is K 1.82 Mn[Fe(CN) 6 ] 0.90 □ 0.1 .nH 2 O. The preparation method of this cathode material comprises the steps:

[0066] 1) Weigh 4mmol of K 4 Fe(CN) 6 , dispersed in 200mL deionized water, stirred to form a uniform solution A;

[0067] 2) Weigh 6mmol of MnSO 4 and 25g of potassium citrate, dispersed in 200mL of deionized water, stirred to form a uniform solution B;

[0068] 3) Use a peristaltic pump to add solution A to solution B at a rate of 5 mL / min, heat and stir at 60°C for 24 hours, and after aging for 15 hours, separate the precipitate from the product through a high-speed centrifuge, and use deionized water and ethanol for 3 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com