Patents

Literature

331results about How to "Reduce hydraulic loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

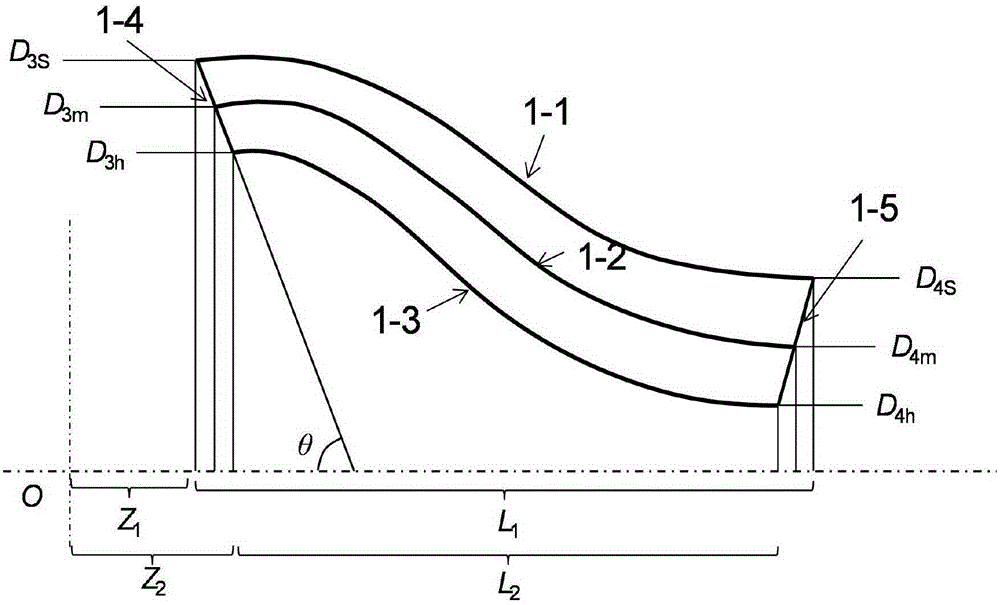

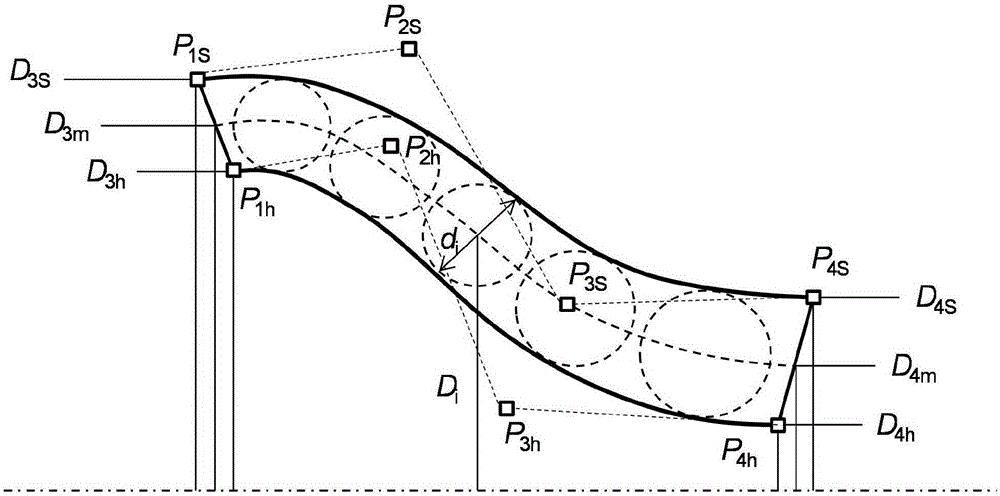

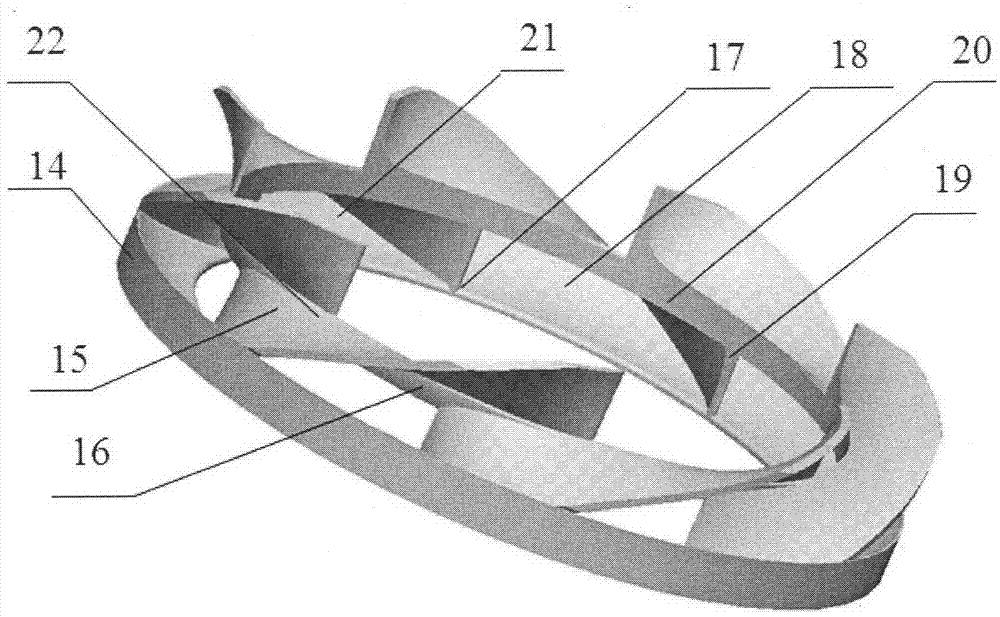

Designing method for hydraulic power of space guide-blade centrifugal pump

ActiveCN105201916AImprove centrifugal pump efficiencyImprove flow stabilityEngine manufacturePump componentsRotation velocityHydraulic structure

The invention discloses a designing method for hydraulic power of a space guide-blade centrifugal pump. An impeller hydraulic structure comprises a front cover plate, blades and a rear cover plate. The method comprises the following steps: (1) according to a given impeller geometric parameter as well as the flow rate, lift and rotation velocity value, solving a calculation method of the space guide-blade shaft surface hydraulic design parameters and a control algorithm of a guide-blade shaft surface shape and blade mold-line bezier curve on the basis of a binary flow theory; carrying out the hydraulic optimization design for space guide blades according to the method; (2) controlling streamlines on the upper cover plate shaft surface and streamlines on the shaft surface of the lower cover plate of the space blades by adopting a ternary Bezier curve equation, and adjusting the shaft surface streamlines on the basis of the variation rule of a guide-blade shaft surface flowing area; (3) controlling the vane mold-line arrangement angle distribution principle of the space blades by adopting a quartic Bezier curve equation; (4) adopting the data obtained in the steps (1) to (3) as dimensional parameters of the centrifugal pump space blades, and manufacturing the centrifugal pump space blades meeting the design requirement. The designed space blade can reduce the hydraulic loss in the vanes, improve the flowing situation inside the blade and improve the operation stability and hydraulic efficiency of the centrifugal pump.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

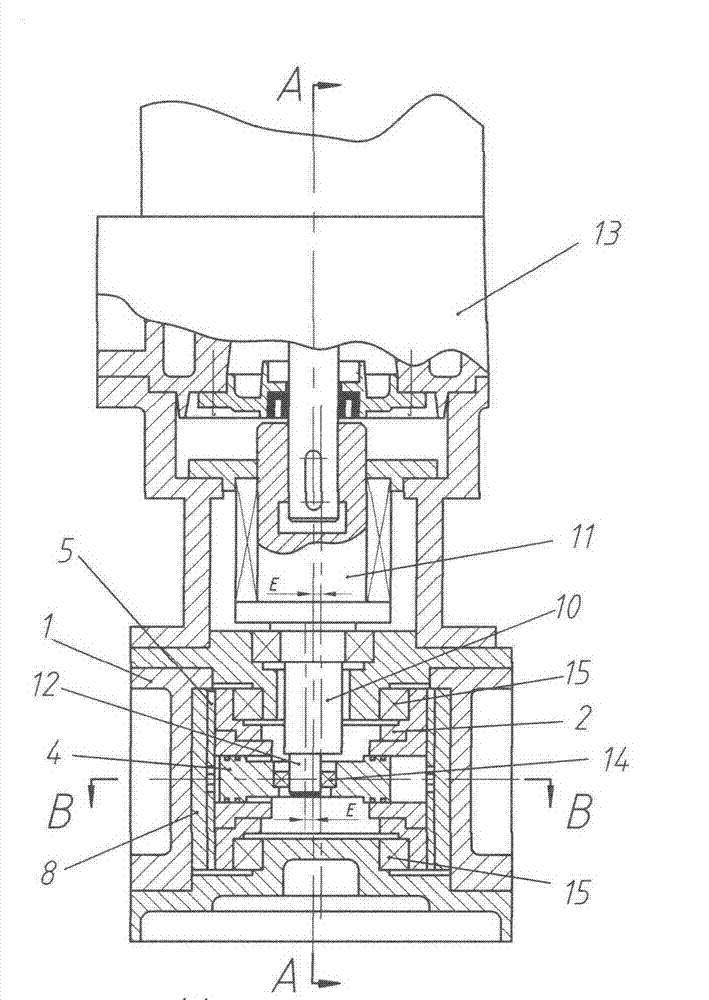

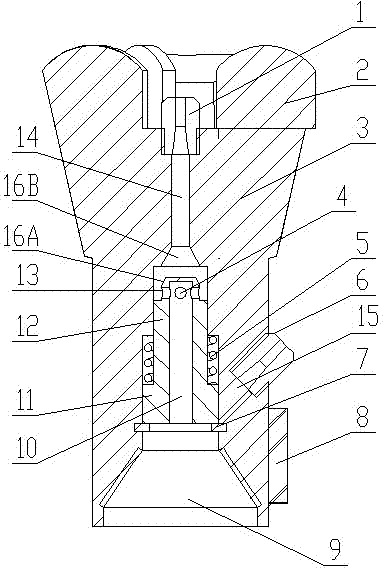

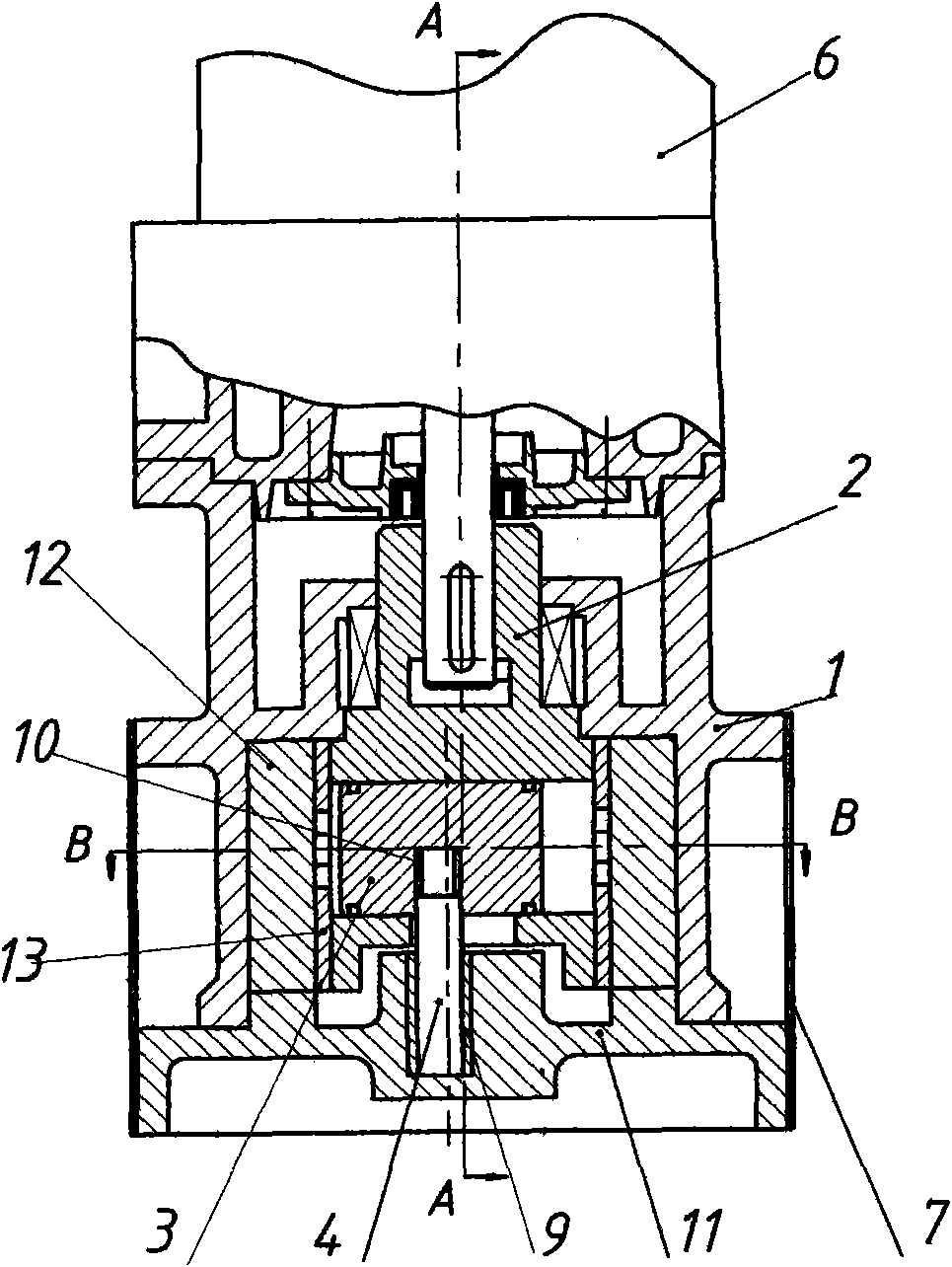

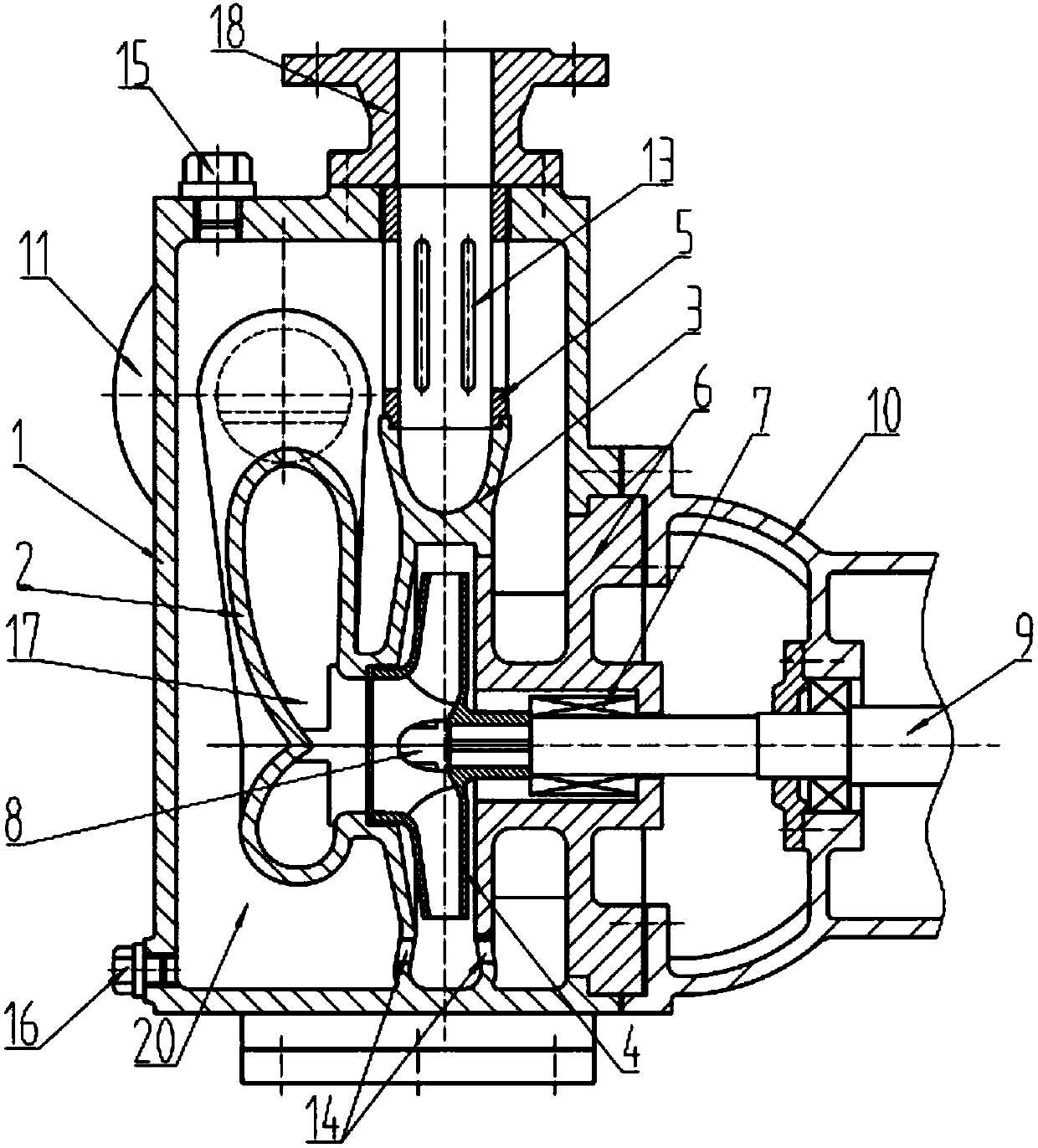

Rotor type immersible pump with eccentric shaft directly connected with motor

InactiveCN103883520AReduce axial sizeCompact structureRotary piston pumpsRotary/oscillating piston combinationsViscous liquidLow noise

The invention discloses a rotor type immersible pump with an eccentric shaft directly connected with a motor and the rotor type immersible pump is applicable to work under liquids. The rotor type immersible pump comprises a pump body, a rotor, a piston, the eccentric shaft, a pump seat and a submersible motor. According to the eccentric mechanism principle, the piston reciprocates; the eccentric shaft is directly arranged on a projecting shaft of the submersible motor; when the eccentric shaft is driven to rotate by the motor, the piston rotates around the eccentric shaft while reciprocating, so that liquid is sucked and discharged. Due to high-speed running, the piston conveys liquid twice when the rotor rotates for every turn and consequently the liquid flow is outputted steadily with no pulse, small vibration and low noise; besides, the rotor type immersible pump with a small size, a few parts, low cost, small hydraulic loss and small volume loss has efficiency of over 70% and remarkable energy-saving effect, and is an upgraded high-efficiency energy-saving product of a centrifugal immersible pump. In addition, the rotor type immersible pump has the good self-pumping performance of a displacement pump, thereby being capable of not only conveying water type liquids, but also pumping viscous liquids such as oils as well as gas-containing liquids; the application range of the rotor type immersible pump is expanded.

Owner:余文凌

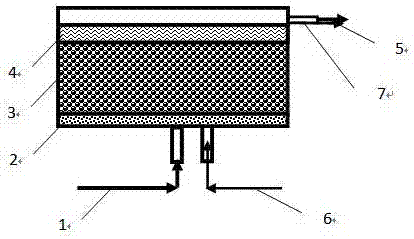

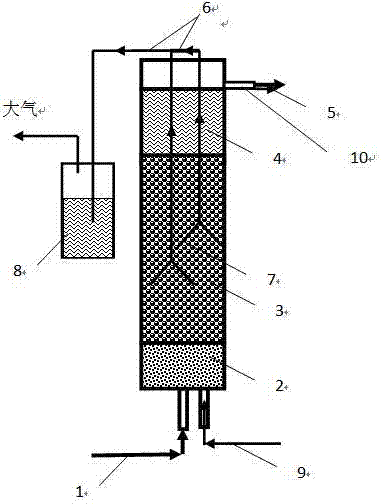

Mixed nutritional type denitrifying filler and preparation and application thereof

ActiveCN107151050AIncrease hydraulic retention timeSolve the problem that the dosage is difficult to controlWater contaminantsTreatment with anaerobic digestion processesActivated carbonSolid carbon

The invention specifically relates to a mixed nutritional type denitrifying biological filler and a preparation and application thereof. The mixed nutritional type denitrifying biological filler adopts the technical principle that activated carbon, sulfur and solid carbon source are used as raw materials to prepare the denitrifying biological filler, and the denitrifying biological filler and anionic clay are mixed and loaded into an applicable reactor; the filter simultaneously has the heterotrophism and autrophism denitrifying effects, so that the problem of secondary pollution caused by adding of liquid carbon sources is effectively solved, and the production of sulfur autrophism byproducts is flexibly controlled.

Owner:知和环保科技有限公司

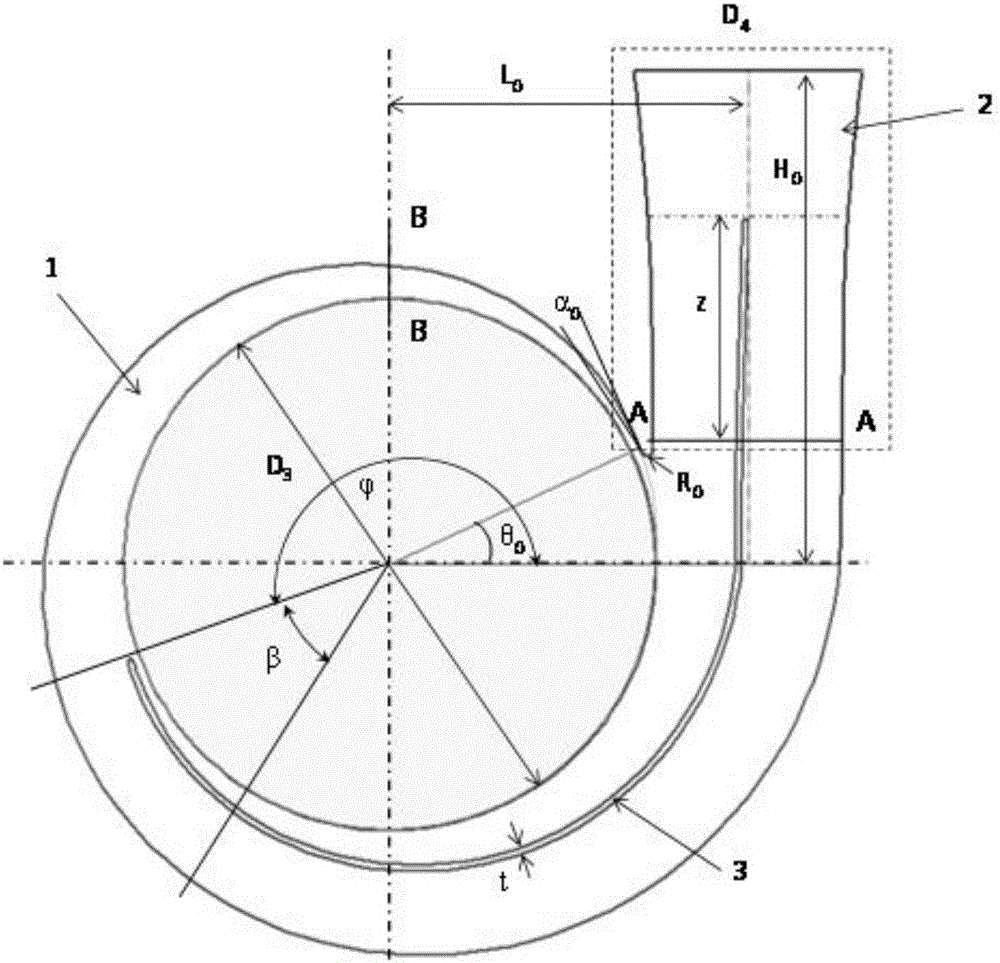

Double-volute hydraulic design method based on RSM model

InactiveCN106570263AReduce design difficultyShorten the design and development cycleGeometric CADPump componentsEngineeringDesign methods

The invention discloses a double-volute hydraulic design method based on an RSM model. The design method comprises the steps of 1) solving double-volute initial hydraulic geometric parameters based on a velocity coefficient method; 2) performing optimization solving on double-volute key geometric parameters by adopting an RSM-based adaptive sequence algorithm; 3) performing parameterization automatic modeling based on a CATIA macroprogram, and outputting to obtain a three-dimensional double-volute model; 4) by adopting a GridPro script file to output a grid file used for numerical value calculation; 5) automatically completing grid loading and boundary condition setting based on a CFX CCL language drive program to complete calculation of related data, and outputting a calculation result; 6) repeatedly executing the steps 3) to 5) to obtain a double-volute scheme with the minimum total pressure loss coefficient; and 7) taking the data obtained in the steps 1) to 6) as the double-volute design parameters to manufacture a double-volute centrifugal pump. By adoption of the double-volute hydraulic design method, the double-volute hydraulic optimization design can be realized.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

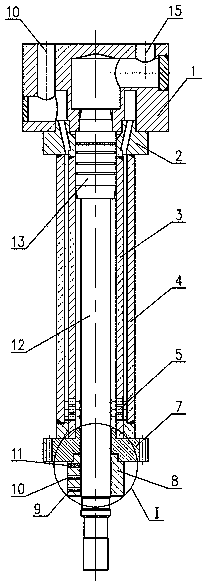

Drilling and punching integrated hydraulic drill bit

InactiveCN103291219AShorten construction timeSimple structureDrill bitsLiquid/gas jet drillingPunchingEngineering

The invention discloses a drilling and punching integrated hydraulic drill bit which comprises a drill bit body. A through hole, extending axially, penetrates the whole drill bit body and comprises a nozzle hole portion in the front and a valve hole portion in the middle. The back end of the nozzle hole is designed into a conical surface, and a reversing valve is arranged in the valve hole portion and comprises a protrusion block and a spring. The protrusion block is provided with a connection hole extending axially and a side hole communicated with the connection hole, the front end of the connection hole is blind, the front end of the protrusion block is designed into a conical surface which is in fitting seal with the conical surface of the back end of the nozzle hole portion. The drill bit body is further provided with a side nozzle hole, and an inner end port of the side nozzle hole leads to a big hole of the valve hole portion while an outer end port of the side nozzle hole leads to the surface of the outer ring of the drill bit body. The drilling and punching integrated hydraulic drill bit overcomes defects of existing hydraulic punching devices. Drilling and punching integration is realized by the aid of the automatic reversing valve. Secondary breaking of big cinders is realized by the aid of secondary breaking tools arranged reasonably, so that blocking of discharging passages due to falling of the big cinders is avoided.

