Patents

Literature

68results about How to "Shorten the design and development cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

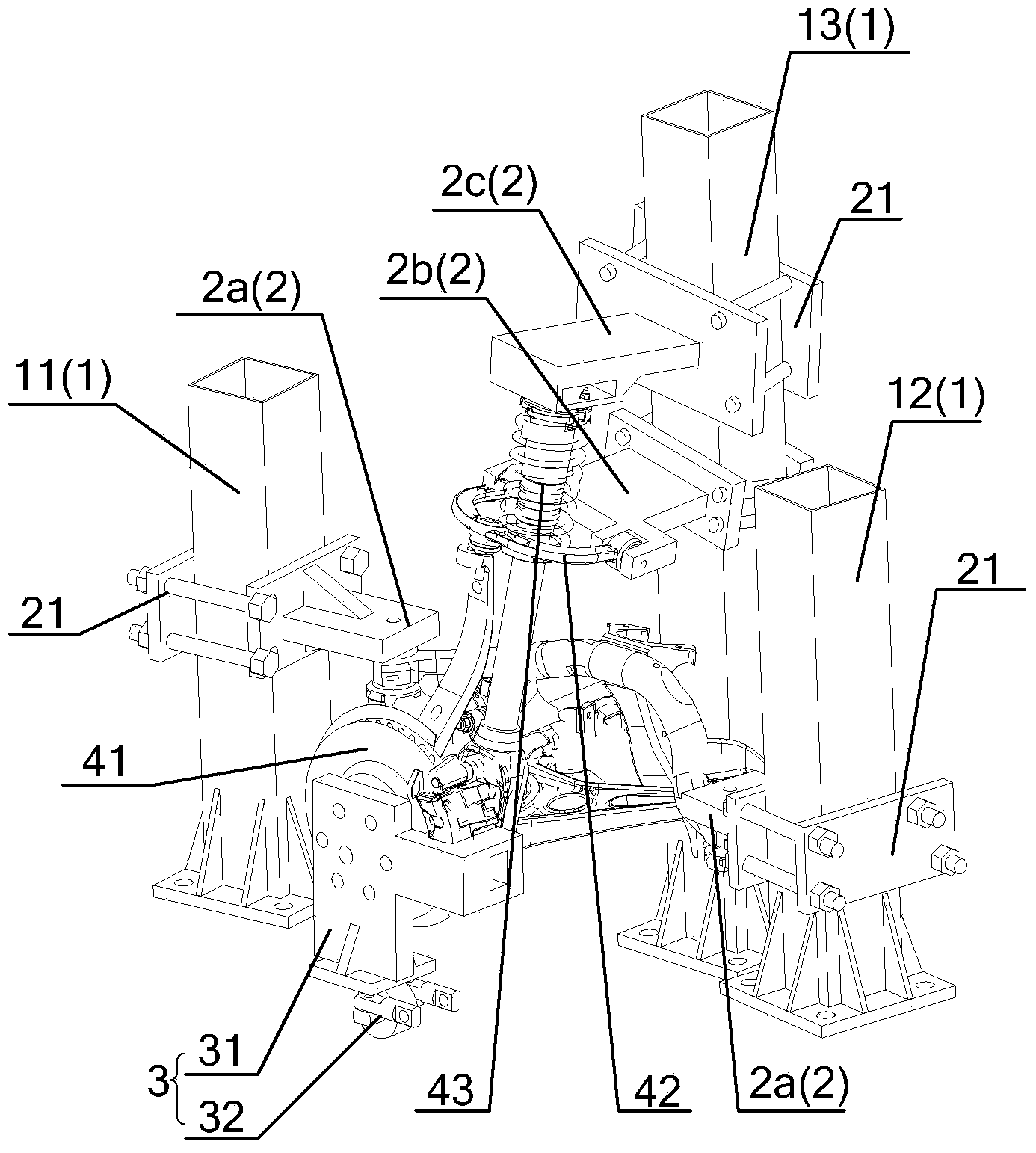

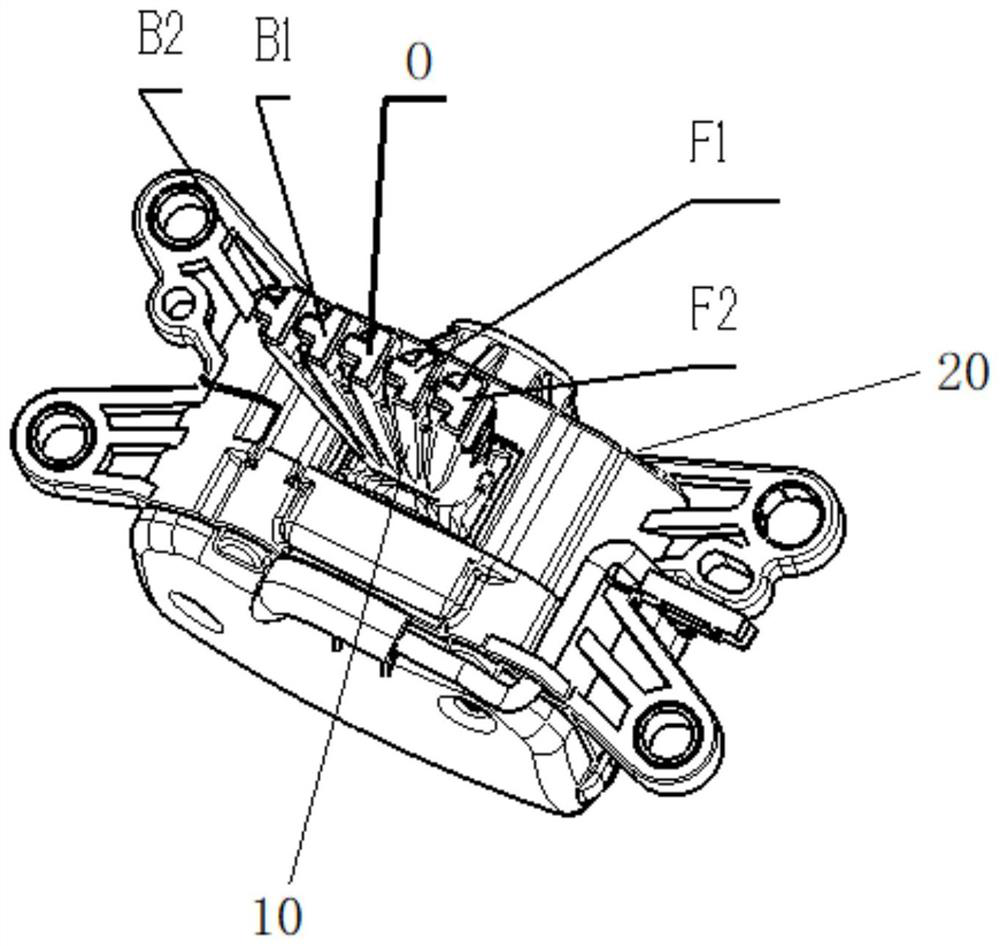

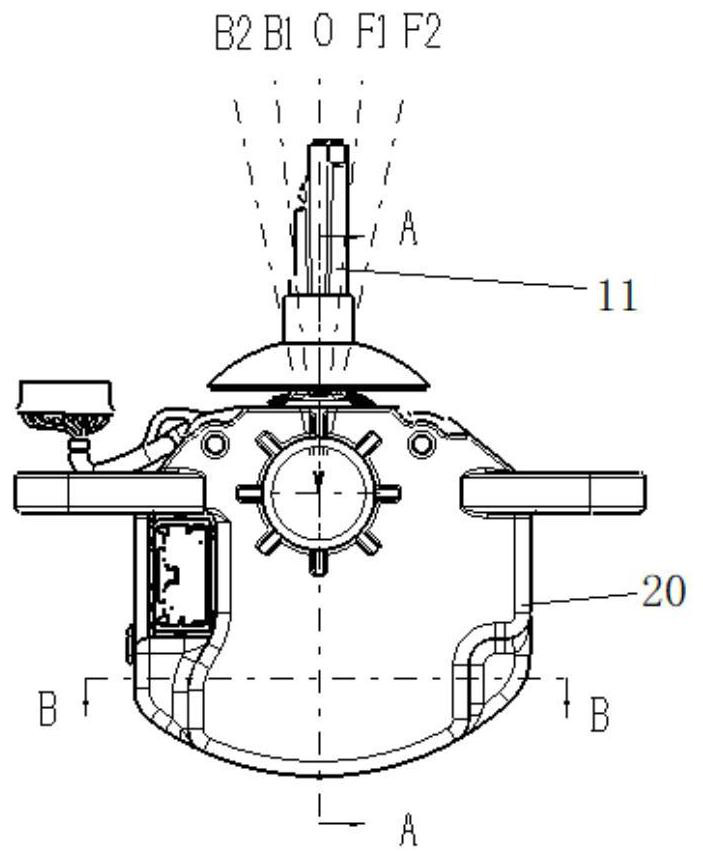

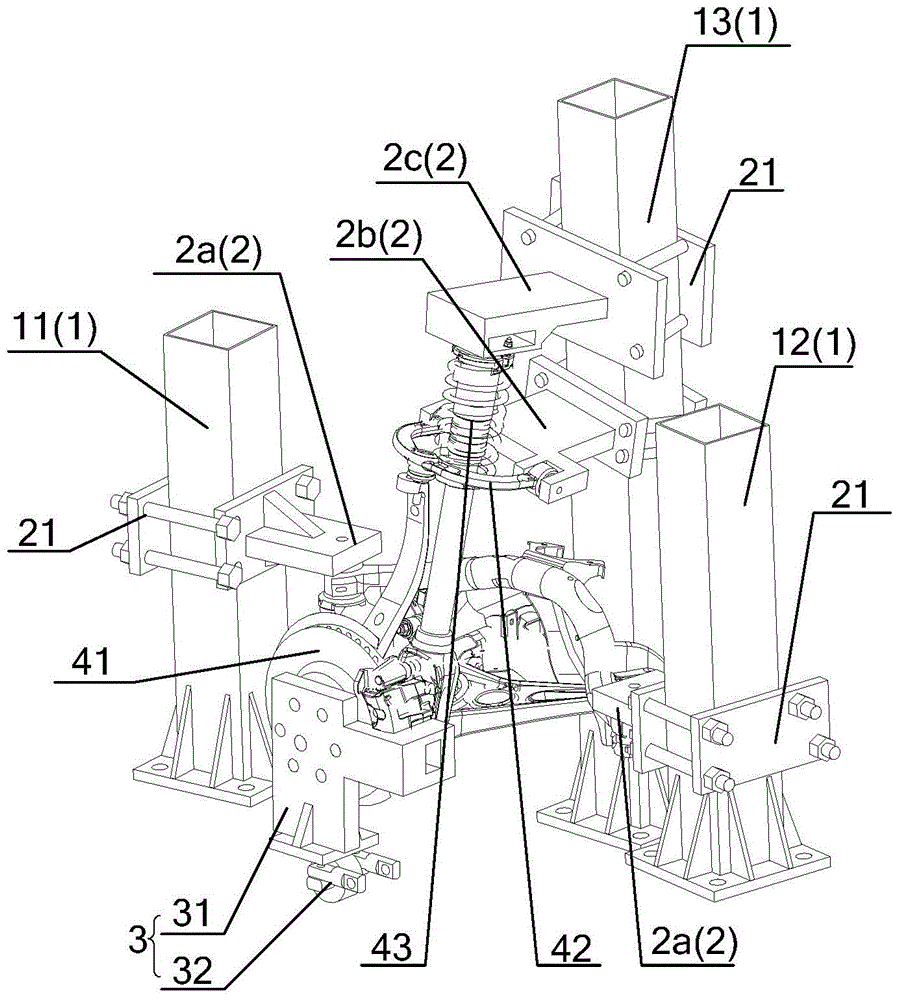

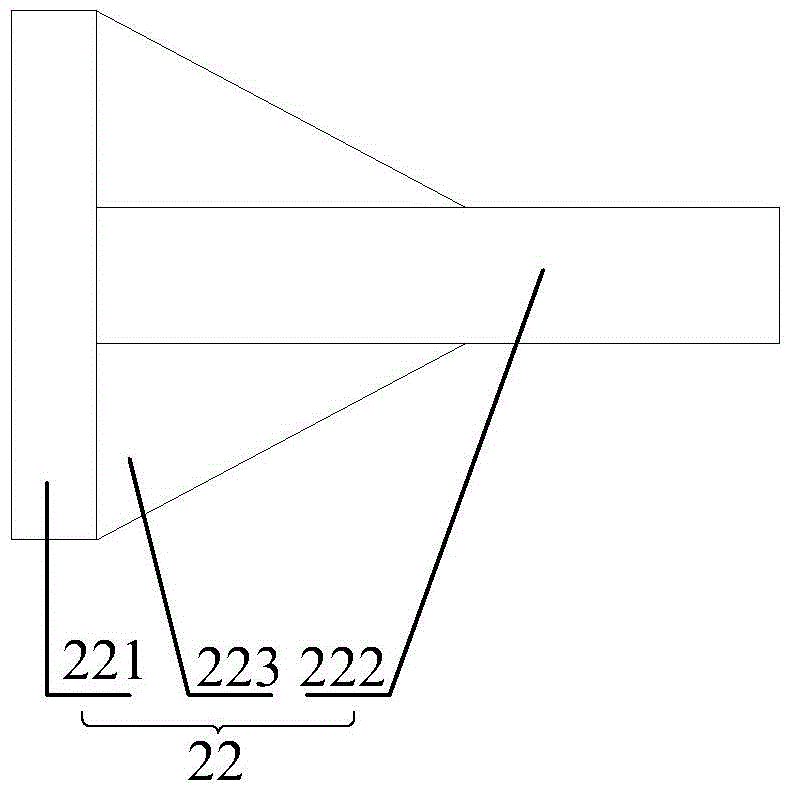

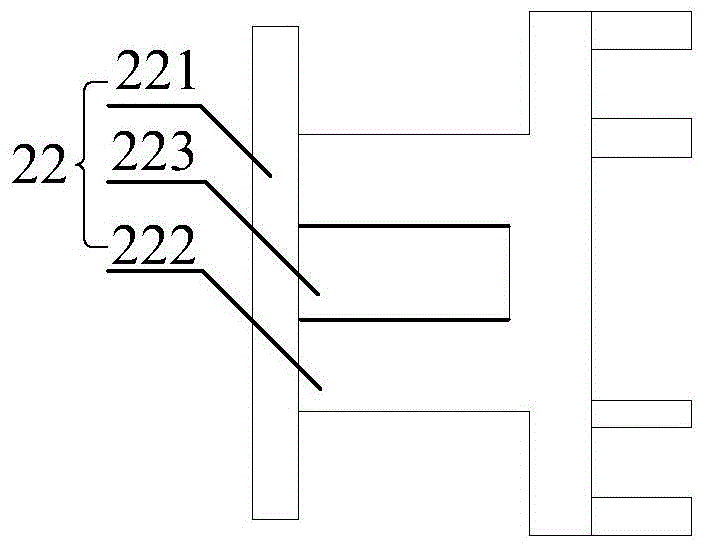

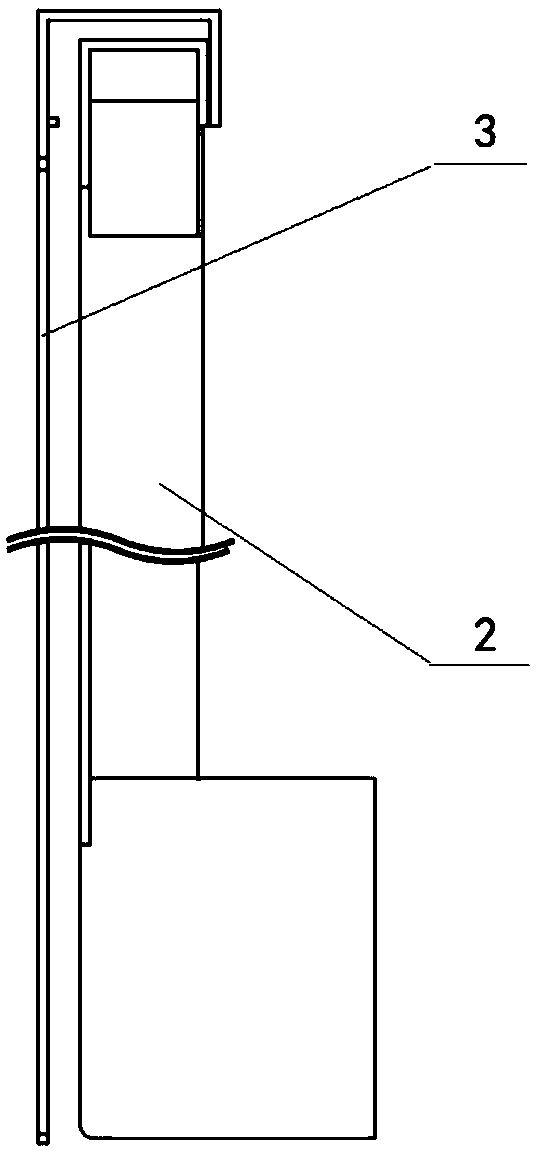

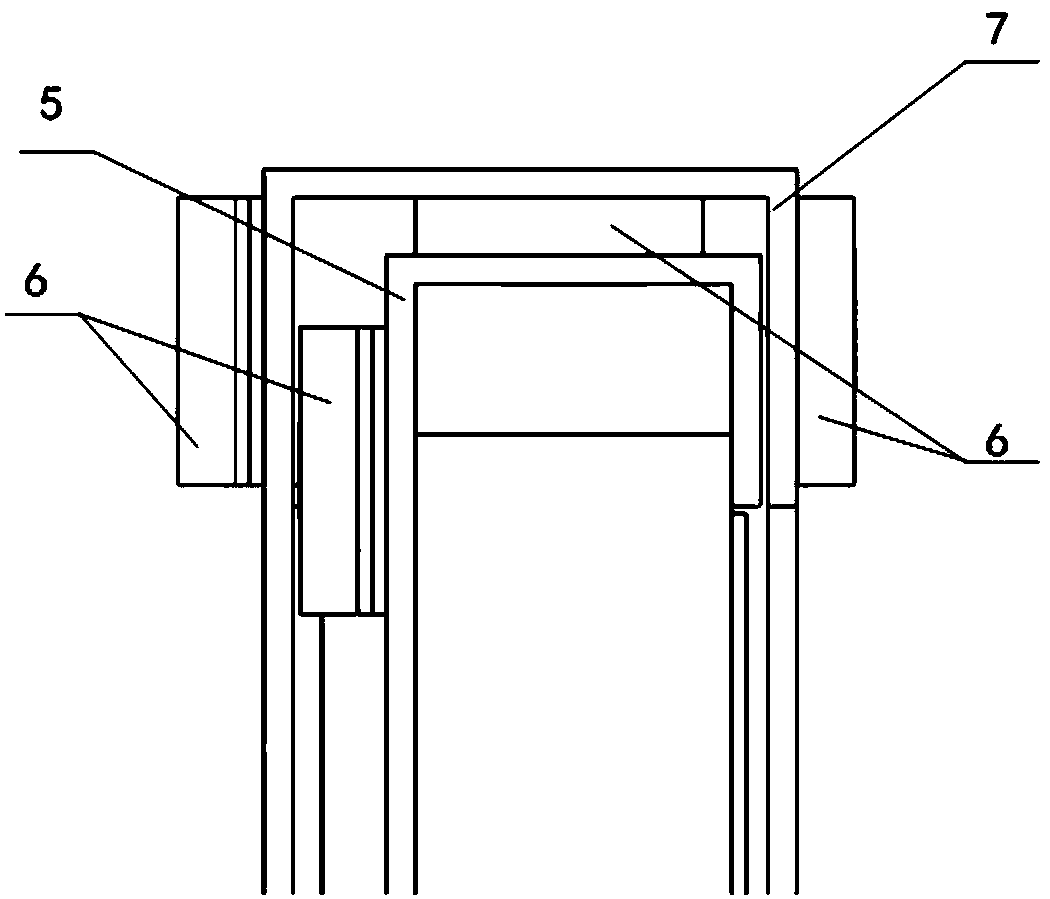

Automotive suspension test bed

ActiveCN103954459AShorten the design and development cycleHigh strengthVehicle suspension/damping testingVehicle frameUltimate tensile strength

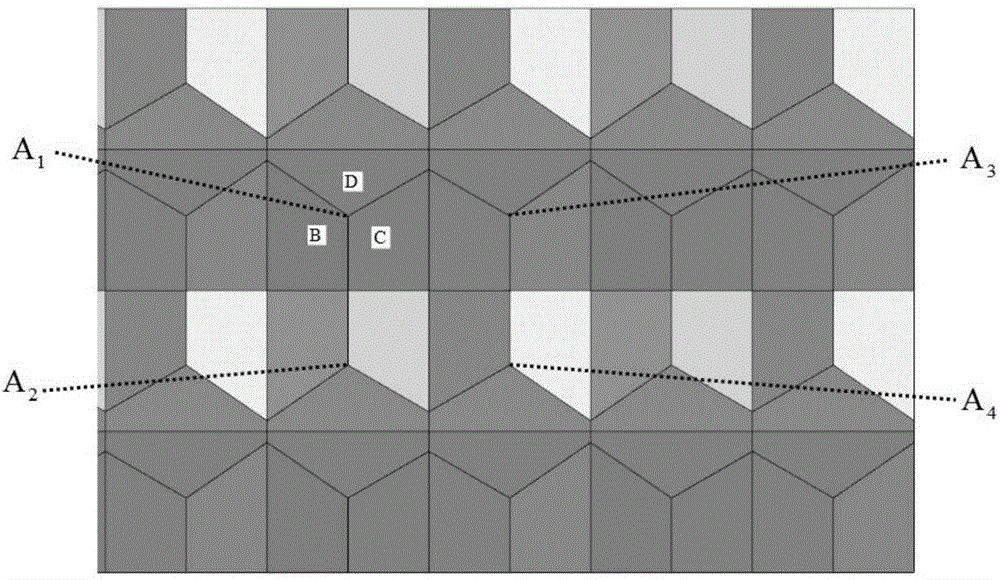

The invention discloses an automotive suspension test bed, relates to the technical field of fatigue verification for an automotive suspension and provides the automotive suspension test bed which is simple in structure, high in strength and capable of shortening the development and verification period of the automotive suspension and reducing test expenditures. The automotive suspension test bed comprises a plurality of stand columns, wherein a clamp plate with the height and the angle adjustable is installed on each stand column, and a calibrating mark is further arranged on each stand column and used for calibrating the installation position of the corresponding clamp plate. The automotive suspension test bed further comprises a loading mechanism used for being connected with a loading device, the stand columns are assembled with an automotive frame through the clamp plates in a matched and connected mode, the loading mechanism is connected with a brake disc on the frame, and the direction of the loading device is controlled so that the loading mechanism can perform suspension endurance verification under different working conditions. The automotive suspension test bed is mainly used in tests of fatigue verification for the automotive suspension.

