Electromagnetic brake

A technology of electromagnetic brakes and brakes, applied in the direction of brake types, axial brakes, gear transmission mechanisms, etc., can solve the problems of small braking torque, reduce equipment cost, disadvantages, etc., achieve large braking torque, simple structure, reduce The effect of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

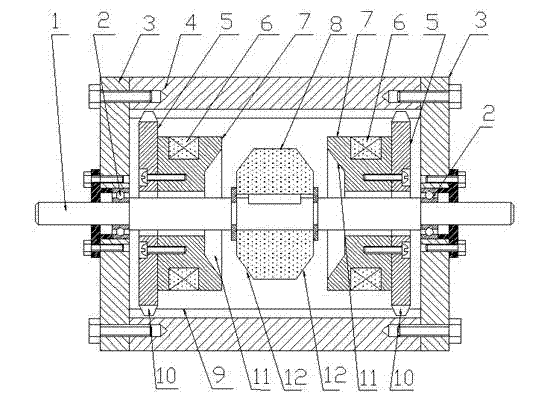

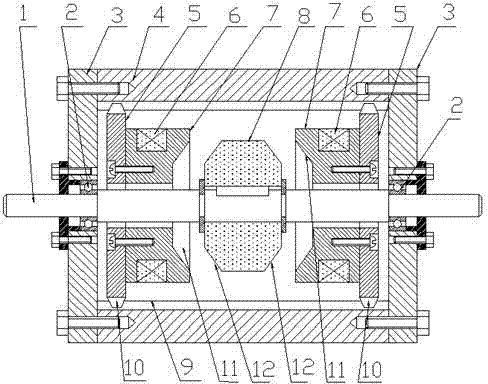

[0009] An electromagnetic brake, which includes: brake shaft 1, bearing 2, end cover 3, brake body 3, guide ring 4, electromagnetic coil 5, electromagnet core 6, brake wheel 7, the middle of the brake body 4 has a straight The round hole is formed with internal spline teeth 9 on the surface of the inner round hole of the brake body 4, and an end cover 3 is installed and fixed at the mouths at both ends of the brake body 4, and the brake shaft passes through two bearings 2 and the ends on the left and right sides. The cover 3 is installed and fixed, and the brake wheel 8 is installed and fixed in the middle of the brake shaft 1. A guide ring 5 is respectively arranged in the inner hole of the brake body 4 on both sides of the brake wheel 8, and the guide ring 5 is annular. The outer spline teeth 10 are formed on the outer circle of the guide ring 5, and the guide ring 5 is installed together by cooperating with the inner spline teeth 9 in the inner hole of the brake body 4 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com