Patents

Literature

458 results about "Carnuba wax" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating combination for pure natural woodenware

The invention relates to a coating combination for pure natural woodenware, which is characterized in that the coating combination is made of natural animal and plant products which are non-toxic, natural and environment-friendly, and capable of sinking into the surface layer of wood and avoiding coating film formation on the surface of the wood when in use, thus enabling the wood to breathe naturally, maintaining the elasticity of the natural wood and preventing the coating combination from cracking, tilting and dropping. The coating combination comprises the following components by weight percent: 30wt% to 70wt% of solvent; 70wt% to 30wt% of natural plant oil derivative; 1wt% to 10wt% of natural wax; 0wt% to 10wt% of pigment; 0wt% to 3wt% of dye and 0wt% to 3wt% of additives, wherein the natural plant oil derivative is particularly one of linseed oil, castor oil, tung oil and soya-bean oil or the product chemically processed from the mixture thereof; and the natural wax is particularly one of carnauba wax, candelilla wax, insect-white wax (Chinese wax) and natural bee wax or the mixture thereof.

Owner:深圳嘉汉林业科技有限公司

Composition of matter comprising particles which contain choline chloride to be administered in a rumen protected and post-ruminally effective form

ActiveUS20050019413A1Reduce degradationIncreasing post-rumen efficiencyBiocidePowder deliveryCarnuba waxRumen

A composition of matter comprising particles which contain choline chloride to be administered in a rumen-protected and post-ruminally effective form, each particle comprising a core which contains choline chloride and a protective coating surrounding the core and protecting choline chloride by ruminal activity while allowing its release into the post-rumen portion of the digestive tract of a ruminant. The core mainly consists of choline chloride in the form of a dry, crystalline powder and, in combination, the protective coating surrounding the core comprises an outer, continuous layer mainly consisting of carnauba wax and an inner, continuous layer consisting of an hydrophobic substance. A feed pellet containing the composition of matter and a premix for feed which contains the composition of matter. A premix for feed which contains feed pellets containing the composition of matter. Mash feed in unpelletted form containing the composition of matter.

Owner:BIOSCREEN TECH SRL

Compositions and methods for suppressing cracking and water loss from cherries

InactiveUS7222455B2Reduce crackingAvoid damageDead plant preservationPre-baking dough/flour preservationEmulsionCarnuba wax

In one aspect, the present invention provides methods for suppressing cracking, stem browning, and water loss in fruit or vegetables, such as cherries. The methods comprise applying to fruit or vegetables an amount of a wax emulsion effective to suppress cherry cracking, stem browning, and water loss. The wax emulsion used in the methods of the invention typically comprises a matrix of complex hydrocarbons, one or more emulsifying agents, and water. In some embodiments, the wax emulsion comprises from about 0.125% to about 25% (weight / weight) of carnauba wax, from about 0.1% to about 16% (weight / weight) of oleic acid, and from about 0.03% to about 6% (weight / weight) of morpholine, and from about 53% to about 99.7% (weight / weight) of water. In some embodiments, the wax emulsions further comprise one or more osmoregulators.

Owner:WASHINGTON STATE UNIVERSITY

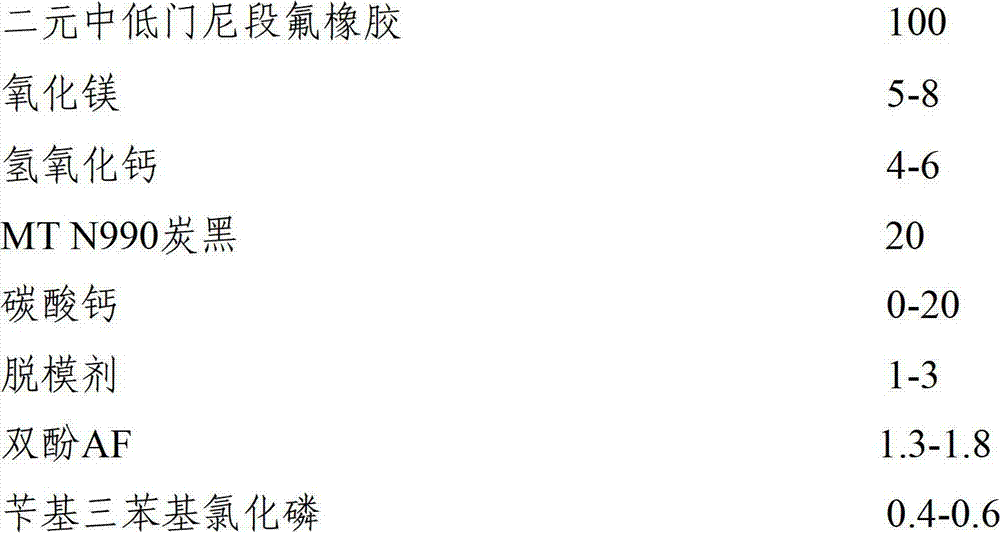

Fluororubber rubber compound and preparation method thereof

The invention provides a fluororubber rubber compound and a preparation method thereof. The fluororubber rubber compound is prepared by mixing binary intermediate-low monney sectional fluororubber rubber, reinforcing system (MT N990 carbon black and inorganic filler), acid absorbing system (active magnesium oxide and superfine calcium hydroxide), vulcanizing system (benzyl triphenyl phosphorus chloride and bisphenol AF), releasing agent (alfux and / or carnauba wax), and multifunctional bisphenol vulcanizing composite assistant vulcanizing agent L; the obtained fluororubber rubber compound has high stretching strength, and high extending rate, increases the scorching time by improving the liquidity of the rubber, therefore, high adaptability of the rubber to different manufacture technical environments and the vulcanizing environments can be ensured, the safety in vulcanizing can be improved, and as a result, the rejection rate of the products can be reduced. The fluororubber rubber compound provided by the invention is applicable to industries such as aerospace, aviation, car, metallurgy, petrochemical industry and electron and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

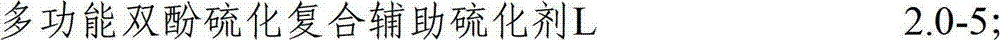

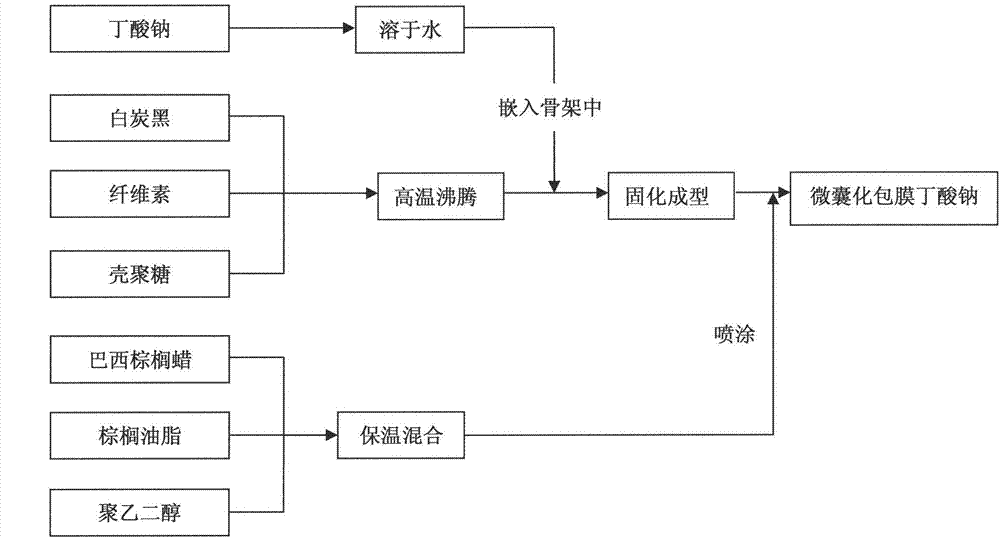

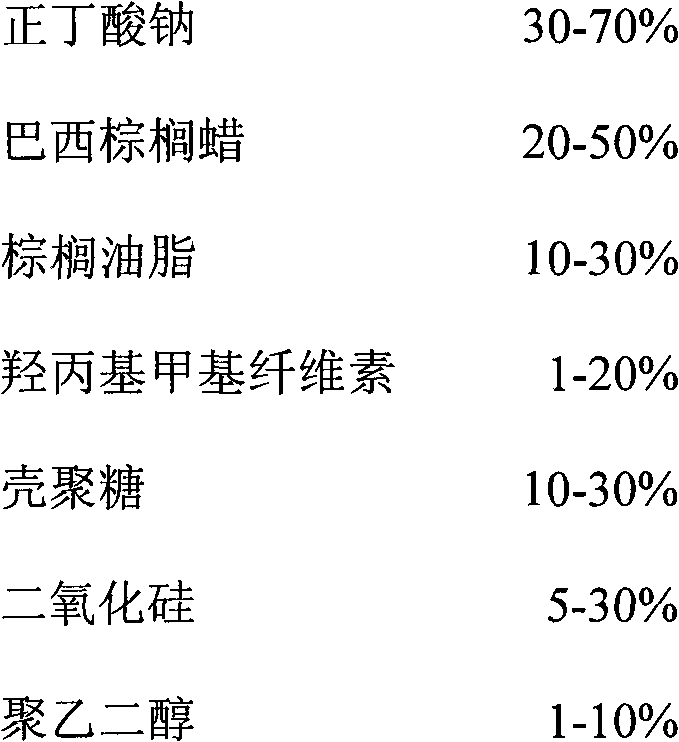

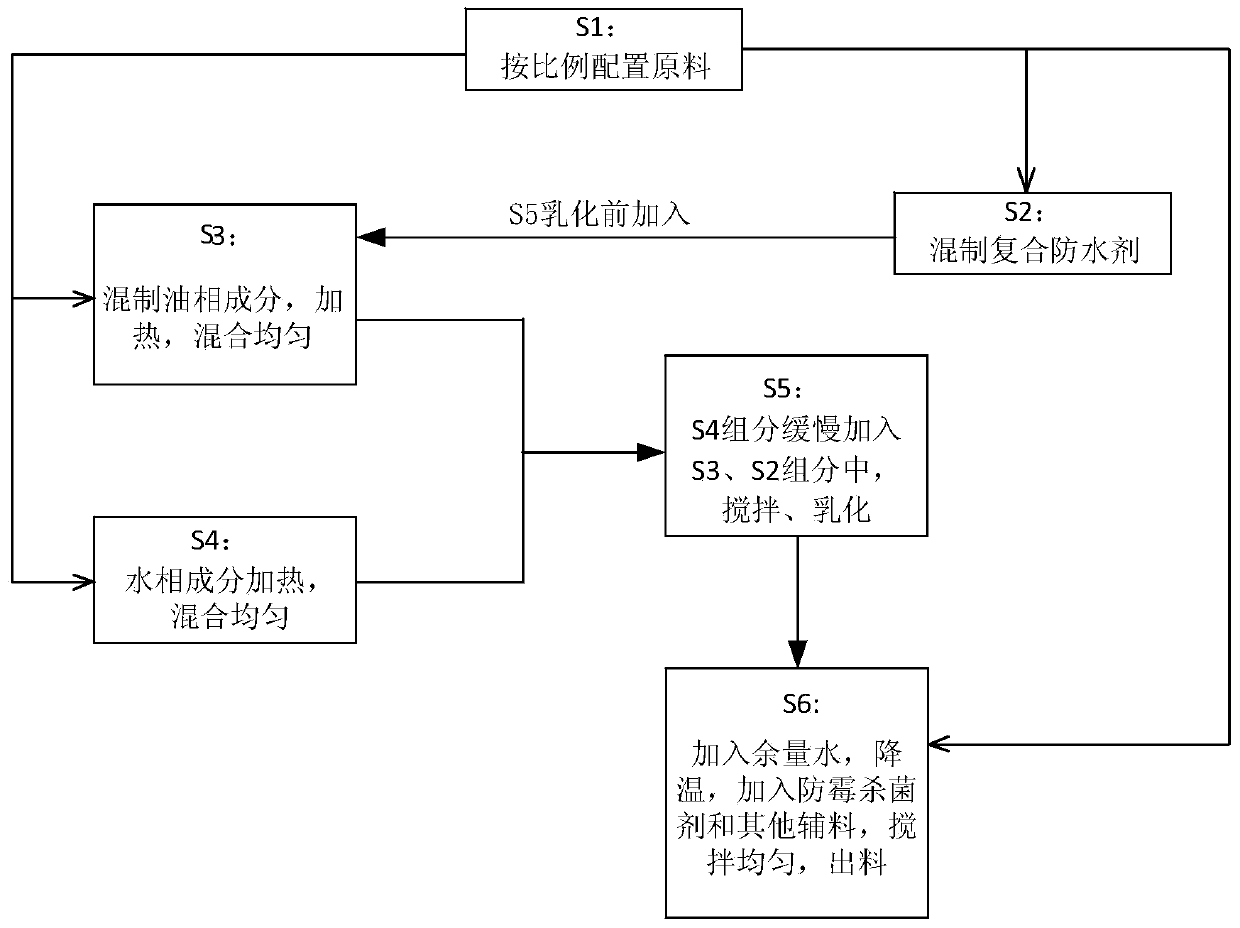

Preparation method of microencapsulation diolame sodium butyrate

ActiveCN103238730ACover up the smellPrevent deliquescenceAnimal feeding stuffLow temperature curingPolyethylene glycol

