Mathematical model based centrifugal pump volute design method

A mathematical model and centrifugal pump technology, applied to components, pumps, and calculations of pumping devices for elastic fluids, can solve problems such as low design accuracy and long design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0135] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

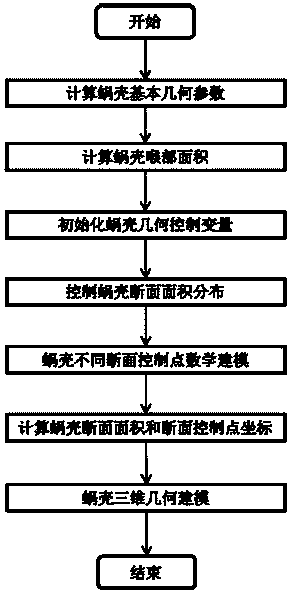

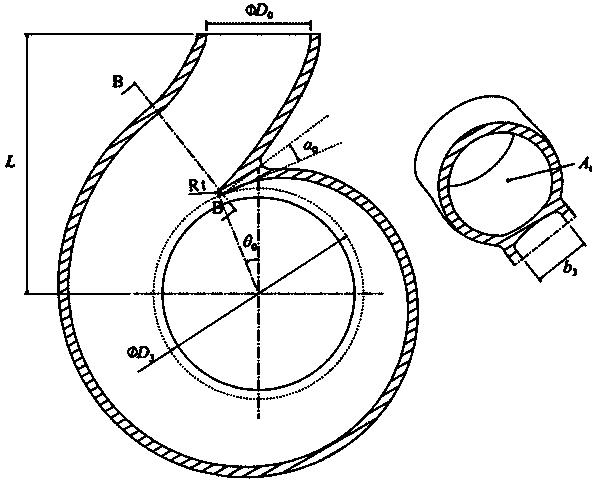

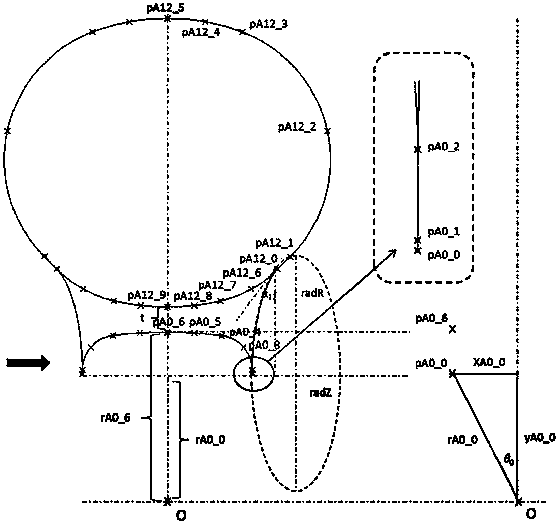

[0136] combine figure 1 , the flow process of the centrifugal pump volute design method based on mathematical model described in the present invention is roughly divided into: 1) adopt velocity coefficient method to calculate volute basic geometric parameter; 2) adopt velocity moment method to calculate volute throat area; 3) Initialize the geometric control variables of the volute; 4) Use the volute section area control equation to control the volute section area; 5) Use mathematical models such as ellipse, circle and line to model the section geometry of the volute, and use the three-dimensional coordinate point Express the volute section control points; 6) Use the successive area approximation iterative algorithm to calculate the volute section area and section control point coordinates; 7) Use 3D software to geometrically model the volute control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com