Owner:GREAT WALL MOTOR CO LTD

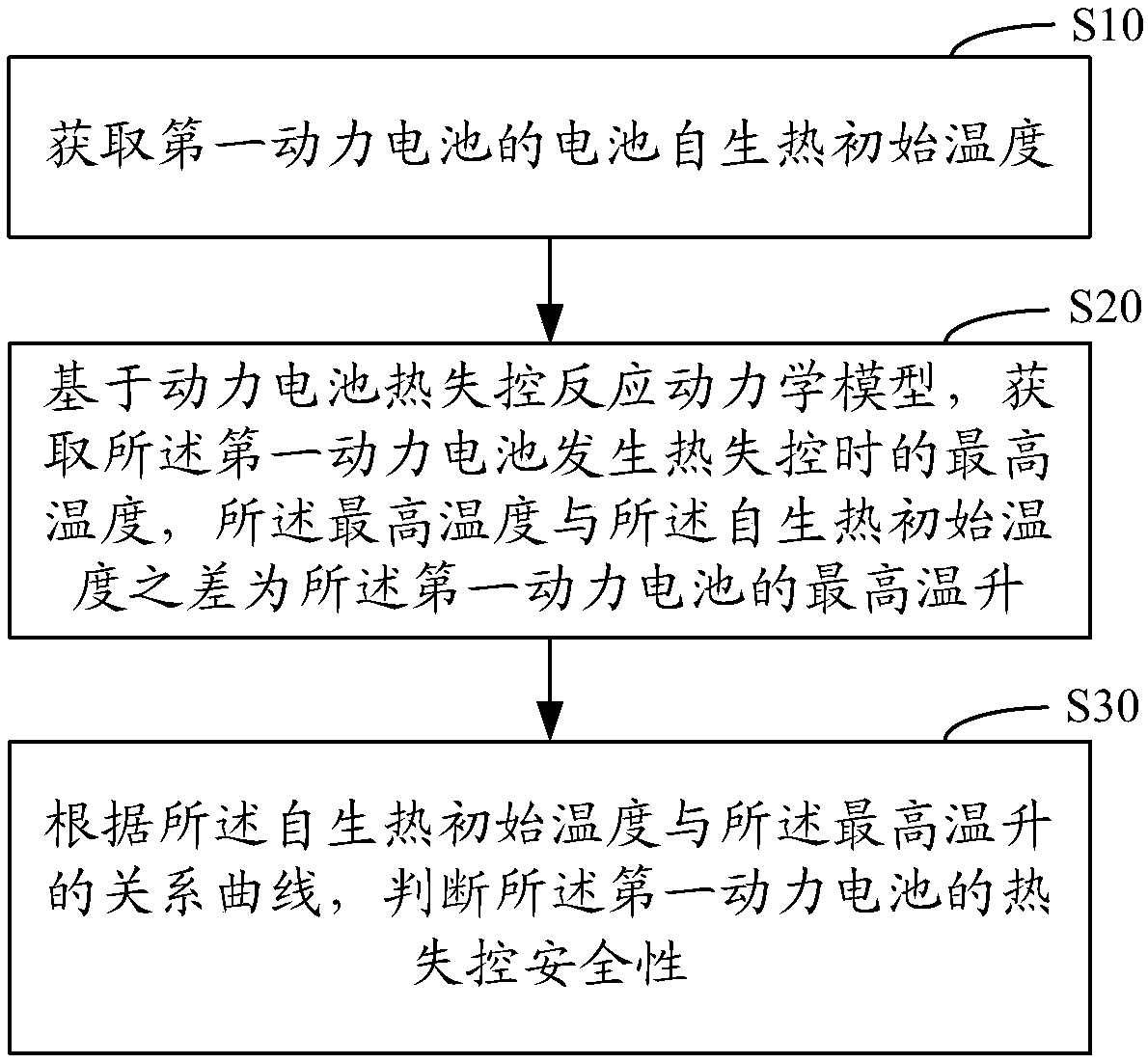

Prediction method and device of thermal-runaway safety of power battery and computer-readable storage medium

ActiveCN108446434AShorten the design and development cycleImprove design efficiencySecondary cellsForecastingPower batteryElectrical battery

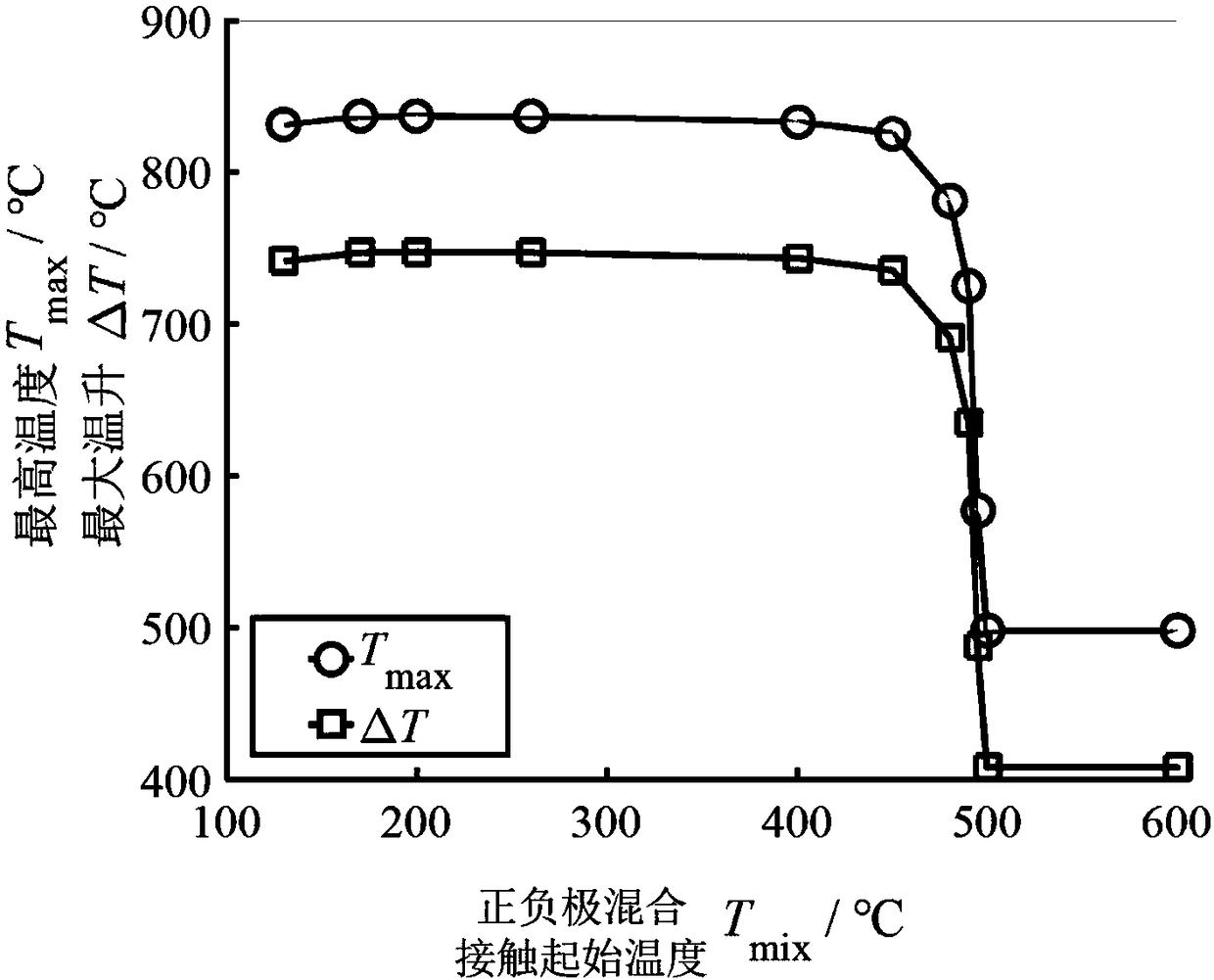

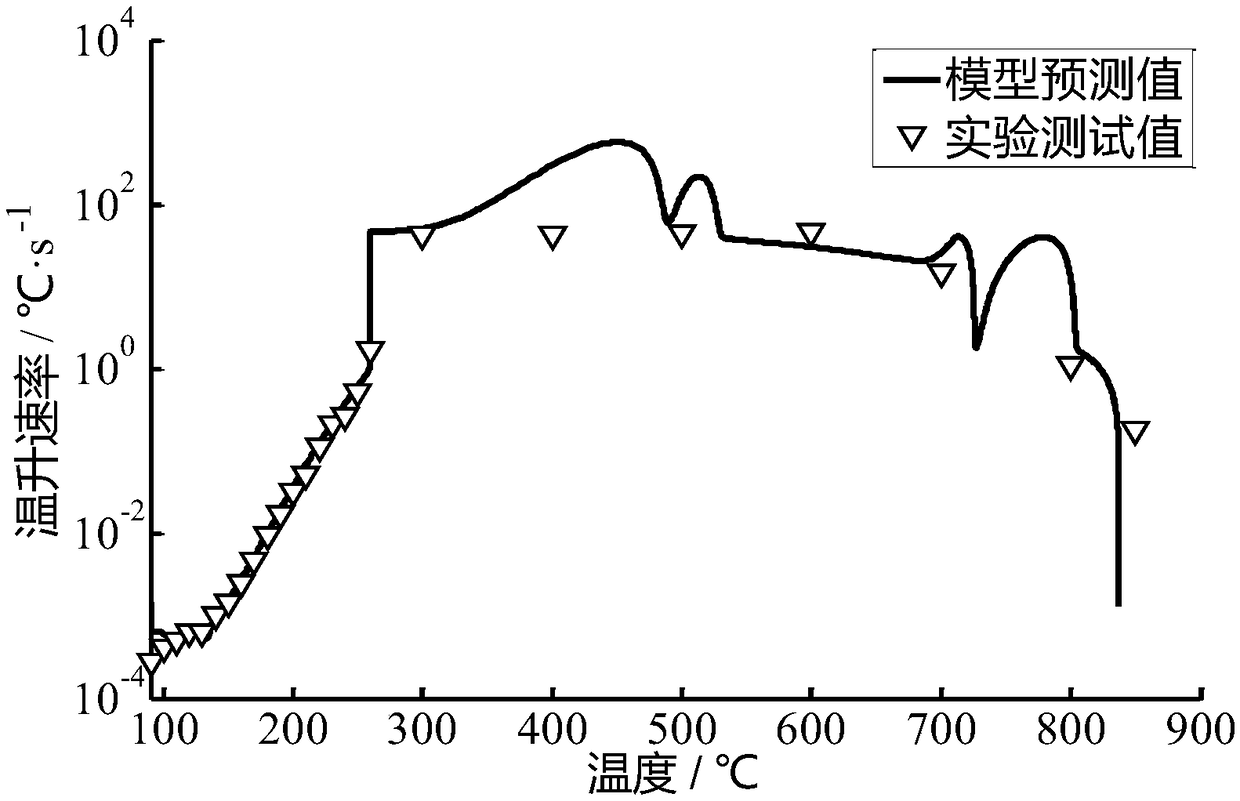

The invention relates to a prediction method and device of thermal-runaway safety of a power battery and a computer-readable storage medium. Initial autogenetic-heat temperature of the first power battery is obtained; the highest temperature at the time when a thermal runaway of the first power battery occurs is obtained on the basis of a thermal-runaway reaction kinetics model of the power battery; and the thermal-runaway safety of the first power battery is judged according to a relationship curve of the initial autogenetic-heat temperature and the highest temperature rise. According to theprediction method of the thermal-runaway safety of the power battery, the thermal-runaway safety of the first power battery can be predicted in a case of not making the whole battery, necessary processes of assembling the whole power battery in a traditional safety design process are reduced, a power-battery design and development cycle is shortened, design and development costs are saved, and efficiency of power-battery safety design is improved.

Owner:TSINGHUA UNIV

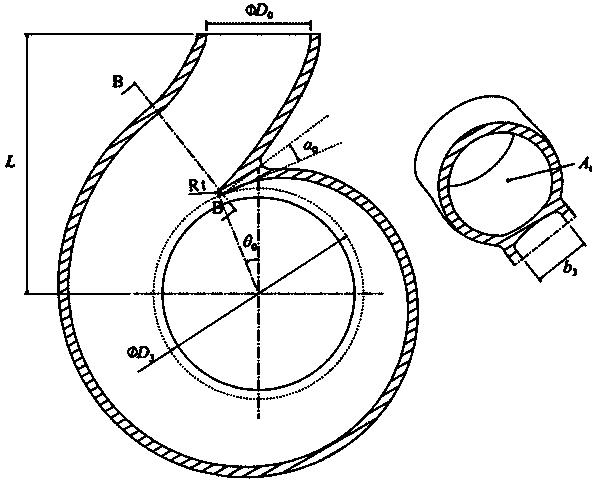

Double-volute hydraulic design method based on RSM model

InactiveCN106570263AReduce design difficultyShorten the design and development cycleGeometric CADPump componentsEngineeringDesign methods

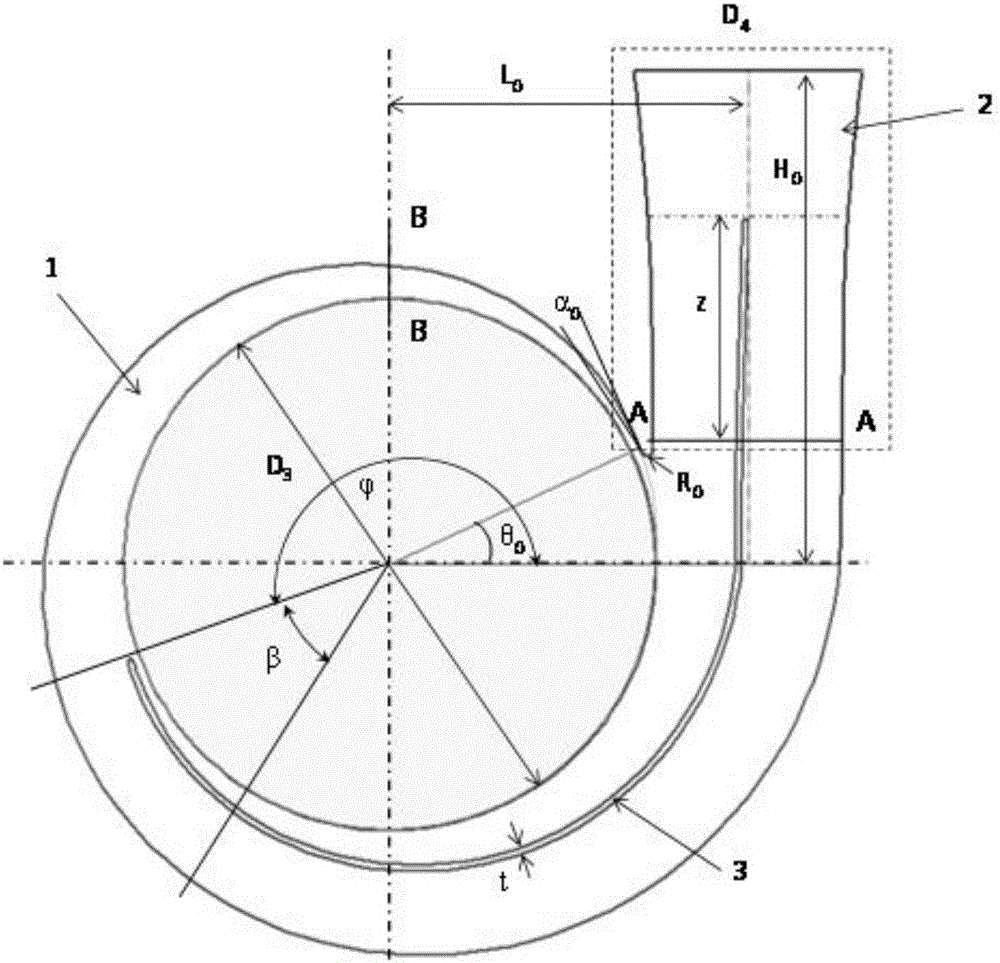

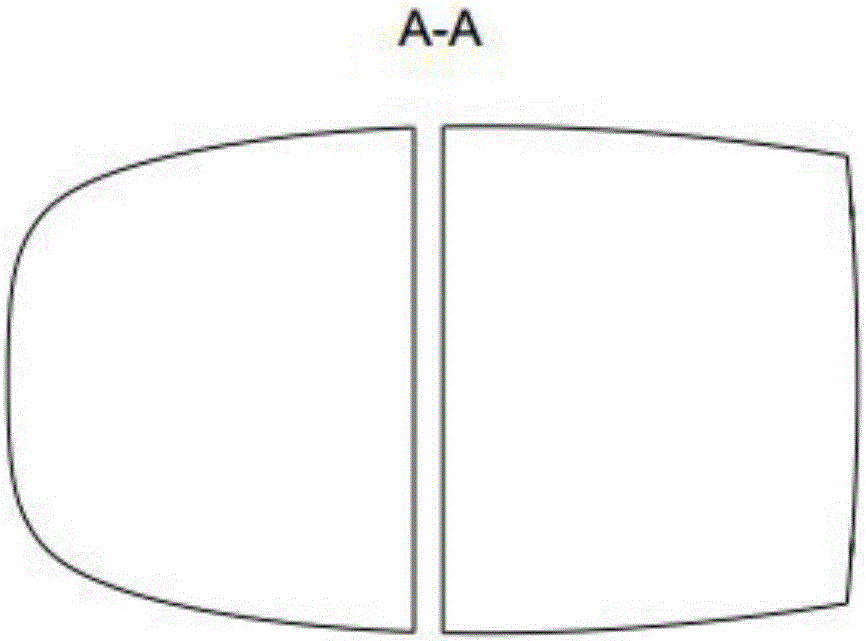

The invention discloses a double-volute hydraulic design method based on an RSM model. The design method comprises the steps of 1) solving double-volute initial hydraulic geometric parameters based on a velocity coefficient method; 2) performing optimization solving on double-volute key geometric parameters by adopting an RSM-based adaptive sequence algorithm; 3) performing parameterization automatic modeling based on a CATIA macroprogram, and outputting to obtain a three-dimensional double-volute model; 4) by adopting a GridPro script file to output a grid file used for numerical value calculation; 5) automatically completing grid loading and boundary condition setting based on a CFX CCL language drive program to complete calculation of related data, and outputting a calculation result; 6) repeatedly executing the steps 3) to 5) to obtain a double-volute scheme with the minimum total pressure loss coefficient; and 7) taking the data obtained in the steps 1) to 6) as the double-volute design parameters to manufacture a double-volute centrifugal pump. By adoption of the double-volute hydraulic design method, the double-volute hydraulic optimization design can be realized.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

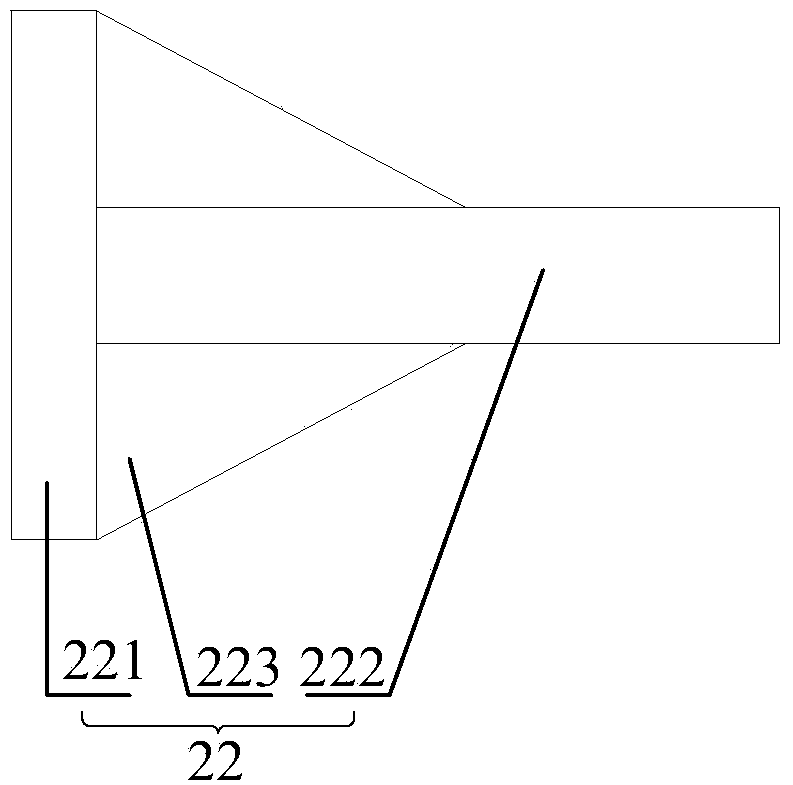

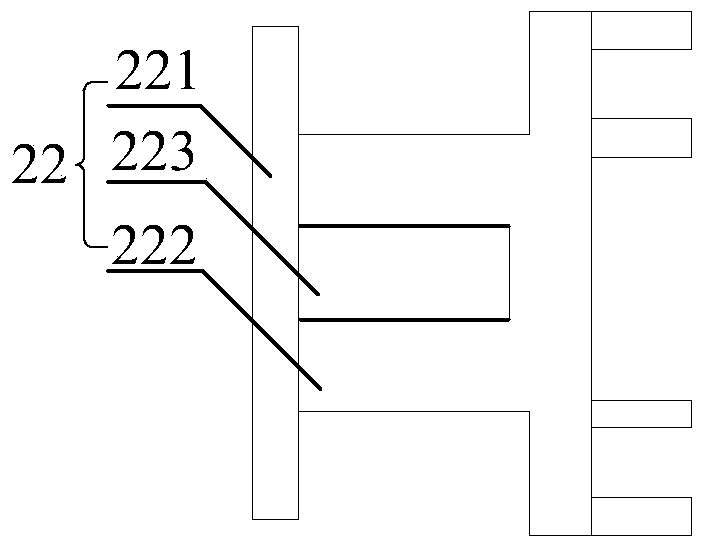

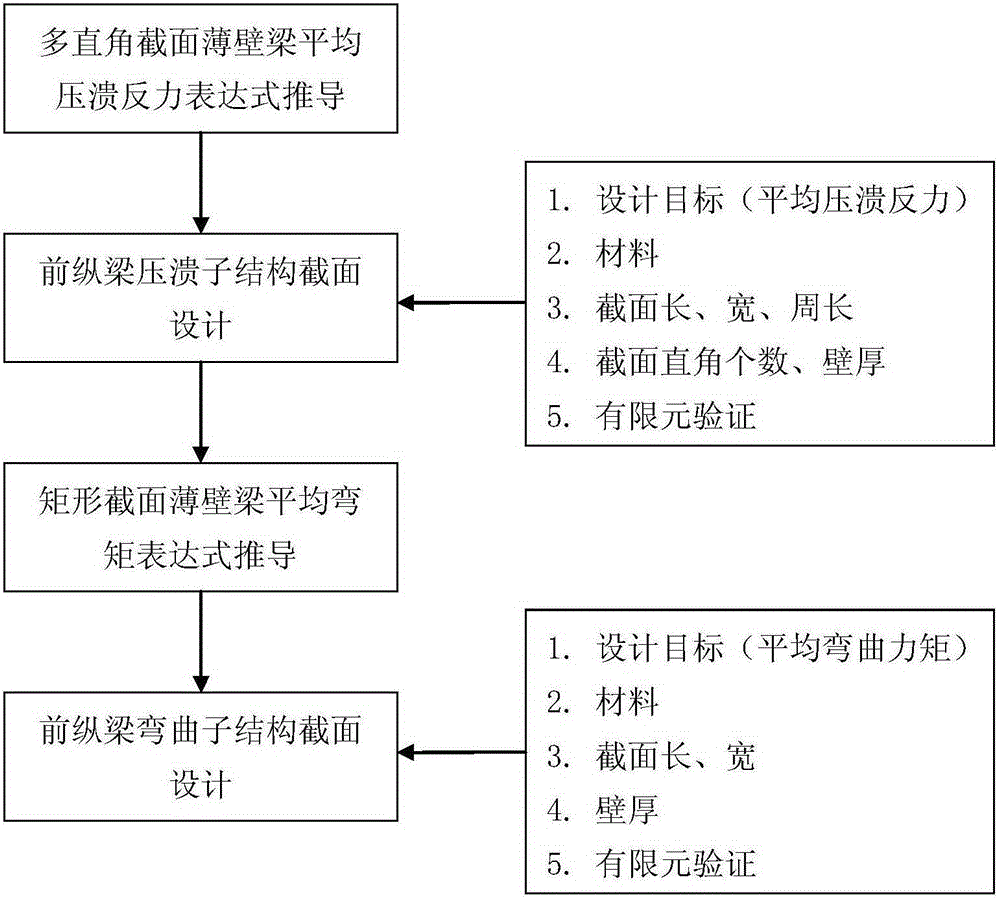

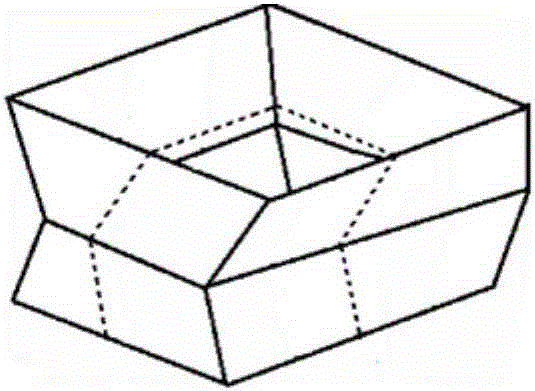

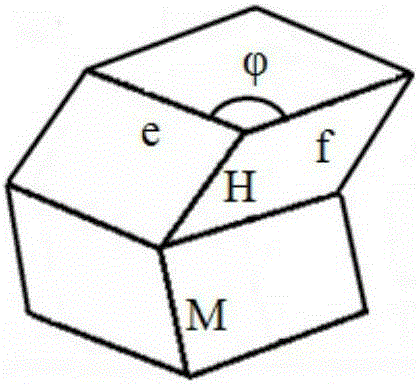

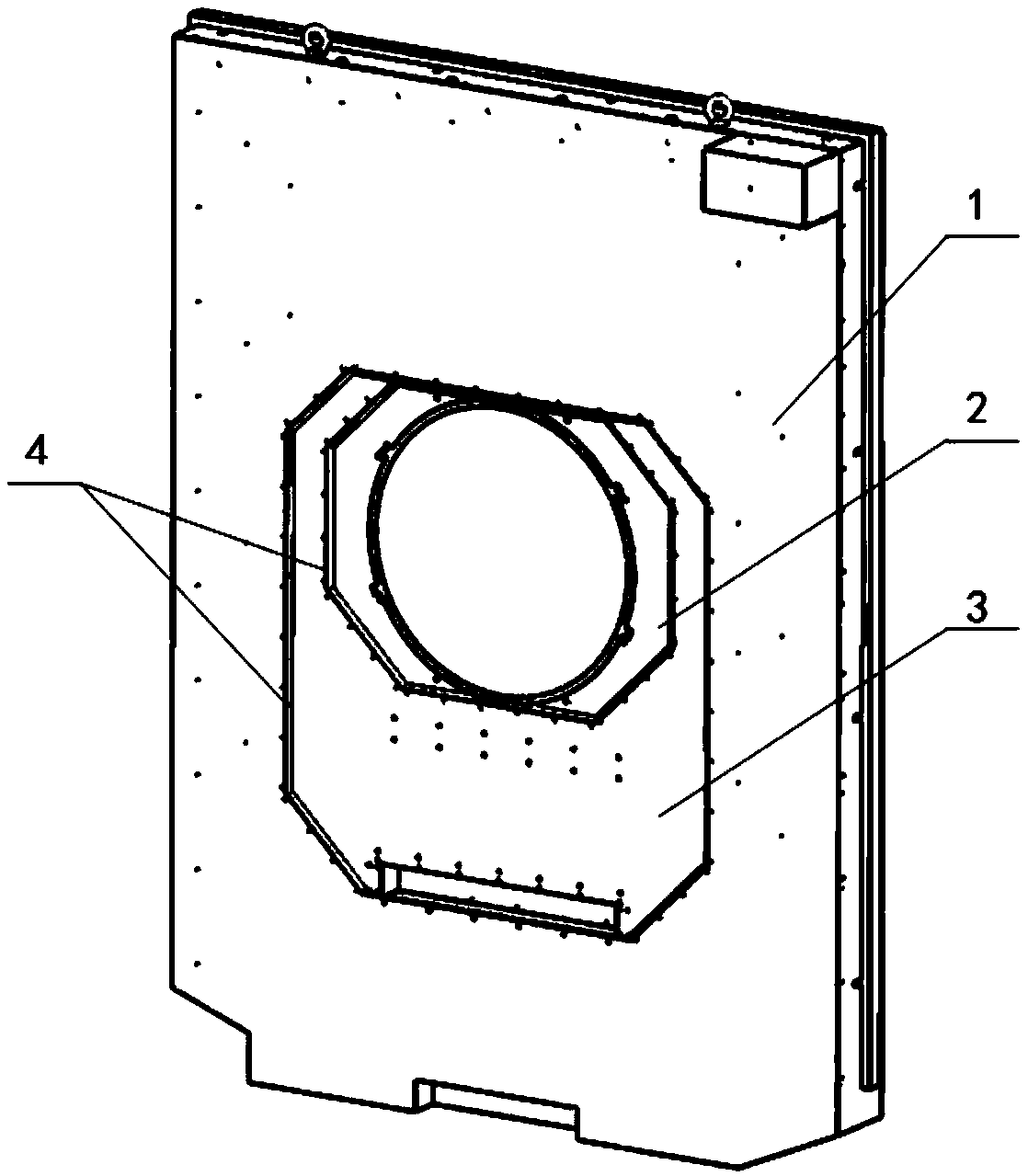

Front longitudinal beam anti-collision performance design method for passenger vehicle

InactiveCN103425848ARapid designShorten the design and development cycleSpecial data processing applicationsEngineeringTrial and error

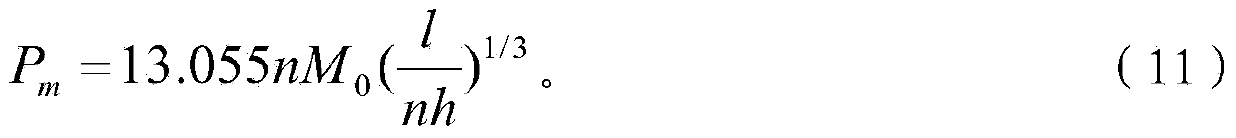

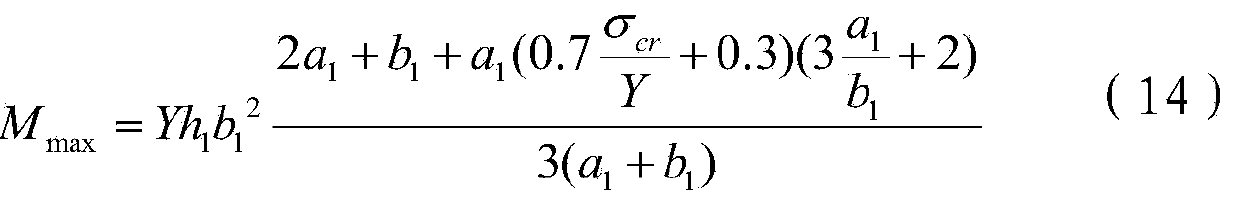

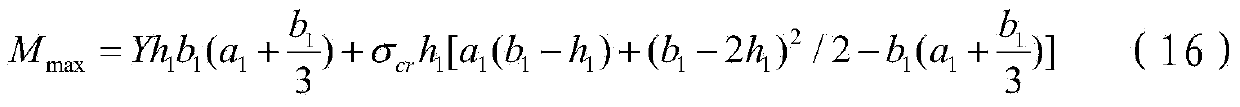

The invention discloses a front longitudinal beam anti-collision performance design method for a passenger vehicle and aims at solving the problems that when the traditional trial-and-error method is used for designing the front longitudinal beam of a car in the prior art, a computer simulation model needs to be repeatedly modified, the testing needs to be repeatedly carried out, and the like. The front longitudinal beam anti-collision performance design method for the passenger vehicle comprises the following steps that 1, the average crushing counter force expression (shown as the accompanying drawing) of a multi-right-angle cross section thin wall beam is deduced, in the expression, Pm is the average crushing counter force, the unit of the Pm is kN, n is the number of the cross section right angles of the multi-right-angle cross section thin wall beam, M0 is the unit length plastic limit bending moment, the unit of M0 is N.mm, l is the cross section circumference of the multi-right-angle cross section thin wall beam, the unit of the l is mm, h is the wall thickness of the multi-right-angle cross section thin wall beam, and the unit of the h is mm; 2, the cross section of the crushing deformation part of the front longitudinal beam is designed; 3, the average bending moment expression (Mm=(0.3-0.5)Mmax) of a rectangular cross section thin wall beam is deduced, in the expression, Mm is the average bending moment of the rectangular cross section thin wall beam, and the unit of the Mm is N.mm; and 4, the cross section of the bending deformation part of the front longitudinal beam is designed.

