Boron carbide-based multiphase ceramic and preparation method and device thereof

A composite ceramic and boron carbide-based technology, which is applied in the field of ceramic materials, can solve problems such as singleness, and achieve the effect of good hardness and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

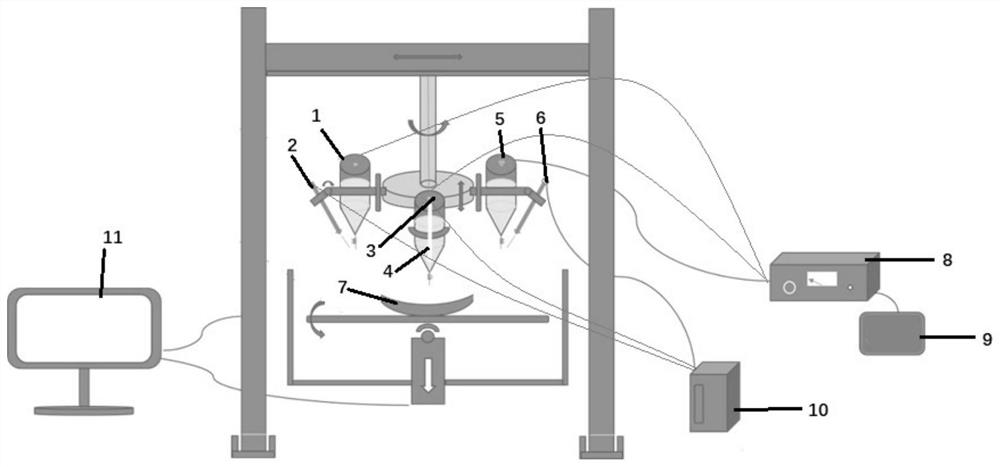

[0074] This embodiment provides a 3D printing device, such as figure 1 shown, including:

[0075] Extrusion unit, the extrusion unit includes a first slurry barrel 1, a second slurry barrel 3 and a third slurry barrel 5; the first slurry barrel 1, the second slurry barrel 3 and the The third slurry barrel 5 is respectively used for extruding reinforced and hardened slurry, medium-hard and medium-tough buffer slurry and reinforced and toughened slurry;

[0076] A curing unit, the curing unit includes an ultraviolet light source generator 10, a first light emitting device 2, a second light emitting device 4 and a third light emitting device 6; the ultraviolet light source generator 10 is connected to the first light emitting device 2, the The second light emitting device 4 and the third light emitting device 6 are connected and arranged; the first light emitting device 2, the second light emitting device 4 and the third light emitting device 6 are respectively used for curing t...

Embodiment 2

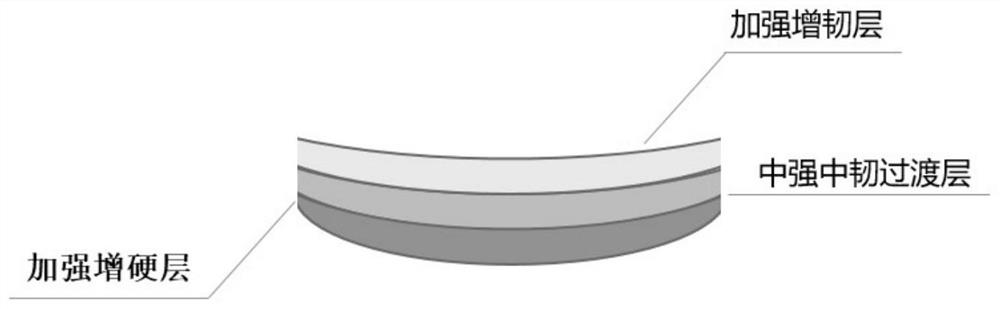

[0084] This embodiment provides a boron carbide-based composite phase ceramic (thickness is 5.5mm), such as figure 2 As shown, it includes a strengthening and hardening layer, a medium-hard and medium-tough buffer layer and a strengthening and toughening layer that are stacked in sequence;

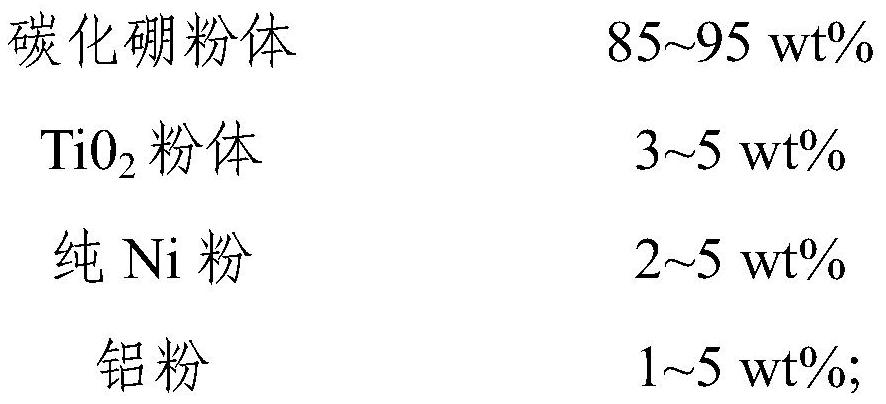

[0085] Wherein, the reinforced and hardened layer includes reinforced and hardened powder, based on the total mass of the reinforced and hardened powder, the reinforced and hardened powder includes the following components in mass percentage:

[0086]

[0087] The medium-hard and medium-tough cushioning layer includes medium-hard and medium-tough cushioning powder, based on the total mass of the medium-hard and medium-tough cushioning powder, the medium-hard and medium-tough cushioning powder includes the following components in mass percentage :

[0088] Boron carbide powder (D50≤0.5μm) 90wt%

[0089] SiC(D50≤0.5μm) 5wt%

[0090] al 2 o 3 Powder (D50≤1μm) 5wt%;

[0091] The stre...

Embodiment 3

[0117] This embodiment provides a boron carbide-based composite phase ceramic (thickness is 9.5mm), such as figure 2 As shown, it includes a strengthening and hardening layer, a medium-hard and medium-tough buffer layer and a strengthening and toughening layer that are stacked in sequence;

[0118] Wherein, the reinforced and hardened layer includes reinforced and hardened powder, based on the total mass of the reinforced and hardened powder, the reinforced and hardened powder includes the following components in mass percentage:

[0119]

[0120] The medium-hard and medium-tough cushioning layer includes medium-hard and medium-tough cushioning powder, based on the total mass of the medium-hard and medium-tough cushioning powder, the medium-hard and medium-tough cushioning powder includes the following components in mass percentage :

[0121] Boron carbide powder (D50≤0.5μm) 87wt%

[0122] SiC (D50≤0.5μm) 10wt%

[0123] Al 2 o 3 Powder (D50≤1μm) 3wt%;

[0124] The st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com