Owner:HENAN POLYTECHNIC UNIV

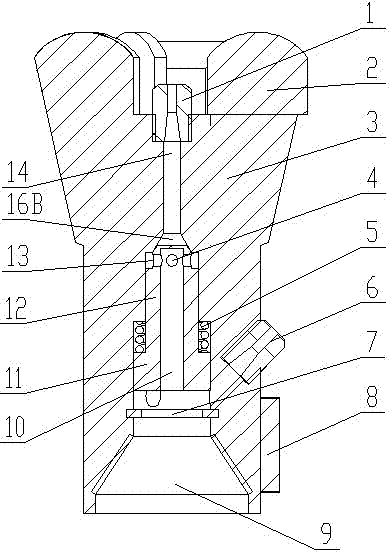

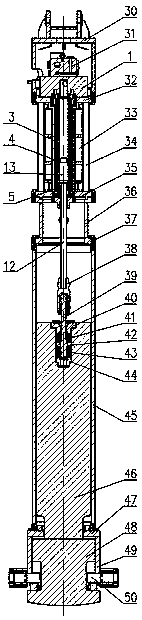

LNG immersed pump

The invention discloses an LNG immersed pump and belongs to the technical field of LNG. A stator and a rotor shaft are arranged in a motor cavity in the LNG immersed pump, and side wall channels are arranged in the side wall of a pump body; a motor upper cover is connected to the rear end of the pump body and provided with a plurality of liquid flowing channels communicated with the side wall channels, and the liquid flowing channels are arranged in an inclined mode and intersect with one another at a liquid outlet; a motor lower cover is connected to the front end of the pump body, liquid via holes communicated with the side wall channels are formed in the motor lower cover, a shell is connected to the motor lower cover to form a working cavity and provided with a first-stage flow guide disc to partition the working cavity into a front cavity and a rear cavity, a flow channel communicated with the front cavity and the rear cavity is arranged on the first-stage flow guide disc, a second-stage impeller is arranged in the rear cavity, a first impeller is arranged in the front cavity, a liquid inlet is formed in the front cavity in a connected mode, and an inducer is arranged in the liquid inlet; the rotor shaft penetrates through the motor lower cover and the working cavity and extends into the liquid inlet, and the first-stage impeller, the second-stage impeller and the inducer are all arranged on the rotor shaft in a sleeved mode. The LNG immersed pump is simple in structure and suitable for being popularized and used.

Owner:CHENGDU ANDERSON MEASUREMENT

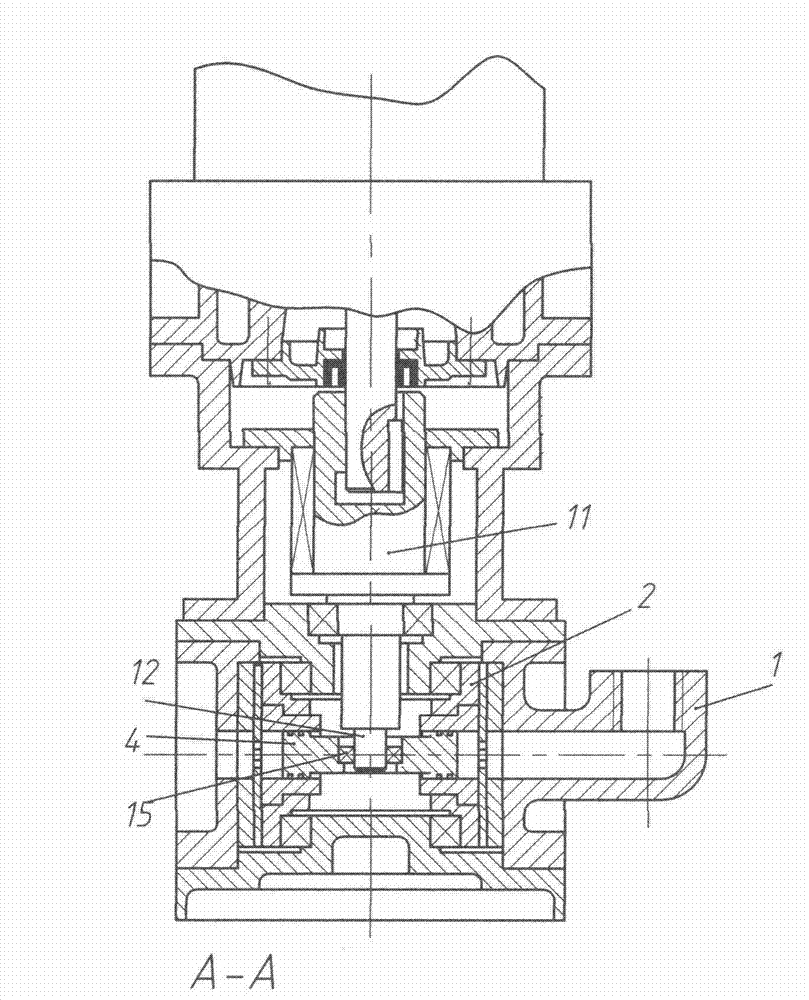

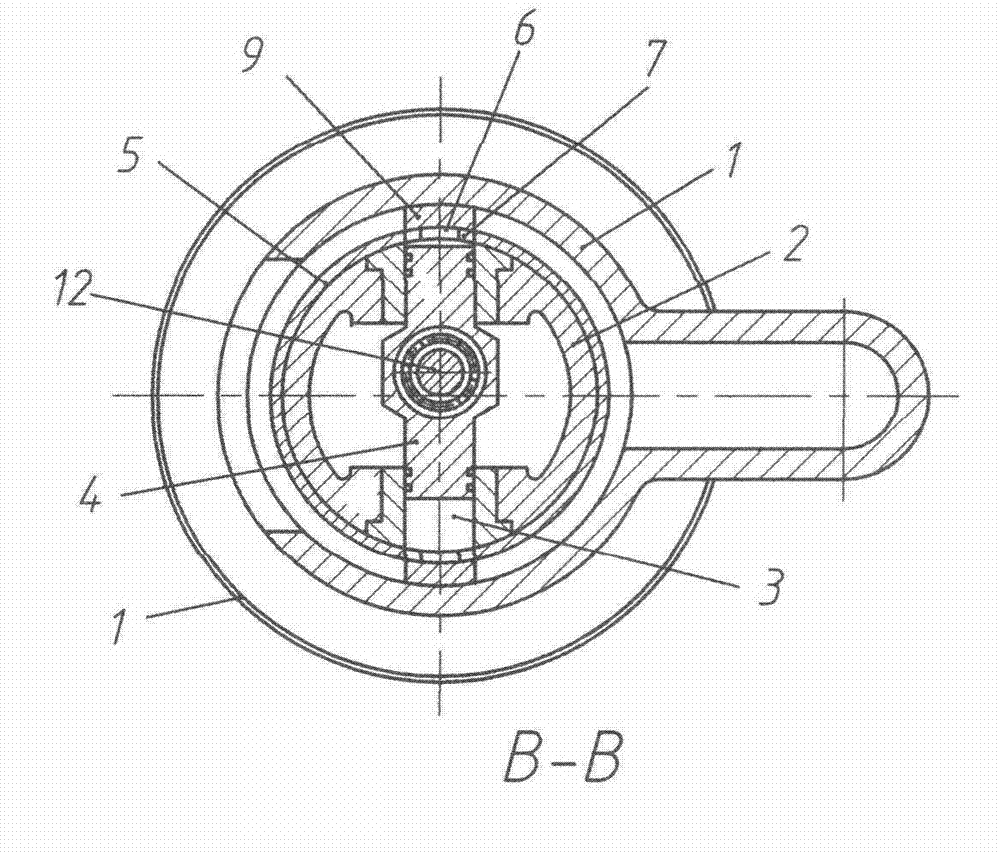

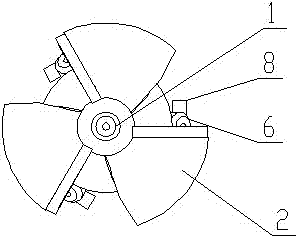

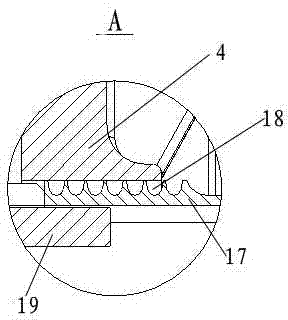

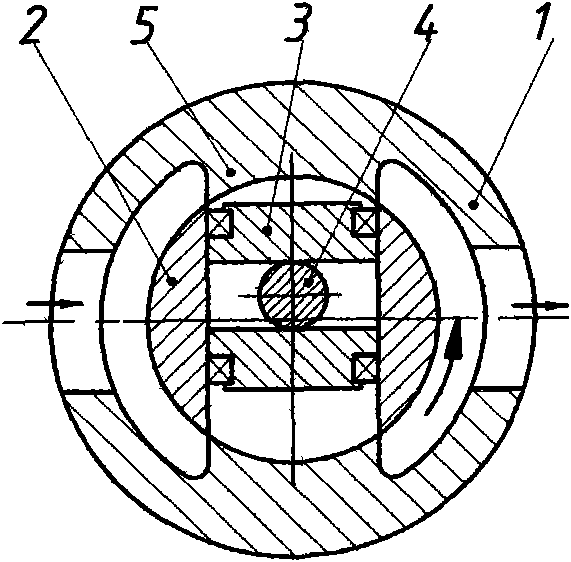

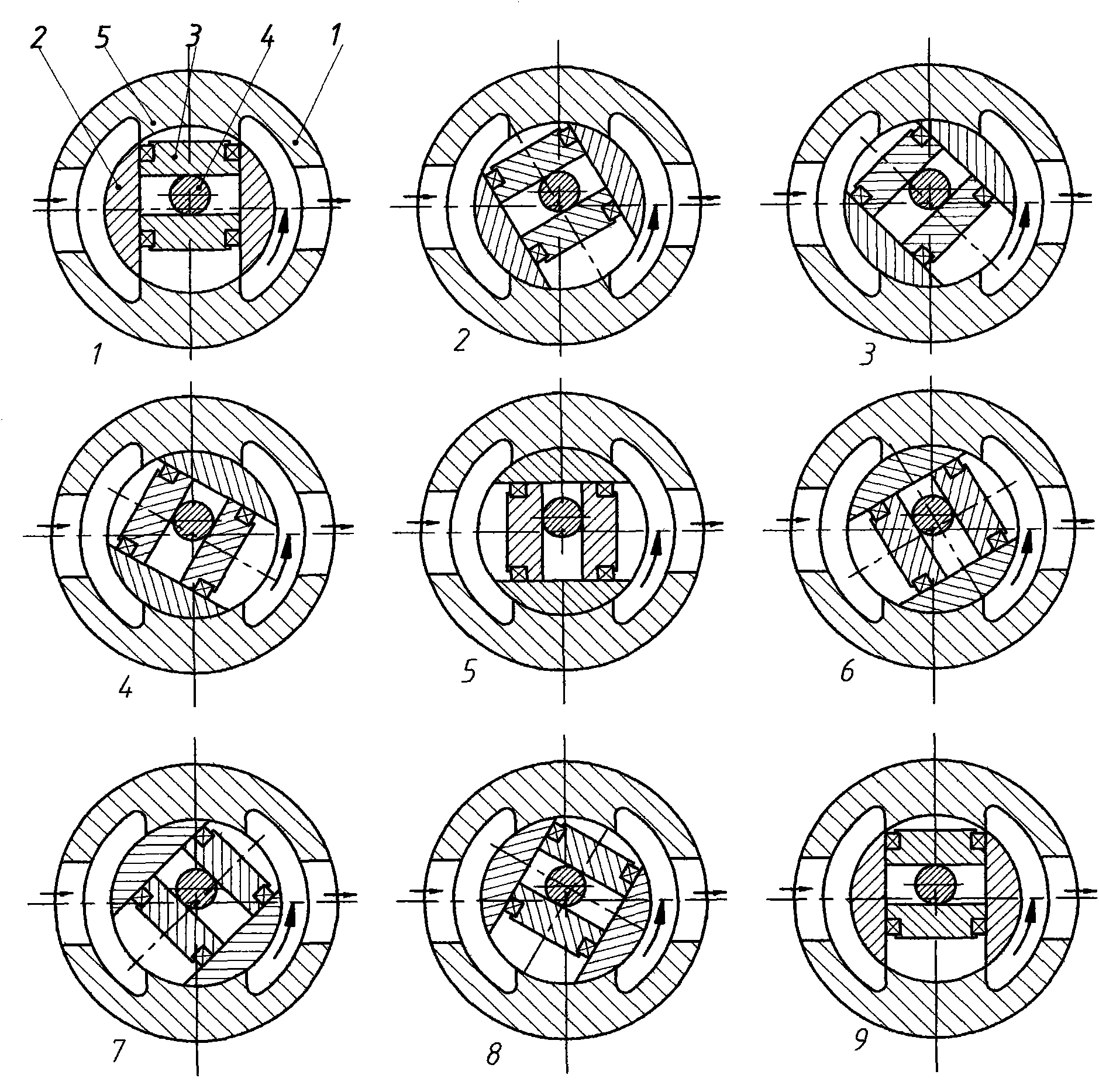

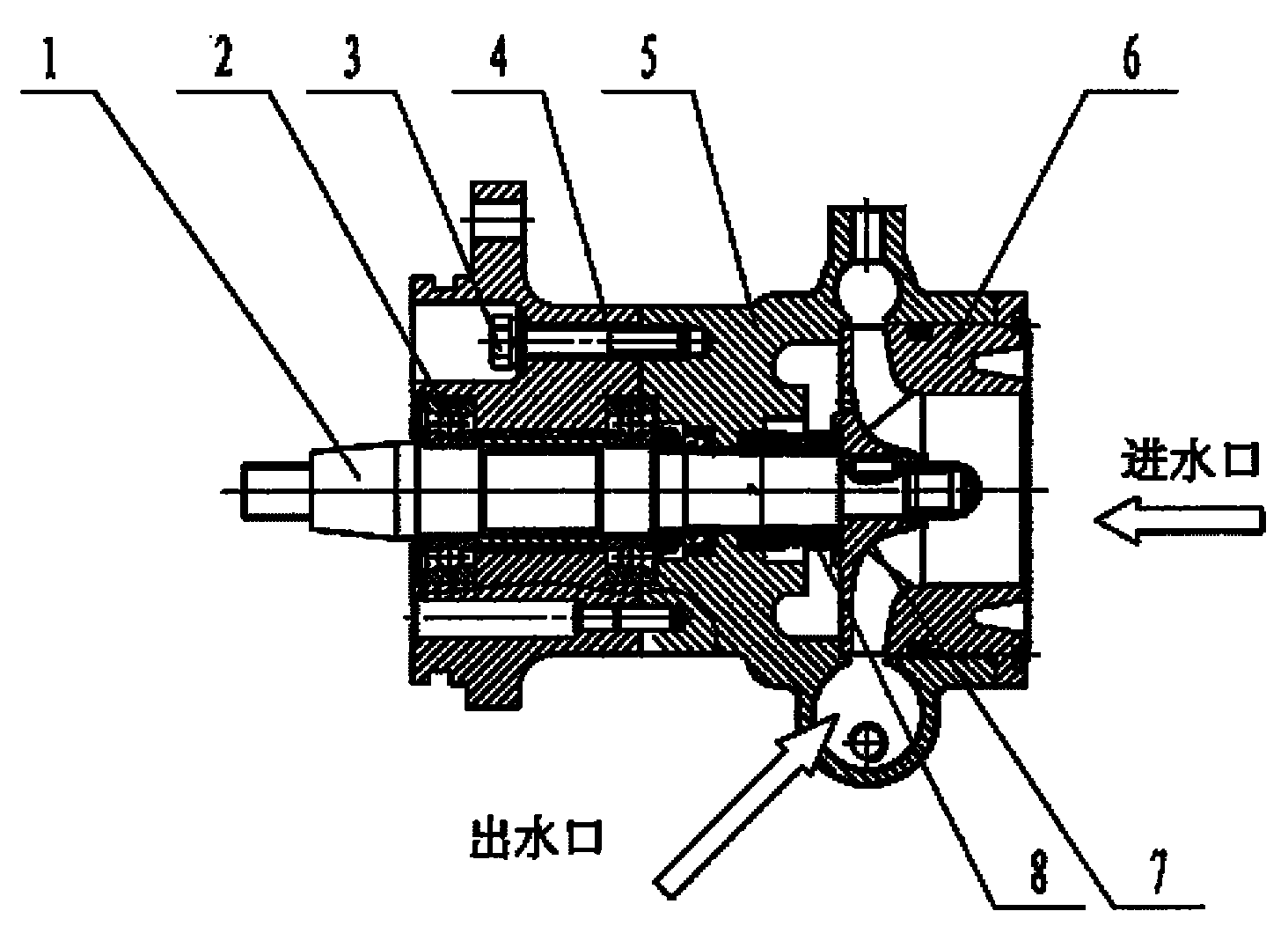

Small rotor-type submersible pump

InactiveCN101871449AGood self-primingWide runnerRotary piston pumpsRotary piston liquid enginesViscous liquidMotor drive

The invention relates to a small rotor-type submersible pump suitable for operation under liquid, which is formed by a pump body, a volute tongue bush, a rotor, a rotor bush, a piston, an eccentric shaft, a pump base, a filter screen and a submersible motor. The invention uses the principle of an eccentric mechanism to realize the reciprocating motion of the piston. When the submersible motor drives the rotor to rotate, the piston rotates around the eccentric shaft while the piston makes reciprocating motion and thereby liquid is drawn in and drained. Under the high-speed rotation, the piston drains liquid two times per turn and thereby the liquid flow output is stable, no pulse is caused, the vibration is low and the noise is low; and moreover, the volume is small, the number of parts is small, the cost is low, the hydraulic loss and the volumetric loss are small, the efficiency is above 70 percent and the pump is a high-efficiency energy-saving product for replacing a centrifugal submersible pump. Moreover, the pump has the good self-absorption performance and the wide runner of a displacement pump and can be used for delivering water liquid and pumping viscous liquid such as petroleum and liquid containing fibrous impurities and particle impurities, and thereby the application scope of the pump is widened.

Owner:余文凌

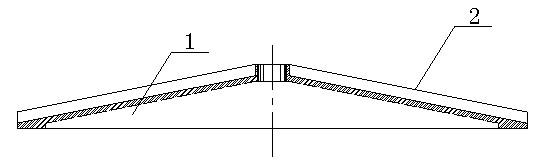

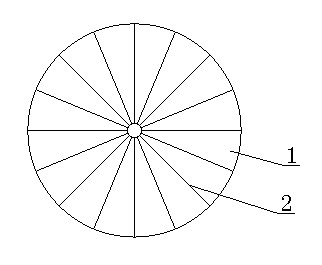

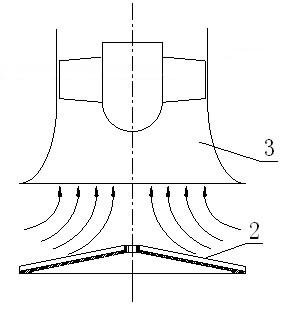

Novel vortex-preventing cone for water feeding of water pump

The invention relates to a novel vortex-preventing cone for water feeding of a water pump, belonging to the technical field of hydraulic engineering. The vortex-preventing cone is arranged under a suction flared pipe nozzle of the water pump, the tip of the vortex-preventing cone is just opposite to the center of the suction flared pipe nozzle of the water pump, vortex-preventing teeth are arranged on the conical surface of the vortex-preventing cone, and the plane area of the vortex-preventing cone is more than the area of the suction flared pipe nozzle of the water pump. The uneven vortex-preventing teeth are arranged on the conical surface of the vortex-preventing cone, and the section shape of a rack of the vortex-preventing teeth is rectangular or triangular or trapezoidal. A cone axial line of a flat cone and a pipe core line of a suction flared pipe of the water pump are arranged on the same straight line. The invention has the advantages of simple and scientific structure and reasonable design; the primary basis of a vortex strip is destroyed from the starting point of the vortex strip, circular quantity of water flow in a water inlet region can not accumulate, and the condition of generating high-intensity vortexes is deprived, the water flow in the water inlet region is smooth, the pressure fluctuation is reduced, and the pump vibration is avoided. The invention is suitable for inlets of various water pumps, ensures no vortex or corresponding hydraulic vibration, reduces hydraulic loss and improves properties of pumps.