Owner:JILIN UNIV

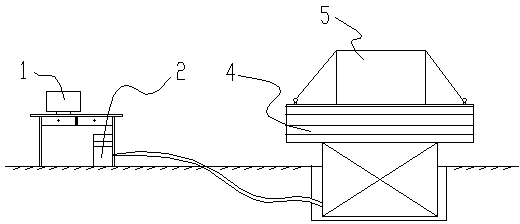

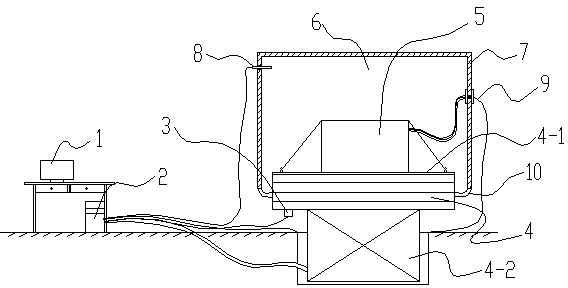

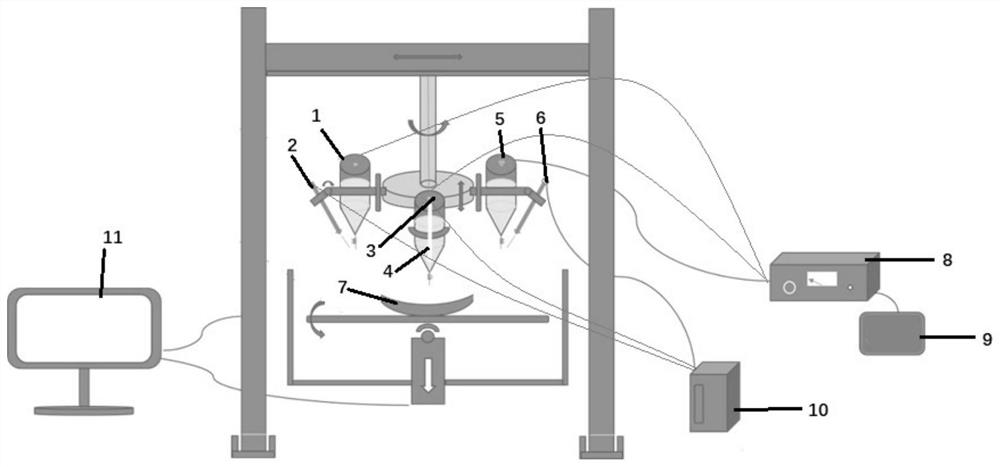

Air-conditioner random vibration comprehensive test device and method thereof

ActiveCN104111153AImprove test efficiencyGuaranteed accuracyVibration testingPhysicsRandom vibration

The invention discloses an air-conditioner random vibration comprehensive test device and a method thereof. The air-conditioner random vibration comprehensive test device comprises a vibrostand body has a vibrostand countertop used for transmitting vibration to an air-conditioner to be tested, a vibration chamber for holding the air-conditioner to be tested, a refrigerant leakage detector for detecting whether a refrigerant of the air-conditioner positioned inside the vibration chamber leaks or not, and a stress-strain testing device for detecting the stress-strain condition of pipelines of the air-conditioner to be tested. According to the invention, exact time of brittle fracture or fatigue crack of the air-conditioner pipeline system under different working conditions and different incentive intensity conditions can be determined rapidly. With the combination of the stress-strain testing device arranged on the pipeline system, an S-N curve of fatigue life of a real product-level brittle fracture part of the air-conditioner pipeline system can be calculated accurately, and reliability and life of the air-conditioner product can be accurately designed according to the curve. In addition, the device provided by the invention is simple to operate and has high testing efficiency.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

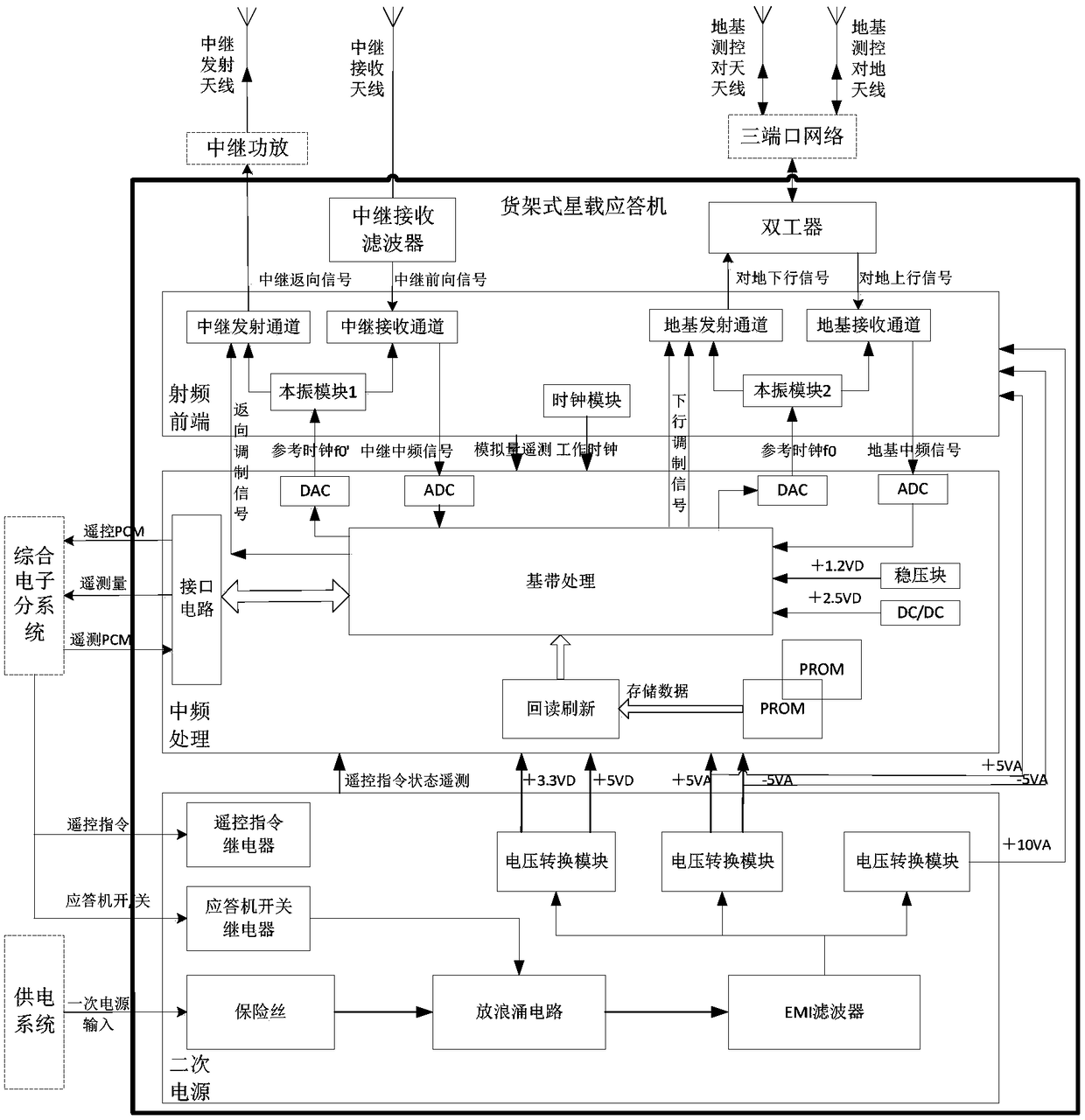

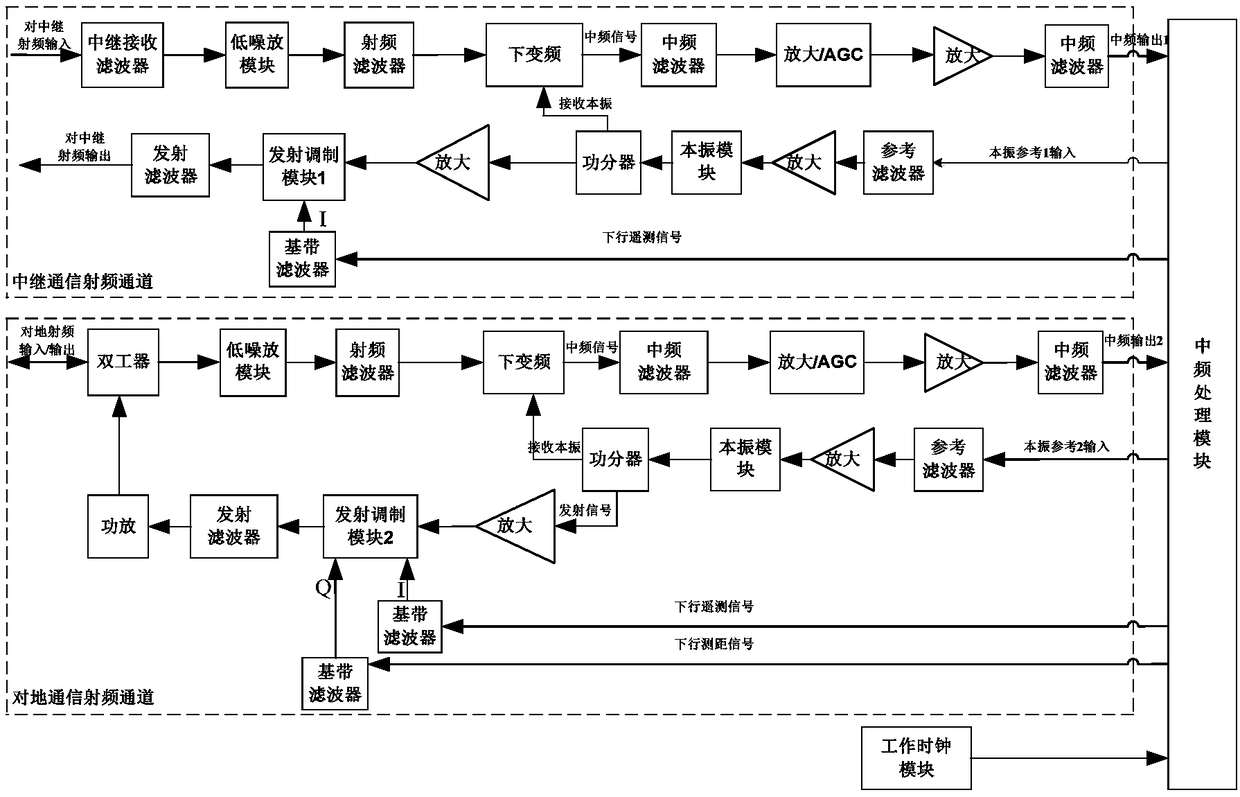

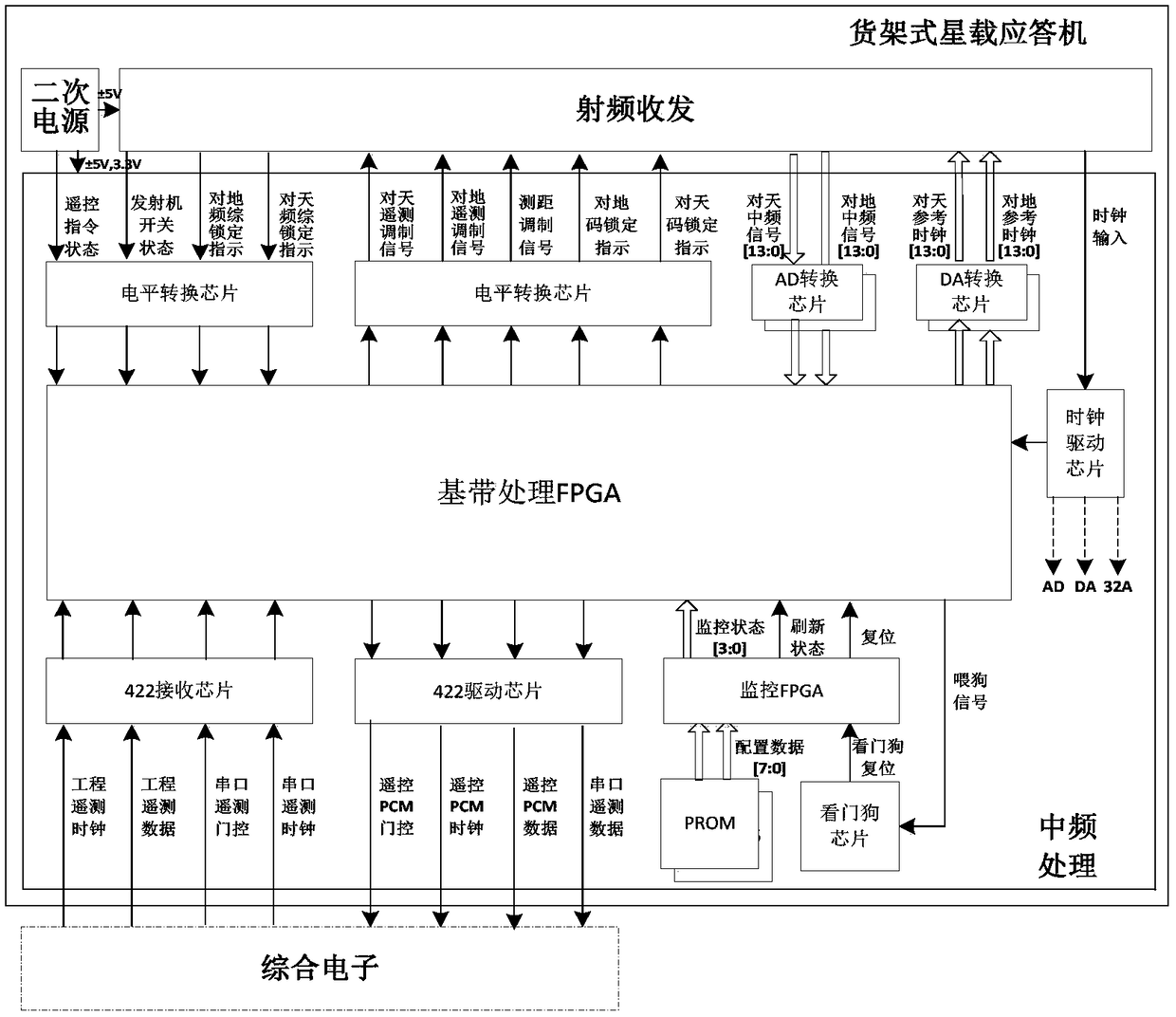

Shelf satellite borne transponder

The invention discloses a shelf satellite borne transponder. The shelf satellite borne transponder comprises a radio frequency transceiver module, an intermediate frequency processing module, a secondary power supply module, a duplexer, a relay receiving filter; wherein the radio frequency transceiver module is used for receiving and transmitting radio frequency signals to the ground or to the relay; the intermediate frequency processing module is used for the A / D conversion of received signals, the D / A conversion of reference signals, the acquisition and tracking of pseudo codes and carriers,and the signal processing of channels; the secondary power supply module is used for power supply filter, voltage conversion and transponder switch execution; the diplexer is used for the filtering processing of ground measurement and control radio frequency receiving signals and radio frequency transmitting signals; and the relay receiving filter is used for preselected filtering of relay measurement and control radio frequency receiving signals. According to the shelf satellite borne transponder disclosed by the invention, a unified hardware platform is adopted; and the purposes of general-purpose design, mass production without considering the models and shelf supply can be achieved through changing different software settings and replacing the diplexer and relay receiving filter withdifferent frequency points.

Owner:SHANGHAI SPACEFLIGHT INST OF TT&C & TELECOMM

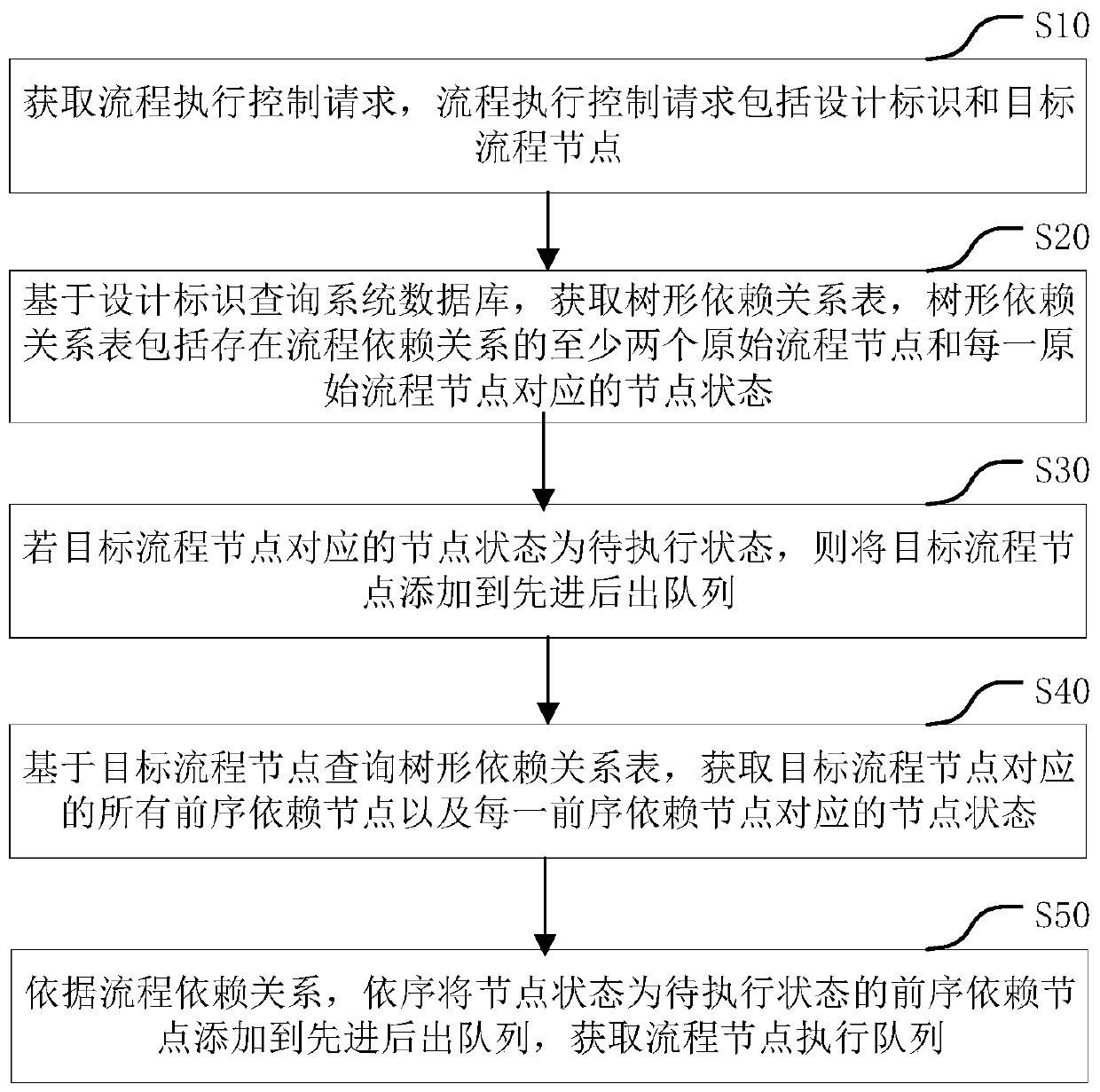

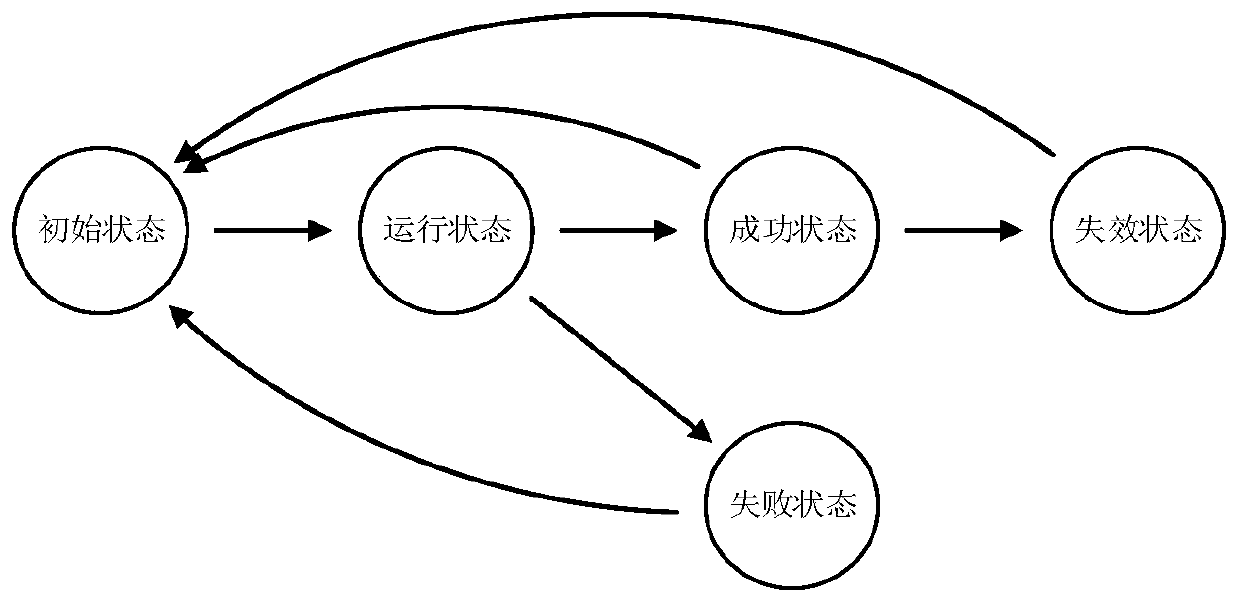

Process execution control method, device, computer equipment and storage medium

ActiveCN110489086AShorten the design and development cycleImprove design and development efficiencySoftware designCode compilationExecution controlTree shaped

The invention discloses a process execution control method, a process execution control device, computer equipment and a storage medium. The method comprises the steps: obtaining a process execution control request which comprises a design identification and a target process node; querying a system database based on the design identifier, and obtaining a tree-shaped dependency relationship table;if the node state corresponding to the target process node is a to-be-executed state, adding the target process node to a first-in last-out queue; querying a tree-shaped dependency relationship tablebased on the target process node, and obtaining all preorder dependency nodes corresponding to the target process node and a node state corresponding to each preorder dependency node; and according tothe process dependency relationship, sequentially adding the preorder dependency nodes of which the node states are the to-be-executed states to a first-in last-out queue, and obtaining a process node execution queue. According to the method, the FPGA design and development period is effectively shortened. The FPGA design and development efficiency is improved, and the design and development costis reduced.