The invention relates to a preparation method of an animal feed additive microencapsulation diolame sodium butyrate. The method comprises the following steps of: mixing hydroxypropyl methyl cellulose, chitosan and silica, boiling at high temperature of 230DEG C in a fluidized bed; spraying sodium butyrate aqueous solution on a mixture of three materials; drying at a high temperature, solidifying at a low temperature, solidifying and molding sodium butyrate particles; dissolving a coated material Brazil palm wax, palm oil and polyethylene glycol into an organic solvent, carrying out bottom-spraying and coating in a fluidized bed to obtain the evenly-coated sodium butyrate particles of which the mass percent of the sodium butyrate is 30-70%. The microencapsulation process is carried out on feed grade sodium butyrate power to avoid the loss of sodium butyrate in poultry crop and pig stomach, so as to reach the rear section of small intestine and cover the whole intestinal tract, meanwhile, overcomes foul smell, prevents air slaking, and protects sodium butyrate from losing in the process of feed processing.

Owner:HANGZHOU KINGTECHINA FEED CO LTD

Agent for cleaning, lustering and protecting surface easy to eliminate and method for producing the same

ActiveCN101220245AWill not burn and explodeNo smellPolishing compositionsParaffin waxSurface cleaning

The invention relates to an easy-erased glazing and protective agent and a preparation method. The invention takes silicon oil, insect wax, paraffine, carnauba wax, stearic acid, trolamine, alkyl phenol polyoxyethylene ether (4), 1.2-benzisothiazdin-3- ketone, essence and de-ionized water as raw materials. In production process, the insect wax, paraffine, carnauba wax and the stearic acid are added to knives barrier emulsified kettle and are heated until reaching from 85 to 88 DEG C; after being hot melted, the raw materials are stirred and then are added with triethanolamine, silicon oil, alkyl phenol polyoxyethylene ether (4) and essence sequentially and stirred evenly. In the process of continuous stirring, the de-ionized water which has a temperature of 85 to 90 DEG C and accounts for from one fifth to two-fifths of the total amount of water is dropped into the emulsified kettle slowly in 30 to 40 minutes, and normal-temperature water is added after phase inversion process of materiels is finished; another 10 minutes is needed for shearing and stirring until all the water are added into the emulsified kettle; the 1.2-benzisothiazdin-3- ketone is added and stirred evenly. At last a nylon screen with 200 meshes is used for filtering, thereby obtaining the easy-erased glazing and protective agent.

Owner:北京绿伞科技股份有限公司

Emulsification type car cleaning polish and preparation method of emulsification type car cleaning polish

InactiveCN102703232AEasy to cleanNo harmInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsParaffin waxAluminium silicate

The invention discloses an emulsification type car cleaning polish and a preparation method of the emulsification type car cleaning polish and belonging to the field of fine chemicals. The emulsification type car cleaning polish is characterized in that the emulsion is prepared by using paraffin wax, carnauba wax and methylsilicone oil as the polish, mineral oil as a penetrating agent, fatty alcohol-polyoxyethylene (7) ether and fatty alcohol-polyoxyethylene (10) ether as an emulsifier, coconutt diethanol amide and coconut fatty alkanolamide as a washing detergent and a synergist, aluminium silicate as a grinding material and water as the medium and adding essences. The emulsification type car cleaning polish disclosed by the invention is an emulsification type car cleaning polish with integration of cleaning, polishing, anti-static, dustproof and waterproof and the like functions; the cleaning capacity to oil strains is very strong and the brightness can be maintained for a long timeafter use; and the emulsification type car cleaning polish is an energy-saving and environmental-friendly product and has no harm to human bodies and no pollution to the environment.

Owner:邹庆

Automobile micro-water cleaning and maintenance agent

InactiveCN102660196ARealize dirt removalRealize the protective paint surfaceNon-ionic surface-active compoundsDetergent compounding agentsUltravioletCarnuba wax

The invention relates to an automobile micro-water cleaning and maintenance agent which can be used as an automobile cleaning and beauty product, and belongs to the automobile cleaning agent technology field. The agent is characterized in that the agent is composed of the following compositions of, by weight, 45%-65% of a carnauba wax, 3%-7% of a penetrating agent JFC-20, 5%-10% of an antifreezing agent, 0.05%-1% of a silicone oil, 2%-4% of a redispersable emulsifier OP-10, 13%-17% of a conditioning agent AET-1, 13%-17% of a conditioning agent AET-2, 13%-17% of a sun-screening agent 1%-5%, 1%-3% of a quality agent, 5%-10% of deionized water, and 0.01%-0.03% of an essence. The agent is prepared by weighing raw materials according to the weight percentage, heating and melting the carnauba wax and to put in a mixer, and putting in a homogenizer for a secondary emulsification after full melting, thus obtaining the product. The agent solves the problems that the traditional automobile washing method has single-function and is difficult to use in low temperature. The agent realizes multiple effects, at one time, of removing dirt, protecting paint surface, brightening, low temperature resistance, ultraviolet resistance, corrosion protection, etc. The agent has no site requirements, is able to serve door to door, and has lower automobile cleaning cost for customers.

Owner:周丽 +1

Treatment for surface treatment and cleaning which contains eucalyptus oil, and wooden building material impregnated with said treatment

InactiveUS6358623B1Add function typesPowerful cleaningBiocideOrganic detergent compounding agentsEucalyptus oilEucalyptus gomphocephala

Cineole C10H18O is used for as treatment agent for surface-treating wooden building materials. Eucalyptus oil mainly containing cineole may be utilized for the solution as a substitute. Japan wax, beeswax, carnauba wax or nonionic surface active agent is available as the additives of the agent. Since cineole has various pharmaceutical effects, wooden building materials impregnated therewith may exhibit preservability and protecting effects from molding and infesting with insects without spoiling natural appearance of wood, besides may contribute to present floorboards being sanitary and hygienic especially in humid climates.

Owner:NIPPON TEKUMA

Adhesive for powder injection forming and application method thereof

ActiveCN104559840AThe degreasing process is simple and easy to controlHigh degreasing efficiencyNon-macromolecular adhesive additivesWax adhesivesParaffin waxPolymer science

The invention discloses an adhesive for powder injection forming and a preparation method thereof. The adhesive comprises the following components in percentage by mass: 5-10% of liquid paraffin, 5-15% of naphthalene, 15-20% of solid paraffin, 10-20% of microcrystalline wax, 15-20% of carnauba wax, 15-30% of first high-molecular polymer, 10-20% of second high-molecular polymer and 1-5% of stearic acid. The first high-molecular polymer and second high-molecular polymer are selected from any two of polyethylene, polypropylene, polyacrylate and acrylonitrile-butadiene-styrene copolymer. The method comprises the following steps: after feeding materials of the adhesive, injecting a green compact, putting in a sintering furnace, and carrying out hot removal on the green compact in the furnace by heating to 600 DEG C at the rate of 2-5 DEG C / minute, thereby completely removing the adhesive; and heating for sintering according to the sintering technique, thereby obtaining the finished product. The adhesive has the advantages of simple and controllable degreasing process and high degreasing efficiency; and the degreasing process can not influence the quality of the green compact, and is clean and environment-friendly.

Owner:DONGGUAN HUAJING POWDER METALLURGY

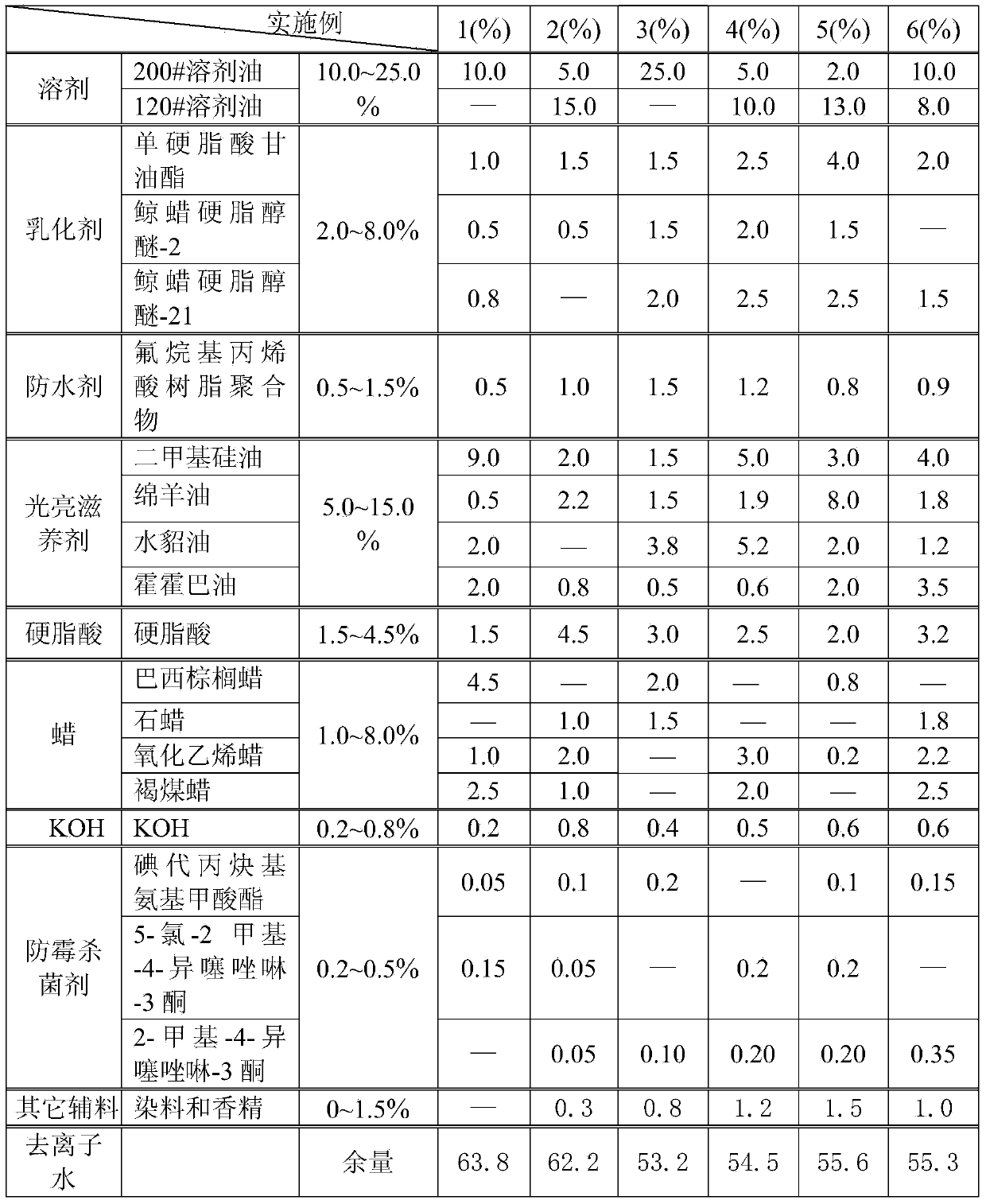

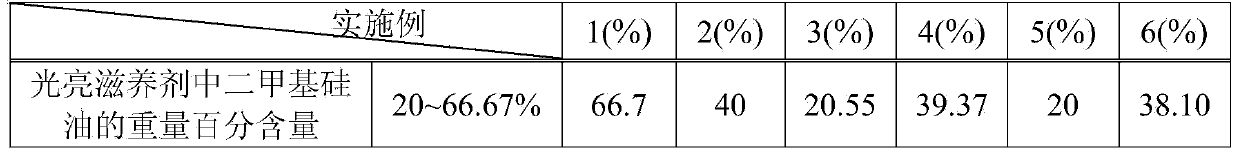

Leather water-proof curing agent and preparing method thereof

ActiveCN103695578AReduce surface tensionImprove waterproof performancePolishing compositionsLeather surface finishingPotassium hydroxideKetone

The invention discloses a leather water-proof curing agent and a preparing method thereof. The water-proof curing agent comprises a solvent, emulsifiers, a water repellent, a brightness nourishing agent, stearic acid, wax, KOH (potassium hydroxide), a mould-proof bactericide, other auxiliary materials and deionized water, wherein the solvent is one or two of solvent oil 120# and solvent oil 200#; two or three of glycerin monostearate, ceteareth-2 and ceteareth-21 are used as the emulsifiers; one or several of the carnauba wax, lignite wax, ethylene oxide wax and paraffin are used as the wax; one or several of iodopropynyl butylcarbamate, 5-chloro-dimethyl-4- isothiazolin-3-ketone and dimethyl-4-isothiazolin-3-ketone are used as the mould-proof bactericide. A unique preparing technology is matched. The water-proof curing agent has efficient and lasting water-proof effect and can well resist oil stains and dust, and the comprehensive curing performance and the water-proof performance are obviously improved.