Owner:YANGZHOU UNIV

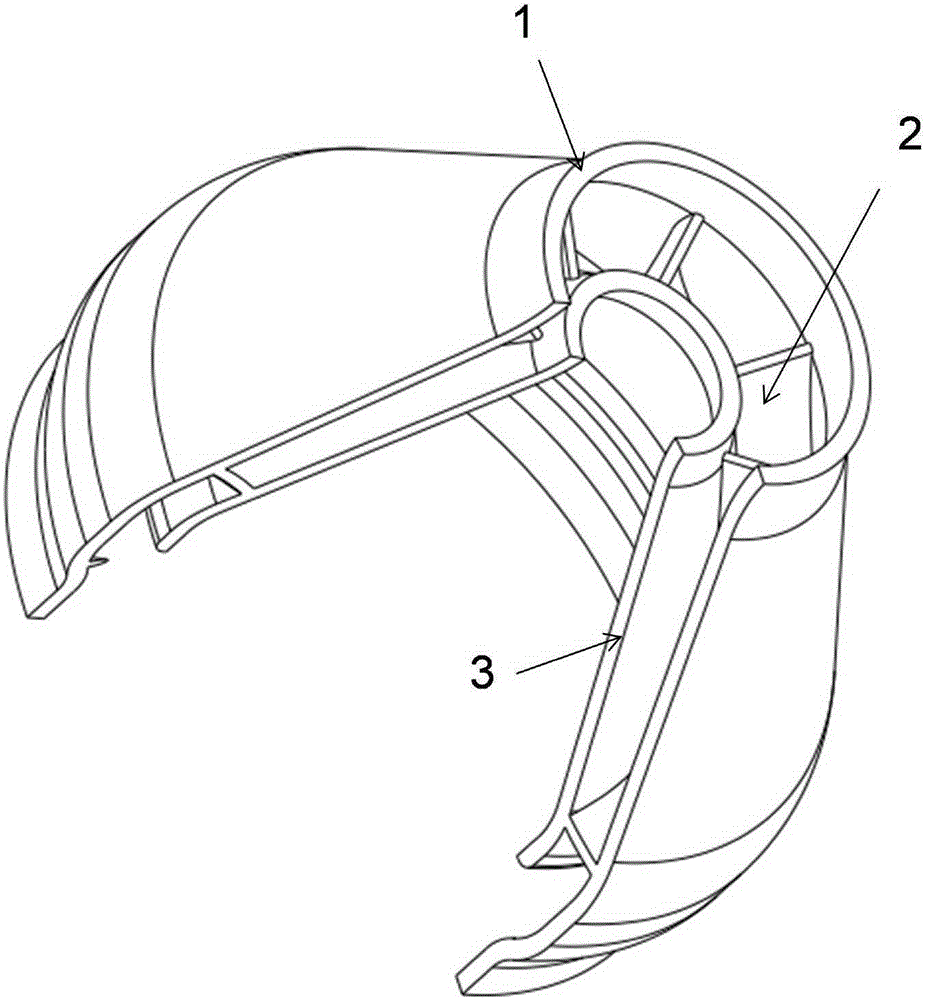

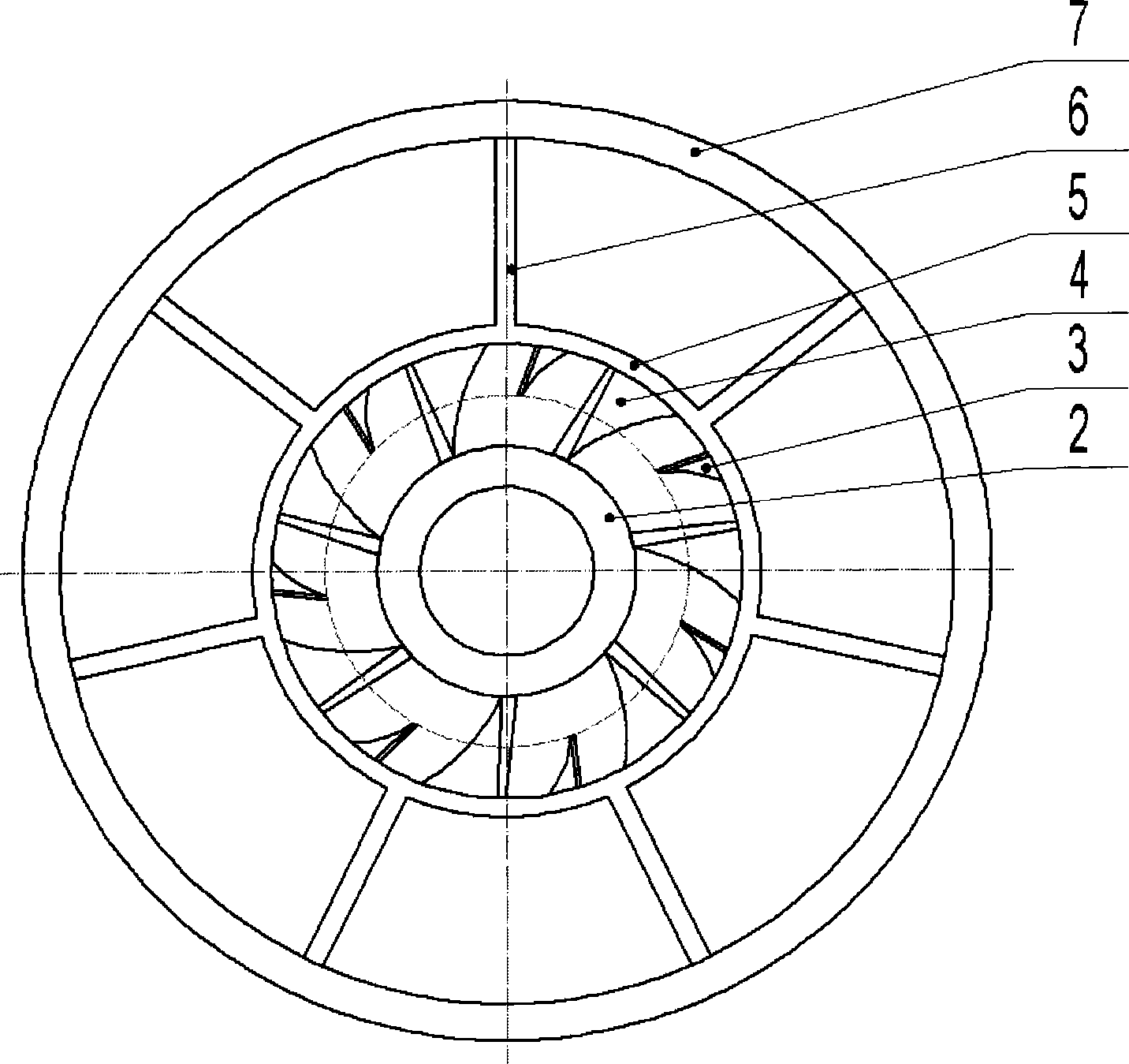

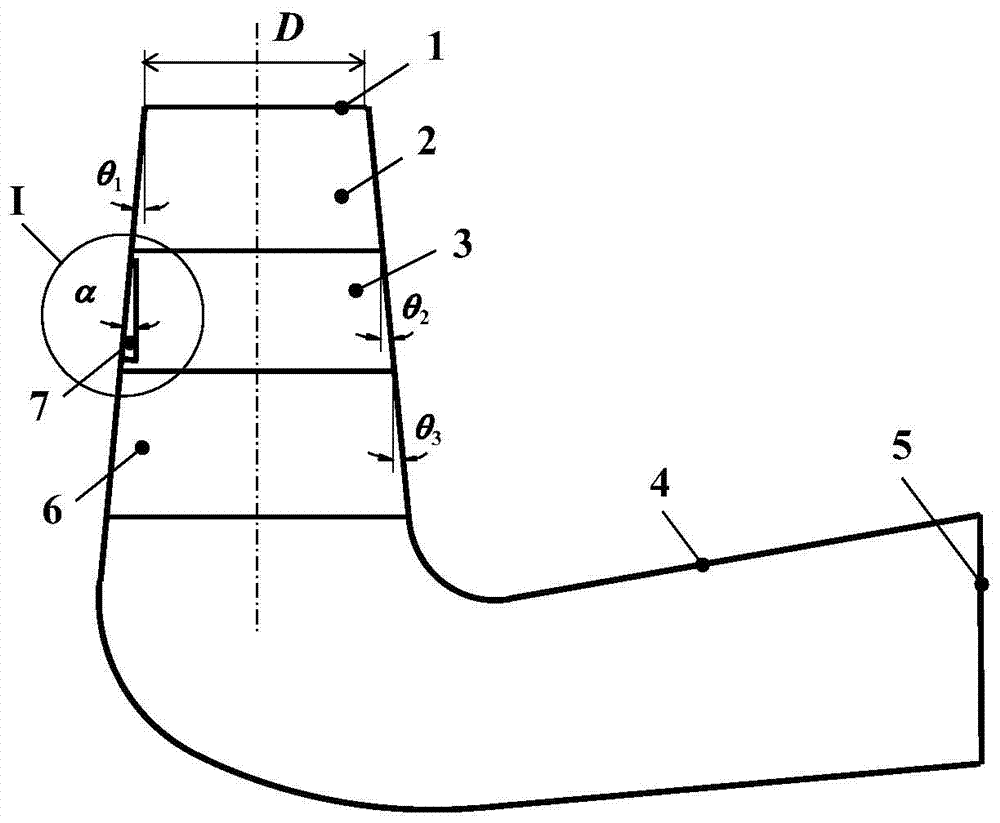

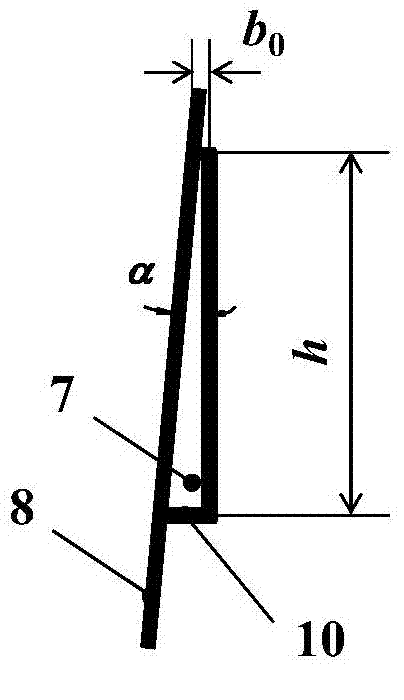

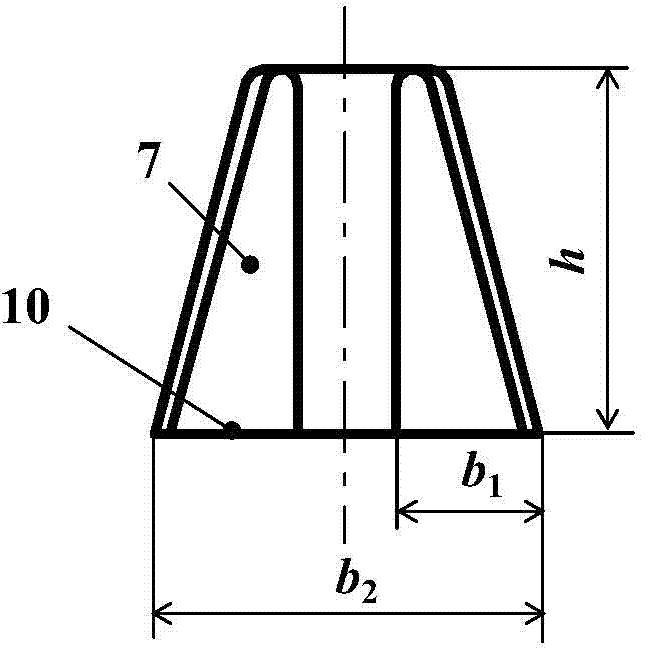

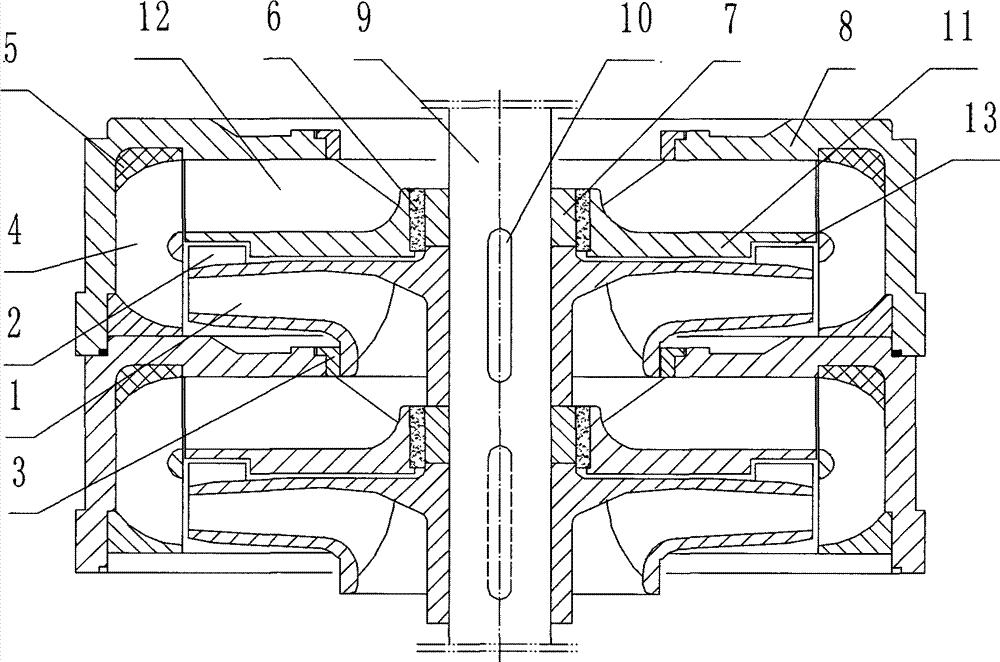

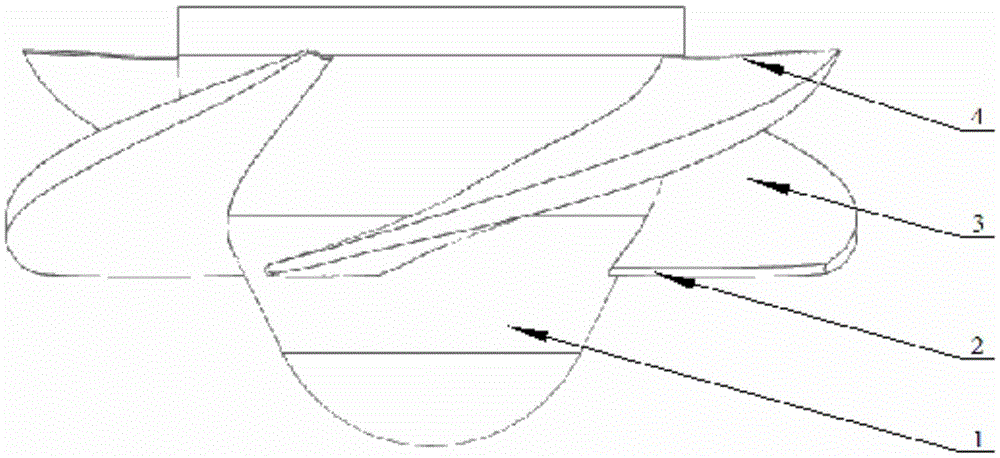

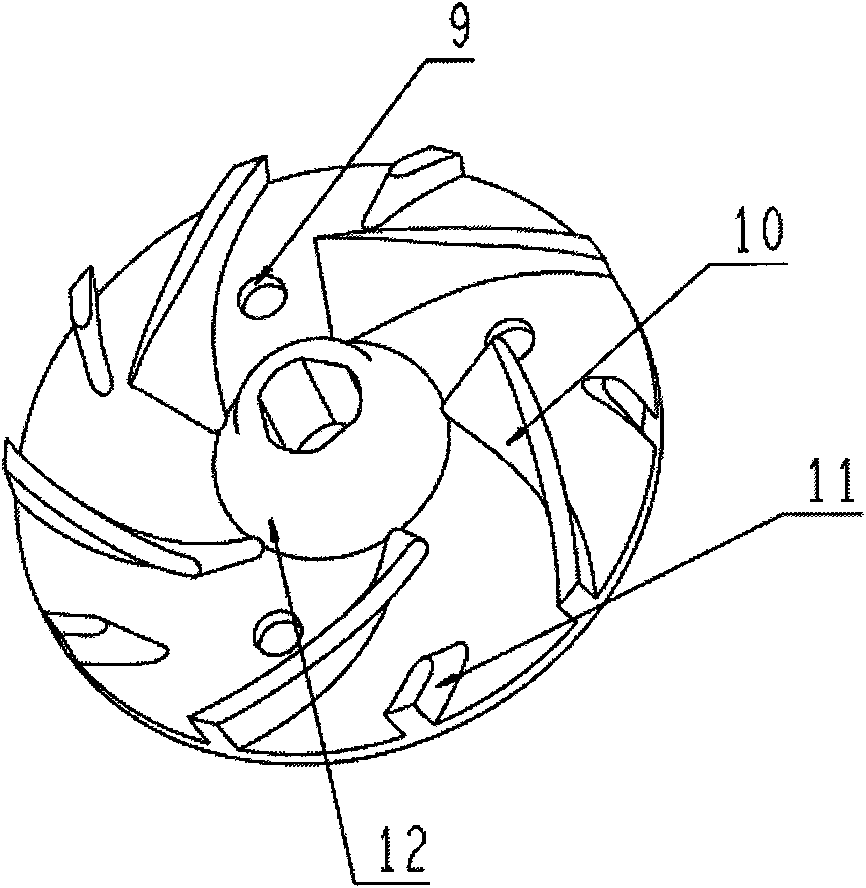

Space guide blade with auxiliary vanes

InactiveCN103591051AImprove overcurrent efficiencySimple structurePump componentsPumpsEngineeringMechanical engineering

The invention discloses a space guide blade which is used for a deep well centrifugal pump or other forms of multi-level centrifugal pumps and provided with auxiliary vanes. The auxiliary vanes are arranged in the middle of all runners of the space guide blade, the change rule of the auxiliary vanes in the axial direction conforms to the streamline shape of vanes of the space guide blade, the thickness of the auxiliary vanes is smaller than that of the vanes of the space guide blade, and the auxiliary vanes occupy small space. The space guide blade is simple in structure, the flowing form that the middle of the space guide blade is attached to a lower cover plate area of the space guide blade can be effectively improved, the probability of vortex and secondary flow is reduced, the hydraulic loss in the runners of the space guide blade can be reduced, and the overflowing efficiency of the space guide blade is improved.

Owner:JIANGSU UNIV

Water turbine draft tube with vortex restraining function

ActiveCN104121138AReduce hydraulic lossReduce volumeHydro energy generationMachines/enginesWater turbineWater flow

The invention relates to a draft tube with the vortex restraining function, and belongs to the technical field of water turbines. The draft tube comprises a draft tube inlet, an upper conical section, a middle conical section, a lower conical section, an elbow tube section, a draft tube outlet and at least one vortex restraining device, wherein the vortex restraining devices are arranged on the inner wall face of the middle conical section, preferably, the number of the vortex restraining devices ranges from two to six, and the upper conical section, the middle conical section and the lower conical section are coaxial. All the vortex restraining devices are of a half-splitting structure and are evenly distributed in the circumferential direction, and the shape, along the axis vertical section, of the half-splitting structure is trapezoidal. The vortex restraining devices are not prone to being damaged by actions of water flow and small in occupied space, does not affect hydraulic performance of a water turbine under other working conditions while restraining vortex actions under the partial load working condition of the water turbine, and can obviously restrain movement of the water flow in the circumferential direction and relieve hydraulic pressure pulses of the water turbine, so that operation stability of the water turbine is improved, the safe operation range of the water turbine is widened, and the working condition adjusting capacity is improved.