Owner:GOWIN SEMICON CORP LTD

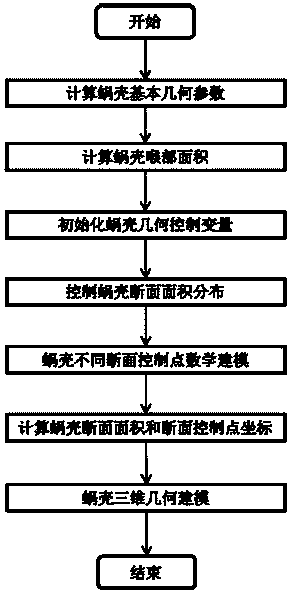

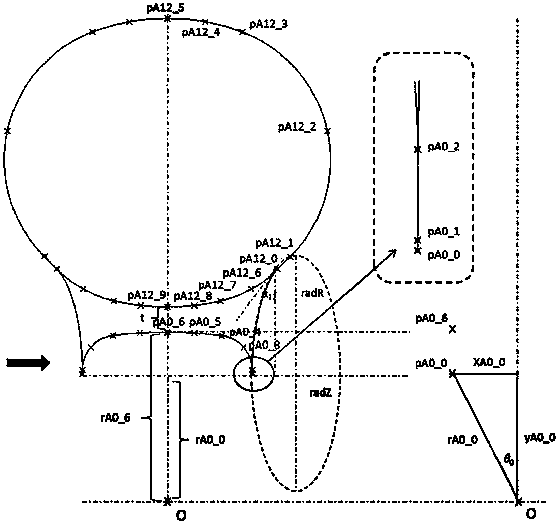

Mathematical model based centrifugal pump volute design method

ActiveCN104251235AReduce design difficultyShorten the design and development cyclePump componentsPumpsGeometric controlMathematical model

A mathematical model based centrifugal pump volute design method includes firstly, solving basic geometrical parameters of a volute according to a velocity coefficient method and calculating throat area of the volute by a velocity moment method; secondly, controlling and calculating different section areas of the volute according to an area control coefficient and a section area calculating equation and changing the control efficient to acquire volute hydraulic models of different section area distributions; thirdly, initializing geometric control variables of the volute, modeling for control points of different sections of the volute through mathematical models such as elliptical, circular, linear models, and expressing the different control points by a three-dimensional coordinate method; fourthly, utilizing a volute section area successive approximation and iteration algorithm to rapidly solve the coordinates of different section areas and section control points of the volute precisely; and fifthly, performing three-dimensional curve modeling to the volutes represented by different control points on the basis of three-dimensional design software.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

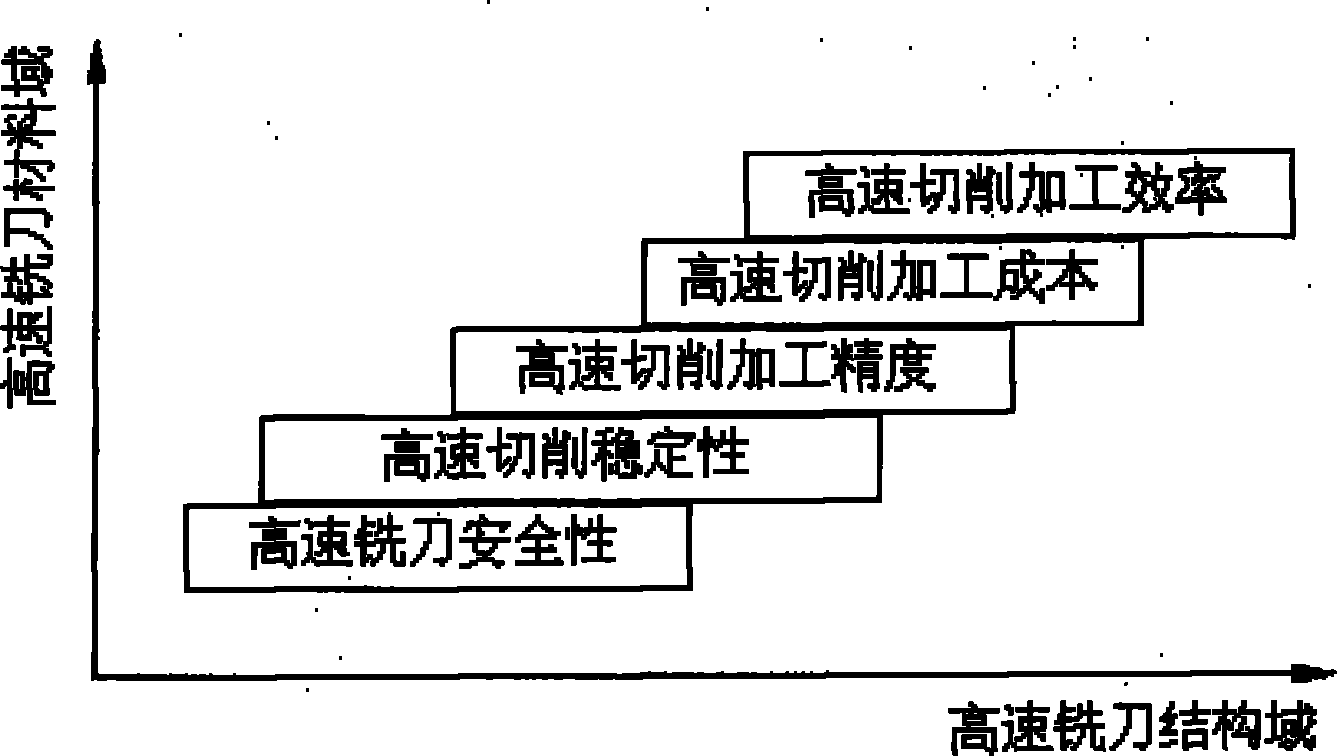

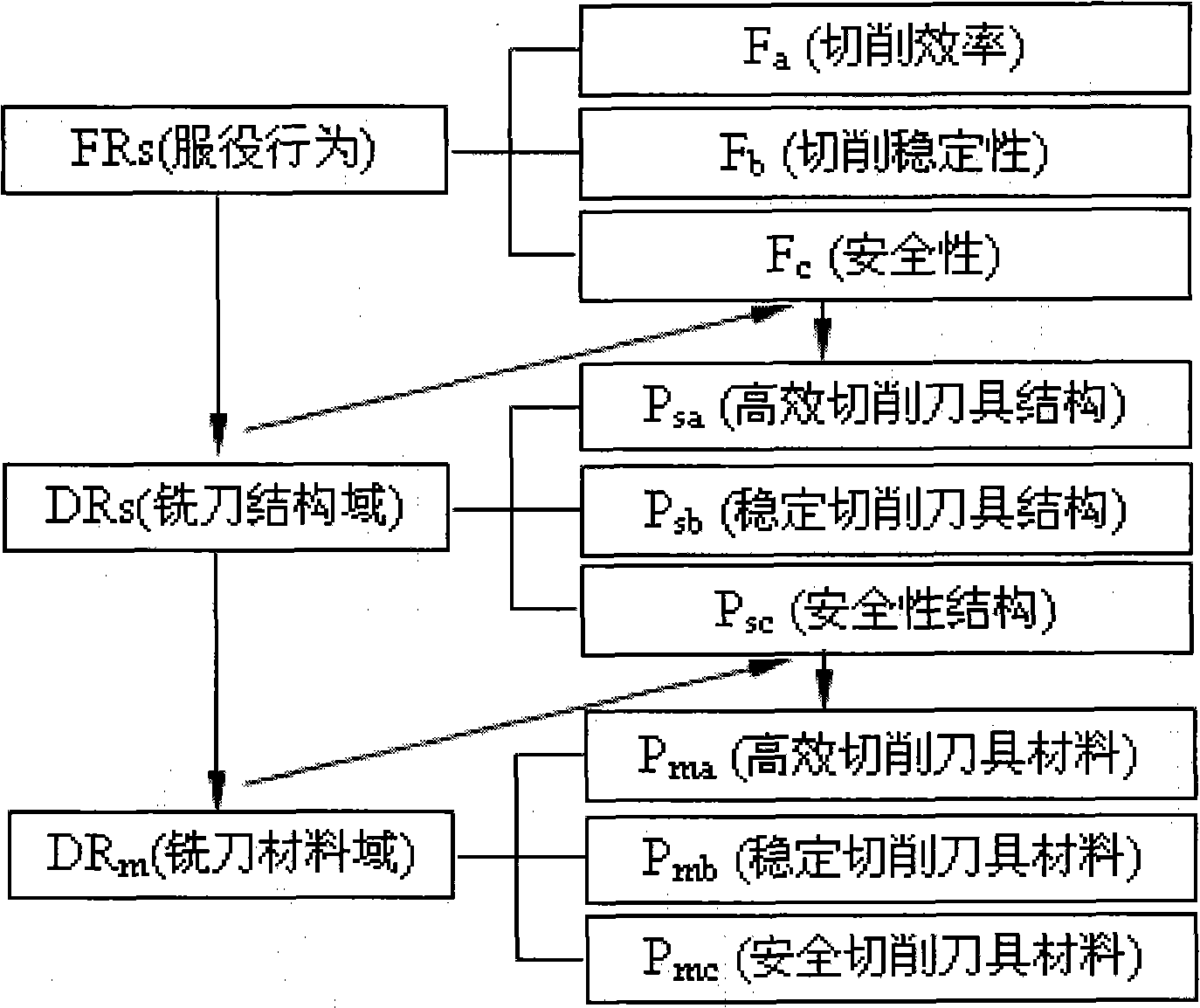

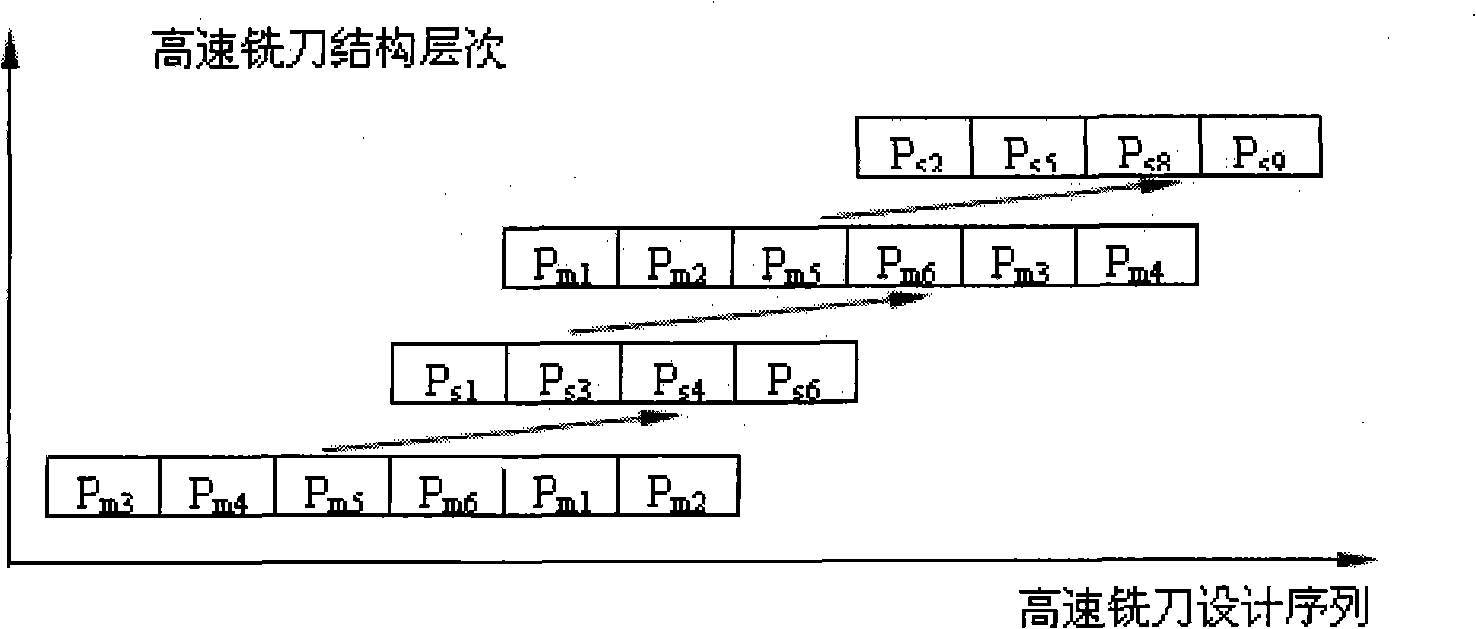

Multi-structure layer design method for high-speed milling tool

InactiveCN102120271AReduce Design CouplingEliminate Structural Design LoopsMilling cuttersDynamic balanceVolumetric Mass Density

The invention discloses a multi-structure layer design method for a high-speed milling tool, which is used for solving the problems of declination of the service performance of the high-speed milling tool, design conflicts and excessive design loops in serial design of the milling tool products, and the like. The method disclosed by the invention comprises the following steps of: (1) establishing a multi-structure layer model of the service behavior of the high-speed milling tool; (2) obtaining a decomposition scheme of the structure layer of the service behavior of the high-speed milling tool; (3) obtaining a design sequence of the structure parameters and material parameters of the high-speed milling tool; (4) completing initial design of the material parameters such as the rigidity matrix and quality matrix of the milling tool, the thermodynamical characteristics of blade material, the friction coefficient between the blade and a workpiece, the yield strength and density of the milling tool material and the like; and (5) completing design of the diameter of the milling tool, the number of teeth, the angle between tool teeth and the front angle of the milling tool, and completing design of the axial length and error of the milling tool, the tool minor cutting edge angle and the dynamic balance precision of the milling tool so as to achieve the aim of designing a milling tool with safe, stable and efficient cutting service behavior. The method disclosed by the invention is applied to the multi-structure layer design for high-speed milling tools.

Owner:HARBIN UNIV OF SCI & TECH

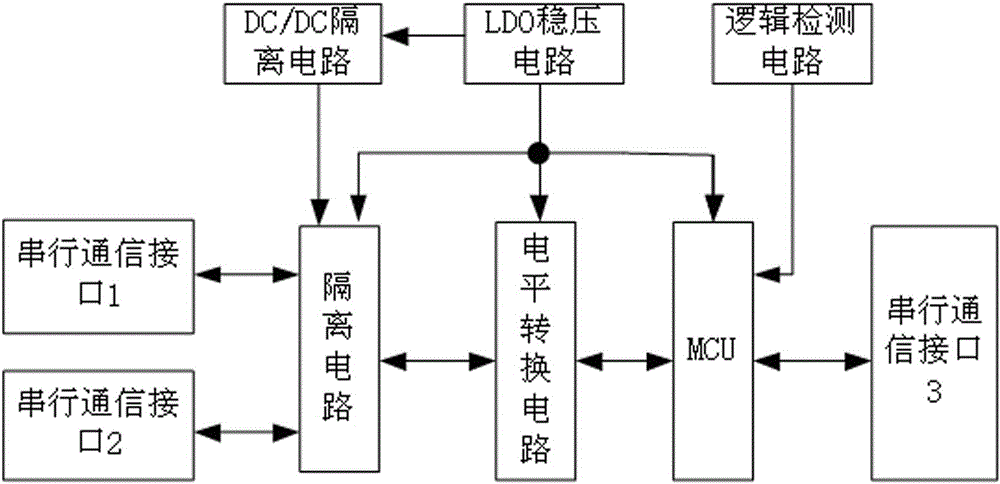

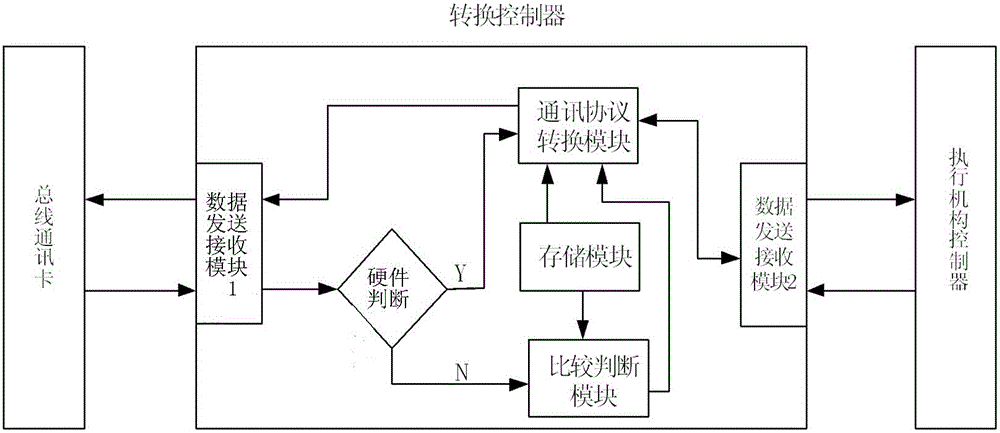

Intelligent bus switching controller

InactiveCN106603363AMake transitions seamlessImprove compatibilityBus networksData transformationCommunications protocol

The invention discloses an intelligent bus switching controller which comprises the components of a switching controller housing, a microcontrol unit and a power supply unit which are arranged in the switching controller housing, a first serial communication interface and a second serial communication interface, wherein the first serial communication interface and the second serial communication interface are in signal connection with the microcontrol unit. The microcontrol unit is used for receiving data of a bus communication card, comparing data which are transmitted by the bus communication card with stored data, judging bus type of the bus communication card, calling a corresponding communication protocol conversion program and converting data that are transmitted by the bus communication card to data which can be identified by an actuator. The microcontrol unit is further used for receiving data of the actuator, calling the corresponding communication protocol conversion program according to the judged bus type of the bus communication card, and converting the data which are transmitted by the actuator to data which can be identified by the bus communication card. The intelligent bus switching controller has advantages of reducing load and memory of an actuating mechanism master control CPU and furthermore realizing seamless switching or compatibility between various field buses.

Owner:CHONGQING CHUANYI AUTOMATION

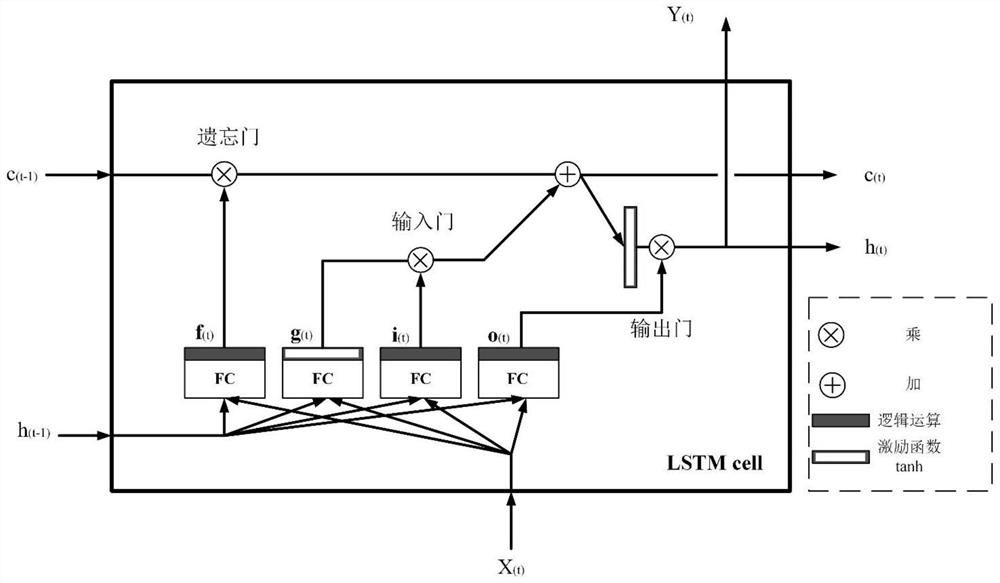

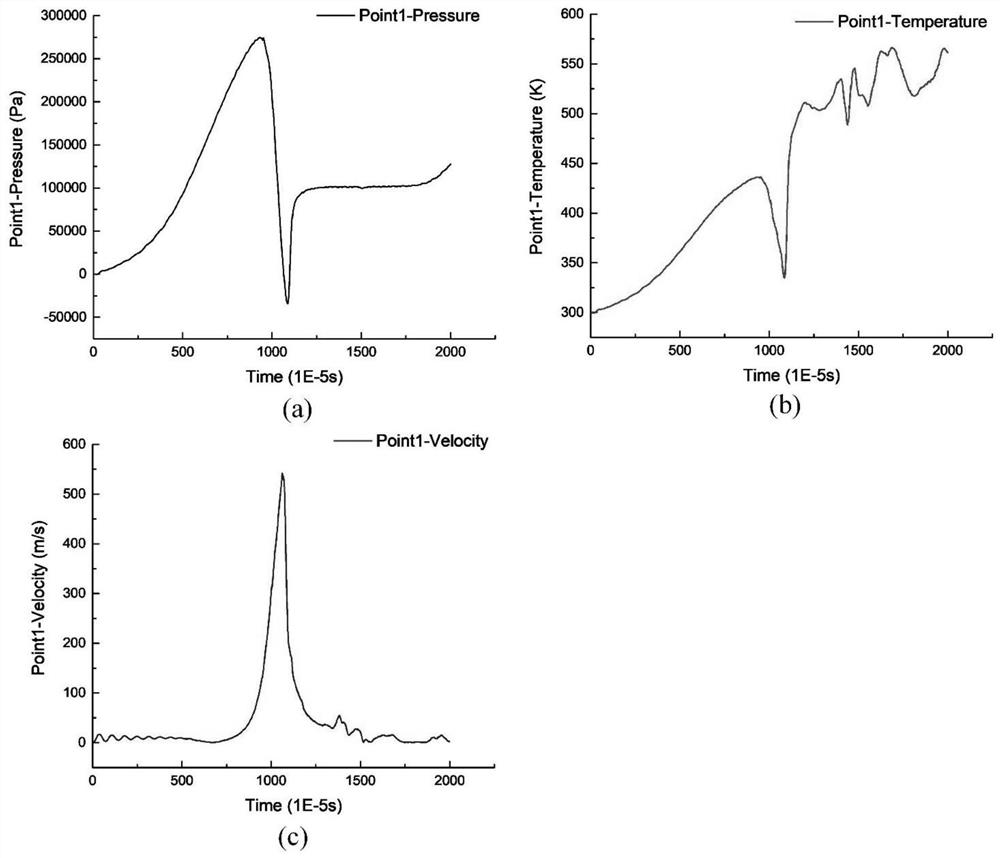

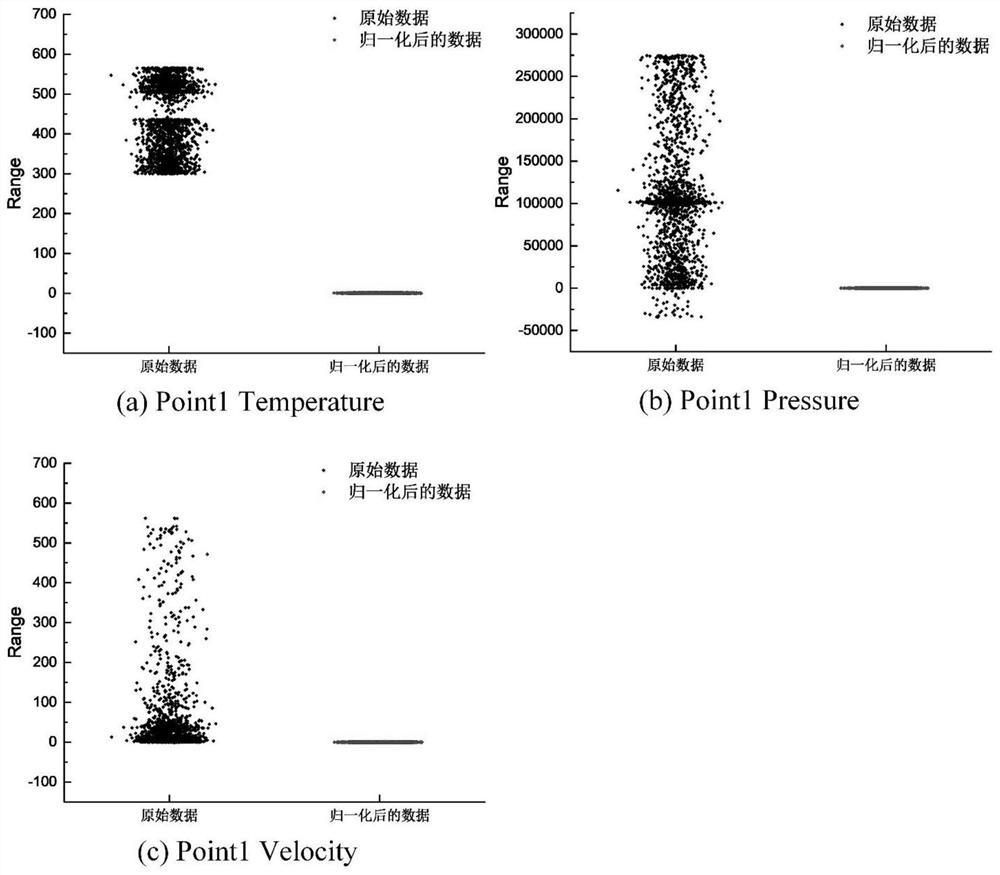

Fluid simulation data prediction model based on LSTM

ActiveCN112182954AHighlight substantiveShorten the simulation cycleDesign optimisation/simulationNeural architecturesObservation pointData prediction

The invention provides a scroll compressor fluid simulation data prediction model based on LSTM. The method comprises the steps: calculating a three-dimensional transient flow field value of an internal working cavity of the scroll compressor during operation by using a method of calculating fluid dynamics; collecting the change conditions of temperature, pressure and speed values at the observation points along with time; finally, substituting the acquired time sequence data into an LSTM network for training, and predicting the change trend of the thermodynamic value of the observation pointalong with time by utilizing the trained prediction model.

Owner:SHANGHAI UNIV

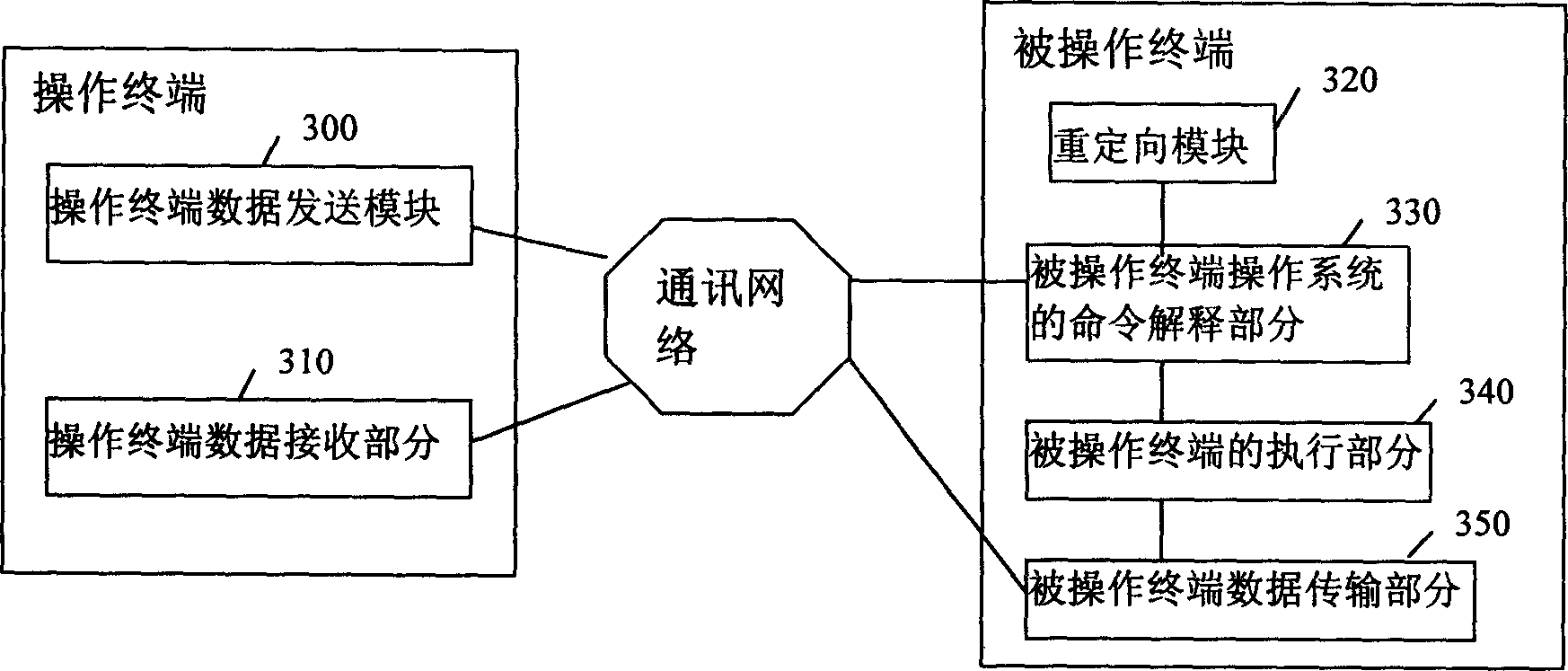

Long-range control method and system for communication device

InactiveCN1581794ALow costReduce workloadData switching networksSpecific program execution arrangementsNetwork terminationOperational system

The method includes following steps: control command to be transferred at operating terminal is transferred to remote communication device i.e. command interpreting part of operation system of operated terminal; command interpreting part of operation system of operated terminal receives control command transferred from operating terminal and processes the command; based processed result, the operated terminal carries out relevant operation so as to realize remote control for operated terminal. The invention also discloses the system including data transmission part, command interpreting part of operation system of operated terminal, and executive part of operated terminal. Advantages are: simplifying server setup at operated terminal; shortening develop cycle; lowering cost of remote controlling system, and raising processing capability of network terminal device.

