Vehicle gap adjustable conical brake device

A technology of brake device and clearance, applied in the direction of brake type, hydraulic brake, brake actuator, etc., can solve the problems of complex brake structure, frequent replacement, and fast wear of friction plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

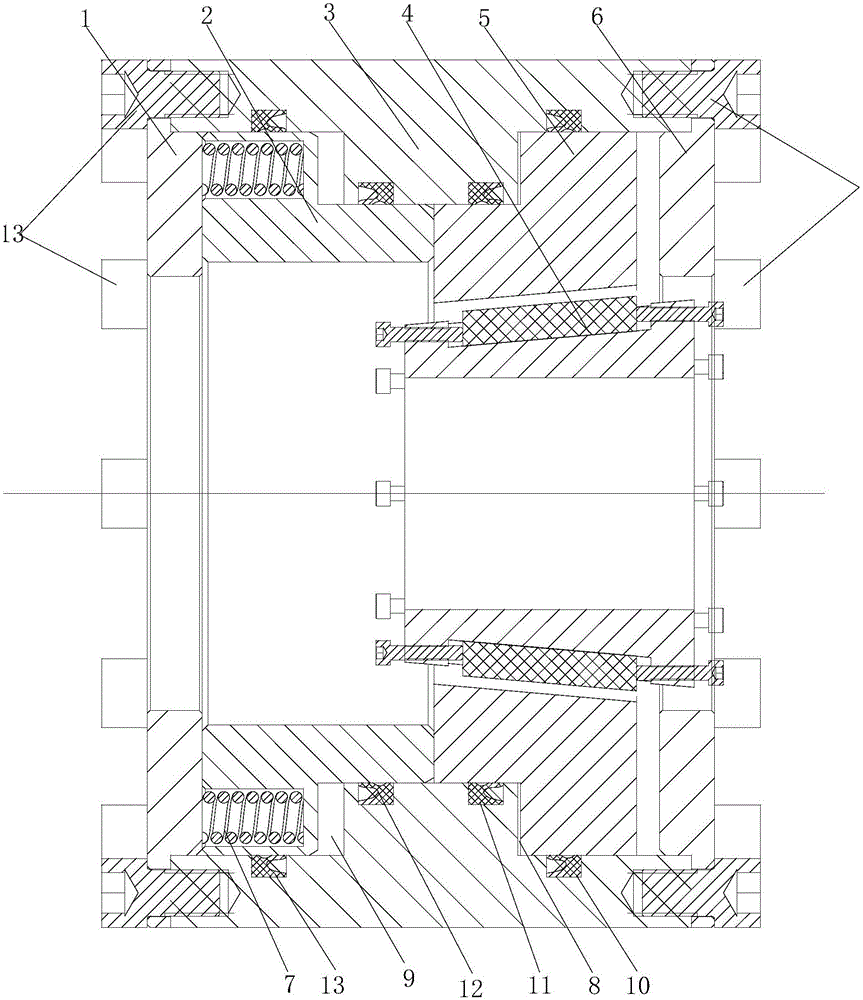

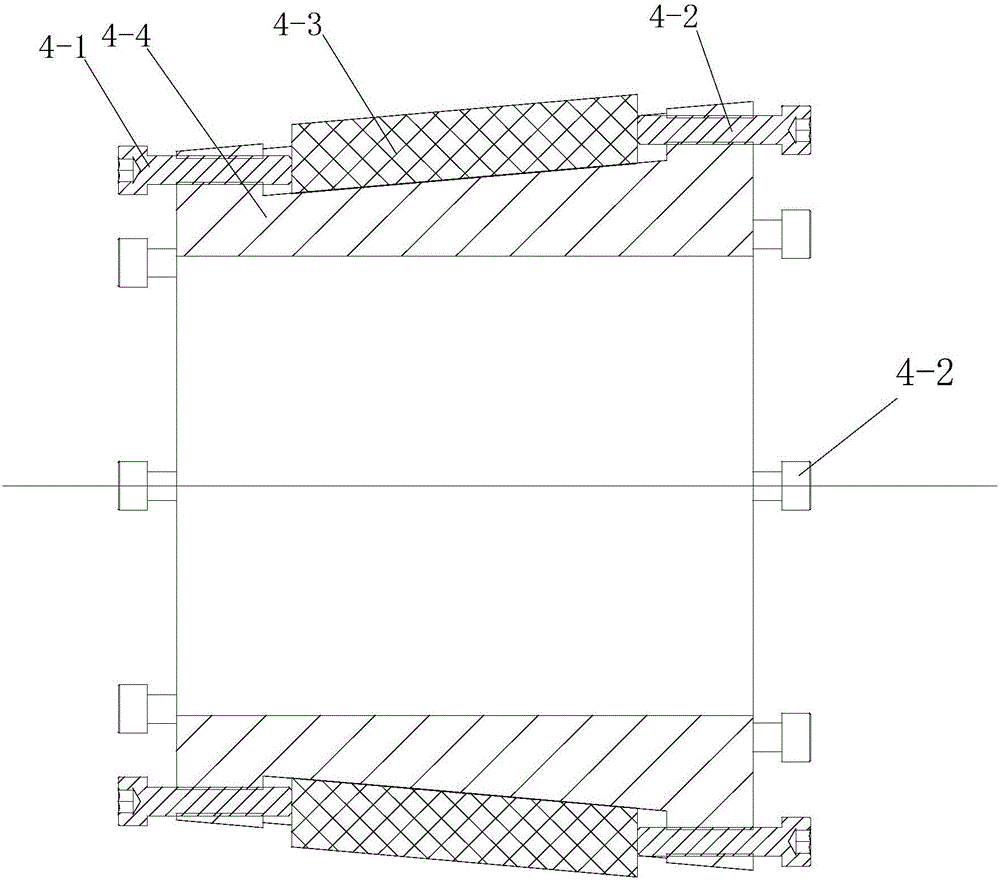

[0023] The gap-adjustable conical braking device for vehicles of this embodiment has a structure such as figure 1 and figure 2 As shown, it includes a cylinder 3, the cylinder 3 has a first port and a second port, the first port is provided with a parking end cap 1, and the second port is provided with a driving end cap 6, so the parking end cap 1, the driving end The cover 6 is respectively fixed to both ends of the barrel 3 by twelve bolts 13 arranged along its circumference. The parking end cap 1, the driving end cap 6 and the cylinder body 3 form a chamber, in which the relative parking piston 2 and driving piston 5 are arranged, wherein the parking piston 1 and the driving piston 5 both include a piston body And the annular boss located at one end of the piston main body, the annular boss of the parking piston 1 is set in the first annular gap formed by the edge part of the parking end cover 1 and the annular protrusion, and the annular boss of the parking piston 2 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com