Owner:TSINGHUA UNIV

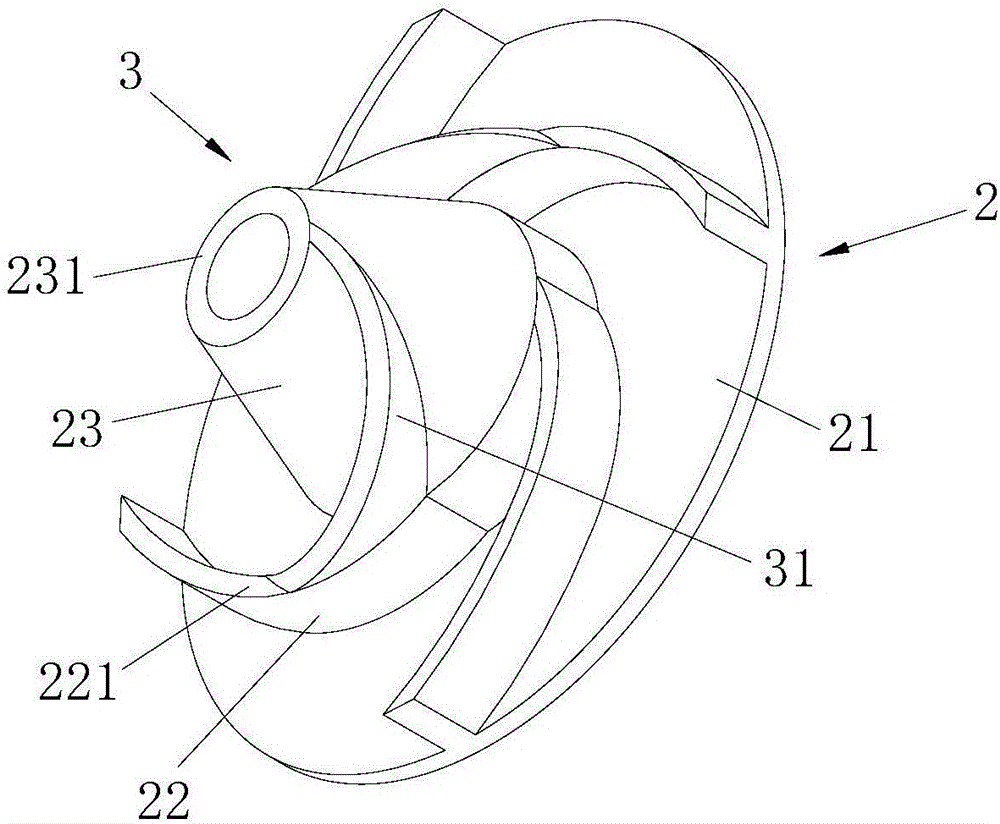

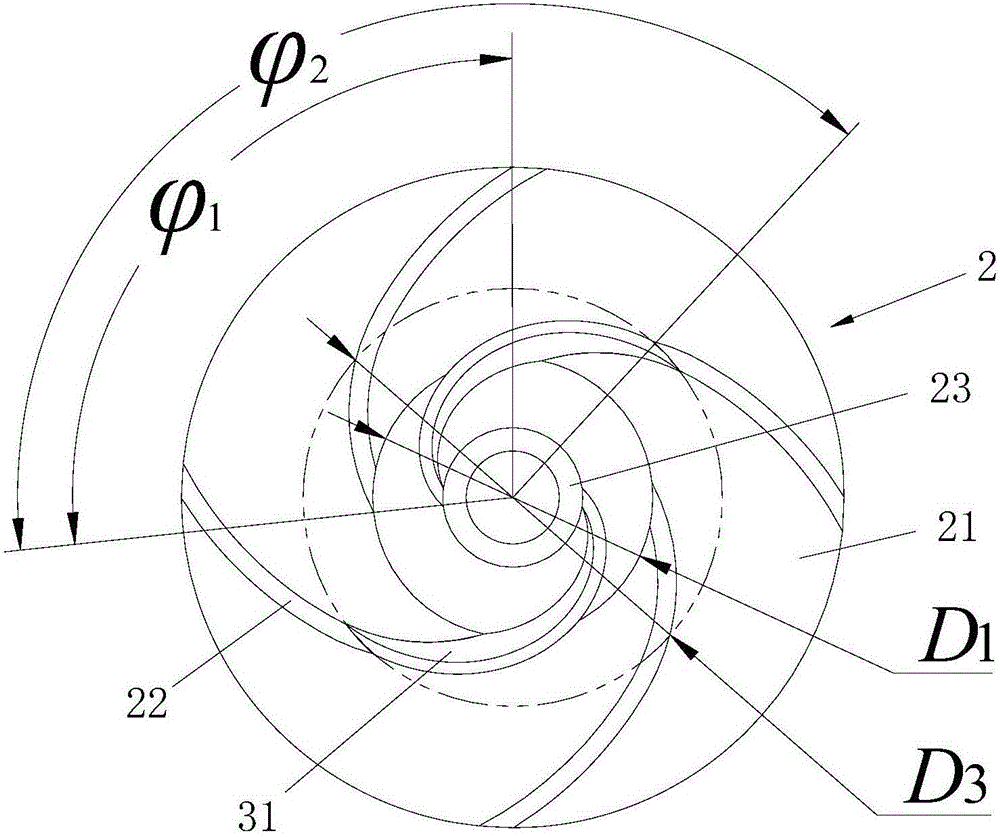

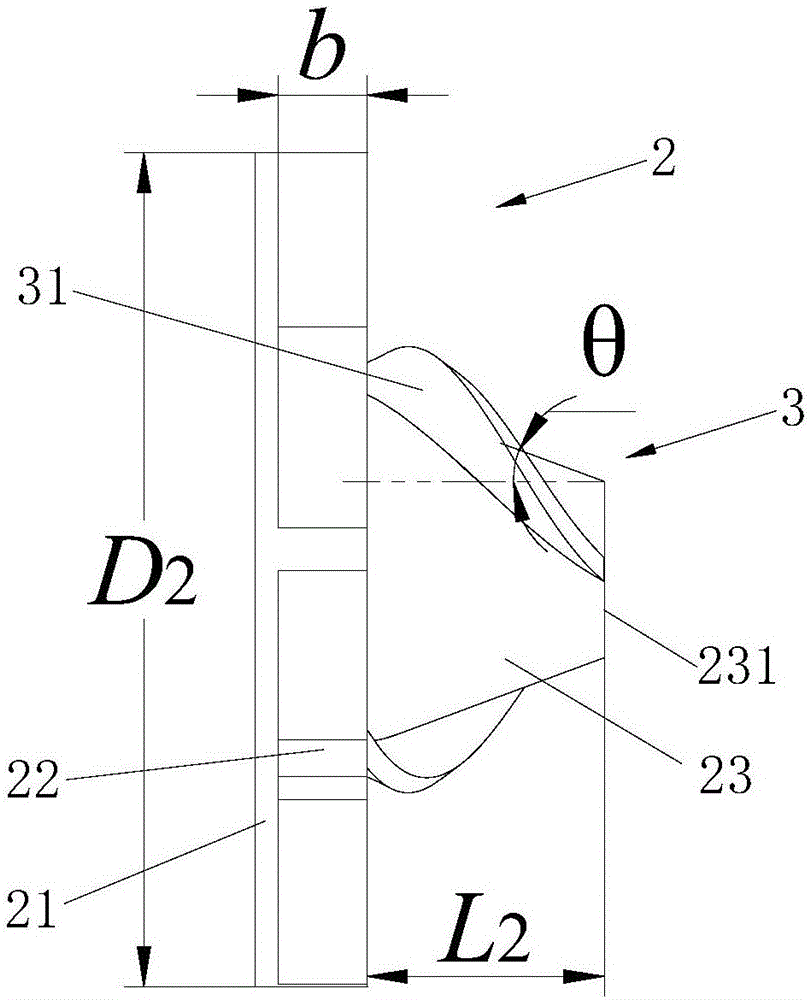

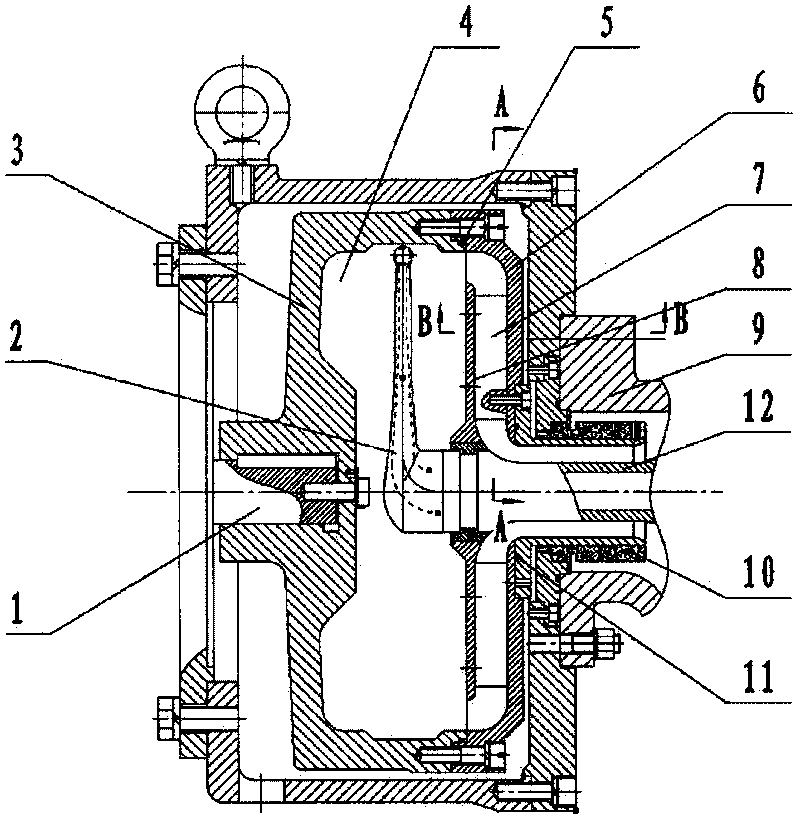

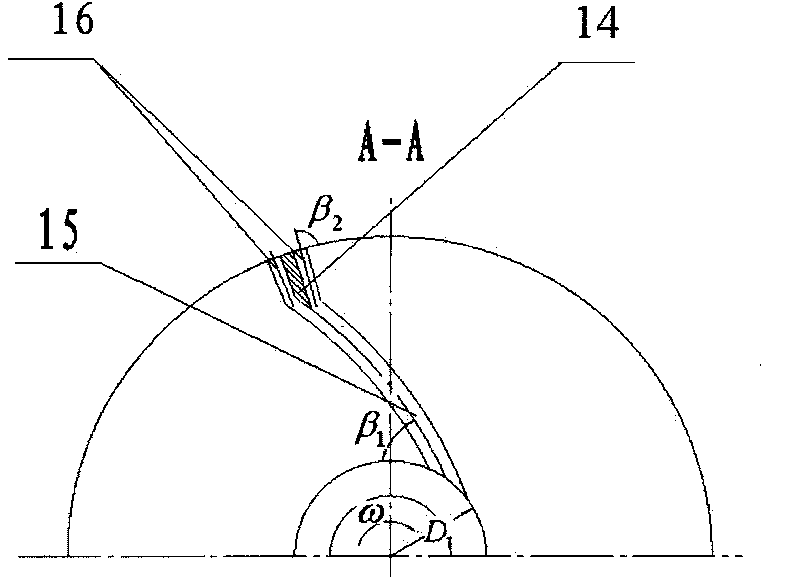

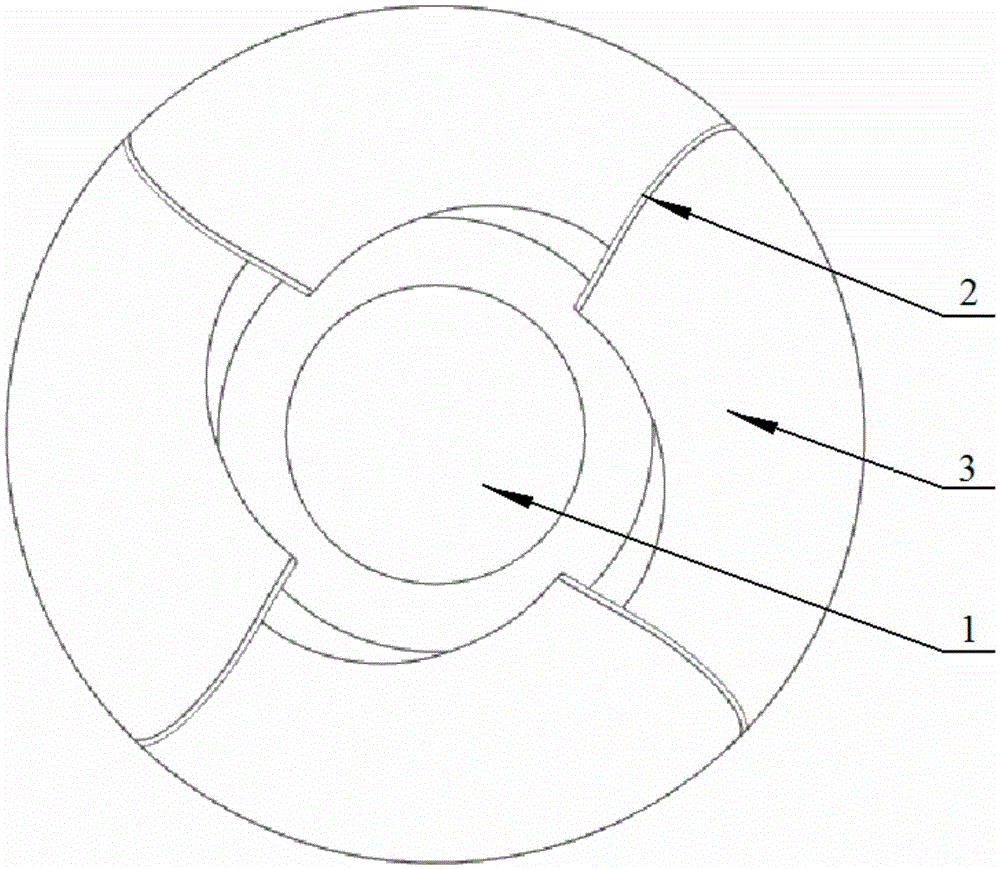

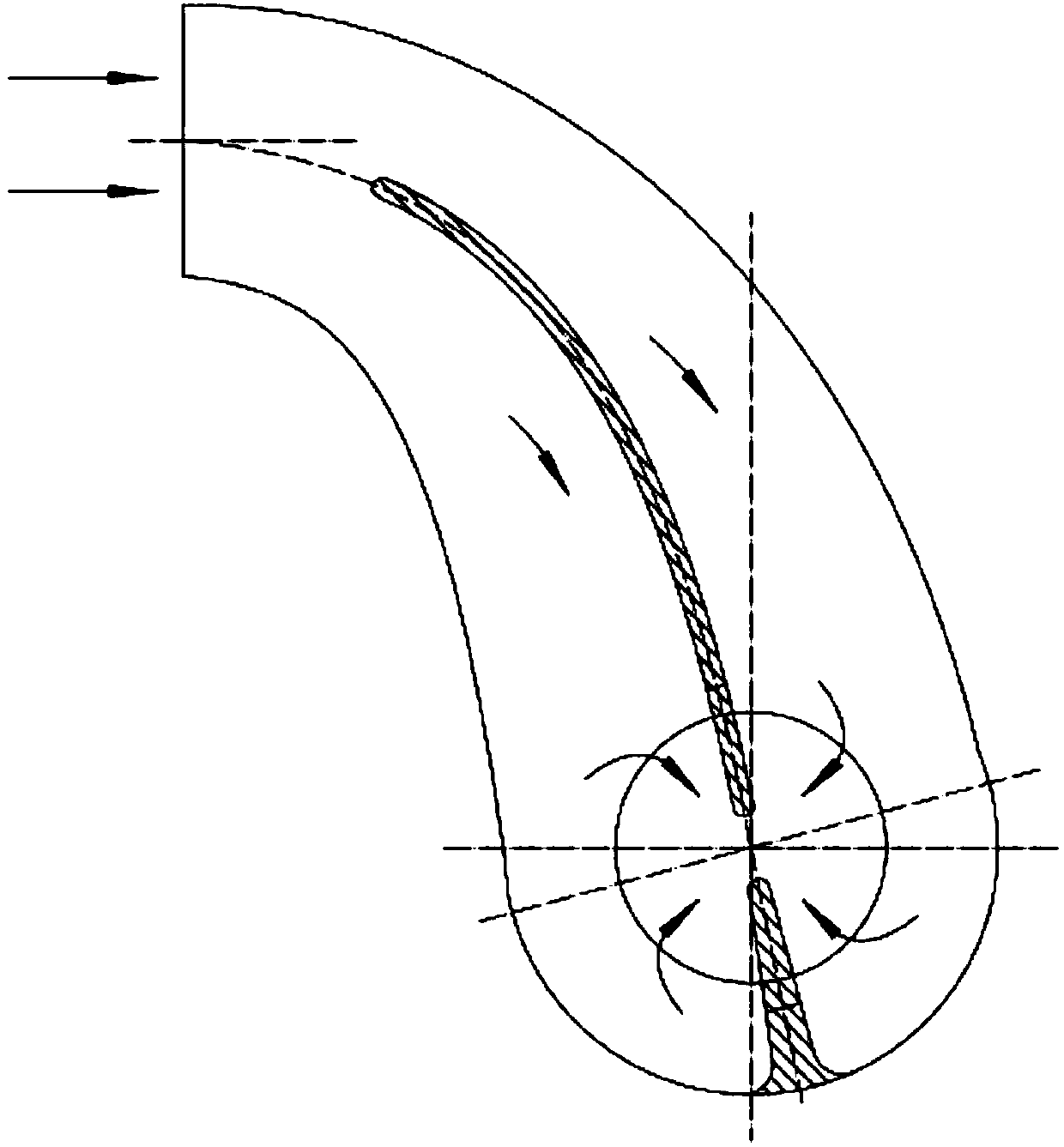

Cyclone pump impeller with spiral structure at front end and design method thereof

The invention discloses a design method of a cyclone pump impeller with a spiral structure at the front end. A semi-open impeller includes a front cover plate, an impeller blade and a hub; the outer surface of the hub is of a round table structure; the hub is fixed to the front cover plate through the lower bottom surface; the end part, far from the front cover plate, of the impeller blade is a blade front end; the spiral structure is arranged at the blade front end; the inlet diameter of the impeller blade is D1; the outlet diameter of the impeller blade is D2; the outer diameter of a spiral blade is D3; the outlet width of the impeller blade is b; the outlet angle of the impeller blade is beta 2; the outlet angle of the spiral blade is beta 4; the axial length of the spiral blade is L2; the wrap angle of the propeller blade is delta 1; and the wrap angle of the spiral blade is delta 2. The design method can effectively improve the pump internal flowing conditions, reduces internal circulating flows, reduces the energy loss, greatly improves the working efficiency of a cyclone pump, and gains excellent economic benefits in large-scale industrial production application. The invention discloses the cyclone pump impeller with the spiral structure at the front end.

Owner:ZHEJIANG SCI-TECH UNIV

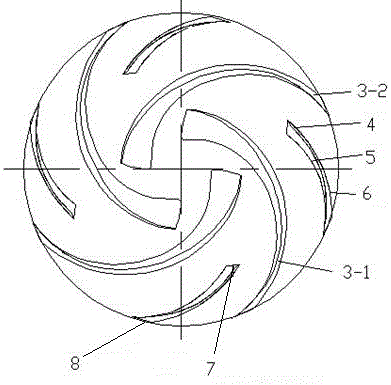

Impeller structure of rotary shell type pump

InactiveCN101725561AGuaranteed dimensional accuracyGuaranteed uniformityPump componentsPumpsImpellerSurface roughness

The invention discloses an impeller structure of a rotary shell type pump, which comprises impeller blades positioned between a front cover plate and a back cover plate. The adjoining impeller blades are formed into impeller flow passageways. The impeller structure is characterized in that each impeller flow passageway consists of an impeller inlet flow passageway and an impeller outlet flow passageway; each impeller inlet flow passageway is an arc flow passageway, wherein the length of the arc flow passageway is 60-70% of that of the impeller flow passageway, and an inclined angle beta1 arranged between the midline of each impeller inlet flow passageway and an inlet distribution circle is from 20 to 40 degrees; and each impeller outlet flow passageway is provided with two outlet radial branch flow passageways. The impeller flow passageways of the impeller structure effectively restrains the generation of axial whirlpool and flow separation; a smaller inlet angle can lead the impact loss of the inlet to be reduced; the branch of the outlet flow passageway leads the liquid which flows into a shell to be more even; and the milling machine of the flow passageways can obtain small surface roughness to achieve the aim for improving the waterpower efficiency of the impeller.

Owner:JIANGSU UNIV

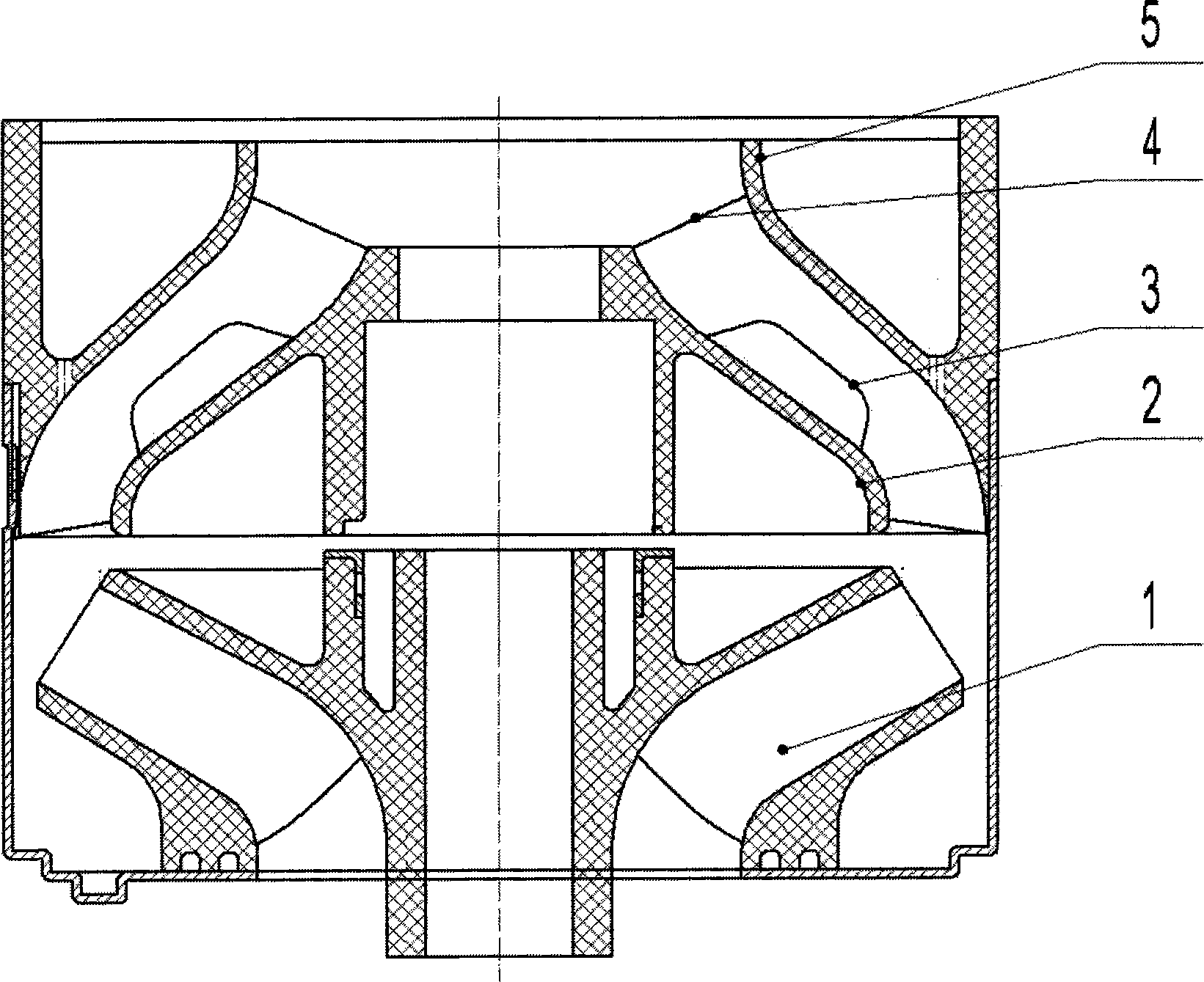

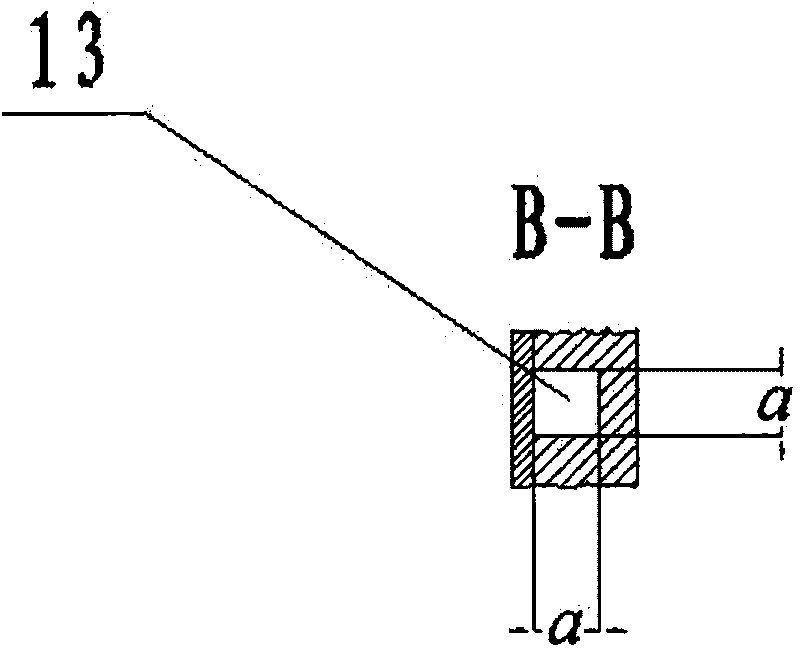

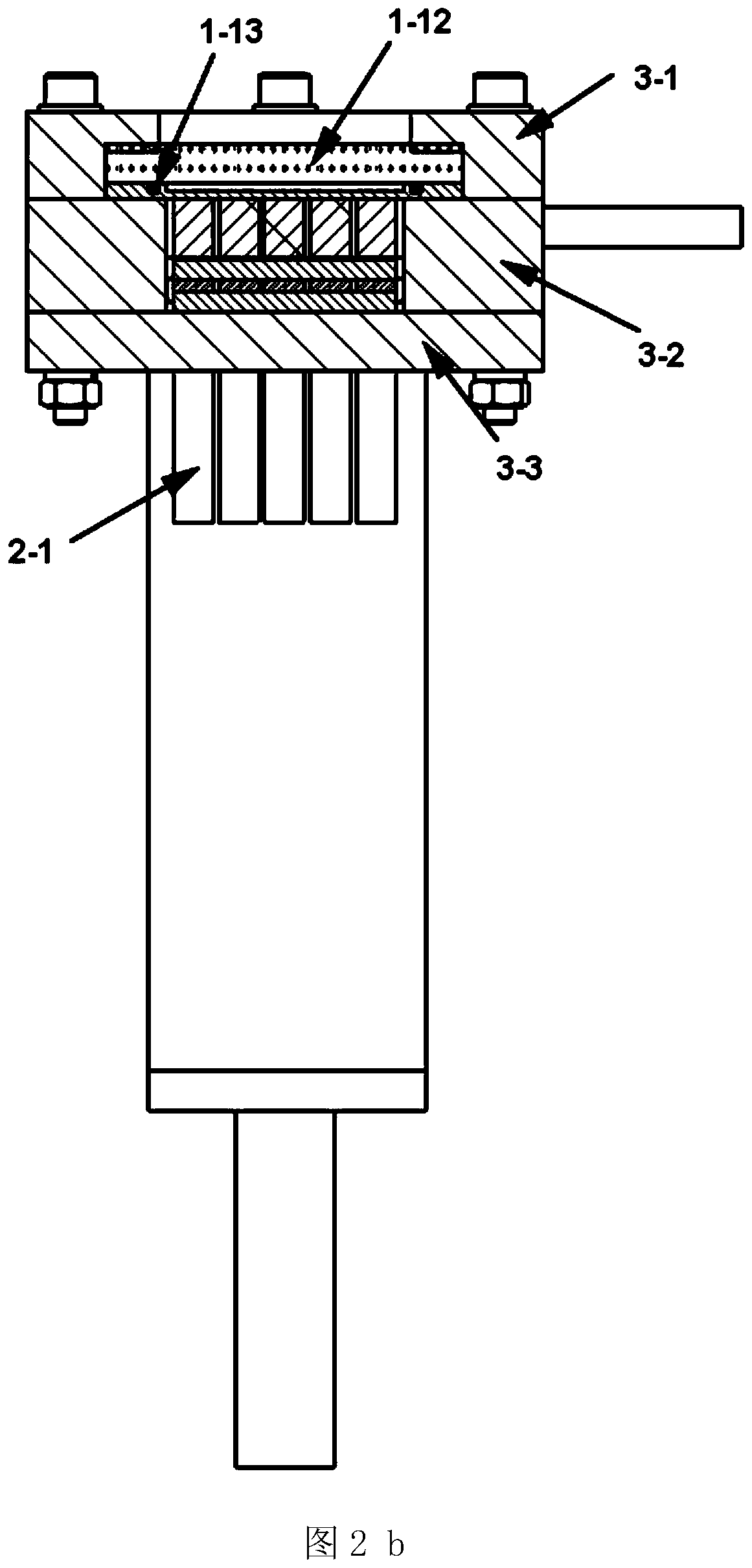

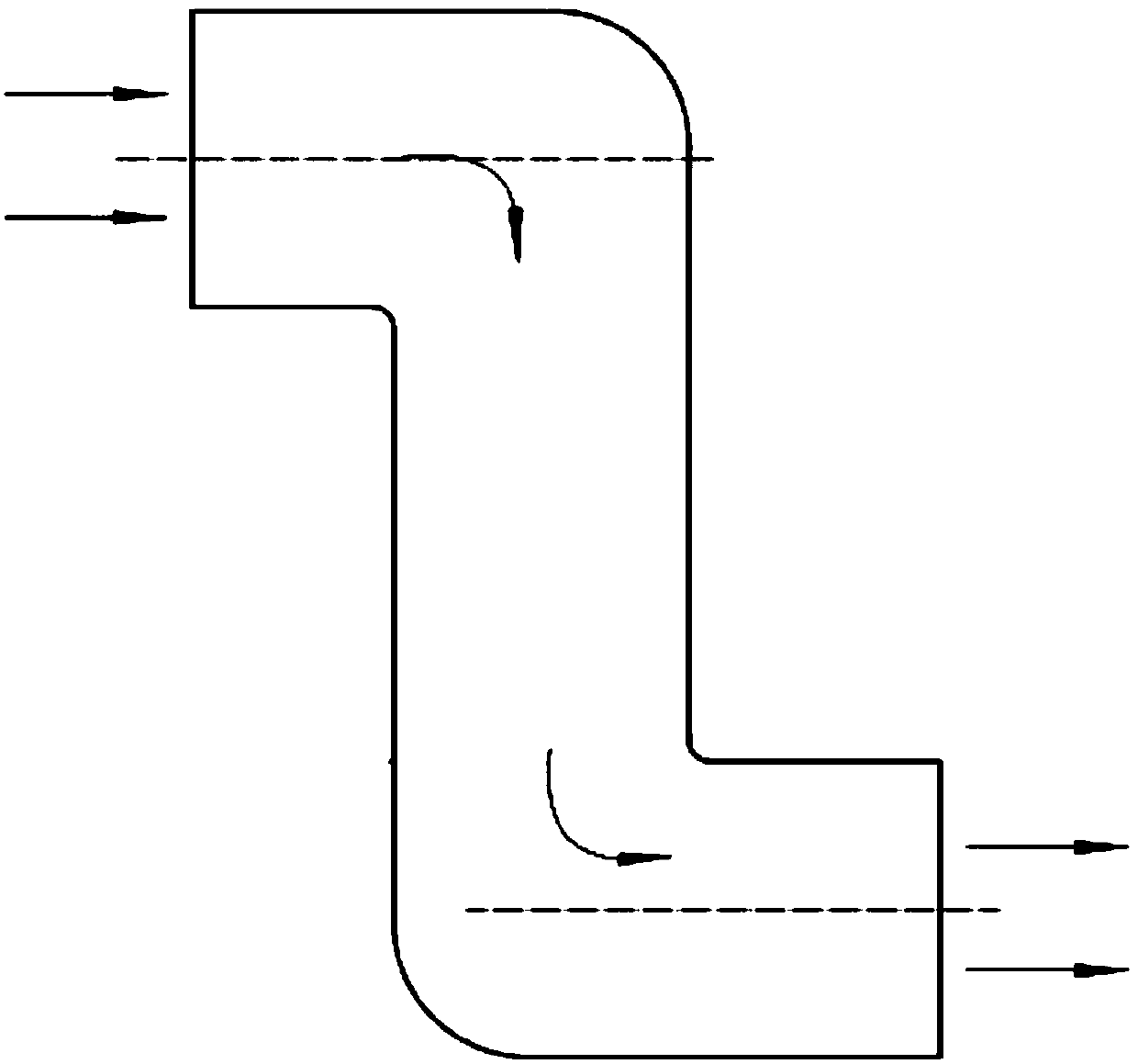

Single-section structure of sectional-type multi-stage pump for sewage

InactiveCN104121203AReduce radial sizeReduce axial sizePump componentsRadial flow pumpsAxial forceEngineering

The invention relates to a sectional-type multi-stage centrifugal pump, in particular to a single-section structure of a sectional-type multi-stage pump for sewage. The single-section structure of the sectional-type multi-stage pump for the sewage is composed of impellers, impeller back vanes, impeller inlet seal rings, spatial guide vanes, guide vane flow guide pads, bearings, shaft sleeves, middle sections, spindles and flat keys. The single-section structure is characterized in that the spindles, the impellers, the shaft sleeves and the flat keys form the rotor part of the single-section structure of the sectional-type multi-stage centrifugal pump for the sewage; the middle sections, the spatial guide vanes, the guide vane flow guide pads, the impeller inlet seal rings and the bearings form the stator part of the single-section structure of the sectional-type multi-stage centrifugal pump for the sewage. The single-section structure has the axial force balancing function of the pump and the independent supporting function; moreover, the spatial guide vanes are adopted, the radial size of the single-section structure is smaller than that of a structure with radial-type guide vanes adopted by more than 5%, liquid flowing out from the impellers is collected separately through single flow channels and is independently conveyed to next-stage impeller inlets respectively and the fluid hydraulic loss is less than that of an existing structure by about three percent.

Owner:杨丽萍

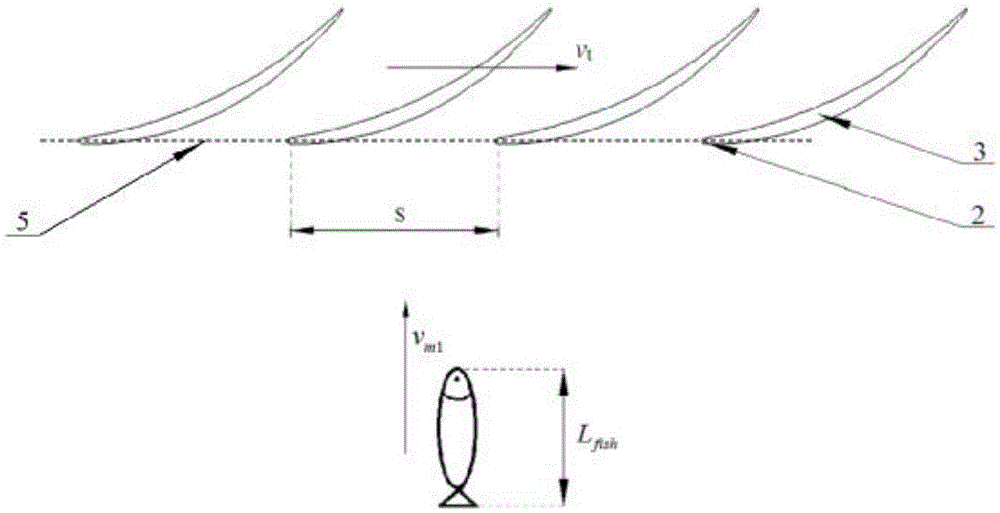

Designing method of fish-friendly axial flow pump based on fish survival rate prediction

InactiveCN105626573AImprove survival rateReduce the probability of impactPump componentsPumpsAxial-flow pumpMathematical model

The invention provides a designing method of a fish-friendly axial flow pump based on fish survival rate prediction. A relation between a pump design parameter and the fish passing survival rate is predicted by adopting a mathematical model, and thus a fish-friendly design of an axial flow pump is guided. The mathematical model is mainly composed of the blade leading edge impact probability and the impact death rate; the impact probability is a ratio of the time that fishes pass through the cross section of passage of the blade leading edge and the time needed by an impeller rotating around a blade pitch; the impact death rate is relevant to the impact velocity, the fish length and the thickness of the blade leading edge; and the impact velocity adoptsa velocity component of a vertical leading edge. The fish-friendly axial flow pump design comprises the following steps: lowering the blade leading edge impact probability by adopting two blade impellers, lowering the impact death rate by adopting the blade leading edge with linear sweepforward protraction, and ensuring good hydraulic performance by virtue of airfoil parameter design. According to the designing method, a fish survival rate prediction model is high in goodness of fit to an experiment value, and the fish-friendly axial flow pump designed by guidance can greatly lower the fish death rate.