Owner:HUAWEI TECH CO LTD

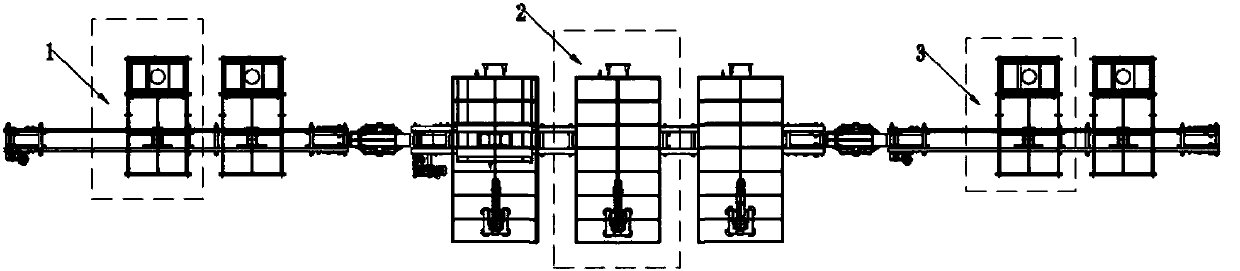

Robot automatic glaze spraying system

ActiveCN107618098AShorten the design and development cycleEasy maintenanceCeramic shaping apparatusModular compositionProduction line

The invention discloses a robot automatic glaze spraying system. The robot automatic glaze spraying system comprises a pretreatment unit, a glaze spraying unit and a posttreatment unit from upstream to downstream in sequence. The pretreatment unit comprises a plurality of pretreatment modules. Each pretreatment module comprises a blank trimming and dust collection position. The posttreatment unitcomprises a plurality of posttreatment modules. Each posttreatment module comprises a detecting and cleaning position. The glaze spraying unit comprises a plurality of glaze spraying modules. Each glaze spraying module comprises a glaze spraying conveying line, a glaze spraying robot and an air extraction and dust collection room. Each unit of the robot automatic glaze spraying system is a detachable module combination. The number of the pretreatment modules, the number of the glaze spraying modules and the number of the posttreatment modules can be set freely according to the production requirements. The production adaptability is greatly improved. The modules can be combined freely according to the production requirements. The design and development cycle of a glaze spraying production line is shortened. The number of the modules can be increased and reduced at will in the production process. The production cost is controlled flexibly.

Owner:FOSHAN PRATIC CNC SCI & TECH

Product structure parameterized design optimization method and system

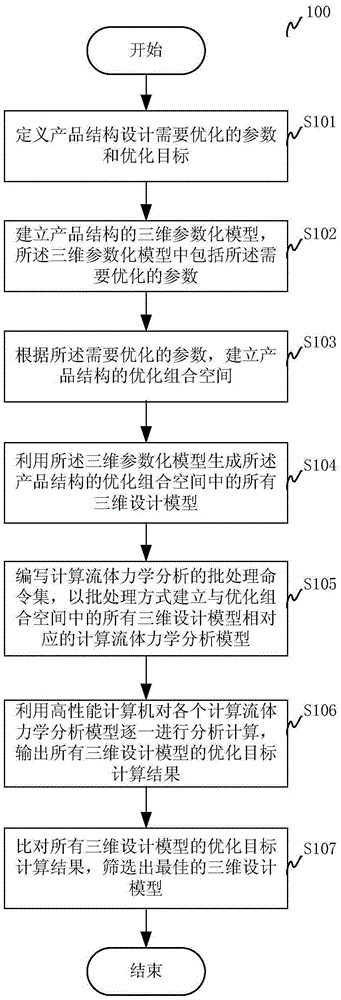

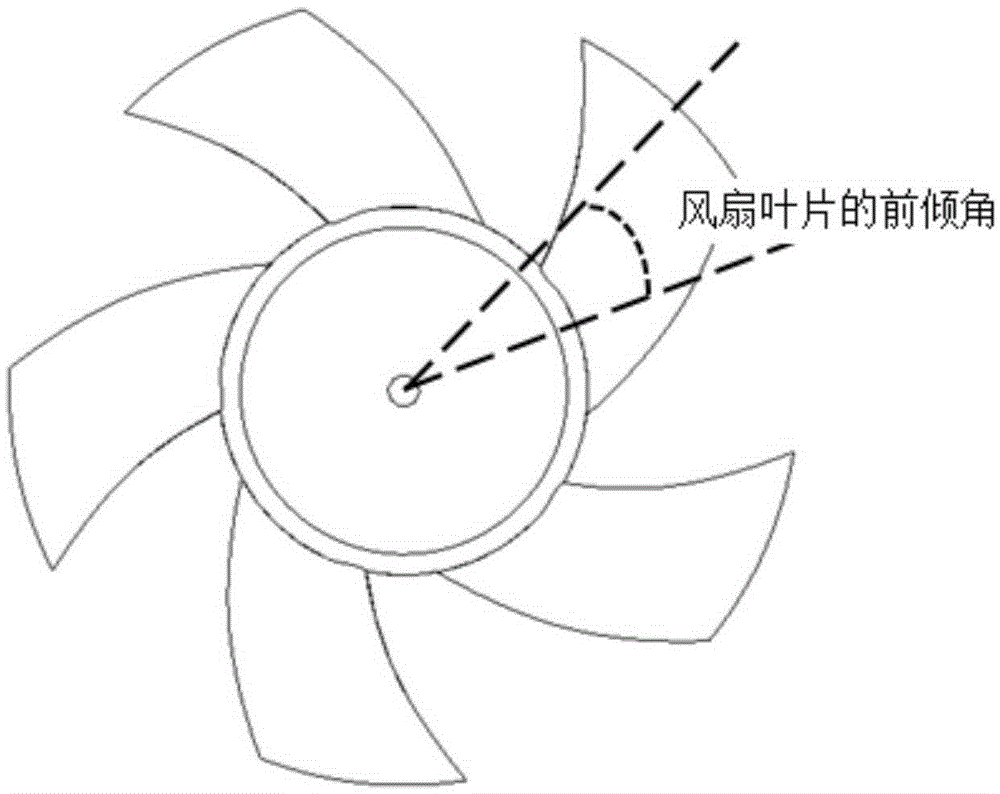

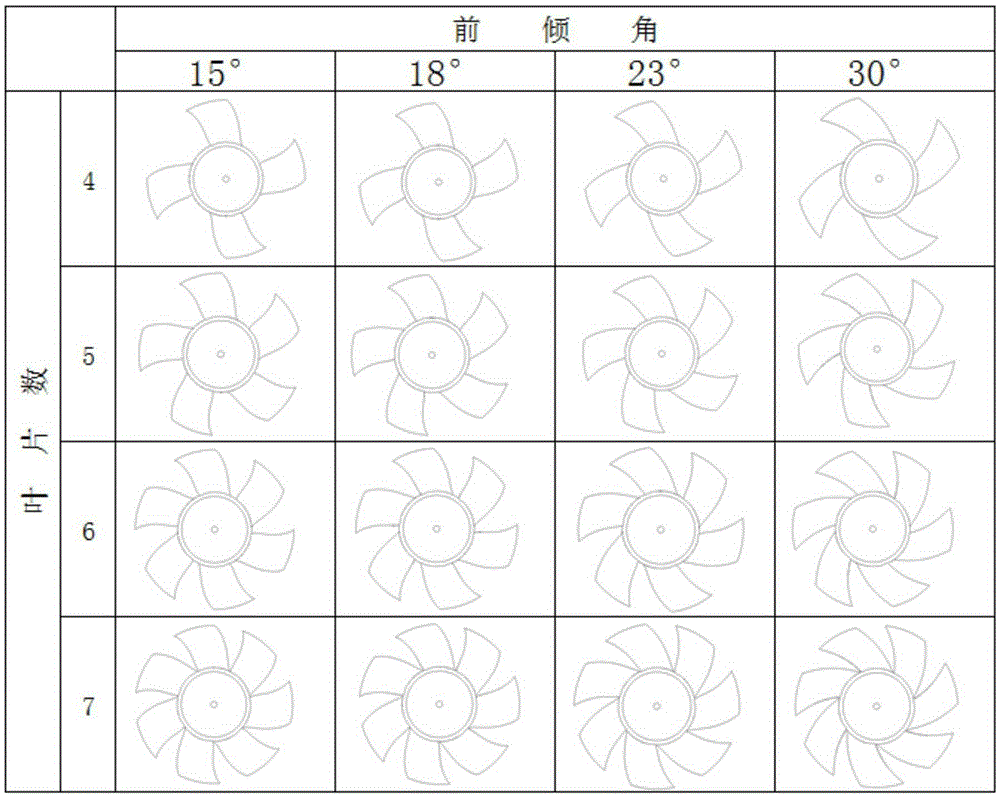

InactiveCN105243183AMeet the requirement of quick responseRapid designSpecial data processing applicationsBatch processingComputer science

The present invention relates to a product structure parameterized design optimization method and system. The method comprises: S1. defining a parameter that needs to be optimized and an optimization goal of product structure design; S2. establishing a three-dimensional parameterized model of a product structure, wherein the model comprises the parameter that needs to be optimized; S3. according to the parameter that needs to be optimized, establishing an optimization combining space of the product structure; S4. generating all three-dimensional design models in the optimization combining space by using the three-dimensional parameterized model; S5. writing a batch processing command set of computational fluid dynamic analysis, and establishing computational fluid dynamic analysis models corresponding to all the three-dimensional design models in a batch processing manner; S6. performing analysis calculation on the computational fluid dynamic analysis models one by one by using a high-performance computer, and outputting all optimization goal calculation results; and S7. comparing all the optimization goal calculation results, and screening out the best three-dimensional design model. According to the product structure parameterized design optimization method and system provided by the present invention, the optimization of product design parameters can be rapidly completed.

Owner:国家超级计算深圳中心(深圳云计算中心) +1

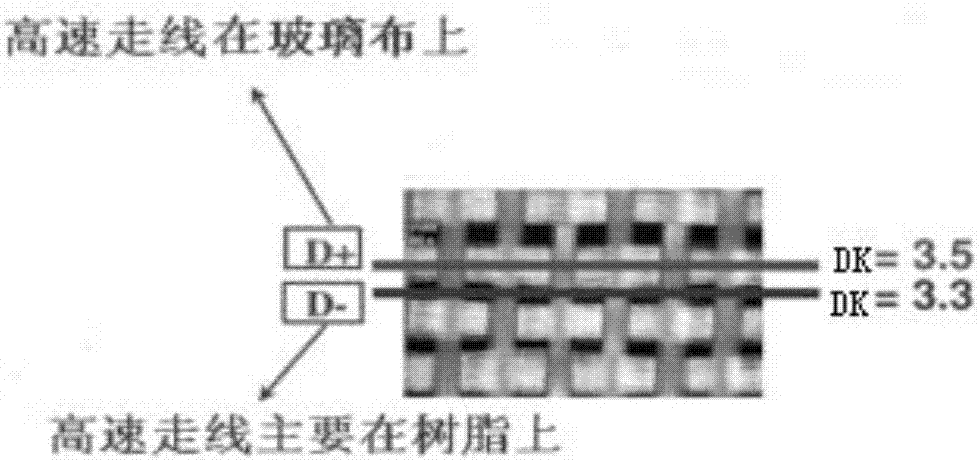

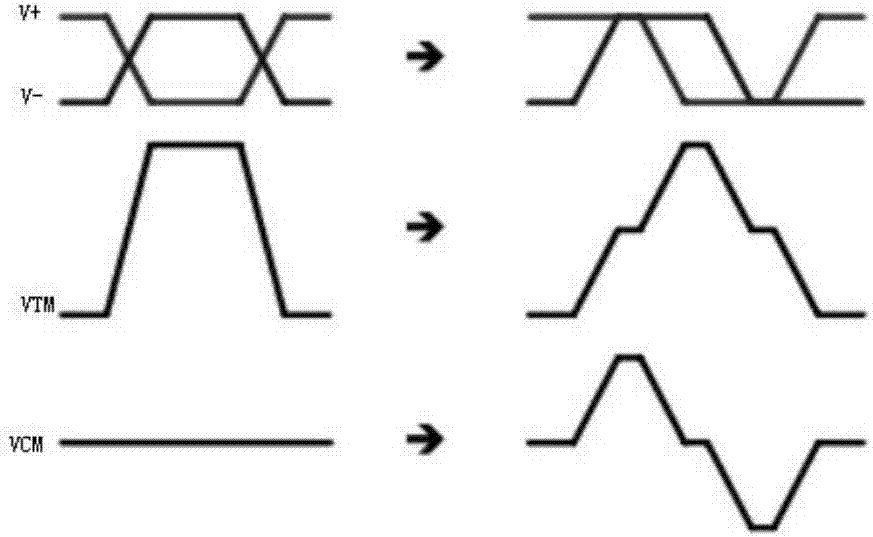

Layout wiring structure and wiring method for improving signal SI quality

InactiveCN107315878AReduce the risk of noiseImprove SI signal qualityCross-talk/noise/interference reductionPrinted circuit aspectsSignal qualityCoupling

The invention discloses a Layout wiring structure for improving signal SI quality. Each of positive and negative differential routes in a PCB comprises a plurality of D1 sections, a plurality of D2 sections and a plurality of D3 sections; the D1 sections and the D2 sections of any differential route are arranged in parallel in a staggered manner; and any adjacent D1 and D2 sections of any differential route are connected through the D3 section. The invention furthermore discloses a Layout wiring method for improving the signal SI quality. The positive and negative differential routes parallel to each other on the PCB are subjected to wiring in a longitudinal repeated shift mode. The signal transmission delays on the positive and negative differential routes in a differential coupling pair are compensated for enabling the delays of signals, reaching a receiving end of a device, on the two routes to be same, so that the risk of differential mode to common mode noises is lowered and the signal SI quality of high-speed signals during long-distance transmission is improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

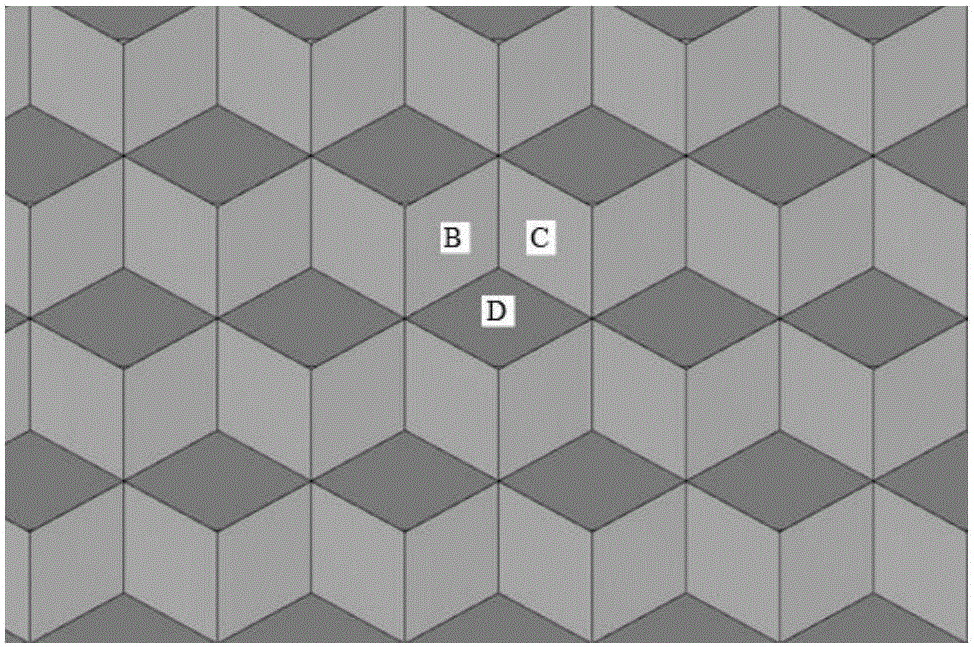

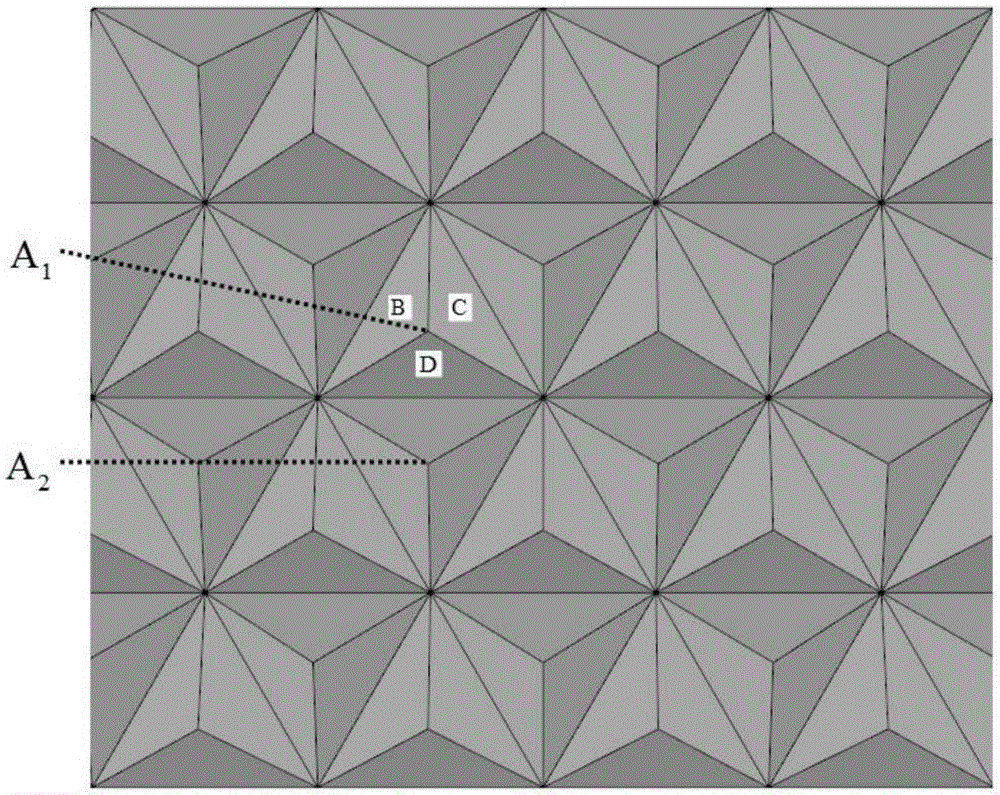

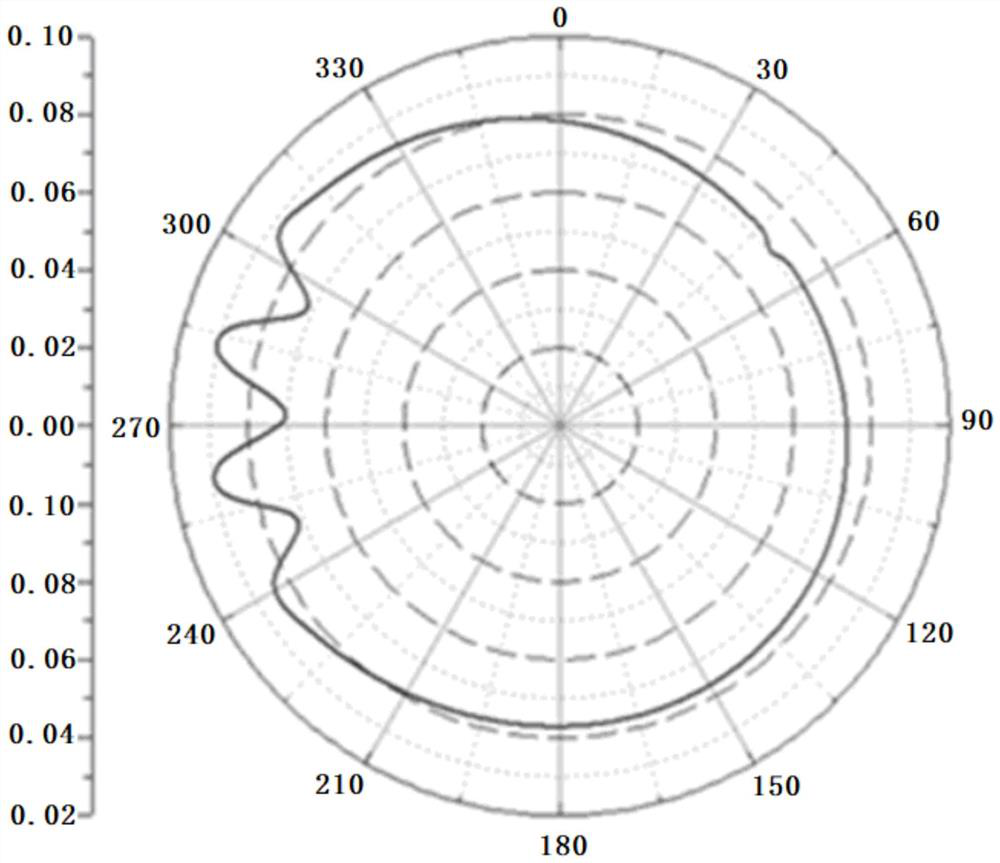

Method for calculating reflected light intensity of cubic pyramid type retroflection material

InactiveCN104991299AImprove accuracyImprove reliabilityOptical elementsMaterial DesignRelative intensity

The invention relates to a method for calculating a reflected light intensity of a cubic pyramid type retroflection material. The method comprises: (1), designing a cubic pyramid type structure; (2), carrying out five steps to realize incident light conversion into retroreflection light; and (3), compiling a calculation flow of the relative intensity of the retroreflection light. According to the invention, accurate calculation is carried out to obtain reflected light intensity distribution of the cubic pyramid type retroflection materials with various structures and the reflected light intensity distribution reflects the retroflection performances of the materials. The method can be used for evaluation of the novel retroflection material performance; and the design of the novel retroflection material optimization structure can be assisted; links of tested manufacturing and testing in the novel material design are saved or reduced; the development expenses are saved; and the development flow is shortened.

