Novel ground polisher structure

A polishing machine and floor technology, which is applied to surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding workpiece planes, etc., can solve the problems of labor stress and heavy labor, and meet the requirements of leveling and polishing the ground 、To overcome the effect of labor stress and labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

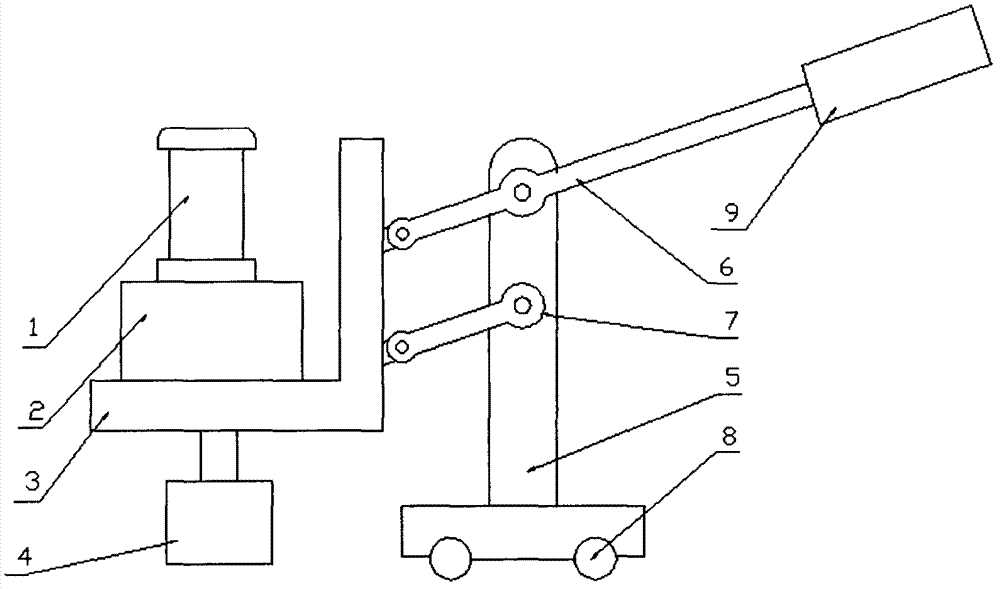

[0010] Wheel 8 is installed on the bottom of vehicle frame 5 to ensure that under the action of external force, wheel 8 can drive vehicle frame 5 to walk freely, and the parts of L-shaped frame 3, short connecting rod 6, long connecting rod 7 and vehicle frame The parts of 5 are hinged with each other to form a parallelogram mechanism, and the handle 9 is set at the end of the long connecting rod 7 at the right part of the vehicle frame 5, and the gear box 2 is installed and fixed on the horizontal position of the L-shaped frame 3, and the motor 1 and the gear box 2 The structural form of installation and combination, the grinding head 4 is installed and fixed on the output shaft of the gear box 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com