Owner:JIANGSU UNIV

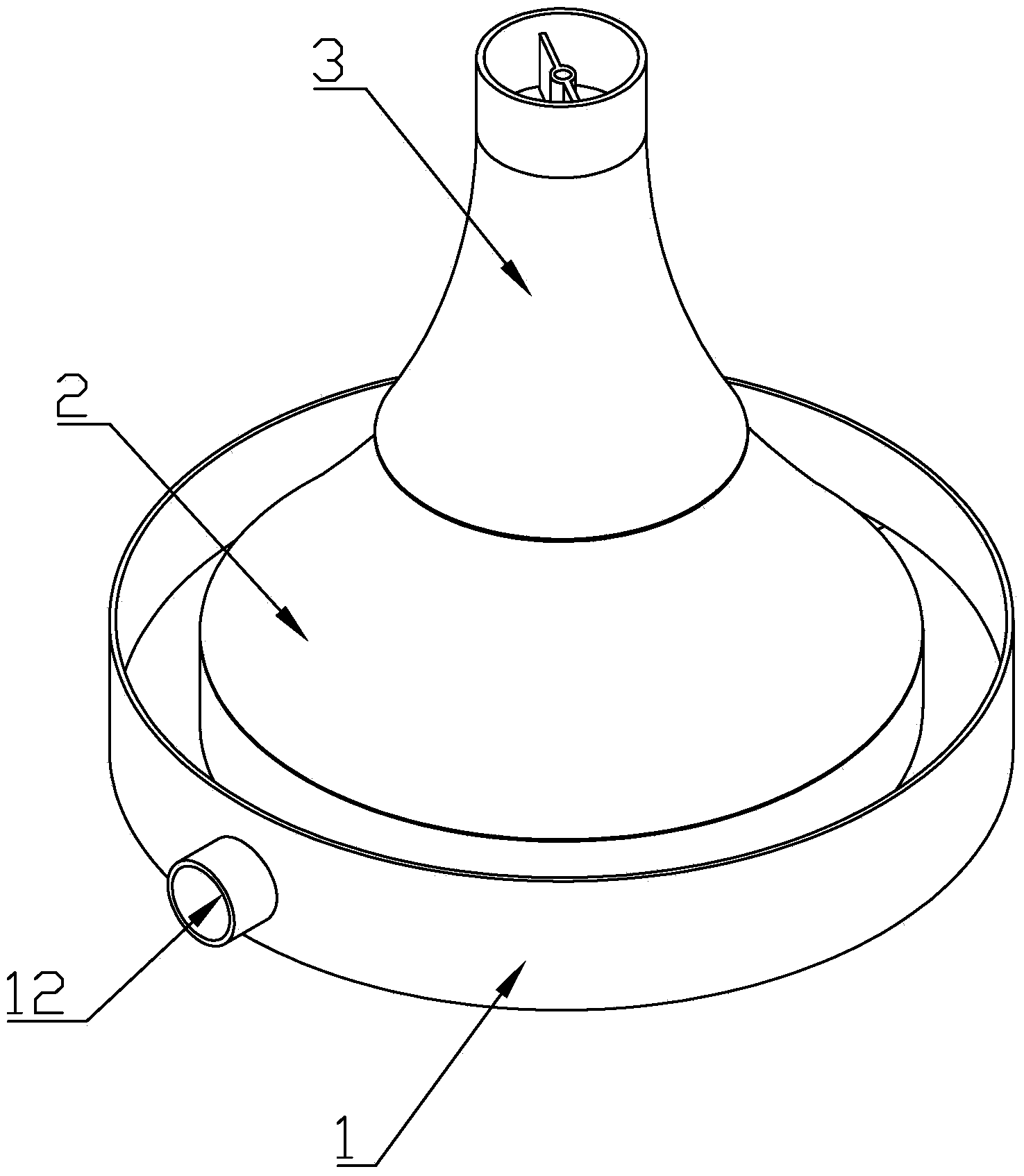

Conical solid-liquid separator

InactiveCN103611350AReduce hydraulic lossImprove processing efficiencySievingDispersed particle filtrationWater flowEngineering

The invention discloses a conical solid-liquid separator. The conical solid-liquid separator comprises a separator body, wherein the separator body is internally provided with a clean water collecting tank and a ring-shaped waste water collecting groove in the outer layer of the clean water collecting groove; at least one layer of conical sieve is arranged above the clean water collecting groove; an arc-shaped cone with a hollow inner part is sheathed above the conical sieve at the topmost layer; the upper end of the arc-shaped cone is connected with a water inlet pipe. The conical solid-liquid separator disclosed by the invention has the advantages that by arrangement of the conical sieve, the sewage flows into the arc-shaped cone from the water inlet pipe, the water flow is dispersed by the arc-shaped cone and then enters the conical sieve to be filtered, so that the solid-liquid separation device and the operation process are simplified, the hydraulic loss is reduced, and the treating efficiency is improved; the structure is simple and compact and the energy consumption is greatly reduced.

Owner:SOLIS HIGHT TECH INC SHENZHEN

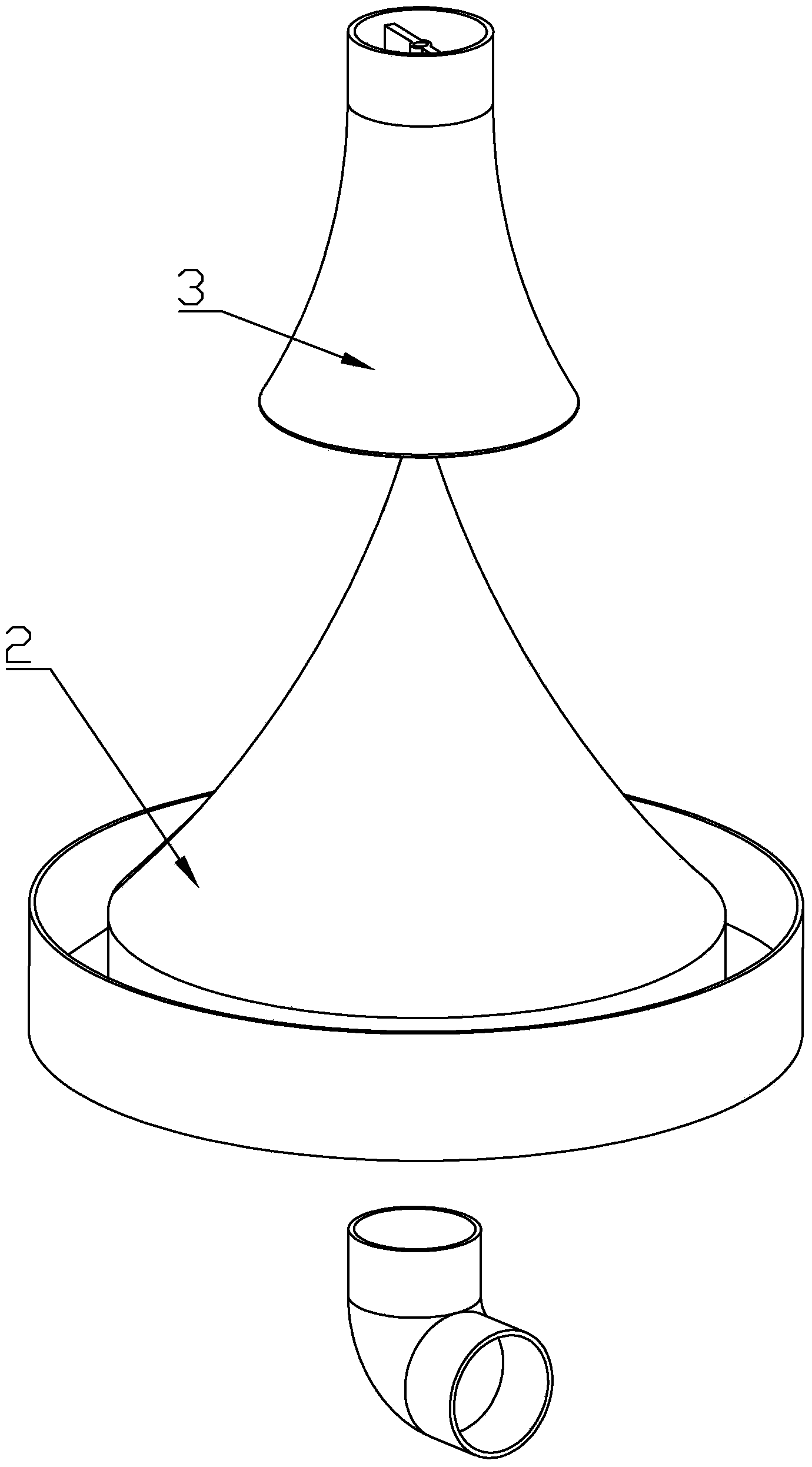

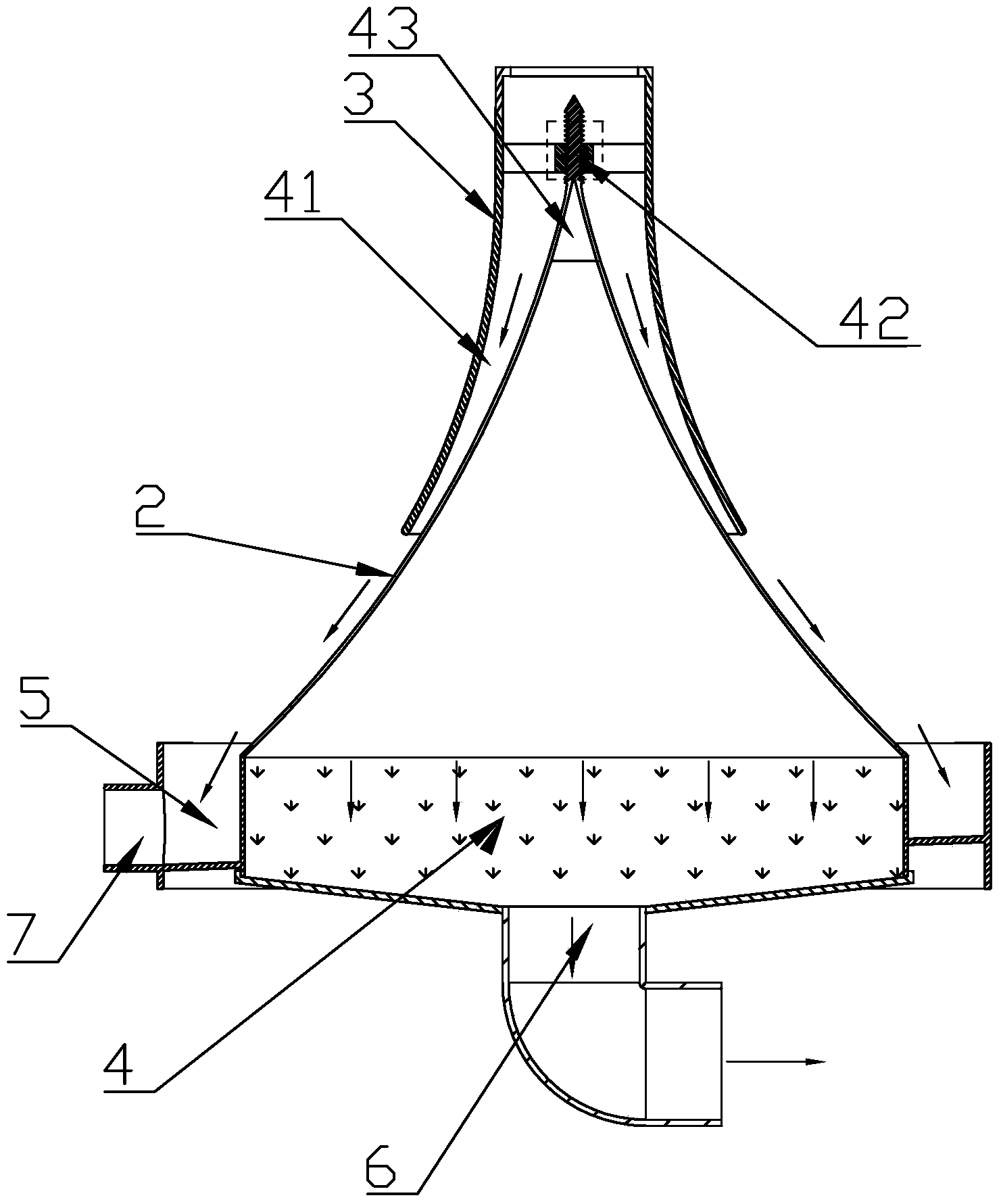

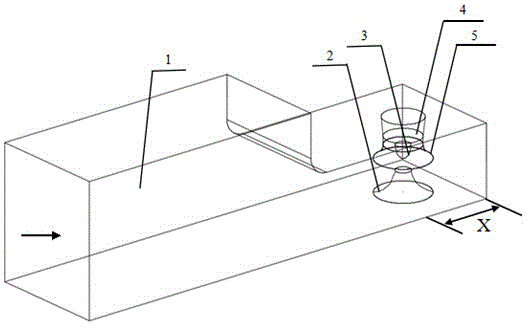

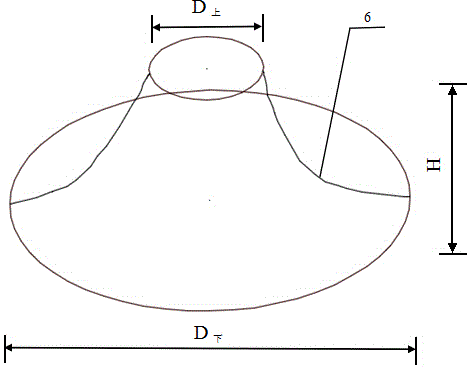

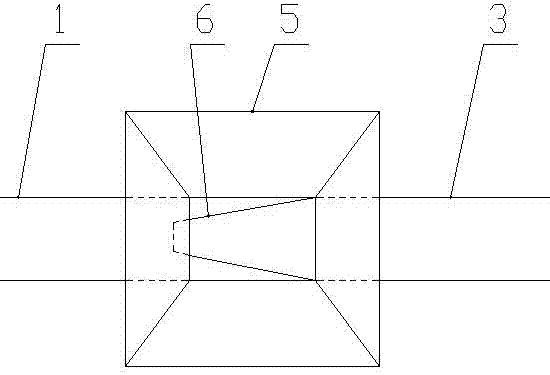

1/4 elliptic cone conical table eddy eliminating device and method for closed intake pool

The invention relates to a 1 / 4 elliptic cone conical table eddy eliminating device and method for a closed intake pool. The device comprises a closed intake pool, and a water pump and a horn pipe mouth mounted in the closed intake pool, wherein a water guide cone is arranged on a baseplate of the intake pool right below the horn pipe mouth. The device is characterized in that the water guide cone is a 1 / 4 elliptic cone conical table; the distance from the 1 / 4 elliptic cone conical table to the back wall of the closed intake pool is equal to the diameter of the horn pipe mouth; the height of the 1 / 4 elliptic cone conical table is 2 / 5 of the diameter of the horn pipe mouth of the water pump; the cone bottom diameter of the 1 / 4 elliptic cone conical table is equal to the diameter of the horn pipe mouth of the water pump; the cone top diameter of the 1 / 4 elliptic cone conical table is 7 / 25 of the diameter of the horn pipe mouth of the water pump; and the elliptic cone section of the 1 / 4 elliptic cone conical table is 1 / 4 of an elliptic cone. The device is reasonable and simple in structure, easy in manufacturing and convenient to use, and enables the section flowing speed of water currents entering the water pump and the pipe to become uniform by rectifying currents and adjusting the pool bottom speed.

Owner:YANGZHOU UNIV

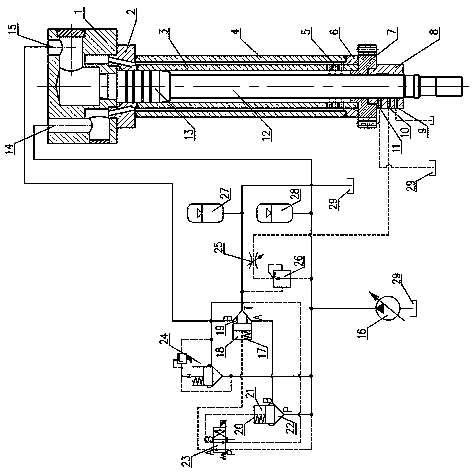

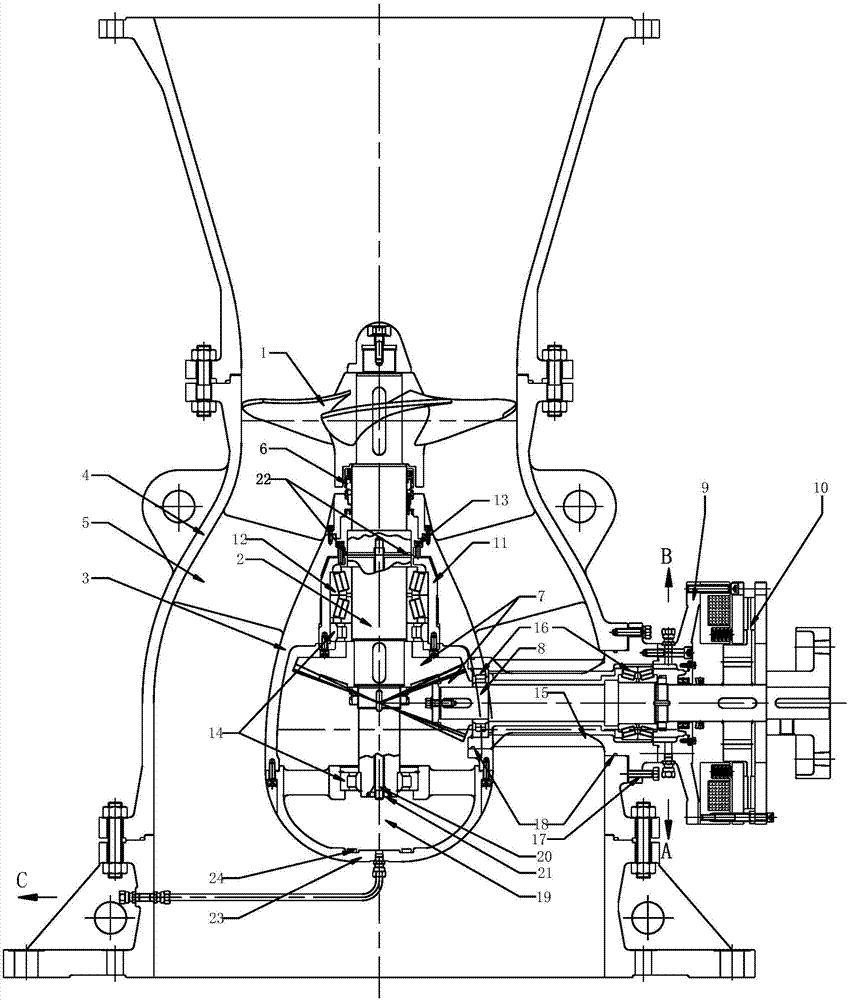

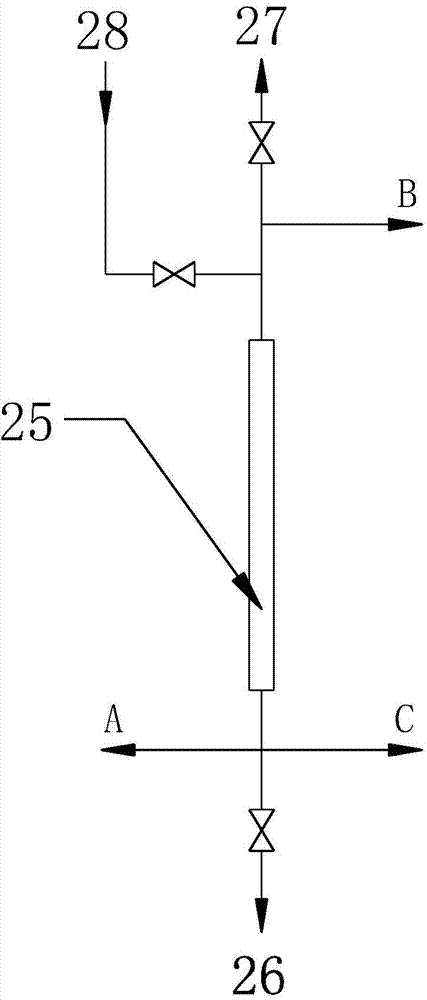

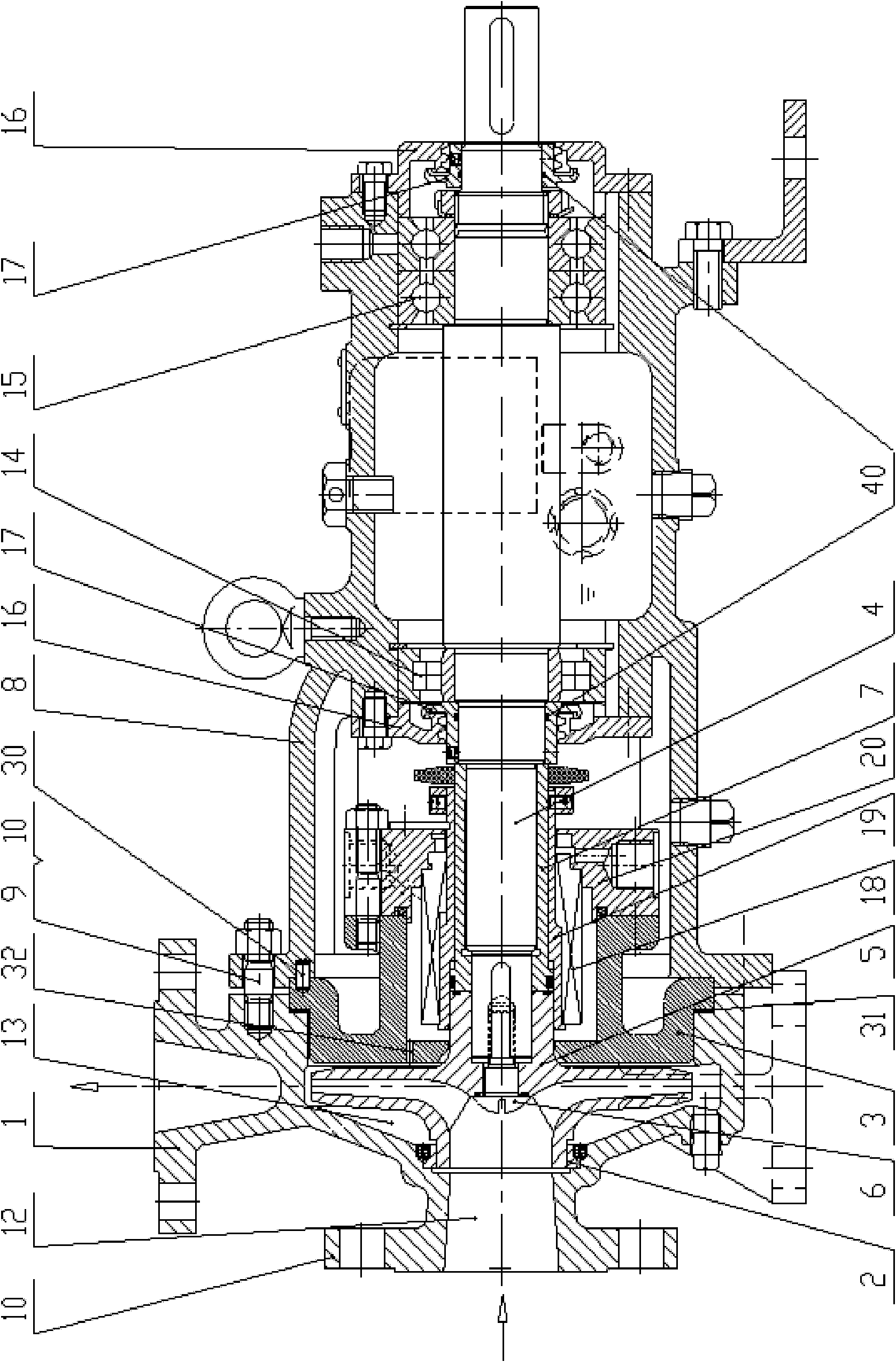

High frequency macro-energy hydraulic pile hammer

PendingCN108239979AImprove rigidityImprove structural stabilityBulkheads/pilesHydraulic cylinderInlet channel

The invention discloses a high frequency macro-energy hydraulic pile hammer which comprises a hydraulic pump and a hammer core, wherein the hydraulic core comprises an inner cylinder sleeve and an outer cylinder sleeve mounted in a spaced manner in a sleeving manner, and an oil inlet channel is formed between the inner cylinder sleeve and the outer cylinder sleeve; a piston rod fixedly connected to a piston penetrates through a cylinder cover and a static supporting sleeve axially to be supported on the static supporting sleeve, a cylinder oil inlet and a cylinder oil outlet are formed in thecylinder bottom, the cylinder oil inlet is communicated to the oil inlet channel between the inner cylinder sleeve and the outer cylinder sleeve; the oil inlet channel is communicated to a rod cavityof the hydraulic cylinder through the oil inlet hole in the inner cylinder sleeve, and a cylinder oil return hole is communicated to a rodless cavity of the hydraulic cylinder; the oil outlet of the hydraulic pump communicates to the cylinder oil inlet and a pressure oil hole of a second inserting valve in parallel, and an oil hole B of the first inserting valve is connected to the cylinder oil outlet; and a control valve as a pilot valve forms a direction control loop with the second inserting valve. The hydraulic pile hammer is simple and reasonable in structure and small in influence on ambient environment, can drive a pile at a high frequency with micro-energy, so that the hydraulic pile hammer is particularly suitable for large foundation pile construction.

