Spindle drive

A drive and spindle technology, applied in the field of door cover components, can solve the problems of expensive structure and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

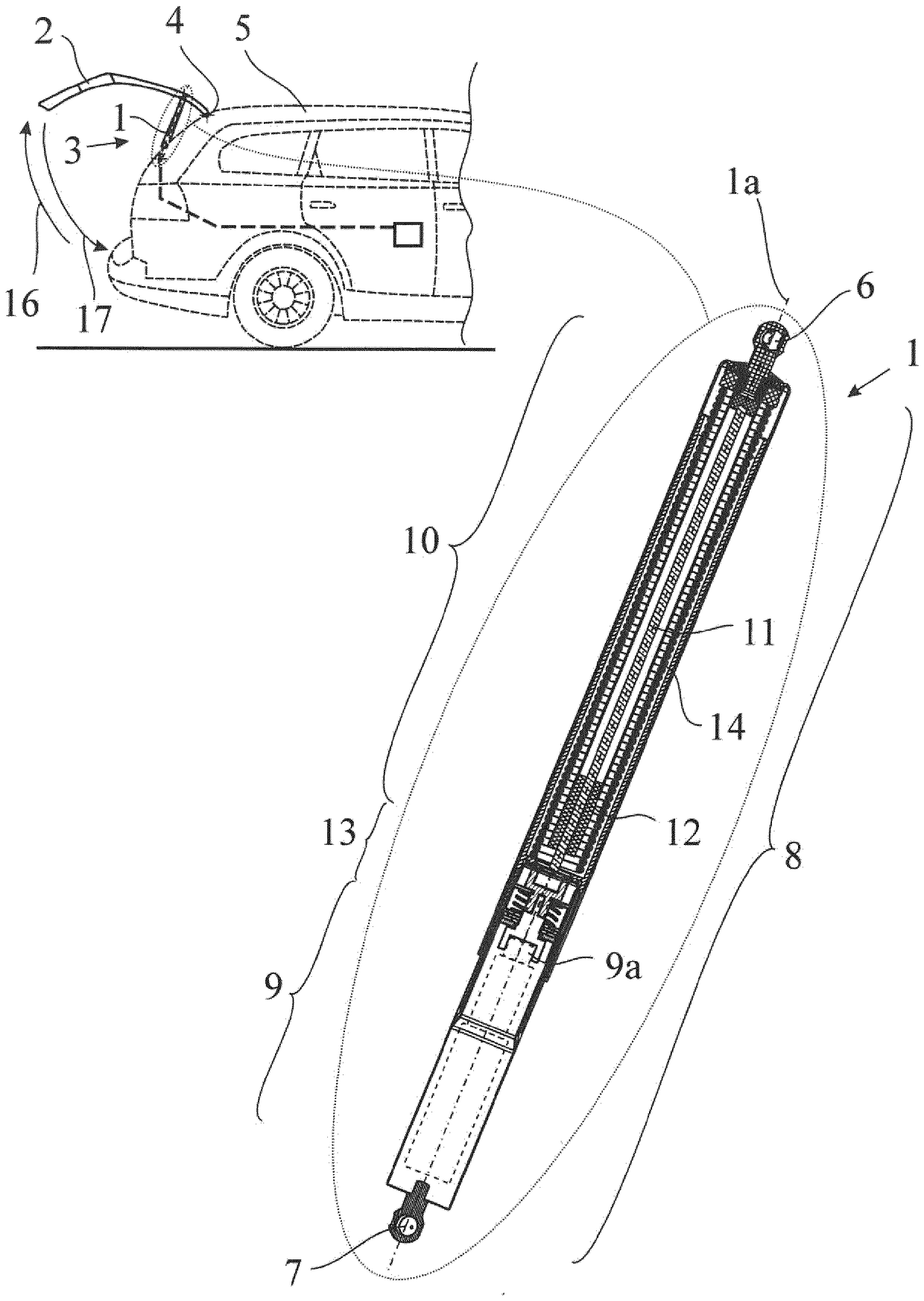

[0029] The spindle drive 1 shown in the drawing is used for the motorized adjustment of a door flap 2 of a motor vehicle, which is designed here as a tailgate. See above for a broad explanation of the concept "door cover".