Owner:QINGHAO ENVIRONMENTAL PROTECTION SCI & TECH SHANGHAI

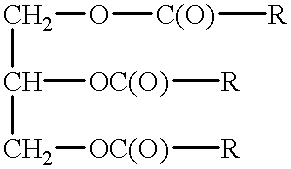

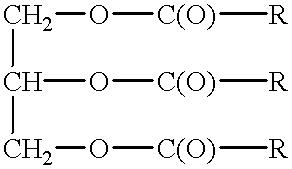

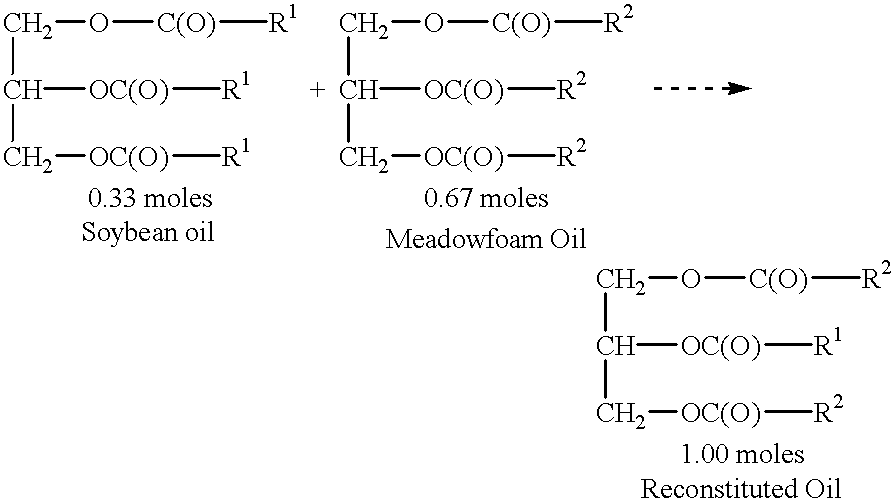

Reconstituted meadowfoam oil in personal care applications

The present invention to provide a process for conditioning hair and skin which comprise contacting the skin or hair with an effective conditioning concentration of a of the reaction product of meadowfoam oil and an ester selected from the group consisting of beeswax, jojoba oil, carnauba wax, and candelilla wax.

Owner:WELLS FARGO BUSINESS CREDIT +1

Lipstick with sun-screening and anti-free radical effects

The invention discloses a lipstick with sun-screening and anti-free radical effects. The lipstick comprises natural beeswax, carnauba wax, coconut oil, jojoba oil, olive oil, shea butter, nanometer-sized titanium dioxide, a polymethylsilsesquioxane coated organic sun-screening agent ethylhexyl methoxycinnamate and additives. According to the invention, nanometer-sized titanium dioxide used as a physical sun-screening agent and the polymethylsilsesquioxane coated organic sun-screening agent are employed, effects of antioxidation and removal of free radicals of vitamin E are cooperatively used, so the lipstick provided by the invention causes no allergy or discomfort to a human body after usage. Long-term usage of the lipstick enables skin aging to be delayed and the skin of a lip to be improved and endows people with healthy, soft, moist and full double lips.

Owner:GUANGZHOU HUANYA COSMETIC SCI & TECH CO LTD

Pregabalin controlled release preparation, and preparation method thereof

InactiveCN103585098AExtended stayProlong the action timeOrganic active ingredientsNervous disorderSodium bicarbonateCellulose

The invention relates to a pregabalin controlled release preparation, and a preparation method thereof. The pregabalin controlled release preparation comprises following ingredients, by weight, 30 to 75% of pregabalin, 5 to 40% of a filling material, 5 to 30% of a sustained-release material, 1 to 10% of an adhesive, and the balance an auxiliary material. The auxiliary material is one or more selected from magnesium stearate, talc, superfine silica powder, cetanol, octadecanol, liquid paraffin, stearic acid, sodium bicarbonate, magnesium carbonate and calcium carbonate; the sustained-release material is one or a mixture of more selected from ethyl cellulose, carbomer, polycarbophil, alginate, hydroxypropyl methyl cellulose, polyacrylic resin, and carnauba wax. The pregabalin controlled release preparation is capable of prolonging residence time of medicine in stomach, releasing long-lasting release and absorption of medicine, and further increasing bioavailability of medicine.