Owner:JIANGSU JUWEI MACHINERY

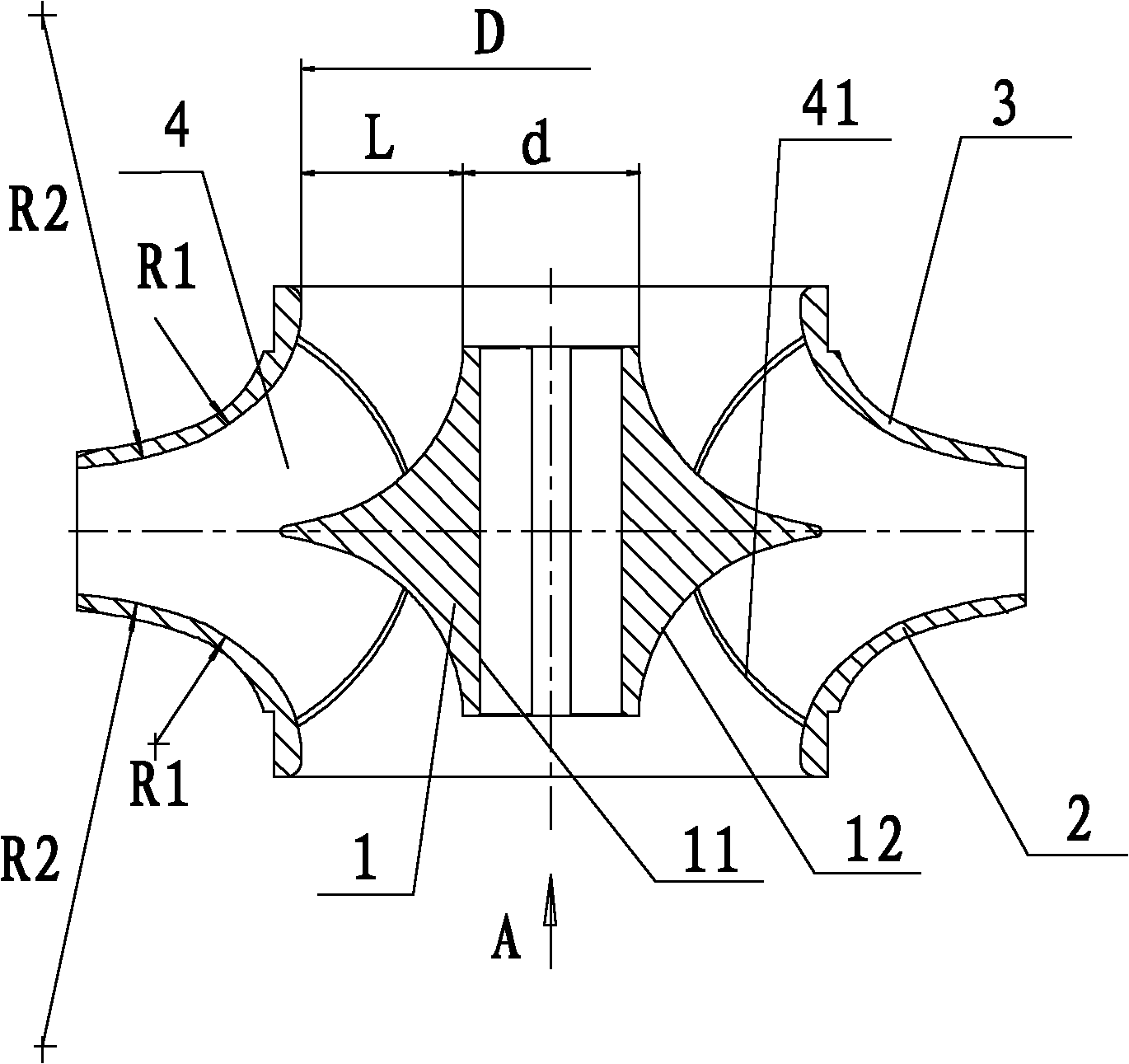

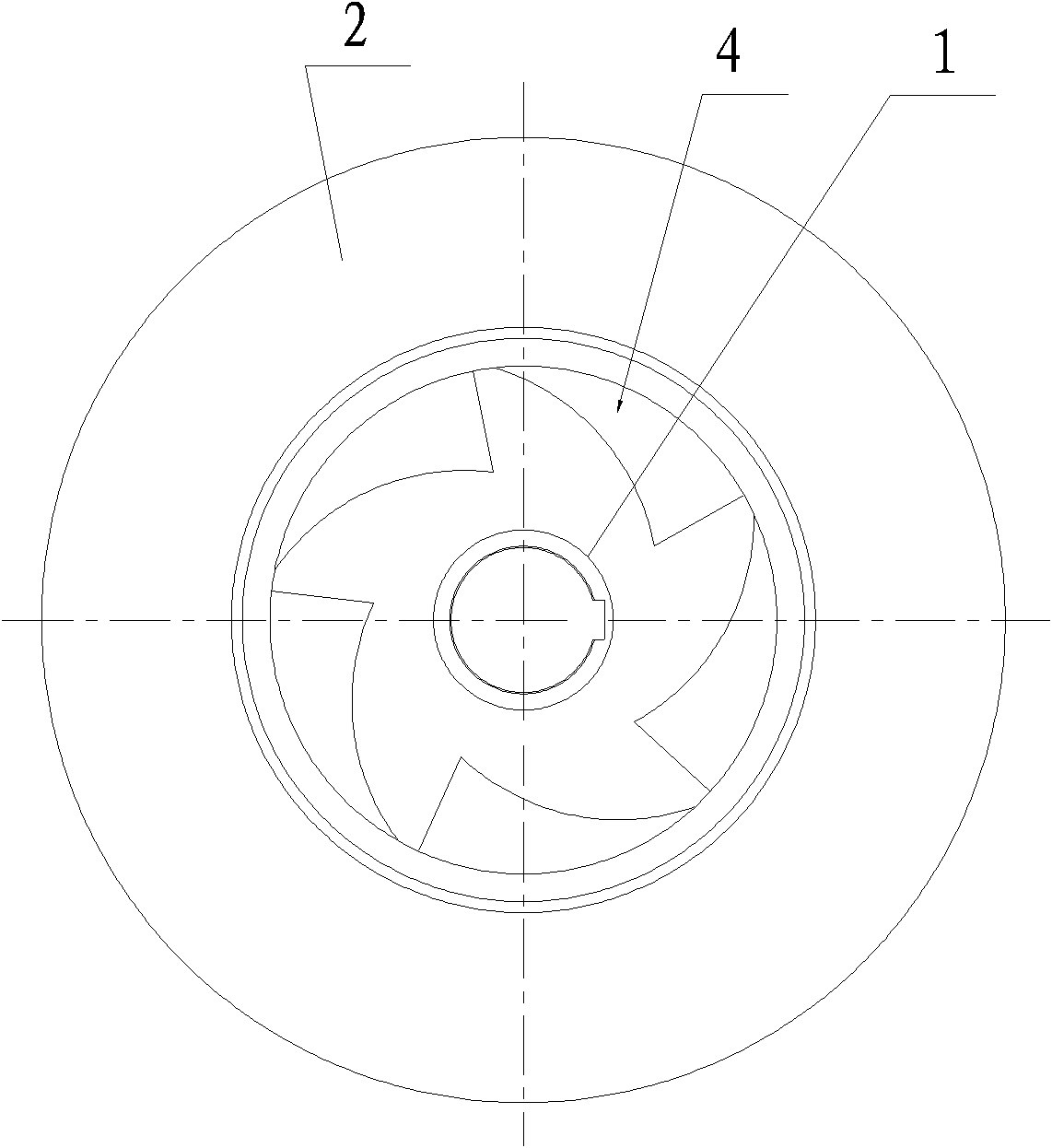

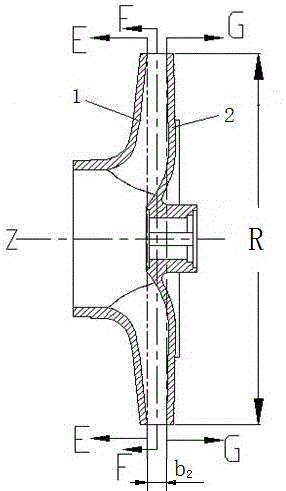

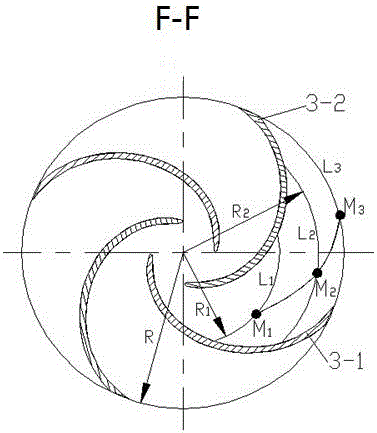

Top-level impeller on condensate extraction pump for nuclear power station

InactiveCN102116311AReduce NPSHImprove anti-cavitation performancePump componentsPumpsImpellerCavitation

The invention discloses a top-level impeller on a condensate extraction pump for a nuclear power station, which comprises a hub, a front cover plate, a rear cover plate and a plurality of blades, wherein the inner end surface of the hub is a cylindrical surface, and the outer end surface of the hub is formed by connecting two sections of trumpet-shaped curved surfaces which are in the same shape and have the same size back to back; the front cover plate and the rear cover plate are trumpet-shaped curved plates which are in the same shape and have the same size; the inner end surface of the front cover plate and the rear cover plate are formed by sequentially connecting a small section of straight surface, a section of first curved surface of which the curvature radius is R1 and a second curved surface of which the curvature radius is R2; the R2 is more than R1; the front cover plate and the rear cover plate are coaxially arranged at the periphery of the hub back to back to ensure that the inlet diameter and the outlet diameter of the top-level impeller are the same as each other; the front edge and the rear edge of each blade are connected on the inner end surfaces of the front cover plate and the rear cover plate respectively; and a V-shaped inner edge formed in the middle of each blade is connected on the outer end surface of the hub to form a double-suction impeller. The top-level impeller can reduce necessary net positive suction head of a small pump and has higher cavitation resistance.

Owner:SHANGHAI APOLLO MACHINERY

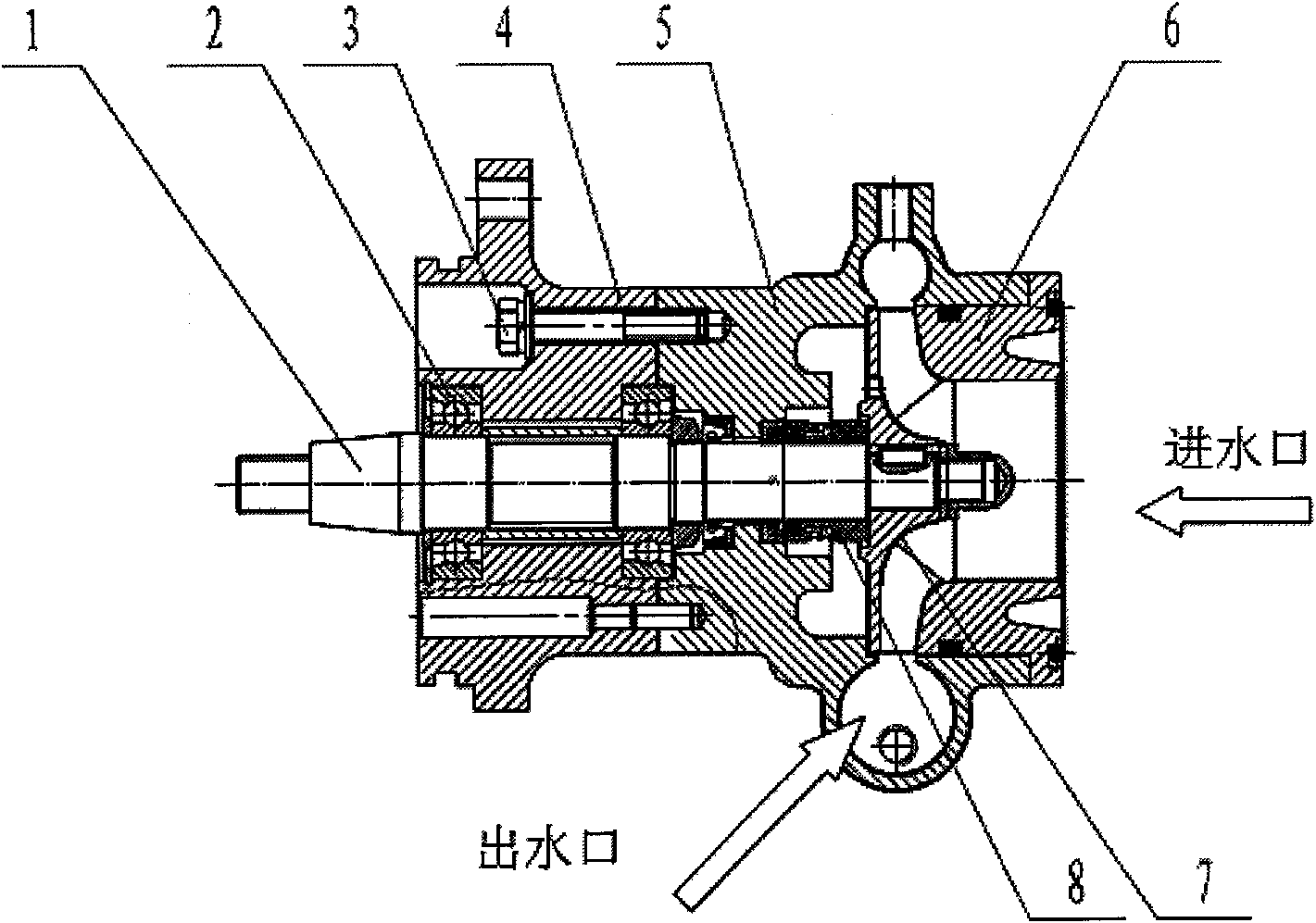

Centrifugal water pump

InactiveCN101865157AReduce hydraulic lossMeet the requirements of high-efficiency and energy-saving water pumpsPump componentsPumpsDrive shaftPulp and paper industry

The invention relates to a centrifugal water pump, belonging to the hydraulic technical field. The centrifugal water pump comprises a transmission shaft, a bearing, a fastening piece, a bearing seat, a volute, an inlet water pan, an impeller and a mechanical seal. The impeller consists of long blades and short blades. Five long blades and five short blades are arranged in a spacing way. The diameter of the middle shaft hole of the impeller is 18mm, the diameter of a hub is 24mm, the outer diameter of the impeller is 133.6mm, the length of each long blade is 46.8mm, the length of each short blade is 26.8mm, the diameter of the inlet of the long blade and the short blade is 66mm, the setting angle of the inlet of the long blade and the short blade is 36 degrees, the height of the inlet of the long blade and the short blade is 17mm, the thickness of the long blade and the short blade is 3.5mm, the setting angle of the outlet of the long blade and the short blade is 45 degrees and the height of the outlet of the long blade and the short blade is 10.3mm. The runner of the volute is matched with the impeller. The taper of the suction chamber of the inlet water pan is 12.5 degrees. The invention has the advantages of high efficiency, energy saving, good workability, light weight and small volume.

Owner:CHINA NORTH IND GRP NO 70 RES INST

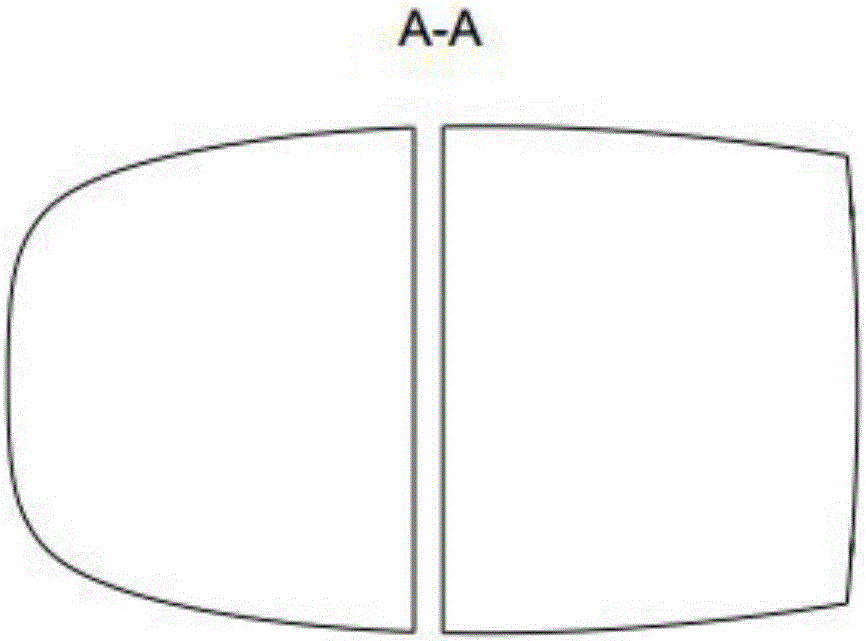

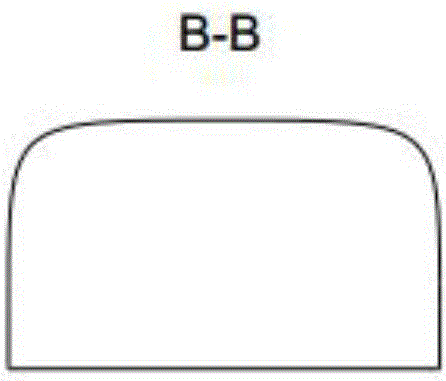

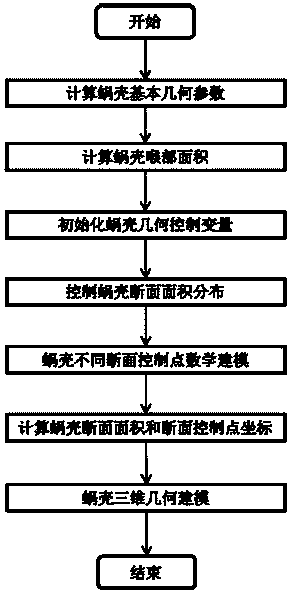

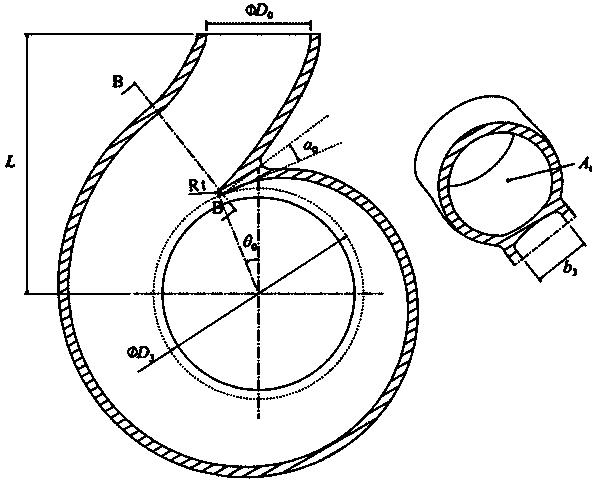

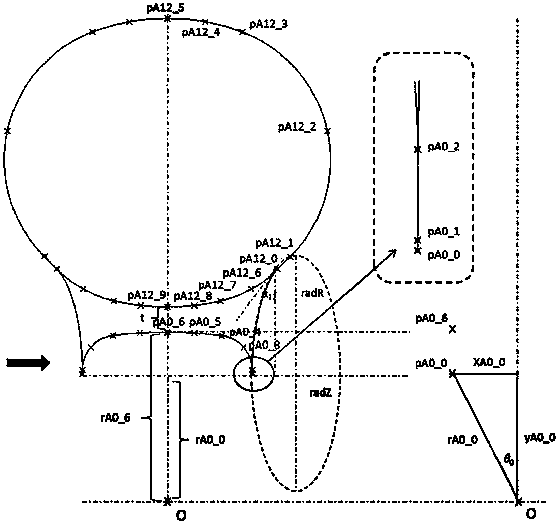

Mathematical model based centrifugal pump volute design method

ActiveCN104251235AReduce design difficultyShorten the design and development cyclePump componentsPumpsGeometric controlMathematical model

A mathematical model based centrifugal pump volute design method includes firstly, solving basic geometrical parameters of a volute according to a velocity coefficient method and calculating throat area of the volute by a velocity moment method; secondly, controlling and calculating different section areas of the volute according to an area control coefficient and a section area calculating equation and changing the control efficient to acquire volute hydraulic models of different section area distributions; thirdly, initializing geometric control variables of the volute, modeling for control points of different sections of the volute through mathematical models such as elliptical, circular, linear models, and expressing the different control points by a three-dimensional coordinate method; fourthly, utilizing a volute section area successive approximation and iteration algorithm to rapidly solve the coordinates of different section areas and section control points of the volute precisely; and fifthly, performing three-dimensional curve modeling to the volutes represented by different control points on the basis of three-dimensional design software.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

Jet pump with volute type flume

InactiveCN106224302AImprove flow statusJet pump efficiency improvementJet pumpsMachines/enginesStraight tubeWater flow

The invention provides a jet pump with a volute type flume. The jet pump comprises a fluid pipeline B, a fluid pipeline A arranged outside the fluid pipeline B in a sleeving mode, a constricted tube, a throat tube and an expansion tube, wherein the constricted tube, the throat tube and the expansion tube are sequentially connected with the water outlet end of the fluid pipeline A. The volute type flume arranged outside the fluid pipeline B in a sleeving mode is arranged at the inlet end of the fluid pipeline A. The diameter of the water outlet end of the fluid pipeline A is decreased gradually in the water flowing direction. The constricted tube is a round tube with the diameter being decreased gradually. The throat tube is a straight tube. The expansion tube is a round tube with the diameter being increased gradually. The jet pump is easy to manufacture and install, the symmetry of internal flow of the jet pump is good, flowing is more stable, and hydraulic performance is improved; the flow losses are reduced, mixing of two fluids is promoted, and the efficiency is improved advantageously; the frictional hydraulic losses are reduced; and the jet pump is suitable for an annular jet pump as well as a central jet pump.

Owner:WUHAN UNIV

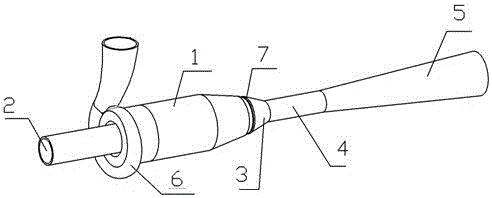

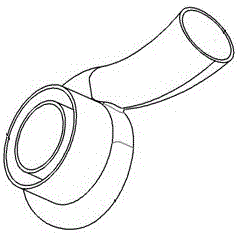

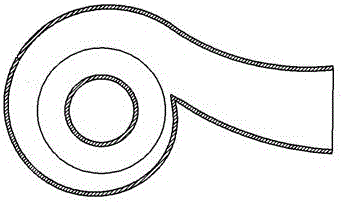

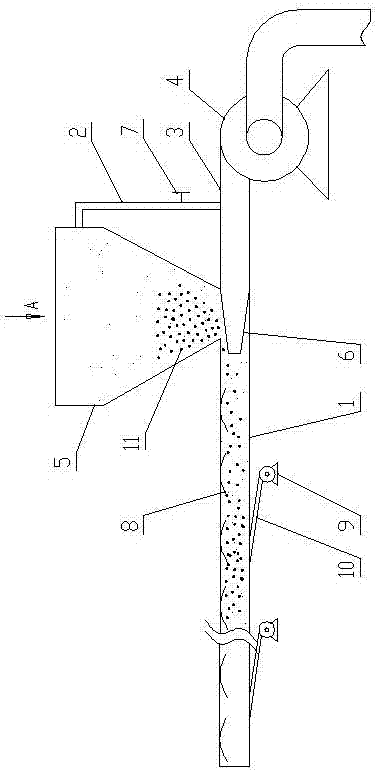

Water conveying device of granular material pipeline

The invention relates to a water conveying device of a granular material pipeline. The water conveying device comprises a material conveying pipe, a water supply pipe, a water spray pipe, a main water pump and a feed hopper, wherein a nozzle is arranged on the front end of the water spray pipe, the front end of the nozzle extends into the back end of the material conveying pipe, the front end of the water spray pipe is fixed to and is in sealing connection with the back end of the material conveying pipe, the back end of the water spray pipe is connected with a water outlet of the main water pump, the lower end of the feed hopper is connected with the top of the material conveying pipe, a feed opening is formed in the bottom of the feed hopper and is located above the nozzle, a water spray opening in the front end of the nozzle is located in the front side of the feed opening in the bottom of the feed hopper, the nozzle is of a conical structure of which the front part is thin and the back part is thick, the outside diameter of the back end of the nozzle is equal to the inside diameter of the material conveying pipe, one end of the water supply pipe is connected to the water spray pipe, the other end of the water supply pipe is connected to the upper part of the feed hopper, and a regulating valve is arranged on the water supply pipe. The water conveying device has the advantages of reasonable design, easiness in operation, high degree of automation, high controllability, high conveying efficiency, difficulty in blocking, high practicability and easiness in popularization and application, and the abrasion influence of solid particles on the main water pump and an enhanced water pump is avoided.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