Owner:SOUTHWEAT UNIV OF SCI & TECH

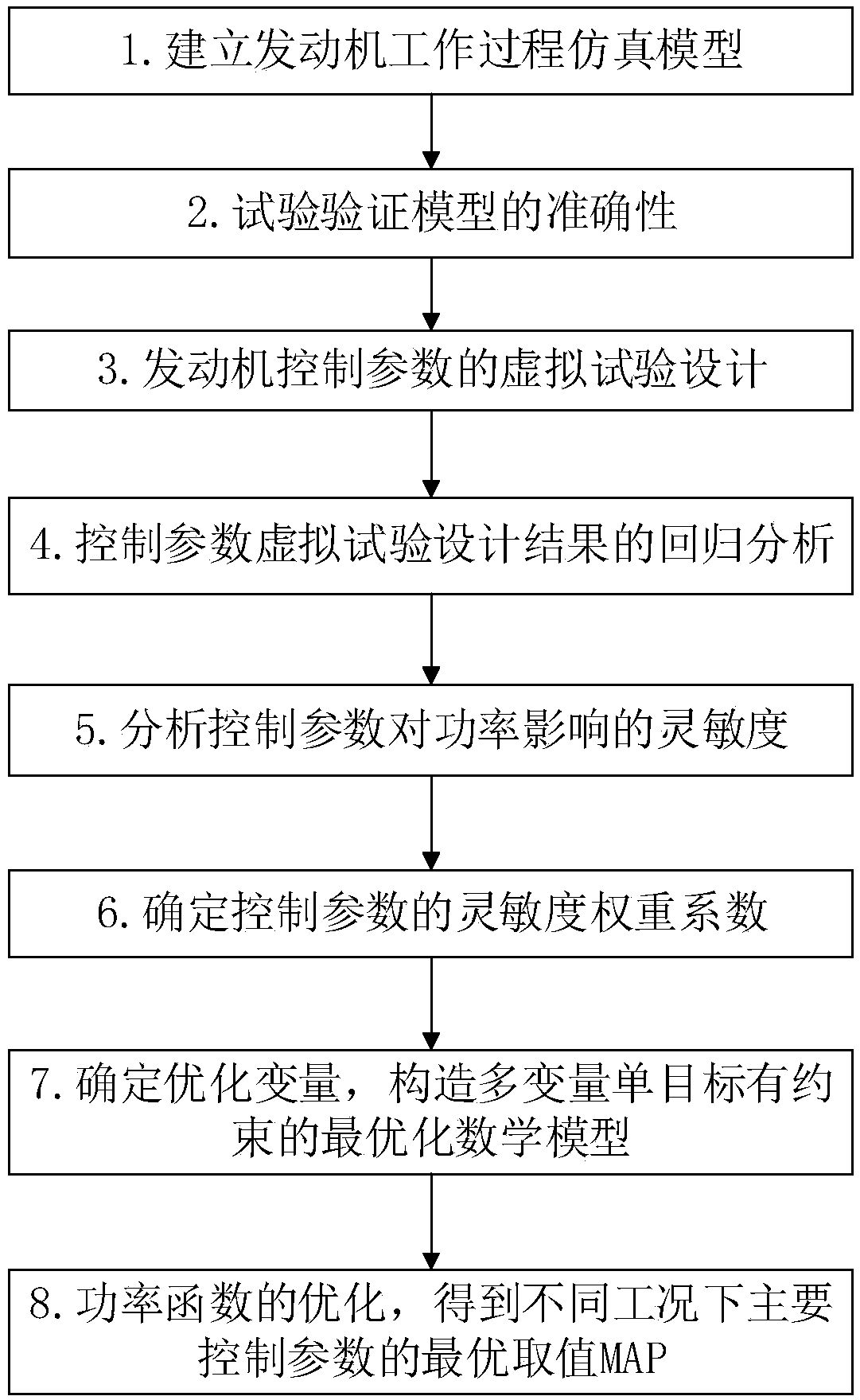

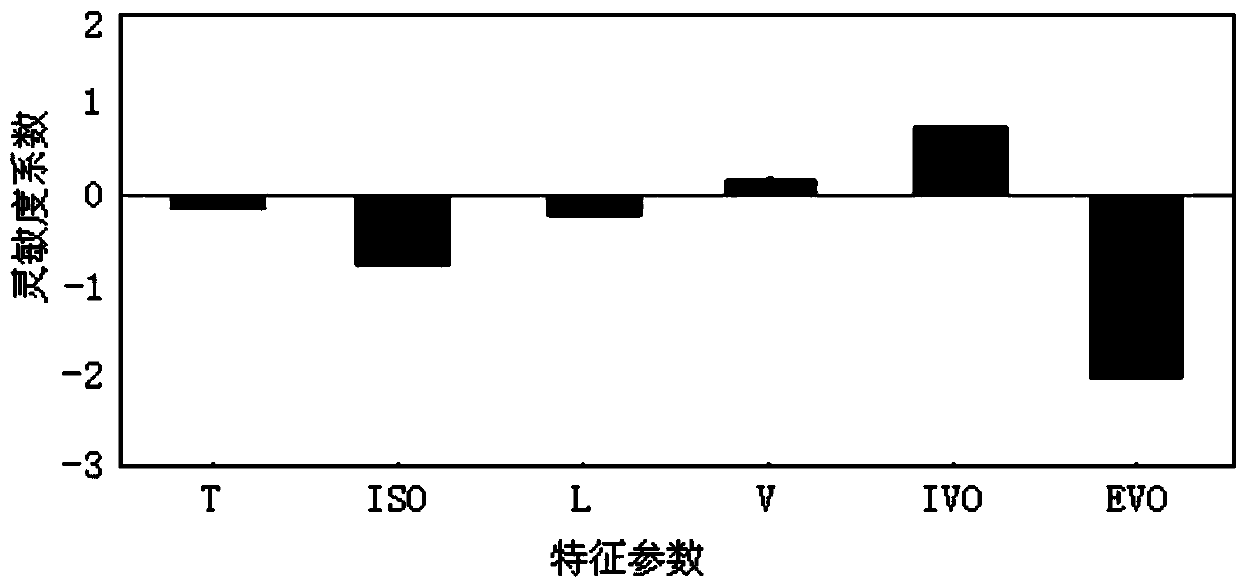

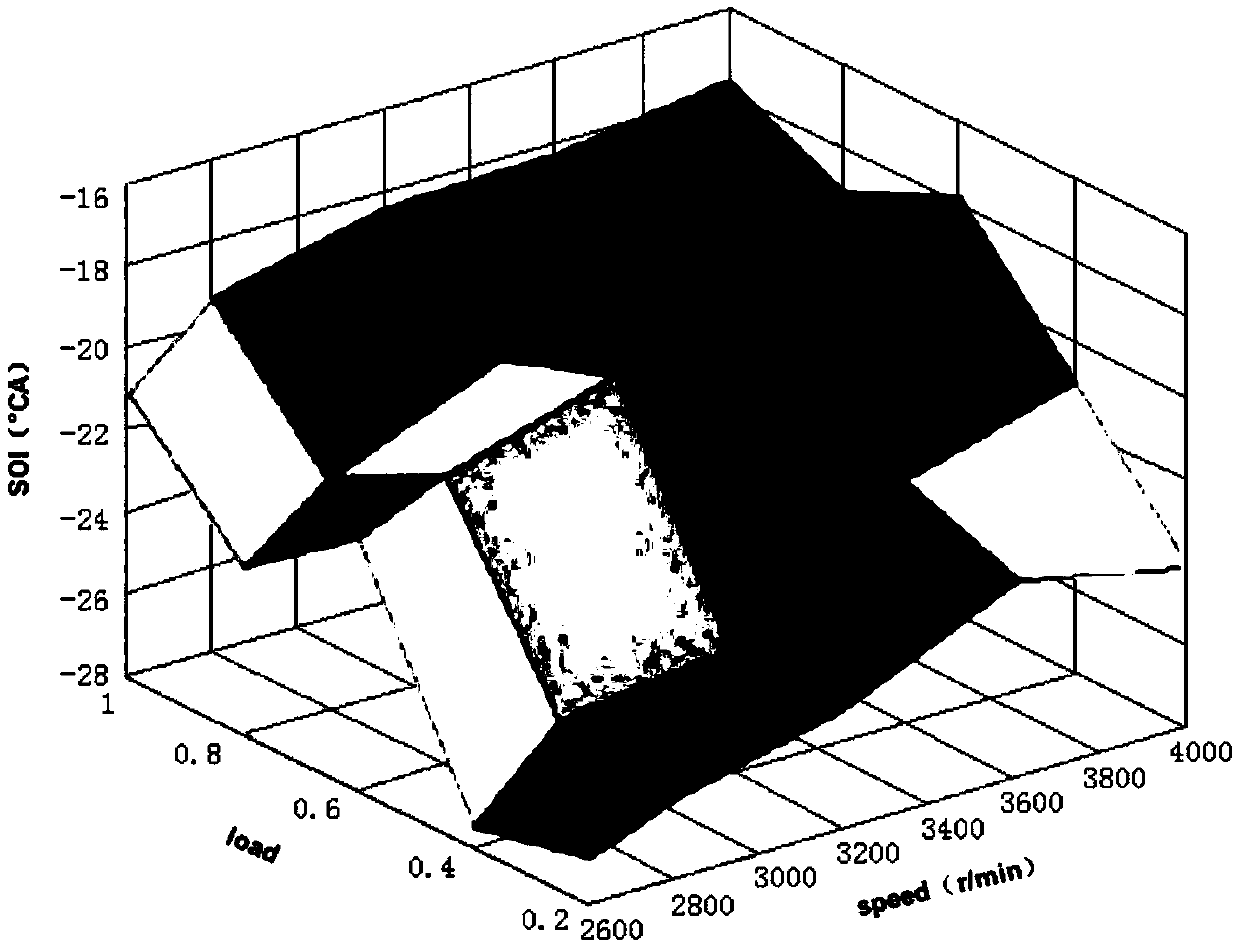

Determination method for engine control parameter optimization MAP

InactiveCN108647389ARealize the optimization of the whole working conditionAvoid blindnessDesign optimisation/simulationMulti-objective optimisationMathematical modelRegression analysis

The invention relates to a determination method for an engine control parameter optimization MAP. The method comprises the steps that (1) an engine working process simulation model is established; (2)the accuracy of the model is verified through a test; (3) virtual test design of engine control parameters is performed; (4) regressive analysis of the virtual test design result of the control parameters is performed; (5) the sensitivity of the control parameters to power influences is analyzed; (6) sensitivity weight coefficients of the control parameters are determined; (7) optimization variables are determined, and a multi-variable single-target constrained optimal mathematical model is constructed; and (8) a power function is optimized, and an optimal value MAP of main control parametersunder different working conditions is obtained. Through the method, the engine control parameters with a large influence on machine power can be quickly determined, the optimization range of the control parameters with high sensitivity can be determined, and therefore an optimization direction is provided for improvement to the machine power under all working conditions; and the development cyclecan be shortened, development cost can be lowered, development efficiency can be improved, and effective guidance can be provided for optimization of engine performance.

Owner:CHINA NORTH ENGINE INST TIANJIN

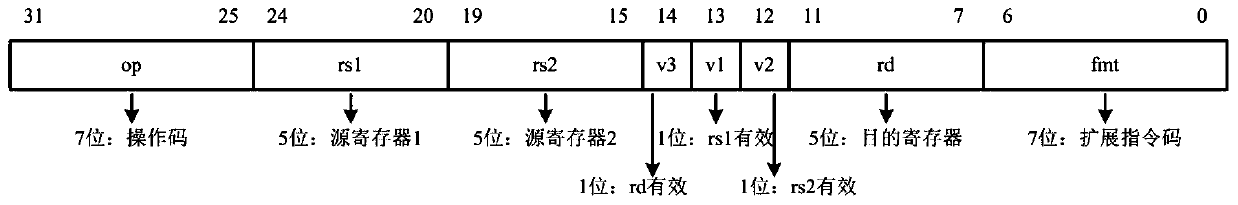

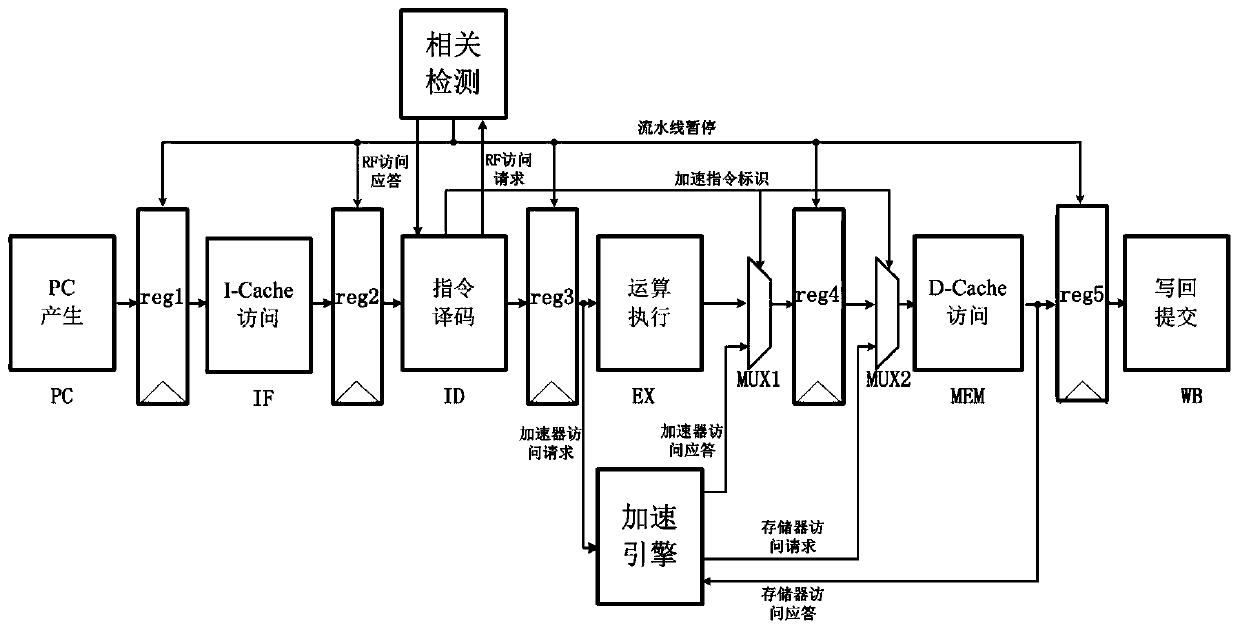

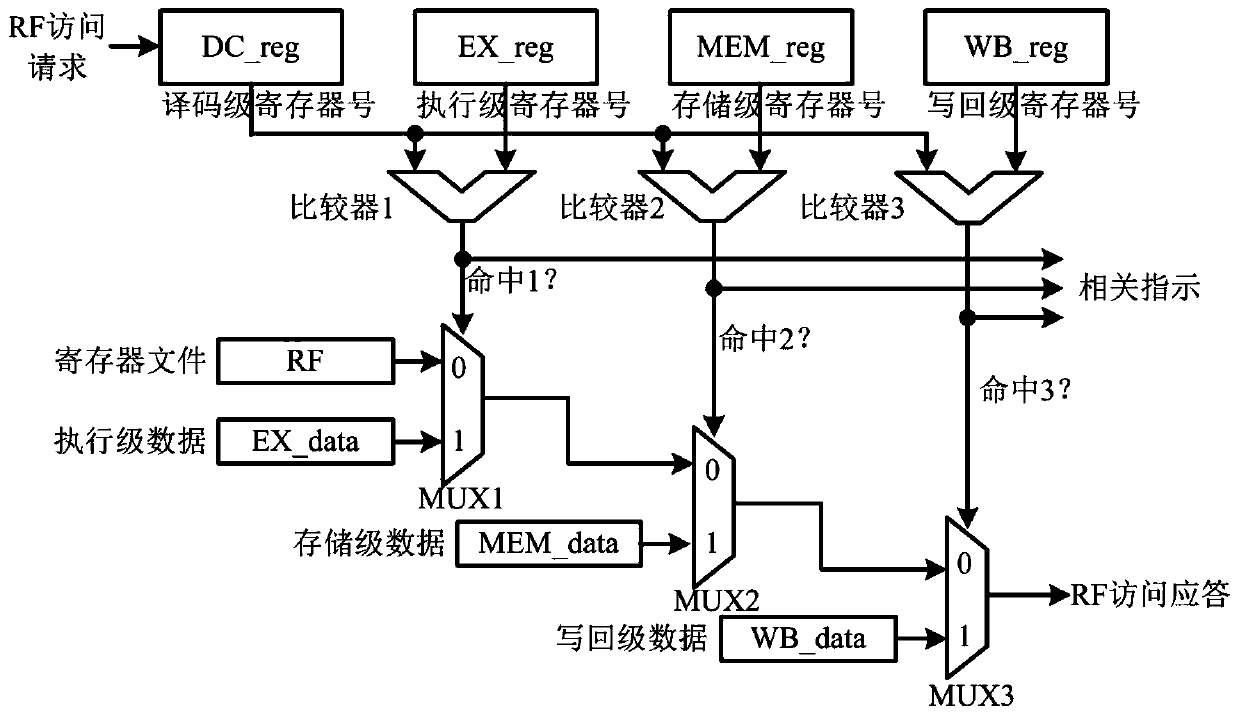

Assembly line tight coupling accelerator interface structure based on instruction extension

ActiveCN110806899AImprove execution efficiencyEnable direct communicationRegister arrangementsConcurrent instruction executionComputer architectureMultiplexer

The invention discloses an assembly line tight coupling accelerator interface structure based on instruction extension, which comprises a correlation detection module and an acceleration engine; the correlation detection module is arranged at a decoding stage and is used for detecting data correlation of an acceleration instruction to register file RF access; after the acceleration instruction enters a decoding stage, a related detection module is started, a register file RF access request is input, and only when it is judged that correlation is generated, a blocking response signal is generated; the acceleration engine is arranged at the operation execution stage; the decoding stage activates an acceleration engine component through an accelerator access request signal sent by an inter-stage register reg3; at the moment, the operation execution component is in a bypass state, access responses of the operation execution component and the accelerator enter the multiplexer MUX1, and themultiplexer MUX1 selects a corresponding result under the action of an acceleration instruction identification signal and sends the result to the inter-stage register reg4. The assembly line tight coupling accelerator interface structure has extremely high universality and is suitable for most processor systems.

Owner:XIAN MICROELECTRONICS TECH INST

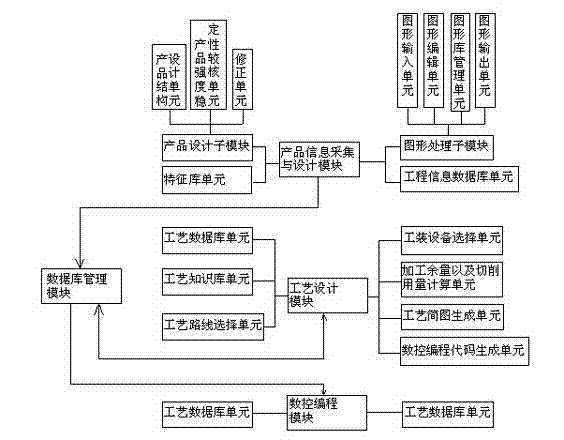

Hydraulic connector integration system

InactiveCN103926876AAchieve coordinationEasy to controlProgramme controlComputer controlGraphicsComputer module

The invention discloses a hydraulic connector integration system which is characterized by comprising a product information collecting and graphic design module, a process design module, a numerical control programming module and a database management module. The product information collecting and graphic design module is used for collecting general information and component information of products according to the products required to be designed to conduct product preliminary design, and component graphics and product assembly graphics are drawn; the process design module is used for selecting a reasonable machining path according to the general information and the component information provided by the product information collecting and graphic design module; the numerical control programming module is combined with information in the product information collecting and graphic design module and manufacturing process information to conduct numerical control programming, then numerical control commands provided by numerical control automatic programming are transmitted to a numerical control system through an interface, and numerical control machining is completed; the database management module is used for completing data transmission and data exchange between modules. By means of the hydraulic connector integration system, the production period is shortened, and the production cost is reduced.

Owner:NANTONG AMC MACHINERY

aircraft landing gear simulator

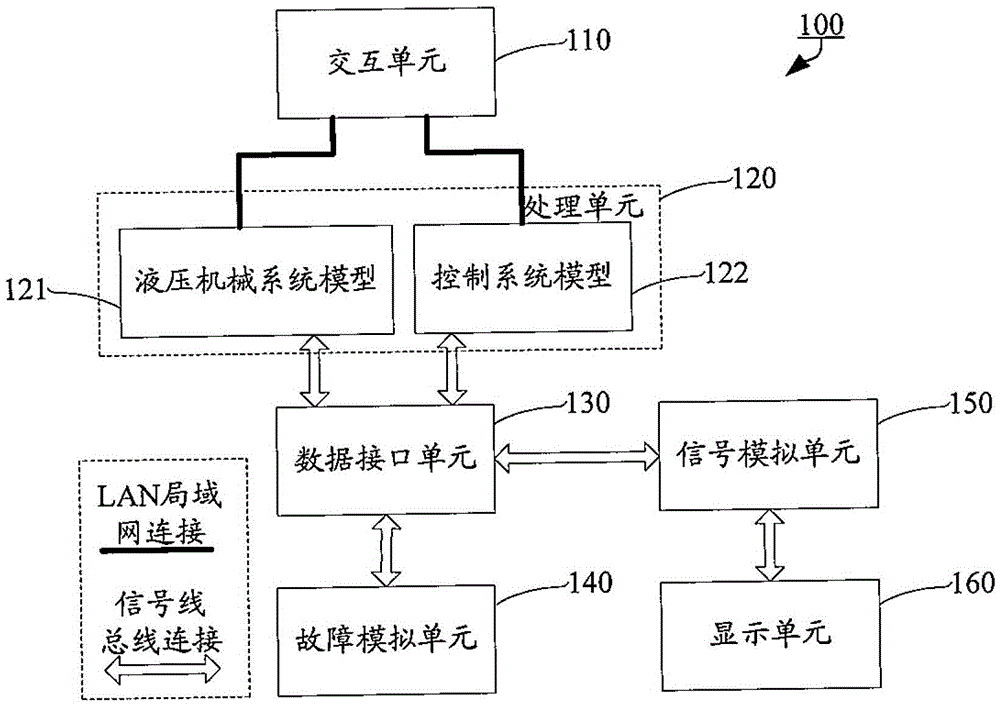

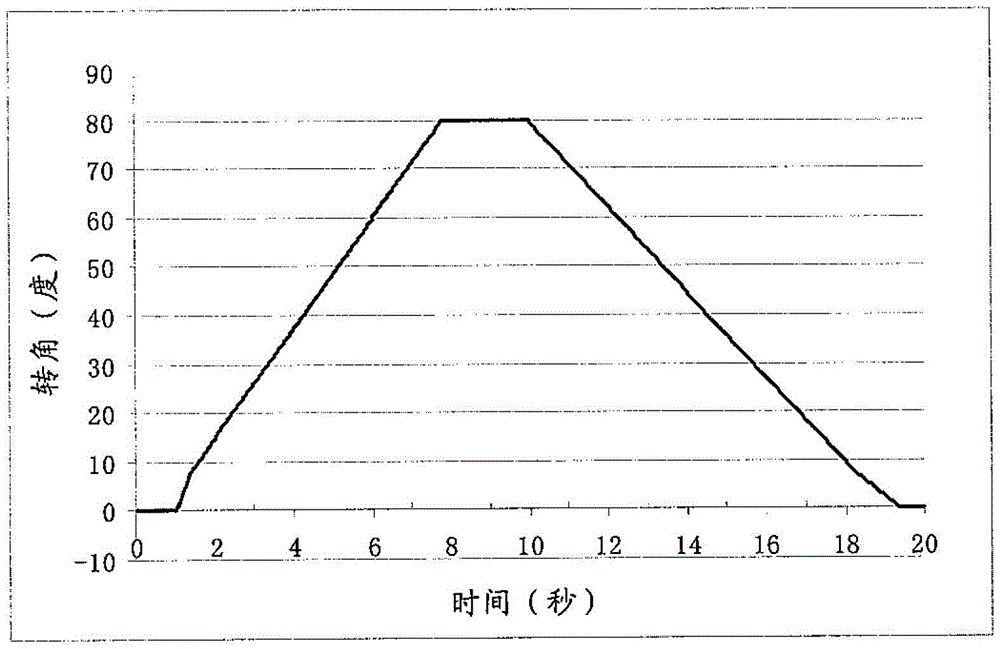

ActiveCN102968059BEnsure safetyShorten the design and development cycleSimulator controlState parameterControl system

The invention relates to an aircraft landing gear simulator which comprises a signal simulation unit for receiving manipulating instructions of a landing gear and a processing unit. The processing unit is coupled with the signal simulation unit, uses the manipulating instructions of the landing gear as the input of an operated aircraft landing gear real-time model, and outputs at least one state parameter to the signal simulation unit and a display unit. The processing unit comprises at least one instrument coupled to the signal simulation unit, wherein the at least one instrument correspondingly displays at least one state parameter, and the aircraft landing gear real-time model comprises a hydraulic mechanical system module and a control system model. The aircraft landing gear simulator does not require any testing member of real physical tests and can finish various parameter testing and analysis of a landing gear collecting and releasing system. Additionally, partial real parts are replaced under the laboratory environment for performing testing, so that testing times and strength can be reduced, testing cost can be saved, and safety of personnel in dangerous testing is ensured.

Owner:COMAC +1

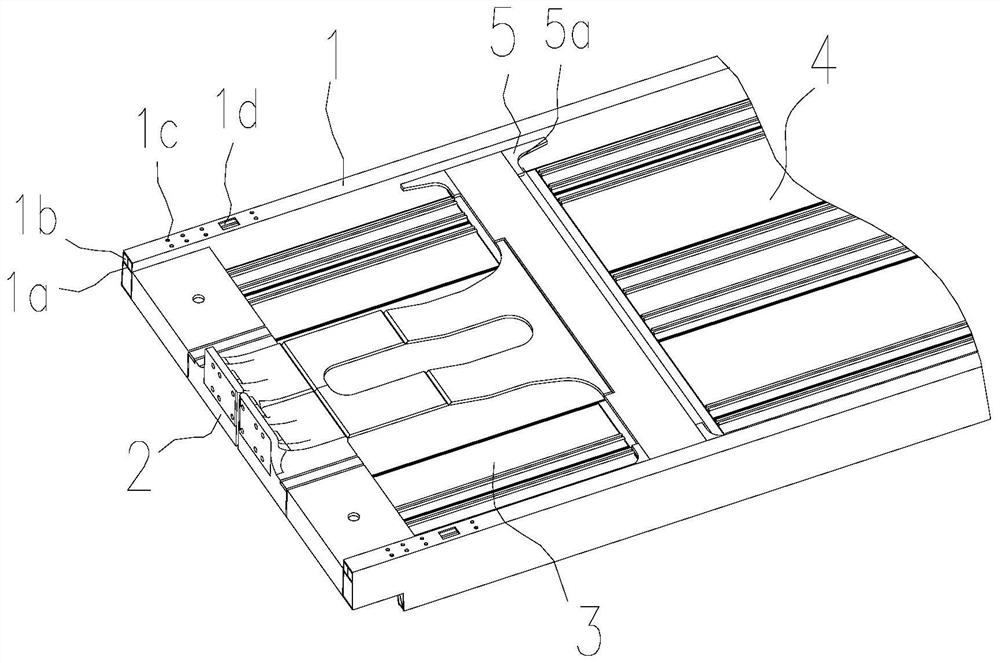

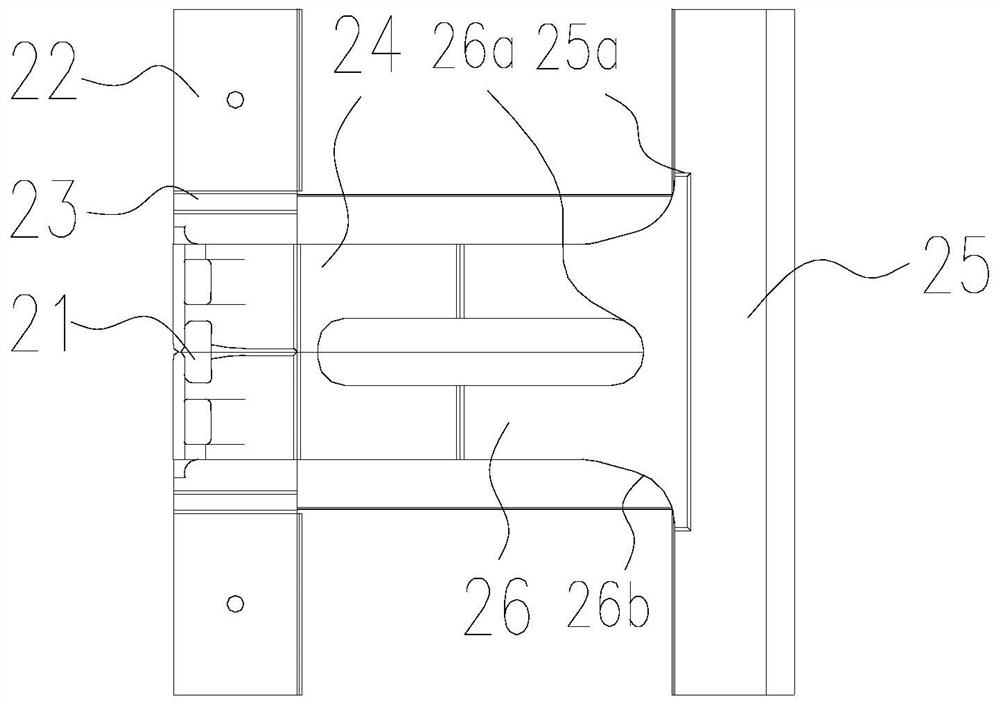

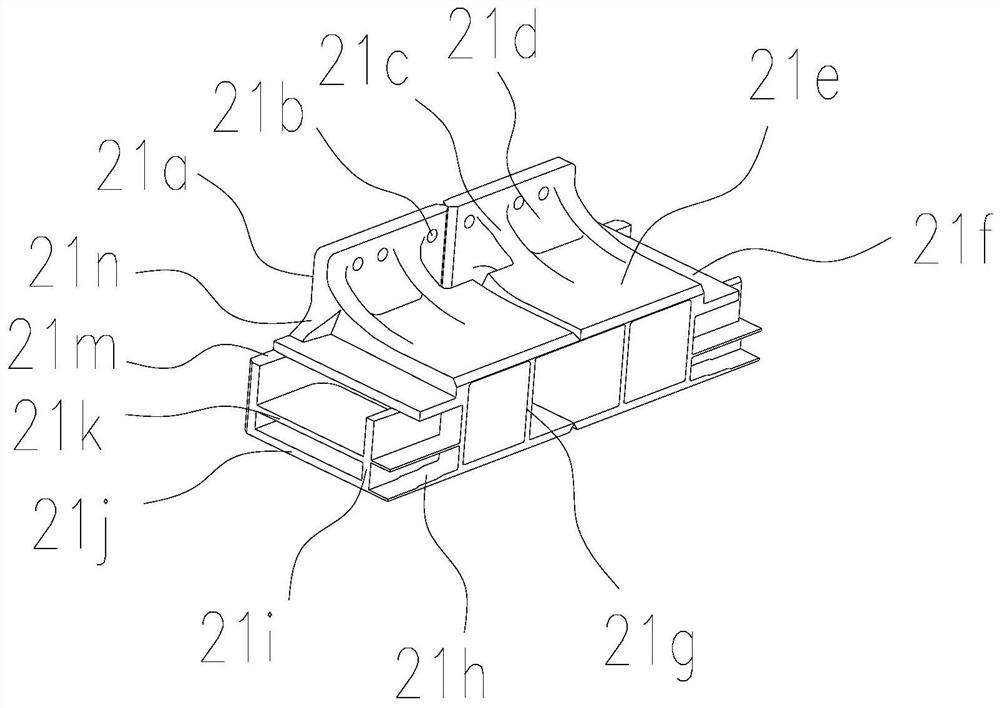

Railway vehicle and vehicle body chassis structure thereof

ActiveCN113184001AIncreased safety marginIncrease productivityUnderframesRailway transportBogieControl theory

