Braking device for vehicle

A braking device and vehicle technology, applied in the field of vehicles, can solve the problems of difficulty in the allocation of design space, short replacement cycle, and high requirements for machining accuracy of parts, so as to save frame space, save maintenance costs, and save vehicle layout. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

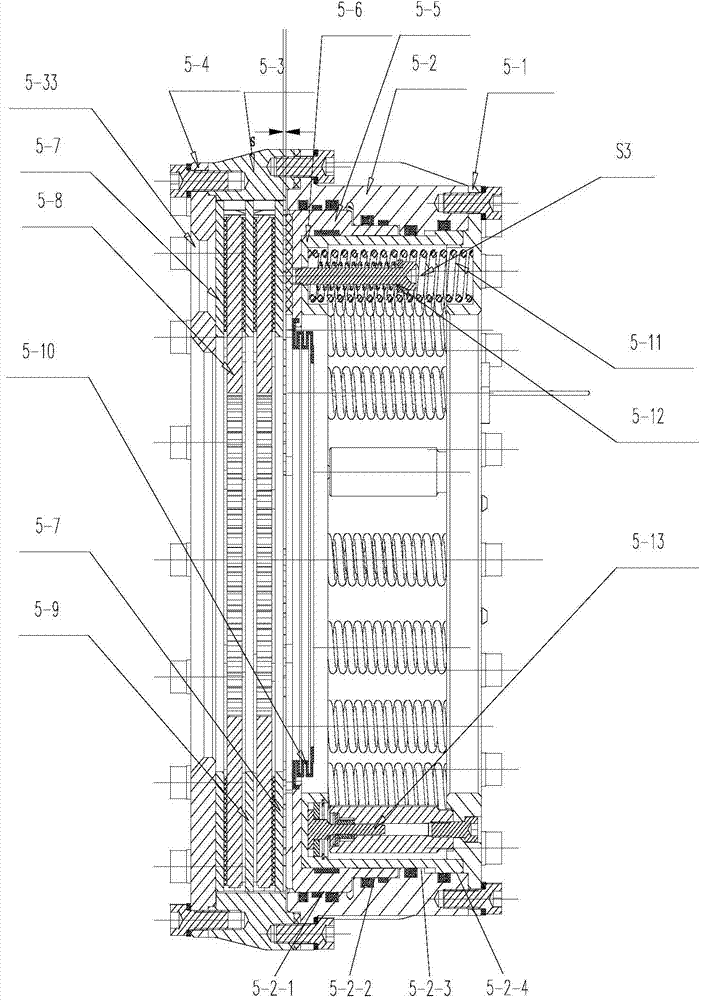

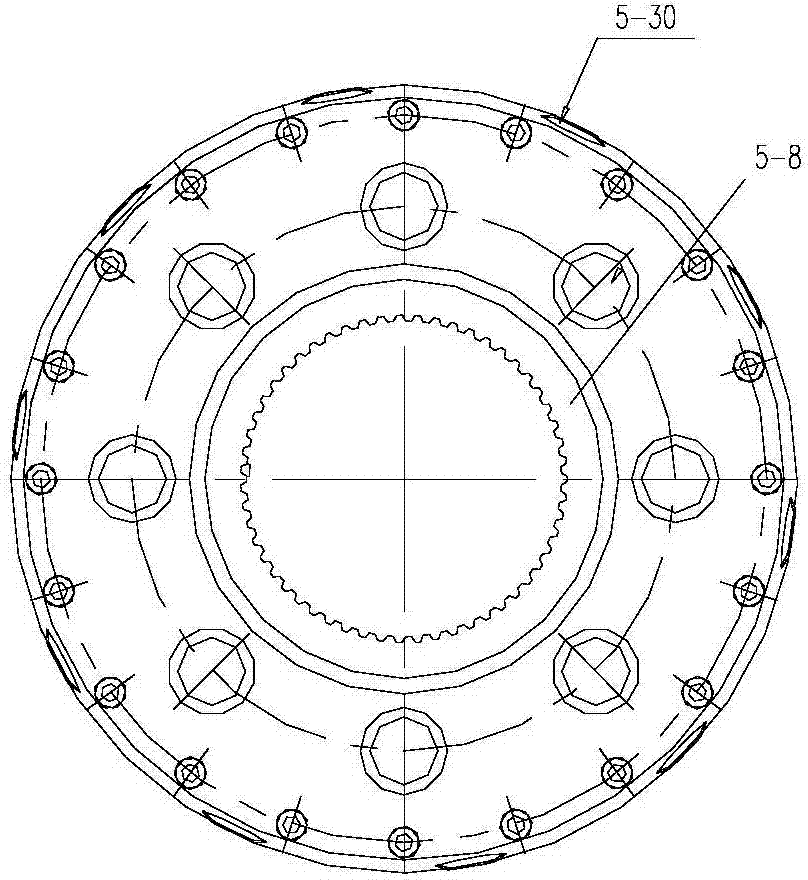

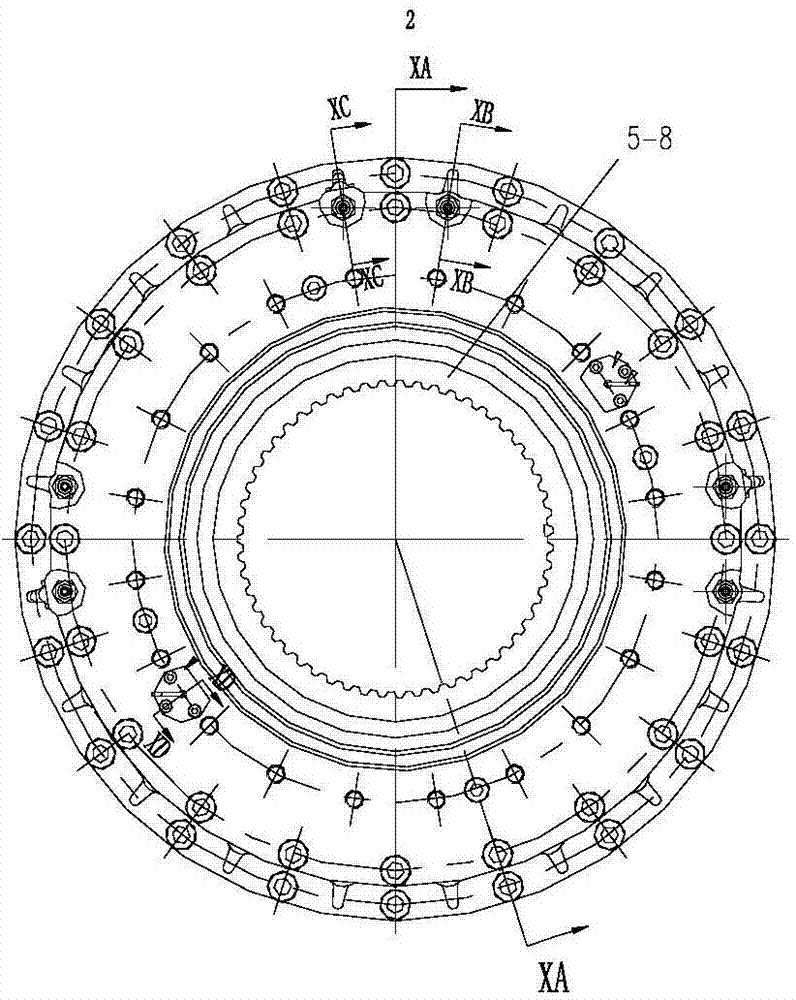

[0020] The vehicle braking device of this embodiment is as figure 1 , 2 , 3, including a group of three outer circles distributed at intervals and the inner hole of the circular intermediate body 5-3 constrained by the spline structure in the circumferential direction and axially constitute the friction plates 5-7, 5-9 of the moving pair, wherein 5-7 are single-sided friction plates with friction layers located inside both ends, and 5-9 are double-sided friction plates with friction layers located on both sides in the middle. A brake disc 5-8 is installed between adjacent friction plates, the inner hole of the brake disc 5-8 and the power output shaft are constrained in the circumferential direction by the inner spline and constitutes a moving pair in the axial direction, and the friction plate and the brake disc form a friction vice. One end of the friction pair is installed with a friction plate end cover 5-4 fixedly connected with the intermediate body 5-3, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com