[0030] In a manner conventional per se, the door cover 2 serves to close the door cover opening 3 . Here, the spindle drive 1 is arranged laterally to the door opening 3 , here and preferably in a drainage channel 4 lateral to the door opening 3 . figure 1 Although only a single spindle drive 1 is shown. However, here and preferably it is provided that the spindle drives 1 are respectively arranged on both sides of the door opening 3 . The two spindle drives 1 are substantially identical in structure.

[0031] from according to figure 1 It can be seen from the illustration that the spindle drive 1 shown there is hinged at one end to the body 5 of the motor vehicle and at the other end to the door cover 2 .

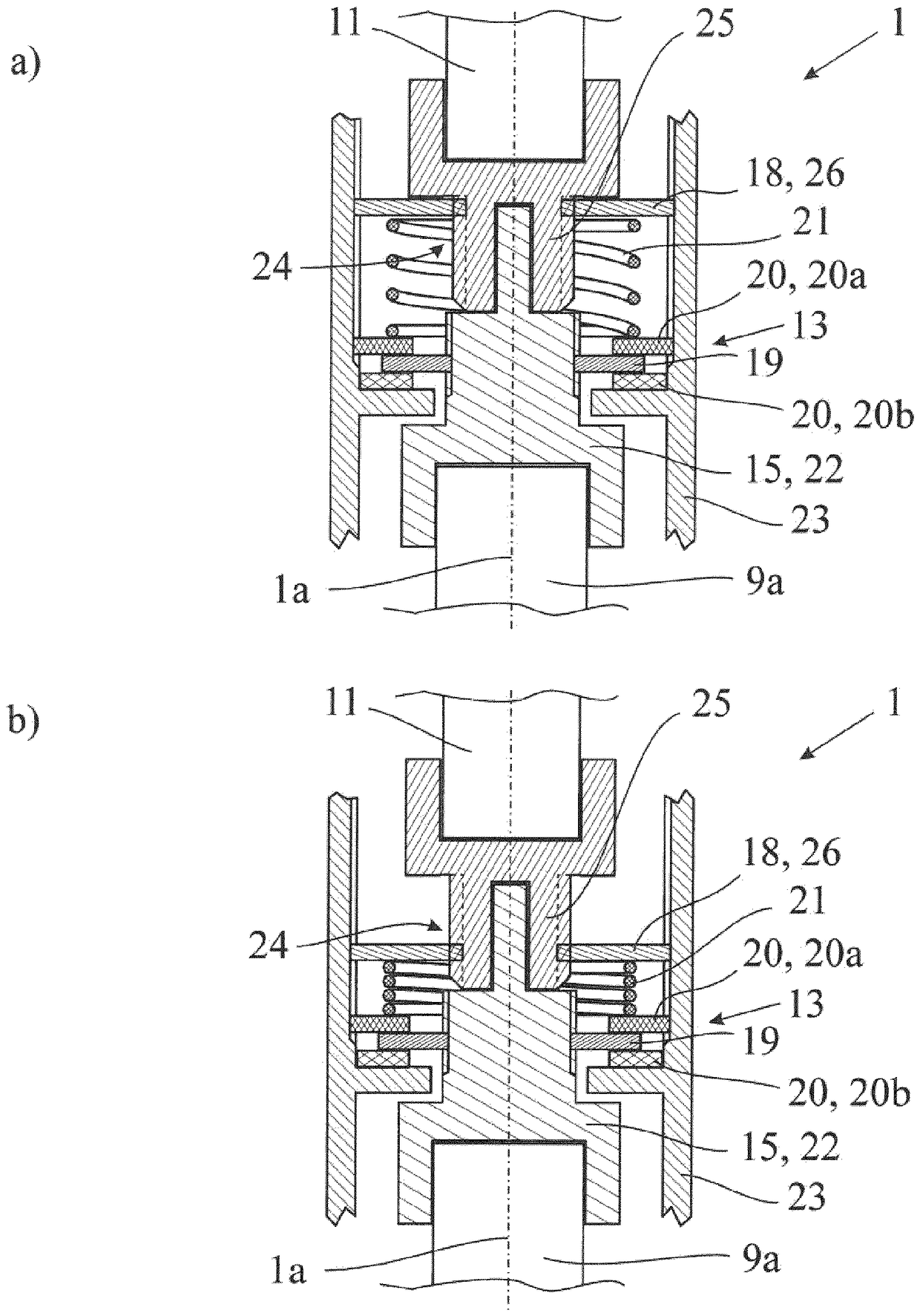

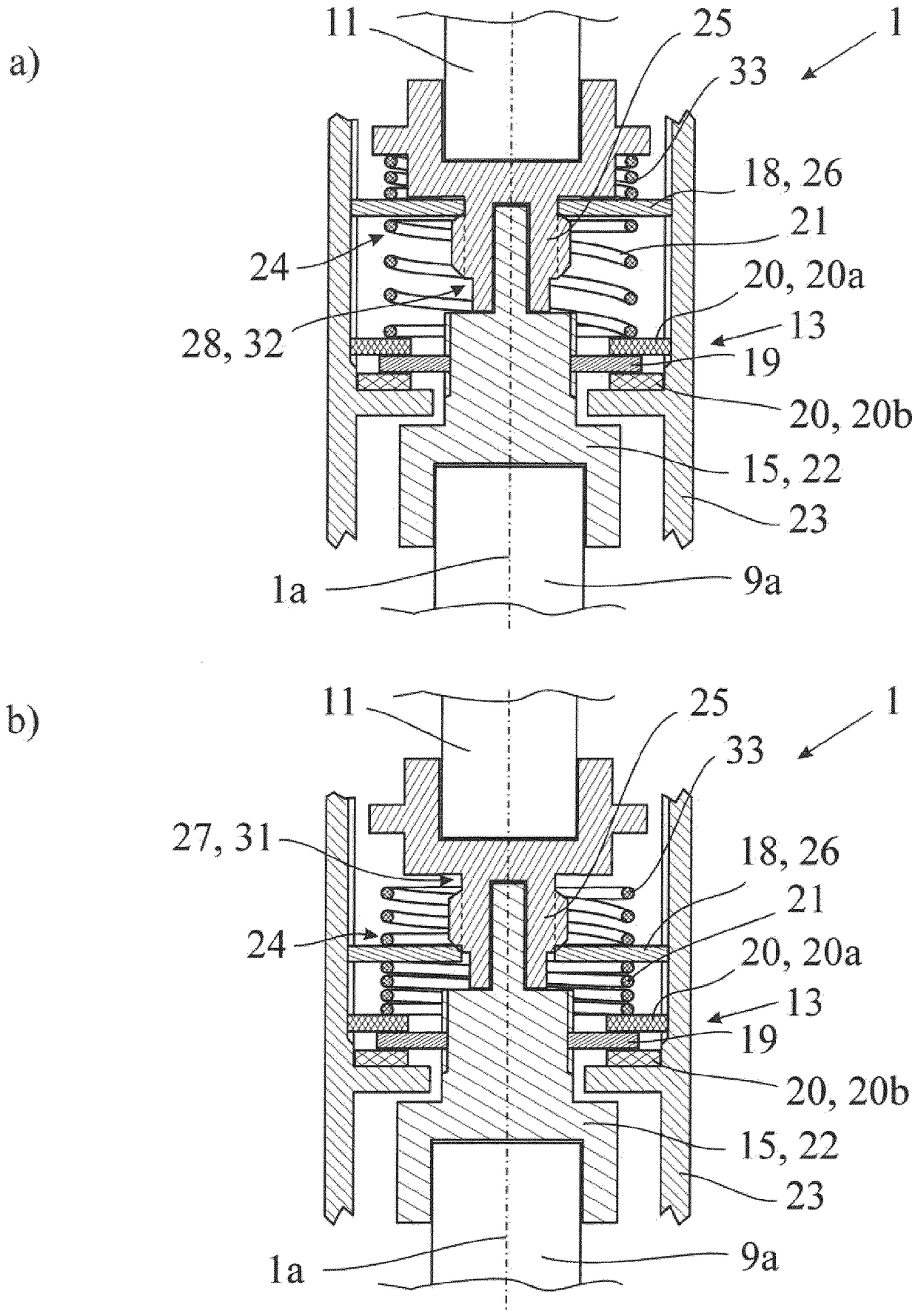

[0032] The spindle drive 1 can be adjusted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com