Owner:HANGZHOU SHARPLY PHARM R&D INSTIT +2

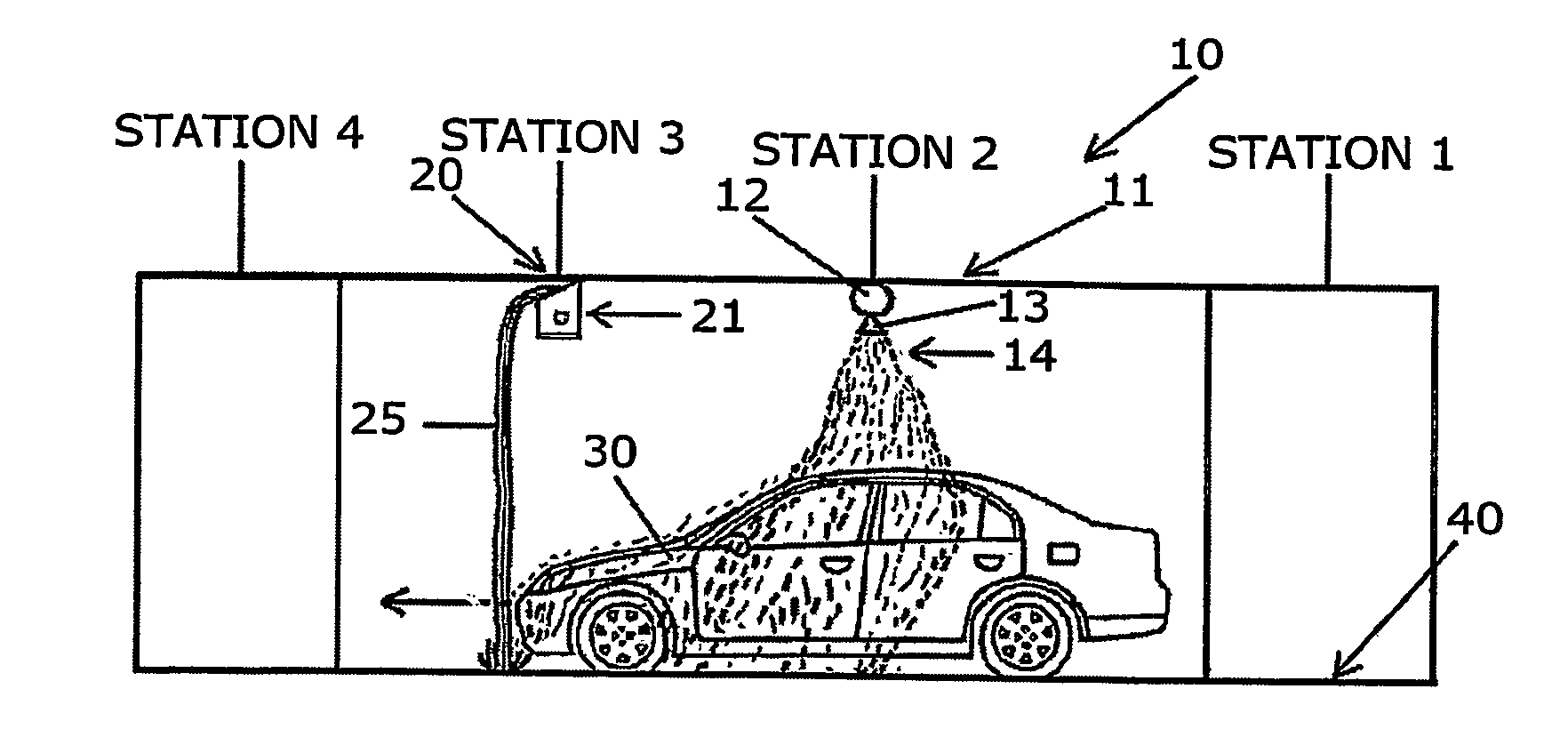

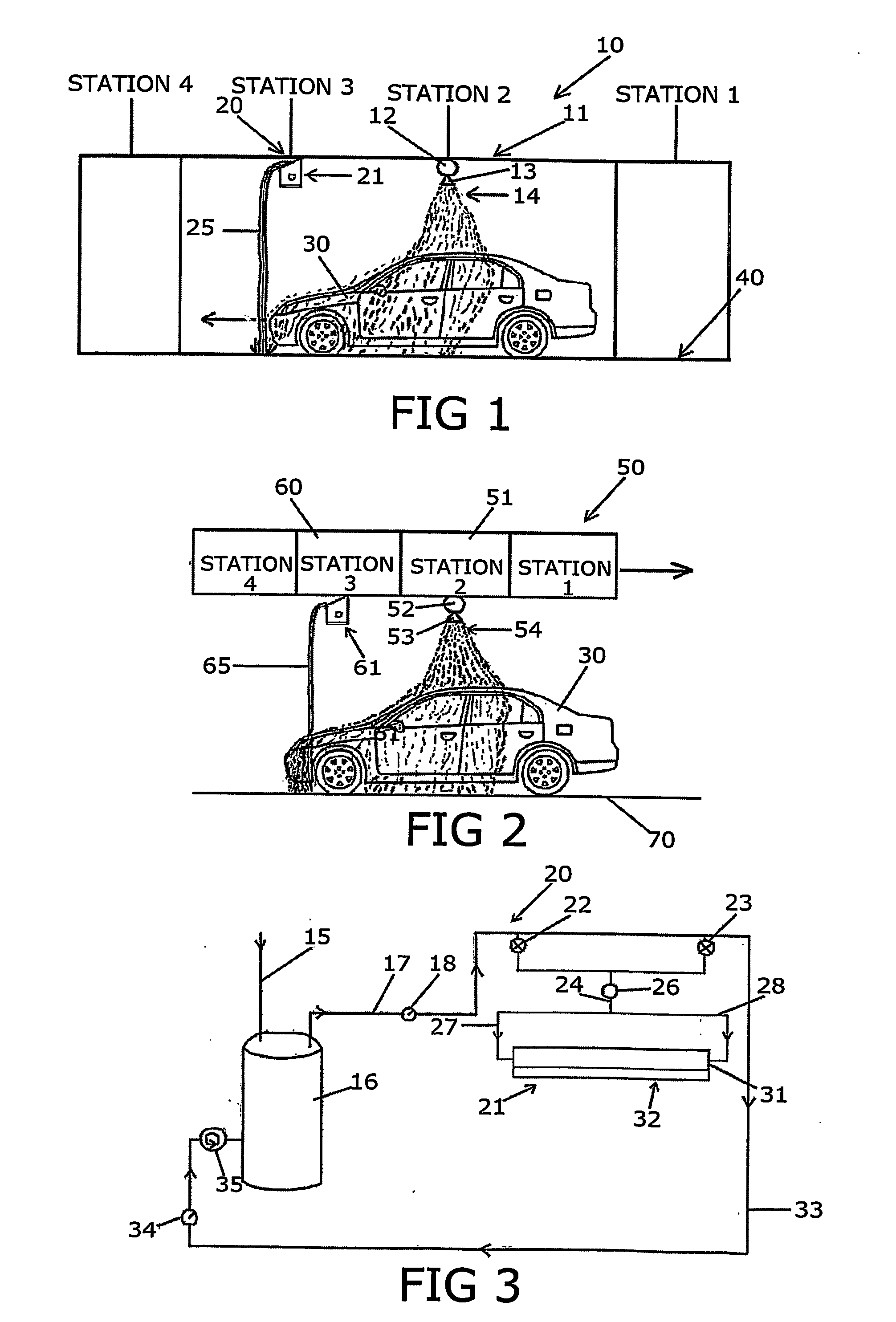

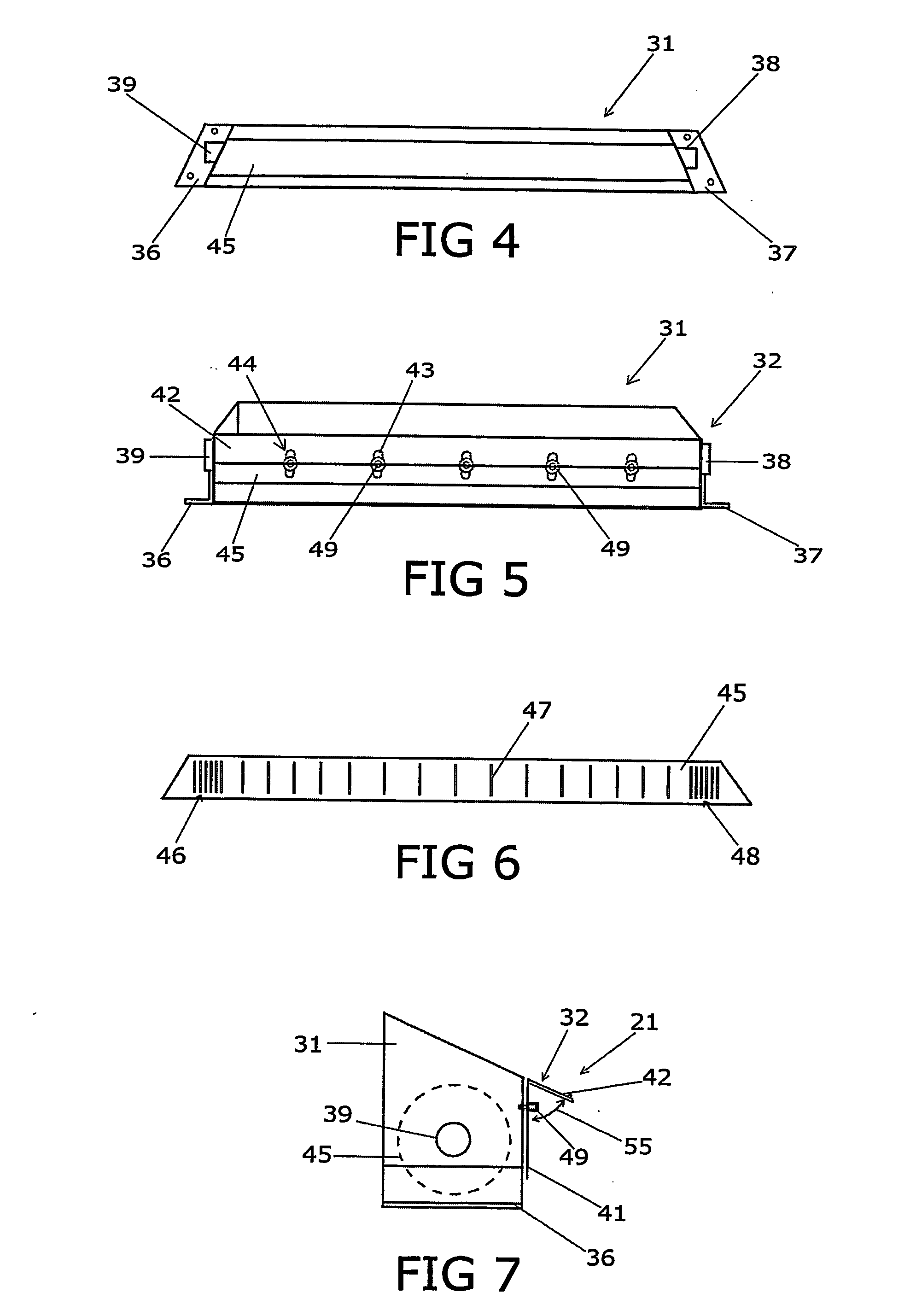

Automatic vehicle wash and wax system

A vehicle wash and wax system (10) comprising a liquid coating dispensing station (11) and a waterfall dispensing station (20) to dump a continuous sheet of fluid (25) onto the liquid coating on the surface of the vehicle (30). The waterfall dispensing station (20) has a tank structure (21) with a weir member (32) to form the continuous liquid sheet dump (25). Chemical agents, such as optical brighteners, dyes and a carnauba wax emulsion may be introduced in the waterfall dispensing station (20) for the continuous liquid sheet dump.

Owner:CAR WASH PARTNERS

Preparation method of cermet material

The invention relates to a preparation method of a cermet material. The method comprises the following steps: raw cermet materials are evenly blended with a binder and are injected for molding to obtain a blank, the obtained blank is degreased, the degreased blank is sintered in vacuum environment or under an inert gas atmosphere to obtain the cermet material, wherein, the raw cermet materials contain stainless steel powder and copper powder; the binder contains paraffin wax, ethylene-vinyl acetate copolymer, high-density polypropylene, carnauba wax and stearic acid. The invention provides the preparation method which help the obtained cermet material have high density, high hardness, high tensile strength, good extensibility, high compressive strength and good impact toughness.

Owner:靖江市华信科技创业园有限公司

Lipstick

InactiveCN104546644AIncrease elasticityKeep hydrated and prevent cracksCosmetic preparationsToilet preparationsJojoba esterCarnuba wax

The invention discloses a lipstick. The lipstick contains grease, a pure natural auxiliary material and wax. The lipstick is characterized in that the wax is pure plant extracted wax and the grease is natural extracted grease; the weight parts are as follows: 35-40 parts of the pure plant extracted wax, 55-65 parts of the natural extracted grease and 2.5-5.5 parts of natural auxiliary material; the pure plant extracted wax is as least one selected from beewax, candelilla wax, carnauba wax, rice bran wax, jojoba ester and olive ester.

Owner:易思成

Car dry cleaning and maintaining liquid and its preparation method

InactiveCN104371835ANo damageGood removal effectOrganic detergent compounding agentsSurface-active detergent compositionsPolyacrylamideBeeswax

The invention relates to a special product for car dry cleaning, and concretely relates to a car cleaning and maintaining liquid and its preparation method. The car maintaining liquid comprises, by mass, 1-6% of Carnauba wax, 1-6% of beeswax, 0.67-4% of a first emulsifier, 1-6% of phenmethyl modified polydimethylsiloxane and / or long-chain alkyl silicone oil, 0.5-3% of a second emulsifier, 1-6% of alkylolamide, 1-6% of triethanolamine, 1-6% of a nonionic osmotic agent, 0.2-2% of polyacrylamide, 1-6% of an antistatic agent, 0.01-0.02% of a bactericide, 0.02% of an essence, and balance of deionized water, the first emulsifier is anyone selected from emulsifiers capable of emulsifying Carnauba wax and beeswax, the second emulsifier is anyone selected from emulsifiers capable of emulsifying phenmethyl modified polydimethylsiloxane and / or long-chain alkyl silicone oil, and the pH value of the car maintaining liquid is 7.0+ / -0.35. Many components of the liquid play respective roles, and coordinate with each other to realize special efficacies of one-step completion of decontamination, waxing, polishing and maintaining.

Owner:徐志铭 +1

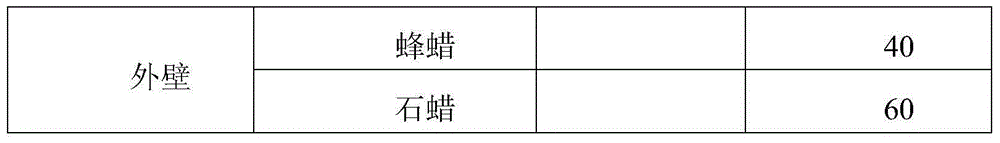

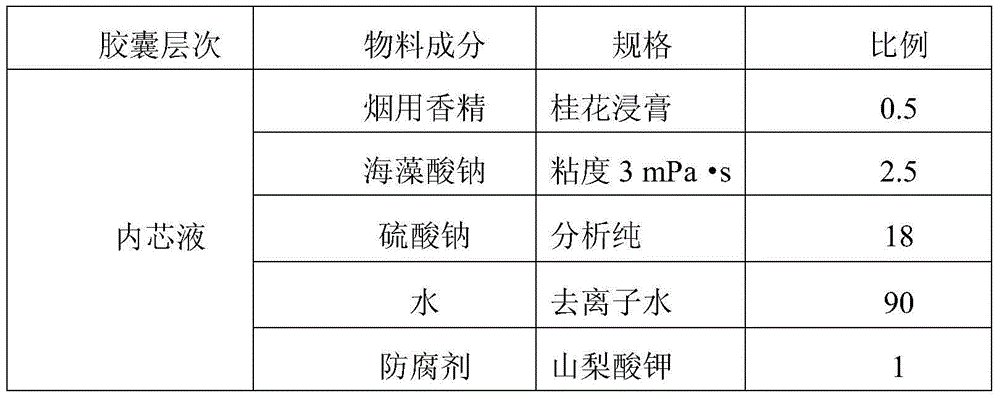

Water capsule for cigarettes using compound salts as wall material and preparation method thereof

InactiveCN104479870AImprove solubilityIncrease humidityTobacco treatmentTobacco smoke filtersInorganic saltsCigarette use

The invention discloses a water capsule for cigarettes using compound salts as a wall material, which comprises an inner core solution, wherein an inner wall is coated outside the inner core solution, and an outer wall is coated outside the inner wall. The inner core solution is composed of the following components in parts by weight: 1-10 parts of sodium alginate, 5-25 parts of inorganic salt, 0.1-2 parts of preservative, 0.1-2 parts of essence for cigarettes and 65-90 parts of deionized water. The inner wall is prepared from sodium alginate and inorganic salts under the action of a curing agent. The outer wall is composed of the following components in parts by weight: 30-80 parts of beeswax, 15-50 parts of paraffin and 0-20 parts of carnauba wax. The invention also a preparation method of the water capsule for cigarettes using compound salts as a wall material. The preparation method is simple and convenient; and the capsule has the advantages of low damage tendency, high yield and favorable uniformity of the capsule wall thickness.