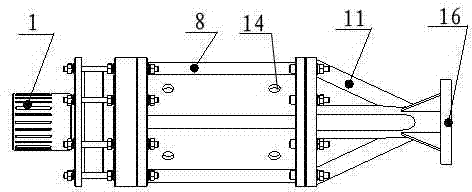

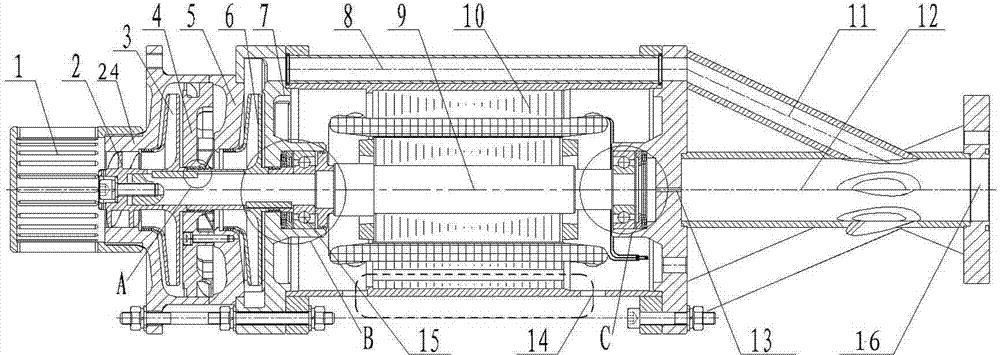

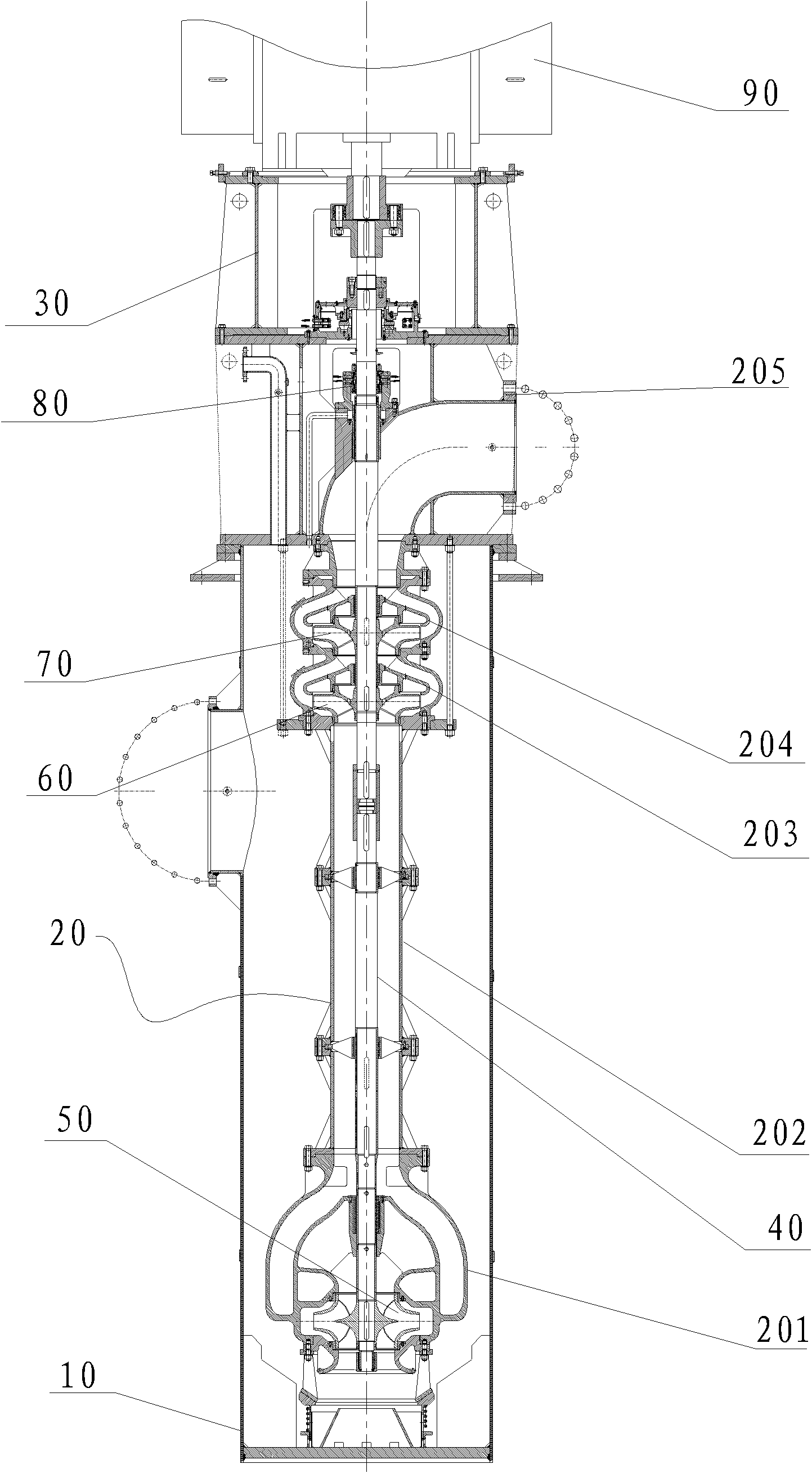

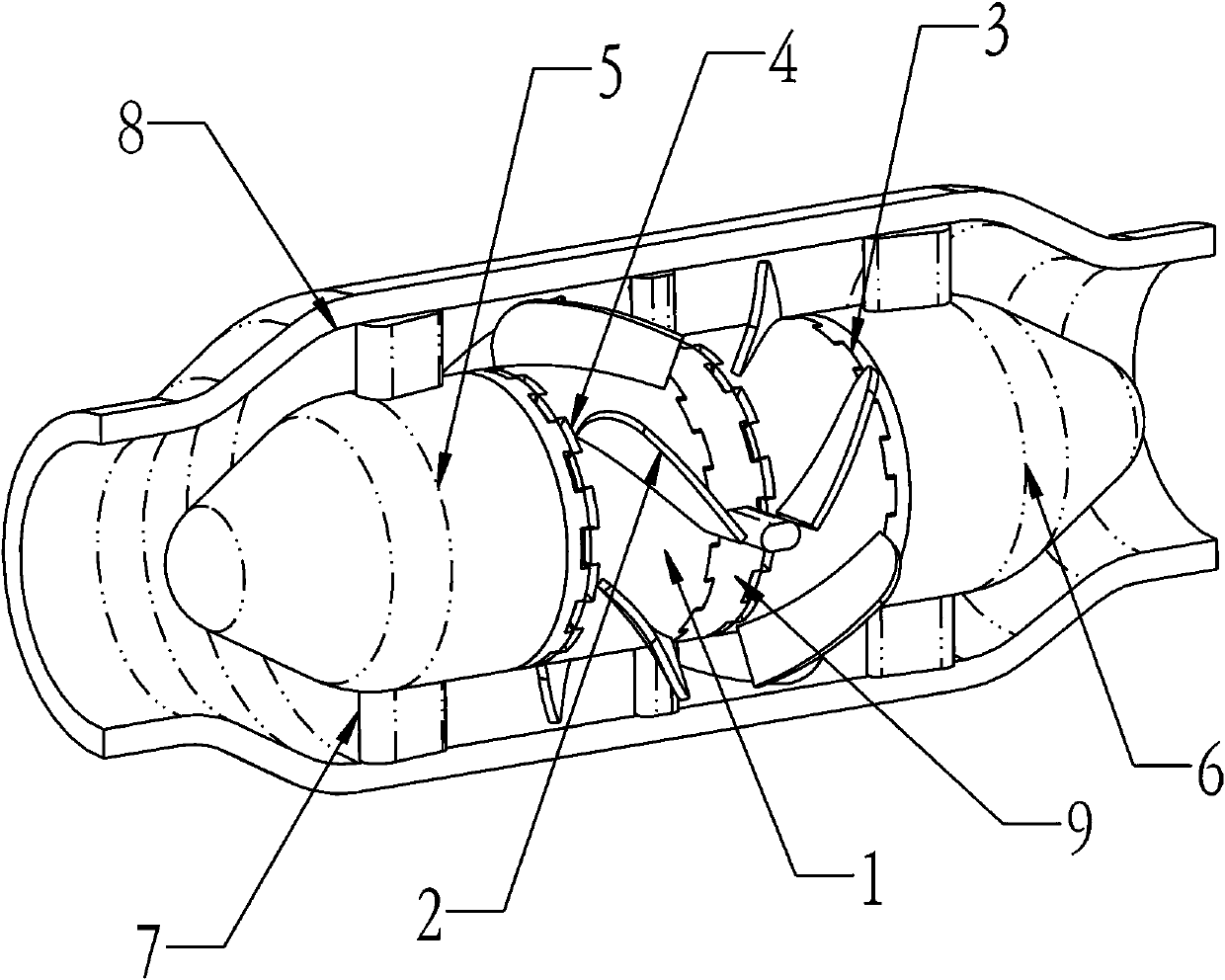

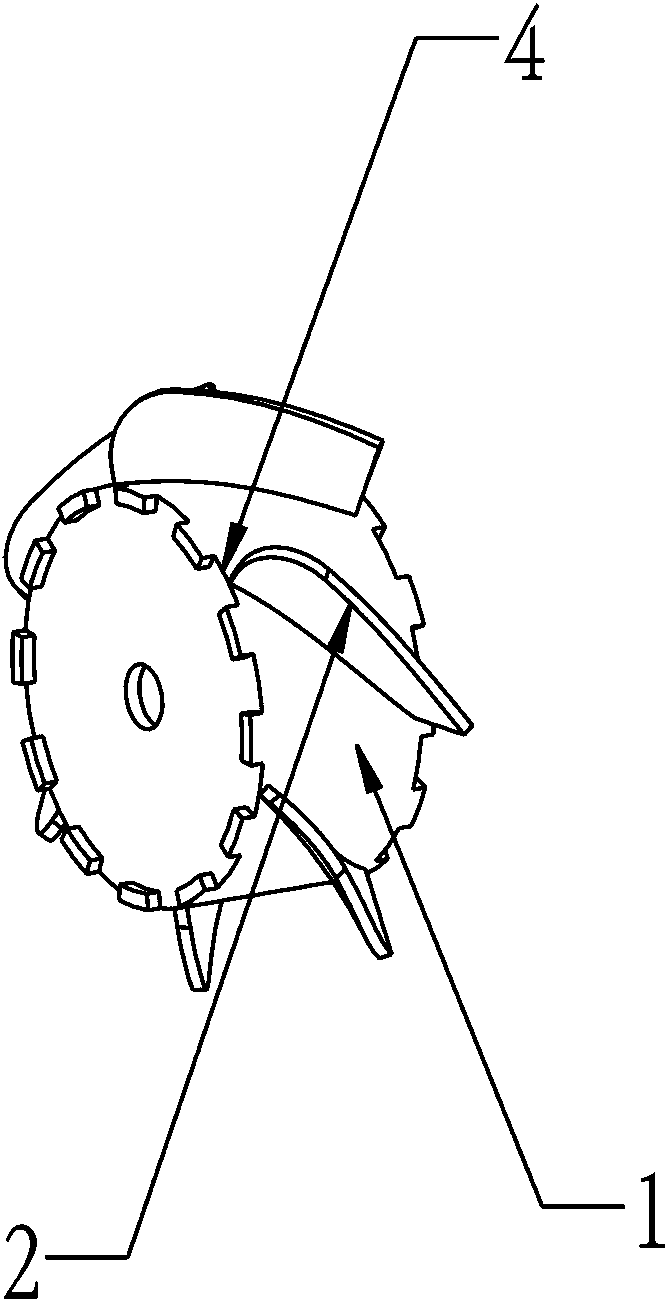

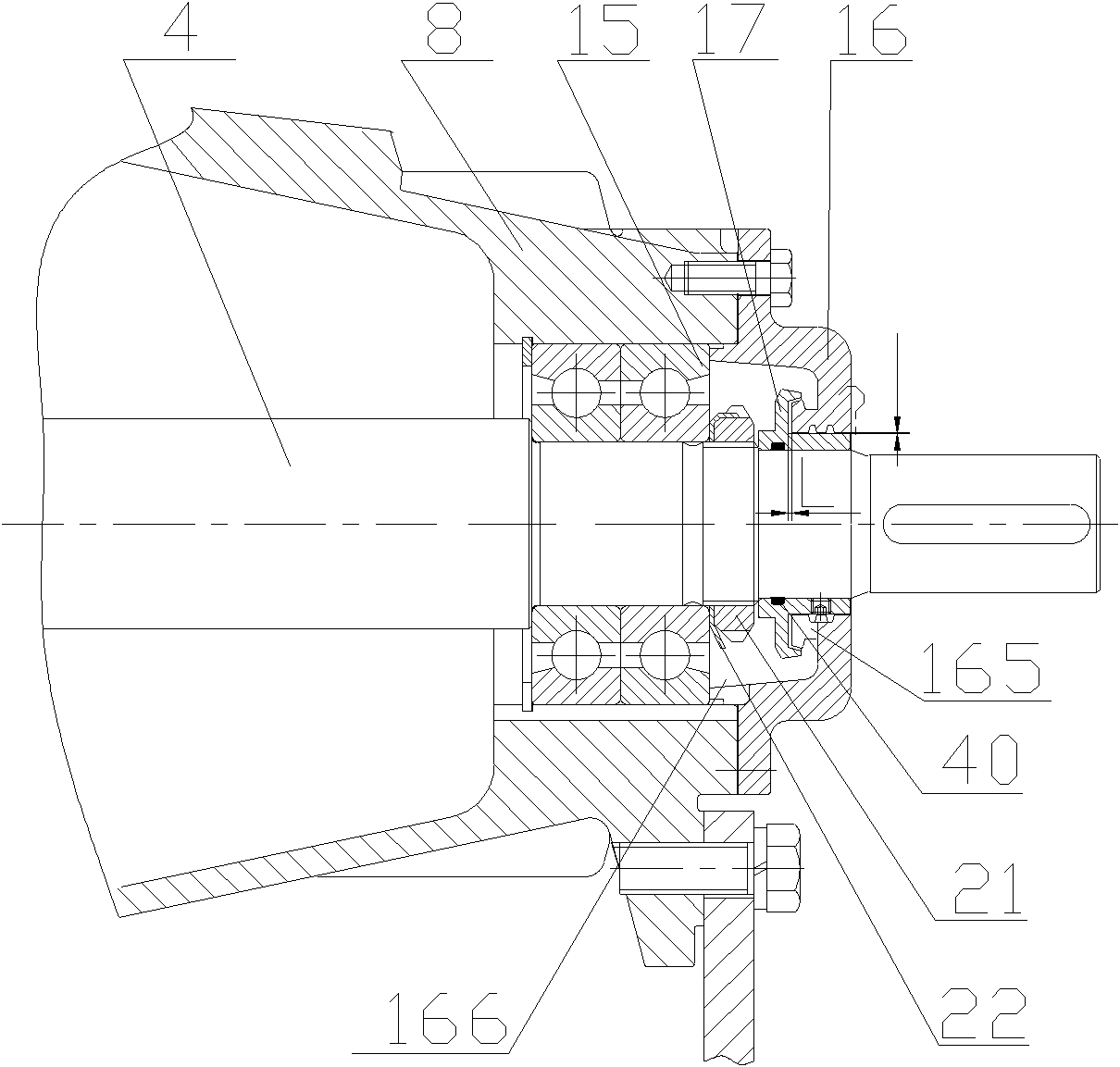

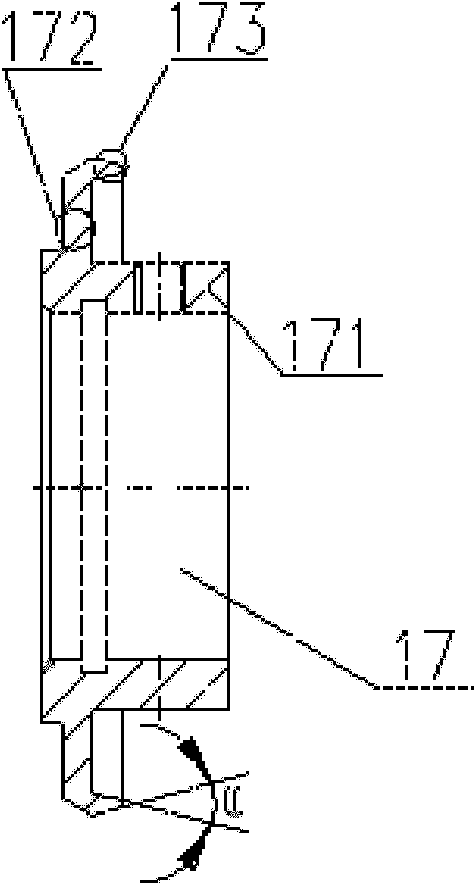

Bi-directional bulb through-flow turbine capable of achieving automatic switching

InactiveCN107676212AReduce hydraulic lossReduce volumeHydro energy generationReaction enginesClutchEngineering

The invention discloses a bi-directional bulb through-flow turbine capable of achieving automatic switching. A spindle stretches out of the tail of a bulb body, and other parts are sealed; the other end of the spindle is connected to a bearing seat, and the exterior of the bearing seat is connected with a support; the exterior of the bulb body is connected with the support, and the exterior of a fixed wheel is connected with the support; the support is connected with a shell; the right sides of two turning wheels are provided with a pair of right clutches, and the left sides of the two turningwheels are provided with a pair of left clutches; half of the clutches which are located on the two sides and close to the exterior can rotate around the spindle, and the fixed wheel is arranged in the middle; the two sides of the fixed wheel are each provided with half of the clutches which cannot rotate; the two turning wheels are arranged, and the two end surfaces of each turning wheel are each provided with half of the clutches; spiral blades are evenly distributed on the outer circles of the turning wheels around the axes, the right spiral blade is arranged on one turning wheel, and theleft spiral blade is arranged on the other turning wheel; circular holes matched with the spindle are formed in the middles of the turning wheels, and the turning wheels can rotate around the spindleand can slide around the axis of the spindle; and the end surfaces of the bearing seat and the bulb body are both provided with transmission mechanisms, and the clutches and a planetary gear train arearranged.

Owner:涪陵善通有限责任公司

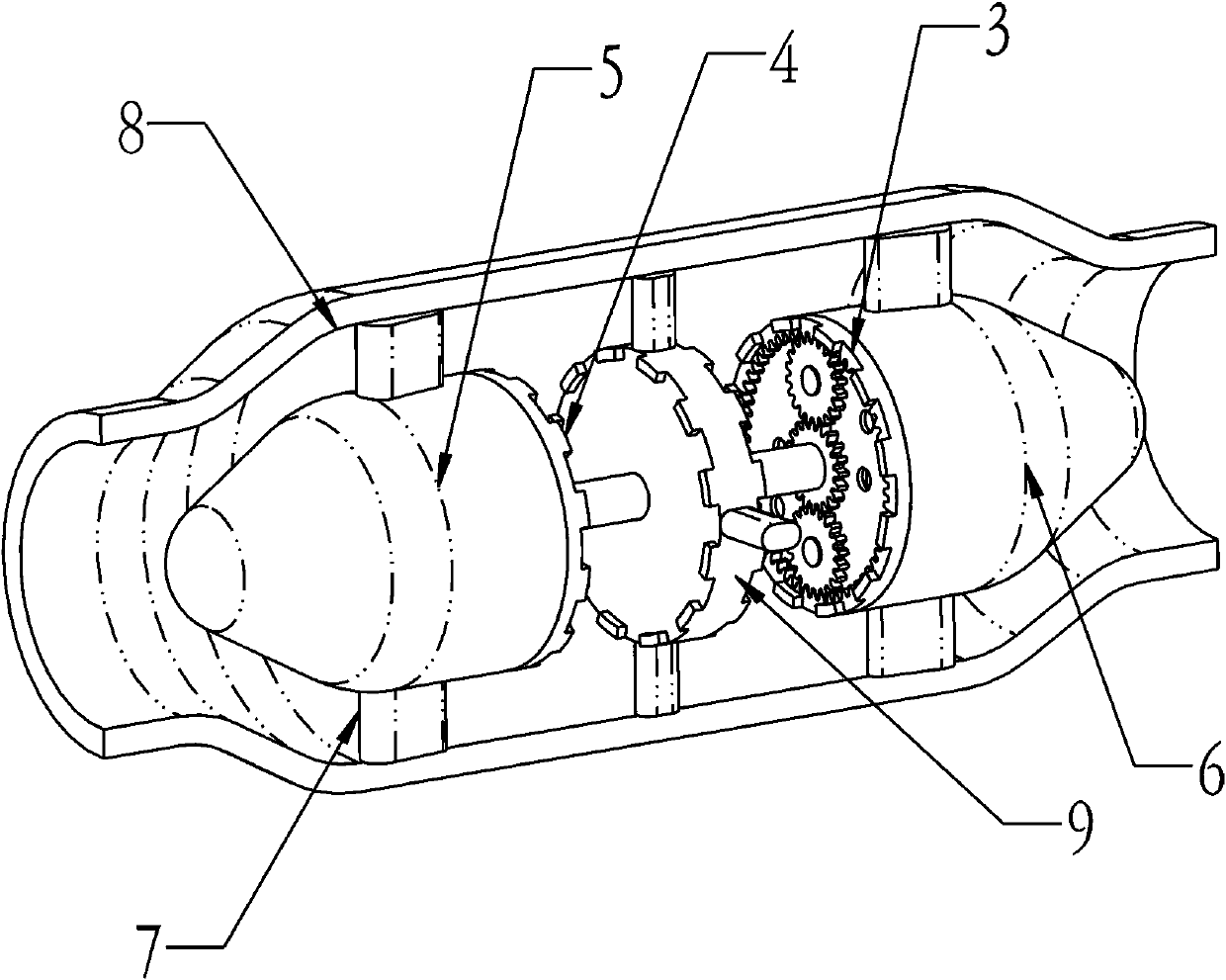

Bulb through-flow turbine

InactiveCN104329202APrevent rotationDoes not affect process flowEngine fuctionsHydro energy generationTurbineBevel gear

The invention belongs to the technical field of hydroelectric power generating equipment of a fluid flow machine and mainly provides a bulb through-flow turbine. The bulb through-flow turbine comprises a shell, a bulb body, a runner and a spindle, wherein the bulb body, the runner and the spindle are arranged in the shell; one end of the spindle extends into the bulb body, and the other end of the spindle is located at the outer part of the bulb body and is connected with the runner; the spindle is provided with a first bevel gear; the first bevel gear is located in the bulb body. The bulb through-flow turbine is characterized by comprising a countershaft; the countershaft is provided with a second bevel gear; the first bevel gear and the second bevel gear are meshed to form a bevel gear pair; transmission is realized between the countershaft and the spindle through the bevel gear pair; the countershaft is provided with an electromagnetic power-off brake; the electromagnetic power-off brake is structurally and electrically connected with the bulb through-flow turbine.

Owner:上海福思特流体机械有限公司

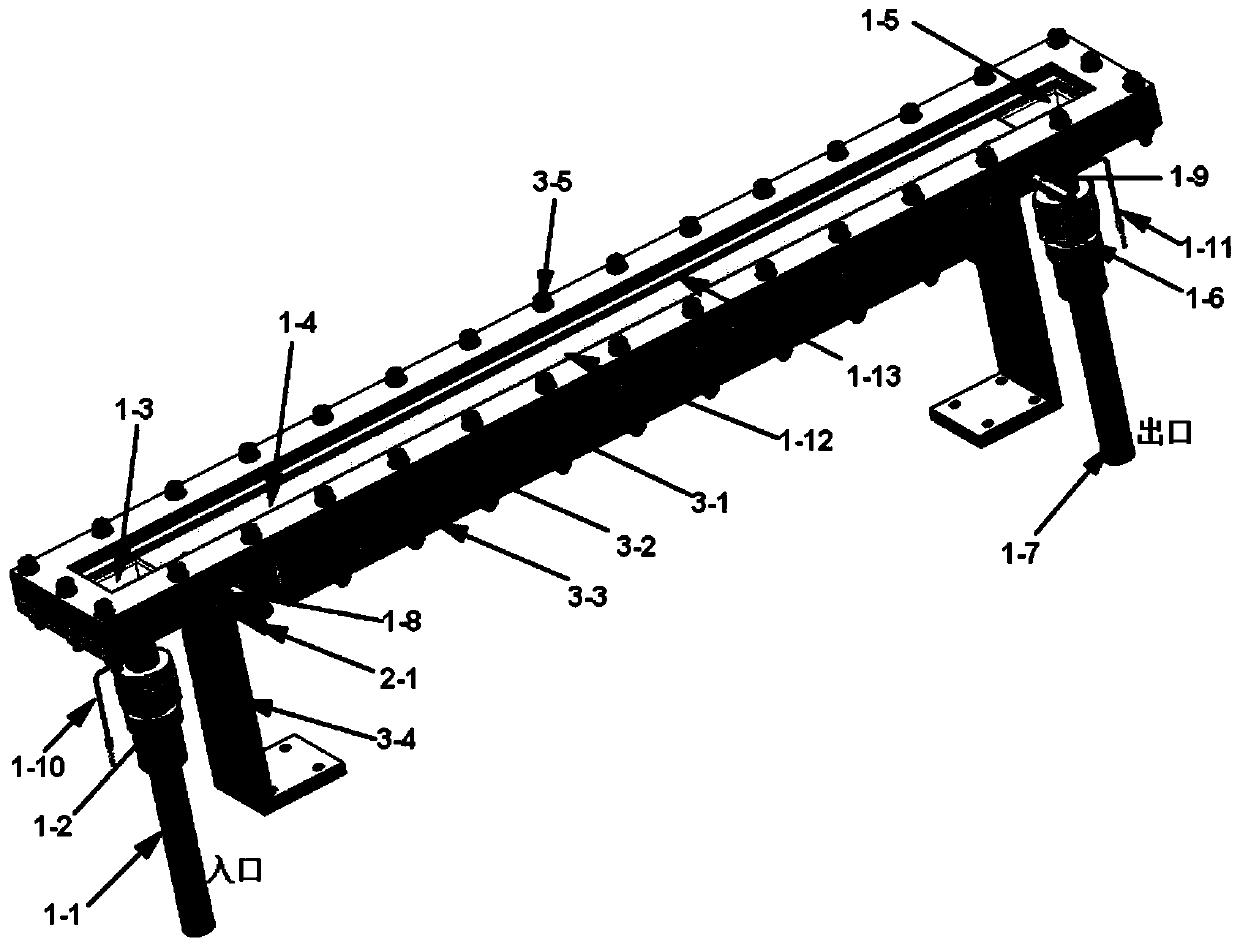

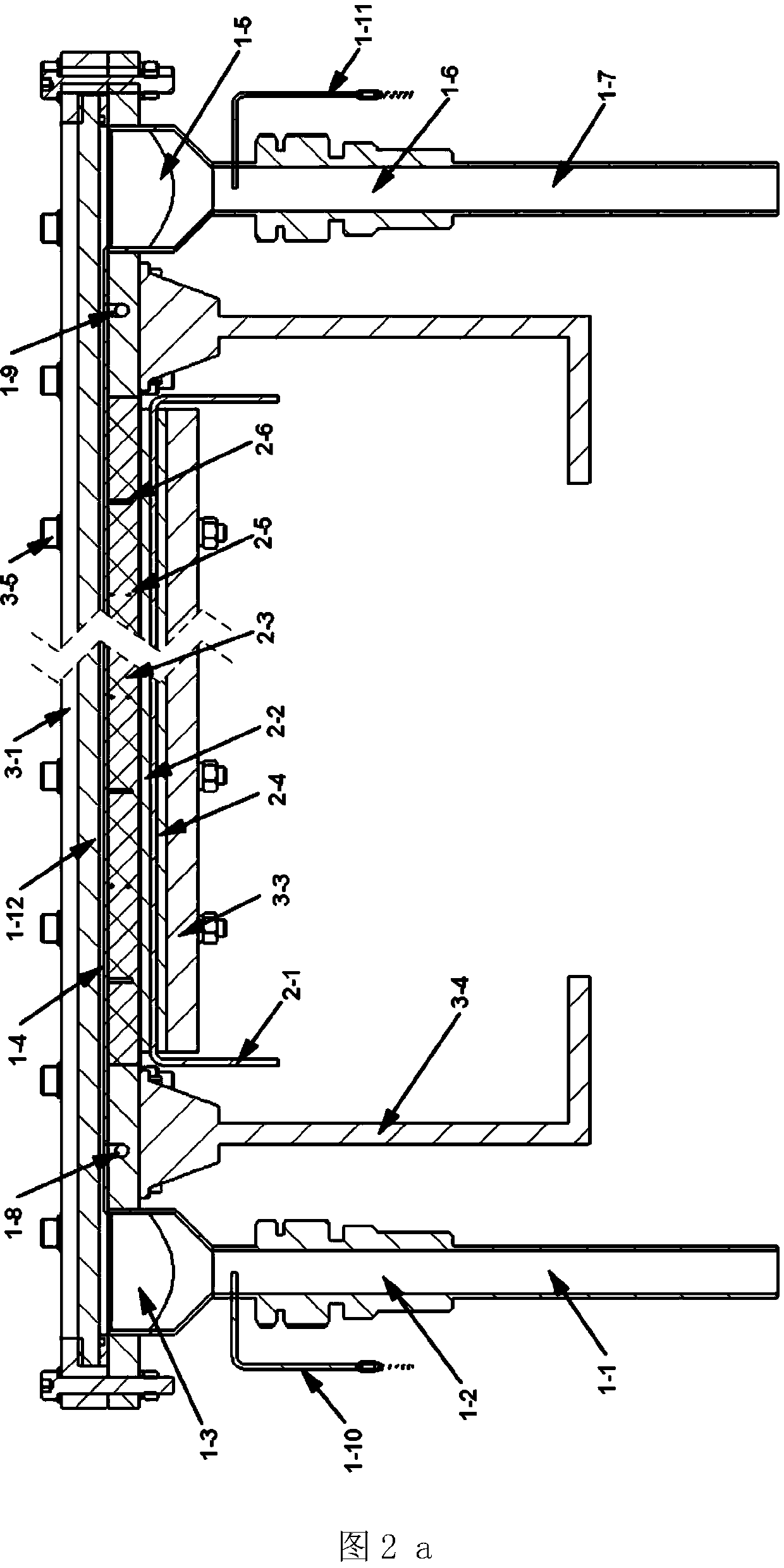

Horizontal non-uniform indirect heating rectangular channel flow visualization test apparatus