The invention discloses a railway vehicle and a vehicle body chassis structure thereof. The chassis structure comprises chassis edge beams, end structures, short floors, long floor assemblies and transition rib plates. The end structures and the chassis edge beams are connected to form an integral frame bearing structure, and the short floors and the long floors are assembled in the integral frame bearing structure to form an chassis structure. Each end structure is mainly composed of a hinged traction device installation base, a sleeper beam, a sealing plate, a traction beam, a cross beam and a cover plate. The hinged traction device mounting seat is connected with chassis edge beams through sleeper beams in the transverse direction, and is assembled and connected with long floors through a traction beam, a cover plate and a cross beam in sequence in the longitudinal direction; the two ends of the long floor assembly are connected with the corresponding underframe boundary beams respectively. According to the chassis structure, the problems that a power hinged type bogie interferes with a vehicle body, and the bearing requirement is higher are solved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

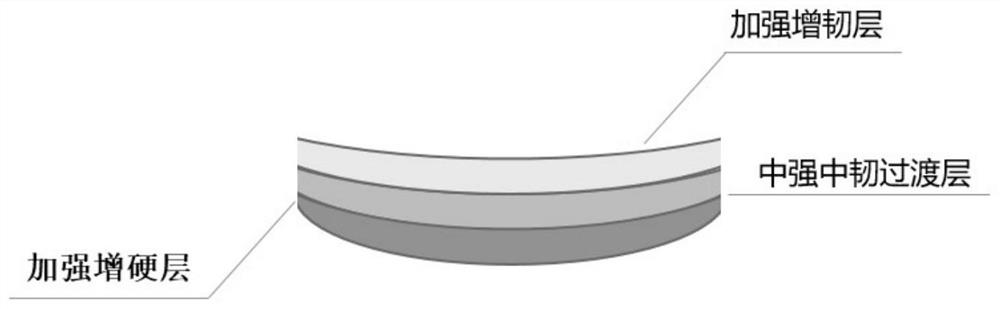

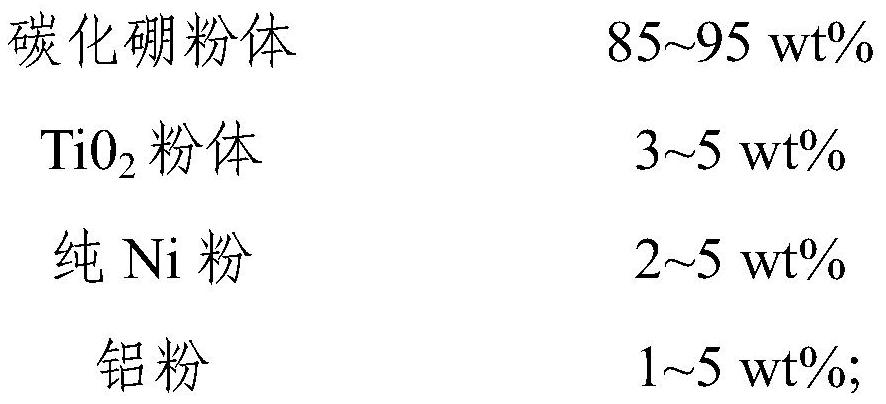

Boron carbide-based multiphase ceramic and preparation method and device thereof

ActiveCN112209718ABoth hardnessToughnessAdditive manufacturing apparatusAuxillary shaping apparatusPhotoinitiatorComposite ceramic

The invention relates to the technical field of ceramic materials, in particular to boron carbide-based composite ceramic and a preparation method and device thereof. The boron carbide-based multiphase ceramic with a gradient function is obtained by adjusting components (taking a photosensitive resin system with low ash content and a photoinitiator as carriers) and subsequent pulping, molding andpost-treatment steps (adopting a three-time glue discharging technology, strengthening a degreasing and glue discharging process and controlling the carbon content in a sintered body) so that the compatibility of material specificity is realized, and maximization of material functions is achieved; meanwhile, simple spatial linear distribution is realized to meet the requirements of various workingconditions. The 3D printing device is based on a photocuring molding technology (SLA), near-net-shape molding is achieved, individuation is high, three-gradient feeding is achieved through the threeslurry barrels, and therefore the boron carbide-based multiphase ceramic of a three-layer structure is prepared.

Owner:沈阳中钛装备制造有限公司

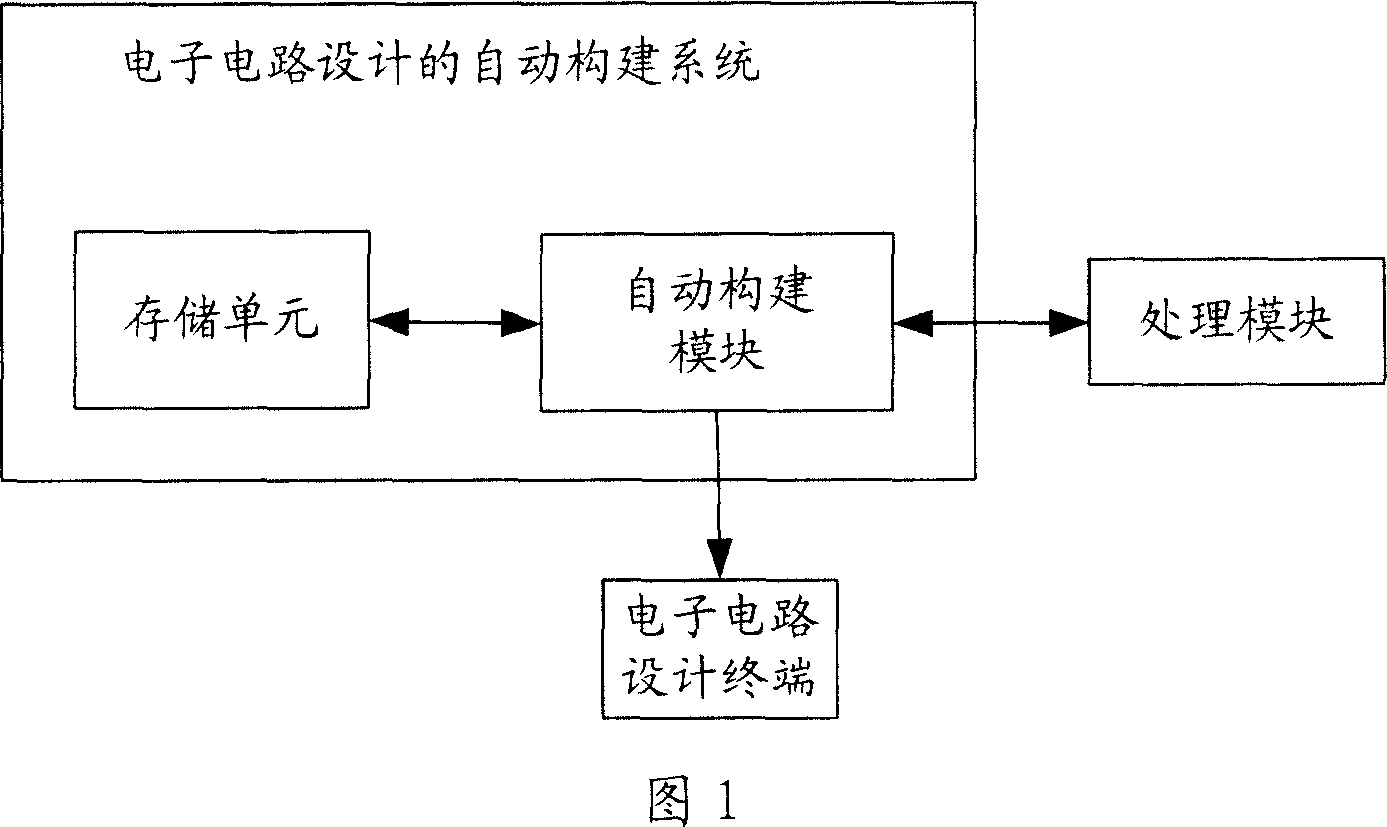

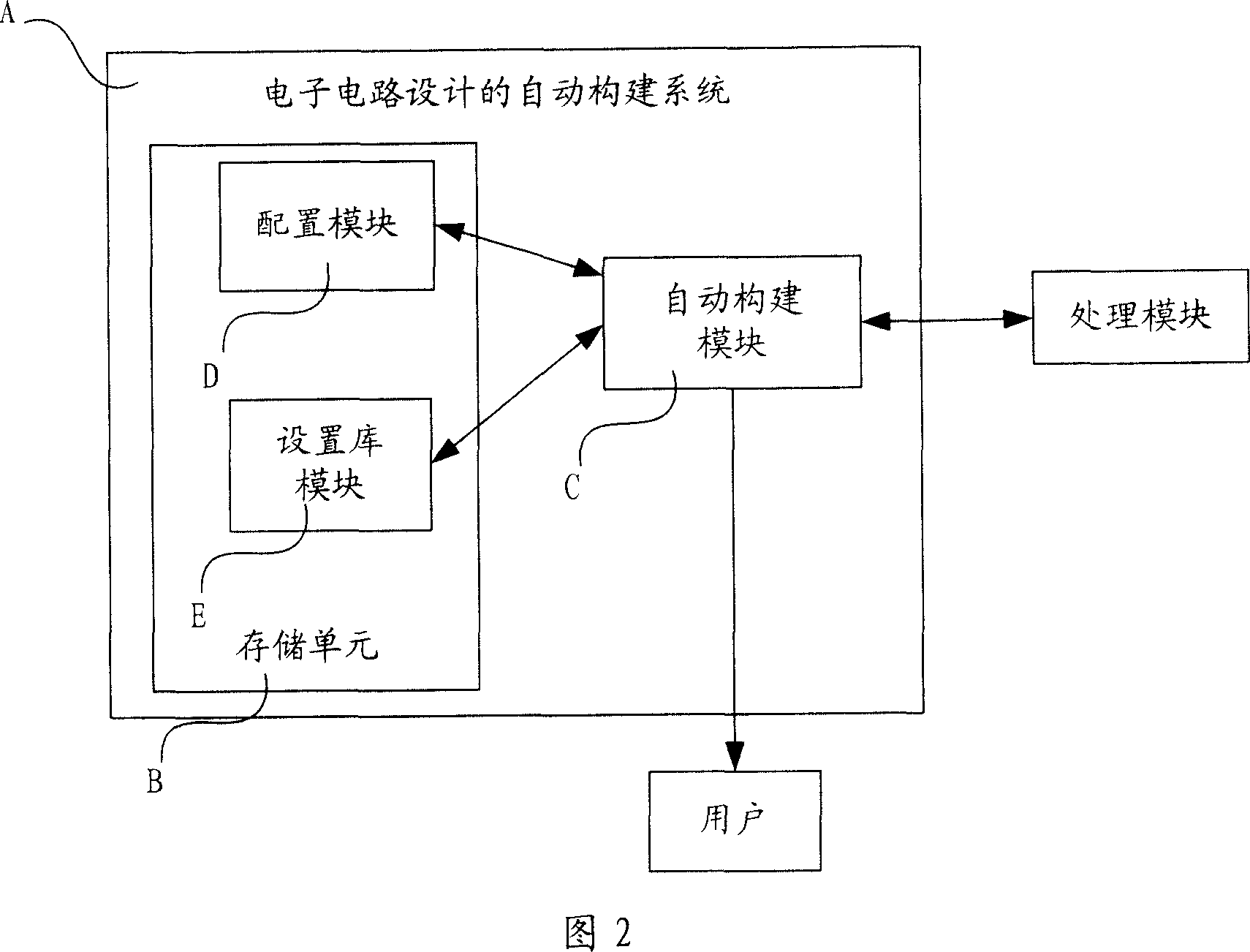

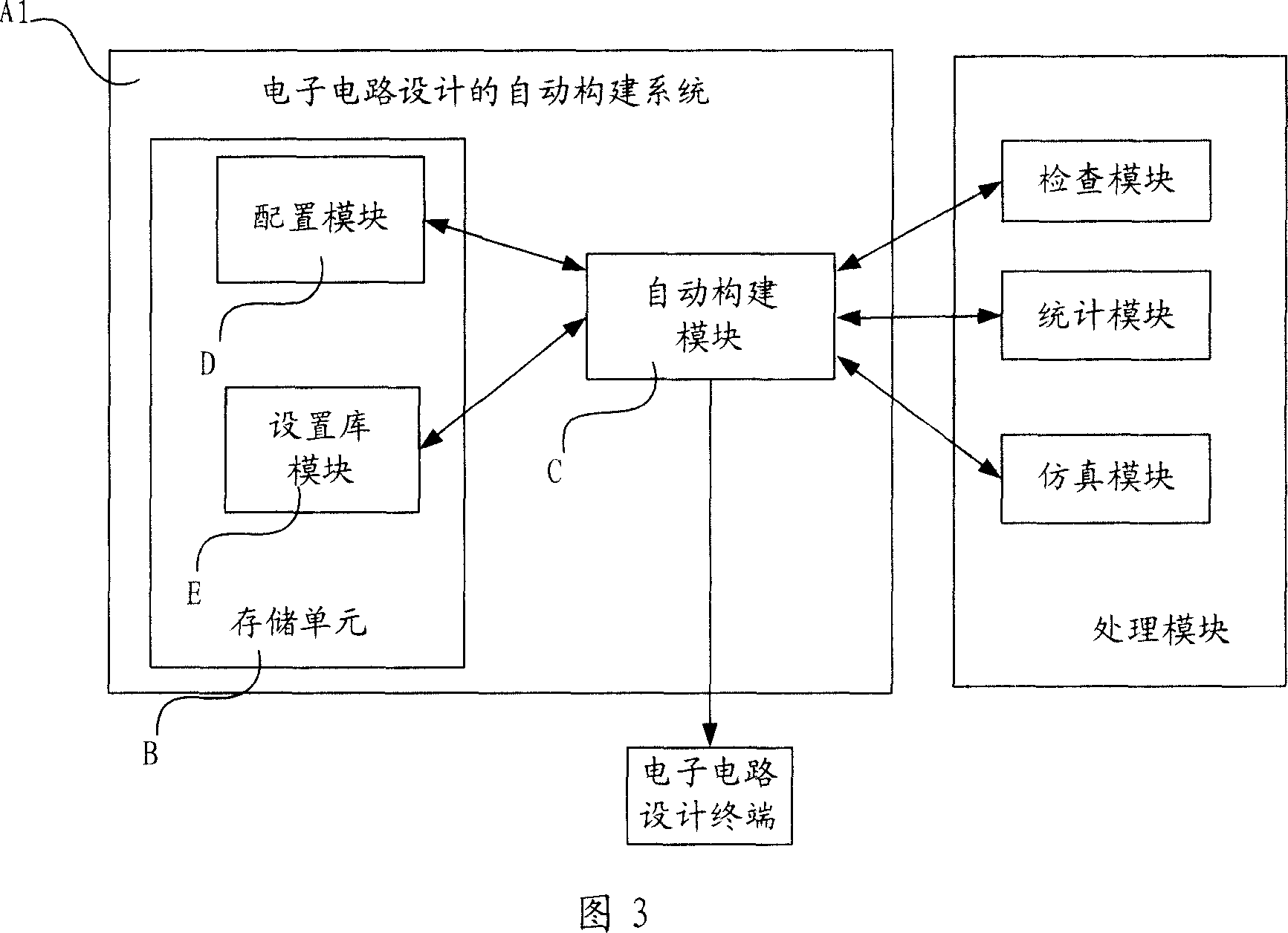

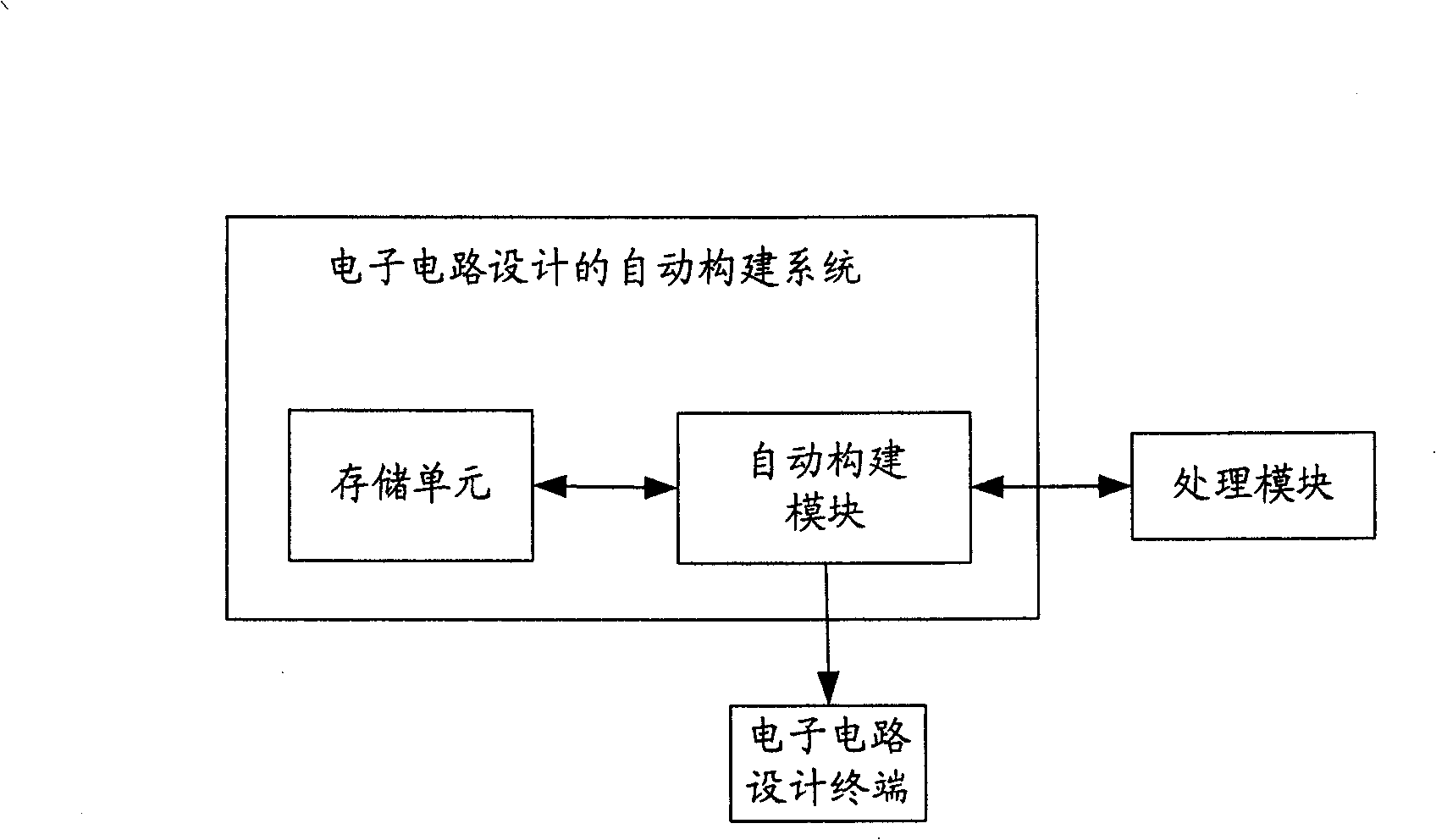

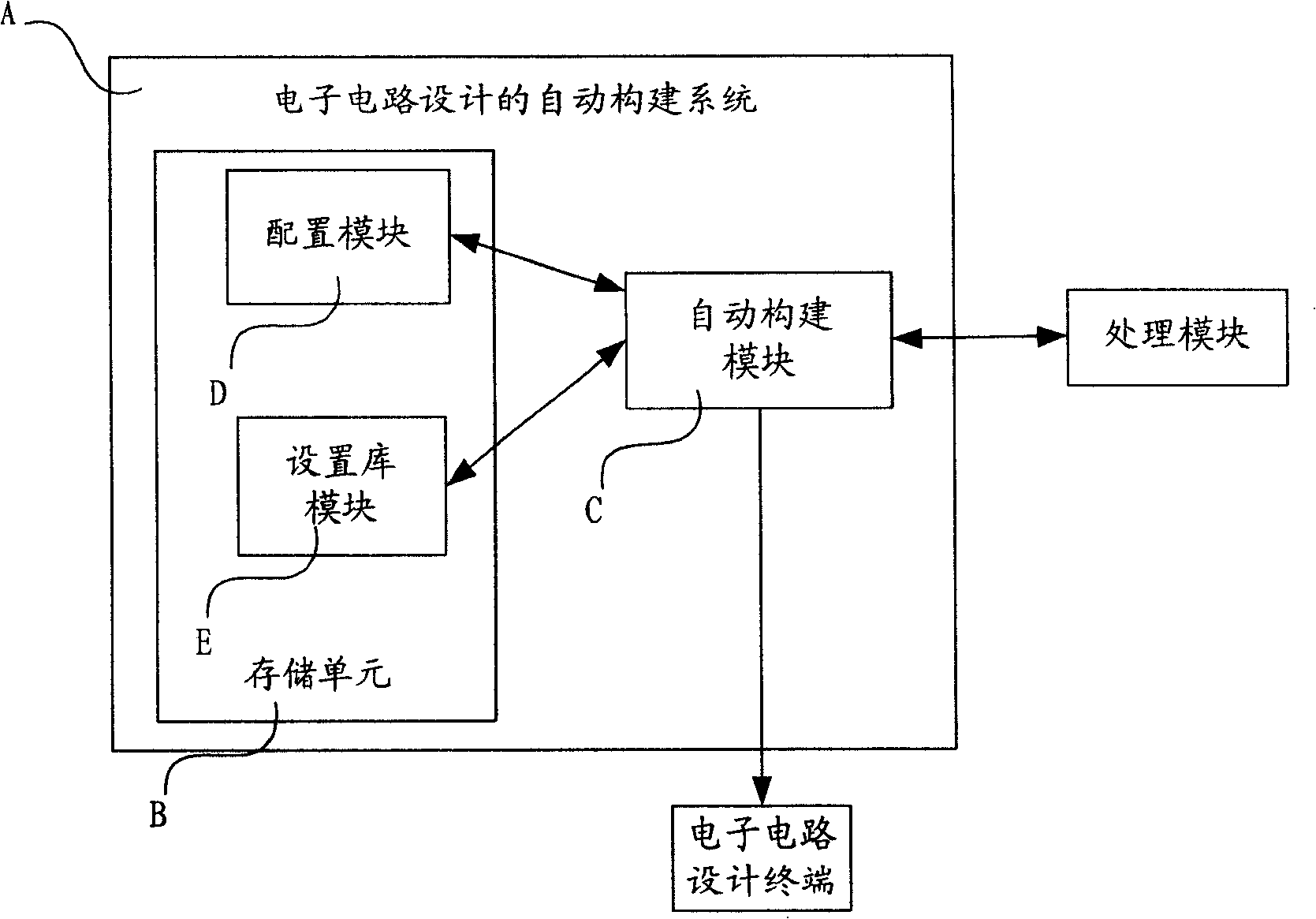

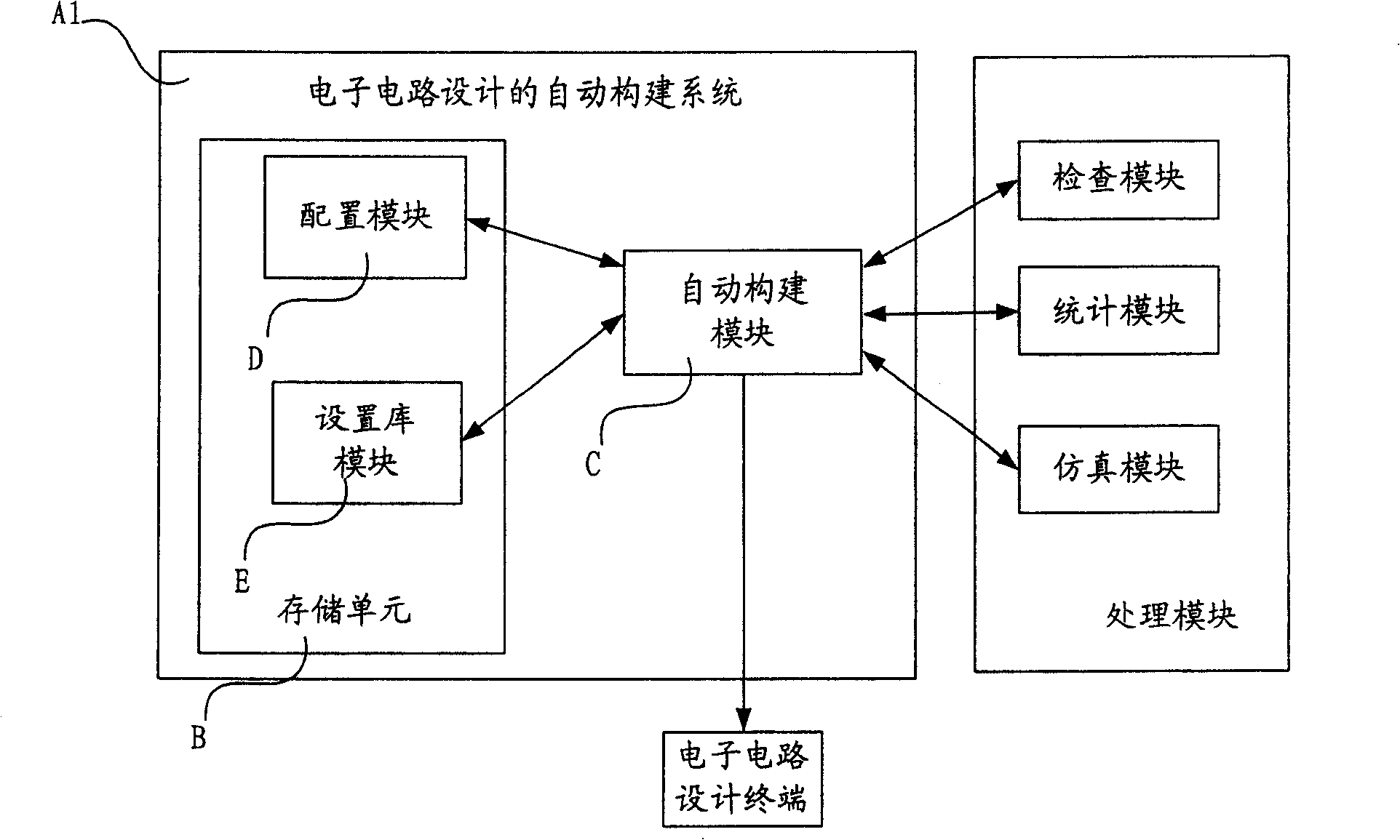

Automatic construction system and method for electronic circuit design

InactiveCN1945586AQuality improvementImprove efficiencySpecial data processing applicationsSystems designElectronic circuit design

The invention discloses an automatic constructing system designed by electronic circuits, including: memory modules and automatic constructing module. It also discloses an automatic method, including: Step 1 during the pre-determined time, according to the pre-determined processing project information, obtaining the documents corresponding to the pre-saved electronic circuit design, Step 2 sending the documents to the corresponding processing module for operation according to the items information of electronic circuits; Step 3 sending the result report returned from the processing module to the corresponding electronic circuit terminal. The invention realizes the automatic processing on electronic circuit design, effectively improving the quality, shortening the development cycle, and reducing manpower costs.