Owner:HUBEI CHINA TOBACCO IND

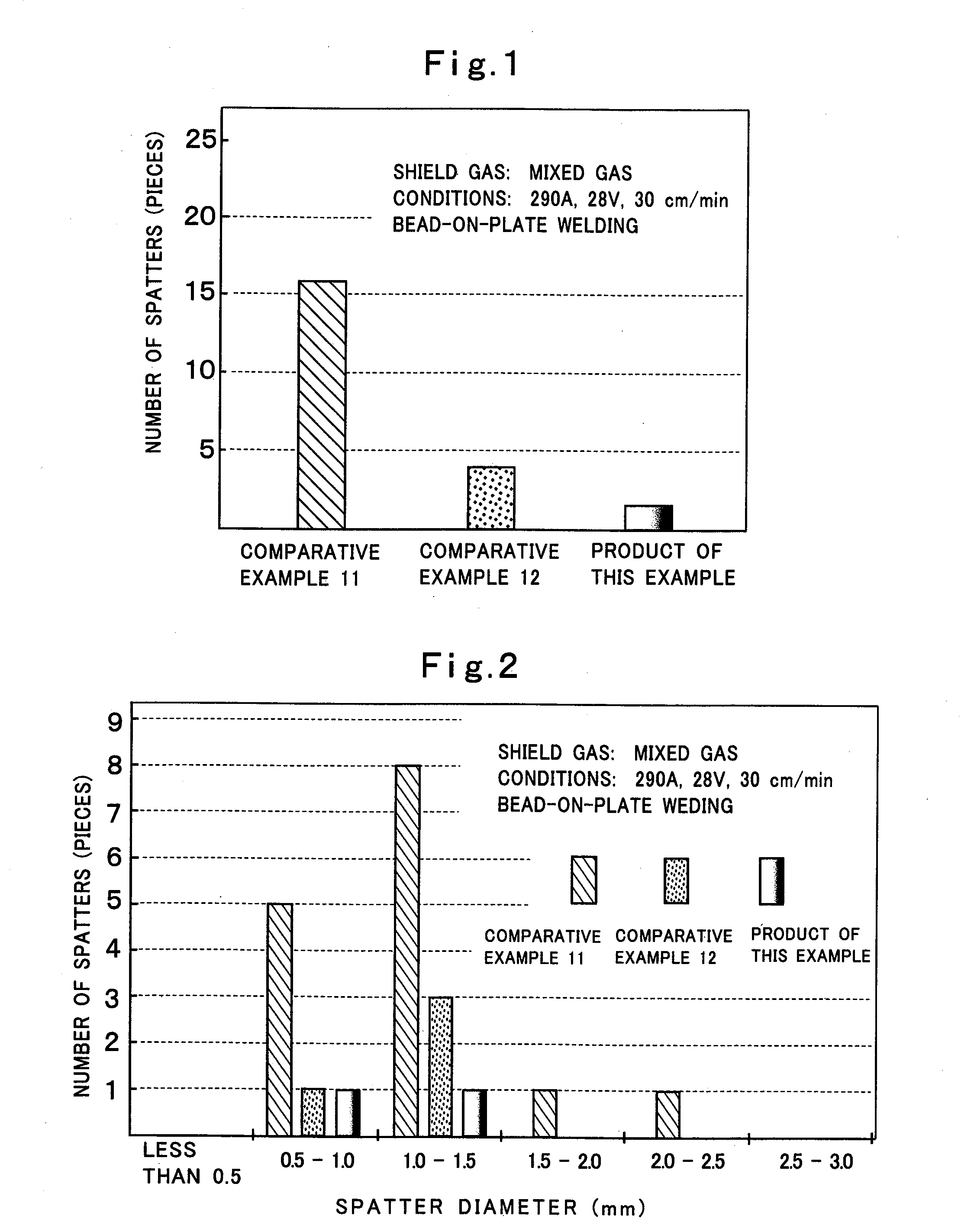

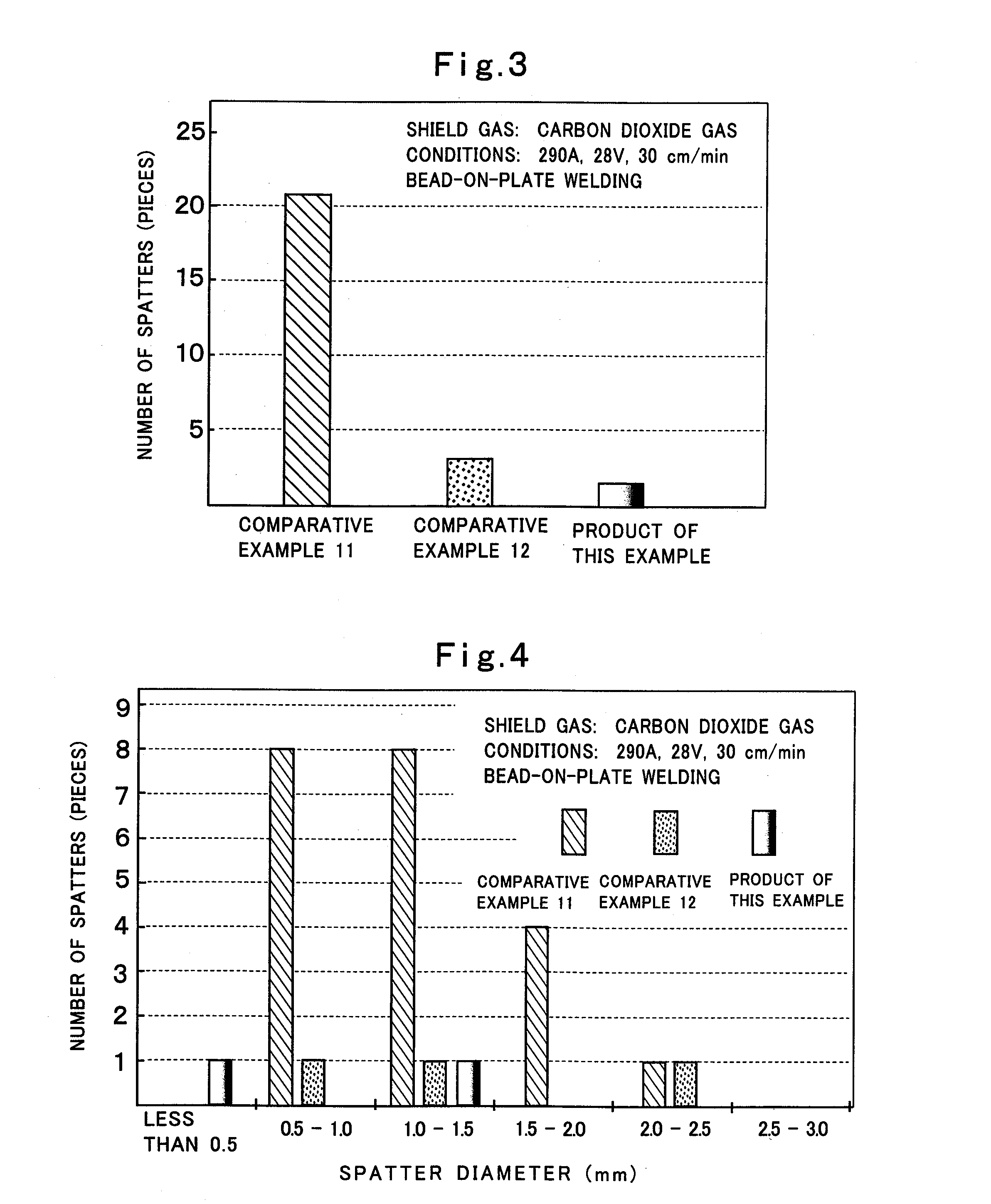

Grease composition and process for production thereof

InactiveUS20110111995A1Improve rust resistanceGood prevention effectThickenersAdditivesOil and greaseSulfonate

In this grease composition, a grease produced by mixing at least one base oil selected from a mineral oil-type lubricant base oil, a synthetic lubricant base oil, and a biodegradable lubricant base oil with a thickener is compounded with a wax and water, and an additive such as a surfactant and a defoamer is optionally compounded therewith. A soap containing a calcium sulfonate complex is used as the thickener. A carnauba wax is preferably used as the wax. Since this grease composition is mainly composed of a grease and a wax, the grease composition extremely facilities its removal operation after application, is environmentally friendly, and has extremely excellent anti-corrosion performance. When the grease composition is used by being applied to a base material of an object to be welded, an effect of preventing the adhesion of welding spatters can be obtained.

Owner:NIHON KENKI CO LTD

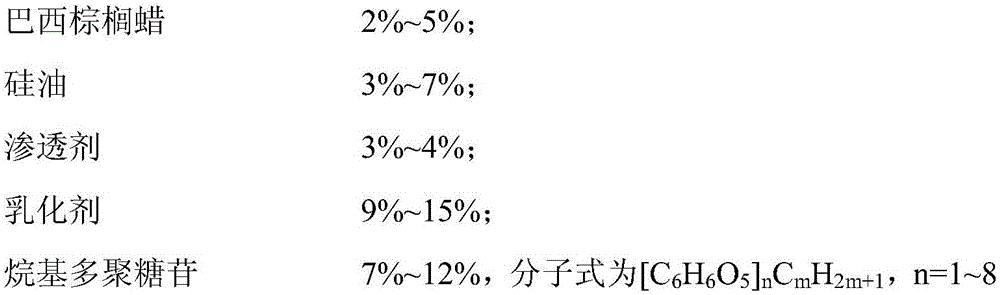

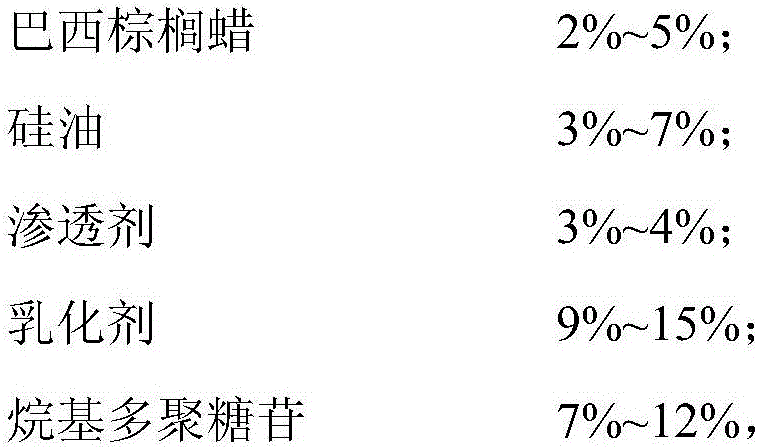

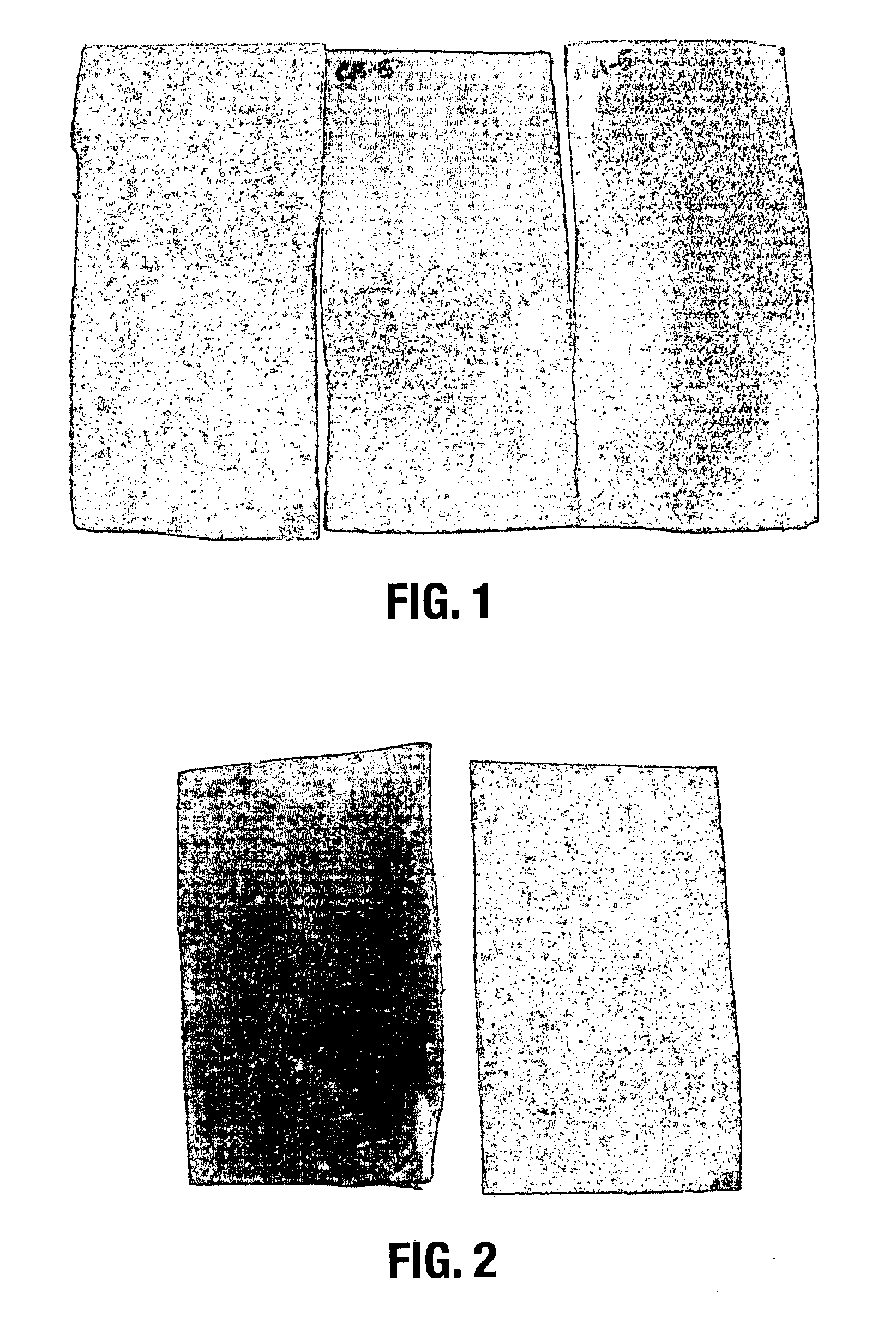

Automobile cleaning and polishing agent capable of avoiding scratches as well as preparation and application of automobile cleaning and polishing agent

InactiveCN105950325ARemove completelyReduce surface tensionInorganic/elemental detergent compounding agentsSurface-active detergent compositionsWater savingCarnuba wax

The invention relates to an automobile cleaning and polishing agent capable of avoiding scratches as well as preparation and application of the automobile cleaning and polishing agent. The automobile cleaning and polishing agent is prepared from components in percentage by mass as follows: 2%-5% of carnauba wax, 3%-7% of silicone oil, 3%-4% of a penetrating agent, 9%-15% of an emulsifier, 7%-12% of alkyl polyglycoside, 2%-6% of a co-emulsifier and 55%-73% of a detergent assistant. The automobile cleaning and polishing agent is prepared from bio-degradable and environment-friendly raw materials, has extremely low surface tension and great permeability and can completely remove traffic films, dust, grease and the like on the surface of the automobile, the automobile does not need to be wiped with sponge in the cleaning process, no scratches are produced, waxing and polishing can be finished in the automobile cleaning process, the secondary waxing process is avoided, the automobile cleaning procedure is greatly simplified, the work efficiency is improved, and the automobile cleaning and polishing agent has the advantages of water saving, energy conservation, time saving and high efficiency.

