Anticorrosion demoulding powder combination and preparation method thereof

The technology of a composition and mold release powder is applied in the field of anti-corrosion mold release powder composition and its preparation, and in the field of anti-corrosion mold release treatment on the surface of rubber and plastic preparation molding mold, which can solve the problem of low contact angle, high curing temperature of pure fluororesin, Complex construction process and other problems, to achieve the effects of both wear resistance and hardness, good continuous mold release, and simple coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

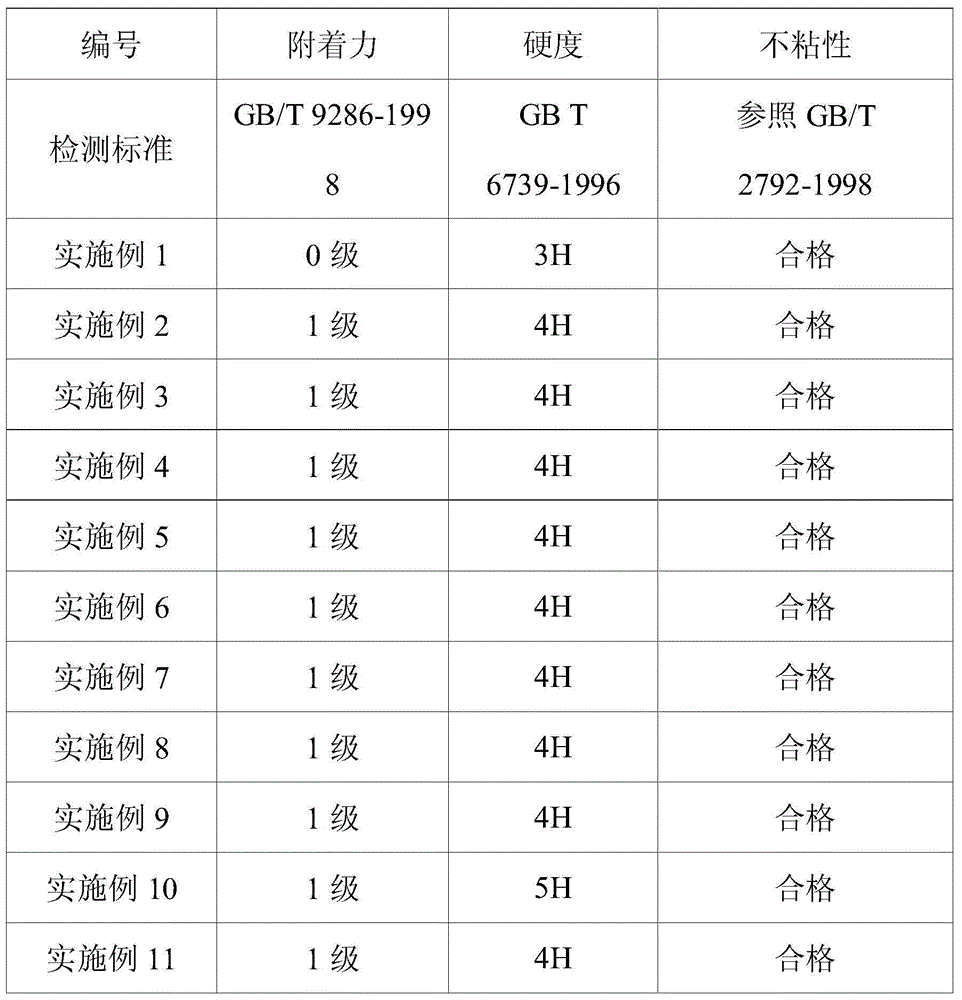

Embodiment 1

[0041] 50 parts of FEVE fluororesin JF-1, 35 parts of PTFE micropowder, 10 parts of nano silicon dioxide, 1.0 parts of leveling agent BYK-368P (German BYK), 0.7 parts of defoamer BYK961 (German BYK), 15 parts of curing agent blocked isocyanate VESTANAT B1358A are pre-mixed, then melted and extruded by a screw extruder, and finally pulverized and ground to prepare the anti-corrosion release powder composition of the present invention.

Embodiment 2

[0043] 40 parts of FEVE fluororesin JF-1, 30 parts of PTFE micropowder, 8 parts of nano silicon dioxide, 0.8 parts of leveling agent BYK-368P (Germany BYK), 0.5 parts of defoamer BYK961 (Germany BYK), 10 parts of curing agent blocked isocyanate 7992 are pre-mixed, then melted and extruded by a screw extruder, and finally pulverized and ground to make the anti-corrosion release powder composition of the present invention.

Embodiment 3

[0045] 40 parts of FEVE fluororesin JF-2, 25 parts of PTFE micropowder, 8 parts of nano-silica, 0.6 parts of leveling agent BYK-368P (Bick, Germany), 1.0 parts of defoamer BYK961 (Bick, Germany), 10 parts of curing agent blocked isocyanate 7992 are pre-mixed, then melted and extruded by a screw extruder, and finally pulverized and ground to make the anti-corrosion release powder composition of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com