ActiveCN110265159AAvoid drastic changes in flow patternReduce hydraulic lossNuclear energy generationNuclear monitoringHeat flowComputer module

The invention discloses a horizontal non-uniform indirect heating rectangular channel flow visualization test apparatus. The apparatus consists of a flow channel body module, a power loading module and a clamping fixing module. By conveniently adjusting an output power of each electric heating element, horizontal heat flow distribution with different forms is realized according to research needs. The test apparatus can be used to carry out a flow visualization test research of a rectangular narrow-slit flow channel under horizontal non-uniform heat flow working conditions, influences of thermal parameters such as pressure, temperature, flow volume and horizontal heat load distribution, and corresponding geometric parameters on flow characteristics in the narrow-slit channel are studied, and corresponding bubble dynamic characteristics and flow pattern transition criteria are obtained. At the same time, the test apparatus can obtain detailed flow field and temperature field information by combining with advanced measuring equipment and testing means. In addition, the test apparatus is designed with the reasonable clamping fixing module to ensure that the test apparatus can be operated within a wide range of thermal parameters to meet test working condition demands of different engineering under practical application backgrounds.

Owner:XI AN JIAOTONG UNIV

Chemical additive mixing pump for nuclear power station

ActiveCN102146936AImprove efficiencyGood for long-term operationPump componentsPumpsImpellerNuclear power

The invention discloses a chemical additive mixing pump for a nuclear power station, which adopts a straight tapered water-absorbing room to lead liquid to flow in a straight tapered contraction pipe, thereby ensuring that the flow velocity is gradually increased, the distribution is uniform, the hydraulic loss is small, and a uniform velocity field is arranged at an inlet of an impeller; the impeller is matched and locked with a locking structure of a pump shaft through external threads of a special locking bolt and internal threads at the shaft end of the pump shaft; the spherical surface of the locking bolt completely conforms to the hydraulic shape of the impeller, so that the locking bolt is integrated with the streamline shape of the impeller into a whole after being installed, thereby maximally ensuring that the inlet water flow of the impeller is not affected; meanwhile, the diameter of the pump shaft and the specification of a bearing can be increased; the larger bearing can be prolonged in service life and also can bear larger load; a pump body is connected with a pump cover in such a manner that the pump cover is directly pressed between the pump body and a bearing body to shorten the overall axial dimension of the pump; and a bearing oil sealing device achieves the ideal sealing effect by adopting the labyrinth sealing, so that no leakage of lubricating oil exists in the endurance test of 400 hours.

Owner:SHANGHAI APOLLO MACHINERY

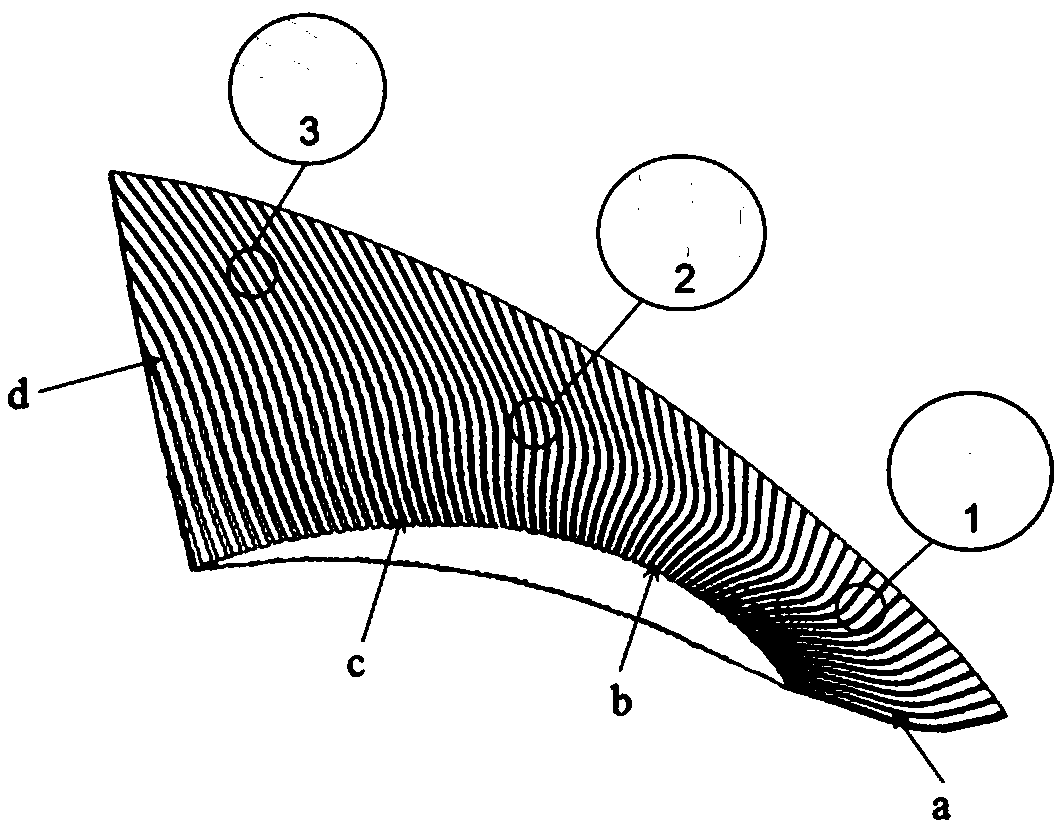

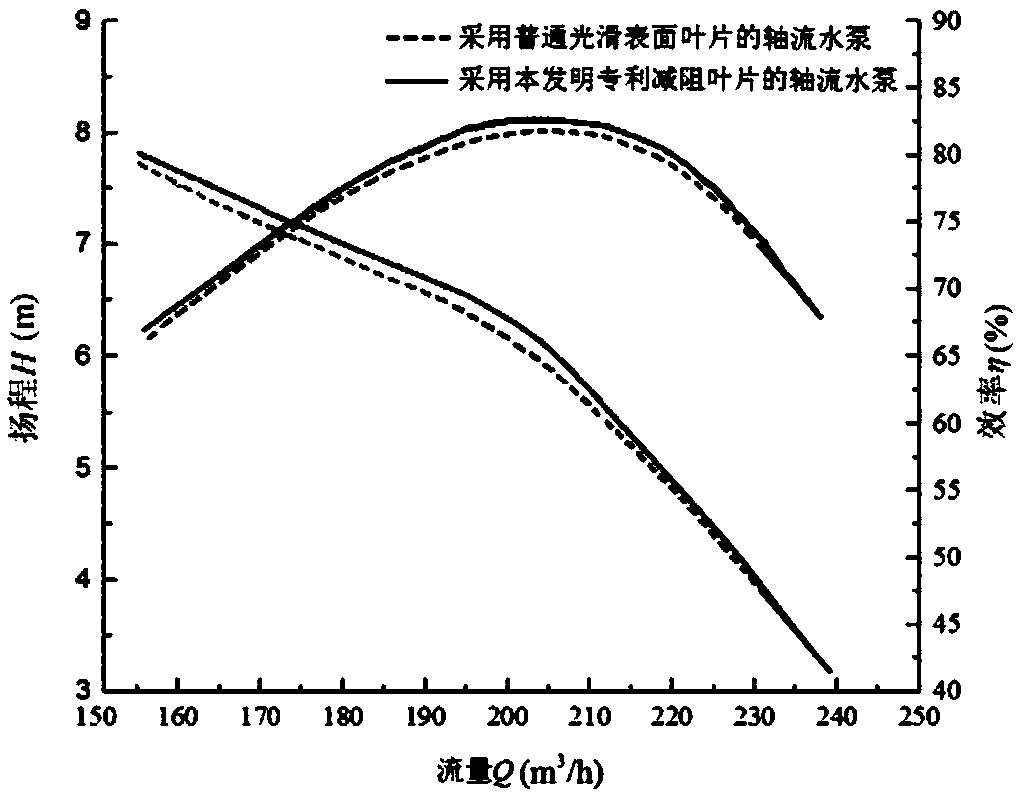

Bionic blade on basis of shark surface drag reduction technologies

ActiveCN108980101AImprove operational efficiencyReduce hydraulic lossPump componentsPumpsShoulder widthGroove width

The invention belongs to the technical field of water pumps, and particularly discloses a bionic blade on the basis of shark surface drag reduction technologies. The bionic blade comprises a front edge drag reduction section, a middle arc front drag reduction section, a middle arc rear drag reduction section and a rear edge drag reduction section. The bionic blade is characterized in that the bionic blade is an axial-flow type blade; the front edge drag reduction section is a circular toothed drag reduction groove, the groove width b<1> ranges from 7.5 k<1> to 11.5 k<1>, the groove depth h<1>ranges from 0.35 b<1> to 0.45 b<1>, and the groove shoulder width t<1> ranges from 0.1 b to 0.2 b; the middle arc front drag reduction section is a circular toothed drag reduction groove, the groove width b<2> ranges from 11.5 k<2> to 14.5 k<2>, the groove depth h<2> ranges from 0.65 b<2> to 0.75 b<2>, and the groove shoulder width t<2> ranges from 0.1 b<2> to 0.2 b<2>; the middle arc rear drag reduction section is a knife-edge-shaped drag reduction groove, the groove width b<3> ranges from 16.5 k<2> to 18.5 k<3>, the groove depth h<3> ranges from 0.45 b<3> to 0.55 b<3>, and the groove shoulder width t<3> ranges from 0.1 b<3> to 0.2 b<3>; the rear edge drag reduction section is a sawtooth drag reduction groove, the groove shoulder inclination beta ranges from 50 degrees to 65 degrees, thegroove width b<4> ranges from 13.5 k<4> to 15.5 k<4>, the groove depth h<4> ranges from 0.95 b<4> to 1.05 b<4>, and the groove shoulder width t<4> ranges from 0.1 b<4> to 0.2 b<4>. The bionic blade has the advantages that the drag reduction efficiency of different drag reduction grooves can be effectively utilized, accordingly, surface drag of the bionic blade and hydraulic loss due to the surfacedrag of the bionic blade can be reduced to the greatest extent, and the operational efficiency of pumps can be improved.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH +1

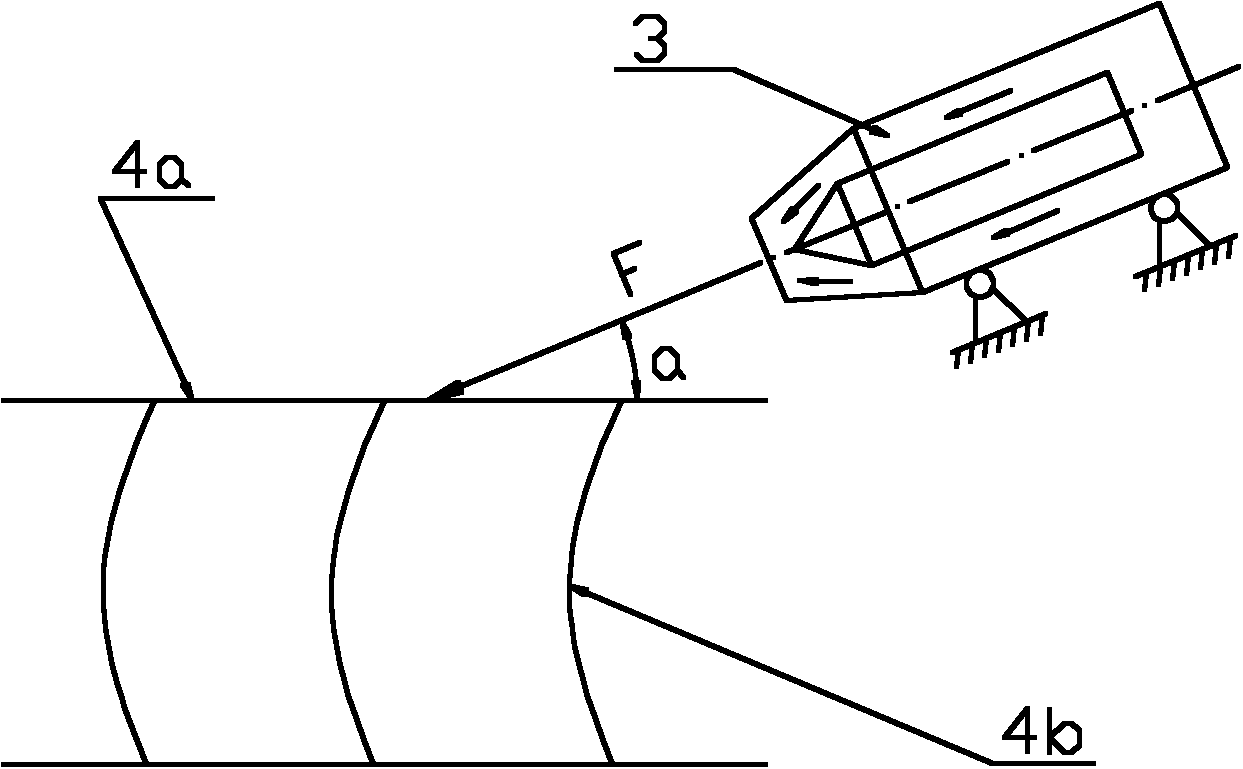

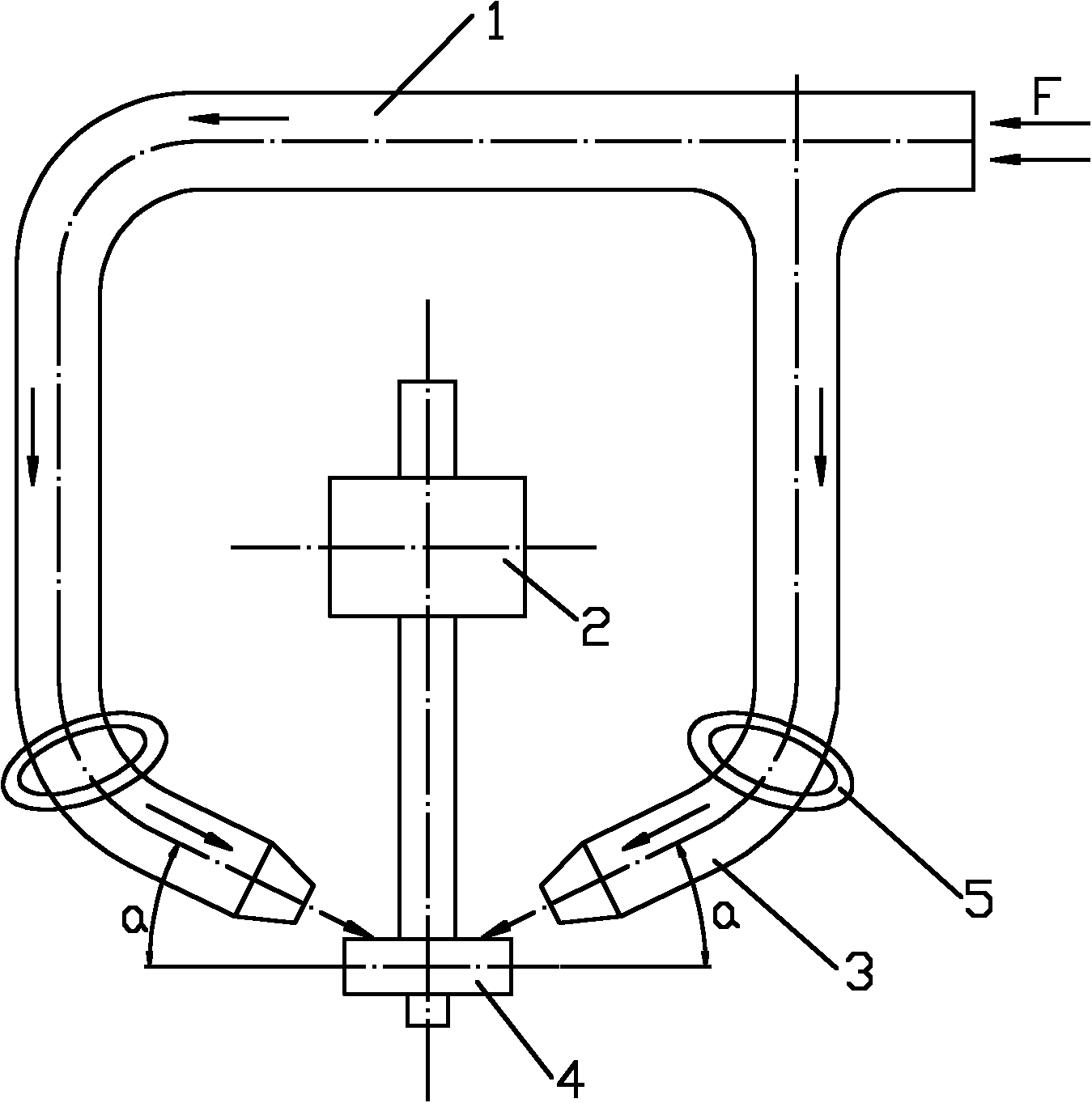

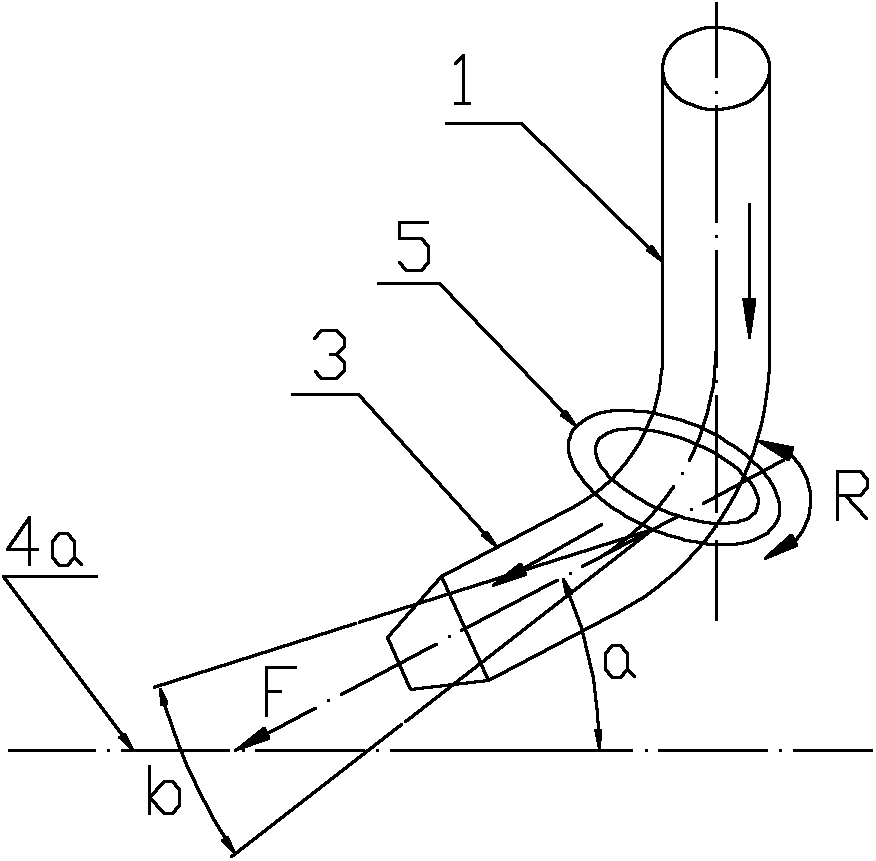

Inclined type water turbine with adjustable jetting angles and multiple nozzles

InactiveCN102606364AHigh trafficHigh outputHydro energy generationImpulse enginesWater turbineSpray nozzle

The invention discloses an inclined type water turbine with adjustable jetting angles and multiple nozzles. The inclined type water turbine comprises a water conduit, the nozzles and a rotating wheel. The nozzles are communicated with the water conduit and are rotatable, the rotation angle of each nozzle ranges from 5.5 degrees to 6.5 degrees, an included angle between a formed water jetting direction of each nozzle and the rotating wheel ranges from 17 degrees to 25 degrees, and joints of the water conduit and the nozzles are rotatable and can be flange rotational connection structures or embedded sliding sleeve rotational connection structures and the like. Internal flowing of a hopper blade and running of each single nozzle are assuredly consistent by means of changing the adjustable jetting angles according to the quantity of flow and the number of the running nozzles, mutual interference of jet stream and internal flow is prevented, hydraulic loss is minimized, hydraulic efficiency of the water turbine is improved, axial force of the water turbine can be reduced, the jetting angles of the nozzles and the number of the running nozzles jointly match with each other, the jetting angles of the nozzles are adjustable, efficiency of water resources is brought into play to the greatest extent, the water turbine runs more stably, and energy efficiency is maximized.

Owner:XIHUA UNIV

Double-outlet multipurpose external mixing type self-priming pump with quasi-spiral suction chamber

PendingCN107588008AImprove self-priming performanceImprove hydraulic performancePump componentsPriming pumpAgricultural irrigationPetrochemical

The invention provides a double-outlet multipurpose external mixing type self-priming pump with a quasi-spiral suction chamber. The double-outlet multipurpose external mixing type self-priming pump mainly comprises an inlet flange, a pump body, an impeller, an air-liquid separating pipe, a rear cover, a suspension body part, an outlet flange and a flange cover, wherein the pump body is formed by the quasi-spiral suction chamber, a spiral compression chamber and a liquid storage chamber through integral casting and is provided with double outlets and the like. The hydraulic performance of the pump is effectively improved while the self-priming performance of the self-priming pump is improved, the flow losses of fluid media in a suction chamber and a water compressing chamber are remarkablyreduced, and the double-outlet multipurpose external mixing type self-priming pump has the advantages of being high in efficiency and reliability, compact in structure, convenient to install and maintain and multipurpose, serving as a pipeline self-priming pump accessed horizontally only by slightly adjusting an installing mode and the like, is suitable for the fields of agricultural irrigation and drainage, river and pond breeding, municipal drainage, petrochemical metallurgy and the like and can be installed on a movable pump truck for fire-fighting operation and the like.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

Method for designing centrifugal impeller splitter blade

InactiveCN105971931AImprove speed distributionReduce hydraulic lossPump componentsPumpsImpellerFront cover

The invention discloses a method for designing a centrifugal impeller splitter blade. The method includes the steps that a middle cross section, a front cover plate cross section and a rear cover plate cross section of an impeller are determined; three split flow points on the three cross sections are determined on the three cross sections respectively according to the principle that flows on the two sides of each split flow point are equal, and three bone lines on the three cross sections are obtained; and the three bone lines are mixed and scanned into a curved surface, the curved surface extends towards a front cover plate and a rear cover plate of the impeller till the curved surface intersects with the front cover plate and the rear cover plate, a work face of the impeller splitter blade is obtained, and the thickness of the work face is increased to obtain the back side of the splitter blade. The designed splitter blade can equally divide water flow in a flow channel between two adjacent long blades into two parts equal in flow, speed distribution at an outlet of the impeller can be effectively improved, hydraulic loss in the impeller is reduced, and the lift and the efficiency of the centrifugal impeller are improved.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com