Owner:浙江金驰环保科技有限公司

Interior protectant/cleaner composition

ActiveUS7381250B2Improves UV protectionEfficient use ofFireproof paintsAntifouling/underwater paintsIn vehicleMedicine

The present invention provides a liquid protectant composition composed of a cationic microemulsion of a natural wax (carnauba wax) nanometer sized particles and zinc oxide nanometer sized particles in combination with a quaternary siloxane compound. The protectant composition of the present invention cleans, protects preserves and enhances the appearances of leather or vinyl surfaces used for covering items in the home or in vehicles. The product is easy to apply to both smooth and textured surfaces and has a transparent appearance. The product dries quickly and does not leave an oily residue. Utilization of nano technology to select components having nano sized particles provides a uniform deposition of the product leaving a thin film having exceptional protection properties. Unlike conventional protectants, the invention of the instant composition dries quickly and leaves no oily residue behind.

Owner:ENERGIZER GRP LTD

Anti-static vehicle paint surface body polishing emulsion wax

The invention aims at manufacturing anti-static vehicle paint surface body polishing emulsion wax. The anti-static vehicle paint surface body polishing emulsion wax is characterized by comprising octadecyl dimethyl benzyl chloride serving as an anti-static agent and cationic surfactant, dodecyl fatty amine polyoxyethylene ether (EO-10) serving as an emulsifier and non-ionic surfactant, waste oil fatty acid polyethylene glycol diester (PEG 400) serving as an emulsifier and non-ionic surfactant, waste oil fatty acid polyethylene glycol monoester (PEG 400) serving as an emulsifier and non-ionic surfactant, stearic acid monoglyceride serving as an emulsifier, an amino silicone oil emulsion, earth wax, paraffin wax, carnauba wax, sorbic acid serving as a preservative, glycerin and soft water thereof. The anti-static vehicle paint surface body polishing emulsion wax provided by the invention is suitable for paint polishing of various automobiles, locomotives, electric vehicles, bicycles and other vehicles. The anti-static vehicle paint surface body polishing emulsion wax provided by the invention has a white milky paste-like appearance, pH value of 6-7, no corrosion to metal and paint surfaces of the vehicles and no irritation to skin of human bodies. The anti-static vehicle paint surface body polishing emulsion wax provided by the invention has an anti-static effect against the surfaces of the vehicles, as well as the effects of brightening, smoothing and preventing dust of the paint surfaces of the vehicles; and the paint surfaces are wiped with a small amount of the anti-static vehicle paint surface body polishing emulsion wax repeatedly, the paint surfaces can be as clean and bright as new.

Owner:TAINJIN BOKNI TECH DEV

Media for inkjet web press printing

A media suitable for inkjet web press printing is disclosed herein. The media includes a paper substrate and an ink receptive layer coated onto at least one surface of the paper substrate. The ink receptive layer includes: inorganic pigments; at least one water-based binder; a water-soluble metallic salt; a colorant durability enhancer selected from the group consisting of boric acid, borax, sodium tetraborate, phenyl boronic acid, butyl boronic acid and combinations thereof; and a coefficient of friction (COF) reducer selected from the group consisting of polyethylene wax, paraffin wax, carnauba wax, polypropylene wax, polytetrafluoroethylene wax, and combinations thereof.

Owner:HEWLETT PACKARD DEV CO LP

Manufacturing method of edible lipstick

The invention discloses an edible lipstick. The edible lipstick is prepared by the following components in proportion: 100-500 parts of carnauba wax, 200-300 parts of candelila wax, 50-100 parts of peanut oil, 50-100 parts of colza oil, 50-100 parts of citrus honey, 50-100 parts of linseed oil, 50-100 parts of sunflower oil, 800 parts of red sorghum pigment and 600-1000 parts of 95% ethyl alcohol. A manufacturing method comprises the following steps of dissolving the carnauba wax; filtering through a polymer dialysis membrane; grinding by a grinding miller; stirring by a stirrer; and carrying out cooling solidification to obtain the edible lipstick.

Owner:陆飞

Spray type mildew-proof leather polishing agent and preparation method thereof

The invention discloses a spray type mildew-proof leather polishing agent which is characterized by comprising the following components in parts by weight: 5-15 parts of aloe fibroin collagen humectant, 30-50 parts of carnauba wax, 5-7 parts of castor oil, 5-20 parts of dimethyl silicon oil, 0.1-0.5 part of mildew preventive, 0.5-2 parts of cationic surfactant, 0.01-0.1 part of essence and 20-30 parts of water. The spray type mildew-proof leather polishing agent is simple and convenient to use, and the cleaning, maintenance and polishing are finished at one time; the spray type mildew-proof leather polishing agent has strong antifouling ability, does not generate static electricity and prevents dust; the spray type mildew-proof leather polishing agent is neutral and phosphorus-free, contains a benzoic acid preservative and can suppress mildew reproduction; the spray type mildew-proof leather polishing agent resists ultraviolet under strong light and prevents aging and cracking; and with natural aloe component, the spray type mildew-proof leather polishing agent can keep the fullness, elasticity and gloss of leather for long time.

Owner:SUZHOU XIELU NETWORK TECH

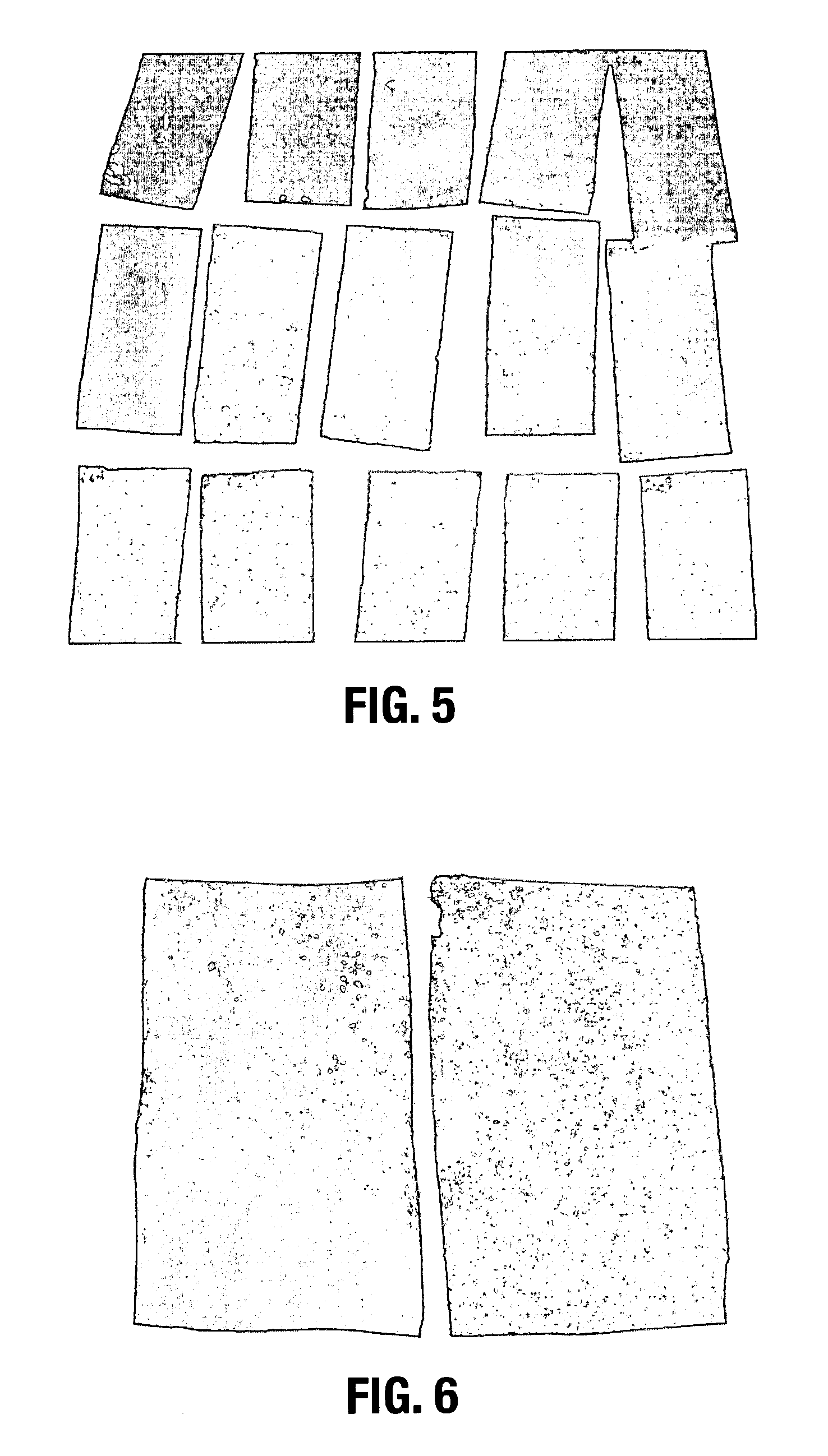

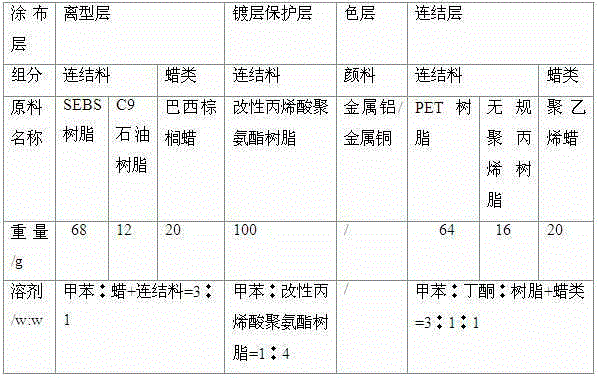

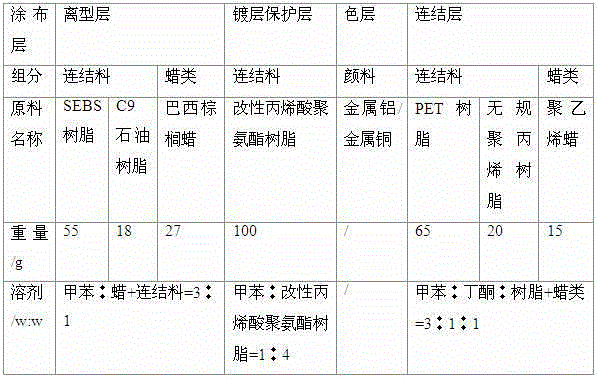

Thermal transfer ribbon for printing golden and silver bar codes and preparation method thereof

ActiveCN105216461AReasonable designEasy to prepareInk ribbonsSynthetic resin layered productsEngineeringPolypropylene

The invention discloses a thermal transfer ribbon for printing golden and silver bar codes and a preparation method thereof, and belongs to the technical field of thermo-printing material. The thermal transfer ribbon for printing the golden and silver bar codes is composed of a ribbon base, a back coating and a thermal transfer printing layer, wherein the back coating and the thermal transfer printing layer are arranged on the two sides of the ribbon base in a coating mode. The thermal transfer printing layer is divided into four parts, namely the release layer, the coating protection layer, the color layer and the connecting layer, wherein the release layer, the coating protection layer, the color layer and the connecting layer are sequentially arranged on the surface of one side of the ribbon base from inside to outside. The release layer is composed of, by weight, connecting material of 73-90% and wax of 10-27%, the connecting material is composed of SEBS resin and petroleum resin, the SEBS resin accounts for 55-80% in total mass of the release layer, the petroleum resin accounts for 0-25% in total mass of the release layer, and the wax can be rice bran wax or polyethylene wax or carnauba wax. The coating protection layer is composed of modified acrylic acid polyurethane resin, wherein the softening point of the modified acrylic acid polyurethane resin ranges from 110 DEG C to 115 DEG C. The color layer is plated to be golden or silver through the vacuum evaporation process. The connecting layer is composed of, by weight, saturated polyester resin of 50-71%, atactic polypropylene resin of 10-30% and polyethylene wax of 10-28%.