Owner:HUAWEI TECH CO LTD

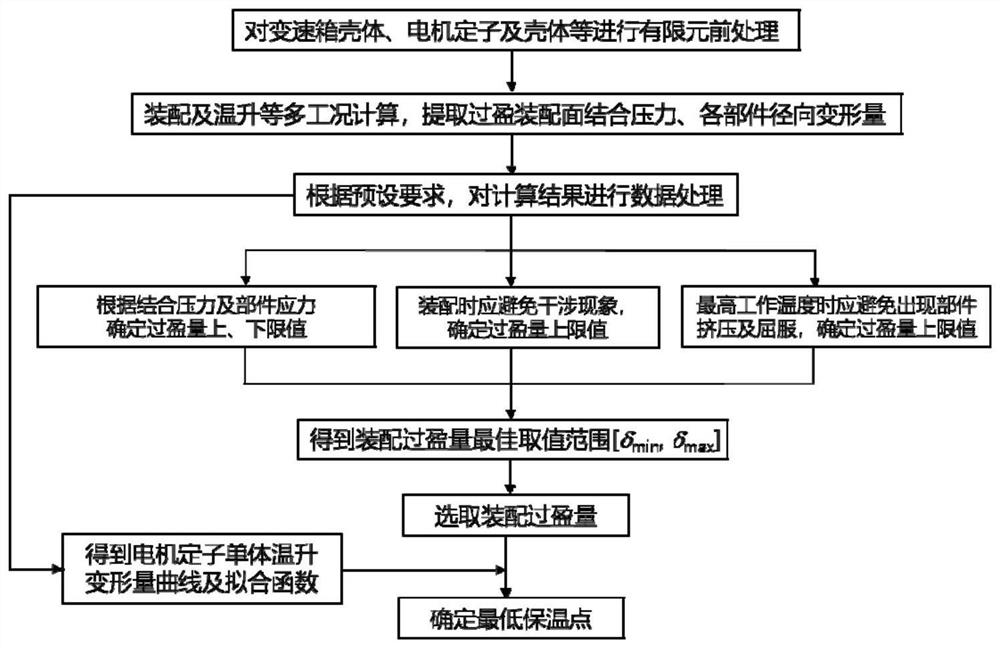

Method for determining assembly interference magnitude and heat preservation point of motor stator

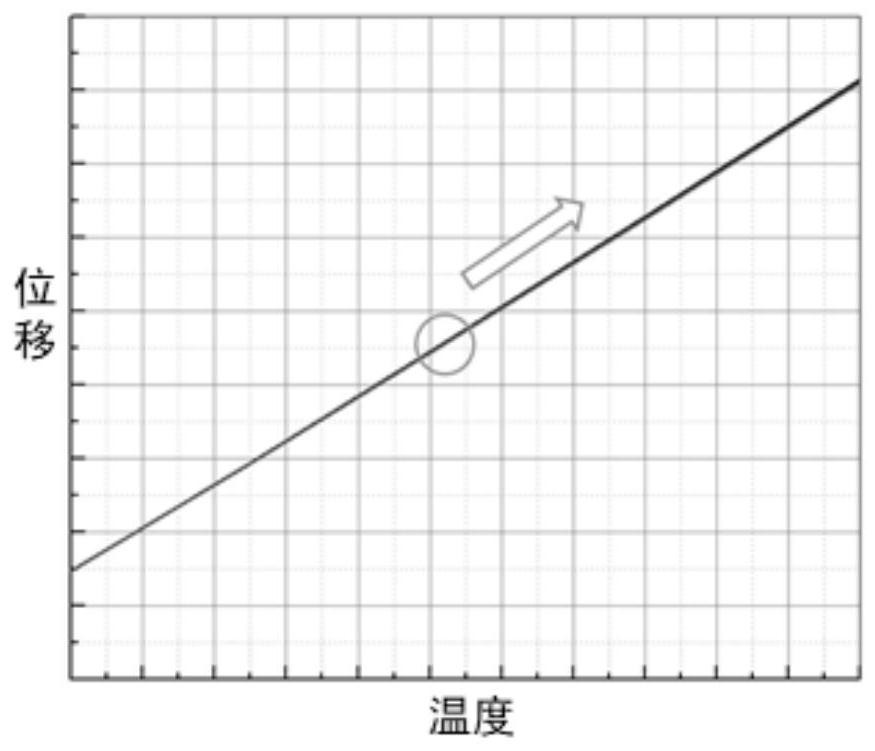

ActiveCN112651077AMeet needsThe value result is clearGeometric CADElectric machinesThermodynamicsElectric machine

The invention discloses a method for determining assembly interference magnitude and heat preservation points of a hybrid motor stator, which comprises the following steps of: firstly, calculating an assembly working condition and a working condition (after temperature rise) to obtain data such as deformation of a motor shell and a gearbox shell, stress dependent variables of all parts, bonding pressure between the motor stator shells and the like; and carrying out evaluation according to judgment standards such as transmission torque, stress strain and maximum deformation to obtain an optimal value range of the motor stator assembly interference, carrying out statistical analysis and data fitting on the motor shell deformation along with the temperature change trend to obtain a heat preservation point change curve and a fitting function, and providing reference for final scheme design. The value result calculated by the method is clearer and more efficient, the product design and development period can be remarkably shortened, the development cost can be saved, and the method can be effectively used for product assembly process design.

Owner:CHERY AUTOMOBILE CO LTD

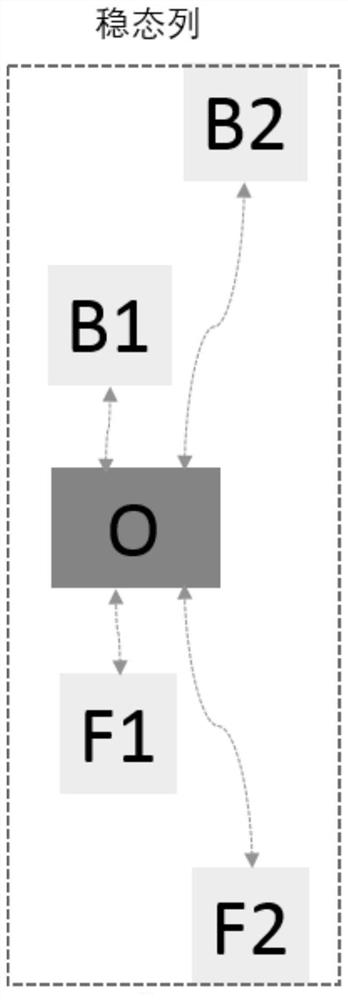

Monostable electronic gear shift device and vehicle having gear shift device

InactiveCN111828609ASimplify shifting operationLow costGearing controlAutomotive engineeringMechanical engineering

The invention is applicable to the technical field of vehicle gear shift devices, and discloses a monostable electronic gear shift device and a vehicle having the gear shift device. The monostable electronic gear shift device comprises a shift lever component, a shell component, a gear block component and a gear signal sensing component; the shift lever component comprises a shift lever rotatablyconnected to the shell component; the gear block component is arranged inside a shell; the gear block component is provided with a steady-state position and a transient position; the gear signal sensing component is respectively connected to the shift lever component and the shell component; the gear block component comprises a silencing guide structure; and the lower end of the shift lever component abuts against the silencing guide structure. The vehicle has the above monostable electronic gear shift device. According to the monostable electronic gear shift device and the vehicle having thegear shift device provided by the invention, by simplifying the structural arrangement of a shifter, the size of parts can be miniaturized, the number of the parts is reduced, the feasibility of quality control is improved, and the user experience is good.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

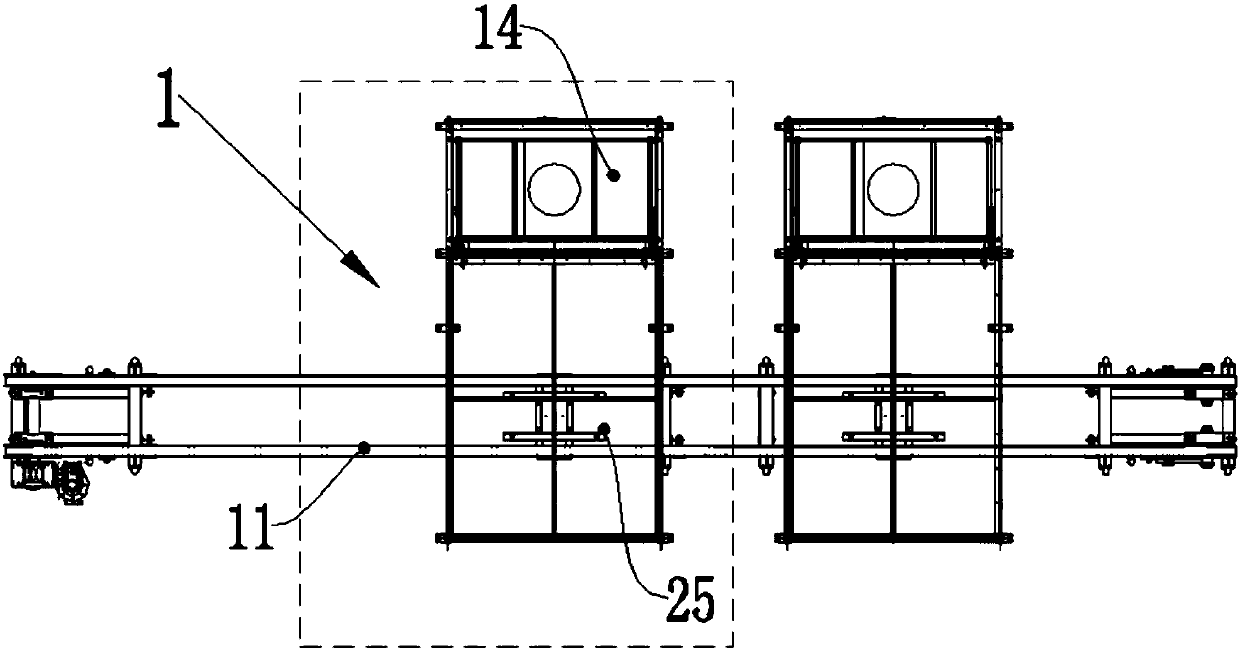

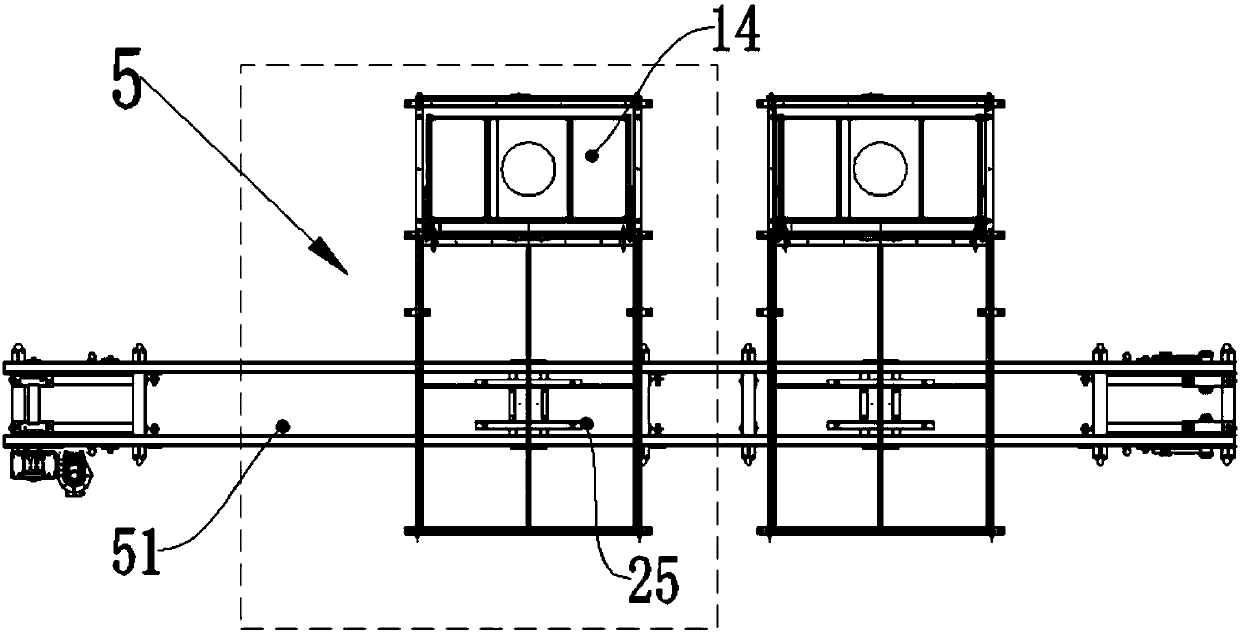

Automobile Suspension Test Bench

ActiveCN103954459BShorten the design and development cycleHigh strengthVehicle suspension/damping testingVehicle frameUltimate tensile strength

The invention discloses an automotive suspension test bed, relates to the technical field of fatigue verification for an automotive suspension and provides the automotive suspension test bed which is simple in structure, high in strength and capable of shortening the development and verification period of the automotive suspension and reducing test expenditures. The automotive suspension test bed comprises a plurality of stand columns, wherein a clamp plate with the height and the angle adjustable is installed on each stand column, and a calibrating mark is further arranged on each stand column and used for calibrating the installation position of the corresponding clamp plate. The automotive suspension test bed further comprises a loading mechanism used for being connected with a loading device, the stand columns are assembled with an automotive frame through the clamp plates in a matched and connected mode, the loading mechanism is connected with a brake disc on the frame, and the direction of the loading device is controlled so that the loading mechanism can perform suspension endurance verification under different working conditions. The automotive suspension test bed is mainly used in tests of fatigue verification for the automotive suspension.

Owner:GREAT WALL MOTOR CO LTD

Crash resistance design method of front side member of passenger car

InactiveCN103425848BRapid designShorten the design and development cycleSpecial data processing applicationsTrial and errorPlastic property

The invention discloses a front longitudinal beam anti-collision performance design method for a passenger vehicle and aims at solving the problems that when the traditional trial-and-error method is used for designing the front longitudinal beam of a car in the prior art, a computer simulation model needs to be repeatedly modified, the testing needs to be repeatedly carried out, and the like. The front longitudinal beam anti-collision performance design method for the passenger vehicle comprises the following steps that 1, the average crushing counter force expression (shown as the accompanying drawing) of a multi-right-angle cross section thin wall beam is deduced, in the expression, Pm is the average crushing counter force, the unit of the Pm is kN, n is the number of the cross section right angles of the multi-right-angle cross section thin wall beam, M0 is the unit length plastic limit bending moment, the unit of M0 is N.mm, l is the cross section circumference of the multi-right-angle cross section thin wall beam, the unit of the l is mm, h is the wall thickness of the multi-right-angle cross section thin wall beam, and the unit of the h is mm; 2, the cross section of the crushing deformation part of the front longitudinal beam is designed; 3, the average bending moment expression (Mm=(0.3-0.5)Mmax) of a rectangular cross section thin wall beam is deduced, in the expression, Mm is the average bending moment of the rectangular cross section thin wall beam, and the unit of the Mm is N.mm; and 4, the cross section of the bending deformation part of the front longitudinal beam is designed.

Owner:JILIN UNIV

Low-speed two-axis linkage type wall type planar protection cover device

InactiveCN109571126AReduce difficultyShorten the timeMaintainance and safety accessoriesFixed frameMachine tool

The invention relates to a low-speed two-axis linkage type wall type planar protection cover device. The low-speed two-axis linkage type wall type planar protection cover device is arranged on a machine tool main body casting and comprises a largest section fixing frame, a sliding layer, scrap scraping strips, a guide strip and a damping pad, the largest section fixing frame is connected and fixedon a machine tool main body casting, the sliding layer is arranged on the inner side of the largest section fixing frame, the scrap scraping strips are arranged on the inner side of the largest section fixing frame and the inner side edge of the sliding layer, the guide strip is arranged inside the sliding layer, and the damping pad is arranged on the edge of the sliding layer. According to the low-speed two-axis linkage type wall type planar protection cover device, the defects that in the case of an existing protection cover, the design period is relatively long, and the mounting requirement is relatively high are overcome, and the low-speed two-axis linkage type wall type planar protection cover device is provided; the protection cover is of an integral linkage structure, the protection effect is better, moreover, installation is facilitated, and equipment maintenance is convenient and fast; the protection function of the operation of a square-shaped region of moving parts such asa main shaft of a machine tool can be realized; and the design and development period of the wall-type protection cover can be effectively shortened.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

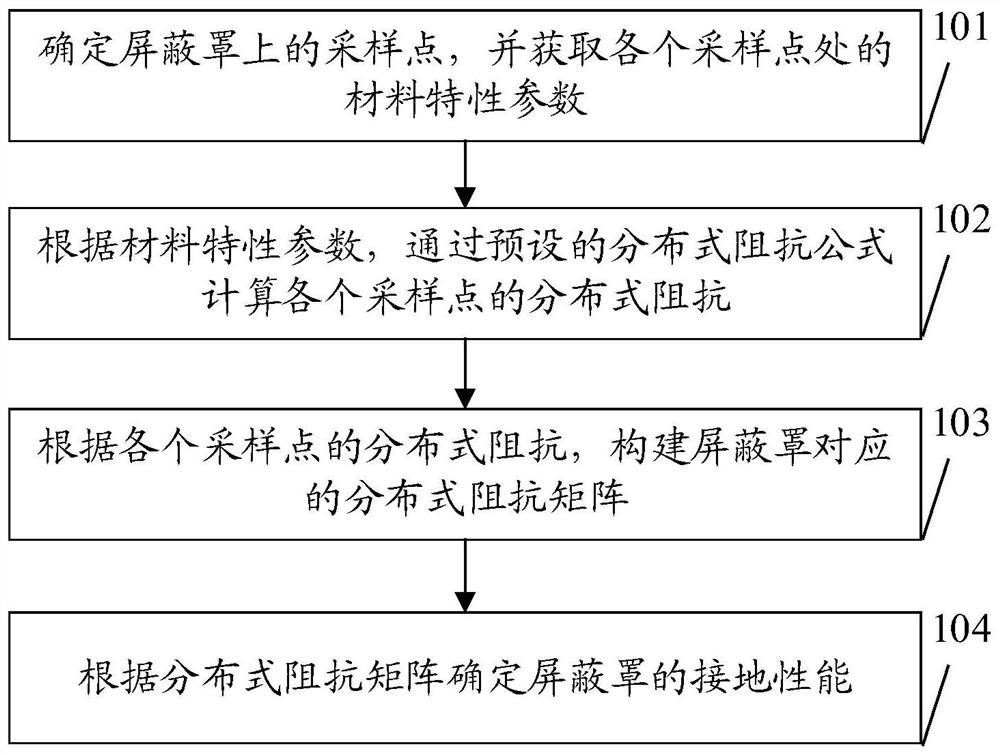

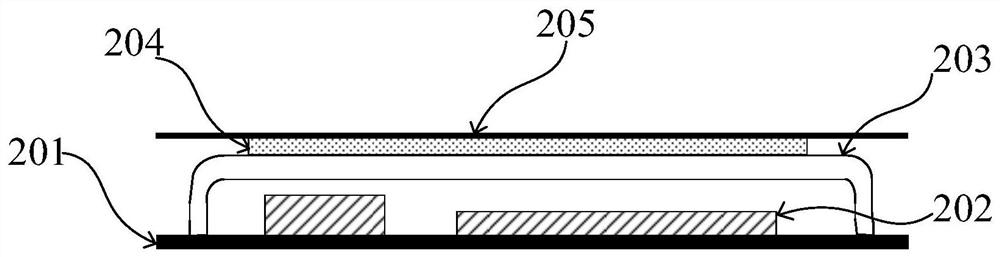

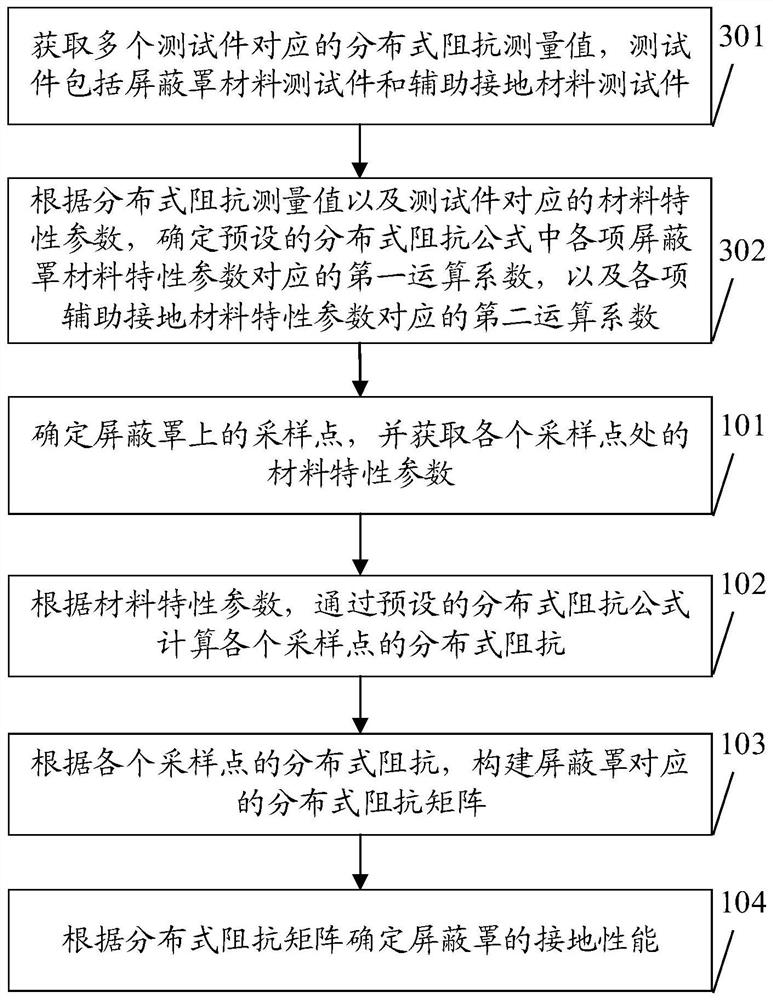

Method and device for determining grounding performance of shielding case, equipment and storage medium

PendingCN112001054AFor improved designShorten the design and development cycleElectrical testingDesign optimisation/simulationProcess engineeringElectrical and Electronics engineering

The embodiment of the invention discloses a method and device for determining the grounding performance of a shielding case, equipment and a storage medium, and belongs to the technical field of terminals. The method comprises the following steps: determining sampling points on the shielding case, and acquiring material characteristic parameters of each sampling point; calculating the distributedimpedance of each sampling point through a preset distributed impedance formula according to the material characteristic parameters; constructing a distributed impedance matrix corresponding to the shielding case according to the distributed impedance of each sampling point; and determining the grounding performance of the shielding case according to the distributed impedance matrix. By adopting the method provided by the embodiment of the invention, the complete evaluation of the grounding conditions of different parts on the shielding case can be realized, the subsequent improved design of the shielding case is facilitated, and the design and research and development period of the shielding case is shortened.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Automatic construction system and method thereof for electronic circuit design

InactiveCN100458800CQuality improvementImprove efficiencySpecial data processing applicationsSystems designElectronic circuit design

The invention discloses an automatic constructing system designed by electronic circuits, including: memory modules and automatic constructing module. It also discloses an automatic method, including: Step 1 during the pre-determined time, according to the pre-determined processing project information, obtaining the documents corresponding to the pre-saved electronic circuit design, Step 2 sending the documents to the corresponding processing module for operation according to the items information of electronic circuits; Step 3 sending the result report returned from the processing module to the corresponding electronic circuit terminal. The invention realizes the automatic processing on electronic circuit design, effectively improving the quality, shortening the development cycle, and reducing manpower costs.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com