Owner:JIAOZUO ZHUOLI STAMPING MATERIAL CO., LTD.

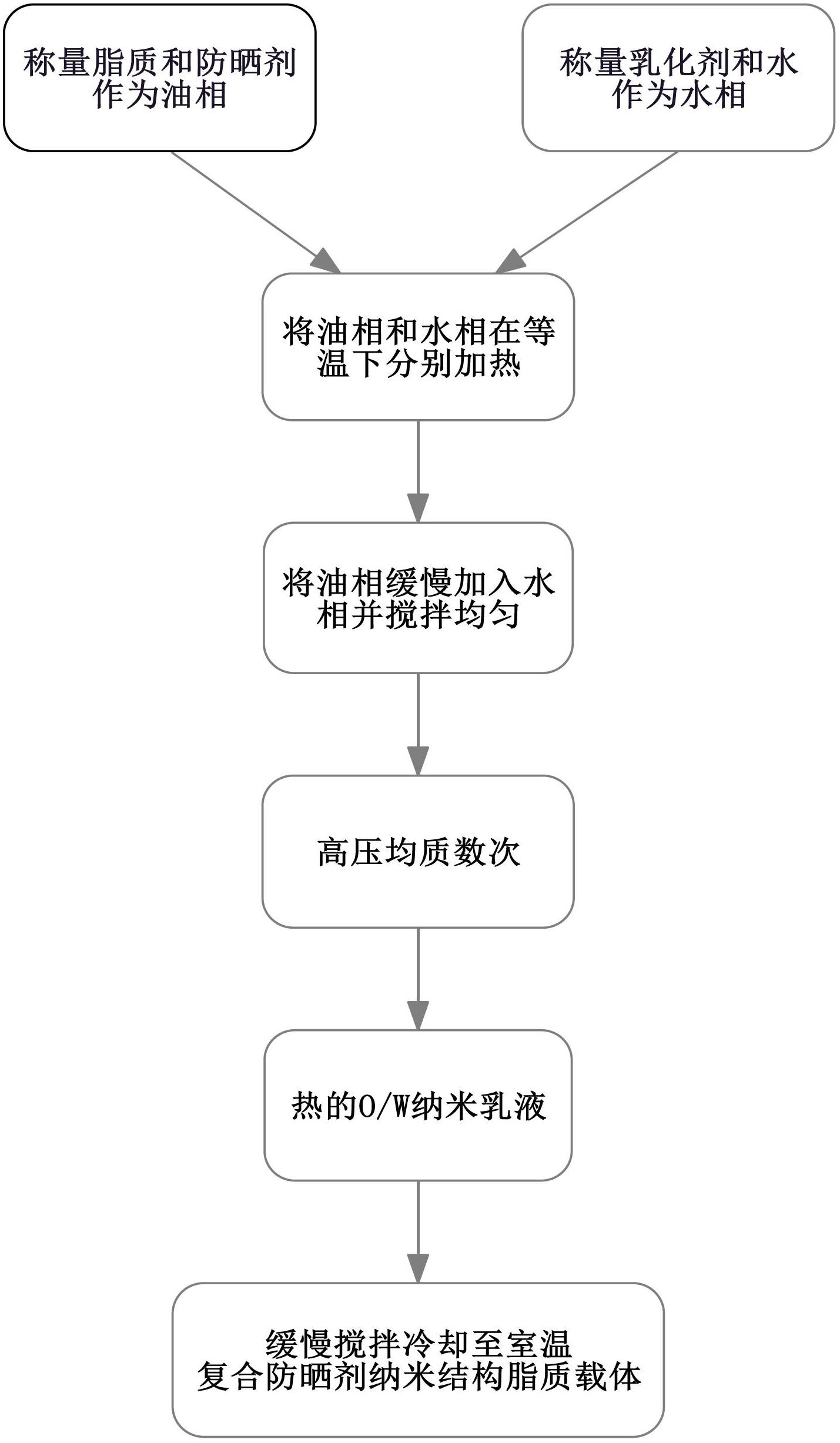

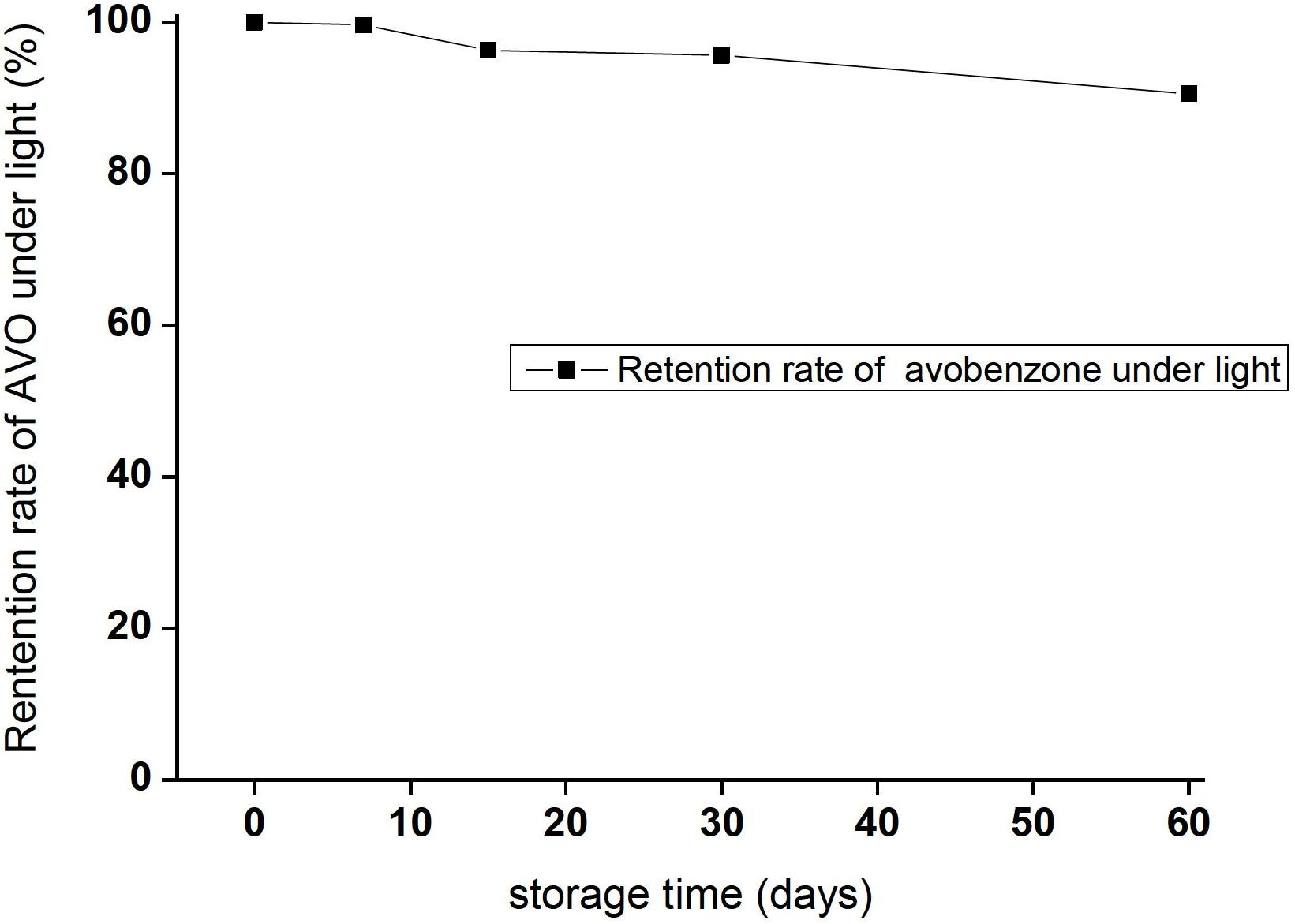

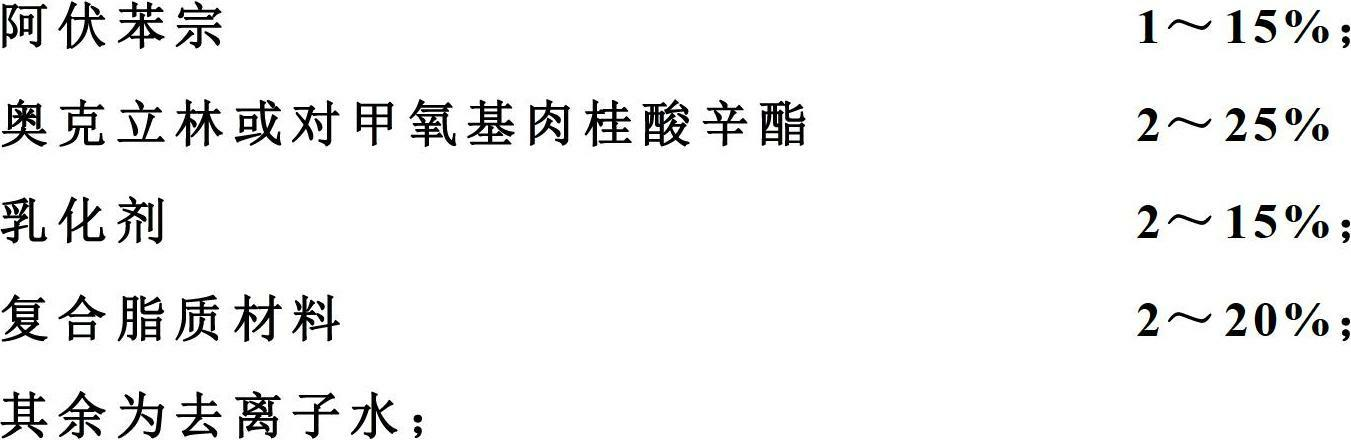

Composite anti-screening agent nanostructured lipid carrier and preparation method thereof

InactiveCN102688152AImprove stabilityGood water solubilityCosmetic preparationsToilet preparationsSolubilityACETYLATED MONOGLYCERIDE

The invention discloses a composite anti-screening agent nanostructured lipid carrier. The carrier carries the active ingredients of all-band anti-screening agent medicines, and is characterized in that: the nanostructured lipid carrier comprises the following components in percentage by weight: 3-40% of composite anti-screening agent, 2-15% of emulsifier, 2-20% of composite lipid material and the balance of water, wherein the UVA anti-screening agent is avobenzone and consists of at least one of the following compounds: octocrilene and iso-octyl p-methoxycinnamate; the composite lipid material is the mixture of solid lipid material and liquid lipid material; and the lipid material consists of at least one of the following compounds: glyceryl triacetate, acetylate monoglyceride, diethyl sebacate, caprylic / capric triglyceride, diisopropyl adipate, diisopropyl sebacate, glyceryl monostearate, carnauba wax and behenate. The nanostructured lipid carrier has good stability and water solubility; the preparation method is simple and controllable and has good repeatability; and the nanostructured lipid carrier can be used for preparing anti-screening cosmetics.

Owner:SOUTHEAST UNIV

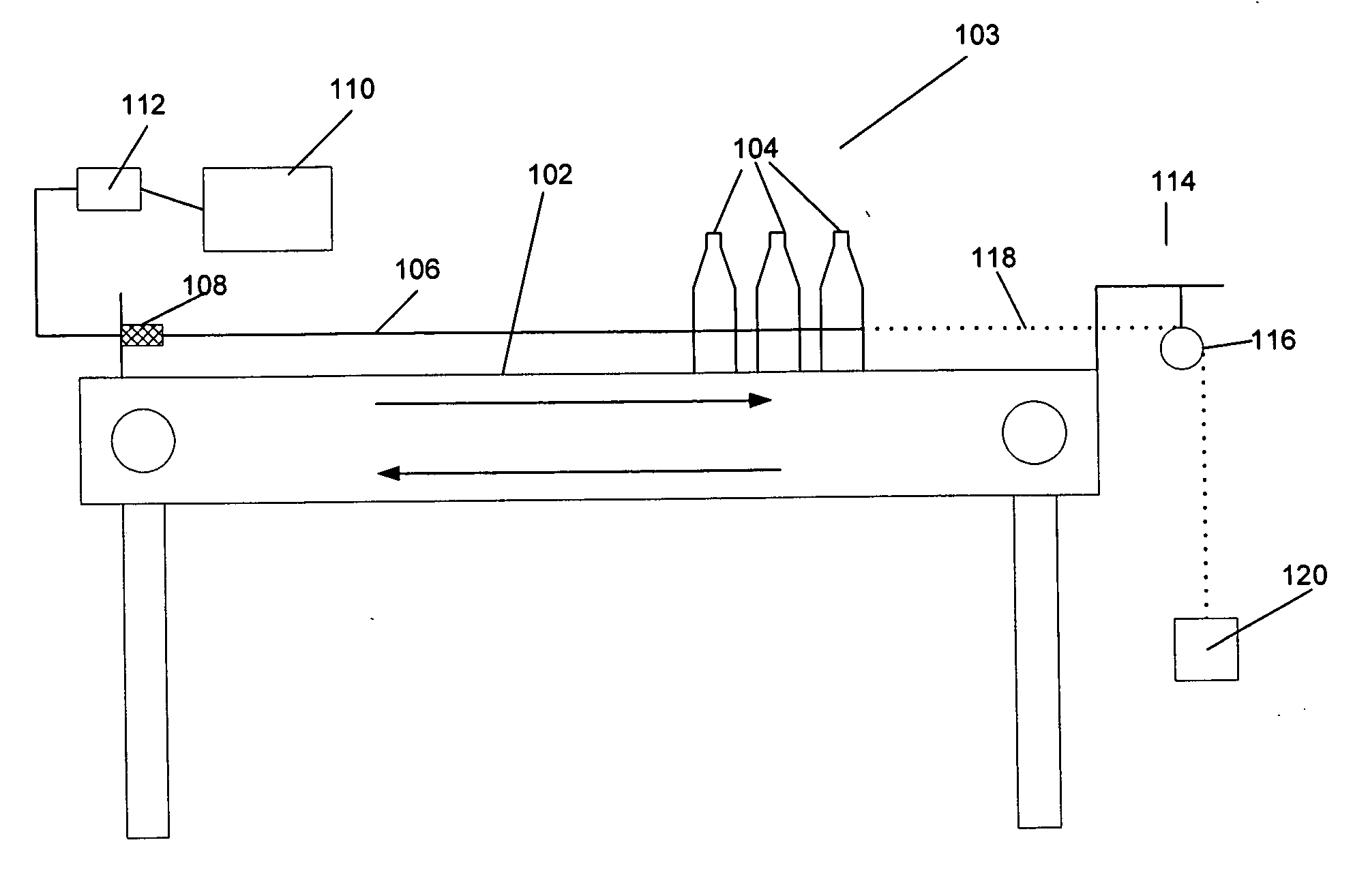

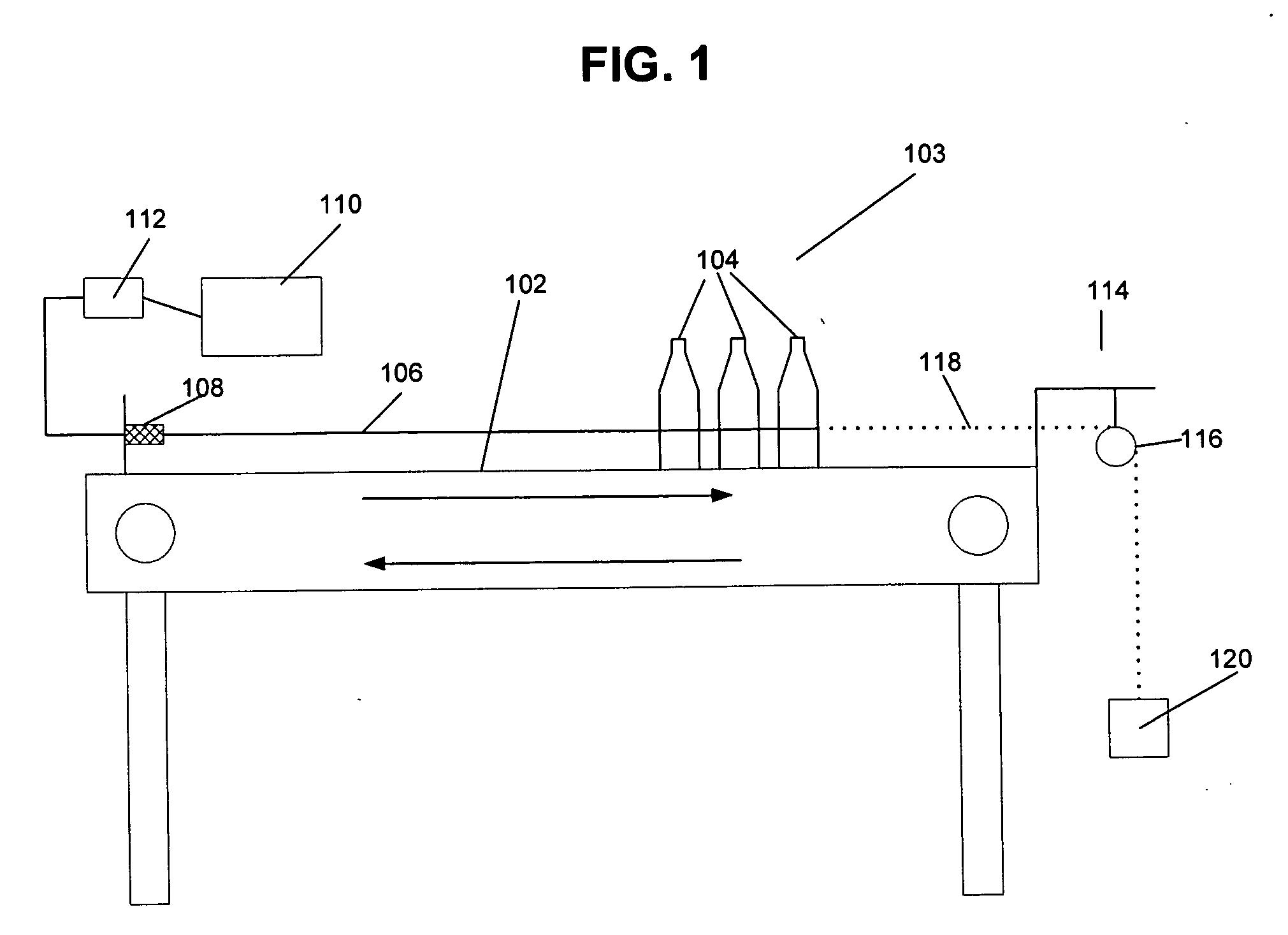

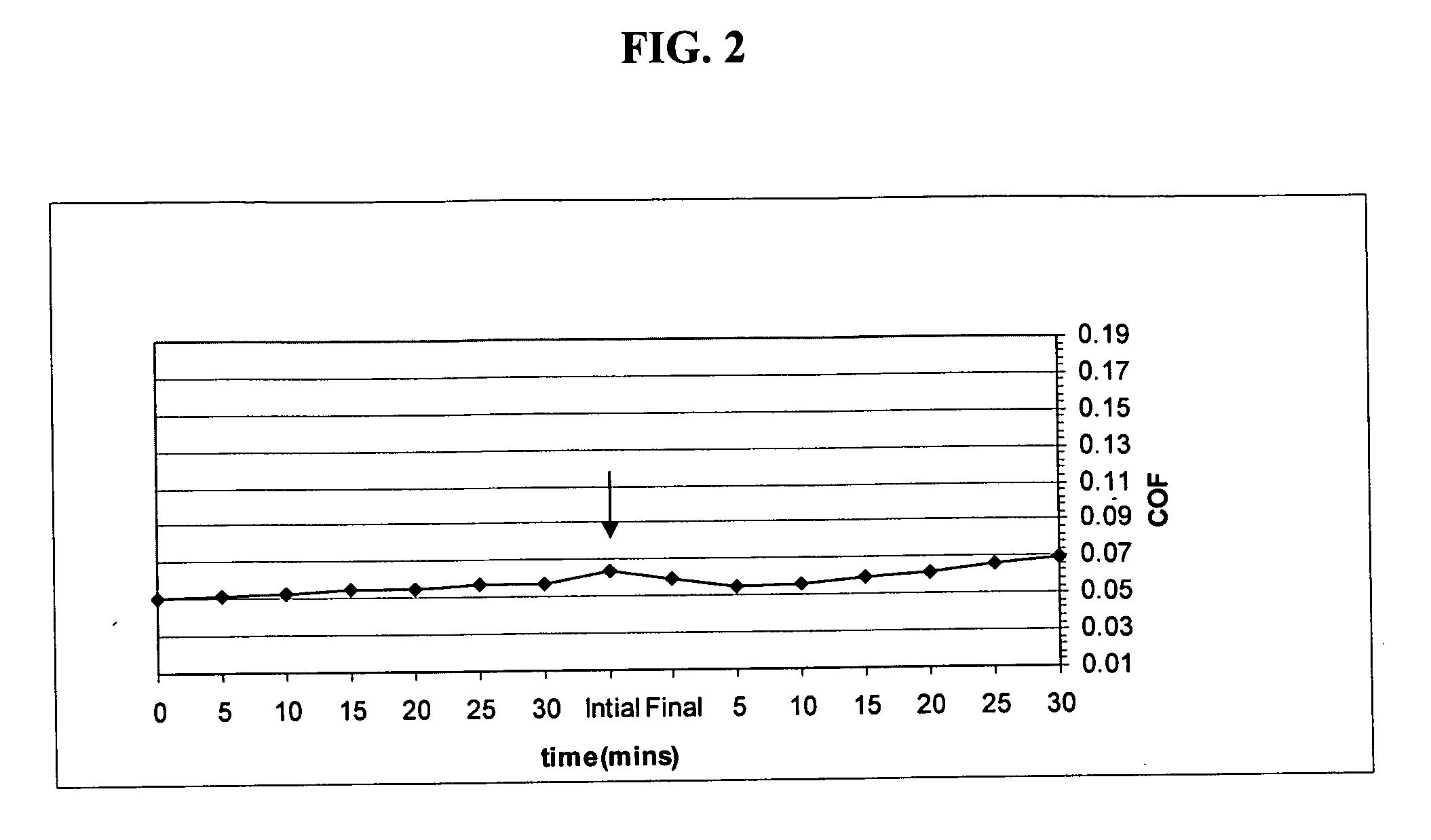

Wax-based lubricants for conveyors

InactiveUS20060089274A1Improve securityImprove hygieneOrganic chemistryBearing componentsCarnuba waxLubricant

Wax-based lubricant coatings for conveyors, and in particular for container transporting conveyors, are provided. The lubricant coatings provide conveyor surfaces having low coefficients of friction. In one embodiment, the lubricant coatings are composed of a mixture of carnauba wax and at least one additional wax. Conveyors having the lubricant coatings applied thereto are also provided.

Owner:JOHNSONDIVERSEY INC

Fluororubber and epichlorophdrin rubber formulation

ActiveCN101081916AHigh electronegativityGood fuel resistanceSynthetic resin layered productsPolymer scienceLead(II,IV) oxide

The present invention is one kind of rubber pipe comprising one inner layer of fluororubber and one middle layer and one outer layer of chlorohydrin rubber. The fluororubber consists of polyfluoroprene, thermal black N990, 2, 5-dimethyl-2, 5-dihexane, triallyl cyanourate and carnauba wax; and the chlorohydrin rubber consists of chlorohydrin rubber C, chlorohydrin rubber H, black N550, anti-ager NBC, processing aid R-300, stearic acid, plasticizer RS-107, red lead, ethylene thiourea NA-22, plasticizer W-305ELS and scorch retarder CTP-80. The rubber pipe with one inner layer of fluororubber and one middle layer and one outer layer of chlorohydrin rubber has high heat resistance, high oil tolerance, high ozone tolerance and high fuel oil osmosis resistance.

Owner:TIANJIN PENGYI GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com